Abstract

The usage of locally available soil for construction purposes is a wise choice for enhancing its engineering properties. Depending on the size of the particles, the silty and clayey soils possess voids at the nano level. Generally, clay soil is affected by increased settlement, decreased stability and altered soil structure due to the increased plasticity index. Hence, it is necessary to enhance the soil properties using various additives. In recent days, nanomaterials have been increasingly utilized for improving soil stability and strength in various geotechnical engineering applications. This paper deals with the effect of nano-clay on the various geotechnical properties of three different silty and three different clayey soil samples. The influence of the wet–dry cycles on the unconfined compressive strength (UCS), coefficient of permeability (k) and settlement were discussed. Furthermore, the UCS and California bearing ratio (CBR) of the nano-clay-treated soil were predicted by using multiple regression analysis based on the index properties. Test results revealed that the optimum dosage of nano-clay was found to be 0.4%, 0.35%, 0.35%, 0.25%, 0.25% and 0.2% for three different silty soil samples and three different clayey soil samples, respectively. The UCS and CBR values were enhanced significantly irrespective of the nano-clay content and the soil type, due to the formation of CSH gels that effectively bonds the soil particles and facilitates the improvement of UCS and CBR and thus reduces the ‘k’ and settlement of soil samples. The predicted UCS and CBR values by regression analysis are in line with the experimental results in both treated and untreated conditions. As a result, this amorphous nano-clay is recommended for stabilizing weak soils irrespective of the type of soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lately, building construction has increased worldwide, especially in urban areas. Due to this, land scarcity is growing, and engineers are expected to construct buildings in undesirable soils. So, soil improvement is necessary to aid the construction of structures in such soil conditions. The particle size of silty soil and clay soil samples ranges from 2 to 75 μm and 1 nm to 2 μm [1]. Due to the presence of nano-level void spaces, the shear strength, compaction and consolidation characteristics of these soils are affected [2]. The prime geotechnical issues associated with these soils are low water-holding capacity, presence of soft minerals and elevated bulk density [3]. Various traditional materials (i.e., cement, lime and fly ash) were utilized to address these issues over the past decades in the construction industry as these materials were used to fill the voids. However, a micro-level void filling has negligible influence on the above-mentioned characteristics [4]. As a result, stabilizing these soils using novel technologies and nanomaterials was initiated in recent days, to fill these nano-level voids [5]. This procedure enhances the geotechnical properties by filling and reinforcing minerals with nanoparticles. Also, utilizing these nanomaterials proved to be cheaper, as it enhances the various geotechnical properties of the problematic soil at very low content [6].

The practice of using nanoadditives such as nanocarbon, nano-clay, graphene oxide and other nanoparticles owing to the advent of nanotechnology for soil enhancement is increased by researchers [4, 6,7,8,9,10,11]. In various studies, nanomaterials like Terrasil, nano-silica, and nano-clay were utilized to enhance the geotechnical properties of locally available weak soil. It shows the attention of civil, geotechnical and geoenvironmental engineers toward the application of nanotechnology and nanomaterials in soil stabilization [12]. From their perspective, nano-clay, a natural sustainable material, is preferred for soil stabilization to overcome environmental concerns.

Literature shows that the admixing of nano-clay with clayey soil provides better index properties and shear strength parameters when compared to the untreated soil at a very low content (i.e., 0.5%) of nano-clay [13]. It enhances the shear strength of the soil and thus reduces the plasticity index of the clayey soil sample.

A few authors studied the effect of nano-clay on enhancing the geotechnical properties like permeability, swelling and UCS characteristics of the raw clay of a compacted clay liner was investigated. The authors reported that the 4% addition of nano-clay reduced the order of permeability of the clay soil from 10–9 to 10–11 cm/s and increased the compressive strength by 36.28% due to the formation of nano-clay clusters in the void spaces which decreases the interlayer spacing [14].

Few researchers investigated the efficacy of nano-clay mixed with two different silty soils of low plasticity and high plasticity in nature. They stated that the addition of nano-clay to the silty soil increased the liquid limit (LL) and plastic limit (PL) of the silty soil and a noticeable change in the shear parameters of the silty soil was observed [2]. Similar results were noticed by the researchers, when the nano-clay was treated with a field clay soil collected from Rasht City, Iran [15]. They found that the optimum content of nano-clay for treating this field clay soil was 1.5% and they observed that the final compressive strength was decreased when the nano-clay content was raised from 1.5 to 2.5%.

