Abstract

The combined effect of heat and mass transfer in Jeffrey fluid flow through porous medium over a stretching sheet subject to transverse magnetic field in the presence of heat source/sink has been studied in this paper. The surface temperature and concentration are assumed to be of the power law form. The linear Darcy model takes care of the flow through saturated porous medium with uniform porosity. Further, first order chemical reaction rate has been considered to account for the effect of the reactive species, exhibiting non-Newtonian behaviour of Jeffery fluid model. Moreover, the present study analyses the result of previous authors’ as a particular case. The present work warrants attention to analytical method of solution by applying confluent Hypergeometric function and the fluid model considered here represents fluids of common interest such as solvent and polymers with zero shear-rate. The method of solution involves similarity transformation. The coupled non-linear partial differential equations representing momentum, concentration and non homogeneous heat equation are reduced into a set of non-linear ordinary differential equations. The transformed equations are solved by applying Kummer’s function. The effect of pertinent parameters characterizing the flow has been presented through the graph. Contributions of elasticity of the fluid, magnetic field and the porous matrix resist the motion of Jeffery fluid resulting a thinner boundary layer where as magnetic field and porous matrix contribute to enhance the temperature distribution in the flow domain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Various non-Newtonian fluid models have been proposed in the literature keeping in view of their different rheological features. Jeffery fluid is one class of non-Newtonian fluid which attracts many researchers for it’s simplicity. Literature survey indicates that interest in the flows over a stretched surface has grown during the past few decades. These flows are arisen in metal and polymer extrusion, drawing of plastic sheets, cable coating, textiles and paper industries, etc. The rate of heat transfer over a surface has a pivotal role in the quality of final product. Industrial applications include fibres spinning, hot rolling, manufacturing of plastic and rubber sheet, continuous casting and glass blowing. MHD flow with heat and mass transfer has been a subject of interest of many researchers because of its varied application in science and technology. Such phenomena are observed in buoyancy induced motions in the atmosphere, in water bodies, quasi-solid bodies such as earth, etc. In natural processes and industrial applications, many transportation processes exist where transfer of heat and mass takes place simultaneously as a result of thermal diffusion and diffusion of chemical species.

Crane [1] studied the boundary layer flow of an incompressible viscous fluid towards a linear stretching sheet. An exact similarity solution for the dimensionless differential system was obtained. Such closed form similarity solutions were obtained for the models exhibiting the features like viscoelasticity, magneto hydrodynamics, suction, porosity and heat and mass transfer (Andersson et al. [2]). Chamkha [3] studied the MHD flow of uniformly stretched vertical permeable surface in the presence of heat generation/absorption and a chemical reaction.

Nadeem et al. [4] have discussed on an optimized study of mixed convection flow of a rotating Jeffrey nanofluid on a rotating vertical cone. Mehmood et al. [5] investigated the effects of transverse magnetic field on a rotating micropolar fluid between parallel plates with heat transfer. Theoretical analysis of slip flow on a rotating cone with viscous dissipation effects is studied by Saleem et al. [6]. Akbar et al. [7] investigated numerically the bioconvection in a suspension of gyrotactic microorganisms and nanoparticles in a fluid flow over a stretching sheet. Moreover, Noor et al. [8] have considered the mixed convection stagnation flow of a micropolar nanofluid along a vertically stretching surface with slip effects.

Bhukta et al. [9] have studied heat and mass transfer on MHD flow of viscoelastic fluid over a shrinking sheet embedded in a porous media. Baag et al. [10] have carried out a numerical investigation on MHD micropolar fluid flow past a vertical surface in the presence of heat source and chemical reactive species. Further, Kar et al. [11] have studied 3-dimensional free convective MHD flow on a vertical channel through porous medium with heat source and chemical reaction. This flow is restricted to Newtonian fluid only. Recently, Baag et al. [12] have considered the viscoelastic fluid flow subject to magnetic field through porous medium and studied the effect of heat and mass transfer. All these above studies are restricted to viscoelastic model of Walters B’ model or Newtonian model. But in the present study we consider a simple viscoelastic model i.e. Jeffery’s model, which represents viscoelastic fluid of common interest.

