Abstract

Reinforcement by fibers is one of the most practical and economic methods to improve some engineering properties and the mechanical behavior of soils in civil engineering. In this paper, the impact of fıber reinforcement on the swelling behavior of bentonite clay was investigated. Virgin homopolymer polypropylene (HPP) and copolymer polypropylene (CPP) with various percentages were used as reinforcement materials, and the influence of fiber contents on one-dimensional swelling pressure was evaluated. At first, sieve and hydrometer analysis and Atterberg limits tests were conducted on bentonite. The standard Proctor compaction test was also used to determine the compaction properties of reinforced and unreinforced bentonite. Then, the oedometer test was carried out on specimens. The results showed that both types of fiber enhanced the swelling potential of bentonite. The optimum amount of fibers was analyzed via test results. Moreover, the most significant improvement in terms of reducing the swelling potential of bentonite was observed due to the use of HPP fiber. The maximum improvement percentages to reduce the swelling pressure of bentonite layers using HPP and CPP fibers were 44.2% and 29.4%, respectively. The statistical analysis was carried out to identify the relationship between the dependent variables (fiber-reinforced samples) and the independent variable (plain bentonite). The result indicated the proper agreement of the model and concerning values. Two significant equations were calculated to estimate the swelling pressure of bentonite with HPP and CPP fibers that showed the use of synthetic fibers additives has a considerable effect on decreasing the swelling pressure of expansive soils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Expansive soils cause a serious hazard to foundations throughout the world [1, 2]. Swelling clays derived from sediment soil can apply uplift pressure of as much as 5.500 PSF, which can lead to considerable damage to buildings and other structures constructed on problematic grounds [3]. Significant researches have been conducted to improve various solution techniques to strengthen expansive soils. These treatment methods are chemical stabilization, pre-wetting, the dissipation of excess pore water pressure, the replacement of problematic soils, the compaction method, moisture control, thermal methods, surcharge loading and reinforcing the soil using natural, and synthetic fibers [4,5,6,7,8,9,10,11]. Sand columns, concrete columns, lime stabilization, lime slurry pressure injection (LSPI) technique and cement stabilization are some of the most effective methods to stabilize potentially expansive soils [5, 12, 13]. Although these methods are used as soil improvement techniques, there are some problems related to their applications. Soil reinforcement is a creative soil improvement technique to solve soil problems in recent years [14,15,16].

A wide range of reinforcements is used to improve engineering properties and to decrease the swelling behavior of expansive soils [17, 18]. In recent decades, there has been increasing use of fiber reinforcements in problematic soil. One of the effective methods to improve some engineering properties and strength behavior of expansive soils is incorporating both natural and human-made discrete fiber materials in soils [19]. Hence, extensive researches have been carried out to investigate the effects of fibers on expansive soils and concerts [20,21,22,23,24,25,26,27,28,29,30]. The results of previous studies show that various factors such as fiber length, fiber–soil friction and fiber ratio in soil mass affect the strength characteristics of fiber-reinforced soils [17, 20, 28].

Puppala and Musenda [17] carried out different unconfined compression and consolidation tests on reinforced expansive clays with various lengths of polypropylene fiber. It was reported that short fibers encouraged stabilization and decreased the swelling pressure of the clay. Punthutaecha et al. concluded that the unconfined compressive strength of the mixture containing polypropylene fibers and fly ash significantly increased while the expansive properties of clayey soils such as shrinkage and swelling characteristics diminished [31].

Ebrahimpour et al. [32] investigated the feasibility of using polypropylene fibers and other additives in the high early strength concrete. Moreover, the bond performance behavior of several mixes containing HES concrete Class 50AF with and without polypropylene fibers was investigated. The result illustrated that bond performance behaves better with polypropylene fiber concrete [33].

In another study, Melakzadeh and Bilsel reported the influence of polypropylene fibers on the swelling potential of expansive soils. The fiber percentages used in the research were 0.0%, 0.5%, 0.75% and 1%. Results revealed that the swelling percentages fell significantly with increasing fiber content rates [34].

İkizler et al. studied the influence of polypropylene fibers on the swelling behavior of bentonite treated with fibrillated polypropylene fiber and multifilament fiber. The results showed a large void distribution as well as a sizeable swelling strain in the fiber-treated soil due to the difficulty in mixing and compacting of samples with increasing the amount of fiber [19].

Twinkle and Sayida reported the effect of polypropylene fiber and lime on the stabilization of black cotton soil. It was found that by increasing the percentages of lime and fiber, the optimum water content dropped, whereas the maximum dry density increased [35].

Khosrowshahi et al. studied the performance of copolymer polypropylene and homopolymer fibers on the bentonite–fiber mixture. The results indicated that both copolymer polypropylene and homopolymer fibers significantly reduced the swelling pressure of bentonite clay. The maximum swelling reduction in both fiber–bentonite mixtures samples was reported at the same percentage of fibers blended with bentonite [36].

The impact of fiber length and ratio on the strength and swelling properties of high potential expansive clayey soils was investigated by Moghal et al. The fiber contents used in the study were 02%, 0.4% and 0.6% by dry weight of the soil, and the fiber lengths were considered between 6 and 12 mm. The results suggested that FC fiber had a better swelling restricted performance. Furthermore, nonlinear best-fit equations were proposed to relate the compression index (Cc) and the recompression index (Cr) of expansive soil based on the result of regression analysis [37, 38].

