Abstract

Over the past decades, quite a few investigations have been carried out to utilize slags as a cementing agent in landfills, road construction, concrete, and mortars. However, a limited number of research studies investigated the use of magnesium slag as a soil stabilizer in geotechnical engineering projects. The manufacturing process of metallic magnesium produces a large volume of magnesium slag which is occasionally dumped in open areas. In this research, the potential use of magnesium slag as an additive agent to improve the properties of lime-stabilized soil was experimentally investigated. For this purpose, a number of different tests such as pH, Standard Proctor Compaction, Unconfined Compressive Strength, Indirect Tensile Strength, Toxicity Characteristic Leaching Procedure, X-ray diffraction, and Scanning Electron Microscopy were performed on the clayey sand containing 0%, 10%, 20%, 30%, 40% and 50% magnesium slag with 4% and 8% lime (by dry weight of the used soil). Samples were cured for 7, 28, and 56 days. The results of the study indicated that the addition of the maximum amount of magnesium slag (50%) at all curing days improved the geotechnical characteristics of soil samples containing 8% Lime. Generally, it was found that magnesium slag can be effectively applied in soil stabilization projects to improve the geotechnical properties and alleviate environmental repercussions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Soil stabilization is one of the common methods used to improve the quality of the subgrade inroad construction industry [1]. This method improves the geotechnical parameters of the materials at the project site and provides the required strength [2,3,4,5]. There are three main benefits of soil stabilization: (i) improving the quality of road pavement and embankment layers, (ii) reducing the thickness of pavement layers, and (iii) decreasing the operation costs [6]. Over the past few years, various additives have been used as soil stabilizing agents. The most important of these materials include different types of cement and lime. Nowadays, cement stabilization is not of great interest due to the environmental repercussions of carbon dioxide in the cement production process [7,8,9]. Lime is one of the most traditional stabilizers that have been used to stabilize clayey soils to reduce plasticity index (PI) and shrinkage and increase strength and California bearing ratio (CBR) [9,10,11]. A large number of studies have been performed on the effects of lime and cement on the chemical and physical properties of the soils in the stabilization process [12,13,14]. The addition of lime causes pozzolanic reactions in the soils. During this process, additives create cation exchange, leading to particle flocculation and soil hardness. The results of the soil particle hardening are coarse-grained soils, lower plasticity, and higher durability [15,16,17]. Moreover, the soil pH increases due to the presence of OH− ions, leading to the development and enhancement of pozzolanic reactions. The pozzolanic chemical equations are described as:

The above reactions are the mechanism of soil stabilization by the occurrence of flocculation agglomeration. The Si and Al that exist within the mineral structure of the soil (or added by the stabilization agents) are combined with the available Ca2+ from the additives. This process results in cementitious compounds such as Calcium Silicate Hydrates (CSH) and Calcium Aluminate Hydrates (CAH). The formation of these compounds improves the resistance properties of the soils [18,19,20]. Additionally, these materials have been utilized as conventional stabilizers.

In recent years, a number of researchers have conducted many studies on the use of waste materials, especially mining wastes, as soil stabilizers. In addition to land occupation, these materials always cause various environmental problems [21,22,23]. Among these waste materials, some of the most common materials are listed as ground granulated blast furnace (GGBF), cement kiln ash, rice husks ash, coal ash, recyclable polymer additives, recycled glass, and fly ash. In addition to improving the geotechnical properties of soils, another purpose of investigating the effect of these materials is to reduce the environmental problems caused by the accumulation of these industrial wastes [24].

Magnesium slag is also another industrial waste that is produced after the Silicotherm reduction process for magnesium metal production. During the production of each ton of magnesium metal, about 5.5 tons of magnesium slag is produced. It is estimated that the accumulation of this waste material in the world was over 10 million tons by 2014. The chemical composition and physical properties of this material prove its potential for the hydration process [25,26,27,28]. Also, the results of previous investigations indicated that the physical, chemical and mineralogical characteristics of the magnesium slag and the Portland cement were occasionally similar [29]. The use of magnesium slag in soil stabilization projects has three advantages: (i) reduction of the use of cement, (ii) alleviation of the environmental problems caused by these industrial wastes, and (iii) protection of the natural resources [29]. The use of this material in the cement production process results in cement that requires less water and lower setting time than that of conventional Portland cement and provides a significant reduction in the kiln temperature, which leads to a reduction in energy consumption [30].

Xiao et al. [31] reported that the addition of magnesium slag and furnace slag with clinker in the cement production process improves the strength parameters of the obtained cement. In some studies, magnesium slag was found to be much more effective than furnace slag in terms of strength development of cementitious materials. The use of magnesium slag in combination with other materials for clinker production was also found to be effective in the production process of this material. In this way, the reduction in temperature is required for calcination of clinker, and the cement obtained from this clinker provided a higher strength [32]. Deng et al. [27] investigated the hydration mechanism of the magnesium slag as one of the main factors increasing the strength of the Portland cement and magnesium slag blends.