The effect of temperature-dependent viscosity on mixed convection flow from vertical plate is investigated by several authors (Hossain and Munir [13] and Mustafa [14]). Ishak et al. [15] investigated theoretically the unsteady mixed convection boundary layer flow and heat transfer due to a stretching vertical surface in a quiescent viscous and incompressible fluid. Mahapatra and Gupta ([16, 17]) considered the stagnation flow on a stretching sheet. Cipolla [18] studied the temperature jump in polyatomic gas, also Kao [19] and Latyshev and Yushkanov [20] studied the temperature jump. The flow and heat transfer of Jeffry fluid near stagnation point on a stretching/shrinking sheet with parallel external flow was investigated by Turkyilmazoglu and Pop [21]; Akram and Nadeem [22] discussed the peristaltic motion of a two dimensional Jeffry fluid. Authors in [23–26] studied more properties of Jeffrey fluid. Different non-Newtonian fluids were considered in studies by Pandey and Tripathi [27, 28], Mishra et al. [29], Pandey et al.[30] and Tripathi [31]. Qasim [32] discussed heat and mass transfer effect on Jeffrey fluid.

The saturated porous medium considered here is having uniform porosity and it is assumed that the flow properties such as thermal conductivity and solid matrix (Porous medium) properties are identical.

The driving force necessary to move a specific volume of fluid through porous medium is in equilibrium with resistance force generated by the internal friction between the fluid and the pore structure. This resistance force is characterized by Darcy’s semi-emperical law established by Darcy [33].

The 3-dimensional generalisation of the Darcy law is

where V is the average velocity, Kp is the permeability of the porous medium, \(-\nabla p\) is the resistance force that results from a pore pressure gradient, \(\rho g\) is the gravitational force. Since the constitutive equations of Newtonian and non-Newtonian fluids are different, the contribution of the term characterizing the permeability of the medium affects the flow phenomena differently.

The Darcy law is valid for low speed flow and works well for a wide domain of flows. It is valid for flow of liquids with small Prandtl number, but in the case of liquids with high velocity or for gas at very low and very high velocities Darcy’s law becomes invalid. The authors in the present study are aware of the limitations. However, the authors [34, 35] have considered the Darcy model which contributes substantially to the flows of Newtonian and non-Newtonian fluids. The authors [36–38] have considered the Darcy flow of non-Newtonian fluid in saturated porous medium.

The novelties of the present study are:

-

(1)

The viscoelastic fluid model considered here, is a dash pot and a voigt model in series. The Voigt model is good for viscoelastic solids and not for fluids but the Jeffery’s model is good for fluids and not for solids. The model is interesting because the Maxwell model is a particular case. Further, the Newtonian fluids arise from Jeffery’s model when the relaxation and retardation times are equal (Joseph [39]).

-

(2)

The magnetic field in conjunction with permeability of the medium, resulting two additional forces, is the main concerned of the present study which has not been addressed so far to the best of authors’ knowledge.

-

(3)

In earlier study [32] the effect of heat source in energy equation has been considered without considering the effect of first order chemical reaction which is of same order of heat source. As far as possible, effects of above phenomena are depicted in the present discussion and the work of previous author is discussed as a particular case.

Formulation of the Problem

Let us consider a particular type of visco-elastic fluid called Jeffrey fluid given by Akram and Nadeem [22]:

where T, the Cauchy stress tensor, p, the pressure \(\mu \), the viscosity, \(\lambda \) the retardation time, \(\lambda _{1}\) the relaxation time of the fluid and \(R_{1}\) is the Rivlin–Ericken tensor defined by \(R_{1}=\nabla v+(\nabla v)^{t}\).