Researchers conducted the UCS and California bearing ratio (CBR) test on soil admixed with nano-clay by varying the weight percentage (0.5%, 1%, 1.5% and 2%) of nano-clay and the results showed that the liquid and plastic limit of soil was increased by increasing the nano-clay content [16]. Also, the addition of 1.5% of nano-clay increased the soil resistance. Similarly, the nano-clay was used along with the cement for stabilizing the sand. It was reported that the 2% of nano-clay along with the 7% of cement to the dry weight of the soil increased 47% elastic modulus of the soil in tension after 28 days of curing [1]. In a study, researchers performed an investigation to study the effect of nano-clay in varying percentages (i.e., 0.5–3% to the dry weight of the soil) on the collapsibility and dispersivity behavior of the loess soil. The addition of nano-clay decreased the cohesion and increased the angle of internal friction, thus increasing the shear strength of the loess soil along with the other geotechnical properties [12].

Even though some previous studies are available for enhancing the various geotechnical properties of the silty and clayey soil samples using nano-clay, the effect of nano-clay with these soils under wet–dry conditions is very limited. Kanigiri City is a rapidly developing city in India and is well connected to the national highways. In this study, three different silty soils and three different clay soils were selected from this city, as the silty and clay soils tend to have poor load-bearing capacities, which can result in settlement issues and structural instability for buildings. The optimum dosage of nano-clay for the stabilization of these different soil samples was found and the effect of wet–dry cycles on the UCS and permeability was discussed. A prediction model for the nano-clay-treated soils was also developed using multiple regression analysis, to estimate the UCS and the CBR based on the laboratory and field measurements.

Materials and Characterization

Soil Samples

The soil samples used in this study were collected from various locations in Kanigiri City, India. The three different silty soil samples, namely, S1, S2 and S3 and three clayey soil samples, namely, S4, S5 and S6 were collected at a depth of 1 m from the ground level. The latitude and longitude of the soil samples of S1, S2, S3, S4, S5 and S6 are 15° 24′ 22.9′′ N 79° 31′ 05.3′′ E, 15° 24′ 42.1′′ N 79° 29′ 40.7′′ E, 15° 24′ 05.3′′ N 79° 29′ 41.5′′ E, 15° 24′ 34.3′′ N 79° 30′ 58.4′′ E, 15° 24′ 20.5′′ N 79° 29′ 53.8′′ E and 15° 24′ 03.1′′ N 79° 30′ 58.3′′ E, respectively. It is also shown in Fig. 1. These soils are not suitable for construction as the layers are so soft. The various geotechnical properties of the collected samples are given in Table 1. All the collected six soil samples were oven-dried at 110 °C and pulverized for performing the various soil tests.

The percentage of silt, clay and organic contents present in the collected soil samples and their soil classification are listed in Table 1 as per IS standard. The soil samples S1, S2 and S3 are classified as Inorganic silts of high (MH), medium (MI) and low plasticity (ML), respectively. Similarly, samples S4, S5 and S6 are classified as inorganic clay of high (CH), medium (CI) and low plasticity (CL).

Based on the UCS values of the collected soil samples, the consistency of soil samples S1, S2, S5, and S6 soils are medium stiff. S3 soil is stiff, but S4 soil is soft due to its 8% organic content and the lowest UCS value. Based on the CBR values of the collected soil samples the soil quality for performance as subgrade seems to be very poor irrespective of the soil samples. The collected soil samples were typically having low permeability values and the final settlement of the soil samples is also listed in Table 1. The settlement, compressibility and low compressive strength of these collected soil samples show that these soil samples seem to be weak and are necessary for soil stabilization.

Nano-Clay

The nano-clay used in this study was purchased from the local market of Bangalore (see Fig. 2a). It is creamish in color and amorphous in nature (see Fig. 2b). The particle size of this nano-clay is less than 100 nm [17]. It has a unit weight of 2.49 kN/m3 and a molecular weight of 550 g/mol. The oxide chemical composition of the nano-clay is shown in Table 2.

