Abstract

Stone columns are widely used as an effective and environmental friendly improvement method for increasing the load-carrying capacity of soft clay soils. In very soft clay soils, reinforced stone columns are used because of the lack of the lateral confinement created by the surrounding soil. To provide lateral additional confinement, geosynthetics are usually used. This study intends to evaluate the use of vertical steel bars and horizontal steel discs as an alternative way to geosynthetics to investigate the effect of reinforcement on the footing load-carrying characteristics. Therefore, some large-scale laboratory tests were conducted on stone columns with diameters of 80 and 100 mm and a length to diameter of 5. The results show that changing the arrangement of the bars to a higher stiffness leads to increase in load-carrying capacity. Reinforcing the full-length of the stone columns with the bars in comparison to half-length reinforced has significant influence in capacity. However, in the case of horizontal discs, this increase is negligible. Also by decreasing the space of the discs, load-carrying capacity increases. Moreover, the performance of the vertical reinforced stone column seemed to be better than the horizontal reinforced stone column. The increase of load-carrying capacity in reinforced stone columns with vertical bars or horizontal discs is higher than geotextile reinforcement in the same conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There are various techniques to improve the mechanical behaviour of soft clay soils. The use of stone columns is one of the methods to improve soft soils. The construction of stone columns involves the replacement of some clay soil with crushed stone aggregates or sand in a cylindrical cavity to form a series of stone columns in clay bed. Using granular materials than soft clay with more stiffness and friction resistance leads the stone columns to transfer vertical loads to more depth and also increase the load-carrying capacity due to the combination of frictional resistance and the end bearing [1,2,3,4,5,6]. Moreover, granular materials have a high permeability of clay, thus stone columns act as drains that reduce the length of the path consolidation of the clay [7,8,9,10]. Therefore, the use of the stone columns will increase the load-carrying capacity, accelerate the rate of consolidation and reduce the total and relative settlements [11, 12] in soft clay soils. The stone columns under the vertical compression loads have three failure mechanisms of bulging [3, 13], shear failure [14] and punching [4].

Early studies show that the capacity of the stone columns is mainly due to the lateral supporting strength provided by the surrounding soil of the stone column [5, 13]. In very soft clay soils with undrained shear strength less than 15 kPa, due to lack of adequate lateral support of surrounding soil, the lateral bulging occurs in the upper part of the stone column. In addition, using the reinforced stone columns (RSCs) prevents this failure [15]. RSCs with additional confinement created by reinforcement, increase the stiffness and reduce the lateral bulging of the stone columns [16, 17].

There are different ways to increase the load-carrying capacity and reduce the settlement and prevent the lateral bulging in ordinary stone columns (OSCs), including geosynthetic encased, vertical and horizontal elements. One of the solutions is the use of vertical reinforcement as geotextile [18,19,20,21,22,23,24,25,26,27,28] and geogrid [29,30,31,32,33,34,35]. The use of bar elements, with increasing stiffness of the stone column, can also have an effective role in increasing the capacity of stone columns. Shivashankar et al. [36, 37] present a series of small-scale laboratory tests using unit cells with 189- and 283-mm diameters tank with a stone column located in the centre of the soft soil. The effects of vertical circumferential bars on the strength, stiffness and lateral bulging of the stone columns also were studied. The results show that RSCs with circumferential bars have more resistance and stiffness compared to OSCs. Moreover, in the case of small area ratio, the effect of such bars is greater.

Moreover, the use of horizontal reinforcing discs increases the load-carrying capacity and reduces the settlement of the stone columns [38]. Some studies have been carried out to investigate the effect of the number of horizontal layers of geogrid and geotextile on the load-carrying capacity and lateral bulging of the stone column [39,40,41,42]. Ali et al. [43, 44] perform laboratory experimental tests on RSCs with horizontal geogrid and geotextile circular discs. The results show that the geogrid encased is better than the geotextile-encased since geogrid stiffness is higher. On the other hand, due to the lesser stiffness of the geotextile, the columns have more lateral bulging and more settlement. Ayadat et al. [45] conducted a laboratory study to evaluate the performance of the sand columns with diameter 23 mm internally reinforced with horizontal discs made of plastic, steel and aluminium materials located in the upper part of the column. The results show that, by increasing in the number of internal reinforcements, the performance of the stone column increases significantly.

Some previous studies [36, 37, 43,44,45] indicated that vertical and horizontal elements are appropriate methods to increase the load-carrying capacity and reduce lateral bulging and settlement. In addition, the behaviour of RSCs with bar elements was studied in a unit cell in small-scale tests. There are also limited studies in RSCs with horizontal steel discs.

