Abstract

Polythene is considered as one of the important object used in daily life. Being versatile in nature and resistant to microbial attack, they effectively cause environmental pollution. In the present study, biodegradation of low-density polyethylene (LDPE) have been performed using fungal lab isolate Rhizopus oryzae NS5. Lab isolate fungal strain capable of adhering to LDPE surface was used for the biodegradation of LDPE. This strain was identified as Rhizopus oryzae NS5 (Accession No. KT160362). Fungal growth was observed on the surface of the polyethylene when cultured in potato dextrose broth at 30 °C and 120 rpm, for 1 month. LDPE film was characterized before and after incubation by Fourier transform infrared spectroscopy, scanning electron microscopy, atomic force microscopy and universal tensile machine. About 8.4 ± 3% decrease (gravimetrically) in weight and 60% reduction in tensile strength of polyethylene was observed. Scanning electron microscope analysis showed hyphal penetration and degradation on the surface of polyethylene. Atomic force microscope analysis showed increased surface roughness after treatment with fungal isolate. A thick network of fungal hyphae forming a biofilm was also observed on the surface of the polyethylene pieces. Present study shows the potential of Rhizopus oryzae NS5 in polyethylene degradation in eco friendly and sustainable manner.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plastics are synthetic long chain polymer molecules (Scott 1999) and its consumption is increasing at a rate of 12% per annum globally and approximately 0.15 billion tones of synthetic polymers are generated worldwide annually (Premraj and Doble 2005; Leja and Lewandowicz 2010; Das and Kumar 2014). Aggregation rate of plastic waste in the environment is 25 million tons/year (Orhan and Buyukgungor 2000; Nayak and Tiwari 2011; Baruah 2011; Kaseem et al. 2012) and consequently causes a serious environmental peril (Sivan et al. 2006; Thompson et al. 2004). Currently used polyethylene thin plastic films and sheets used in product packaging are Polyolefin-derived plastics. Further out of these LDPE constitutes, ≃60% of the aggregate plastics production of plastic bags and most prevalent solid waste (Harper 2006). LDPE is characterized by good strength, resistance to chemicals, plasticity, and limpidity. Hydrophobicity interferes its availability to microorganisms (Albertsson and Karlsson 1993). These are characteristically inert their degradation rate is very slow approximated in decades and, therefore, they persist in the nature (Potts 1978). Its recalcitrant nature is due to its high molecular weight, complex three-dimensional structure (Contat-Rodrigo and Ribes Greus 2002; Nanda et al. 2010).

Land filling and incineration are prevalent operations for the management of LDPE but they have various environmental constraints so biodegradation appears as the best option for the plastic waste management (Restrepo-Flórez et al. 2014). Low-density polyethylene can be degraded in various methods as follows: chemical degradation, photodegradation and biological degradation (Da Luz et al. 2014). Biodegradation is the tendency of a polymer to get break down into its components by microorganisms. 17 bacterial and 9 fungal genera are known which are capable of degrading polyethylene (Sen and Raut 2015; Restrepo-Flórez et al. 2014). Degradation of polyethylene with fungi is preferred over bacteria because of their high production potential and good penetrating ability (Hanaa et al. 1998). Biodegradation of polyethylene by fungi has formerly been reported using Mucor rouxii NRRL 1835 and Aspergillus flavus (Hanaa et al. 1998), Penicillium simplicissimum YK (Yamada et al. 2001) and Phanerochaete chrysosporium (Liyoshi et al. 1998). Biodegradation of Polythene bag and plastic cup by Rhizopus sps have been reported (Kannahi and Sudha 2013). In this study, we have chosen fungus for bioremediation because they are very versatile and play a crucial role in the decay of lignocelluloses polymer, and have extensive metabolic capabilities (Gajendiran et al. 2016). Degradation of low density polyethylene by Rhizopus oryzae NS5 has not done yet. Therefore, the objective of the present study was to process biodegradation of LDPE using Rhizopus oryzae NS5. The confirmation of degradation was analyzed by Weight loss, FTIR, SEM, AFM and Universal tensile strength.

