Abstract

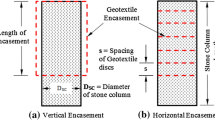

The application of stone columns increases the stiffness of soft soils which contributes to its load carrying capacity and accelerates the process of consolidation leading to reduction in settlement. However, under external loading, squeezing of adjacent soil into the columns not only compromises the integrity of the columns but also reduces its stiffness, strength and drainage properties. The present study investigates the use of vertically and horizontally reinforced stone columns, as a remedial measure for ordinary unreinforced stone columns. The vertical reinforcement is done by encasing the stone columns in geotextile and horizontally by placing geotextile circular discs within the columns at regular interval. Model tests on group of 3 and 4 unreinforced and reinforced stone columns have been conducted in weak sandy soil. The load–settlement response and failure modes for both reinforced and unreinforced groups have been studied. It is observed that reinforced group of stone columns depict better load bearing capacity as compared to unreinforced group. Moreover, bearing capacity for vertically encased and horizontally reinforced is almost similar, with horizontally reinforced group of 4 stone columns depicting slightly higher (1–2%) bearing capacity for a settlement of 30 mm. The experimental results are also validated with theoretical results and are found to be in good agreement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The concept of stone column construction was introduced in the year 1956 as a technique for the ground improvement and to strengthen the bearing capacity of soft cohesive soils. Till date, many research groups have invested effort to understand the behaviour of stone columns under different soil conditions, configurations, installation methods, different kinds of reinforcements and various loading conditions. The ultimate objective of all these studies was to improve the performance of stone columns with respect to serviceability and stability rendered to the weak/soft ground conditions. The previous studies conducted in regard of stone columns can be classified into two sections as:

Conventional (unreinforced) stone columns

The conventional stone columns have proved to be an effective ground improvement method for weak soils by effectively reducing the settlement of the structure in case of soft cohesive soils and soil liquefaction potential for poor cohesion less soils. The three-way advantage provided by conventional stone columns is due to the formation of a composite soil mass of greater stiffness and stability as compared to the untreated soil, due to increase in rate of consolidation and thus minimization of settlement post construction [1, 2], increase in bearing capacity of adjacent weak soil due to increase in coefficient of lateral earth pressure caused by the radial deformation during installation of stone columns [3,4,5]. Thus, widespread use of the technique is found in supportingof geotechnical structures ranging from small footings, river embankments, building foundations, roadway embankments to the construction of oil storage tanks and bridge supports [6,7,8,9,10].

A great deal of investigations has been conducted to study the load carrying capacity and settlement reduction of buildings constructed on the soil using the concept of stone columns by varying the various design parameters like width and depth of treated zone, area ratio, and distribution of columns (uniformity and concentration at edges or at centre) [11,12,13,14,15]. The investigations have revealed the development of stress concentrations in the columns followed by the reduction in stress in the surrounding soil during the reinforcement of ground with stone columns. The probable explanation lies in the fact that after loading, there is almost same vertical settlement of the stone column and surrounding soil, resulting in stress concentration in the column due to its more rigidity in comparison to the nearby soil [16]. The bearing capacity of stone columns and cavity expansion factors have been found to vary inversely with the undrained shear strength and confining pressure available to the columns at failure. The observation was reported in the study of evaluation of analytical models applied to the footings spread on the aggregate pier (stone columns) reinforced soil [17]. The settlement performance of stone columns has been found to be dependent on the area ratio, column length and number of column. However, the influence of column length has been found to be dominating at low area ratios [3, 18, 19].

The research reports have indicated better performance of a group of stone columns than that of a single column in terms of its footing capacity, reduction on soil settlement and load bearing ability of the soil. The investigation of response for clay beds reinforced with stone columns was conducted by Wood et al. [20] by utilizing an exhumation technique. The exhumation technique was utilized to examine the various deformed column shapes and load–transfer mechanism from columns to the surrounding clay. The authors evaluated two possible load–transfer mechanisms: by bulging or by forming a failure plane. Furthermore, a significant interaction between the footing and individual stone columns within the group leading to different load settlements at different locations under the footing was found to be precisely evaluated through laboratory model tests. Ambily and Gandhi [21] experimentally determined the behaviour of a single and group of seven columns by varying the parameters viz. column diameter (d), column spacing (s), shear strength of the soft clay and loading conditions. The axial capacity of the column was found to decrease, whereas an increase in settlement with an increase in spacing up to s/d of 3 was reported. It was also suggested that any further increase in s/d ratio depicted a negligible change in settlement.

Reinforced stone columns

However, scrutinizing under serviceability criteria, the mechanism of load transfer for conventional (unreinforced) stone columns by undergoing bulging up to a depth of 4D (where D = diameter of the stone column) resulted in lateral squeezing of aggregates into the surrounding soft soil. Thus, the degree of compactness, efficiency of load transfer to deeper stratum, strength of stone columns and the drainage potential (due to higher susceptibility to clogging) is often compromised. Although, utilization of stone columns for stabilization of natural soil has been well established for almost every soil type, but relatively weak soil often fails to provide the required lateral confining pressure. Therefore during installation of stone columns in such soil conditions, bulging of stone columns is observed.