As mentioned above, many studies have investigated the impact of reinforcement on the swelling parameters of expansive soils. However, most studies were carried out without a focus on determining the optimum amount of reinforcement and the effect of reinforcing doses on the swelling pressure of expansive soil using a reliability approach [19, 31, 34, 39,40,41,42]. In addition, the regression analysis was not considered to develop an illustrative model to predict the swelling pressure of fiber-reinforced expansive soils. Hence, considering previous studies, the effect of randomly oriented discrete fiber on reducing swelling tendency in expansive soil needs to be investigated further.

This study aims to investigate the effects of reinforcing bentonite with randomly fibrillated virgin homopolymer polypropylene (HPP) and copolymer polypropylene (CPP) fibers on the swelling characteristics of bentonite clay with high swelling potential. The effect of fibers contents on the swelling pressure of bentonite was also evaluated. Furthermore, the regression analysis was employed for compaction parameters and two parabolic equations were computed based on fiber types for the swelling pressure of fiber-reinforced expansive soils.

Materials specifications

Bentonite

Bentonite is absorbent aluminum phyllosilicate clay which consists mainly of montmorillonite. There are different types of bentonite named based on dominant elements, such as calcium (Ca), aluminum (Al), potassium (K) and sodium (Na). The bentonite used in this study is high-plasticity sodium bentonite supplied by Canbensan Corporation in the North of Ankara (Turkey). Tables 1 and 2 present information about the physical and chemical properties of bentonite utilized in this research, respectively [43,44,45]. The percentage of montmorillonite is above 75% which plays a significant role in the swelling characteristics of clay soil (Table 1).

Fiber types

There has been a growing interest in soil reinforcement with both natural and synthetic fibers in recent years. Polypropylene is a human-made fiber used to improve some engineering properties of soil such as shear strength and to control the swelling potential of expansive grounds. One of the main benefits of polypropylene is its low cost [46, 47]. Figure 1 shows photographs of two different synthetic fibers (copolymer polypropylene and virgin homopolymer polypropylene) used in the current study.

Copolymer polypropylene fiber

Copolymer polypropylene fiber is a synthetic fiber made of pure virgin copolymer polypropylene. It consists of a twisted bundle of non-fibrillating monofilament which is generally used in concrete reinforcement systems. This type of fiber significantly reduces plastic shrinkage and increases the impact strength of concrete. The copolymer polypropylene used for this study is polypropylene twisted fiber FORTA Ferro Macrofiber. The physical properties of this fiber are summarized in Table 3.

Virgin homopolymer polypropylene

Virgin homopolymer polypropylene fiber (HPP) is used as a concrete reinforcement to mitigate some crucial problems of reinforced concrete such as settlement shrinkage. Table 4 shows the physical properties of HPP.

Research method

To investigate the effect of polypropylene fibers on the swelling characteristics of bentonite, a series of reinforced and unreinforced bentonite clays was prepared. Various contents of both fibers (0.1%, 0.2%, 0.3%, 0.4% and 0.7% of the dry weight of soil) with the length of 54 mm were added to bentonite. Then, the soil and the fibers were mixed by hand thoroughly into a pan and water was added as per requirements. The experimental tests were performed in Prof. Hamdi Peynircioğlu’s Soil Mechanics Laboratory of Istanbul Technical University. The sieve and hydrometer tests were carried out on bentonite to classify soil materials. Regarding the test results and the unified soil classification system (USCS), bentonite was classified as the fine-grained soil. Then, the optimum moisture content and the maximum dry unit weight of unreinforced and reinforced specimens were determined by the standard Proctor compaction test. Atterberg limits tests which are the liquid and plastic limits of soils were also carried out [49]. The plasticity index was used to identify the type of soil based on the unified soil classification system. All specimens were prepared with the optimum water content obtained from the standard Proctor compaction test to perform the one-dimensional swell test. Figure 2 displays a schematic illustration of the test setup including the standard Proctor compaction equipment, the one-dimensional swell test, the oedometer (consolidometer) apparatus and the test setup with a consolidometer apparatus used in this research. The experimental procedure is shown in Fig. 3. As can be seen, in order to obtain more accurate results, the one-dimensional pressure test was applied for each specimen. Whenever a difference was observed between the swelling pressures of the same two specimens compacted under the same conditions, the test was repeated.

Test procedure

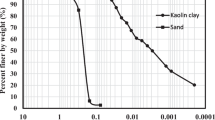

Sieve and hydrometer analysis and the standard Proctor compaction test

A sieve analysis evaluates the grain size characteristics of predominantly coarse-grained soils. A hydrometer analysis was used to determine the specific gravity value of the bentonite. The gradation test was also performed on the bentonite sample to obtain the particle size distribution. Regarding the Unified Soil Classification System (USCS), bentonite was categorized in the fine material group (CH). It was observed that 93% of the soil particles passed through the No. 200 sieve and hydrometer test data indicated the grain size distribution of bentonite as illustrated in Fig. 4a.

One of the most useful methods for determining soil compaction parameters is the Proctor compaction test which is widely used in many geotechnical laboratories. In this study, the optimum water content (ωopt) and the maximum dry density (γdmax) of bentonite were evaluated by the standard Proctor compaction test based on the ASTM-D698 [50] standard. The compaction properties of bentonite were obtained as indicators. Accordingly, the effect of different fiber contents on these parameters was measured using the standard Proctor test. Figure 4b displays the results of the standard Proctor compaction test carried out on original bentonite to determine the compaction parameters of plain bentonite in the absence of additive materials. The maximum dry unit weight and the optimum water content of the original bentonite were 11.9 kN/m3 and 39%, respectively.

