Abstract

Biodegradation of plastics, which are the potential source of environmental pollution, has received a great deal of attention in the recent years. We aim to screen, identify, and characterize a bacterial strain capable of degrading high-density polyethylene (HDPE). In the present study, we studied HDPE biodegradation using a laboratory isolate, which was identified as Klebsiella pneumoniae CH001 (Accession No MF399051). The HDPE film was characterized by Universal Tensile Machine (UTM), Fourier Transform Infrared Spectroscopy (FTIR), Scanning Electron Microscope (SEM), and Atomic Force Microscope (AFM) before and after microbial incubation. We observed that this strain was capable of adhering strongly on HDPE surface and form a thick biofilm, when incubated in nutrient broth at 30 °C on 120 rpm for 60 days. UTM analysis showed a significant decrease in weight (18.4%) and reduction in tensile strength (60%) of HDPE film. Furthermore, SEM analysis showed the cracks on the HDPE surface, whereas AFM results showed an increase in surface roughness after bacterial incubation. Overall, these results indicate that K. pneumoniae CH001 can be used as potential candidate for HDPE degradation in eco-friendly and sustainable manner in the environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plastics, a synthetic polymer, are consumed in trillions of amount (about 140 million tons) annually as packaging materials (Caruso 2015; Roy et al. 2008) which are increasing continuously day by day Sekhar et al. 2016). Among plastics, high-density polyethylene (HDPE) is widely used in packaging industry due to its effectiveness and versatility (such as light weight, inexpensiveness, durability, easy processing, etc.) (Rivard et al. 1995; Begum et al. 2015; Witt et al. 2001; Muller et al. 2001). It shows less branching and more linearity than low-density polyethylene (exhibiting random branching resulting in low packing of chains), which provides it a high packing density (Arutchelvi et al. 2008). Polyethylene is xenobiotic in origin and resistant to degradation in nature. Moreover, its hydrophobic character leads to a very slow degradation (Orhan and Büyükgüngör 2000; Hadad et al. 2005). Studies indicate towards no clue of deterioration in polyethylene sheet incubated in moist soil for 12 years (Otake et al. 1995). Polyethylene wastes are normally discarded as landfill or thrown in water bodies to decompose/degrade (Priyanka and Archana 2011). Its accumulation rate is 25 million tons per annum, so its degradation is great challenge to the scientists (Sangale et al. 2012; Orhan and Büyükgüngör 2000).

Recycling of polyethylene is one of the environmentally attractive solutions. Currently, a very small part of the plastics are recycled and the remaining goes to the burial sites (Bhardwaj et al. 2012). Landfills are less in number and are rarely satisfactory, whereas incineration creates highly toxic fumes, causing air pollution (Bhatia et al. 2013). The potential hazardous emissions from incinerating polyethylene include hydrogen chloride, dioxin, cadmium, and fine particulate matter. Moreover, chlorinated plastics can release harmful chemicals into the surrounding soil, which harms organisms by reaching ground water or other surrounding water. However, biodegradation could be the best alternative to combat this environmental pollution by polyethylene (Satlewal et al. 2008; Gu 2003). Biodegradation is bio-chemical in nature in which enzymes released from microorganisms act as a catalyst. So far, the richness of microorganisms able to degrade polyethylene is limited to 17 genera of bacteria and 9 genera of fungi (Restrepo-Flórez et al. 2014). Aerobic metabolism results in carbon dioxide and water (Starnecker and Menner 1996), whereas anaerobic metabolism results in carbon dioxide, water, and methane as the end products, respectively (Gu et al. 2000). The metabolites released after biodegradation are non-toxic to the environment and redistributed through the carbon, nitrogen, and sulfur cycles. Thus, biodegradation does not create environmental pollution.

The microbial degradation of plastics leads to a cleavage of the polymer chain into oligomers and monomers, which is promoted by certain enzymatic activities. Microbial cells absorb these water soluble degradation products for use in their metabolism. Biodegradability is defined as the propensity of a material to breakdown into its constituent molecules by natural biological processes (often microbial digestion). The vulnerability of the polymers to microbial attack generally depends on enzyme availability, availability of a site in the polymers for enzyme attack, enzyme specificity for that polymer, and the presence of coenzyme if required (Reich and Stivala 1971). According to some reports, partial degradation of polyethylene could be achieved after UV irradiation (Cornell et al. 1984) thermal treatment (Awasthi et al. 2017; Albertsson et al.1998) and oxidation with nitric acid (Brown et al. 1974). Thermal or radiation treatments on polyethylene reduce the polymeric chain size and form oxidized groups such as carboxyl, carbonyl, and hydroxyl which are more easily degraded by microorganisms (Albertsson et al. 1995). Oxidized groups modulate the microbial attachment by increasing the surface hydrophilicity (Tribedi and Sil 2013). Therefore, polyethylene degradation will be boosted if a more oxidized surface is used as a substrate (Awasthi et al. 2017). These treatments modify the properties such as crystallinity level and morphological changes of the original polymer, and facilitate the polymer biodegradation (Lee et al. 1997).