Hence, to restrict the bulging of stone columns under loading, confinement of stone columns is done so as to increase the serviceability and also preserve the integrity of the method. The lateral collapsing of stone columns is thus checked by the insertion of geosynthetic material in the column. The usage of this reinforcing material increases the compactness of the composite system through densification and provides more rigidness to the structure. Consequently, the permeability and strength of the treated soil is also increased which in turn helps minimize the bulging of stone columns. Further, the geosynthetic reinforcement of stone columns has been reported to significantly improve performance of stone columns by providing the lateral confinement to the columns either by friction mobilization or by mobilization through hoop stresses.

Vertically reinforced stone columns

Murugesan et al. [22,23,24] have investigated the qualitative as well as quantitative improvement of individual load capacity of single and a group of stone columns by performing laboratory model tests. The stone columns were installed in clay surface prepared under organized condition in a large scale testing tank. The results showed that axial load capacity is directly proportional to the modulus of encasement and the diameter of the column. The increase in stress concentration on encased stone columns in comparison to ordinary columns indicated that encased columns act like semi rigid piles. In addition to preventing the excessive bulging and crushing of stone into the soil, the encasement of stone columns also increases the bearing capacity and reduces the settlement of the composite foundation [25]. Also the stabilization of slopes has been reported using reinforced stone columns, thereby increasing the safety factor of the structure [26].

Horizontally reinforced stone columns

The mechanism of vertically encased stone columns are governed by resistance to hoop stress generated under loading, while interface friction can also be utilized to increase the bearing capacity as well as reduce the slenderness ratio and thereby minimizing the bulging by placing horizontal circular discs of geosynthetics within the columns at regular intervals [27,28,29]. Ali et al. [27] investigated 50 mm single stone column both vertically and horizontally reinforced by varying various parameters like diameter of the column, spacing between the columns and different area replacement ratios. The failure mechanism for different types and configurations was also studied by Ali et al. [30] using the exhumed deformed column shapes. The geogrid reinforcement was found to be the best suited geosynthetic encasement for end bearing columns. However, for floating columns, both geotextile and geogrid were equally good for horizontal circular discs and encasement configurations.

It can be seen from review of past literature that significant studies has been conducted to investigate the behaviour of unreinforced stone columns. Recent literature also reflects that majority of studies on vertically reinforced stone columns are conducted on unit cell with few reporting about group stone columns. Very few studies [31,32,33,34] have been reported regarding ground improvement of weak/soft sandy soils with available literature mainly focusing only on liquefaction potential mitigation of sandy soil by the insertion of stone columns. Moreover, for horizontal reinforced stone columns, very little literature exists with virtually non-existent data regarding horizontal reinforced stone column group. Thus, the present research work investigates the behaviour of group of stone columns for both unreinforced and reinforced stone columns. The group of stone columns is arranged as per field practice of triangular and rectangular arrangements. The reinforcement of stone columns is attained both in vertical (along stone column length) and horizontal (circular disc) using geotextile (woven polypropylene). The behaviour of unreinforced and reinforced group of stone columns is studied for bearing capacity and settlement characteristics. The work also focuses on examining the effect of geotextile on floating stone columns and its failure mechanisms for different cases have also been checked.

Experimental program

Materials used

Soil

The properties of soil used in the present study are evaluated using the following test in accordance to procedure as given by IS codes. The testing method along with the evaluated soil property is summarized in Table 1.

From the particle size distribution curve (Fig. 1), values of Coefficient of curvature (Cc = 1.5) and uniformity coefficient (Cc = 4.5) are obtained. Hence, the soil used in the present study is classified as well graded sand (SW) as per the IS classification.

Aggregates

The size of the aggregates needs to be decided carefully from constructing the stone columns. According to Ali et al. [30], the crushed stones of size in between 6 and 40 mm can be chosen as aggregates so as to satisfy the d/D ratio used for prototypes. However, the use of this particular particle size range is dependent on the fact that in practice, diameter of stone column (d) varying between 0.6 and 1.0 m are usually constructed using crushed aggregates/gravels of size (D) = 25–50 mm. Thus, depicting d/D ratio in range of 12–40 for all practical purposes or prototypes [20, 30]. Thus, for the present study, crushed stones of size varying between 2 and 10 mm were used so that for model stone columns of 40 mm, d/D ratio varies from 4 to 20. Aggregates of 10 mm (passing) were procured from Hardik Construction Company, Panipat, India. With 25% of aggregates retained on 10 mm IS sieve and 63% of the aggregates retained on 2 mm IS sieve, its particle size distribution curve as given in Fig. 2 was obtained. The aggregate sizes (D10–), (D30) and (D60) are 0.20, 0.47 and 0.65, respectively. With Cu and Cc corresponding to 3.25 and 1.69, the aggregates are classified as poorly graded gravel (GP) according to IS classification. The dry unit weight γd = 22.78 kN/m3, (γd)min. = 19 kN/m3 and (γd)max. = 25.54 kN/m3 was also found similar to the reported literature [35,36,37,38,39]. Direct shear tests conducted at a shearing rate of 1.25 mm/min under normal stress of 100 kPa, 150 kPa, 200 kPa and 300 kPa was used for determination of angle of internal friction of stone aggregates. The angle of internal friction was found to be 43º.

