Abstract

Stone columns are used as a technique for improving the strength and enhancing the bearing capacity of soft soils. Due to the low confinement of the soil typically surrounding the stone columns, reinforcement materials like geotextile are needed to improve such weakness. Although the technique is now well established, little research has been undertaken on the use of various positions of the reinforcement materials. In this paper, some small-scale laboratory tests were performed on reinforced floating stone columns with diameters of 80 mm and 100 mm and the length of 400 mm and 500 mm, respectively, to study the influence of various positions of geotextile. They were included vertical encasement stone columns, horizontal reinforcement stone columns and combined vertical–horizontal encasement stone columns. The impacts of the different diameters of the columns, the length of the reinforcement and the spaces of the reinforcement have been studied. Based on the results, by increasing the diameter of the vertical encasement stone column, the benefit of encasement decreases, while in horizontal and vertical–horizontal encasement stone column, the performance of the reinforcement increases. Moreover, the load-carrying capacity of combined vertical–horizontal encasement stone columns increases considerably in comparison with the other types.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the ever-increasing population of the world, the need for construction in urban areas with poor soils has become a major problem. Among a variety of techniques for ground improvement, stone columns are usually used where an increase in load-carrying capacity or reduction in the settlement is required. Increasing the shear resistance of soil and reducing the time of consolidation settlement, are also other benefits of this technique. Most experimental studies summarized the mechanisms of failure for a single stone column subjected to axial compressive load: punching failure, shear failure and bulging failure [1,2,3,4,5]. The effectuality of ordinary stone columns (OSCs) will be reduced in very soft soil [6]. In OSCs, the columns usually fail in bulging because of the lack of lateral confinement. Thus, encasing stone columns with reinforcing materials such as geosynthetics could be one solution to this problem. Van Impe [7] was the first who propounded this idea. Malarvizhi and Ilamparuthi [8], as well as Verma et al. [9], suggested that the load-carrying capacity of the stone column and the settlement performance of the loaded plate supported on stone columns can be improved using geosynthetics encasement.

Vertical encasing of the stone columns with geosynthetics has been a subject of most experimental studies [10,11,12,13,14,15,16,17]. Bhatia and Kumar [10] have done a series of model tests performed on single columns. The results showed that geosynthetic encasement affects the ultimate load-carrying capacity of the column and decreases the settlement of treated fly ash fill bed. The results for laboratory model tests with various geosynthetic revealed that the increase in load-carrying capacity of stone columns depends on the stiffness of the geosynthetic used in the column [11]. The effectiveness of the length of the geosynthetic encasement on the capacity and the modulus of the encasement has been studied in laboratory and small-scale model tests [12,13,14].

A few laboratory tests have dealt with the use of horizontal reinforcement layers [18,19,20,21,22,23,24]. Madhav [18] was the first who proposed this shape of reinforcement. Sharma et al. [19] developed laboratory tests to find the influence of the use of horizontal geogrid. Ayadat et al. [20] employed horizontal plastic, steel and aluminum layers and found that the use of such horizontal reinforcing layers improved load-carrying capacity. Also, by increasing the number of these layers in the column, the performance of the column was significantly enhanced. The use of circular geogrid layers indicates that reducing the spaces of the geogrid layers raised the ultimate load of the stone column and decreased the settlement of the soil [21, 22]. Horizontal geogrid and geotextile were the best reinforcement for end-bearing and floating stone columns, respectively [23].

Another possibility for reinforcing stone column is combining vertical and horizontal reinforcement. Hasan and Samadhiya [25] investigated such a case with unit cell model tests conducted on a column with a diameter of 75 mm with 375 and 525 mm height in the clay soil. They found that this type of reinforcing contributed to increase the load-carrying capacity of columns.

Most previous experimental studies have been performed small-scale tests using unit cell concept in the case of end-bearing stone columns. Indeed, the laboratory tests have not covered the various positions of the reinforcements in stone columns. In this study, some small-scale laboratory tests of floating stone columns in kaolin clay bed were performed to compare the load-carrying capacity of a single stone column encased with geotextile in the form of the vertical encasement, horizontal layers and combined vertical–horizontal encasement. To control the bulging failure, the minimum length-to-diameter ratio of the stone column was 4 [1]. Therefore, in this study, the length-to-diameter ratio was 5. The tests focused on studying the effect of varying the positions of the reinforcements in stone columns with diameters (D) of 80 mm and 100 mm and length (L) of 400 mm and 500 mm, respectively.