As mentioned for enhancing the performance of the stone columns in weak soils, it is essential that the tendency of the column to bulge should be restricted. This situation is overcome by encasing the stone columns with suitable geosynthetics to impart the necessary confinement to improve their strength and stiffness, although the external reinforcement in the form of encasing the column with a geosynthetic will prevent the column failing by bulging or shear. Thus, this encasing will not allow the column to dilate and leads to increase the in situ stresses [36, 37, 45]. Moreover, the use of geotextile is limited to sand and fine gravel and installation methods and coarser aggregates can damage the geotextile. In addition, to minimize the potential damage caused to the geotextile encasement, columns receive little compaction during installation. Finally, hoop strains in the order of 1–4% are required to mobilize the hoop forces in the encasement [31], resulting in significant radial expansion of the columns during loading. These combined factors can result in greater settlements than desired for some cases. Hence, there is a need to identify effective and alternative methods which should be practically feasible to enhance the performance of the stone columns in very soft soil. Using vertical steel bars along the circumference of the stone column can be a good alternative to enhance the performance of stone columns. On the other hand, internal reinforcement leads to increase in the stiffness of the stone column and the lateral stresses in the surrounding soil, and accordingly its bearing capacity.

This paper presents the results and findings of some large body experimental loading tests carried out on single floating stone columns with various diameters reinforced with vertical bars and horizontal discs. The main objective of this research is to investigate the effectiveness of vertical steel bars reinforcement with the various arrangement, lengths and numbers on load-carrying capacity. In addition, the effect of horizontal circular steel discs reinforcement with different numbers and spacing along the stone column and the comparison of the behaviour of RSCs with vertical bars and horizontal discs with a geotextile reinforcement will be studied.

Description of the Experiment

Material Properties

The soil used in this study was kaolin clay and crushed stone aggregates. Kaolin clay was used for soil bed that the stone columns were constructed inside it. To determine the moisture content corresponding to 15 kPa undrained shear strength of the kaolin clay, a series of unconfined compression tests [ASTM D 2166] were carried out on remolded soil samples with different moisture content by strain rate of 0.8 mm/min. The results of these tests are shown in Fig. 1.

As seen, the moisture content corresponding to 15 kPa undrained shear strength was found to be 23%. This amount of moisture content was kept the same in all tests. Other properties of kaolin clay are shown in Table 1.

In practice, OSCs with a diameter (D) of 0.60 to 1.00 m were constructed and the diameter of the stone particles (d) used for these columns was 25 to 50 mm. Therefore, the ratio of the diameter of the stone column to the diameter of the stone particles (D/d) was between 12 and 40 [46]. In the present study, for construction of the stone columns, crushed stone aggregates with a particle size ranging 2–10 mm were used. Also, the diameters of the stone columns were 80 and 100 mm. Thus, the ratio D/d in the model tests had values ranging from 8 to 50. So, the scale effects of particle size were minimized in the present study. The particle size distribution for kaolin clay and stone aggregates is shown in Fig. 2. The properties of crushed stone aggregates are listed in Table 2.

Steel bars and discs were used for vertical and horizontal reinforcing, respectively. For reinforcing vertical reinforced stone column (VRSCs), steel plain bars with diameters of 2 and 3 mm were used. Moreover ,in the Horizontal reinforced stone column (HRSCs), circulate steel discs with the thickness of 2 mm and the same diameter of the stone column with different spaces were placed.

Presentation of the Experimental Model

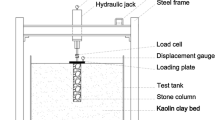

In this study, in order to perform physical model tests on the stone columns, a loading device was designed and constructed similar to that used by Ghazavi and Afshar [22]. The test setup consists of a large rigid steel box with a size of 1.20 × 1.20 m in plan and a height of 1.0 m, with a rigid steel frame on it and loading system by a hydraulic jack in the centre of the box (Fig. 3). The dimension of the steel box was chosen in such a way that the results of the tests were not affected by the boundaries of the box. The values of loads and vertical displacement were measured by the load cell and the displacement gauge. A rigid loading steel plate was used with the diameter of 200 mm and thickness 30 mm.