Reinforcement material: geotextile

Goetextiles are permeable material which can be used in association with soil to separate, filter, reinforce, protect, or drain. These fabrics come in 3 forms: woven, needle punched or heat bonded. The geotextile used n the present study for reinforcing the stone column is Woven Polypropylene Geotextile. The used geotextile has a high load capacity and poor drainage property. These textiles find their application in roads, airfield, reservoirs, retaining structures, etc. They improve soil strength at a lower cost and they also allow planting on steep slopes. The geotextile and its corresponding properties were obtained from Suntech Geotextile Pvt. Ltd., Chhattisgarh, India and are given in Table 2.

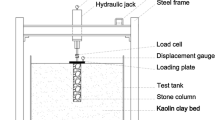

Model test tank

The modeling of test tank and stone column parameters [diameter (d) and length (l)] are determined after considering the geometric similitude ratio, l/d ratio and boundary effects. For prototype stone columns, diameter range between 0.6 and 1.0 m with length of 5–20 m is generally used [20]. Moreover, the minimum diameter of stone column which can be installed with complete integrity is about 13 mm [40]. However, for the present study, diameter of stone column used is 40 mm rendering a similitude ratio (dmodel/dprototype) of 0.04–0.06. Similarly, l/d ratio used for prototypes varies from 5 to 20 [40]. Keeping in line with the mentioned norm, l/d ratio for the present study is maintained at 8. For dimensioning of the model tank, the most important parameter is that insignificant induced stresses are generated at the tank boundaries. This implies that the boundaries of the tank should be distant enough so that no constrained are developed and hence overestimation of results can be checked. In order to attain this, a hypothetical footing of width (B = 120 mm) resting on stone column of length (L) of 300 mm is considered. The adopted dimensions of B = 120 mm and L = 300 mm are considered for the maximum adopted model column dimensions. As adopted from the settlement concept of pile group, an equivalent footing is considered at two-third column length (i.e. at depth of 200 mm from ground). Using 2:1 dispersion method, the effect of vertical stress from footing resting on stone columns at the ground surface is calculated at depth of twice the footing width (2B = 240 mm below the equivalent footing location).

It is found that only 11% of stresses are developed at tank boundaries. However, considering the critical length for settlement criteria of 1.5 B [1, 3], the vertical stresses developed due to footing surcharge are calculated at 180 mm below the location of hypothetical footing situated at 200 mm from ground level. It is found that only 16% of the total applied vertical stress is found at a depth of 380 mm from ground surface and it further reduces to 11% at a depth of 440 mm. Hence, considering any depth for model tank above 440 mm can be treated to be free from boundary effects. Similar approach for dimensioning of model cylindrical tank of diameter 300 mm and 600 mm—depth was also adopted by Shahu and Reddy [40]. On similar line, cylindrical model tanks for single and group of reinforced stone columns were also considered by Ali et al. [27, 30]. In the present work, the depth of model tank taken is 550 mm, which applies that only 3% of the applied vertical stress reaches the tank boundaries. However, for soft compressible soil, 16% of overburden stress can be significant, but that is only corresponding to the depth of 1.5 the footing width. The adopted depth in the present case is significantly higher (550 mm) depicting only 3% overburden stress which can be considered insignificant for soft compressible soils too.

For considering the lateral tank boundaries, in addition to the 2:1 dispersion method, the concept of tributary area has also been taken into account. As per IS 15284-1 [45], the tributary area (i.e. surrounding volume of soil) contributing to a stone column group arranged in triangular pattern is generally hexagonal and square for stone group column arranged in square pattern, respectively. The tributary area is transformed into a circle (cylinder) of the same cross-sectional area having an equivalent diameter of 1.05 times spacing between stone columns (s) for triangular arrangement and 1.13s for square pattern [43]. Based on this, it is found that for the present triangular arrangement of stone columns of diameter 40 mm and spacing (s) of 120 mm, the equivalent unit cell diameter of 126 mm is obtained. This suggests that the each outermost stone column should be installed at a minimum distance of 63 mm from the tank boundaries. Similar for square arrangement, the minimum clear distance between centre of outermost stone column and lateral boundary should be at least 68 mm. In the present study, a clear distance between centre of outermost stone column and lateral tank boundaries is taken as 70 mm for all the model testing. Moreover, the lateral boundary distance of 70 mm also provides for development of complete pressure bulb formation 1.5d = 60 mm [43], where d = diameter of stone column = 40 mm primarily near the top of the stone column without any interference from the lateral boundaries. Hence, it can be seen from Fig. 3 that induced stresses become insignificant at the adopted model tank dimensions of 300 mm (length) × 300 mm (width) × 550 (depth) mm with 3 sides made up of iron and 1 side of acrylic sheet.