Klebsiella pneumonia, a Gm-negative bacterium, has shown importance in waste water treatment (Maal et al. 2014), citrate decomposition (Brynhildsen and Rosswall 1989), nitrogen fixation (Iniguez et al. 2004), and hydrogen production from biodiesel waste containing glycerol (Liu and Fang 2006). Moreover, it qualifies as a suitable microorganism for LDPE degradation (Anbuselvi and Pandey 2015). It has been stated that Klebsiella pneumoniae secretes lipase (Peil et al. 2016), tyrosinase, laccase, and peroxidase enzymes (Dhanve et al. 2008), which are capable of degrading polyethylene via groove formation. In addition, the extracellular polymers released by this microorganism act as surfactants which facilitate the exchanges between hydrophilic and hydrophobic phases. Such exchanges favor the penetration of microbial species into the polyethylene. However, studies on biodegradation of polyethylene, particularly HDPE, by Klebsiella bacterium are scarce. In the present paper, biodegradation study of thermally treated HDPE is described, using an indigenous bacterial stain K. pneumoniae CH001.

Materials and methods

Pretreatment of high-density polyethylene

High-density Polyethylene (HDPE) carry bags, (40 μm in thickness) which are used in cloth packaging, were procured from local market for use in the present study. HDPE strips of 10 × 4.5 cm size were treated thermally in a preheated hot air oven at 70 °C for 10 days to enhance the biodegradation. Thermally pretreated HDPE biodegrades easily as oxidized polyethylene chain leads to the carbonyl group formation. These strips were washed and disinfected with a solution containing (7 ml Tween-80, 10 ml bleach, and 983 ml sterile water). These films were transferred aseptically into 70% (v/v) ethanol solution for 30 min incubation, and dried overnight at 45–50 °C, and weighed before biodegradation.

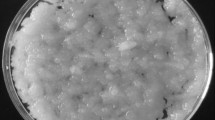

Screening of bacteria for the biodegradation of HDPE

Isolation and screening of bacteria were done from a plastic waste dumpsite, Diesel Locomotive Works (DLW), Varanasi, India. Bacterial culture was isolated by serial dilution method and all the assays for studying colonization and degradation of HDPE were carried out in Nutrient Broth. The isolates were further screened for their ability to utilize HDPE as a primary C source against polyethylene films of different weight. Furthermore, nutrient agar plates treated separately with increasing concentration of polyethylene were inoculated with loopful culture of overnight grown bacterial strain and were incubated at 30 °C for a week. Bacterial isolate showing the clear zone around their colonies was further screened for their degradation ability in broth (Nutrient broth, NB). Liquid cultures (100 ml) were incubated in flasks (250 ml) on a rotary shaker (120 rpm) at 30 °C for 60 days. Thermally oxidized, sterile polyethylene films incubated in culture medium containing 0.05% sodium azide (to check microbial contamination) were used as control in the present study. The experiment was carried out in triplicates, and mean and standard deviation are reported here.

Biodegradation assay

The biodegradation assay was performed in 250-ml flasks by adding 1000 µl of active bacterium into 100 ml of NB containing HDPE film (NB was prepared by dissolving 1.3-g nutrient broth in 100-ml double distilled water). The assay was performed using (1) NB + bacterium + HDPE as treatment taking NB + HDPE as controls. The flasks were incubated at 30 + 2 °C with continuous shaking (120 rpm) for 2 months. Degraded samples were recovered from the nutrient broth for characterization only after the bacterium had attained its stationary growth phase.

Evaluation of biodegradation

The extent of Biodegradation of HDPE film was done using weight loss, change in pH, mechanical strength, and spectroscopic and microscopic analyses.

Weight loss measurement

The reduction of polymer integrity due to the microbial attack results into weight loss. As biodegradation is a surface phenomenon, so the weight loss is proportional to surface area. To estimate the actual weight loss, the bacteria-laden HDPE was washed with 2% (v/v) aqueous sodium dodecyl sulfate (SDS) solution for 4 h and further washed with distilled water to remove the bacterial biofilm from the HDPE surface (Gilan et al. 2004). Multiple samples were weighed with an accurate five-digit balance (Elico) and average values are reported here. The washed HDPE was placed on a filter paper and dried overnight at 60 °C before weighing.