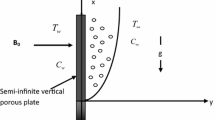

The steady two dimensional flow of an electrically conducting visco-elastic fluid (Jeffrey model) over a stretching sheet in the presence of heat source/sink has been considered. The effect of first order chemical reaction has also been considered in this study. The sheet in xz-plane is stretched along the x-direction such that the velocity component in the x-direction varies linearly along it (Fig. 1). The governing boundary layer equations are

The corresponding boundary conditions are:

Solution of the Flow Field

Equation (2) is satisfied if we chose a dimensionless stream function \(\psi \)(x, y) so that

Introducing the similarity transformations

and substituting in (3), we get

The corresponding boundary conditions are:

where f is the dimensionless stream function and \(\eta \) is the similarity variable. \(\beta =\lambda _{1}c\), the Deborah number, (where \(\lambda _{1}\) is the relaxation time of fluid), \(M= \sigma B_{0}^{2}/\rho c\), the magnetic parameter.

The exact solution of Eq. (9) with boundary conditions (10) is obtained as

Heat Transfer Analysis

Introducing non-dimensional quantities \(\theta (\eta )=\frac{T-T_\infty }{T_w -T_\infty },\) non-dimensional temperature, \(\hbox {P}_\mathrm{r} =\rho C_p /K\), Prandtl number, \(\gamma =\frac{Q\upsilon }{\rho C_p }\), Heat source parameter and using Eq. (8), Eq. (4) becomes

and corresponding boundary conditions become

Further, introducing the variable \(\xi =\frac{P_r e^{-\alpha \eta }}{\alpha ^{2}}\) the Eq. (13) is transformed to

with the boundary conditions

Now, the solution of Eq. (15) is obtained as follows by using Kummer’s function (Wang and Guo [40]), given in “Appendix”.

where, \(a=\hbox {P}_\mathrm{r} /2\alpha ^{2},b= \sqrt{\left( {\hbox {P}_\mathrm{r} } \right) ^{2}-4\alpha ^{2}\gamma }/2\alpha ^{2}\) and \(_{1}F_{1}\)(\(\alpha _{1},\alpha _{2};~x)\) is the Kummer’s function defined by \({ }_1F_1 (\alpha _1,\alpha _2;x)=1+\mathop {\sum }\limits _{n=1}^\infty {\frac{\left( {\alpha _1 } \right) _n }{\left( {\alpha _2 } \right) _n }} \frac{x^{n}}{n!}, \alpha _2 =-1,-2\ldots \).

Here(\(\alpha _{1})_{n}\) and (\(\alpha _{2})_{n}\) are the Pochhammer’s symbols defined as

In terms of variable \(\eta \) Eq. (17) can be written as

Mass Transfer Analysis

Introducing the non-dimensional variable \(\varphi (\eta )=\frac{C-C_\infty }{C_p -C_\infty }\) and using (8), the Eq. (5) becomes,

With the boundary conditions

Again introducing a new variable \(\zeta =-\frac{S_c }{\alpha ^{2}}e^{-\alpha \eta }\), the Eq. (20) becomes

The corresponding boundary conditions are

The solution of Eq. (22) in terms of Kummer’s function using the boundary condition (23) is given by

Results and Discussion

The Non-Newtonian property of Jeffery’s fluid model is exhibited through material parameters \(\lambda \) and \(\lambda _{1}\). This model represents Newtonian fluid when the relaxation and retardation times are equal. If the stress is put to zero, then the strain relaxes and its time of relaxation becomes the time of retardation. The Jeffery’s model allows for relaxation of stress and strain rate and, in general, they relax at different times Joseph [39]. The following discussion reveals the effects of interaction of the material property of the fluid with the applied magnetic field on the flow past a stretching sheet embedded in a saturated porous medium in the presence of chemically reactive species.

In course of discussion, the work of Qasim [32] is derived as a special case in the absence of magnetic field and porous matrix. The flow, heat and mass transfer phenomena are characterised by Deborah number \(\beta \), Magnetic parameter M, Prandtl number \(P_{r}\) and Schmidt number \(S_{c}\). Figure 2 exhibits the streamline patterns towards the free stream.