Test program

Material properties

Soil bed and stone column material

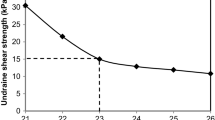

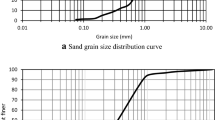

For very soft soils (undrained shear strength ≤ 15 kPa), a technique of using geotextile coating around the stone column is used to obtain lateral support, thus avoiding lateral spreading of the column [26]. It is well known that in clayey soils, the variation in water content will affect the strength of the soil. So, the undrained shear strength of 15 kPa was found to be corresponding to a water content of 23% and was kept constant in all tests. The properties of the kaolin clay soil prepared by this method are listed in Table 1. The ratio of the column diameter to the diameter of the fill particles lies within the range 12-40, as this is the practical ratio used in the field [27]. So, crushed stone aggregates with sizes in the range of 2-10 mm were used as fill material. All physical and mechanical properties of the crushed stone aggregates are also listed in Table 1.

Reinforcement material

Scaling effect is the main difficulty of experimental tests. Three parameters, stone column material unit weight, the diameter of the stone column and the stiffness of the reinforcement material, play a fundamental role in the simulation of the tests. Iai [36] derived the following equation to describe the relationship between these three parameters:

where J is the stiffness of the reinforcement, D is the stone column diameter, and γ is the unit weight of crushed stone aggregates. Also, m and f represent model and field condition, respectively. The unit weight of crushed stone aggregates used for both model and field condition was the same. So, it does not affect Eq. 1. The stone columns with diameters of 80 mm and 100 mm were used equivalent 0.10 of the field conditions. However, since the value of the diameter in Eq. 1 has the power of 2, so to establish equality in Eq. 1, secant stiffness of the model tests is 0.01 field tests. The stiffness of the reinforcement varies in the range of 1000-4000 kN/m in the field condition [37]. Therefore, the geotextile used in the experiments, according to the above explanations, will have a secant stiffness of 10–40 to observe the effect of scale as in previous studies [16, 20, 30, 31, 34, 35]. In this study, nonwoven polypropylene geotextile with secant stiffness of 15 kN/m was used as the reinforcing material. The specifications of the geotextile are shown in Table 2.

Experimental setup

The test facility, which was designed and constructed for the proposed research work, consists of loading frame, test tank, hydraulic jack and pumping unit and devices for measuring load and settlements similar to that used by Murugesan and Rajagopal [14] and Mohammad Rezaei et al. [39] (Fig. 1). The boundaries of the tank were chosen in such a way that the resulting stresses should remain small at the boundaries. Assuming a loading plate placed at two-thirds of the column depth and a 2: 1 spread, the stress distribution showed that the induced stresses become very small at the boundaries [15, 40]. Based on this, to avoid the effects of geometry, the model boundary was assigned greater than that amount. Hence, the steel tank was built in a 1.2 m × 1.2 m × 1 m (length × width × height). According to the guidelines given in IS 15284 [41], the loading plate’s diameter was 2 times larger than that of the columns. In this case, both the column and the weak soil surrounding it were loaded. Also, the thickness of the loading plate was 30 mm and it was sufficiently rigid so that the vertical displacement will be uniformly transferred to the stone column and the surrounding soil through this rigid plate.

Experimental procedure

Preparation of clay bed

The amount of water needed for dry soil with a dry unit weight of 15.5 kN/m3 to achieve a moisture content of 23% was obtained. To obtain a homogeneous mixture, a large container was used to mix the kaolin clay soil with water. To reduce the friction between the tank wall and the clay, a thin layer of grease was applied to the inner surface of the tank [42]. Then kaolin clay soil was filled in the test tank at a proper bulk unit weight of 19.1 kN/m3 in 18 equal layers, where a 10-kg square tamper (with dimensions of 150 mm) was used to compact the soil in each layer [43]. This procedure has continued up to filling the test tank. Then, the top surface of the tank was covered by nylon and left for seven days to gain uniformity of the moisture content. During the filling of the test tank, the soil moisture test has been repeated several times to ensure that the moisture content was 23%, which was equivalent to the undrained shear strength of 15 kPa.

Preparation of stone column

Replacement technique was used to construct the stone column in the present study. This technique has been developed in the laboratory and causes less disturbance to the soils during installation [44, 45]. A thin seamless pipe with an outer diameter equal to the stone column diameter (80 or 100 mm), was pushed into the kaolin clay soil via a hydraulic jack. The inner and outer surfaces of the pipe were considered smooth and greasy enough to minimize any potential friction created between the soil and the surface of this pipe. The kaolin clay soil inside the pipe was scooped out using helical augers. Then, the pipe was slowly lifted up to prevent any damage to the inner of the hole. The formed borehole was filled with the stone aggregates in 10 equal layers, and the amount of stone aggregates for making a column was calculated based on unit weight of 16 kN/m3. To gain a uniform density, the compaction was carried out by a 20-mm-diameter steel tamper with a mass of 2 kg falling through a distance of 100 mm with 15 blows [46]. This specific compaction was used in such a way that it did not cause any significant lateral deformation during the construction of the stone column. In addition, preventing the penetration of stone aggregates into the soil and thus not disturbing the surrounding soil was also an advantage of this soil compaction. It should be noted that in order to maintain constant compaction energy in the case of 80-mm-diameter stone columns, the number of tamper blows was reduced by half. The similar procedure was used to prepare reinforced stone columns (Fig. 2).