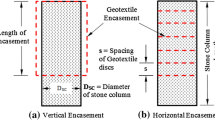

According to Barksdale and Bachus [5] in order to control the lateral bulging failure, the minimum ratio of length to diameter of the stone column was 4. Therefore, the ratio of length to diameter of the stone column in all tests was 5. In this study, 19 tests were carried out on single floating stone columns with diameters 80 and 100 mm and heights 400 and 500 mm, respectively. The schematic representation of steel bars and discs arrangements is shown in Fig. 4.

A summarized list of performed tests is shown in Table 3. It should be mentioned that some tests were repeated to ensure repeatability and compatibility and as a result, tests were in good agreement between each other.

To study the effect of the diameter of the vertical steel reinforcement, stone columns D = 80 and 100 mm were reinforced with steel bars with d = 2 and 3 mm in four types of arrangement (Fig. 5). The geometric percentage of the bars used in stone columns was defined as ρ = As/Ac × 100, where As was the total cross-section of the bars, and Ac was the area of the stone column. The stone columns in all tests were approximately reinforced with ρ = 0.50%.

To investigate the effect of horizontal reinforcing, the stone columns D = 80 and 100 mm with horizontal discs with the diameters equal to the diameter of the stone column (80 and 100 mm) at intervals of S = D and S = D/2 were reinforced. To evaluate the effect of the reinforced length, stone columns were reinforced once full-length and then again in half-length in both the VRSCs and HRSCs.

Preparation of Kaolin Clay Bed

Preparation of kaolin clay bed in a large test box was done. Initially, the amount of water required for dry kaolin clay with a dry unit weight of 15.5 kN/m3 was obtained to reach a moisture content of 23%, which is equivalent to the undrained shear strength of 15 kPa and was mixed in a plastic box with kaolin clay. Then the inner surface of the box wall was covered with a thin layer of silicone grease and then covered with thin polyethylene nylon to reduce the friction between the soil and the wall of the box. As seen in Fig. 6, the kaolin clay masses were filled each 50 mm layers by weight in the tank to reach a certain bulk unit weight of 19.1 kN/m3. A tamper with 150 × 150 mm in plan and 10 kg mass was used for kaolin clay compaction similar to the tamper used in the study of Debnath and Dey [29]. The drop height of the tamper was 200 mm and the compaction energy applied to the kaolin clay bed was 261 kJ/m3. This will continue until the box was filled up to 900 mm high. The prepared kaolin clay bed was covered with a thick nylon and left for 7 days for uniforming moisture content. To ensure the constancy of moisture content, it was checked at the end of all the tests that a variation of moisture content was less than 1.1% in the kaolin clay bed.

Construction of Reinforced and Unreinforced Stone Column

In all the tests, stone columns were constructed by the replacement method in the centre of a large test box. Seamless steel pipes with an outer diameter equal to the diameter of the stone column (80 and 100 mm) and the wall thickness of 2 mm were used to make stone columns. The inner and outer surfaces of the steel pipe were coated with a thin layer of oil to facilitate the penetration of the pipe into the kaolin clay bed and also to decrease the disturbance to the surrounding soil around the penetration area of the pipe. Then, the steel pipe was driven into the bed by the jack to the height of the length of the stone column. This method was used in the study of Hamidi and Lajevardi [47].

Two different types of helical steel augers were designed and used to scoop out the clay from the inner part of the steel pipe. The augers diameters were slightly less than the internal diameters of the steel pipes for excavation of the clay. Drilling was continued until reaching the depth that required to build a stone column. To reduce the suction effects, 50 mm of kaolin clay was removed at each stage. The steel pipe was slowly and carefully pulled out to prevent any distribution of the soil around the steel pipe on completion of the drilling. The amount of crushed stone aggregates for constructing a stone column was calculated based on a unit weight of 16.00 kN/m3. The construction of a stone column at each stage was done by filling a distance of D/2 (half of the stone column diameter) and this continued until the cavity was filled. To achieve a uniform density, a compaction operation was performed with the metal hammer in diameter of 20 mm and a weight of 2 kg from a height of 100 mm and 15 blows [22]. This compaction was chosen to have no effect on the distribution of the surrounding soil and lateral bulging during the construction of the stone column. This procedure was continued until the whole stone column was built. Figure 7 shows the construction steps of VRSC.

Test Procedure

After the construction of the stone column, loading was done by a plate located at the centre of the stone column and kaolin clay bed. The load was applied based on the displacement control method with a constant displacement rate of 1 mm/min. The loading of each test was continued to a displacement of up to 50 mm. The bearing pressure–settlement behaviour of kaolin clay bed and the bed treated with stone columns were studied. It should be noted that the bearing pressure is achieved from the division of load into the area of the load plate.