Materials and methods

Chemical and reagents

The nutrient media used for culturing the fungus were purchased from Hi-Media, India. LDPE film used in this work was having a thickness of 20 microns carrier bag, were collected from local market, Varanasi, Uttar Pradesh, India and all analytical chemicals were procured from Titan Biotech and CDH.

Low density polyethylene and its thermal oxidation

To enhance the degradation of LDPE films via fungal culture, the films were treated thermally by placing them in a preheated hot air oven at 70 °C for 10 days. Prior to transfer to liquid medium, strips were cut (10 × 4.5 cm), washed and disinfected with a solution containing 7 ml Tween-80, 10 ml bleach, and 983 ml sterile water. The films were then transferred aseptically into 70% (v/v) ethanol solution for 30 min, to sterilize them followed by drying them overnight at ≃45 to 50 °C, and weighed.

Screening and molecular identification of the fungal isolate

The selected fungal culture was isolated by serial dilution method and maintained on potato dextrose agar for sub culturing purposes on a rotary shaker (120 rpm) at 37 °C.

In-vitro degradation study

For the biodegradation assay, 100 ml potato dextrose broth (pH 7.0 ± 0.2) was taken in 250 ml Erlenmeyer flasks. The flasks containing preweighed and disinfected LDPE films (10 × 4.5) were inoculated with active fungal discs under sterilized conditions. The experiment was performed with respective positive (containing broth + fungus) and negative (containing broth + LDPE) controls, respectively. These flasks were incubated at 37 °C with continuous shaking at 120 rpm for 1 month.

Film harvesting

After 30 days of incubation, polyethylene films were removed, to remove cells mass from the residual films they were washed in 70% ethanol as much as possible, and then dried at 45 °C overnight and used for analysis purpose.

Statistical analysis

All the experiments were done in triplicate, and the means and standard deviation (SD) values were calculated using the excel program.

Analysis of the LDPE film biodegradation

Weight reduction measurement

The weight after 1 month incubation was compared to the mass before incubation. For comparison the mass of film in the control was also measured. The percent weight reduction was calculated with the formula:

where W 1 is the weight of polyethylene film before incubation and W 2 is the weight of polyethylene film after 1 month incubation.

Change in tensile strength

The material testing machine (Model INSTRON 4206) with a crosshead speed of 10 mm/min was used to estimate the mechanical strength of the degraded sample as well as the control at room temperature. Average value of three such observations was reported as the final result.

Change in the pH

pH of the media was measured by Elico LI614 pH Analyzer before and after incubation.

Contact angle measurements of LDPE films

The contact angle of films was measured at room temperature using contact angle measuring unit (Digital drop method) Kruss, Contact Angle Analyzer Serial no: 30001712, Model no: DSA255. The wetting liquid used for this purpose was Millipore grade distilled water. Calculations were averaged from three measurements.

Surface morphology of LDPE films

Pieces of treated polyethylene films were incubated at 4 °C in 4% glutaraldehyde at (pH 7.3). The 0.05 M phosphate buffer was used to rinse the samples (three times, 10 min each) and were then subsequently dehydrated in a series of alcohol. After dehydration samples were dried, mounted, and sputter coated with gold and then observed in a scanning electron microscope for SEM analysis and for AFM analysis all the images were obtained with a scan speed of 1.0 Hz and a resolution of 60 k.

Results and discussion

Identification of fungal isolate

The molecular identification of the selected fungal isolate designated as NS5 was established via molecular characterization. The phylogenetic analysis which was grounded on BLAST search applying 18S rDNA gene sequence demonstrated maximum homology (100%) with the fungus Rhizopus oryzae strain with gene bank Accession Number: AY213625.1. Based on the cladistic analysis as well as homology valuation, it was concluded that the selected fungal isolate could be regarded as Rhizopus oryzae strain NS5 (Fig. 1). The sequence of Rhizopus oryzae NS5 has been deposited in NCBI with accession no. KTI60362. Fungus Rhizopus oryzae is known for potential degradation of complex compound (Alberts 2009).