For encasing vertical geotextile in field and laboratory conditions, an open-toe, thin-walled steel tube (casing) equal in diameter to geotextile sock was pushed from the surface down to the underlying founding layer. The geotextile was then placed inside the casing and filled from the surface with stone aggregates by the method which mentioned for the nonreinforced stone column. After the geotextile sock has been filled, the steel casing was raised around the encased column, leaving it in situ [37]. For placing horizontal geotextile, after making the borehole, circular layers of geotextile with a diameter of the column were put in the borehole. After that, the column was filled with stone aggregates until it reaches the next horizontal layer. This process continues until the borehole is filled with stone aggregates and a certain number of layers of geotextile.

Test conducted

The behavior of the stone column with and without reinforcement in kaolin clay soil was captured by applying vertical load on the rigid loading plate. The axial load was applied at a displacement rate of 1 mm/min up to a settlement of 50 mm [15, 24]. A 50-mm settlement is equivalent to a 10% strain for 100-mm-diameter stone columns. Also, the allowable settlement for structures is generally equivalent to the 50-mm settlement, so the tests have continued until this settlement. The tests here were also conducted on the kaolin clay bed, OSCs and the stone column reinforcements which included vertical encasement stone column (VESC), horizontal reinforcement stone column (HRSC) and combined vertical–horizontal encasement stone column (VHESC).

As it is shown in Fig. 3, in the VESCs, three different tests were conducted using different lengths of the vertical geotextile (Lr), and in the HRSCs, two different tests were conducted using horizontal geotextile by considering the space (S) of layers. In VHESCs, three different tests have been done by using both vertical and horizontal geotextile at the same time. It should be noted that the VHESC consists of a combination of VESC and HRSC. For example, for D = 80 mm, VESC1 refers to the stone column with full-length reinforcement and HRSC1 refers to the stone column with 11 horizontal layers (the space of the layers = 0.5 D). Thus, VHESC1 defined as the stone column with full-length reinforcement and 11 horizontal layers (Fig. 4).

To study the effect of different positions of the reinforcements on the load-carrying capacity of the kaolin clay bed, 19 tests were conducted on kaolin clay bed using different stone column diameters (D = 80 mm and 100 mm) with column length-to-diameter ratio of 5 (Table 3). In these tests, stone columns were installed in kaolin clay bed without ground water level. Moreover, some tests were performed twice to confirm the measured results and verify the repeatability of tests.

Results and discussion

VESCs

Load–settlement behavior

Figure 5a, b demonstrates the load–settlement behavior of single stone columns with vertical encasement geotextile for column diameters of 80 mm and 100 mm, respectively.

As can be seen, OSCs and VESCs increase the load-carrying capacity of kaolin clay bed. The amount of this increase for OSC1 and OSC2 was 25.6% and 44.4% for D = 80 mm and 100 mm, respectively. Reinforcing the kaolin clay bed with VESC1 and VESC4 increased the load-carrying capacity of the kaolin clay bed by 84.8% and 103.7% for D = 80 mm and 100 mm, respectively. This rise for VESC2 and VESC3 was 66.3% and 74.0% for D = 80 mm and for VESC5 and VESC6 was 89.4% and 98.5% for D = 100 mm, respectively.

The results show that using OSCs leads to increase in load-carrying capacity of kaolin clay bed. Also, by encasing OSCs with vertical geotextile, the increase of load-carrying capacity is more. It is because the reinforcing material provides additional lateral confinement and reduces the bulging in columns.

Influence of the diameter of the stone column

Figure 5a, b shows a comparison between OSC1 and OSC2 and indicates that the increase of the diameter from 80 mm to 100 mm leads to increase in the load-carrying capacity by 15%. Furthermore, the average magnitude of this increase for all types of VESCs was 12.7%. The result indicates that in all cases, by increasing the stone column diameter from 80 to 100 mm, the increase in the load-carrying capacity is evident. However, in VESCs, by increasing the stone column diameter, the performance of encasement decreases. It is because of the mobilization of higher confining stresses in smaller diameter stone columns. The higher confining stresses in the column lead to higher stiffness of smaller diameter encased column, and also, as the diameter of the stone column increases, the effect of the encasement decreases due to the increase in lateral deformation.