Methods

Sample Preparation

All the collected soil samples were mixed with the nano-clay in dry form of powder in varying percentages of 0.05%, 0.1%, 0.15%, 0.2%, 0.25%, 0.3%, 0.35%, 0.4%, 0.45% and 0.5% by dry weight of the soil. After thorough mixing in dry conditions, the samples were added to the distilled water and mixed again to attain a homogeneous mixture. These nano-clay mixed soil samples were used for further investigation such as compaction test, permeability test, unconfined compression strength test, wet–dry test and consolidation test. The range of minimum and maximum dosage of nano-clay for each soil sample was found using the trial and error method in the laboratory based on its workability. The sample images of the soil sample preparation for the UCS test are shown in Fig. 3

Experimental Investigation

The preparation of soil samples was done according to the IS 2720 (Part I)—1983 [18]. The soil classification of soil samples was found using IS 1498 (1970) [19]. The liquid limit and Plastic limit were determined as per IS: 2720 (Part V)—1985 [20]. The light compaction test, Unconfined compression strength test and California Bearing Ratio test were performed based on the IS: 2720 (Part VII)—1980, IS: 2720 (Part II)—1973 and IS: 2720 (Part XVI)—1987 [21,22,23]. IS 2720 (Part XVII)—1986 was employed for the determination of the coefficient of permeability for untreated and nano-clay-treated soil samples [24]. The wetting and drying test of the soil with and without nanomaterial was investigated based on the outlines given in IS: 4332 (Part IV)—1968 [25]

Development of Regression Models for the Prediction of UCS and CBR Values for Nano-Clay-Treated Soils

To estimate the UCS and unsoaked CBR values in terms of index and compaction properties, regression models, both simple linear and multiple linear, were created in this work. This experiment looks at data on soil parameters like fines (silt, clay), LL, PL, MDD, OMC and free swell (FS). These parameters are used to make models that estimate UCS and unsoaked CBR values. Using a wide range of fine-grained soils, models are made to predict the values of subgrade soil and the foundation of any building. The UCS and CBR prediction processes are done by simple linear regression analysis (SLRA) and multiple linear regression analysis (MLRA).

Fines (silt, clay), LL, PL, MDD, OMC and FS depend on untreated soils, whereas UCS and unsoaked CBR values are independent variables. For treated soils, MDD, OMC and percentage of nano-clay are all dependent factors, whereas UCS and unsoaked CBR values are independent variables. This model’s coefficients of correlation (R) and determination (R2) are the greatest, and its standard error is the lowest. There is a difference between correlation and linear regression. Using correlation, we may determine how closely connected two variables are linked. There is no association if R is zero (0.0). An excellent relationship exists when R equals 1. R2 in the upper case indicates the quality of fit in linear regression. The R2 value means how effectively the model can predict future events. Correlations with an R2 value greater than or equal to 0.80 are considered the best matches. Models 5, 1, 7, 2, 4 and 3 may be identified by the decreasing order of their R and R2 values. So, both simple and multiple linear models are used to estimate the UCS and un-soaked CBR values in terms of index and compaction properties.

Results and Discussions

Determination of Optimum Dosage of Nano-Clay for the Stabilization of Collected Soil Samples

The optimal amount of nano-clay in soil depends on compaction parameters (MDD and OMC), UCS and CBR values. The above-mentioned geotechnical tests were performed for the prepared untreated and nano-clay-treated soil samples in the laboratory and their results are shown in Table 3. The nano-clay-treated soil mixture which has the highest UCS and CBR value was chosen as the optimum dosage of each soil sample. From the test results it is seen that the optimum dosage of nano-clay for the silty soil samples (S1, S2 and S3), are 0.4%, 0.35% and 0.35%, respectively. For the clayey soil samples (S4, S5 and S6), it is noted as 0.25%, 0.25% and 0.2%, respectively. For the clayey soil sample, the percentage of nano-clay required for the soil stabilization is less when compared to the silty soil samples due to the presence of less void ratio in clay soil samples.