Results and Discussion

VRSCs with Steel Bars

Figure 8 illustrates the bearing pressure–settlement behaviour of kaolin clay bed, OSCs and VRSCs with D = 80 and 100 mm by using different diameters and length of reinforcement up to a settlement of 50 mm.

As it can be observed from Fig. 8, by reinforcing the kaolin clay bed with OSCs, the increase of load-carrying capacity is compared to the kaolin clay bed 98.8% and 154.1%, respectively, for the diameters of 80 and 100 mm. Moreover, comparing of VRSC1 and VRSC5 (reinforced with steel bars) to kaolin clay bed shows that the increase of load-carrying capacity is 240.7% and 290.7%, respectively. Therefore, reinforcing the kaolin clay bed with OSCs increases the amount of load-carrying capacity. By reinforcing the OSCs with vertical bars, more increases in the load-carrying capacity can be seen too.

Influence of Diameter of Stone Column

The results of the comparison between Fig. 8a, b in OSCs indicate that by increasing the stone column diameter from 80 mm to 100 mm, the load-carrying capacity of the column increased to 27.7%. Comparison of the results for the largest bearing pressure of RSCs with diameters of 80 and 100 mm (VRSC1 with VRSC5) represents an increase of 14.6% in load-carrying capacity. This increase for VRSCs to OSC is in the range of 40.1–71.3%. As Fig. 8b shows, this range is 28.2–53.7%.

The result shows that in all cases with increasing the stone column diameter, the load-carrying capacity increases. However, in VRSCs, the benefit of reinforcement decreases with increasing the stone column diameter, the reason for this is the development of larger additional confining stresses in smaller diameter encased columns. The VRSCs have developed much higher pressures compared to the OSCs.

Influence of the Arrangement of Bars

D = 80 mm

Figure 8a shows an increase of 15.9% on load-carrying capacity for the full-length reinforced stone column by changing the arrangement from (b) to (a) for VRSC3 to VRSC1 (see Fig. 5). This increase for stone columns with half-lengths reinforced (comparing VRSC2 to VRSC4) is also visible at 4.5%.

D = 100 mm

Figure 8b shows that the load-carrying capacity of stone column full-length reinforced with the arrangement (d) for VRSC5 increases by 15.6% as compared to arrangement (c) for VRSC7. By comparing VRSC6 with VRSC8, this amount of increase for the half-lengths reinforced column is 4.2%.

Therefore, the comparison of the results shows that the arrangement of (a) and (c) has more efficiency than the arrangement of (b) and (d), respectively. It is because of the increase in the stiffness of the reinforcing bars in these arrangements.

Influence of the Reinforced Length

D = 80 mm

By comparing the results of VRSC1 and VRSC2 shown in Fig. 8a, it is observed that by increasing the length of the bars from half-length to full-length, the load-carrying capacity increases by 16.9%. Moreover, the same comparison of VRSC3 and VRSC4 shows that the amount of this increase is 5.4%.

D = 100 mm

Similarly from Fig. 8b, the increase of the load-carrying capacity by comparing VRSC5 with VRSC6 and VRSC7 with VRSC8 are equal to 15% and 3.6%, respectively. Therefore, full-length bars have better performance than half-length bars for VRSCs.

In the case of reinforcing the stone column with vertical steel bars with a low stiffness (2 mm diameter), it seems that, due to the low resistance of the bars, the bulging depth in half-length and full-length stone columns is almost the same, so the variation of the load-carrying capacity is negligible. However, by reinforcing the full-length of the stone column with a high stiffness bar (3 mm in diameter), the depth of bulging occurs in the lower depth in comparison with the half-length reinforced, thus the increase of load-carrying capacity is more.

HRSCs with Steel Discs

Bearing pressure–settlement behaviour of kaolin clay bed, OSCs and HRSCs with D = 80 and 100 mm reinforced with horizontal discs by using different intervals of reinforcement up to a settlement of 50 mm is shown in Fig. 9. As seen, in all the cases, by reinforcing kaolin clay bed with HRSCs, load-carrying capacity increases.

Influence of the Number of Discs

D = 80 mm

Figure 9a shows that by reinforcing of stone columns with 11 discs and S = D/2 (HRSC1), compared with the HRSC3 with 6 number of discs with S = D, the load-carrying capacity increases by 25.4%.

D = 100 mm

In Fig. 9b, by comparing the results of HRSC5 with HRSC7 if the number of discs rises from 6 to 11, the load-carrying capacity of the stone columns increased by 25.2%.