Influence of the length of the reinforcement

The influence of the length of VESCs was studied for three different lengths of geotextile. The increase of the geotextile length from half length (VESC2 and VESC5) to full length (VESC1 and VESC4) resulted in enhanced load-carrying capacity by 11.1% and 7.5% for D = 80 mm and 100 mm, respectively. So, the performance of the fully encased stone column is higher than the half-length stone column. Due to the increase in the length of encasement, the column stiffness increases. So, the load-carrying capacity increases. However, due to the presence of encasement at the depth of D to 2D, by considering the double use of geotextiles, this increase is not very large. On the other hand, by comparing VESC2 and VESC5 (half length continues: 0.5 L) with VESC3 and VESC6 (interrupted encasement: 0.6 L), the variations of the load-carrying capacity of the kaolin clay bed were 4.6% and 4.8%, respectively. The performance of VESC3 and VESC6, which had vertical interrupted reinforcement, was almost the same as that of VESC2 and VESC5, respectively. The efficiency of stone columns encased to partial heights (0.6 L) is very close to that of half encased stone columns (0.5 L). This shows that the confinement is needed only where bulging takes place.

It is seen that encasing the stone column in the top of the column plays a fundamental role in the performance of stone columns. The reason is that the bulging failure occurs at the depth of D to 2D from the top of the stone columns. From another perspective, it might be obvious that half-length stone column is more economical than the other types.

HRSCs

Load–settlement behavior

Figure 6a, b illustrates the load–settlement behavior of a single stone column with horizontal geotextile layers for column diameters of 80 mm and 100 mm, respectively.

As seen, HRSCs increase the load-carrying capacity of kaolin clay bed. In D = 80 mm, the use of HRSC1 (with 11 horizontal layers with space of 0.5 D) and HRSC2 (with 6 horizontal layers with space of D) enhanced the load-carrying capacity of the kaolin clay bed by 62.0% and 50.4%, respectively. Also, in D = 100 mm, the amount of this increase for the HRSC3 and HRSC4 has been 85.3% and 76.9%, respectively. The increase in the diameter of the stone columns from D = 80 mm to 100 mm, led to an increase in load-carrying capacity. On the other hand, by decreasing spaces of horizontal layers of geotextile, the number of layers of geotextile increases. Hence, the stiffness and the load-carrying capacity increased. More details were discussed in the following sections.

Influence of spacing of geotextile layers

The comparison of HRSC1 (S = 0.5 D with 11 layers of geotextile) and HRSC2 (S = D with 6 layers) revealed that the load-carrying capacity of the stone column increased by 7.7%, and this amount, in the case of using HRSC3 and HRSC4, was 5.5%. So, the columns reinforced with 11 horizontal layers with S = 0.5 D (HRSC1 and HRSC3) did offer better performance in comparison with 6 horizontal layers with S = D (HRSC2 and HRSC4). This is because of the restrictions of the column materials between the layers of geotextile providing confinement due to shear stress mobilization between the column materials and the horizontal layers of geotextile. Also, in the stone columns reinforced with horizontal layers of geotextile with the space of S = 0.5 D, small columns form between the layers which eventually causes limited lateral bulging and leads to more increase in the load-carrying capacity.

As mentioned above, it should be noted that the geotextile area used in the case of S = D is almost the half of area in the case of S = 0.5 D, while the increase in load-carrying capacity is negligible. Thus, using the stone columns reinforced with 6 horizontal layers of geotextile with the space of S = D is more economical.

Influence of the diameter of the stone column

In all cases, as with VESCs, the load-carrying capacity increased by increasing the stone column diameter. Comparing HRSC1 (S = 0.5 D) with HRSC3 (S = 0.5 D) as well as comparing HRSC2 (S = D) with HRSC4 (S = D) showed that by increasing the diameter from D = 80 mm to 100 mm, load-carrying capacity increased by 15.7% and 18.2%, respectively. Also, by considering that in OSCs, increasing the diameter from D = 80 mm to 100 mm increased the load-carrying capacity by 15%. So, it is concluded that the performance of horizontal layers increases by increasing the diameter of the stone column. It is because in the stone column with larger diameters, more interactive shear mobilization is provided above and below the surfaces of the geotextile layers with the crushed stone materials.

Comparison of HRSCs and VESCs

The increase of the load-carrying capacity of the stone column in VESCs is greater than that of HRSCs. By considering the maximum load-carrying capacity of both VESCs and HRSCs, it can be concluded that the benefit of VESCs is greater than HRSCs. From a practical viewpoint, locating the horizontal geotextile layers in stone columns is easier than placing the vertical geotextile encasement in the stone columns.

VHESCs

Load–settlement behavior

Figure 7 demonstrates the load–settlement behavior of VHESCs. VHESC1 (full-length encasement with 11 horizontal layers and the column diameter of 80 mm) and VHESC4 (full-length encasement with 11 horizontal layers and the column diameter of 100 mm) have the largest impact in increasing load-carrying capacity of kaolin clay bed.