It is seen from Fig. 3 that decrease in Deborah number, decreases the velocity of fluid for both M \(=\) 0 and M \(=\) 1.0 in the absence of porous matrix (Kp \(=\) 100). This observation, agrees well with Qasim [32] in the case of absence of magnetic field (M \(=\) 0). The physical interpretation of this effect runs as follows. The decrease of Deborah number (relaxation time) decreases the velocity producing thinner boundary layer, consequently gathers less momentum during the flow. This occurs both in presence/absence of magnetic field. Moreover, it is revealed that the retarding effect of magnetic field reduces the velocity further, producing less momentum in the flow field.

On careful observation of Fig. 4 reveals that presence of porous matrix opposes the fluid motion reducing the momentum of flow significantly resulting a thinner boundary layer.

Figure 5 exhibits the effect of elastic parameter, \(\lambda \), on velocity profile. An increase in the value of \(\lambda \) decreases the velocity irrespective of presence/absence of porous matrix or magnetic field. This well agrees with the observation of Qasim [32].

Figure 6 shows the effect of \(\beta \) on the temperature distribution. The number \(\beta \) (\(=\lambda _{1}c)\) contributes to the material property as well as stretching rate of the sheet/plate. It is interesting to note that the temperature distribution remains invariant under the individual or combined effects of magnetic field and permeability of the porous medium in a layer little far off the stagnation point i.e. \(\eta =4.5\) but no such characteristic is exhibited in the absence of both (Curve-I). This result is a striking outcome of the present study in the absence of magnetic field and porous medium, not reported earlier. Another point is to note that the temperature decreases significantly in all the layers in the absence of the retarding force due to magnetic filed and permeability of medium. Further, it is interesting to note that an increase in \(\beta \) reduces the temperature in the layer nearer to the stagnation point. Thereafter, reverse effect is observed. This may be attributed to the elastic property of the fluid which absorbs some heat near the stagnation point.

From Fig. 7 it is remarked that high Prandtl number fluid i.e. flow with low thermal diffusivity, produces thinner thermal boundary layer in the presence of magnetic field irrespective of the presence or absence of porous matrix but the magnetic field enhances the temperature significantly at all the layers(Curves-I and II).

Figure 8 exhibits the effect of heat source/sink on the temperature field in the presence of both magnetic field and porous medium. It is evident that magnetic field as well as permeability of the medium increases the temperature at all the layers in the presence of source/sink. An interesting feature is that a point of intersection of the temperature profiles irrespective of the presence of heat source is marked near \(\eta =4.5\) due to interplay of the effect of high magnetic field and permeability of the medium. This is also supported by the velocity distribution.

Figure 9 shows the effect of surface temperature variation on temperature profiles. The two cases are discussed; for r \(=\) 1 (linear) and r \(=\) 2(quadratic). The nonlinear variation of surface temperature reduces the fluid temperature in all the layers incompareson with linear one.

Figure 10 displays the concentration distribution in the presence of first order chemical reaction with nonlinear variation of wall concentration (\(r=2.0\)). It is seen that presence of magnetic field contributes to enhance slightly the concentration where as the chemical reaction parameter, \(K_{c}\) increases significantly but the reverse effect is observed with an increasing value of \(S_{c}\) that is for heavier reactive species. Thus, it is concluded that the reactive species with positive reaction rate coefficient enhances the concentration level where as species with low diffusivity i.e. for high values of \(S_{c}\) decreases it.

Conclusions

-

In the absence of magnetic field and porous medium the results of the present study coincide with the observation made by Qasim [32] and hence generality and consistency of the findings are assured of.

-

Contribution of elasticity of the fluid, magnetic field on a conducting fluid and the presence of porous medium resists the motion of Jeffery fluid resulting a thinner boundary layer where as magnetic field and porosity enhances the temperature distribution.