Amini and Ghasemi [33] investigated the effect of adding magnesium slag to cement-stabilized soil. They found that the magnesium slag increased pH and particle size of soil and enhanced compaction properties such as maximum dry density (MDD) and optimum moisture content (OMC). Also, up to 20% magnesium slag (by dry weight of soil) increased the uniaxial compressive strength of soil from 1.3 to 5.5 MPa, and by adding more magnesium slag, the compressive strength of the soil decreased. By adding 6% cement to the soil containing 20% magnesium slag, the compressive strength reached 14.3 MPa [33].

This study aims to reduce the environmental effects of magnesium slag and to investigate possibility of this waste material in soil improvement projects. In the present research, the authors evaluated the effect of magnesium slag on soil stabilization when lime is added. In this regard, some experiments such as pH, Laser Particle Size, Compaction Test, Uniaxial Compressive Strength (UCS) test, Indirect Tensile Strength (ITS), X-ray diffraction (XRD), scanning electron microscopy (SEM), and Toxicity Characteristic Leaching Procedure (TCLP) Test are carried out. These experiments simulate conditions within a landfill and determine whose contaminants, identified by the United States Environmental Protection Agency (EPA) [34]. These pollutants exist in the leachate as well as their concentrations.

2 Materials and Methods

2.1 Materials

In this study, the soil sample was sourced from a depth of 1 m from Haft Bagh Alavi region (30.237394, 57.101819) in the south of Kerman city, Iran. In this research, soil samples that were used had an average particle size of 0.241 mm, liquid limit (LL) of 39%, plastic limit (PL) of 20%, the maximum specific gravity of 2.13 g/cm3, and optimum moisture content of 12%. Based on the Unified Soil Classification System and ASTM D2487 [35], the soil used in this study is classified as clayey sand (SC).

Soil characteristics and soil gradation curve are shown in Table 1 and Fig. 1, respectively. To investigate the minerals in the soil, XRD analysis was performed and its result is shown in Fig. 2. The soil contains quartz, albite, calcite, and phillipsite. Also, soil chemical composition was determined by X-Ray Fluorescence (XRF) analysis based on ASTM E1621 [40] and the result is presented in Table 2.

Two types of quick lime and hydrated lime are commonly used in soil stabilization projects. The quick lime is more voluminous and more effective in the stabilization process than the hydrated lime. However, during the experiments, due to the smaller volume change of hydrated lime than quick lime, hydrated lime was utilized to eliminate the shrinkage and creep.

The lime gradation curve used is shown in Fig. 1. The chemical composition of the lime can also be seen in Table 2. Magnesium slag was obtained from a magnesium metal production factory in Ferdows city, Iran (33.954294, 58.203146). Magnesium slag with a specific gravity of 3.19 g/cm3 was formed as a bright gray powder and its gradation curve is shown in Fig. 1.

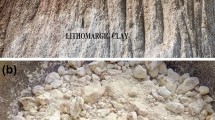

The chemical composition of magnesium slag is also presented in Table 2. Particles of raw materials which include soil, lime, and magnesium slag can be seen in SEM micrographs. These SEM micrographs illustrate that the particles have sharp edges with non-uniform shapes (Fig. 3).

The quality of water can also affect the geotechnical characteristics of stabilized soils and cementitious materials [41,42,43,44]. Therefore, in the current research, distilled water was used for both characterization tests and sample preparation [45,46,47,48].

2.2 Sample Preparation

All the samples were prepared at 95% compaction energy. Dry soil, lime, and magnesium slag were mixed. Distilled water was then gradually added to the mixture and the mixing procedure was continued for one minute until a homogeneous mixture was obtained. The samples were pounded in three layers in a steel mold with a diameter of 50 mm and a height of 100 mm. After demolding, the samples were placed in plastic bags and cured for 7, 28, and 56 days at \(20 \pm 1\) °C. To ensure the accuracy of test results, four replicate samples were prepared for each test, and the average values were calculated.

3 Laboratory Tests

To investigate the effects of adding magnesium slag and lime on the alkalinity of the soil, the pH test was performed based on ASTM D4972 [36]. Also, laser radiation was used to compare grain size distribution (GSD) curves for the soil samples before and after the addition of Stabilizing material in the same way that was used by Sol-Sáncheza et al. [18]. The dispersion unit used (analysette 22 NanoTec) is capable to detect the particle size in the range of 0.02–2000 mm. The standard Proctor compaction test was performed based on ASTM D698 [37]. Uniaxial compressive strength test was carried out following ASTM D2166 [49], and additionally, tensile strength test was performed according to ASTM D3967 [50] on the samples. TCLP) Toxicity Characteristic Leaching Procedure (test was performed to analyze the contamination of groundwater resources with heavy metals from stabilized layers. Accordingly, 10 g of the sample was added to 200 mg of deionized water and acetic acid, and then the mixture was vibrated at 20 rpm for 18 h at 20 °C. The samples were placed on a fiberglass filter, and the acetic acid solution was added to the water of the sample to bring the pH of the water to less than 2. The resulting solution was examined by the spectrometer and the concentration of heavy metals was measured. Figure 4 shows a schematic description of the experimental process performed in this study.