For the column with a diameter of 80 mm, the load-carrying capacity of the stone column has been augmented by 123.3%, 103.7% and 92.7%, respectively, for VHESC1, VHESC2 and VHESC3. The amount of this increase for VHESC4, VHESC5 and VHESC6 (D = 100 mm) has been 170.3%, 144.6% and 122.3%, respectively. The stone column with interrupted reinforcement (VHESC3 and VHESC6) has the least benefit in the load-carrying capacity in this group. It is because the stone column is not completely confined by geotextiles, which causes the most bulging and reduces the load-carrying capacity.

Influence of spacing of geotextile layers

The comparison of the VHESC2 and VHESC5 (with 6 horizontal layers with the space of D) with VHESC1 and VHESC4 (with 11 horizontal layers with the space of 0.5D) reveals an increase of 9.6% and 10.5% in load-carrying capacity for D = 80 mm and 100 mm, respectively. Thus, the number of horizontal layers has little effect on increasing the load-carrying capacity of VHESCs. It is because the vertical encasement provides more lateral confinement than horizontal reinforcement.

Influence of the diameter of the stone column

The comparison of different diameters of VHESCs, VHESC1 and VHESC4, for example, indicated that by increasing the stone column diameter from 80 to 100 mm, the load-carrying capacity increased by 21.0%. So, the performance of the reinforcement increases by increasing the stone column diameter. In VHESCs, by increasing the diameter from D = 80 mm to 100 mm, due to the higher surface of horizontal layers of geotextiles, there is more friction between stone aggregates and geotextiles. On the other hand, encasing these horizontal layers by vertical geotextile leads the column to act coherently. So, these factors create additional confinement and the amount of lateral bulging decreases in large diameter. As the bulging failure becomes to punching failure, more force is required to penetrate the column with large diameter to the clay bed. Hence, the performance of the reinforcement in VHESC increases in large diameter.

Comparison of VESCs with VHESCs

By comparing VESC1 (full-length encasement) with VHESC2 (combined full-length encasement with 6 horizontal layers) for D = 80 mm, the load-carrying capacity of stone columns increased by 10.2% and similar comparing for VESC4 with VHESC5 for D = 100 mm, showed 20.1% increase in the load-carrying capacity. As the numbers of geotextile layers increased, comparing VESC1 with VHESC1 (11 horizontal layers, S = 0.5 D) and VESC4 with VHESC4 (11 horizontal layers, S = 0.5 D), the load-carrying capacity of stone column increased by 20.9% and 32.7% for D = 80 mm and 100 mm, respectively. In the case of using interrupted encasement, comparing VESC3 with VHESC3 and VESC6 with VHESC6, the magnitude of these increases was 10.7% and 12.0%, respectively.

It is seen the best case for increasing the load-carrying capacity, using the combined full-length encasement with 11 horizontal layers (S = 0.5 D). It is because the vertical encasement provides lateral confinement and also horizontal layers result in the formation of small columns between the horizontal layers; thereby, the load-carrying capacity increases.

Deformation and failure mode

After completion of each test, the slurry of plaster was poured into the stone column, and then the cast mixture was left to rest for 24 h. This work leads to prevent dissipation of stone aggregate. Then, the surrounding soil was cleaned out and the column’s shape could then be obtained. In Fig. 8, deformed shapes of OSC, VESC and VHESC can be seen. In OSC and VESC bulging failure mechanism occurred at the depth of 1.2D and D from the top of the column, respectively. Also, by measuring the samples obtained from the laboratory tests for the stone columns with the diameter of 100 mm, the size of lateral bulging in OSC was 24 mm, while this value for VESC was 12 mm. So, the bulging of VESC is smaller than the bulging of OSC. Moreover, in VHESC, limited bulging occurred between the horizontal layers throughout the entire length of the column and the size of bulging became much limited as the column length increased.

Load ratio

Load ratio (LR) parameter is defined as the ultimate load-carrying capacity of reinforced soil, to the ultimate load-carrying capacity of soft soil without reinforcement. This dimensionless parameter helps to determine the efficiency of reinforced or unreinforced stone columns on improving the load-carrying capacity of the soft soil [47]. Figure 9 displays the LR variations with the settlement for various stone columns with a diameter of 80 mm and 100 mm, respectively. It is found that the LR value, in 50 mm settlement, varies within the range of 1.26–3.08 and 1.44–4.20, for stone columns with diameters of 80 mm and 100 mm, respectively. The minimum LR belongs to OSCs, while the maximum LR is associated with VHESC1 and VHESC4. The value of LR increases for all types with increasing the column diameters from 80 to 100 mm. For VESCs, the LR value increases with increasing the length of the reinforcement. In HRSCs, the LR value increases with decreasing the spaces between the horizontal layers. It is because geotextiles create a lateral restriction in columns and results in a decrease in bulging.