The results show that the stone columns reinforced with 11 discs with the space of S = D/2 give better performance than that of with 6 discs (S = D). When the stone columns are reinforced in spaces of S = D, due to the less friction between steel discs and stone aggregates, sliding occurs. By decreasing the space of discs to S = D/2, the load-carrying capacity increases more. This increase in load-carrying capacity, due to the confinement of crushed stone materials between the horizontal reinforced layers by mobilizing the shear stress between the discs and crushed stone materials, creates additional confinement. Moreover, reinforcing stone columns by 11 discs (S = D/2) lead to the formation of small stone columns between discs, so that the limited lateral bulging occurs and the load-carrying capacity increases.

Influence of the Reinforced Length

D = 80 mm

The comparison of HRSC1 (full-length reinforced) and HRSC2 (half-length reinforced) in Fig. 9a shows that by increasing the number of discs from 4 to 6 with S = D, the load-carrying capacity increased by 2.4% and by comparing HRSC3 (6 discs) and HRSC4 (11 discs) with S = D/2, by increasing the number of discs, load-carrying capacity increased by 5.4%.

D = 100 mm

Comparing HRSC5 with HRSC6 and HRSC7 with HRSC8 in Fig. 9b shows that the increase is 2.5% and 11.3%, respectively.

The results show that reinforcing the top of the stone columns, that are more susceptible to lateral bulging, have more influence on load-carrying capacity. However, by reinforcing the full-length of the stone columns, the increase of load-carrying capacity is negligible.

Due to the fact that the bulging failure mode in OSCs governed at the depth of D to 2D, so reinforcing the stone column with horizontal discs in the higher depth, compared to reinforcing the full-length of the column, has little effect on increasing the load-carrying capacity. So, it could be said that using half-length reinforcing stone column is economically beneficial to the project.

Improvement Factor

The increase in load-carrying capacity is defined by the dimensionless parameter of the Improvement Factor (IF), which is defined as the ultimate capacity of the reinforced kaolin clay bed to the bearing capacity of the kaolin clay bed. This parameter helps to determine the efficiency of stone columns on improving the load-carrying capacity of the soft clay. In Fig. 10, the IF variation with the settlement for stone columns with diameters of 80 and 100 mm with different types of vertical reinforcing is shown.

As it can be seen in Fig. 10, the IF value varies in the range of 1.30–1.68 and 1.42–4.33 for stone columns with diameters of 80 and 100 mm, respectively, in 50 mm settlement. The minimum IF is for OSCs and maximum is for VSRC5 (with 6 number of bars in diameter of 3 mm and Lr = L).

Figure 11 shows the value of IF for HRSCs. As seen, the IF varies in the range of 1.30–3.10 for stone columns D = 80 mm, and 1.42–3.48 for stone columns D = 100 mm. For HRSCs, the IF value increases by increasing the reinforced length of the stone columns. This is because the discs create an additional lateral confinement on the stone columns and lead to decrease in the amount of lateral bulging.

Figures 10 and 11 show that in vertical reinforced cases, with increasing the load up to about 16 mm settlement, the value of IF increases. Beyond about 16 mm settlement, the IF value decreases or is constant, due to the occurrence of lateral bulging and the column reaches its final strength. Also, for horizontal reinforced cases by getting to 20 mm settlement, the value of IF increases.

Comparison of VRSCs and HRSCs

In this section, for comparison of VRSCs and HRSCs, in each case, best conditions are chosen which have the greatest load-carrying capacity. For comparison of load-carrying capacity and value of IF, VRSC5 and HRSC7 are selected.

Figures 8, 9, 10 and 11 show that VRSC5 with the arrangement of (c) has a bearing pressure of 111 kPa and the maximum value of IF is 4.33 that occurs in 22 mm settlement. Moreover, for HRSC7 with S = D/2 and Lr = L, the amount of load-carrying capacity is 100.5 kPa and the maximum value of IF is 4.33 that occurs in 30 mm settlement. Results show that reinforcing with vertical bars works better than horizontal discs.

In the early stages (about 10% of settlement) of all the cases, by applying the load, the stone aggregates tend to compress. So load capacity increases. By continuing this process, the tendency to the occurrence of lateral bulging is seen and due to the low resistance of kaolin clay to the bulging, the increase of bearing capacity is negligible.