The weight loss (cf. Fig. 1) was calculated by the formula written below:

Change in residual weight of HDPE with incubation time. The graph shows that there is regular decrease in weight during incubation of HDPE film with K. Pneumoniae. Values represent the average of three independent experiments. Error bars indicate standard deviation (± SD). Statistical significance between the groups was evaluated at p = 0.05 significance level

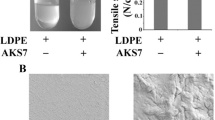

Reduction in mechanical strength

The material testing machine (Model INSTRON 4206) with a crosshead speed of 10 mm/min was used to estimate the mechanical strength of the treated and control HDPE strips at room temperature. Tensile strength of the incubated HDPE films was measured in 10-day interval. A regular pattern of reduction in comparison to control polyethylene films was investigated in 60 days (cf. Fig. 2). The result was reported as average value of three observations. The testing conditions for both treatment and control were maintained at room temperature (35–37 °C) with a relative humidity of 50%.

Change in tensile strength of HDPE with incubation time. Tensile strength of control film remains unchanged in the 60 days, while there is a regular pattern of decrease in tensile strength of incubated films. Values represent the average of three independent experiments. Error bars indicate standard deviation (± SD). Statistical significance between the groups was evaluated at p = 0.05 significance level

Change in pH

Change in pH of NB was measured by Elico LI614 pH Analyzer at every 15th day for biodegradation study of HDPE. It was observed to change from 7 to 5.7 in 60-day duration (Fig. 3) which confirms biological degradation.

Change in pH of media with incubation time. There was decrease during incubation: at day 0, pH was 7.0, and after 60 days, it was reported 5.7. Values represent the average of three independent experiments. Error bars indicate standard deviation (± SD). Statistical significance between the groups was evaluated at p = 0.05 significance level

Microscopic analysis of HDPE degradation

Microscopic analysis was performed to examine the degradation of HDPE film by the bacterium K. pneumoniae. HDPE films were recovered from the conditioned media and washed with 2% SDS to remove the adhered organisms, if any. Thereafter, the films were air-dried overnight, and the surface morphology of the microbe-treated or untreated films was examined by scanning electron microscopy (SEM) (ZEISS, EVO18) (Fig. 4a, b) and atomic force microscopy (AFM) (Fig. 5a, b) Oxford INSTRUMENT X-act NT-MDT). The polythene films were cut into small strips, coated with gold, and examined under SEM. In AFM analysis, all images were obtained with a scan speed of 1.0 Hz and a resolution of 512 × 512 pixels.

Fourier transform infrared (FTIR) analysis

The Shimadzu 8400S was used to determine the formation of new or disappearance of any functional groups from the sample. FTIR is a decisive and precise method to detect structural changes occurring in polymers due to thermal and biological treatments. Three types of polyethylene samples were analyzed: (i) untreated, (ii) thermally treated, and (iii) thermally treated and then incubated with bacterial strain. It was done using the frequency range of (4000–400 cm−1). HDPE films were affixed directly to the standard infrared sample plates. Spectra of untreated sample were recorded as control and spectra of treated sample were taken after 60 days (Fig. 6).

FTIR of HDPE a control, b thermally treated HDPE, and c thermally treated HDPE after bacterial degradation. Note It is clear in Fig. 6a that there are various groups in the control film in Fig. 6b; carbonyl group appears at 1765 cm−1 which indicates oxidation of film after abiotic treatment, and in Fig. 6c, formation of carboxylic group (3423 cm−1) denotes further oxidation of abiotically treated film after incubation with K. Pneumoniae

GC–MS

Incubated NB medium of control and treated HDPE film was subjected to GC–MS analysis to analyze the degradation intermediates (Fig. 7) and understand the mechanism of HDPE biodegradation using gas chromatography–mass spectrometer (JEOL GCMATE II GC–MASS SPECTROMETER, JNU, New Delhi). For this, the bacterial pellets were removed by filtration after 2 months of incubation period, and the filtrates were extracted with diethyl ether.

Note It is clear in Fig. 7a that GC–MS of control HDPE film is different from the treated HDPE film which has various monomers, acidic compounds, and oxidized compounds which are present at less retention time after biodegradation

Statistical analysis

Data were subjected to one-way ANOVA to observe the variation in weight loss, tensile strength, and media pH with incubation time. Post-hoc (Tukey) test (P < 0.05) was performed to observe the significance of difference between control and treated HDPE films in varying days of incubation. Statistical analysis was carried out using the software SPSS-16.