Figure 9 shows that with increasing the loading up to about 1.2% of the settlement, the value of LR increases. After that LR value decreases because of bulging and reaching the column to its ultimate resistance. In the early stages of loading, the stone columns materials tend to be compressed, so the load-carrying capacity increases. However, as the loading process continues, bulging occurs and the increase in load-carrying capacity is negligible. Therefore, LR value either decreases or remains constant.

Reinforcement ratio

Reinforcement ratio (RR) is defined as the load-carrying capacity of the RSC to OSC [48]. This parameter shows the impact of reinforcement on the load-carrying capacity of stone columns. Replacement area ratio (RAR) is a crucial dimensionless parameter which provides the percentage of soft soil replaced by crushed stone aggregate [49]. It is defined as the area of the stone columns divided by the loaded area. Table 4 presents the variation of RR with RAR.

As seen, for VESCs, the RR value varies in the range of 1.41–1.47, 1.31–1.32 and 1.37–1.39 for stone column having full-length encasement (Lr = L), half-length encasement (Lr = 0.5 L) and interrupted encasement (Lr = 0.6 L), respectively. So, encasing the stone column at full length leads to more increase in load-carrying capacity. Also, the RR value decreases with increasing the RAR. In other words, in VESCs, by increasing the stone column diameter, the performance of encasement decreases. For HRSCs, the RR value varies in the range of 1.20-1.30 and by comparing the same manner as mentioned above, the performance of encasement increases by increasing the stone column diameter. This result is also true in VHESCs.

Stress level in model and field condition

By comparing the stress level in model and filed conditions, it should be noted that in real conditions, in Almeida et al. [50] as a case study, the stress level in encased stone columns at a strain of 10% was 280 kPa. However, in the present study, according to the load–settlement diagrams of VESCs (Fig. 5), the stress level was between 367 and 468 kPa, which indicated that by reducing the stiffness of the geotextile and the dimensions of the stone column in the laboratory conditions, the stress level will be in accordance with the field conditions.

Conclusions

In the present study, small-scale laboratory tests were carried out on 80-mm and 100-mm-diameter floating stone columns with length of 400 and 500 mm, respectively, and these columns were installed in kaolin clay bed. Three types of RSCs including VESC, HESC and VHESC were studied. By improving the kaolin clay bed with OSCs, the load-carrying capacity could be increased from 26 to 44%. However, in stone column reinforced with geotextiles, the increase in the load-carrying capacity would increase 3 to 4 times. This indicates that the reinforced stone column technique has a good degree of improvement for such soils. The tests focused on the effects of various positions of the geotextile on the load-carrying capacity. The following results were obtained:

-

1.

Reinforcing the OSCs with geotextile leads to increase in load-carrying capacity. It is because the reinforcing material provides additional lateral confinement and reduces the lateral bulging of the stone columns.

-

2.

In VESCs, it is observed that encasing the stone column in the top of the column plays a fundamental role in the performance of the stone column. The reason is that the bulging failure usually occurs at the depth of D to 2D from the top of the stone columns. So, it is obvious that half-length stone column is more economical than the other types of the group.

-

3.

In HRSCs, increasing of the load-carrying capacity of the stone column depends on the spaces between the horizontal geotextile layers. Decreasing these spaces (from S = D to S = 0.5 D) leads to minor increase in the load-carrying capacity. Thus, HRSCs with the space of D are more economical.

-

4.

VHESCs have the greatest increase in the load-carrying capacity, while VESCs and HRSCs are in the next position, respectively.

-

5.

The size of lateral bulging in OSC and VESC was 24 mm and 12 mm, respectively. It is because of the lateral confinement provided by geotextile. Moreover, in VHESC, limited bulging occurred between the horizontal layers in the total length of the stone column and the size of bulging became much limited within the column length.

-

6.

The LR value depends on the length of the encasement and the spaces of the reinforcement. It decreases or remains constant after the occurrence of bulging.

-

7.

The RR value varies in the range of 1.31–1.47, 1.20–1.30 and 1.53–1.87 for VESCs, HRSCs and VHESCs, respectively. By comparing the above, it is concluded that the performance of reinforcement decreases with increasing the stone column diameter in VESCs, whereas it increases with increasing the diameter column in HRSCs and VHESCs.