Atterberg limit test

The Atterberg limits are the primary measurement for the critical moisture content of fine-grained soils. As bentonite is a high water absorbent clay, the Atterberg limit tests were applied to determine its liquid, plastic and shrinkage limits parameters according to the ASTM-D4318 [51] standard. The Atterberg limits of the bentonite used are shown in Table 5.

One-dimensional swelling test

The oedometer test method is carried out to measure the swelling pressure which is one of the critical parameters to determine the heave potential of expansive soils. There are two types of oedometer test: (1) the consolidation–swelling test and (2) the constant volume or swelling pressure test [6]. The consolidation–swelling test approach was adopted in this study in which soil sample swelling is allowed to occur under known pressure after inundating the sample. The swelling pressure is then defined as the pressure required to re-surpassing the swollen sample to its pre-swelling volume [6, 52].

The one-dimensional swelling test can be carried out in an oedometer on undisturbed soil specimens or re-compacted ones in accordance with AASHTO T256 [53] and ASTM D4546 [54]. In this study to investigate the swelling characteristics of the original bentonite and fiber-reinforced specimens, the one-dimensional swelling experiment was carried out by the oedometer apparatus according to the C-method of the ASTM-D4546 [54] Standard. First, the samples with different contents of both fibers (0.1%, 0.2%, 0.3%, 0.4%, 0.5% and 0.7%) were compacted at maximum dry density and optimum water content in a consolidation ring with a height of 20 mm and a 50 mm inner diameter and were then put in the consolidometer. Next, they were saturated with water to be exposed to the swelling pressure. It should be noted that the quality of water has a substantial effect on the engineering properties of concretes and stabilized soils [55,56,57,58,59,60,61,62,63,64,65,66]. Therefore, distilled water was used for characterization tests while tap water was used for molding specimens [67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86]. The swelling pressure of the specimens was measured by adding weight and keeping the dial gauge at zero until the dial gauge no longer indicated swelling movements. Eventually, the results of the swelling pressure of bentonite–fiber admixture specimens blended with CPP and HPP fibers were compared with the outcome of the swelling pressure of plain bentonite (as indicators). During the test procedure, all specimens were confined laterally, but unconfined in the bottom by porous stone to keep them in a saturation condition.

Figure 5 gives more information about the swelling pressure measurement technique based on the C-method [54], and a schematic image of this process is shown in Fig. 6. This method is based on keeping the height of the specimen constant in the consolidometer ring by adding weight after inundating the sample. Initially, compaction parameters of plain and fiber-reinforced bentonite were obtained for HPP and CPP fibers. Then, the swelling pressure was measured, and the samples for the oedometer test were prepared using compaction parameters obtained from compaction tests. Finally, the one-dimensional swelling analysis was applied to specimens in the oedometer apparatus for each sample. Figures 7 and 8 show the oedometer apparatuses and consolidometer cell equipment along with a soil sample in the ring, respectively.

Deformation versus vertical stress, loading-after-wetting test method C [ASTM D4546-08 [54])]

Schematic image of the deformation of the sample, according to swelling and vertical stress, loading-after-wetting (ASTM D4546 [54] Method C)

Results

Effect of copolymer polypropylene fiber on compaction parameters

The standard Proctor test was performed to obtain the compaction characteristics of plain bentonite and bentonite–fiber mixture samples [50]. The bentonite–fiber mixture samples with different water contents were compacted in the standard mold in 3 layers and 25 blows on each layer. The statistical results of the mentioned test are presented as the scatter plot in Fig. 9. The maximum dry density and optimum moisture content values of bentonite blended with different CPP contents were obtained. The results show that the optimum moisture content changed inconsiderably between 36 and 39% due to the impermeability of polypropylene fiber. However, there was an insignificant reduction in optimum water content by increasing the fiber content. Otherwise, the dry unit weight of the reinforced samples rose moderately. It reached a peak of 12.8 kN/m3 in the sample with 0.5% CPP fiber content; it then dropped to 12.1 kN/m3 in the sample with 0.7% CPP fiber. By increasing the fiber content, the maximum dry density rose, followed by a significant decrease in samples with more than 0.5% copolymer polypropylene fiber contents.

The statistical analysis results of compaction parameters for bentonite blended with CPP fiber are shown in Tables 6 and 7. These tables give details of the regression analysis of samples with different additives, dry unit weights and optimum water contents. As shown in the tables, the regression model values of R-squared (R2), root mean squared error (RMSE) and the mean absolute error (MAE) for soil samples with different percentages of fiber are calculated.

Effect of HPP fiber on the compaction parameters of bentonite

The statistical analysis of the dry unit weight of bentonite and its admixture is shown in Fig. 10a. It can be observed that the maximum dry unit weight of bentonite grew slightly with increasing fiber content and reached its maximum values in samples with 0.1% and 0.2% fiber contents. However, it was followed by a decrease in values by increasing the fiber percentages after the optimum point. By changing the percentages of additives, the optimum water content of bentonite and HPP–bentonite mixture varied slightly. Figure 10b shows insignificant changes in the optimum moisture contents of bentonite–HPP fiber admixtures. To check the accuracy of the model, a regression analysis was performed on samples with HPP and CPP fiber admixture. Statistical analysis values such as R2, RMSE and MAE were calculated for each sample with different amounts of additives. As can be seen, Tables 8 and 9 provide details of the regression model.