Construction of stone columns

The stone column parameters [diameter (d) and length (l)] are determined after considering the geometric similitude ratio, l/d ratio and boundary effects. For prototype stone columns, diameter range between 0.6 and 1.0 m with length of 5–20 m is generally used [20]. Moreover, the minimum diameter of stone column which can be installed with complete integrity is about 13 mm [40]. However, for the present study, diameter of stone column used is 40 mm rendering a similitude ratio (dmodel/dprototype) of 0.04–0.06. Similarly, l/d ratio used for prototypes varies from 5 to 20 [40]. Keeping in line with the mentioned norm, l/d ratio for the present study is maintained at 8.

Casting of unreinforced stone column

The column was cast in the following steps:

Step 1

Filling up the soil

The soil was filled in layers of 10 cm each. After every 10 cm, compaction was provided by using the rammer. Soil was compacted by giving uniform 15 blows. Thereafter, the tracer was placed and the next layer was filled up, as shown in Fig. 4. The tracer is a red and yellow powder dye used for marking after every 10 cm layer so as to identify the deformation patterns developed during stone column testing. The soil was filled up to 50 cm height from the bottom of the tank while the stone column was simultaneously cast as explained below.

Step 2

Hollow pipe for casing

The casting of stone column has been done using the soil replacement technique. This technique has been employed by other researchers in the past [41, 42] for small-scale stone column installation in comparison to soil displacement, frozen and force intrusion techniques. For casting of stone columns, a PVC casing of internal diameter 40 mm and thickness of 2 mm was used. Using a hydraulic jack, the PVC casing was inserted into the sandy soil. The main reason for using the top down techniques was to avoid the caving of soil during borehole formation.

Step 3

Casting of unreinforced stone column

Since floating columns were modelled, after filling the soil up to 20 cm, the hollow cylindrical pipe was placed in the model tank (Fig. 5a, b). The soil within the PVC casing was removed using a screw type augur of 38 mm diameter. The remaining soil was scooped out from inside the casing. Prior to placing of aggregates, the interior walls of the casing were greased so as to avoid wall friction and facilitate easy retrieval of casing. The IS light compaction hammer weighing 2.6 kg was used to compact the stone aggregates. The height of fall and number of blows was determined through trial and error prior to casting for a 100 mm stone aggregate thickness so that a desired relative density of 65% (γd ≈ 23 kN/m3) is attained. The high relative density of 65% is attributed for attaining efficient load transfer (strength) over its drainage facility as the surrounding soil itself is permeable by nature. However, in the reported literature [30, 41, 42], relative densities of 50–80% have been used for stone column in clayey soil domain. The aggregates are placed within the casing and tamped while the casing is retrieved simultaneously. Care is taken that only 80 mm of casing is retrieved after laying of each layer so that a seating of 20 mm is available for placement of following stone aggregate layer. The variation of relative density was assumed to be 65 ± 2% during aggregate placement.

Vertically reinforced stone column

The vertical reinforcement was provided by using a geotextile encasement. The encasement was stitched to size of the cylindrical pipe as shown in Fig. 6. The following steps were followed:

Step 1

Filling the soil

The soil was filled in a similar manner to the casting of unreinforced column. After compaction and placement of tracer on 2 layers of 10 cm each, the hollow pipe was introduced.

Step 2

Casting the column

The hollow pipe encased in geotextile is placed in the tank. To reduce friction, the external sides of the pipe were coated with grease. The aggregates were poured in and tamped lightly with a tamping rod with the pipe being withdrawn simultaneously. The casting procedure is identical to casting of unreinforced stone columns. This procedure allowed the geotextile to act as a sort of sack to carry the aggregates.

Horizontally reinforced stone columns

The following are the steps for casting of stone columns with horizontal circular discs:

Step 1

Marking the pipe

The pipe is scaled at every 3 cm, and the same is marked with paint to enable placing of the circular discs as shown in Fig. 7a, b.

Step 2

Casting the column

Circular discs of diameter (39.5 mm) are cut out from the Geotextile (Fig. 9). The discs were to be placed at a distance of 3 cm from each other. Ali et al. [30] reported that maximum increase in failure stress is attained for horizontal reinforcement spacing of d/2 (where d is the diameter of the stone column) or s/d = 0.5 (where ‘s’ is the spacing between the reinforcement). Likewise, the horizontal spacing of reinforcement for the present work should have been 2 cm for column dia. of 40 mm. However, the failure stress is also found to vary with increasing x/l ratio from 0.5 to 1.0, where ‘x’ = distance of horizontal reinforcement from top of stone column and ‘l’ is column length. The failure stress is found to increase from 18% for x/l = 0.5 to 25% for x/l = 1. Thus, to assess the variation of x/l ratio and s/d criteria, the present work adopts spacing at 3 cm. This enables evaluation of x/l ratio from 0.1 to 0.9 and s/d ratio of 0.75. The pipe is placed in the soil at 20 cm from the bottom. The aggregates are filled in and tamped; thereafter the discs are inserted at every marking using a pipe with diameter smaller than the casting pipe. The variation of relative density within the casted column was assumed to be 65 ± 2% during aggregate placement. However, the %age variation in relative density of casted columns with horizontal reinforcement is assumed to be higher as precise compaction of stone layer thickness of only 30 mm was difficult to execute.