Comparison of Steel Bars and Discs with Geotextile Reinforcement

In this part, for comparison of VRSCs and HRSCs, in each case, best conditions are selected which had the greatest load-carrying capacity for comparison of geotextile-encased stone column. Considering that the use of geotextiles to create the additional confinement is common in stone columns, it is needed to compare the results with vertical geotextile-encased stone columns (VGESCs) and horizontal geotextile reinforced stone columns (HGRSCs). It should be noted that in vertical mode (full-length reinforced), comparing VRSC1 and VRSC5 with VGESC1 and VGESC2, is done, respectively. In the horizontal mode (S = D/2), HRSC3 and HRSC7 with HGRSC1 and HGRSC2, are compared, respectively, too. The properties of nonwoven geotextile used in the current study are listed in Table 4.

The VGESCs and HGRSCs are constructed in the same way as constructing VRSC and HRSC, respectively. Figure 12 shows the bearing pressure–settlement behaviour of the VGESCs and HGRSCs with 80 and 100 mm in diameter.

In order to compare the results, the dimensionless parameter (β) is defined, where β is the bearing pressure of VRSC and HRSC by the corresponding bearing pressure of the same state as the geotextile reinforcement VGESCs and HGRSCs, respectively. In Fig. 13, the values of β for D = 80 and 100 mm diameter of vertical and horizontal reinforced column are given for a 50 mm settlement.

This figure implies the value of β for the vertical case in the range of 1.16, 1.21 and for the horizontal case in the range of 1.07, 1.19. The high amounts of β are because of more stiffness of the steel bars and discs in comparison with the geotextile reinforcement. So, the VRSCs and HRSCs worked better than the VGESCs and HGRSCs.

Conclusions

In this large-scale laboratory study, the effects of vertical reinforced stone columns and horizontal reinforced stone columns with the various arrangement on load-carrying capacity in D = 80 and 100 mm are studied. To investigate the effect of the reinforced length in all the cases, the stone column is also reinforced full-length and half-length. A comparison is done between the vertical reinforced stone column and horizontal reinforced stone column with vertical geotextile-encased stone column and horizontal geotextile reinforced stone column, respectively. The following results are obtained:

-

1.

The load-carrying capacity of kaolin clay bed increases by using ordinary stone columns. By using reinforcement bars and discs, due to the higher stiffness of the column and additional lateral confinement, load-carrying capacity can be increased. This increase in vertical reinforced stone columns is more than horizontal reinforced stone columns.

-

2.

In vertical reinforced stone columns considering the constant of geometric percentage of the bars, an arrangement with more bar diameters have better performance. It is because of that by increasing the diameter of the bars, the stiffness of the columns increases and prevents lateral bulging.

-

3.

In vertical reinforced stone columns, the performance of the full-length reinforced column is better than the half-length reinforced column. However, in horizontal reinforced stone columns, reinforcing the full-length of the column in comparison with half-length reinforced column does not have much effect on the load-carrying capacity.

-

4.

The load-carrying capacity of the horizontal reinforced stone columns with 11 numbers of discs (S = D/2) is more than the capacity of the 6 numbers of discs (S = D). In the intervals D/2, by forming shorter columns between the discs, the lateral bulging amount decreases. While the failure mechanism reinforced column with D intervals is more likely to slide, it is because of the less friction between the stone aggregates and the discs.

-

5.

In the early stages, by applying the load to the stone column, the stone aggregates tend to compress. So the load-carrying capacity is highly increased. However, by continuing the process of loading, due to the occurrence of lateral bulging, the increase in bearing capacity is negligible.

-

6.

The use of vertical reinforced stone column and horizontal reinforced stone column offers more load-carrying capacity than vertical geotextile-encased stone column and horizontal geotextile reinforced stone column in the same condition, respectively.

References

Greenwood DA (1970) Mechanical improvement of soils belowground surfaces. Proceedings of Conference on Ground Engineering, Institute of Civil Engineers, London, pp. 11–22

Vesic AS (1972) Expansion of cavities in infinite soil mass. J Soil Mech Found Div 98(SM3):265–290

Hughes JMO, Withers NJ (1974) Reinforcing of the soft cohesive soils with granular columns. Ground Eng 7(3):42–49

Aboshi H, Ichimoto E, Harada K, Emoki M (1979) The composer—a method to improve the characteristics of soft clays by inclusion of large diameter sand columns. Proceedings International Conference on Soil Reinforcement, Paris, pp. 211–216

Barksdale RD, Bachus RC (1983) Design and construction of stone columns. Report No. FHWA/RD-83/026, Office of Engineering and Highway Operations Research and Development. Federal Highway Administration, Washington, DC