Effect of CPP and HPP fibers on the swelling potential of bentonite

Figure 11 shows the swelling pressure of bentonite–fiber mixtures containing fibrillated virgin homopolymer polypropylene fiber (HPP) and copolymer polypropylene fiber (CPP) with various fiber contents. At first sight, it can be seen that there is a dramatic reduction in the swelling pressure of the soil by increasing the percentages of both fibers. Regarding the curve of CPP fiber and comparing results with plain bentonite, the swelling potential dropped at the optimum point in the sample with 0.5% fiber and the optimum amount of the swelling pressure reduced up to 29.4%. In the case of HPP fiber, the swelling pressure experienced a 44.2% reduction and reached 173 kPa for a fibrillated sample with 0.4% HPP fiber. Then the swelling pressure increased again by adding fiber content.

Regression model development

The regression analysis method is widely used to obtain the relationship between dependent and independent variables [38, 40, 52, 87,88,89,90]. In the present research, a relationship between swelling pressure and additive materials was found. Due to fitting a linear or nonlinear model of experiments, the regression analysis was applied to data obtained from experimental results. The forecast parameter was the swelling pressure of the reinforced expansive clay with HPP and CPP fibers. Three critical parameters of regression analysis are the coefficient of determination (R2), the root mean square error (RMSE) and the mean absolute error (MAE) values calculated for the swelling pressure of bentonite and bentonite–fiber additives. The best-fit nonlinear equation for estimating the swelling pressure of bentonite with CPP (SwPcpp) and HPP (SwPhpp) fibers is given in Eqs. 1 and 2, respectively. With respect to the regression analysis, the coefficient of determination (R2) values of 0.974 and 0.990 and root mean square error (RMSE) values of 4.753 kPa and 4.298 kPa were calculated for the swelling pressure of bentonite blended with CPP and HPP fibers, respectively. These values indicate the goodness of fit for the model.

Comparing the effect of CPP and HPP on the swelling potential of bentonite

Figure 12 reveals a comparison between the swelling potential of bentonite blended with various amounts of HPP and CPP. It is evident that both HPP and CPP fibers critically impacted the swelling potential of bentonite and reduced the swelling pressure of bentonite. Although these fibers showed a similar pattern, the test results indicated significantly different values for the swelling stress of bentonite–fiber mixtures in the same fiber content for both CPP and HPP. According to Fig. 12, the values of the swelling pressure (σs) of bentonite blended with HPP fiber were higher than those of bentonite–CPP mixture. Moreover, the maximum swelling improvement for samples with HPP fiber occurred at 0.4% fiber content in the soil mass, whereas the maximum swelling improvement for samples with CPP fiber occurred at 0.5% fiber content.

Discussion

Recently, the potential use of synthetic fibers such as polypropylene to improve the swelling characteristics of expansive soils has been investigated. The results show that synthetic fibers have a remarkable effect on the swelling potential of expansive grounds. Malekzadeh and Bilsel [34] indicated that the use of polypropylene fiber and copolymer decreases the swelling pressure of expansive soils. The amount of swelling pressure of the original soil samples varies because of their chemical properties and soil activities.

In a study conducted by Khosrowshahi et al. [36], copolymer polypropylene (CPP) and homopolymer polypropylene (HPP) were used as synthetic stabilizers to improve the swelling characteristics of bentonite. Khosrowshahi et al. [36] reported that both CPP and HPP fibers had a significant effect on reducing the swelling pressure of bentonite. The results also showed that by increasing the copolymer fiber content, the pressure values of bentonite reduced. Moreover, the greatest reduction in the swelling pressure occurred with the inclusion of a 0.7% fiber ratio.

Figure 13 compares the effect of the copolymer on the swelling pressure of bentonite between the current study and earlier research by Khosrowshahi et al. [36]. As can be seen, the swelling pressure and the swelling pressure reduction versus fiber contents are shown in Fig. 13. Concerning similarities in the results, it is noticeable that copolymer plays a key role in reducing the swelling pressure of bentonite. By increasing the percentages of copolymer fibers, the swelling pressure dropped before reaching a peak. While the maximum swelling pressure for fiber-reinforced soil specimen was observed at 0.5% fiber content and the swelling pressure reduction in this point approached to 29.4%, this amount was 68% in a specimen with 0.7% fiber content obtained by Khosrowshahi et al. [36]. Similar to the result of an earlier study by Khosrowshahi et al., any further addition of copolymer fiber after an optimum dosage showed less effect on the swelling pressure of the soil. Khosrowshahi et al. reported an erratic trend in swelling pressure reduction which may be due to the type of soil and the chemical properties of soils. In addition to the above-mentioned parameters, the compaction parameters (dry unit weight and water content) and temperature can be effective in the swelling pressure of expansive grounds which create some differences between values in Fig. 13.