Results and discussion

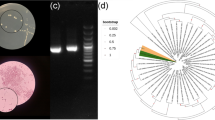

Characterization of potential strains and phylogenetic analysis

The selection criteria of the bacterial culture were based on effectiveness of polyethylene degradation in nutrient broth media. The isolated bacterial strains were morphologically and biochemically characterized and identified on the basis of 16S rRNA gene sequence analysis. A phylogenetic tree was constructed by software version 8 of Molecular Evolutionary Genetics Analysis (MEGA). The phylogenetic analysis was grounded on BLAST search applying 16S rDNA gene sequence, which demonstrated its maximum homology (100%) with bacterium K. pneumoniae strain AANP1 with gene bank Accession Number: KY494861.1. Based on the cladistic analysis as well as homology valuation, it was concluded that the selected bacterial isolate could be regarded as K. pneumoniae CH001. The sequence of K. pneumoniae strain CH001 has been deposited in NCBI with accession no. MF399051 (http://blast.ncbi.ntm.nih.gov).

Weight loss

ANOVA result indicates that weight loss with incubation time was significant (F = 2152, P < 0.001). Klebsiella pneumoniae CH001 was found to significantly degrade (18.4%) of the thermally pretreated HDPE after 60 days of incubation (Fig. 1). Similar results were also reported by Sudhakar et al. (2008) where thermal pretreatment was found to increase HDPE degradation when incubated with B. sphericus (i.e., 9% against the 3.5% in case of untreated HDPE). Thus, increased weight loss was observed after thermal treatment as compared to untreated HDPE. Similarly, Balasubramanian et al. (2010) also observed a respective loss of 12 and 15% in HDPE weight after 30 days of incubation with Arthrobacter sp. and Pseudomonas sp. Moreover, the HDPE films were found to develop a biofilm on the surface within 15 days of incubation with K. pneumoniae CH001. It might be attributed to the fact that thermal pretreatment oxidizes polyethylene chain which leads to the carbonyl group formation supporting biofilm development on HDPE. The biofilm reduces the hydrophobicity of the polymer, which resulted in the enhancement of the degradation rate in the present study. However, strong adhesion and relatively high survival rate of K. pneumoniae biofilm to the polyethylene surface (unpublished data) might be attributed to the production of protein which enables the formation of a stable biofilm. Such attributes, in spite of the low carbon availability, confirm its efficiency in utilizing polyethylene as a carbon and energy source.

Change in tensile strength

ANOVA result indicates that tensile strength was found to significantly reduce with incubation time (F = 204, P < 0.001). In the present study, a significant reduction in tensile strength (approximately 50%) was observed after 60-day incubation (Fig. 2). Similar results were also reported by Hanaa et al. (1998) and Lee et al. (1991). Nowak et al. (2011) reported that biodegradation reduces the percentage elongation of polyethylene films. Similarly, Jakubowicz et al. (2006) showed a reduced elongation of thermally treated LDPE film after incubation with compost microorganisms.

Change in pH of nutrient media

ANOVA result indicates that pH of the media showed a significant decrease with incubation time (F = 89.5, P < 0.001). We observed a significant reduction in pH of media containing thermally treated HDPE incubated with Klebsiella as compared to control (media not containing Klebsiella) in the present study (Fig. 3). The reduction in pH from 7 to 5.7 proves that the culture is metabolically active in media containing thermally treated HDPE incubated with Klebsiella and is utilizing HDPE as source of carbon for its growth. However, it also indicates towards the production of several monomers post-degradation (Awasthi et al. 2017; Arutchelvi et al. 2008). It has been further confirmed by FTIR and GC–MS analysis (Figs. 6 and 7).

Surface morphology

SEM and AFM

As evident in the SEM micrographs (Fig), we observed some localized degradation of the polyethylene around the bacterial cells in the biofilm in the present study. The bacterial biofilm showed a cell-like molded pattern in the polyethylene. Such shapes have previously been noticed for biodegradable polymers, e.g., poly-β-hydroxybutyrate (Otake et al. 1995). Skariyachan et al. (2015, 2017) observed similar alteration in surface topology for HDPE films that were treated with bacterium via SEM image. The treated HDPE film showed rough surface with a number of cracks and grooves after 60 days of incubation (cf. Fig. 4d). On the contrary, the untreated film retained a smooth surface under the same condition. Similar alterations in the surface topology have also been observed from AFM image analysis (cf. Fig. 5b). It indicates that bacterium K. pneumoniae CH001 secretes enzymes capable of degrading polyethylene, resulting in grooves formation.