4 Results and Discussion

4.1 pH Test

The pH is an important indicator to indicate the effectiveness of lime treatment [51]. In the beginning, the initial pH of the soil, lime, and magnesium slag were 8.36, 13.09, and 12.97, respectively. Figures 5, 6 and 7 illustrated the results of the pH test on the samples treated with 10%, 20%, 30%, 40%, and 50% magnesium slag and 0%, 4%, and 8% lime after 7, 28, and 56 days of curing, respectively.

Furthermore, results related to the addition of magnesium slag to the soil show an increase in the soil pH. Results obtained after 7 days of curing show that 8% of lime alone raised the soil pH to 12.8, and increased to 13.75 with the addition of magnesium slag 50%. This increase is due to the high ratio of CaO in magnesium slag (50.7%) which increases the amount of calcium ions in the sample.

CaO, Fe2O3, and Al2O3 are the most important compounds that increase soil pH to facilitate pozzolanic reactions. At the high levels of pH, soil minerals dissolve more rapidly, and then the secondary minerals (e.g., hydrated calcium silicate and hydrated calcium aluminate) are formed, and additionally, the soil particles become more stable [33]. Higher mechanical strength was obtained at higher pH values because alkali activator concentration was higher [52,53,54]. From Figs. 5, 6 and 7, it was inferred that the pH of the soil composition decreases with an increase in the curing time. Several reactions such as the mineral dissolution, formation of C–S–H phases, and the carbonation of Ca (OH)2 consume OH– groups, resulting in a decrease in the pH with an increase in the curing period [55]. The main result of this experiment shows the positive effect of lime and magnesium slag on increasing the soil pH, indicating an improvement in the geotechnical properties of soil samples.

4.2 Soil Particle Size Distribution

One of the physical effects of additives on soil properties is a significant change in the particle size distribution. Increasing the particle size of the soil after the addition of stabilizers often leads to improved soil geotechnical properties. This increase in size is due to the flocculation of the soil particles, which is the result of cation exchange due to the soil hydration by stabilizing additives.

The increase in particle size can be seen by comparing the soil gradation curve before and after the addition of stabilizers. The amount of change in soil particle size decreases over time. Sol-Sáncheza et al. [18] considered the 28-day curing period to be the appropriate time to evaluate and compare soil particle size after the addition of stabilizing agents. In the present research, another result was the positive effect of hydrated lime on increasing the particle size of soil in this processing period.

This period which seems to be appropriate to complete the change in soil particle size is consistent with another recent study [56]. Compared with the gradation curves, Fig. 8 illustrates the variations in the particle size of the studied soil with the addition of 8% lime and various amounts of magnesium slag after 28 days of the curing period. Soil particle size increases with the addition of magnesium slag and additionally, the gradation curve tends to the right due to the addition of magnesium slag to the soil.

According to Fig. 8, the average size of soil particles without stabilizing materials was 241 microns, which increased to 367 microns by adding stabilizing materials up to 50% magnesium slag and 8% lime. The addition of stabilizing materials to the soil causes the particles to become more granular, which reduces the plasticity of the soil, increases the permeability and bearing capacity of the soil [33, 57].

The main result of this experiment indicates the positive effect of adding different percentages of magnesium slag to the soil treated with lime, which increases the particle size and improves soil geotechnical properties.

4.3 Standard Proctor Compaction Test

Table 3 demonstrated changes in maximum dry density (MDD) and optimum moisture content (OMC) after the addition of different percentages of lime and magnesium slag. The results of this experiment indicate an increase in soil MDD and OMC due to the addition of magnesium slag (A1–A6). The increase in MDD depends on the particle size and specific gravity of the additives and soil.

Magnesium slag, due to the difference in gradation with the soil, fills the voids among the soil particles and as a result, increases the specific gravity to 2.8 g/cm3. An increase in specific gravity indicates the improvement of soil geotechnical properties [58,59,60,61]. The addition of lime also reduces the specific gravity of the soil, which could be due to the lower specific gravity of the lime and a large amount of calcium hydroxide in the soil–lime composition.

In this case, the initial reactions could also occur rapidly, which increase the soil resistance to compaction and reduce the MDD of the stabilized soil [62]. Also, another reason for reducing the maximum specific gravity of soil in the lime addition state can be due to the replacement of soil particles in a certain volume with lime particles with lower weight. Despite the difference in the trend of changing the maximum dry density of soil with the addition of each magnesium slag and lime, the addition of both stabilizers up to 50% magnesium slag and 8% lime caused this parameter to reach 2.64 g/cm3. Table 3 shows that both stabilizers increase the dependence of soil on water. Adding lime and magnesium slag to the soil increases the optimum moisture content.