Determination of Maximum Dry Density and Optimum Moisture Content

The standard proctor compaction test was performed for all six soil samples with the addition of nano-clay in various percentages ranging from 0.05 to 0.5%. It is observed from Table 3 that the maximum dry density is increased by increasing the percentage of nano-clay up to the optimum content irrespective of all untreated silt and clayey soil samples. Almost 26.83%, 21.05% and 27.19% of dry unit weight was increased by adding 0.4%, 0.35% and 0.35% of nano-clay to the silty samples (i.e., S1, S2 and S3) from its initial value. Similarly, for clayey samples (i.e., S4, S5 and S6), it is increased to 12.77%, 12.37% and 10.20% after adding 0.25%, 0.25% and 0.2% of nano-clay to the clay soil samples. It is seen that the percentage of increase in MDD is lower for clay samples when compared to the silty samples at their optimum dosages. Clay soil, due to its compact and dense nature, might exhibit a comparatively limited response to the introduction of nano-clay, resulting in a less pronounced increase in maximum dry density when compared to the more porous and loose structure of silty soil samples. It is also seen that there is a sudden drop in the O.M.C from 26%, 22%, 19%, 19%, 18% and 16.2% to 9%, 8%, 7%, 16%, 15% and 15% for the nano-clay-treated soil samples by adding a minimum percentage of 0.35%, 0.25%, 0.25%, 0.15%, 0.15% and 0.05% to the weight ratio of soil, respectively. The optimum moisture content of the silty soil samples S1, S2 and S3 was decreased by 65.38%, 63.64% and 63.16%. Similarly, it is 15.79%, 16.67% and 16.67% decreased for clayey soil samples S4, S5 and S6 at the above-mentioned lower nano-clay contents, respectively. Further addition of nano-clay seems to increase the O.M.C. value moderately. Authors observed a similar trend of M.D.D and O.M.C by adding the nano-clay to the silty as well as clayey soils in the previous studies [2, 12].

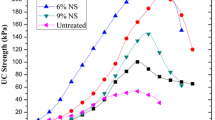

Unconfined Compression Strength Test and CBR Test

The nano-clay-treated soil specimens were prepared for the UCS test and CBR test at their respective MDD and O.M.C and the test results are shown in Table 3. From UCS test results, it is seen that the maximum UCS for S1 was achieved to be 329 kN/m2 (untreated 86 kN/m2) by the addition of 0.4% of nano-clay, similarly S2 achieved 381 kN/m2 (untreated 99 kN/m2) at 0.35% of nano-clay, S3 achieved 451 kN/m2 (untreated 124 kN/m2) at 0.35% of nano-clay, S4 attained 186 kN/m2 (untreated 46 kN/m2) at 0.25% of nano-clay, S5 attained 237.6 kN/m2 (untreated 61 kN/m2) at 0.25% of nano-clay, and for S6 it was 318 kN/m2 (untreated 84 kN/m2) at 0.2% of nano-clay.

From the test results it is seen that the addition of nano-clay to the collected soil samples at their optimum content increased the UCS strength by almost 73.86%, 74.02% and 72.51% for silty soils (i.e., S1, S2 and S3) and 75.27%, 74.33% and 73.58% for clayey samples (S4, S5 and S6) when compared to its initial UCS values of untreated soil samples, respectively (refer Fig. 4a). Nano-clay has nanosized particles with 44% of SiO2, forming strong bonds and making a CSH gel because of the gel’s tight link between soil particles and the decreased number of nano-voids. Nano-clay improves pozzolanic activity as well as soil particle binding strength. It provides the maximum strength to the soils after stabilizing with the nano-clay.

Researchers witnessed that the addition of 3% of nano-clay to the sandy clay of intermediate plasticity increased the unconfined compressive strength by 15% to its initial value [26]. It is attributed to the presence of a large surface area in the nano-clay and it was readily reacted with the soil sample and increased the strength of the soil. Similarly, a few authors in their research found that there is a significant increase in the cohesion of the nano-clay-treated soil samples and a slight decrease in the friction angle of the soil sample [12]. Thus, the previous study results are in line with the present study.

It is seen from Fig. 4c, when treating the collected soil samples with nano-clay at their optimum content, the CBR value for silty soil samples S1, S2 and S3 was increased from 3.4 to 12.2% (i.e., 3.59 times), 3.1 to 13.4% (i.e., 4.32 times) and 5.5 to 15.1% (2.75 times), respectively. Similarly, for clay samples S4, S5 and S6, it was increased to 7.4% from 1.47% (i.e., 5.03 times), 9% from 2.1% (i.e., 4.29 times) and 11.3% from 2.5% (i.e., 4.52 times), respectively. This improvement in CBR value is due to the formation of more resistant bonding between the soil grains and the nano-clay. In previous studies, it is reported that the addition of 2% of nano-clay to the sand tends to increase the CBR value by 33.17% when compared to the CBR value of untreated soil [13]. These results coincide with the present study.