-

The temperature distribution becomes independent of the effects of magnetic field, elasticity and permeability at a particular point under the influence of either magnetic field or permeability or both.

-

Elasticity of the fluid reduces the temperature near the bounding surface.

-

The reactive species with positive reaction rate contribute to the growth of concentration level where as heavier reactive species causes a decay.

Abbreviations

- C :

-

Concentration

- \(C_{w}\) :

-

Wall concentration

- D :

-

Diffusion coefficient

- l :

-

Characteristic length

- M :

-

Magnetic parameter

- \(p_{r}\) :

-

Prandtl number

- S :

-

Stress tensor

- T :

-

Fluid temperature

- u, v :

-

Velocity components

- \(c_{p}\) :

-

Specific heat

- \(C_{\infty }\) :

-

Ambient concentration

- r :

-

Wall temperature parameter

- \(K_{p}\) :

-

Permeability of the porous medium

- \(S_{c}\) :

-

Schmidt number

- \(R_{1}\) :

-

Rivlin–Ericksen tensor

- \(T_{w}\) :

-

Wall temperature

- \(T_{\infty }\) :

-

Ambient temperature

- \(\beta \) :

-

Deborah number

- \(\eta \) :

-

Similarity variable

- \(\upsilon \) :

-

Kinematic fluid viscosity

- \(\gamma \) :

-

Heat generation\(\backslash \)absorption parameter

- \(\psi \) :

-

Stream function

- \(\lambda _{1}, \lambda \) :

-

Material parameters

- \(\mu \) :

-

Dynamic viscosity

- \(\rho \) :

-

Fluid density

References

Crane, L.J.: Flow past a stretching plate. Z. Angew. Math. Phys. 21, 645–647 (1970)

Andersson, H.I., Aerseth, J.B., Braud, B.B., Dandapat, B.S.: Flow of a power-law fluid film on an unsteady stretching sheet. J. Non-Newton. Fluid Mech. 62, 1–8 (1996)

Chamkha, A.J.: MHD flow of a uniformly stretched permeable surface in the presence of heat generation/absorption and a chemical reaction. Int. Commun. Heat Mass Transf. 30, 413–422 (2003)

Nadeem, S., Saleem, S.: An optimized study of mixed convection flow of a rotating Jeffrey nanofluid on a rotating vertical cone. J. Comput. Theor. Nanosci. 12, 3028–3035 (2015)

Mehmood, R., Nadeem, S., Masood, S.: Effects of transverse magnetic field on a rotating micropolar fluid between parallel plates with heat transfer. J. Magn. Magn. Mater. 401(1), 1006–1014 (2016)

Saleem, S., Nadeem, S.: Theoretical analysis of slip flow on a rotating cone with viscous dissipation effects. J. Hydrodyn. Ser. B 27(4), 616–623 (2015)

Akbar, N.S., Nadeem, S., Khan, Z.H.: The numerical investigation of bioconvection in a suspension of gyrotactic microorganisms and nanoparticles in a fluid flow over a stretching sheet. KSCE, J. Civ. Eng. (2015, in press)

Noor, N.F.M., Haq, Rizwan Ul, Nadeem, S., Hashim, I.: Mixed convection stagnation flow of a micropolar nanofluid along a vertically stretching surface with slip effects. Meccanica 50(8), 2007–2022 (2015)

Bhukta, D., Dash, G.C., Mishra, S.R.: Heat and mass transfer on MHD flow of a viscoelastic fluid through porous media over a shrinking sheet. Int. Sch. Res. Not. 2014, 11 (2014). doi:10.1155/2014/572162

Baag, S., Mishra, S.R., Dash, G.C., Acharya, M.R.: Numerical investigation on MHD micropolar fluid flow toward a stagnation point on a vertical surface with heat source and chemical reaction. J. King Saud Eng. Sci. (2014). doi:10.1016/j.jksues.2014.06.002