Utilizing the unit cell approach, the model tank is defined as cylinder with an influence zone diameter hemming in the surrounding soil and 3 & 4 stone column. The group of stone columns used in practice are uniformly distributed in triangular (3) or square (4) pattern. Due to this orientation, each column of the stone column group projects a tributary area to the surrounding soil which is in form of a hexagon for triangular grid and square for square grid, respectively. Thus, for easy of theoretical analysis and converting the problem to an axi-symmetric condition, the tributary areas is transformed into circles (cylinder in 3D) of equivalent cross-sectional area. Hence, for triangular shape, the equivalent diameter of the corresponding unit cell is equal to 1.05 times the column spacing ‘s’ and 1.13s for square shaped group distribution [43]. The detailed casted and installed group of unreinforced and reinforced stone columns are shown in Fig. 8a, b.

Testing procedure

In practice, loading of stone columns is carried out such that with an area replacement ratio (Ar) varying between 10 and 35% [42]. In the present study, uniform load is applied on the group of 3 and 4 stone columns using a square plate of dimensions 200 mm × 200 mm and thickness of 10 mm. The thickness of the loading plate was determined after trial and error method, so that negligible plate deformation occurs under loading. The dimensions of the plate was determined such that the Ar = 18% for group of 3 stone columns and Ar = 26% for group of 4 stone columns. The Ar so adopted is in accordance to Ali et al. [30] where a constant Ar equal to 25% was adopted. The load was then applied using a modified plunger of diameter 80 mm so that for a unit cell the tank dimensions are 3–5 times the diameter of the loaded area. The plunger was attached to the UTM machine and compressive load at a rate of 1 kN/min was applied (Fig. 9). The load application was ceased when settlement of stone column group reached 30 mm. The applied vertical stress was measured in terms of footing pressure which was calculated as ratio of total load by area of the footing. However, load on individual stone column was not measured.

Results from model testing

Load–settlement behaviour

The load–settlement behaviour of both unreinforced and reinforced (vertically and horizontally) for group of 3 stone columns is shown in Fig. 10. It can be seen from Fig. 10 that reinforced stone columns depict a higher load bearing as compared to unreinforced stone columns. Moreover, it can be seen that the response of both vertical and horizontal reinforced groups is identical. This can be attributed to the fact that vertical reinforcement increases the confinement effect. Due to this, hoop stresses generated within the stone column under loading is not dissipated and gets restricted. This is similar to increase in lateral pressure from the surrounding soil thereby resisting the column bulging and providing efficient load transfer to stone column bottom. Likewise, in case of horizontal reinforcement in form of circular discs, the interface friction is mobilized as the column deforms. Moreover, with circular discs at regular interval of 3 cm, the total length of stone columns is divided into section of 10 mm each. Thus, within this reduced aspect ratio, the tendency of column bulging is reduced and significant load transfer is achieved. However, in both cases, the group of stone columns undergo settlement in absence of any available end-bearing.

Similarly, for group of 4 stone columns, load–settlement behaviour is given in Fig. 11. Again, it is observed that identical nature of vertically and horizontally reinforced stone column. Moreover, reinforced stone column perform better in comparison to unreinforced ones. The behaviour of reinforced stone columns can be attributed to resistance to hoop stress and mobilization of interface friction for vertically and horizontally reinforced stone columns respectively. Moreover, in case of vertically encased columns, downward movement of the encased floating stone columns is also governed by the friction acting between the soil–geotextile interface. It is assumed that due to high angular nature of the aggregates and hoop stresses generated due to column bulging, the aggregate–geotextile interface is significantly higher as compared to soil–geotextile interface. Hence, the settlement failure of vertically encased floating stone columns is dependent on the mobilized interface friction between soil and geotextile. In the present study, the interface friction between geotextile and soil is evaluated using direct shear test (DST). The modification in the set-up has been carried out by placing reinforcement geotextile at the shearing surface of the lower mould and soil in the upper mould of DST apparatus. The interface friction angle between geotextile and soil is found to be 38.73º in comparison to 20° as obtained for soil–soil interface. Thus, high interface friction angle further contributes in increasing the load carrying capacity.

The following observations are also evident from Figs. 10 and 11.

-

(a)

Unreinforced columns experience settlement very early, at a loading of less than 5 kN for group of three stone columns and less than 7 kN for an assembly of four stone columns.