Permeability and Consolidation Test

The falling head permeability test was used to determine the permeability of both untreated and nano-clay-treated soil samples. It was observed that there was no water movement in the stand pipe of the permeability apparatus while conducting the falling head permeability test. It is attributed to the formation of nano-clay gels in the void spaces which arrest the movement of water and thus decrease the permeability of soil. In the previous study, the effect of nano-clay on the hydraulic properties of kaolinite was investigated and it was seen that the coefficient of permeability was decreased from the order 10–5 to 10–10 cm/s which is the almost impermeable state that coincides with the present study results [27].

A consolidation test was performed on soil samples before and after treatment with the nano-clay. Test results show that similar to the other tests the final settlement value of all the six soil samples was decreased when compared to the untreated soil samples at their optimum dosage. From Fig. 4b, the final settlement was controlled for both silty and clay soil samples. For instance, its value was decreased to 1.36 mm, 1.2 mm and 1 mm from its initial value of 3.1 mm, 3.5 mm and 4 mm for S1, S2 and S3. Similarly, for S4, S5 and S6 it was decreased from 4.3 mm, 4.8 mm and 5 mm to 1.76 mm, 1.56 mm and 1.4 mm, respectively, when the soil samples were treated with nano-clay at their optimum dosages. In addition, few researchers in the previous study reported that nano-clay stabilization decreases the soil erosion, collapsibility and dispersion behavior of the soil deposit [12].

Effect of Wet–Dry Cycles on the UCS and Coefficient of Permeability of Untreated and Nano-Clay-Treated Soil

It is important to study the effect of wet–dry cycles on the strength characteristics of the soil. The untreated soil samples and nano-clay-treated soil samples at their optimum content were prepared and exposed to continuous wet–dry cycles to study the effect of nano-clay against wetting and drying conditions. The UCS test and permeability test were performed for the first wet–dry cycle and eighth wet–dry cycles and the results are reported in Table 4. The moisture flow was regulated during wet–dry cycles. The wetting process may lead to the loss of soil structure on the surface and in the interior section of the soil structure. On the other hand, the drying process causes a decrease in moisture content, leading to cracks and rapid failure. To measure the permeability and UCS of the produced samples, they were subjected to W–D cycles and then tested. The test results are shown in Table 4.

It is observed that the untreated soil samples were more permeable after W-D cycles, and the cracks in the soil expanded as water levels fluctuated. Drying the soil samples with continuous cracks also became more challenging since the water flow channel became longer. Soil samples were subjected to W–D cycles with an unconfined load in a UCS test. When wet–dry cycles were increased, UCS values decreased to zero, as seen in Table 4. Soil samples were soaked in water to make them wet, which increased their volume. Also, deep cracks were observed during the drying cycle of the test. Exposure of foundation soil to wet–dry cycles could cause severe damage to buildings, and the excessive settlement of buildings beyond the permissible limits. Hence the effect of nano-clay was investigated in wet–dry conditions of the collected soil samples and shown in Table 4.

After the nano-clay treatment, the soil voids were clogged and seemed to have less or no voids when compared to untreated soil samples. During wetting phenomena, the water absorption was minimized and the formation of cracks was reduced when drying the nano-clay-treated soil sample. The final settlement was more tightly controlled under wet–dry cycles with more nano-clay. It is seen that the wet–dry cycles affect the permeability and the UCS values of the nano-clay-treated soil samples but still, the values are higher than the untreated soil. It is due to the formation of silica gel (CSH) which protects the soil from wet–dry cycles. The nano-clay was unaffected by the several wet–dry cycles. As a result, nano-clay has the potential to reduce surface erosion and moisture loss.

Prediction Models

Prediction Models for Untreated Soils

The R value of 1 and the R2 value of 1 mean that the MLRRA may be better than the SLRA for getting the most important results. To put it another way, UCS and unsoaked CBR values may be estimated using the model. The traditional F-test method determines if the suggested model for estimating UCS and CBR values that have yet to be treated is good enough. In addition, an analysis of variance (ANOVA) was used to examine the significance of regressions. Equations 1 and 2 are untreated soils whose geotechnical properties can be used to figure out their UCS and CBR values.

where MDD—maximum dry density (kN/m3), OMC—optimum moisture content (%), Ip-plasticity index (%), PL—plastic limit (%), LL—liquid limit (%), Or—organic content (%), C—clay (%) and S—silt (%).