Kar, M., Dash, G.C., Rath, P.K.: Three dimensional free convective MHD free flow on a vertical channel through a porous medium with heta source and chemical reaction. J. Eng. Thermophys. 22(3), 203–215 (2013)

Baag, S., Acharya, M.R., Dash, G.C., Mishra, S.R.: MHD flow of a visco-elastic fluid through a porous medium between infinite parallel plates with time dependent suction. J. Hydrodyn. 27(5), 840–847 (2015)

Hossain, A., Munir, S.: Mixed convection flow from a vertical plate with temperature dependent viscosity. Int. J. Thermal Sci. 39, 173–183 (2000)

Mustafa, A.A.: A Note on variable viscosity and chemical reaction effects on mixed convection heat and mass transfer along a semi-infinite vertical plate. Math. Prob. Eng. 10, 1–7 (2007)

Ishak, A., Nazar, R., Pop, I.: Unsteady mixed convection boundary layer flow due to a stretching vertical surface. Arab. J. Soc. Eng. 31, 165–182 (2006)

Mahapatra, T.R., Gupta, A.S.: Heat transfer in stagnation point flow towards a stretching sheet. J. Heat Mass Transf. 38, 517–521 (2002)

Mahapatra, T.R., Gupta, A.S.: Stagnation point flow towards a stretching surface. Can. J. Chem. Eng. 81, 258–263 (2003)

Cipolla Jr., J.W.: Heat transfer and temperature jump in a polyatomicgas. Int. J. Heat Mass Transf. 14(10), 1599–1610 (1971)

Kao, T.-T.: Laminar free convective heat transfer response alonga vertical flat plate with step jump in surface temperature. Lett. Heat Mass Transf. 2(5), 419–428 (1975)

Latyshev, A.V., Yushkanov, A.A.: An analytic solution of the problem of the temperature jumps and vapour density over a surface when there is a temperature gradient. J. Appl. Math. Mech. 58(2), 259–265 (1994)

Turkyilmazoglu, M., Pop, I.: Exact analytical solution for the flow and heat transfer near the stagnation point on a stretching/shrinking sheet in a Jeffrey fluid. Int. J. Heat Mass Transf. 57(1), 82–88 (2013)

Akram, S., Nadeem, S.: Influence of induced magnetic field and heat transfer on the peristaltic motion of Jeffrey fluid in an asymmetric channel: closed form solutions. J. Magn. Magn. Mater. 328, 11–20 (2013)

Siewert, C.E., Valougeorgis, D.: The temperature-jump problem for a mixture of two gases. J. Quant. Spectrosc. Radiat. Transf. 70(3), 307–319 (2001)

Nadeem, S., Hussain, A., Khan, M.: Stagnation flow of a Jeffrey fluid over a shrinking sheet. Z. Nat. A 65(6–7), 540–548 (2010)

Pandey, S.K., Tripathi, D.: Unsteady model of transportation of Jeffrey-fluid by peristalsis. Int. J. Biomath. 3(4), 473–491 (2010)

Hayat, T., Awais, M., Asghar, S., Hendi, A.A.: Analytic solution for the magneto hydrodynamic rotating flow of Jeffrey fluid in a channel. J. Fluids Eng. 133(6), 7 (2011). doi:10.1115/1.4004300

Pandey, S.K., Tripathi, D.: Influence of magnetic field on the peristaltic flow of a viscous fluid through a finite-length cylindrical tube. Appl. Bionics Biomech. 7(3), 169–176 (2010)

Pandey, S.K., Tripathi, D.: Effects of non-integral number of peristaltic waves transporting couple stress fluids in finite length channels. Z. Nat. A 66(3–4), 172–180 (2011)

Mishra, S.R., Dash, G.C., Acharya, M.: Mass and heat transfer effect on MHD flow of a visco-elastic fluid through porous medium with oscillatory suction and heat source. Int. J. Heat Mass Transf. 57(2), 433–438 (2013)