References

Barksdale RD, Bachus RC (1983) Design and construction of stone columns. Report No. FHWA/RD-83/026, Office of Engineering and Highway Operations Research and Development, Federal Highway Administration, Washington

Greenwood DA (1970) Mechanical improvement of soils below ground surfaces. In: Proceedings of conference on ground engineering, Institute of Civil Engineers, London, pp 11–22

Vesic AS (1972) Expansion of cavities in infinite soil mass. J Soil Mech Found Div 98(SM3):265–290

Madhav MR, Vitkar PP (1978) Strip footing on weak clay stabilized with a granular trench or pile. Can Geotech J 15(4):605–609. https://doi.org/10.1139/t78-066

Aboshi H, Ichimoto E, Harada K, Emoki M (1979) The composer-a method to improve the characteristics of soft clays by inclusion of large diameter sand columns. In: Proceedings international conference on soil reinforcement, Paris, pp 211–216

Shivashankar R, Babu MRD, Nayak S (2011) Performance of stone columns with circumferential nails. Proc Inst Civil Eng 164(2):97–106. https://doi.org/10.1680/grim.2011.164.2.97

Van Impe WF (1986) Improving of the bearing capacity of weak hydraulic fills by means of geotextiles. In: Proceedings of the 3rd international conference on geotextiles, Vienna, Austria, pp 1411–1416

Malarvizhi SN, Ilamparuthi K (2007) Comparative study on the behavior of encased stone column and conventional stone column. Soils Found 47(5):873–885. https://doi.org/10.3208/sandf.47.873

Verma S, Kumar V, Priyadarshee A (2018) An experimental test study on ring footing resting on clay bed reinforced by stone column. Innov Infrastruct Solut 3(1):64. https://doi.org/10.1007/s41062-018-0169-9

Bhatia R, Kumar A (2019) Model tests on geosynthetic-encased construction concrete debris column in fly ash fill. Innov Infrastruct Solut 4:31. https://doi.org/10.1007/s41062-019-0217-0

Murugesan S, Rajagopal K (2007) Model tests on geosynthetic-encased stone columns. Geosynth Int 14(6):346–354. https://doi.org/10.1680/gein.2007.14.6.346

Chen JF, Wang XT, Xue JF, Zeng Y, Feng SHZ (2018) Uniaxial compression behavior of geotextile encased stone columns. Geotext Geomembr 46(3):227–283. https://doi.org/10.1016/j.geotexmem.2018.01.003

Gniel J, Bouazza A (2009) Improvement of soft soils using geogrid encased stone columns. Geotext Geomembr 27(3):167–175. https://doi.org/10.1016/j.geotexmem.2008.11.001

Murugesan S, Rajagopal K (2010) Studies on the behavior of single and group of geosynthetic encased stone columns. J Geotech Geoenviron Eng 136(1):129–139. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000187

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic-reinforced stone columns: a comparative study. Geosynth Int 19(4):292–305. https://doi.org/10.1680/gein.12.00016

Dash SK, Bora MC (2013) Influence of geosynthetic encasement on the performance of stone columns floating in soft clay. Can Geotech J 50:754–765. https://doi.org/10.1139/cgj-2012-0437

Lajevardi SH, Enami S, Hamidi M, Shamsi HR (2018) Experimental study of single and groups of stone columns encased by geotextile. J Sci Technol. https://doi.org/10.22060/CEEJ.2018.12789.5269

Madhav MR (1982) Recent development in the use and analysis of granular piles. In: Proceedings of symposium on recent development in ground improvement techniques, Bangkok, pp 117–129

Sharma RS, Phani Khumar BR, Nagendra G (2004) Compressive load response of granular piles reinforced with geogrids. Can Geotech J 41(1):187–192. https://doi.org/10.1139/t03-075

Ayadat T, Hanna AM, Hamitouche A (2008) Soil improvement by internally reinforced stone columns. Proc Inst Civ Eng-Ground Improv 161(2):55–63. https://doi.org/10.1680/grim.2008.161.2.55

Ghazavi M, Yamchi AE, Nazari Afshar J (2018) Bearing capacity of horizontally layered geosynthetic reinforced stone. Geotext Geomembr 46:312–318. https://doi.org/10.1016/j.geotexmem.2018.01.002

Prasad SSG, Satyanarayana PVV (2016) Improvement of soft soil performance using stone columns improved with circular geogrid discs. Indian J Sci Technol 9(30):1–6. https://doi.org/10.17485/ijst/2016/v9i30/99186

Ali K, Shahu JT, Sharma KG (2014) Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement. Geosynth Int 21(2):103–118. https://doi.org/10.1680/gein.14.00002

Mohammad Rezaei M, Lajevardi SH, Saba HR, Ghalandarzadeh A, Zeighamie E (2019) Experimental and numerical studies on load-carrying capacity of single floating aggregate piers reinforced with vertical steel bars. Amirkabir J Civil Eng. https://doi.org/10.22060/CEEJ.2019.15640.5991

Hasan M, Samadhiya NK (2017) Performance of geosynthetic-reinforced granular piles in soft clays: model tests and numerical analysis. Comput Geotech 87:178–187. https://doi.org/10.1016/j.compgeo.2017.02.016

Madhav MR, Miura N (1994) Soil improvement. Panel report on stone columns. In: Proceedings of the 13th international conference on soil mechanics and foundation engineering, vol 5, New Delhi, India, pp 163–164