For CBR and UCS prediction, this test uses an F-distribution with a d.o.f. of 8. It was decided to use a 95% confidence level in this test. If the computed F value is greater than the tabulated F value, which means that the null hypothesis is wrong, there is a real relationship between the dependent and independent variables. Table 5 shows the comparison between the expected and actual values of UCS and CBR values of untreated soils. As a result, the model may be considered legitimate.

Model Validity Tested for Untreated Soils

A few researchers reported that the suggested model for predicting UCS and CBR values was correct and is almost similar to the experimental values [28, 29]. Table 6 compares the expected and actual values of UCS and CBR values of untreated soils. A regression model was built using the equation to estimate the UCS and CBR values. Observed soaked CBR values and anticipated soaked CBR values have a high degree of similarity. Therefore, subgrade soil’s soaking CBR may be determined quickly and cost-effectively using the suggested approach if it is used with sound judgment and technical expertise.

The proposed model is based on multiple nonlinear polynomial regression analyses. Fines (silt, clay), LL, PL, MDD, OMC and FS are dependent factors, whereas UCS and unsoaked CBR values are independent variables. Figure 5 represents the model validity for UCS and CBR of untreated soils. It is observed from Fig. 5 that the coefficient of determination (i.e., R2 value) is obtained to be 0.9973 and 0.9844 for UCS and CBR of untreated soils. The predicted UCS and CBR values are almost equal to the experimental results.

Prediction Models for Treated Soils with Nano-Clay

R value of 0.8 and R2 value of 0.64 for UCS and R value of 0.86 and R2 value of 0.74 for CBR value of nano-clay-treated soil samples imply that the greatest results may be attained by using the multiple linear regression analysis (MLRA) rather than the simple linear regression analysis (SLRA). Analysis of variance (ANOVA) was used to examine the significance of regressions. Equations 3 and 4 are treated soils predicted UCS and CBR values with nano-clay based on the geotechnical properties.

where P is the percentage of nano-clay (%).

For CBR and UCS prediction, this test uses an F-distribution with d.o.f. is 3. It was decided to use a 95% confidence level in this test. There is a true relationship between dependent and independent variables if the computed F value exceeds the tabulated F value and hence rejects the null hypothesis. As a result, the model may be considered legitimate.

Model Validity Tested for Treated Soils with Nano-Clay

A few researchers’ data on soil parameters confirmed the validity of the suggested model for predicting UCS and CBR [28, 29]. Table 6 compares the actual UCS and CBR values of treated soils with nano-clay. The proposed model is based on multiple nonlinear polynomial regression analyses. MDD, OMC and percentage of nano-clay are dependent factors, whereas UCS and unsoaked CBR values are independent variables. There is an R value of 0.8 and an R2 value of 0.64 for UCS, an R value of 0.86 and an R2 value of 0.74 for the CBR coefficient of determination. The proposed model is based on multiple nonlinear polynomial regression analyses. UCS and unsoaked CBR values are regarded as dependent factors, whereas MDD, OMC, and P are independent variables. The predicted UCS and CBR values are almost equal to the experimental results. Figure 6 represents the model validity for UCS and CBR of treated soils with nano-clay.

From Fig. 6, it is observed that the coefficient of determination (i.e., R2 value) is obtained to be 0.8473 and 0.9283 for UCS and CBR of nano-clay-treated soils. The predicted UCS and CBR values are almost equal to the experimental results.

Conclusions

The study investigated the effect of nano-clay on various silt and clay samples and came to the following conclusion based on geotechnical factors and nano-clay stabilization.

-

Based on the compaction, UCS, and CBR tests, the optimal content of nano-clay for the collected soil samples S1, S2, S3, S4, S5 and S6 were found as 0.4%, 0.35%, 0.35%, 0.25%, 0.25%, and 0.2%, respectively.

-

The addition of nano-clay to the collected soil samples at their optimum content increased the UCS strength by almost 73.86%, 74.02% and 72.51% for silty soils (i.e., S1, S2 and S3) and 75.27%, 74.33% and 73.58% for clayey soils (i.e., S4, S5 and S6) when compared to its initial UCS values, respectively.