Bergado DT, Anderson LR, Miura N, Balasubramaniam AS (1996) Soft ground improvement in lowland and other environments. ASCE, New York

Munfakh GA, Sarkar SK, Castelli RJ (1983) Performance of a test embankment founded on stone columns. Proceedings of the International Conference on Advances in Piling and Ground Treatment for Foundation, Thomas Telford, London, pp. 259–265

Han J, Ye SL (1992) Settlement analysis of buildings on the soft clays stabilized by stone columns. Proceedings International Conference on Soil Improvement and Pile Foundation, vol 118, pp. 446–451

Han J, Ye SL (2001) Simplified method for consolidation rate of stone column reinforced foundation. J Geotech Geoenviron Eng 127(7):597–603

Castro J, Cimentada A, Costa A, Canizal J, Sagaseta C (2013) Consolidation and deformation around stone columns: comparison of theoretical and laboratory results. Comput Geotech 49:326–337. https://doi.org/10.1016/j.compgeo.2012.09.004

Balaam NP, Booker JR (1985) Effect of stone column yield on settlement of rigid foundations in stabilized clay. Int J Numer Anal Meth Geomech 9(4):331–351

Priebe HJ (1995) The design of vibro replacement. Ground Eng 28(10):31–37

Hughes JMO, Withers NJ, Greenwood DA (1975) Field trial of reinforcing effect of a stone column in soil. Geotechnique 25(1):31–44. https://doi.org/10.1680/geot.1975.25.1.31

Madhav MR, Vitkar PP (1978) Strip footing on weak clay stabilized with a granular trench or pile. Can Geotech J 15(4):605–609. https://doi.org/10.1139/t78-066

Madhav MR, Miura N (1994) Soil improvement. Panel report on stone columns. In: Proceedings of the 13th International Conference on Soil Mechanics and Foundation Engineering, New Delhi, India, vol 5, pp. 163–164

Van Impe WF (1989) Soil improvement techniques and their evolution. Balkema, Rotterdam

Raithel M, Kempfert HG (2000) Calculation model for dam foundations with geotextile coated sand columns. In: International Conference on Geotechnical and Geological Engineering, Melbourne, Australia

Alexiew D, Brokemper D, Lothspeich S (2005) Geotextile encased columns (GEC): load capacity, geotextile selection and pre-design graphs. In: Geo-frontiers Conference, Austin, Texas 497–510. https://doi.org/10.1061/40777(156)12

Murugesan S, Rajagopal K (2007) Model tests on geosynthetic-encased stone columns”. Geosynth Int 14(6):346–354. https://doi.org/10.1680/gein.2007.14.6.346

Murugesan S, Rajagopal K (2010) Studies on the behavior of single and group of geosynthetic encased stone columns. J Geotech Geoenviron Eng 136(1):129–139. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000187

Lo SR, Zhang R, Mak J (2010) Geosynthetic-encased stone columns in soft clay: a numerical study. Geotext Geomembr 28(3):292–302. https://doi.org/10.1016/j.geotexmem.2009.09.015

Ghazavi M, Afshar JN (2013) Bearing capacity of geosynthetic encased stone columns”. Geotext Geomembr 38:26–36. https://doi.org/10.1016/j.geotexmem.2013.04.003

Hong YS, Wu CS, Yu YS (2016) Model tests on geotextile-encased granular columns under 1-g and undrained conditions. Geotext Geomembr 44(1):13–27. https://doi.org/10.1016/j.geotexmem.2015.06.006

Miranda M, Costa AD (2016) Laboratory analysis of encased stone columns. Geotext Geomembr 44(3):269–277. https://doi.org/10.1016/j.geotexmem.2015.12.001

Hasan M, Samadhiya NK (2016) Experimental and numerical analysis of geosynthetic-reinforced floating granular piles in soft clays. Int J Geosynth Ground Eng 2(22):1–3. https://doi.org/10.1007/s40891-016-0062-6

Muzammil SP, Varghese RM, Joseph J (2018) Numerical simulation of the response of geosynthetic encased stone columns under oil storage tank. Int J Geosynth Ground Eng 4(4):1–12. https://doi.org/10.1007/s40891-017-0122-6

Lajevardi SH, Enami S, Hamidi M, Shamsi HR (2018) Experimental study of single and groups of stone columns encased by geotextile. J Sci Technol. https://doi.org/10.22060/CEEJ.2018.12789.5269