Wood DM, Hu W, Nash DFT (2000) Group effects in stone column foundations: model tests. Geotechnique 50(6):689–698. https://doi.org/10.1680/geot.2000.50.6.689

ASTM D4253-00, 2006 (2006) Standard test methods for maximum index density and unit weight of soils using a vibratory table. ASTM International, West Conshohocken. https://doi.org/10.1520/D4253-00R06

ASTM D4254-00, 2006-e1 (2006) Standard test methods for minimum index density and unit weight of soils and calculation of relative density. ASTM International, West Conshohocken. https://doi.org/10.1520/D4254-00R06E01

ASTM D2216-10 (2010) standard test methods for laboratory determination of water (moisture) content of soil and rock by mass. ASTM International, West Conshohocken. https://doi.org/10.1520/D2216-10

ASTM D2166-06 (2006) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken. https://doi.org/10.1520/D2166-06

ASTM D854-06e1 (2006) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM International, West Conshohocken. https://doi.org/10.1520/D0854-06E01

ASTM D4318-05 (2005) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM International, West Conshohocken. https://doi.org/10.1520/D4318-05

ASTM D3080-98 (2003) Standard test method for direct shear test of soils under consolidated drained conditions. ASTM International, West Conshohocken. https://doi.org/10.1520/D3080-03

ASTM D2487-06e1 (2006) Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM International, West Conshohocken. https://doi.org/10.1520/D2487-06E01

Iai S (1989) Similitude for shaking table tests on soil-structure fluid models in 1 g gravitational field. Soil Found 29(1):105–118. https://doi.org/10.3208/sandf1972.29.105

Alexiew D, Brokemper D, Lothspeich S (2005) Geotextile encased columns (GEC): load capacity, geotextile selection and pre-design graphs. In: Geo-frontiers Conference, Austin, Texas, pp 497–510. https://doi.org/10.1061/40777(156)12

ASTM D4595-11 (2011) Standard test method for tensile properties of geotextiles by the wide-width strip method. ASTM International, West Conshohocken. https://doi.org/10.1520/D4595-11

Mohammad Rezaei M, Lajevardi SH, Saba HR, Ghalandarzadeh A, Zeighami E (2019) Laboratory study on single stone columns reinforced with steel bars and discs. Int J Geosynth Ground Eng 5(2):1–14. https://doi.org/10.1007/s40891-019-0154-1

Shahu JT, Reddy YR (2011) Clayey soil reinforced with stone column group: model tests and analyses. J Geotech Geoenviron Eng 137(12):1265–1279. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000552

Indian Standard (IS) (2003) Design and construction for ground improvement-Guidelines. Part 1: stone columns. IS: 15284, Bureau of Indian Standards, New Delhi, India

Kumar G, Samanta M (2020) Experimental evaluation of stress concentration ratio of soft soil reinforced with stone column. Innov Infrastruct Solut. https://doi.org/10.1007/s41062-020-0264-6

Debnath P, Dey AK (2017) Bearing capacity of geogrid reinforced sand over encased stone columns in soft clay. Geotext Geomembr 45(6):653–664. https://doi.org/10.1016/j.geotexmem.2017.08.006

Hamidi M, Lajevardi SH (2018) Experimental study on the load-carrying capacity of single stone columns. Int J Geosynth Ground Eng 4(26):1–10. https://doi.org/10.1007/s40891-018-0142-x

Ambily AP, Grandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. J Geotech Geoenviron Eng 133(4):405–415. https://doi.org/10.1061/(ASCE)1090-0241(2007)133:4(405)

Nazari Afshar J, Ghazavi M (2014) Experimental studies on bearing capacity of geosynthetic reinforced stone columns. Arab J Sci Eng 39(3):1559–1571. https://doi.org/10.1007/s13369-013-0709-8

Ghazavi M, Nazari Afshar J (2013) Bearing capacity of geosynthetic encased stone columns. Geotext Geomembr 38:26–36. https://doi.org/10.1016/j.geotexmem.2013.04.003

Lajevardi SH, Shamsi HR, Hamidi M, Enami S (2018) Numerical and experimental studies on single stone columns. Soil Mech Found Eng 55(5):340–345. https://doi.org/10.1007/s11204-018-9546-9

Castro J (2017) Groups of encased stone columns: influence of column length and arrangement. Geotext Geomembr 45:68–80. https://doi.org/10.1016/j.geotexmem.2016.12.001

Almeida MSS, Hosseinpour I, Riccio M, Alexiew D (2013) Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J Geotech Geoenviron Eng 141(3):04014116. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001256

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bazzazian Bonab, S., Lajevardi, S.H., Saba, H. et al. Experimental studies on single reinforced stone columns with various positions of geotextile. Innov. Infrastruct. Solut. 5, 98 (2020). https://doi.org/10.1007/s41062-020-00349-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-00349-0