FTIR

The changes in bond scission, chemical transformation, and formation and disappearance of new functional groups to determine any changes in the chemical structure of the polyethylene were determined with the help of FTIR (Usha et al. 2011; Suresh et al. 2011). Control spectra of HDPE film, non-treated with bacterium, displayed a number of peaks reflecting the complex nature of the HDPE (Fig. 6a). In the present study, an increase in wavenumber at 1765 was observed for all samples during the thermal pretreatment at 70 °C for 10 days (Fig. 6b). It is consistent with some previous studies (Albertsson et al. 1998; Karlsson and Albertsson 1998; Khabbaz et al. 1998, 1999). These studies reported that ester- and keto-carbonyls are the major products formed during abiotic oxidation of polymer under thermal oxidation or after oxidoreductase activity. Polyethylene samples oxidized when kept in oven for 10 days as indicated by the absorption band around 1765 cm−1.(Figure 6b) It indicates toward Norrish-type II reaction, which lead to the formation of double bonds in the polymer chain. It is assigned to the C=O stretching vibration of a ketone group, which grows in intensity with prolonged aging. However, the FTIR of the thermal-treated HDPE incubated with K. pneumoniae showed considerable changes in the absorption intensities, as compared to the control. The disappearance/or utilization of carbonyl groups (i.e. 1765 cm−1) might be due to the enzymatic attack of K. pneumoniae through Norrish-type mechanism. It is consistent with Dolezel (1967) who observed a decrease in the amount of carbonyl groups with prolonged exposure to a microbial environment. Awasthi et al. (2017); Albertsson et al. (1998); Weiland et al. (1995) also observed a reduction in the carbonyl group after 150 days of incubation with a mixed fungal culture.

The intensity of 1765 cm−1, which determines the extent of degradation, decreased with increase in incubation time in the present study. The decrease in weight complemented the decrease in carbonyl index. Gajendiran et al. 2016; Das and Kumar 2015; Balasubramanian et al. 2010 reported that carbonyl groups once formed (after heat treatment) can further be attacked by microorganisms. It is consistent with observed higher carbonyl and double-bond groups in thermal-pretreated than untreated HDPE samples after exposure to K. pneumoniae. Oxidized polyethylene molecules are hydrolyzed by the extracellular enzymes into fatty acids which are further metabolized by ß-oxidation (Albertsson et al. 1998). It is also consistent with the new absorption bands at 3423 cm−1 (Fig. 6c) observed in the present study due to the formation of carboxylated compound. Bhatia et al. have carried out a similar work with a bacterial consortium, and observed a relative shift in the peaks. These peaks were observed due to the vibrations in the stretching of the O–H bond in alcohols and phenols. An absorbance range of 3500–3200 cm−1 corresponds to the presence of alcohols and phenols (Bhatia et al. 2014).

GC–MS

Incubated NB medium of control and treated HDPE film was subjected to GC–MS analysis to identify the degradation intermediates of HDPE biodegradation. The organic compounds were found as carboxylic acids and alkanes. It is consistent with (Pramila and Ramesh 2015; Mahalakshmi et al. 2012). The carboxylic acids were n-deconic acid, docosanoic acid, undeconic acids, n-deconoic acid, hexadeconoic acid, propanoic acids, oleic acids, oxalic acids, cyclopropanetetradeconic acid, benzene dicarboxylic acid, phthylic acid, octadecatrienoic acid, acetic acid, hexanoic acid, octadeconoic acid, butanoic acid, oxamimidic acid, undecanonic acid, docosanoic acid, tetradecanoic acid, and I propyldodecanoic acid (cf. Fig. 7). Thus, it confirms the production of carboxylic acids as observed in FTIR analysis (cf. Fig. 6a–c). We observed a further degradation of carboxylic acids by K. pneumoniae sp. which produced alkane compounds such as ethane, pentane, decane, tetradecane, pentadecane, hexadecane, heptadecane, octadecane, undecane, dodecane, and non-adecane. It indicates towards the cleavage of polymer chain yielding carbonyl radical, which can react with an alkoxy radical on the polyethylene chain (Norrish I-type reaction). It is consistent with the findings of Albertsson et al. (1998) who observed that the long chain of HDPE was cut into small pieces as alkanes and carboxylic acids.

As already noted, a significant amount of low-molecular-weight compounds was released to aqueous media from oxidized polyethylene film. We observed 2-Butene, 2-methyl at 7.2 retention time, Ethene-1,2-dichloro-(2)-1,1 di at 7.6 retention time, acetic acid ethyl ester at 12.71, and Methane, trichloro- at 13.22 retention time. In a similar study, Kounty et al. (2006) observed a similar release of low molecular compounds to water media by Rhodococcus rhodochrous. Konduri et al. (2010) stated that alkanes and carboxylic acids (i.e., ethane, pentane, decane, acetic acid, n-deconic acid, propanoic acids, oleic acids, and oxalic acids) were degraded by A. terreus MF12 by β-oxidation after consumption.