Lajevardi SH, Shamsi HR, Hamidi M, Enami S (2018) Numerical and experimental studies on single stone columns. Soil Mech Found Eng 55(5):340–345. https://doi.org/10.1007/s11204-018-9546-9

Madhav MR, Alamghir M, Miura N (1994) Improving granular column capacity by geogrid reinforcement. In: Proceedings of the 5th International Conference on Geotextiles, Geomembranes and Related Products, Singapore, pp. 351–356

Malarvizhi SN, Ilamparuthi K (2007) Comparative study on the behavior of encased stone column and conventional stone column. Soils Found 47(5):873–885. https://doi.org/10.3208/sandf.47.873

Gniel J, Bouazza A (2009) Improvement of soft soils using geogrid encased stone columns. Geotext Geomembr 27(3):167–175. https://doi.org/10.1016/j.geotexmem.2008.11.001

Yoo C, Lee D (2012) Performance of geogrid-encased stone columns in soft ground: full-scale load tests. Geosynth Int 19(6):480–490. https://doi.org/10.1680/gein.12.00033

Dash SK, Bora MC (2013) Influence of geosynthetic encasement on the performance of stone columns floating in soft clay. Can Geotech J 50:754–765. https://doi.org/10.1139/cgj-2012-0437

Gu M, Zhao M, Zhang L, Han J (2016) Effects of geogrid encasement on lateral and vertical deformations of stone columns in model tests. Geosynth Int 23(2):100–112. https://doi.org/10.1680/jgein.15.00035

Debnath P, Dey AK (2017) Bearing capacity of geogrid reinforced sand over encased stone columns in soft clay. Geotext Geomembr 45(6):653–664. https://doi.org/10.1016/j.geotexmem.2017.08.006

Shivashankar R, Babu MRD, Nayak S, Manjunath R (2010) Stone columns with vertical circumferential nails: laboratory model study. Geotech Geol Eng 28(5):695–706. https://doi.org/10.1007/s10706-010-9329-1

Shivashankar R, Babu MRD, Nayak S (2011) Performance of stone columns with circumferential nails. Proc Inst Civil Eng 164(2):97–106. https://doi.org/10.1680/grim.2011.164.2.97

Madhav MR (1982) Recent development in the use and analysis of granular piles. In: Proceedings of Symposium on Recent Development in Ground Improvement Techniques, Bangkok, pp. 117–129

Sharma RS, Phani Khumar BR, Nagendra G (2004) Compressive load response of granular piles reinforced with geogrids. Can Geotech J 41(1):187–192. https://doi.org/10.1139/t03-075

Samadhiya NK, Maheshwari P, Zsaki A, Basu P, Kundu A (2009) Strengthening of clay by geogrid reinforced granular pile. Int J Geotech Eng 3:377–386. https://doi.org/10.3328/IJGE.2009.03.03.377-386

Hasan M, Samadhiya NK (2016) Soft soils improvement by granular piles reinforced with horizontal geogrid strips. Int J Geotech Eng 12(1):101–108. https://doi.org/10.1680/grim.2011.164.2.97

Ghazavi M, Yamchi AE, Afshar JN (2018) Bearing capacity of horizontally layered geosynthetic reinforced stone. Geotext Geomembr 46:312–318. https://doi.org/10.1016/j.geotexmem.2018.01.002

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic-reinforced stone columns: a comparative study. Geosynth Int 19(4):292–305. https://doi.org/10.1680/gein.12.00016

Ali K, Shahu JT, Sharma KG (2014) Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement. Geosynth Int 21(2):103–118. https://doi.org/10.1680/gein.14.00002

Ayadat T, Hanna AM, Hamitouche A (2008) Soil improvement by internally reinforced stone columns. Proc Inst Civil Eng 161(2):55–63. https://doi.org/10.1680/grim.2008.161.2.55

Wood DM, Hu W, Nash DFT (2000) Group effects in stone column foundations: model tests. Geotechnique 50(6):689–698. https://doi.org/10.1680/geot.2000.50.6.689

Hamidi M, Lajevardi SH (2018) Experimental study on the load-carrying capacity of single stone columns. Int J Geosynth Ground Eng 4(26):1–10. https://doi.org/10.1007/s40891-018-0142-x

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rezaei, M.M., Lajevardi, S.H., Saba, H. et al. Laboratory Study on Single Stone Columns Reinforced with Steel Bars and Discs. Int. J. of Geosynth. and Ground Eng. 5, 2 (2019). https://doi.org/10.1007/s40891-019-0154-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-019-0154-1