When these stabilizers are added to the soil, air cavities form among the particles due to the instantaneous reaction of cation exchange and flocculation of soil particles, creating a porous media with the lower maximum dry density. Hence, a higher volume of water is needed to fill the pores. The main result of compaction experiments indicates the positive effect of stabilizing additives in improving the compaction properties of the studied soil, which is one of the most important geotechnical properties of the soil.

4.4 Compressive and Tensile Strength Tests

The effects of adding magnesium slag on the uniaxial compressive strength of unstabilized and stabilized soils with 4% and 8% lime after different curing days of 7, 28, and 56 are shown in Figs. 9 and 10, respectively. The effect of the mentioned factors on indirect tensile strength can also be seen in Figs. 11 and 12, respectively.

Figures 9 and 11 show the effect of adding lime and magnesium slag along with an increase in the curing period, compressive strength and the tensile strength of the stabilized soil also increases. This physical behavior is due to the change in the particle size of the stabilized soils (described in Sect. 4.2) and an increase in the cation exchange between the soil and the stabilizers. Also, the increase in resistance over the passage of the curing time may be due to a decrease in pH level as a result of calcium ion consumption. This subject is also discussed in Sect. 4.1. Another reason leading to the increase in resistance is the high percentage of CaO in magnesium slag, which leads to the production of Ca(OH)2 after mixing with water. Ca(OH)2 reacts with SiO2 (found in soil and additives) and produces CSH gel. As the hydration process of Ca(OH)2 production continues, a large volume of C–S–H gel is formed, leading to the formation of strong and resistant soil masses. Additionally, C–S–H gel has a strong positive effect on the compressive strength of soil composition [63]. In the state of the strength of soil samples with 0% lime, Figs. 9a and 11a show compressive and tensile strengths increased with the replacement of magnesium slag up to 20% of soil weight. But, for larger amounts of magnesium slag, the compressive and tensile strengths were on the decrease. The reason for this decrease in resistance at percentages higher than 20% of magnesium slag can be due to the high percentage of MgO. The high content of MgO in the chemical composition of magnesium slag increases the volume and thus reduces the strength of the sample [33]. Magnesium slag is suitable if the amount of MgO is less than 8% [27]. In this study, magnesium slag contains 10% magnesium oxide (MgO), which can cause swelling and reduce resistance to high percentages of magnesium slag in the soil [33]. Then, Figs. 9b,c and 11b,c illustrated that the strength of the samples increased with the addition of lime. Lime neutralizes the effect of an increase in the sample volume due to the high percentage of magnesium slag and additionally, the strength of samples with 50% magnesium slag significantly increased. Therefore, the sample treated with 50% magnesium slag and 8% lime achieved a compressive strength of 14.19 MPa and a tensile strength of 2 MPa after 56 days of curing period, showing the positive effect of the combined use of lime and magnesium slag in reducing the swelling potential of soil. Adding lime to the soil with high swelling capability increased the compressive strength and decreased the swelling of this type of soil. Similar results have been reported by Kumar et al. [64].

Amini and Ghasemi [33] indicated that the maximum compressive strength in the sample with 20% magnesium slag and 6% cement reached 14.3 MPa after 56 days of curing time. Although the result of the compressive strength test (14.19 MPa) is in good agreement with the study performed by the authors’ (14.3 MPa), the present research has a subtle superiority in two ways. The first is due to an increase in the percentage of magnesium slag while utilizing lime instead of cement, which can reduce the accumulation of this industrial waste and the related environmental concerns. Meanwhile, this increase in the percentage of magnesium slag can be due to the low percentage of silica and alumina in lime compared to cement, which leads to the use of more pozzolanic materials to improve soil behavior. The second one is the potential usability of lime instead of cement, which in turn results in lower costs and environmental pollution.

5 Microstructural Analysis

Lime and magnesium slag contain aluminosilicates, hence; they can be considered as soil stabilizers. In Evan's report [65], it has been mentioned that aluminosilicate compounds in unstabilized soil composition are the cause of cementitious calcium materials for performing the long-term pozzolanic reactions. On the other hand, according to the results of this study, some other pozzolanic materials in lime and magnesium slag were very useful for soil stabilization. SEM and XRD images of the samples with 8% lime and 50% magnesium slag in 7, 28, and 56 days of curing were used to observe soil changes after stabilization with these additives.