Conclusion

Biodegradation of HDPE has received great deal of attention in recent years, which has limited research so far. Despite use in LDPE degradation, exploration of Klebsiella in HDPE degradation has been little explored. We observed a tremendous efficiency of a novel K. pneumoniae CH001, isolated from a landfill site, as compared to the other microbial species reported for HDPE degradation in the literature. The relatively significant degradation ability of our isolated strain in the present study indicates that microbes might be adapting towards the HDPE use as C and energy source by natural evolution. It suggests that microbes seem to be able to remodel their enzyme-based metabolic pathway for the biodegradation of synthetic HDPE polymers for carbon quenching in the absence of other carbon sources. The biofilm formation on the HDPE surface in the present study was viable and a high number in population strengthens this fact. The limited studies on HDPE biodegradation indicate that this strain could be of potential use in management of plastic waste.

References

Albertsson AC, Barenstedt Karlsson CS, Lindberg T (1995) Degradation product pattern and morphology changes as means to differentiate abiotically and biotically aged degradable polyethylene. Polymer 36(16):3075–3083

Albertsson AC, Erlandsson B, Hakkareinen M, Karlsson S (1998) Molecular weight changes and polymeric matrix changes correlated with the formation of degradation products in biodegraded polyethylene. J Environ Polym Degr 6:187–195

Anbuselvi S, Pandey V (2015) A comparative study of LDPE degradating bacteria from polythene dumped garbage, Int J Pharm Technol, ISSN: 0975-766X

Arutchelvi J, Sudhakar M, Arkatkar A, Doble M, Bhaduri S, Uppara VP (2008) Biodegrdation of polyethylene and polypropylene. Ind J Biotechnol 7:9–22

Awasthi S, Srivastava N, Singh T, Tiwary D, Mishra PK (2017) Biodegradation of thermally treated low density polyethylene by fungus Rhizopus oryzae NS 5. 3 Biotech 7:73. doi:10.1007/s13205-017-0699-4

Balasubramanian V, Natarajan K, Hemambika B, Ramesh N, Sumathi CS, Kottaimuthu R, Rajesh Kannan V (2010) High-density polyethylene (HDPE)-degrading potential bacteria from marine ecosystem of Gulf of Mannar, India. Lett Appl Microbiol. doi:10.1111/j.1472-765X.2010.02883.x

Begum MA, Varalakshmi B, Umamagheswari K (2015) Biodegradation of Polythene Bag using Bacteria Isolated from Soil. Int J Curr Microbiol App Sci 4(11):674–680

Bhardwaj H, Gupta R, Tiwari A (2012) Communities of microbial enzymes associated with biodegradation of plastics. J Polym Environ. doi:10.1007/s10924-012-0456-z

Bhatia M, Girdhar A, Chandrakar B, Tiwari A (2013) Implicating nanoparticles as potential biodegradation enhancers: a review. J Nanomed Nanotechol 4(175):2

Bhatia M, Girdhar A, Tiwari A, Nayarisseri A (2014) Implications of a novel pseudomonas species on low density polyethylene biodegradation: an in vitro to in silico approach. Springer Plus 3:497

Brown BS, Mills J, Hulse JM (1974) Chemical and biological degradation of plastics. Nature 250:161–163

Brynhildsen L, Rosswall T (1989) Effects of cadmium, copper, magnesium, and zinc on the decomposition of citrate by a Klebsiella sp. Appl Environ Microbiol 55(6):1375–1379

Caruso G (2015) Plastic degrading microorganisms as a tool for bioremediation of plastic contamination in aquatic environments. J Pollut Eff Cont 3:112

Cornell JH, Kaplan AM, Rogers MR (1984) Biodegradation of photooxidized polyalkylenes. J Appl Polym Sci 29:2581–2597

Das PM, Kumar S (2015) An approach to low-density polyethylene biodegradation by Bacillus amyloliquefaciens. 3 Biotech 5(1):81–86. doi:10.1007/s13205-014-0205-1

Dhanve RS, Shedbalkar UU, Jadhav JP (2008) Biodegradation of diazo reactive dye navy blue HE2R (Reactive Blue 172) by an isolated Exiguobacterium sp. RD3. Biotechnol Bioproc E 13:53–60. doi:10.1007/s12257-007-0165-y

Dolezel B (1967) Corrosion of plastic materials and rubbers. Br J Plast Surg 49:105–113