-

(b)

Up to 20 mm settlement, the unreinforced columns tolerate a load of around 14.5 kN and 18.6 kN for group of three and four stone columns respectively. Thereafter, the columns keep on settling without bearing any load. Therefore, graphs show constant phase, which implies that the unreinforced columns fail at 17.2 kN for three stone columns group and 20.4 kN for four stone columns assembly.

-

(c)

The settlement of vertically reinforced columns does not occur up to a load of 15 kN and 17 kN for assembly of three and four stone columns respectively.

-

(d)

Unlike the unreinforced columns, the vertically reinforced column have not failed up to a load of 22.2 kN for three stone columns group and 24.4 kN for four stone columns assembly. This has also implied that the bearing capacity of soil increases more for vertically reinforced columns than for the unreinforced ones. This is due to the lesser bulging of vertically encased columns and lesser penetration of columns into the nearby soil [44].

-

(e)

No settlement of horizontally reinforced columns with equidistant circular discs is observed up to a loading of 16.2 and 18.4 kN for assemblies of three and four stone columns respectively.

-

(f)

Similar to the vertically reinforced columns, the horizontally reinforced columns do not undergone failure till a settlement of 30 mm is reached at load application of 22.2 kN for group of three stone columns and 24.4 kN for four stone columns group. This failure of the columns may be due to the combined effect of bulging and buckling due to shear failure [29]. The load bearing capacity for both 3 and 4 reinforced and unreinforced stone column groups are summarized in Table 3.

Table 3 Comparison of experimental and theoretical bearing capacities of unreinforced and reinforced stone column groups -

(g)

As per the previous studies done on cohesive soils [22, 27], vertically reinforced stone columns are found to perform better than the horizontal reinforcement. But in present case for sandy soil, the horizontal reinforcement emerges out to be more effective than vertical reinforcement.

Modes of failure

From exhumation of stone columns after model testing, it is observed that all groups of 3 and 4 stone columns experienced failure at the top at about a depth of twice the column diameter due to bulging. This can be attributed to the fact that in case of floating columns, applied vertical stresses become high enough to cause penetration and thus failure of the columns before net outward force becomes significant and causes bulging. The failure modes of stone column groups are in accordance to failure observed by Ali et al. [30]. The failure mode for unreinforced columns was also similar but failed at a lower load than reinforced stone columns.

Validation of experimental results

The bearing capacity of reinforced stone columns has been validated using theoretical bearing capacity equation for stone columns as given by IS: 15284 [45] and design guidelines as reported by Murugesan and Rajagopal [24] for encased stone columns.

The maximum footing pressure ‘σv’ acting on unreinforced stone columns can be calculated using Eq. (1) as given in IS: 15284 [45]:

where \({\sigma_{ro}}\) represents the initial effective radial stress calculated as 2[1 − sin(φsoil)]γd. For the present case, cu = 0 and \(Kp_{\text{col}} = \tan^{2} (45 + \varphi /2)\) where φ is the internal frictional angle of the stone aggregates = 43°. Using Eq. (1), Load on unreinforced group of stone columns (P) in kN is calculated by Eq. (2) as:

where area \(A = \pi \times (0.525s)^{2}\) for triangular arrangement (3 stone column group) and \(A = \pi \times (0.564s)^{2}\) for square arrangement (4 stone column group). The theoretical bearing capacity as obtained from Eqs. (1) and (2) are summarized in Table 3.

Evaluation of bearing capacity of vertically reinforced stone column groups is done in accordance to the design guidelines stated by Murugesan and Rajagopal [24]. The area replacement ratio (Ar) based on stone column diameter ‘d’ and spacing‘s’ is calculated using Eqs. (3) and (4):

-

For 3 stone column group:

$$A_{\text{r}} = 0.907\left( {\frac{d}{s}} \right)^{2}$$(3) -

For 4 stone column group:

$$A_{\text{r}} = 0.786\left( {\frac{d}{s}} \right)^{2}$$(4)

Using the Ar corresponding values of normalized tension [T/(d × σv)] in the stone column encasement for \(\varphi\) = 43° and c = 0 is obtained from the design chart as given by Murugesan and Rajagopal [24]. With tensile strength of geotextile (T) for the present case = 45 kN/m and ‘d’ = 0.04 m, σv for 3 and 4 stone groups is evaluated. Thus, from Eq. (2), load on vertically reinforced stone column groups is determined and listed in Table 3. However, for horizontally reinforced stone columns, currently any empirical relationship is virtually non-existent. It can also be seen from Table 3, that a good agreement is found between experimental and theoretical values with deviation of less than 4 and maximum variation of 18% only.

Conclusions

In the present work model testing of 3 and 4 stone column groups has been carried out for both unreinforced and reinforced stone columns. The geotextile reinforcement of stone columns is executed both in vertical direction along stone column length and horizontally by using circular discs placed at 3 cm interval within the stone columns. Based on the results recorded from the response of unreinforced and reinforced stone column groups, the following conclusions are made:

-

1.