As shown in Fig. 13a, after 7 days of curing time, the soil structure has become denser and has reduced soil porosity in comparison with Fig. 3a. The pozzolanic reactions between soil and additives result in greater density and stronger cohesion among soil particles, ultimately; reduced soil porosity. An increase in density and a decrease in soil porosity increase the compressive strength of the stabilized lateritic soil [66]. After the curing time, more dense masses are formed and the soil structure becomes more cohesive. As illustrated in Fig. 13c, the soil particles are completely surrounded by gel of the compounds such as CSH, leading to an increase in soil strength. This result is consistent with the results obtained from the uniaxial compressive strength and tensile strength.

Figure 14 shows the diffraction peaks of the hydrated calcium silicate) C–S–H( obtained by X-ray diffraction and then, the diffraction peaks became higher at various extensions of curing time. The diffraction peaks for C–S–H and Ca(OH)2 were observed at of 29.4° and 36.5°, respectively. Higher peaks of Ca(OH)2 were detected at the extension of shorter curing times. At the curing times of 28 and 90 days, the diffraction peaks at various diffraction angles were reduced. Calcium hydroxide (Ca(OH)2) produces stronger hydration with an increase in the reaction time. Calcium hydroxide can also react with soil aluminosilicates or additives (lime and magnesium slag). These pozzolanic reactions can produce hydrated calcium silicate and hydrated calcium aluminate. The C2S was also associated with a decrease in reflection intensity after 56 days of curing time. In general, it can be concluded that the decrease in C2S and Ca (OH) 2 is due to the growing process of hydration which produces more CSH. Hence, Ca2+ reacts with aluminosilicates to produce calcium silicate and hydrated calcium aluminate. This means that the additives were able to compact the soil particles.

5.1 TCLP Analysis

Using the toxicity characteristic leaching procedure (TCLP) test, the concentration of heavy metals (i.e., Zn, Cu, As, Hg, Ni, Pb, Cr, and Cd) of the samples of magnesium slag and C6 (50% magnesium slag and 8% lime) sample which had the highest compressive and tensile strength in the whole periods of the curing time, were determined. The results of this test are presented in Table 4 along with Regulatory levels. Regulatory levels are the maximum amount of heavy metal concentrations that have been defined by this institute for non-hazardous material [34].

According to Table 4, the concentrations of Pb, Cr, and Cd related to the magnesium slag are higher than permissible levels. The result of this test on the magnesium slag shows that if the material is stored, groundwater pollution in the depot for a long time is seen. The combination of magnesium slag with soil as a stabilizer produced different results. The test results on the C6 sample showed that the concentration of all heavy metals decreased significantly and was within the specified standard range. Furthermore, a single-point test such as TCLP often estimates potentially toxic elements release under leaching conditions that are unlikely to occur in actual situations [67]. This indicates the positive impact of using magnesium slag as a soil stabilizer from an environmental perspective. Amini and Ghasemi [33] also performed this test on the sample with the highest compressive strength containing 20% magnesium slag and 6% cement (relative to the dry weight of soil). Quantitative comparisons of the present results with the result of C6 of the present study was given in Table 5.

This comparison aims to compare the status of the two samples and select the best sample in terms of environmental parameters. Due to the same conditions of the two samples in terms of the type of primary soil and the combined magnesium slag, the difference in the amount of magnesium slag and the choice of the second stabilization material (between cement and lime) is important. Furthermore, there is small difference between the compressive strength of the two specimens. Despite the fact that magnesium slag in the sample with lime was more than 2 times as much as in the sample with cement, the concentration of heavy metals in the sample with lime is less than the concentration reported in the sample with cement. If the solution to the environmental problems is prioritized, the selection of a sample with lime has a good priority. This sound priority is due to the cement whose production process causes air pollution will not be used. Also, more magnesium slag is used to minimize environmental damage caused by the depot of this industrial waste material.

6 Conclusions

In this research, the influence of the combined use of magnesium slag and lime on soil improvement was evaluated. According to the results, the following main conclusions were drawn:

-

1.

By increasing the percentages of either lime or magnesium slag or their combination, the pH of clayey sand soil increases. The combination of lime and magnesium slag raises the pH of the stabilized soil more than when the stabilizers are separately used. The pH of the stabilized soil decreased gradually with an increase in the curing time due to the chemical reactions.

-

2.

Both magnesium slag and lime increased the soil particle size. Also, between the particle size distribution of soil and the results of the pH test, a relationship was observed that can be used to evaluate the variations in physical properties during soil stabilization. This result was due to the relatively identical changes in the process of soil particle size change with the trend of pH changes in the same time intervals. Changes in these parameters were higher in the first days of curing and then decreased by an increase in the curing times.

-

3.

3-By adding magnesium slag to the soil, the maximum dry density and optimum moisture content increased. While adding lime to the soil-magnesium slag composition slightly reduced MDD and increased OMC to 2.64 gr/cm3 and 21.5%, respectively.

-

4.