-

When treating the collected soil samples with nano-clay at their optimum content, the CBR value for silty soil samples (i.e., S1, S2 and S3 was increased 3.59 times, 4.32 times and 2.75 times, when compared to the untreated soil samples, respectively. Similarly, for clay samples (i.e., S4, S5 and S6), it was 5.03 times, 4.29 times and 4.52 times increased when compared to the untreated soil samples, respectively.

-

The coefficient of permeability value of all the collected soil samples was reduced and became impermeable when it is treated with nano-clay at their optimum dosages irrespective of the soil type. Similarly, the settlement of the soil samples also decreased moderately.

-

The UCS and Coefficient of permeability of all soil samples were diminished when exposed to wet–dry conditions and the cycle is increased from 1 to 8, but it is still high when compared to the untreated soil values.

-

It is also observed that the absorption of water and the formation of cracks were reduced during the wetting and drying cycles of nano-clay-treated soil samples. In addition, the final consolidation settlement was more firmly controlled in wet–dry cycles with more nano-clay. Based on these findings, we may say that the silica gel (CSH) produced with soil is resistant to wet–dry cycles. Further, the increased silica concentration in treated soils improved all geotechnical properties.

-

The predicted UCS and CBR values are almost equal to the experimental results even if untreated or treated with nano-clay in regression analysis.

-

The above results justify that the addition of nano-clay at a very small percentage improves the geotechnical properties of the soil without harming the environment and can be used as a sustainable soil stabilizer. Further tests are required to know the practical difficulties in stabilizing the soil in the field when treating the soil in mass quantity using the nano-clay.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ghasabkolaei N, Choobbasti AJ, Roshan N, Ghasemi SE (2017) Geotechnical properties of the soils modified with nanomaterials: a comprehensive review. Arch Civ Mech Eng 17:639–650

Bahari M, Nikookar M, Arabani M, Haghi AK, Khodabandeh H (2013) Stabilization of silt by nano-clay. In 7th National Congress on Civil Engineering (pp 7–8)

Zoriyeh H, Erdem S, Gürbüz E, Bozbey İ (2020) Nano-clay modified high plasticity soil as a building material: micro-structure linked engineering properties and 3D digital crack analysis. J Build Eng 27:101005. https://doi.org/10.1016/j.jobe.2019.101005

Karumanchi M, Avula G, Pangi R, Sirigiri S (2020) Improvement of consistency limits, specific gravities, and permeability characteristics of soft soil with nanomaterial: nano-clay. Mater Today 33:232–238. https://doi.org/10.1016/j.matpr.2020.03.832

Arora A, Singh B, Kaur P (2019) Performance of nano-particles in stabilization of soil: a comprehensive review. Mater Today 17:124–130. https://doi.org/10.1016/j.matpr.2019.06.409

Tran KQ, Satomi T, Takahashi H (2019) Tensile behaviors of natural fiber and cement reinforced soil subjected to direct tensile test. J Build Eng 24:100748. https://doi.org/10.1016/j.jobe.2019.100748

Karumanchi M, Nerella R (2022) Influence of extracted nanosilica on geotechnical properties of soft-clay soil subjected to freeze-thaw cycles. J Build Pathol Rehabil 7(1):1–11. https://doi.org/10.1007/s41024-022-00179-w

Kulanthaivel P, Selvakumar S, Soundara B, Kayalvizhi VS, Bhuvaneshwari S (2022) Combined effect of nano-silica and randomly distributed fibers on the strength behaviour of clay soil. Nanotechnol Environ Eng 7(1):1–12. https://doi.org/10.1007/s41204-021-00176-3

Selvakumar S, Kulanthaivel P, Soundara B (2021) Influence of nano-silica and sodium silicate on the strength characteristics of clay soil. Nanotechnol Environ Eng 6(3):1–10. https://doi.org/10.1007/s41204-021-00142-z

Chanu NB, Alice AK, Thokchom A, Singh MC, Chanu NT, Singh YD (2021) Engineered nanomaterial and their interactions with plant–soil system: a developmental journey and opposing facts. Nanotechnol Environ Eng 6(2):1–15. https://doi.org/10.1007/s41204-021-00114-3

Onyelowe KC, Ebid AM, Nwobia L, Dao-Phuc L (2021) Prediction and performance analysis of compression index of multiple-binder-treated soil by genetic programming approach. Nanotechnol Environ Eng 6(2):1–17. https://doi.org/10.1007/s41204-021-00123-2