Effective biodegradation of oxidised polyethylene using L. fusiformis bacterium has been observed by Mukherjee et al. (2016). Kathiresan (2003) reported biodegradation of plastics and polyethylene bags by microbes present in soil which showed their active association. Priyanka and Archana (2011) conducted a comparative analysis between the biodegradation of polythene and plastic by five different types of soil sample collected from different sources. Among various species of bacteria and fungus, Bacillus subtilis, A. niger, Aspergillus nidulance, Aspergillus flavus, Aspregillus glaucus, Penicillium, Pseudomonas, Staphylococcus aureus, Streptococcus lactis, Proteus vulgaris, Micrococcus were found to degrade polythene and plastic efficiently (Abrusci et al. 2011; Aswale and Ade 2008; Kathiresan 2003; Nanda et al. 2010; Reddy 2008). Esmaeili et al. (2013) reported that Aspergillus sp., and Lysinibacillus sp., isolated from landfill soil sample were able to degrade LDPE efficiently.

Evaluation of biodegradation

Reduction in weight measurement of LDPE films

To quantify the LDPE degradationefficiency of Rhizopus oryzae NS5 the reduction in weight was measured at different time intervals after incubating them with Rhizopus oryzae NS5 at 37 °C. There was time dependent weight loss of LDPE and 8.4 ± 3% weight loss of starting material of LDPE was found to be degraded by fungus (Table 1). However, weight loss was not observed in control experiment. Reduction in weight might be because of consumption of LDPE film as a sole carbon source by fungus which confirms the potential capability of Rhizopus oryzae NS5 in LDPE degradation.

Moreover, biodegradation of polyethylene was studied by Hanaa et al. (1998) who explored the propensity of fungi and Streptomyces strains to rush the degradable polyethylene consisting of disposed polyethylene bags. Further, Aspergillus flavus, isolated from sanitary landfills was also found to be able to degrade polyethylene (Méndez et al. 2007). Yamada et al. (2001) have identified a fungus, named Penicillium simplicissimum YK, which could degrade the untreated high-density polyethylene. Use of a pure culture system permits the distinction between chemical and biological degradation of a polymer by providing necessary controls and also facilitates the experimental replication needed to obtain statistical evaluation of the data (Hanaa et al. 1998; Lee al. 1991). The biodegradation rate obtained in the present study is in agreement with the earlier reports ranging from 3.5 to 8.4% for polyethylene incubated in soil for 10 years (Albertsson and Karlsson 1990). This decrease in weight is in association to the others’ findings (Singh et al. (2012), Gilan et al. (2004), Manzur et al. (2004), Salleh et al. (1993)) carried out degradation of LDPE using Aspergillus fumigatus and Penicillium sp. According to their work, A. fumigatus was able to degrade 4.65% of polyethylene and Penicillium sp. degraded 6.58%. After bacterial treatment of thermally oxidised polyethylene, maximum weight loss of 7.006 ± 0.05% is achieved after 1 month for polyethylene oxidised in the presence of SDS.

The bacteria that degrade PE have been reported to Pseudomonas sp. (Balasubramanian et al. 2010), Bacillus sp. (Sudhakar et al. 2008), Mycobacterium sp. (Sudhakar et al. 2008), and Nocardia sp. (Bonhomme et al. 2003).