By analyzing the tensile and compressive strengths of the samples with magnesium slag in all curing times, up to 20% slag, these two parameters increased and then decreased by increasing the amount of magnesium slag. By adding lime to this composition, different results can be obtained. The tensile and compressive strengths increased with an increase in the percentage of lime and magnesium slag in all curing times. The highest compressive and tensile strengths were obtained in samples with 50% magnesium slag and 8% lime. At 7, 28, and 56 days of curing, compressive strength values of 7.8, 12.6, and 14.1 MPa and tensile strength of 0.9, 1.6, and 1.98 MPa were recorded, respectively.

-

5.

Microscopic analysis showed that the addition of lime and magnesium slag to the soil caused a change in soil morphology. XRD test results showed that CSH is an effective factor in increasing the strength of samples stabilized with lime and magnesium slag. An increase in the intensity of CSH gels along with increasing the curing time and compressive and tensile strengths, as well as the results of SEM images, indicated positive effect of CSH on improving soil properties. These cementitious phases induced significant improvements in the engineering properties of the soil such as workability, compaction, and strength.

-

6.

TCLP test results showed the necessity of using magnesium slag to avoid its deposition and the resulting environmental issues due to the presence of heavy metals. The results of this test on the sample with the highest amount of tensile and compressive strengths were within the specified standard range and thus do not pose a risk of groundwater contamination.

It seems that the usability of lime and magnesium slag to stabilize the subgrade in road construction can be considered as an economic and ecological solution since magnesium slag is a waste material and can reduce CO2 emissions when compared to other cementitious agents such as cement.

References

Jahandari, S.; Mojtahedi, S.F.; Zivari, F.; Jafari, M.; Mahmoudi, M.R.; Shokrgozar, A.; Kharazmi, S.; Vosough Hosseini, B.; Rezvani, S.; Jalalifar, H.: The impact of long-term curing period on the mechanical features of lime-geogrid treated soils. Geomech. Geoeng. 1–13 (2020)

Sadeghian, F.; Haddad, A.; Jahandari, S.; Rasekh, H.; Ozbakkaloglu, T.: Effects of electrokinetic phenomena on the load-bearing capacity of different steel and concrete piles: a small-scale experimental study. Can. Geotech. J. 1–16

Jahandari, S.; Saberian, M.; Tao, Z.; Faridfazel Mojtahedi, S.; Li, J.; Ghasemi, M.; Rezvani, S.S.; Li, W.: Effects of saturation degrees, freezing thawing, and curing on geotechnical properties of lime and lime-cement concretes. Cold Reg. Sci. Technol. 160, 242–251 (2019)

Saberian, M.; Jahandari, S.; Li, J.; Zivari, F.: Effect of curing, capillary action, and groundwater level increment on geotechnical properties of lime concrete: experimental and prediction studies. J. Rock Mech. Geotech. Eng. 9(4), 638–647 (2017)

Jahandari, S.; Toufigh, M.M.; Li, J.; Saberian, M.: Laboratory study of the effect of degrees of saturation on lime concrete resistance due to the groundwater level increment. Geotech. Geol. Eng. 36(1), 413–424 (2017)

Jahandari, S.; Li, J.; Saberian, M.; Shahsavarigoughari, M.: Experimental study of the effects of geogrids on elasticity modulus, brittleness, strength, and stress-strain behavior of lime stabilized kaolinitic clay. GeoResJ. 13, 49–58 (2017)

Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H.: Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mater. 252 (2020)

Al-Swaidani, A.; Hammoud, L.; Meziab, A.: Effect of adding natural pozzolana on geotechnical properties of lime stabilized clayey soil. J. Rock Mech. Geotech. Eng. 8(5), 714–725 (2016)

Mallela, J.; Harold Von Quintus, P.; Smith, K.L.: Consideration of Lime-Stabilized Layers in Mechanistic-Empirical Pavement Design. The National Lime Association, Arlington (2004)

Sakr, M.A.; Shahin, M.A.; Metwally, Y.M.: Utilization of lime for stabilization soft clay soil of high organic content. Geotech. Geol. Eng 27, 105e13 (2009)

Rogers, C.; Glendinning, S.: Modification of Clay Soils Using Lime. Ground Engineering, p. 99e114. Thomas Telford Limited, London (1996)

Bell, F.G.: Lime stabilization of clay minerals and soils. Eng. Geol. 42(4), 223e37 (1996)

Ghobadi, M.H.; Abdilor, Y.; Babazadeh, R.: Stabilization of clay soils using lime and effect of pH variations on shear strength parameters. Bull. Eng. Geol. Environ. 73(2), 611e9 (2014)

Kassim, K.A.; Chern, K.K.: Lime stabilized Malaysian cohesive soils. Jurnal Kejuruteraan Awan 16(1), 13e23 (2004)

Rao, S.M.; Shivananda, P.: Compressibility behavior of lime-stabilized clay. Geotech. Geol. Eng. 23, 309e19 (2005)

Kinuthia, J.M.; Wild, S.; Jones, G.I.: Effects of monovalent and divalent metal sulphates on consistency and compaction of lime-stabilised kaolinite. Appl. Clay Sci. 14, 27–45 (1999)