Tabarsa A, Latifi N, Meehan CL, Manahiloh KN (2018) Laboratory investigation and field evaluation of loess improvement using nano-clay—a sustainable material for construction. Constr Build Mater 158:454–463. https://doi.org/10.1016/j.conbuildmat.2017.09.096

Sani AM, Arabani M, Haghi AK, Chenari RJ (2010) Effect of nanoclay additive on the geotechnical properties of silty sands. In: Proceeding of 4th International Conference on Geotechnical Engineering and Soil Mechanics, Tehran, pp 2–3

Kananizadeh N, Ebadi T, Khoshniat SA, Mousavirizi SE (2011) The positive effects of nano-clay on the hydraulic conductivity of compacted Kahrizak clay permeated with landfill leachate. Clean-Soil Air Water 39(7):605–611. https://doi.org/10.1002/clen.201000298

Mohammadi M, Niazian M (2013) Investigation of nano-clay effect on geotechnical properties of Rasht clay. Int J Adv Sci Tech Res 3(3):37–46

Nohani E, Alimakan E (2015) The effect of nanoparticles on geotechnical properties of clay. Int J Life Sci 9(4):25–27

Khazaleh MA, Karumanchi M, Bellum RR (2022) Stabilization of soils with nano-clay subjected to freeze-thaw cycles. Nanotechnol Environ Eng. https://doi.org/10.1007/s41204-022-00290-w

IS: 2720, Part – 1 (1983) Methods of tests for soils: preparation of dry soil samples for various tests. Bureau of Indian Standards (BIS)

IS 1498 (1970) Classification and identification of soils for general engineering purposes. Bureau of Indian Standards (BIS)

IS: 2720, Part – 5 (1985) Methods of tests for soils: determination of liquid and plastic limit. Bureau of Indian Standards (BIS)

IS: 2720, Part – 7 (1980) Methods of tests for soils: determination of water content-dry density relation using light compaction. Bureau of Indian Standards (BIS)

IS: 2720 (Part II) (1973) Methods of tests for soils: determination of water content. Bureau of Indian Standards (BIS)

IS: 2720 (Part XVI) (1987) Methods of tests for soils: laboratory determination of CBR. Bureau of Indian Standards (BIS)

IS 2720 (Part XVII) (1986) Methods of tests for soils: laboratory determination of permeability. Bureau of Indian Standards (BIS)

IS: 4332 (Part IV) (1968) Methods of test for stabilized soils. Wetting and drying, and freezing and thawing tests for compacted soil-cement mixtures. Bureau of Indian Standards (BIS)

Khalid N, Mukri M, Kamarudin F, Abdul Ghani AH, Arshad MF, Sidek N, Ahmad Jalani AZ, Bilong B (2015) Effect of nanoclay in soft soil stabilization. In: Hassan R, Yusoff M, Alisibramulisi A, Mohd Amin N, Ismail Z (eds) InCIEC 2014. Springer, Singapore. https://doi.org/10.1007/978-981-287-290-6_79

Fakhri Z, Pourhoseini R, Ebadi T (2015) Improvement in the hydraulic properties of kaolinite with adding nano-clay. AmirKabir J Sci Res Civ Environ Eng (ASJR-CEE) 47:17–20

Ramasubbarao G, Sankar SG (2013) Predicting soaked CBR value of fine-grained soils using index and compaction characteristics. Jordan J Civ Eng 7(3):354–360

Sai Chandu A, Rao GVRS (2021) Strength and durability characteristics of red soil stabilized with foundry sand and cement. Arab J Sci Eng 46(5):5171–5178. https://doi.org/10.1007/s13369-021-05423-y

Acknowledgements

The authors acknowledge the infrastructure, laboratory facilities and consistent support for this study by the Aditya Engineering College and ABR College of Engineering and Technology.

Funding

This research work was not supported by any funding agency.

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception. Material preparation and testing were performed by MK. Data collection, analysis and interpretation were performed by RRB. The manuscript was written and reviewed by AKS and MAK. All the authors read and approved the fnal manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors have made a declaration that they have no competing interests in having this research published.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al Khazaleh, M., Karumanchi, M., Bellum, R.R. et al. Experimental Assessment of Geotechnical Properties of Nano-Clay-Stabilized Soils: Advanced Sustainable Geotechnical Solution. Int. J. of Geosynth. and Ground Eng. 10, 8 (2024). https://doi.org/10.1007/s40891-023-00517-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-023-00517-z