Comparison between the swelling pressures of CPP fiber-reinforced soil in the current study and Khosrowshahi et al. [36]

A number of researches have been carried out to investigate the influence of homopolymer polypropylene fiber on the swelling potential of expansive soils. In recent studies done by Khosrowshahi et al. and Malekzadeh and Bilsel [34, 36], the swelling pressure of expansive soil blended with homopolymer polypropylene was investigated. Malekzadeh and Bilsel prepared clay soil specimens with different percentages (0.0%, 0.5%, 0.75% and 1%) of homopolymer polypropylene fiber [34]. In another study conducted by Khosrowshahi et al. [36], to determine the impact of homopolymer polypropylene fiber on the swelling pressure of expansive soil, soil was blended with six percentages of 0.0%, 0.1%, 0.2%, 0.3%, 0.5%, 0.7% and 1% of fiber using a one-dimensional swelling test. In order to investigate the behavior of fiber-reinforced soils, the outcomes of previous studies were compared with the current studies. As can be seen, the swelling pressure decreased significantly in all studies. In this case, Malekzadeh and Bilsel [34] reported that the swelling pressure dropped substantially by using fiber and reducing the swelling pressure continued without reaching the optimum point (see Fig. 14a). Khosrowshahi et al. [36] concluded that the addition of 0.1% homopolymer polypropylene fiber had a negligible effect on decreasing swelling pressure. However, by increasing fiber contents, the swelling pressure declined noticeably until adding 0.7% of HPP fiber resulted in a 68% reduction (see Fig. 14b) in the swelling pressure of soil. It should be noted that the maximum reduction in swelling pressure occurred in a sample with 0.7% of HPP fiber content blended with the soil and the addition of any further HPP fiber showed less mitigation than other dosages.

Similar to earlier studies, the current study showed that homopolymer polypropylene fiber has a significant effect on decreasing the swelling pressure of expansive soil. In the research conducted by Khosrowshahi et al. [36], the results revealed that there is an optimum dosage of fiber content causing a maximum decrease in the swelling pressure while with increasing the fiber ratio above to the optimum dosage, the swelling pressure got smaller. Concerning Fig. 14 in the current study, adding 0.4% of HPP resulted in the maximum decrease in the swelling pressure up to 29.4%, and then with an increase in fiber content, the swelling pressure increased again.

Regarding Fig. 14, despite homopolymer, polypropylene fiber reduced the swelling pressure of soils, but this trend varies during research. In the case of Khosrowshahi et al. [36], although the general process showed a decrease in swelling pressure, this trend was erratic. The result of the research of Malekzadeh and Bilsel [34] displayed a normal decline in the swelling pressure of the soil, but this trend continued without any change in the process. It is not apparent that with an increase in the fiber content what may happen to swelling pressure.

In summary, the results of the present study and the above-mentioned researches reveal that increasing the percentage of homopolymer polypropylene fiber leads to a significant decrease in the swelling pressure of expansive soils and any further addition of fiber shows less mitigation [34, 36].

Overall, Figs. 13 and 14 present information on the influence of reinforcement on the swelling potential of expansive soils. It can be concluded that the fibers have an effective role in decreasing the swelling pressure of expansive grounds, but some other parameters may affect the results during the process. However, it should be noted that material properties including chemical and physical properties of soils and additives affect the swelling pressure.

Conclusions

A series of laboratory experiments were carried out to study the effect of two different types of synthetic fibers (CPP and HPP) inclusion on the compaction and the swelling pressure of bentonite. The following conclusions were drawn based on test results:

- 1.

The addition of HPP and CPP fibers significantly decreased the swelling pressure of bentonite to a maximum amount. Then, by adding more percentages of fibers, the swelling pressure increased slightly.

- 2.

The greatest reduction in the swelling pressure of HPP treated bentonite occurred at about 0.4% fiber content, whereas in the case of CPP fiber, results show that the greatest reduction in the swelling pressure was 29.4% compared with bentonite without additive materials. However, by increasing the CPP content, the decrease in the swelling potential was smaller after the 0.5% optimum point in fiber content. This can be clarified by the fact that at higher percentages of copolymer fiber, compaction is difficult due to the massive void distribution in fiber-treated bentonite.

- 3.

In the case of HPP fiber, the maximum reduction in the swelling pressure of bentonite was about 44.2% which happened in a sample with 0.4% fiber content. The results show that HPP fiber is more effective than CPP fiber in reducing the swelling pressure of bentonite. It seems that the texture of fibrillated homopolymer polypropylene has a significant influence on reducing the swelling potential of bentonite compared to copolymer polypropylene. Due to the shape of CPP, it is harder than HPP and has a rough surface. Unlike CPP, HPP has a texture that is softer and spreads out when mixed with bentonite, so it can hold bentonite particles together with a lower mixture void ratio.

- 4.

In both CPP and HPP fibers, the swelling pressure increased after the optimum point when the higher dosages of fibers were used. Increasing the fiber dosages higher than 0.5% and 0.4% for a bentonite–fiber mixture containing fibrillated copolymer polypropylene and virgin homopolymer polypropylene, respectively, had no influence on swelling pressure. On the other hand, when the dosage level of fibrillated CPP and HPP fibers increased after an optimum point, the swelling pressure declined. According to research results, a dosage level between 0.4 and 0.5% of copolymer polypropylene and fiber content ranging from 0.3 to 0.5% for virgin homopolymer polypropylene would be better for improving the swelling behavior of bentonite. It can be concluded that although both types of fibers are influential in reducing the swelling pressure of bentonite, HPP fiber has a significant effect on decreasing the swelling pressure compared to copolymer fiber.