Lin, D.F.; Lin, K.L.; Hung, M.J.; Luo, H.L.: Sludge ash/hydrated lime on the geotechnical properties of soft soil. J. Hazard. Mater. 145, 58–64 (2007)

Sol-Sáncheza, M.; Castrob, J.; Ureña, C.G.; Azañón, J.M.: Stabilisation of clayey and marly soils using industrial wastes: pH and laser granulometry Indicators. Eng. Geol. 200, 10–17 (2016)

Sargent, P.: Handbook of Alkali-Activated Cements, Mortars and Concretes (2015)

Fauzi, A.; Nazmi, W.M.; Abdul-Rahman, W.; Jauhari, Z.: Utilization waste material as stabilizer on Kuantan clayey soil stabilization. Procedia Eng 53, 42–47 (2013)

Jafari, M.; Esna-ashari, M.: Effect of waste tire cord reinforcement on unconfined compressive strength of lime stabilized clayey soil under freeze–thaw condition. Cold Reg. Sci. Technol. 82, 21–29 (2012)

Lee, S.H.; Kim, E.Y.; Park, H.; Yun, J.; Kim, J.G.: In situ stabilization of arsenic and metal-contaminated agricultural soil using industrial by-products. Geoderma 161(1–2), 1–7 (2011)

Ansari Mahabadi, A.; Hajabbasi, M.A.; Khademi, H.; Kazemian, H.: Soil cadmium stabilization using an Iranian natural zeolite. Geoderma 137(3–4), 388–393 (2007)

Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H.: Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 103, 774–783 (2015)

Liu, D.B.; Sun, Q.: China Metal Bulletin, vol. 7, pp. 32–33 (2011)

Xu, R.Y.; Liu, H.Z.: World Nonferrous Metals, vol. 1, pp. 16–19 (2006)

Deng, J.; Wang, X.; Guo, Y.: Research on the hydration mechanism of portland cement with magnesium slag. Appl. Mech. Mater. 576, 57–62 (2014)

Ilić, M.; Miletić, S.; Munitlak, R.: Enviromental protection by utilization of the slag from magnesium production in building materials. Toxicol. Environ. Chem. 69, 217–224 (1999)

Oliveira, C.; Gumieri, G.; Gomes, M.; Vasconcelos, L.: Characterization of magnesium slag aiming the utilization as a mineral admixture in mortar (1997)

Cai J, Gao G, Bai R, Lu F and Li L. Research on Slaked Magnesium Slag as a Raw Material and Blend for Portland Cement. 2011; Trans Tech Publications, Switzerland.

Xiao, L.; Luo, F.; Li, R.; Liu, C.: The Study of Alkaline-activated Magnesium Slag Cementitious Material. Trans Tech Publications, Switzerland (2012)

Lu, F.; Bai, F.; Cai, J.: Study on Clinker Production using Magnesium Slag on a 4500tpd Line. Trans Tech Publications, Switzerland (2013)

Amini, O.; Ghasemi, M.: Laboratory study of the effects of using magnesium slag on the geotechnical properties of cement stabilized soil. Constr. Build. Mater. 223, 409–420 (2019)

USEPA 1311: Toxicity Characteristics Leaching Procedure. United States Environment Protection Agency, USA (1992)

ASTM D2487-11: Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International, West Conshohocken (2011)

ASTM D4972-13 Standard Test Method for pH of Soils, Annual Book of ASTM Standards (2007)

ASTM D698: Standard test method for Laboratory Compaction Characteristics of Soil Using Standard Effort. Annual Book of ASTM Standards, West Conshohocken (2012)

ASTM D854-92: Standard Test Method for Specific Gravity of Soils. ASTM International, West Conshohocken (1994)

ASTM D4318: Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International, West Conshohocken (2010)

ASTM E1621-13: Standard Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry. Annual Book of ASTM Standards, USA (2010)

Afshar, A.; Jahandari, S.; Rasekh, H.; Shariati, M.; Afshar, A.; Shokrgozar, A.: Corrosion resistance evaluation of rebars with various primers and coatings in concrete modified with different additives. Constr. Build. Mater. 262 (2020)

Kazemi, M.; Li, J.; Harehdasht, S.L.; Yousefieh, N.; Jahandari, S.; Saberian, M.: Non-linear behavior of concrete beams reinforced with GFRP and CFRP bars grouted in sleeves. Structures 23, 87–102 (2020)

Kazemi, M.; Hajforoush, M.; Khakpour Talebi, P.; Daneshfar, M.; Shokrgozar, A.; Jahandari, S.; Saberian, M.; Li, J.: In-situ strength estimation of polypropylene fibre reinforced recycled aggregate concrete using Schmidt rebound hammer and point load test. J. Sustain. Cement Based Mater. 1–18 (2020)