For an equal settlement criterion of 30 mm, reinforced group of 3 stone columns depicted a higher load bearing capacity as compared to both 3 and 4 unreinforced stone column groups. Hence, it can be concluded that reinforcing floating stone columns increases the bearing capacity in comparison to unreinforced floating stone columns.

-

2.

Moreover, bearing capacity obtained from reinforced 3 stone column group is 10% more than the bearing capacity of unreinforced 4 stone column group signifying that reinforcement facilitates use of less number of stone column in a group with significant bearing capacity increase. Hence, making the method economical.

-

3.

The group of 3 vertically encased stone columns renders 76.7% increase in bearing capacity in comparison to horizontally reinforced group of 3 stone columns which depicts an increase of 77.4%. Similarly, for a set of 4 vertically encased stone columns, an increase of 81.9% in load carrying capacity was observed against 83.6% for 4 stone columns with horizontal discs. From the percentage increase recorded for vertical and horizontal reinforcement, it can be concluded that both reinforcement methods are equivalent in terms of performance. The vertical encasement serves by resisting the hoop stresses during failure stress while interface friction mobilization between aggregate and geotextile as the column undergoes bulging facilitates better load transfer, thereby increasing the bearing capacity. However, for floating columns in weak sandy soil as in the present case, the latter can be concluded as better reinforcement method.

Limitation and scope for future work

Since increase in bearing capacity obtained from vertically encased and horizontally reinforced stone columns is almost equivalent, a combined vertical and horizontal reinforcement was not studied in the present work. Moreover, field studies regarding combined vertical and horizontal reinforcement are virtually non-existent. Hence, investigation of stone column reinforced both vertically and horizontally can be taken up by future researchers through small scale or field scale testing.

References

Munfakh GA, Sarkar SK, Castelli RP (1983) Performance of a test embankment founded on stone columns. In: Proceedings of international conference on advances in piling and ground treatment for foundations, London, pp 259–265

Yan J, Ye SL (2001) Simplified method for consolidation rate of stone column reinforced foundations. J Geotech Geoenviron Eng (ASCE) 127(7):597–603

Choobbasti AJ, Zahmatkesh A, Noorzad R (2011) Performance of stone columns in soft clay: numerical evaluation. Geotech Geol Eng 29:675–684

Elshazly HA, Hafez DA, Mossaad ME (2008) Reliability of conventional settlement evaluation for circular foundations on stone columns. Geotech Geol Eng 26(3):323–334

Guetif Z, Bouassida M, Debats JM (2007) Improved clay characteristics due to stone column installation. Comput Geotech 34:104–111

Shirazi MR, Zarrin O, Valipourian K (2015) The role of vibro-stone column for enhancing the soft soil properties. Int J Civ Environ Eng 9(5):616–620

Thevanayagam S, Martin GR, Nashed R, Shenthan T, Kanagalingam T, Ecemis N (2006) Liquefaction remediation in silty soils using dynamic compaction and stone columns. Technical Report MCEER-06-0009, August 2006

McKelvey D, Sivakumar V, Bell A, Graham J (2004) Modelling vibrated stone columns in soft clay. Geotech Eng 157(GE3):137–149

Zhan Y, Jiang G, Yao H (2014) Dynamic characteristics of saturated silty soil ground treated by stone column composite foundation. Adv Mater Sci Eng, Article ID 745386, 1–7

Luo M (2018) Finite element analysis of gravel pile composite foundation under flexible foundation of Airport Engineering. IOP Conf Ser Earth Environ Sci 113:012093

Liu CY, Ku CY, Xiao JE, Huang CC, Hsu SM (2017) Numerical modeling of unsaturated layered soil for rainfall-induced shallow landslides. J Environ Eng Landsc Manag 25(4):329–341

Meshkinghalam H, Bonab MH, Azar AK (2017) Numerical investigation of stone columns system for liquefaction and settlement diminution potential. Int J Geo-Eng 8:Article no. 11

Liu W, Hutchinson TC (2018) Numerical investigation of stone columns as a method for improving theperformance of rocking foundation systems. Soil Dyn Earthq Eng 106:60–69

Etezad M, Hanna AM, Asce F, Ayadat T (2015) Bearing capacity of a group of stone columns in soft soil. Int J Geomech 15(2):Article ID 04014043 (1–15)

Nehab N, Baba K, Ouadif L, Bahi L (2016) Three-dimensional modeling of a group of stone columns in “Bouregreg Valley” soft ground. ARPN J Eng Appl Sci 11(24):14537–14544

Gueguin M, Hassen G, de Buhan P (2015) Stability analysis of homogenized stone column reinforced foundations using a numerical yield design approach. Comput Geotech 64:10–19

Stuedlein AW, Holtz RD (2013) Bearing capacity of spread footings on aggregate pier reinforced clay. J Geotech Geoenviron Eng 139(1):49–58