References

Jahandari S (2015) Laboratory study of moisture and capillarity impact on lime concrete resistance due to the increase of ground water level. Department of Geotechnical Engineering, Faculty of Civil and Surveying Engineering, Graduate University of Advanced Technology, Kerman, Iran

Jahandari S et al (2017) Experimental study of the effects of geogrids on elasticity modulus, brittleness, strength, and stress-strain behavior of lime stabilized kaolinitic clay. GeoResJ 13:49–58

Rogers JD, Olshansky R, Rogers RB (1993) Damage to foundations from expansive soils. Claims People 3(4):1–4

Sridharan A, Gurtug Y (2004) Swelling behaviour of compacted fine-grained soils. Eng Geol 72(1–2):9–18

Chen F (1975) Foundations on expansive soils. Elsevier, Amsterdam

Nelson J, Miller DJ (1997) Expansive soils: problems and practice in foundation and pavement engineering. Wiley, New York

Steinberg M (1998) Geomembranes and the control of expansive soils in construction. Construction series. McGraw Hill, New York, NY

Saberian M et al (2017) Experimental and phenomenological study of the effects of adding shredded tire chips on geotechnical properties of peat. Int J Geotech Eng 12(4):347–356

Saberian M et al (2017) Effect of curing, capillary action, and groundwater level increment on geotechnical properties of lime concrete: experimental and prediction studies. JRMGE 9(4):638–647

Jahandari S et al (2017) Experimental study of the effects of curing time on geotechnical properties of stabilized clay with lime and geogrid. Int J Geotech Eng 13(2):172–183

Jahandari S et al (2017) Laboratory study of the effect of degrees of saturation on lime concrete resistance due to the groundwater level increment. Geotech Geol Eng 36(1):413–424

Jahandari S et al (2019) Effects of saturation degrees, freezing-thawing, and curing on geotechnical properties of lime and lime-cement concretes. Cold Reg Sci Technol 160:242–251

Kazemi M et al (2019) Non-linear behaviour of concrete beams reinforced with GFRP and CFRP bars grouted in sleeves. Structures 23:87–102

Nataraj M, McManis K (1997) Strength and deformation properties of soils reinforced with fibrillated fibers. Geosynth Int 4(1):65–79

Shoabjareh SS, Soltani F, Heidaripanah A, Jahandari S, Abedi M (2015) Laboratory study of the effect of temperature on strength and stress–strain curve of lime-stabilized soil. Bull Environ Pharmacol Life Sci 4(1):376–381

Ameri M, Kalantari B, Jahandari S (2015) Laboratory study of determination of optimum amount of water and clay in mortar made with lime and fly ash. In: International conference on research in science and technology. Kualalumpur, Malaysia

Puppala A, Musenda C (1998) Investigation of geofiber reinforcement method on strength, swell, and shrinkage characteristic of soils. In: Fifth international conference on composites engineering, Las Vegas

Puppala AJ, Musenda C (2000) Effects of fiber reinforcement on strength and volume change in expansive soils. Transport Res Rec 1736(1):134–140

Ikizler S et al (2009) Effect of Fibers on swelling Characteristics of Bentonite. In: 2nd international conference on new developments in soil mechanics and geotechnical engineering

Ziegler S et al (1998) Effect of short polymeric fibers on crack development in clays. Soils Found 38(1):247–253

Alwahab R, Alqedra M (1995) Using fibres to reduce tension cracks and shrink/swell cycles in a compacted clay. In: Proceedings of the speciality conference on geotechnical practice in waste disposal, vol 1, number 2. ASCE, New Orleans, LA, USA

Kaniraj SR, Gayathri V (2003) Geotechnical behavior of fly ash mixed with randomly oriented fiber inclusions. Geotext Geomembr 21(3):123–149

Kaniraj SR, Havanagi VG (2001) Behavior of cement-stabilized fiber-reinforced fly ash-soil mixtures. J Geotech Geoenviron 127(7):574–584

Gray D, Maher A (1989) Admixture stabilization of sands with random fibers. In: Proceedings of the 12th international conference on soil mechanics and foundation engineering. AA Balkema

Mandal J, Murthi M (1989) Potential use of natural fibres in geotechnical engineering. In: Proceedings of the international workshops on geo-textiles, Bangalore

Maher M, Ho Y (1994) Mechanical properties of kaolinite/fiber soil composite. J Geotech Eng 120(8):1381–1393

Prabakar J, Sridhar R (2002) Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr Build Mater 16(2):123–131

Abdi M, Ebrahimi A (2005) Effect of polypropylene fiber content and length on mechanical properties of kaolinite. In: 2nd national civil engineering conferences, Science and Technology University, Tehran, Iran (in Persian)

Akbulut S, Arasan S, Kalkan E (2007) Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl Clay Sci 38(1–2):23–32

AzariJafari H et al (2016) Effects of pre-soaked super absorbent polymers on fresh and hardened properties of self-consolidating lightweight concrete. Constr Build Mater 113:215–220

Punthutaecha K et al (2006) Volume change behaviors of expansive soils stabilized with recycled ashes and fibers. J Mater Civil Eng 18(2):295–306

Ebrahimpour A et al (2018) Effectiveness of high-early strength concrete class 50AF with polypropylene fibers as a cost-effective alternative for field-cast connections of precast elements in accelerated bridge construction. Idaho Transportation Department, Research Program. Contracting Services, Division of Engineering Services

Clauson C, Shokrgozar A (2018) Idaho Transpo

Malekzadeh M, Bilsel H (2012) Swell and compressibility of fiber reinforced expansive soils. IJAERS 1(2):42–45

Twinkle S, Sayida M (2011) Effect of polypropylene fibre and lime admixture on engineering properties of expansive soil. In: Proceedings of Indian geotechnical conference, Kochi (Paper No. H-085)