Jahandari, S.; Saberian, M.; Zivari, F.; Li, J.; Ghasemi, M.; Vali, R.: Experimental study of the effects of curing time on geotechnical properties of stabilized clay with lime and geogrid. Int. J. Geotech. Eng. 13(2), 1–12 (2017)

Rasekh, H.; Joshaghani, A.; Jahandari, S.; Aslani F.; Ghodrat, M.: Rheology and workability of SCC. In: Woodhead Publishing Series in Civil and Structural Engineering, pp. 31–63 (2020)

Darvishi, A.; Vosoughifar, H.; Saeidijam, S.; Torabi, M.; Rahmani, A.: An experimental and prediction study on the compaction and swell–expansion behavior of bentonite clay containing various percentages of two different synthetic fibers. Innov. Infrastruct. Solut. 5(1), 1–5 (2020)

Rezania, M.; Moradnezhad, H.; Panahandeh, M.; Kami, M.J.; Rahmani, A.; Hosseini, B.V.: Effects of diethanolamine (DEA) and glass fibre reinforced polymer (GFRP) on setting time and mechanical properties of shotcrete. J. Build. Eng. 1(31), 101343 (2020)

Hanaei, F.; Sarmadi, M.S.; Rezaee, M.; Rahmani, A.: Experimental investigation of the effects of gas oil and benzene on the geotechnical properties of sandy soils. Innov. Infrastruct. Solut. (2021)

ASTM D2166: Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. West Conshohocken, Pennsylvania (1982)

ASTM: Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM D3967 (2008)

Elert, K.; Nieto, F.; Azañón, J.M.: Effects of lime treatments on marls. Appl. Clay Sci. 135, 611–619 (2016)

Phair, J.W.; Van Deventer, J.S.J.: Effect of the silicate activator pH on the microstructural characteristics of waste-based geopolymers. Int. J. Miner. Process. 66(1), 121–143 (2002)

Khale, D.; Chaudhary, R.: Mechanism of geopolymerization and factors influencing its development: a review. J. Mater. Sci. 42(3), 729–746 (2007)

Ghadir, P.; Ranjbar, N.: Clayey soil stabilization using geopolymer and Portland cement. Constr. Build. Mater. 188, 361–371 (2018)

Gaucher, E.C.; Blanc, P.: Cement/clay interactions—a review: experiments, natural analogues, and modeling. Waste Manag. 26, 776–788 (2006)

Cardoso, R.; Maranha das Neves E: Hydro-mechanical characterization of lime treated and untreated marls used in a motorway embankment. Eng. Geol. 133–134, 76–84 (2012)

Al-Amoudi, O.; Khan, K.; Al-Kahtani, N.S.: Stabilisation of a Saudi calcareous marl soil. Constr. Build. Mater. 24, 1848–1854 (2010)

Degirmenci, N.; Okucu, A.; Turabi, A.: Application of phosphogypsum in soil stabilization. Build. Environ. 42(9), 3393–3398 (2007)

Nalbantoğlu, Z.: Effectiveness of class C fly ash as an expansive soil stabilizer. Constr. Build. Mater. 18(6), 377–381 (2014)

Harichane, K.; Ghrici, M.; Kenai, S.: Effect of the combination of lime and natural pozzolana on the compaction and strength of soft clayey soils: a preliminary study. Environ. Earth Sci. 66(8), 2197–2205 (2012)

Basha, E.; Hashim, R.; Mahmud, H.; Muntohar, A.: Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 19(6), 448–453 (2005)

Yi, Y.; Gu, L.; Liu, S.: Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl. Clay Sci. 103(1), 71–76 (2015)

Barišic, I.; Dimter, S.; Rukavina, T.: Strength properties of steel slag stabilized mixes. Compos. Part B Eng. 58, 386–391 (2014)

Jha, A.K.; Sivapullaiah, P.V.: Potential of fly ash to suppress the susceptible behavior of lime-treated gypseous soil. Soils Found. 58(3), 654–665 (2018)

Evans, P.: Update on lime stabilization. In: QMR Technology Transfer Seminar, pp. 1–18 (1997)

Venkatarama Reddy, B.V.: Stabilized Soil Blocks for Structural Masonry in Earth Construction. Woodhead Publishing Limited (2012). https://doi.org/10.1533/9780857096166.3.324

Thorneloe, S.A.; Kosson, D.S.; Sanchez, F.; Helms, G.; Garrabrants, A.C.: Improved leaching test methods for environmental assessment of coal ash and recycled materials used in construction. In: Proceedings of the International Waste Management and Landfill Symposium, S. Margherita di Pula, Cagliari, Italy (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Omid, A., Mojtaba, G. Geotechnical Properties of Lime-Magnesium Slag Stabilized Clayey Sand: Experimental Study. Arab J Sci Eng 47, 13673–13685 (2022). https://doi.org/10.1007/s13369-022-07288-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07288-1