Gajendiran A, Krishnamoorthy S, Abraham J (2016) Microbial degradation of low-density polyethylene (LDPE) by Aspergillus clavatus strain JASK1 isolated from landfill soil. 3 Biotech 6:52

Gilan I, Hadar Y, Sivan A (2004) Colonization, biofilm formation and biodegradation of polyethylene by a strain of Rhodococcus ruber. Appl Microbiol Biotechnol 65:97–104

Gu J-D (2003) Microbiological deterioration and degradation of synthetic polymeric materials: recent research advances. Int Biodeterior Biodegrad 52(2):69–91. doi:10.1016/S0964-8305(02)00177-4

Gu JD, Ford TE, Mitton DB, Mitchell R (2000) Microbial corrosion of metals. The Uhlig corrosion handbook, 2nd edn. Wiley, New York

Hadad D, Geresh S, Sivan A (2005) Biodegradation of polyethylene by the thermophilic bacterium Brevibacillus borstelensis. J Appl Microbiol 98(5):1093–1100

Hanaa A, El-Shafei Nadia H, El-Nasser A, Kansoh AL, Ali AM (1998) Biodegradation of disposable polyethylene by fungi and Streptomyces species. Polym Degrad Stab 62:361–365

Iniguez, L Dong Y, and Triplett EW. (2004) Phytopathological society nitrogen fixation in wheat provided by klebsiella pneumoniae 342. Mol Plant-Microb Interact 17(10), 1078–1085. Publication No. M-2004-0726-01R

Jakubowicz I, Yarahmadi N, Petersen H (2006) Evaluation of the rate of abiotic degradation of biodegradable polyethylene in various environments. Polym Degrad Stab 91:1556–1562

Karlsson S, Albertsson A (1998) Biodegradable polymers and environmental interaction. Polym Eng Sci 38(8):1251–1253

Khabbaz F, Albertsson AC, Karlsson S (1998) Trapping of volatile low molecular weight photoproducts in inert and enhanced degradable LDPE. Polym Degrad Stab 61(2):329–342

Khabbaz F, Albertsson AC, Karlsson S (1999) Chemical and morphological changes of environmentally degradable polyethylene films exposed to thermo-oxidation. Polym Degrad Stab 63(1):127–138

Konduri MKR, Anupam KS, Vivek JS, Kumar RDB, Narasu ML (2010) Synergistic effect of chemical and photo treatment on the rate of biodegradation of high density polyethylene by indigenous fungal isolates. Int J Biotechnol Biochem 6:157–174

Kounty M, Lemaire J, Delort AM (2006) Biodegradation of polyethylene films with pro-oxidant additives. Chemosphere 64:1243–1252

Lee B, Pometto AL, Fratzke A, Bailey TB (1991) Biodegradation of degradable plastic polyethylene by phanerochaete and streptomyces species. Appl Environ Microbiol 57:678–685

Liu F, Fang B (2006) Optimization of bio-hydrogen production from biodiesel waste. Biotechnol J. doi:10.1002/biot.200600102

Maal KB, Delfan AS, Salmanizadeh S (2014) Isolation identification of Klebsiella pneumonia and Klebsiella oxytoca bacteriophages and their applications in waste water treatment and coliform’s phage therapy. Res J Environ Sci 8(3):123–133. doi:10.3923/rjes.2014.123.133. ISSN 1819-3412/

Mahalakshmi V, Siddiq AS, Andrew N (2012) Analysis of polyethylene degrading potentials of microorganisms isolated from compost soil. Int J Pharm Biol Arch 3(5):1190–1196

Muller RJ, Kleeberg I, Deckwer WD (2001) Biodegradation of polyesters containing aromatic constituents. J Biotechnol 86:87–95

Nowak B, Pajak J, Drozd-Bratkowicz M, Rymarz G (2011) Microorganisms participating in the biodegradation of modified polyethylene films in different soils under laboratory conditions. Int Biodeterior Biodegrad 65(6):757–767

Orhan Y, Büyükgüngör H (2000) Enhancement of biodegradability of disposable polyethylene in controlled biological soil. Int Biodeterior Biodegrad 45:49–55

Otake Y, Kobayashi T, Ashabe H, Murakami N, Ono K (1995) Biodegradation of low-density polyethylene, polystyrene, polyvinyl chloride, and urea formaldehyde resin buried under soil for over 32 years. J Appl Polym Sci. doi:10.1002/app.1995.070561309

Peil GHS, Kuss AV, Rave AFG, Villarreal JPV, Hernandes YML, Nascente PS (2016) Bioprospecting of lipolytic microorganisms obtained from industrial effluents. Ann Braz Acad Sci ISSN 1678-2690. doi: 10.1590/0001-3765201620150550