Change in Tensile strength

Tensile strength was measured at 10 days interval. There is a clear pattern of reduction in tensile strength in comparison to blank polyethylene films in 30 days (cf Figure 2). Approximately 60% reduction in tensile strength was noted. This finding is in agreement with earlier studies by Hanaa et al. 1998; Lee et al. 1991 showing tensile strength reduction of polyethylene film after incubation with microorganisms. Jakubowicz et al. 2006 reported that percentage elongation of the LDPE film was reduced after thermal oxidation. In addition, Orhan and Buyukgungor 2000 reported that biodegradability of disposable polyethylene was enhanced in controlled biological soil and Nowak et al. 2011 investigated a reduction in the percentage elongation of polyethylene films after the biodegradation process.

pH change in biodegradation process

The reduction in pH validates that the culture was still metabolically active and LDPE is utilized for its growth (Table 2). The reduction in pH not only affirms the consumption of the polyethylene film as their sole carbon source (Duddu and Guntuku 2015; Das and Kumar 2015; Arutchelvi et al. 2008). Microorganisms secrete variety of intra and extracellular enzymes into the media which might be responsible for the degradation of polymer. During the polymer degradation process, complex polymers are first broken down into short chains or monomers by exoenzymes that are small enough to permeate through the cell walls to be utilized as carbon and energy sources by a process of depolymerization (Dey et al. 2012). Initial pH was 5.1 ± 0.27 while pH after 30 days incubation was measured as 4.2 ± 0.30 (Table 2). It may be most probably due to the optimum pH range for Rhizopus oryzae growth, pH ~3.4 to 6 (Kurniawati et al. 2014 ).

Contact angle measurement of LDPE film

The contact angle of LDPE film without treatment was 98.6 98.6 +3.5, which remained to 91.5 + 3.5 after abiotic degradation. This decrease of the contact angle is an evidence of the hydrophilicity increment of the polymer surface. After this thermally treated film was exposed to the biotic environment for 4 weeks, the wettability and the corresponding hydrophilic character of the polyethylene increased further, showing the contact angle 67 + 2.6 (Table 3). Though there was no decrease in the contact angle for the control set of sample. This indicated that the polymer surface became relatively hydrophilic with increasing immersion period, which was also reported earlier by several authors (Sonak and Bhosle 1995; Sudhakar et al. 2008).

Surface morphology study of LDPE

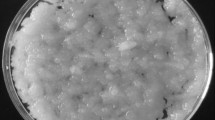

The surface morphology of Polyethylene film was observed by AFM micrographs (Fig. 4a, b) of LDPE films without any treatment, and thermally pretreated followed with fungus incubation after 30 days of incubation with Rhizopus oryzae showed hyphal growth on the surface of polyethylene and degradation of the polyethylene around the fungal cells in the biofilm, causing the formation of grooves in the treated polyethylene after the incubation with Rhizopus oryzae NS5. It is possibly because of Rhizopus secretes lipase, (Coenen et al. 1997) tyrosinase, peroxidase (León-Santiesteban et al. 2008) and laccase (Shinkafi et al. 2014) enzymes capable of degrading polyethylene, and consequence of such enzymatic activities is the grooves formation. It has been identified that the fungus also undergo change in shape upon biofilm formation (Raaman 2012). There are several reports reporting that initial attack generally begins with a surface adherence. Scanning electron microscopy (SEM) allows direct observation of biodegradation and superficial growth of fungal hyphae for thermally treated films is presented in Fig. 3. The biodegradation of polyethylene was clear through the formation of cavities on the surface of polyethylene and the hyphal penetration and colonization of fungal hyphae and spores to the surface, as shown in Fig. 3a, b. Mathur et al. (2011) the microbial adhesion to the surface of polymer is a preliminary step for biodegradation to take place (Moriyama et al. 1993). Microorganisms colonize the polymer surface and adhere by extracellular polymer production. The results obtained are in close association with earlier reports (Manzur et al. 2004; Volke-Sepulveda et al. 2002).

This change in growth rate could be a cellular response to the change in surface topography of the LDPE film during degradation whereby pits are formed on the film surface due to enzymatic digestion. Similar changes in surface topology have also been noticed from AFM analysis (Tribedi and Sil 2013).