Khosrowshahi S, Şenol A, Yildirim H (2014) Improvement of expansive soils using fiber materials. In The 11th international congress on advances in Civil Engineering, Istanbul, Turkey

Moghal AAB, Chittoori BC, Basha BM (2018) Effect of fibre reinforcement on CBR behaviour of lime-blended expansive soils: reliability approach. Road Mater Pavement 19(3):690–709

Moghal AAB et al (2017) target reliability approach to study the effect of fiber reinforcement on UCS behavior of lime treated semiarid soil. J MATER CIVIL ENG 29(6):04017014

Vali R et al (2019) A three-dimensional numerical comparison of bearing capacity and settlement of tapered and under-reamed piles. Int J Geotech Eng 13(3):236–248

Phanikumar B, Singla R (2016) Swell-consolidation characteristics of fibre-reinforced expansive soils. Soils Found 56(1):138–143

Al-Akhras N et al (2008) Influence of fibers on swelling properties of clayey soil. Geosynth Int 15(4):304–309

Mousavi F, Abdi E, Rahimi H (2014) Effect of polymer stabilizer on swelling potential and CBR of forest road material. KSCE J Civ Eng 18(7):2064–2071

AzariJafari H et al (2014) Studying effects of chemical admixtures on the workability retention of zeolitic Portland cement mortar. Constr Build Mater 72:262–269

AzariJafari H et al (2018) Reducing variations in the test results of self-consolidating lightweight concrete by incorporating pozzolanic materials. Constr Build Mater 166:889–897

Hajforoush M, Madandoust R, Kazemi M (2019) Effects of simultaneous utilization of natural zeolite and magnetic water on engineering properties of self-compacting concrete. Asian J Civ Eng 20(2):289–300

Gray DH, Ohashi H (1983) Mechanics of fiber reinforcement in sand. J Geotech Eng 109(3):335–353

Nalbantoglu Z, Tuncer ER (2001) Compressibility and hydraulic conductivity of a chemically treated expansive clay. Can Geotech J 38(1):154–160

Fiber AS, Fibrillated or monofilament polypropylene fibers engineered and designed for use in concrete pavement, complying with ASTM C 1116. Type III, 1/2″ to 3/4″ inches long

ASTM D, 4318-05 (2005). In Standard test methods for liquid limit, plastic limit, and plasticity index of soil

ASTM D, 698-91 (1994) Test method for laboratory compaction characteristics of soils using standard effort, 600 kN m/m3, Annual Book of ASTM Standards, ASTM, Philadelphia, USA 4:69–76

D-05, A (2005) Standard test method for liquid limit, plastic limit, and plasticity index of soils

Vanapalli S, Lu L (2012) A state-of-the art review of 1-D heave prediction methods for expansive soils. Int J Geotech Eng 6(1):15–41

AASHTO, T 256 (1977) In: Standard method of test for pavement deflection measurements

ASTM, D (2008) Standard test methods for one-dimensional swell or collapse of cohesive soils

Gholhaki M, Hajforoush M, Kazemi M (2018) An investigation on the fresh and hardened properties of self-compacting concrete incorporating magnetic water with various pozzolanic materials. Constr Build Mater 158:173–180

Madandoust R, Bazkiyaei ZFZ, Kazemi M (2018) Factor influencing point load tests on concrete. Asian J Civ Eng 19(8):937–947

Mohammadi M, Kafi MA, Kheyroddin A, Ronagh HR (2019) Experimental and numerical investigation of an innovative buckling-restrained fuse under cyclic loading. Structures 22:186–199

Shariati M, Rafiei S, Zandi Y, Fooladvand R, Gharehaghaj B, Shariat A, Trung NT, Salih MN, Mehrabi P, Poi-Ngian S (2019) Experimental investigation on the effect of cementitious materials on fresh and mechanical properties of self-consolidating concrete. Adv Concr Constr 8(3):225–237

Bahmani M, Fatehi H, Noorzad A, Hamedi J (2019) Biological soil improvement using new environmental bacteria isolated from northern Iran. Environ Geotech 29:1–3

Rasekh H, Joshaghani A, Jahandari S, Aslani F, Ghodrat M (2019) Rheology and workability of SCC, Book: self-compacting concrete: materials, properties and applications. Woodhead Publishing Series in Civil and Structural Engineering, pp 31–63

Mohammadi M, Kafi MA, Kheyroddin A, Ronagh HR, Rashidi M (2020) experimental and numerical investigation of innovative composite buckling-restrained fuse. In: ACMSM25. Springer, Singapore, pp 113–121

Ghadir P, Ranjbar N (2018) Clayey soil stabilization using geopolymer and Portland cement. Constr Build Mater 188:361–371

Jarrah M, Khezrzadeh H, Mofid M, Jafari K (2019) Experimental and numerical evaluation of pistonmetallic damper (PMD). J Constr Steel Res 154:99–109

Jafari K, Tabatabaeian M, Joshaghani A, Ozbakkaloglu A (2018) Optimizing the mixture design of polymer concrete: an experimental investigation. Constr Build Mater 167:185–196

Jarrah M, Pournamazian Najafabadi E, Houshmand Khaneghahi M, Vatani Oskouei A (2018) The effect of elevated temperatures on the tensile performance of GFRP and CFRP sheets. Constr Build Mater 190:38–52