Nassaji F, Asakereh A (2013) Effect of Granular bed on behavior of stone column improved ground. Int J Sci Eng Investig 23(2):67–71

Killeen MM, McCabe BA (2014) Settlement performance of pad footings on soft clay supported by stone columns: a numerical study. Soils Found 54(4):760–776

Muir Wood D, Hu W, Nash DFT (2000) Group effects in stone column foundations: model tests. Geotechnique 50(6):689–698

Ambily AP, Gandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. J Geotech Geoenviron Eng 133:405–415

Murugesan S, Rajagopal K (2007) Model tests on geosynthetic-encased stone columns. Geosynth Int 14(6):346–354

Murugesan S, Rajagopal K (2008) Performance of encased stone columns and design guidelines for construction on soft clay soils. In: Proceedings of the 4th Asian Regional Conference on Geosynthetics, pp 729–734

Murugesan S, Rajagopal K (2010) Studies on the behavior of single and group of geosynthetic encased stone columns. J Geotech Geoenviron Eng 136:129–139

Tandel YK, Solanki CH, Desai AK (2012) Reinforced granular column for deep soil stabilization: a review. Int J Civ Struct Eng 2(3):720–730

Nasiri M, Hajiazizi M (2019) An experimental and numerical investigation of reinforced slope using geotextile encased stone column. Int J Geotech Eng. https://doi.org/10.1080/19386362.2019.1651029

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic-reinforced stone columns: a comparative study. Geosynth Int 19(4):292–305

Dash SK, Bora MC (2013) Improved performance of soft clay foundations using stone columns and geocell-sand mattress. Geotext Geomembr 41:26–35

Ghazavi M, Yamchi AE, Afshar JN (2018) Bearing capacity of horizontally layered geosynthetic reinforced stone columns. Geotext Geomembr 46:312–318

Ali K, Shahu JT, Sharma KG (2014) Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement. Geosynth Int 21(2):103–118

Shenthan T, Nashed R, Thevanayagam S, Martin GR (2004) Liquefaction mitigation in silty soils using composite stone columns. Earthq Eng Eng Vib 3(1):39–50

Zahmatkesh A, Choobbasti AJ (2010) Settlement evaluation of soft clay reinforced by stone columns, considering the effect of soil compaction. Int J Recent Res Appl Sci 3(2):159–166

Maduro IJ, Molina CR, Castillo LV, Renoud-Lias B, Salvi GJ (2004) The use of stone columns on settlement and liquefaction susceptible soils. In: International conference on case histories in geotechnical engineering, p 6

Chenari RJ, Fard MK, Chenari MJ, Sosahab JS (2019) Physical and numerical modeling of stone column behavior in loose sand. Int J Civ Eng 17:231–244

Malarvizhi SN, Ilamparuthi K (2007) Comparative study on the behaviour of encased stone column and conventional stone column. Soils Found 47:873–885

Alexiew D, Raithel M (2015) Geotextile-encased columns: case studies over twenty years. In: Embankments with special reference to consolidation and other physical methods. Butterworth-Heinemann, Oxford, pp 451–477

Chen JF, Li LY, Xue JF, Feng SZ (2015) Failure mechanism of geosynthetic-encased stone columns in soft soils under embankment. Geotext Geomembr 43:424–431

Elshazly H, Elkasabgy M, Elleboudy A (2008) Effect of inter-column spacing on soil stresses due to vibro-installed stone columns: interesting findings. J Geotech Geol Eng 26:225–236

Adam D, Schweiger HF, Markiewicz R, kNabe T (2010) Euro 2008 Stadium Klagenfurt—prediction, monitoring and back calculation of settlement behavior. In: Proceedings of the from research to design in European practice, Bratislava, Slovak Republic, 2–4 June 2010

Shahu JT, Reddy YR (2011) Clayey soil reinforced with stone column group: model tests and analyses. J Geotech Geoenviron Eng 137(12):1265–1274

Black JA, Sivakumar V, Bell A (2011) The settlement performance of stone column foundations. Geotechnique 61(11):909–922

Mohanty P, Samanta M (2015) Experimental and numerical studies on response of the stone column in layered soil. Int J Geosynth Ground Eng 1(3):27

Castro J (2017) Modeling stone columns. Materials 10(7):782. https://doi.org/10.3390/ma10070782.

Mehrannia N, Nazariafshar J, Kalantary F (2017) Experimental investigation on the bearing capacity of stone columns with granular blankets. Geotech Geol Eng. https://doi.org/10.1007/s10706-017-0317-6

BIS IS 15284-1: 2003 Design and construction for ground improvement—guidelines—part 1: stone columns. Bureau of Indian Standards, ManakBhavan, 9 Bahadur Shah ZafarMarg, New Delhi, India

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Thakur, A., Rawat, S. & Gupta, A.K. Experimental study of ground improvement by using encased stone columns. Innov. Infrastruct. Solut. 6, 1 (2021). https://doi.org/10.1007/s41062-020-00383-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-00383-y