Pandey, S.K., Tripathi, D.: Unsteady peristaltic flow of micro-polar fluid in a finite channel. Z. Nat. A 66(3–4), 181–192 (2011)

Tripathi, D.: A mathematical model for the peristaltic flow of chime movement in small intestine. Math. Biosci. 233(2), 90–97 (2011)

Qasim, M.: Heat and mass transfer in Jeffery fluid over a stretching sheet with heat source/sink. Alex. Eng. J. 52(4), 571–575 (2013)

Bear, J.: Dynamics of Fluids in Porous Media. Dover Publications, New York, p. 123 (1972)

Acharya, A.K., Dash, G.C., Mishra, S.R.: Free convective fluctuating MHD flow through porous media past a vertical porous plate with variable temperature and heat source. Phys. Res. Int. 2014, 8 (2014). doi:10.1155/2014/587367

Tripathy, R.S., Dash, G.C., Mishra, S.R., Baag, S.: Chemical reaction effect on MHD free convective surface over a moving vertical plane through porous medium. Alex. Eng. J. 54(3), 673–679 (2015)

Shenoy, A.V.: Non-Newtonian fluid heat transfer in porous media. Adv. Heat Transf. 24, 101–190 (1994)

Nield, A.Donald, Bejan, A.: Convection Heat Transfer in Porous Media. Springer, Berlin (2013)

Bejan, A.: Convective Heat Transfer in Porous Media-Hand Book of Single-Phase Convective Heat Transfer. Wiley, New York (1987)

Joseph, Daniel D.: Fluid Dynamics of Visco-elastic Liquid. Springer, Berlin (1990)

Wang, Z.X., Guo, D.R.: Special Functions. World Scientific Publications, Singapore (1989)

Acknowledgments

Authors express their deepest sense of gratitude to the learned referee for their constitutive suggestions and authorities of Siksha ‘O’ Anusandhan University and Centurion University for providing the facilities to carry on the work.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The new equation obtained from a differential equation by the confluence of two or more of its singularities is called the confluent equation of original equation. After confluence, the singularities of the new equation usually have properties more complicated than those of original ones; it follows that the properties are different. According to theory of differential equation only the singularities of differential equation could be the singularities of its solution.

The equation

The singularities of the above equation are \(0,b,\infty \) all being regular. Now let \(b=\beta \rightarrow \infty \) we obtain

This new confluent hypergeometric equation (Kummer’s equation) has only two singularities \(0 \hbox { and } \infty \); the former is still a regular singularity, but the latter, being the confluence of two original regular singularity, becomes an irregular singularity. The Kummer’s function \(F(\alpha ,\gamma ,z)\) is a single valued analytic function in the whole Z-plane whose properties are different from hypergeometric function \(F( \alpha ,\beta ,\gamma ,z)\).

Further, solution of Kummer’s function depends upon roots of the indicial equation i.e. \(\rho =0 \hbox { and } 1-\gamma \), when \(1- \gamma \) is not an integer we obtain two linear independent solutions known as confluent hypergeometric function also known as Kummer’s function.

When \(\gamma \) is an integer, sign of \(\gamma \) will decide only one solution among the earlier two i.e. for \(1-\gamma \) is not an integer. Another solution or the second solution can be obtained independently by other method.

The integral representation of Kummer’s function is as follows

where \(\hbox {Re}(\gamma )>\hbox {Re}(\alpha )>0, \arg (t)=\arg (1-t)=0\).

The integral representation, though comparatively simple, are rather restricted in its parameters \(\alpha \hbox { and } \gamma \).

These are the limitations of Kummer’s function.

Rights and permissions

About this article

Cite this article

Jena, S., Mishra, S.R. & Dash, G.C. Chemical Reaction Effect on MHD Jeffery Fluid Flow over a Stretching Sheet Through Porous Media with Heat Generation/Absorption. Int. J. Appl. Comput. Math 3, 1225–1238 (2017). https://doi.org/10.1007/s40819-016-0173-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40819-016-0173-8