Siddique R et al (2019) Self-compacting concrete: materials, properties and applications. Woodhead Publishing Series in Civil and Structural Engineering, pp 1–396

Ardalan RB, Emamzadeh ZN, Rasekh H, Joshaghani A, Samali B (2019) Physical and mechanical properties of polymer modified self-compacting concrete (SCC) using natural and recycled aggregates. JSCM 3:1–6

Kazemi M, Madandoust R, de Brito J (2019) Compressive strength assessment of recycled aggregate concrete using Schmidt rebound hammer and core testing. Constr Build Mater 224:630–638

Madandoust R, Kazemi M, Talebi PK, de Brito J (2019) Effect of the curing type on the mechanical properties of lightweight concrete with polypropylene and steel fibres. Constr Build Mater 223:1038–1052

Moghadam SY, Madandoust R, Ranjbar MM, Kazemi M (2017) Analytical study on the behavior of corrosion damaged reinforced concrete beams strengthen with FRP. Rom J Mater 47(4):514–521

Ghasemi M, Rasekh H, Berenjian J, AzariJafari H (2019) Dealing with workability loss challenge in SCC mixtures incorporating natural pozzolans: a study of natural zeolite and pumice. Constr Build Mater 222:424–436

AzariJafari H, Shekarchi M, Berenjian J, Ahmadi B (2015) Enhancing workability retention of concrete containing natural zeolite by superplasticizers’ combination. Special Publication 302:416–424

AzariJafari H, Amiri MJ, Ashrafian A, Rasekh H, Barforooshi MJ, Berenjian J (2019) Ternary blended cement: an eco-friendly alternative to improve resistivity of high-performance self-consolidating concrete against elevated temperature. J Clean Prod 223:575–586

Xu C, Zhang X, Haido JH, Mehrabi P, Shariati A, Mohamad ET, Hoang N, Wakil K (2019) Using genetic algorithms method for the paramount design of reinforced concrete structures. Struct Eng Mech 71(5):503–513

Fatehi H, Bahmani M, Noorzad A (2019) Strengthening of dune sand with sodium alginate biopolymer. In: Geo-congress: soil improvement. American Society of Civil Engineers, Reston, VA, USA 157–166

Li J, Saberian M, Nguyen BT (2018) Effect of crumb rubber on the mechanical properties of crushed recycled pavement materials. J Environ Manage 218:291–299

Saberian M, Rahgozar MA (2016) Geotechnical properties of peat soil stabilised with shredded waste tyre chips in combination with gypsum, lime or cement. Mires Peat 18(16):1–6

Saberian M, Li J, Boroujeni M, Law D, Li CQ (2020) Application of demolition wastes mixed with crushed glass and crumb rubber in pavement base/subbase. Resour Conserv Recycl 1(156):104722

Saberian M, Li J, Nguyen BT, Boroujeni M (2020) Experimental and analytical study of dynamic properties of UGM materials containing waste rubber. Soil Dyn Earthq Eng 1(130):105978

Saberian M, Shi L, Sidiq A, Li J, Setunge S, Li CQ (2019) Recycled concrete aggregate mixed with crumb rubber under elevated temperature. Constr Build Mater 20(222):119–129

Saberian M, Li J, Setunge S (2019) Evaluation of permanent deformation of a new pavement base and subbase containing unbound granular materials, crumb rubber and crushed glass. J Clean Prod 1(230):38–45

Saberian M, Li J, Cameron D (2019) Effect of crushed glass on behavior of crushed recycled pavement materials together with crumb rubber for making a clean green base and subbase. J Mater Civil Eng 31(7):04019108

Rahgozar MA, Saberian M (2016) Geotechnical properties of peat soil stabilised with shredded waste tyre chips. Mires Peat 1:18

Usefi N, Ronagh HR, Mohammadi M (2018) Finite element analysis of hybrid cold-formed steel shear wall panels. In: Streamlining information transfer between construction and structural engineering: proceedings of the fourth Australasia and South-East Asia structural engineering and construction conference, Brisbane, Australia STR-41

Rashidi M, Ghodrat M, Samali B, Mohammadi M (2018) Decision support systems, management of information systems, Maria Pomffyova. IntechOpen. https://doi.org/10.5772/intechopen.79390

Hataf N, Ghadir P, Ranjbar N (2018) Investigation of soil stabilization using chitosan biopolymer. J Clean Prod 170:1493–1500

Vinod P, Bindu J (2010) Compression index of highly plastic clays—an empirical correlation. IGJ 40(3):174–180

Işık NS (2009) Estimation of swell index of fine grained soils using regression equations and artificial neural networks. Sci Res Essays 4(10):1047–1056

Sridharan A, Nagaraj H (2000) Compressibility behaviour of remoulded, fine-grained soils and correlation with index properties. Can Geotech J 37(3):712–722

Tiwari B, Ajmera B (2011) New correlation equations for compression index of remolded clays. J Geotech Geoenviron 138(6):757–762

Acknowledgements

We would like to offer our special thanks to Prof. Aykut Senol for reading the present article and giving appropriate suggestions and the ITU Soil Mechanics Laboratory staff for all their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Darvishi, A., Vosoughifar, H., Saeidijam, S. et al. An experimental and prediction study on the compaction and swell–expansion behavior of bentonite clay containing various percentages of two different synthetic fibers. Innov. Infrastruct. Solut. 5, 31 (2020). https://doi.org/10.1007/s41062-020-0280-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-020-0280-6