Pramila R, Ramesh KV (2015) Potential biodegradation of low density polyethylene (LDPE) by Acinetobacter baumannii. Afr J Bacteriol Res 7(3):24–28

Priyanka N, Archana T (2011) Biodegradation of polythene and plastic by the help of microorganisms: a way for brighter future. J Environ Anal Toxicol 1:111. doi:10.4172/2161-0525.1000111

Reich L, Stivala SS (1971) Elements of polymer degradation. McGraw Hill, New York, p 71

Restrepo-Florez JM, Bassi A, Thompson MR (2014) Microbial degradation and deterioration of polyethylene—a review. Int Biodeterior Biodegrad 80:83–90. doi:10.1016/j.ibiod.2013.12.014

Rivard C, Moens L, Roberts K, Brigham J, Kelley S (1995) Starch esters as biodegradable plastics: effect of ester group chain length and degree of substitution on anaerobic biodegradation. Enzym Microb Technol 17:848–852

Roy PK, Surekha P, Tulsi E, Deshmukh C, Rajagopal C (2008) Degradation of abiotically aged LDPE films containing pro-oxidant by bacterial consortium. Polym Degrad Stab 93:1917–1922

Sangale MK, Shahnawaz M, Ade AB (2012) A Review on biodegradation of polythene: the microbial approach. J Bioremed Biodeg 3:164. doi:10.4172/2155-6199.1000164

Satlewal A, Soni R, Zaidi M, Shouche Y, Goel R (2008) Comparative biodegradation of HDPE and LDPE using an indigenously developed microbial consortium. J Microbiol Biotechnol 18(3):477–482

Sekhar VC, Nampoothiri KM, Mohan AJ, Nair NR, Bhaskar T, Pandey A (2016) Microbial degradation of high impact polystyrene (HIPS), an e-plastic with decabromodiphenyl oxide and antimony trioxide. J Hazard Mater 318:347–354

Skariyachan S, Megha M, Kini MN, Mukund KM, Rizvi A, Vasist K (2015) Selection and screening of microbial consortia for efficient and ecofriendly degradation of plastic garbage collected from urban and rural areas of Bangalore. India Environ Monit Assess 187(1):1–14

Skariyachan S, Setlur AS, Naik SY, Naik AA, Usharani M, Vasist KS (2017) Enhanced biodegradation of low and high-density polyethylene by novel bacterial consortia formulated from plastic-contaminated cow dung under thermophilic conditions. Environ Sci Pollut Res Int 24(9):8443–8457. doi:10.1007/s11356-017-8537-0

Starnecker A, Menner M (1996) Assessment of biodegradability of plastics under stimulated composting conditions in a laboratory test system. Int Biodeterior Biodegrad 37:85–92

Sudhakar M, Doble M, Sriyutha Murthy P, Venkatesan R (2008) Marine microbe-mediated biodegradation of low- and high-density polyethylene. Int Biodeterior Biodegrad 61:203–213

Suresh B et al (2011) Influence of thermal oxidation on surface and thermo-mechanical properties of polyethylene. J Polym Res 18(6):2175–2184

Tribedi P, Sil AK (2013) Low-density polyethylene degradation by pseudomonas sp. AKS2 biofilm. Environ Sci Pollut Res Int 20(6):4146–4153. doi:10.1007/s11356-012-1378-y

Usha R, Sangeetha T, Palaniswamy M (2011) Screening of polyethylene degrading microorganisms from garbage soil. Libyan Agric Res Cen J Int 2(4):200–204

Weiland M, Daro A, David C (1995) Biodegradation of thermally oxidized polyethylene. Polym Degrad Stab 48:275–289

Witt U, Einig T, Yamamoto M, Kleeberg I, Deckwer WD, Müller RJ (2001) Biodegradation of aliphatic-aromatic copolyesters: evaluation of the final biodegradability and ecotoxicological impact of degradation intermediates. Chemosphere 44:289–299

Acknowledgements

Shraddha Awasthi gratefully acknowledges the Ministry of Human Resource Development (MHRD) through Department of Chemistry, Indian Institute of Technology (Banaras Hindu University), Varanasi, India for financial support.

Funding

The funding agency has been duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest between authors.

Ethical approval

There is no environment of human cell or animal cell in this work.

Rights and permissions

About this article

Cite this article

Awasthi, S., Srivastava, P., Singh, P. et al. Biodegradation of thermally treated high-density polyethylene (HDPE) by Klebsiella pneumoniae CH001. 3 Biotech 7, 332 (2017). https://doi.org/10.1007/s13205-017-0959-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0959-3