FTIR

A number of peaks are present in the control film manifesting the complex nature of the LDPE (Fig. 5a). There was an alteration in the band intensities in different regions when test samples (after incubation with fungus) were analyzed (Fig. 5c). For control samples, the characteristic absorption bands were present at 719 cm−1 (C–H bend-mono), 1472 cm−1 (C=C stretch), 2660 cm−1 (CHO stretch), and 2919, 2850 cm−1 (both due to C–H stretch). The increase in carbonyl absorption band at 1720 cm−1 region was mainly due to the formation of carbonyl bond through oxidation of the polyethylene moieties during the thermal treatment. Remarkable changes were found for fungal strain and the peak at 2727 cm−1 corresponds to CHO stretching vibration that has been disappeared while a new band has been detected at 939 cm−1 (O–H bend) and 3375 (Acid O–H) which supports the depolymerization activity of the microbial isolates. The strong absorption peaks at 719 and 1472 cm−1 became weaker after fungal treatment whereas peaks at 2919 and 2850 cm−1 became intensified in the treated sample than the control one. The change in the peak values of almost all functional groups confirming the configurational change on polymer surface (Das and Kumar 2015; Gilan et al. 2004; Drímal et al. 2007; Hadad et al. 2005; Arboleda et al. 2004).

Conclusion

In the present study, lab isolate fungal strain, Rhizopus oryzae NS 5, capable of not only adhering to the surface of LDPE but also utilizing it as the source of carbon efficiently. The degradation has been confirmed by morphological changes, weight loss, mechanical properties changes and change in functional groups. Even though it is a slow technique, the prevailing examine gives an insight to the evidences of biodegradation of LDPE. It shows that there is a remarkable possibility of finding microorganisms from the surroundings that may degrade artificial plastics. Knowledge of the enzyme device of Rhizopus oryzae NS5 will provide an insight to its role in biodegradation of LDPE. Currently our efforts are focused on elucidating the pathway for the degradation of low density polyethylene and developing a new bioremediation strategy using this fungus.

References

Abrusci C, Pablos JL, Corrales T, Lopez-Marín J, Marín I et al (2011) Biodegradation of photo-degraded mulching films based on polyethylenes and stearates of calcium and iron as pro-oxidant additives. Int Biodeterior Biodegrad 65:451–459

Alberts JF (2009) Degradation of aflatoxin B1 by fungal laccase enzymes. Int J Food Microbiol. doi:10.1016/j.ijfoodmicro.2009.07.022

Albertsson AC, Karlsson S (1990) The influence of biotic and abiotic environments on the degradation of polyethylene. Prog Polym Sci 15:177–192

Albertsson AC, Karlsson S (1993) aspects of biodeterioration of inert and degradable polymers. Int Biodeterior Biodegrad 161–170. doi:10.1016/0964-8305(93)90002-J

Arboleda CE, Mejía AIG, López BLO (2004) Poly (vinylalcohol-co-ethylene) biodegradation on semi solid fermentation by Phanerochaete chrysosporium. Acta Farm Bonaer 23:123–128

Arutchelvi J, Sudhakar M, Arkatkar A, Doble M, Bhaduri S, Uppara VP (2008) Biodegrdation of polyethylene and polypropylene. Ind J Biotech 7:9–22

Aswale P, Ade A (2008) Assessment of the biodegradation of polythene. Bioinfolet 5:239

Balasubramanian V, Natarajan K, Hemambika B, Ramesh N, Sumathi CS, Kottaimuthu R, Rajesh Kannan V (2010) High-density polyethylene (HDPE)-degrading potential bacteria from marine ecosystem of Gulf of Mannar, India. Lett Appl Microbiol. doi:10.1111/j.1472-765X.2010.02883.x

Baruah SD (2011) Biodegradable polymer: the promises and the problems. Sci Cult 77:466–470

Bonhomme S, Cuer A, Delort AM, Lemaire J, Sancelme M, Scot G (2003) Environmental biodgradation of polyethylene. Polym Degrad Stab 81:441–452

Coenen TM, Aughton P, Verhagen H (1997) Safety evaluation of lipase derived from Rhizopus oryzae: summary of toxicological data. Food Chem Toxicol 35:315–322

Contat-Rodrigo IL, Ribes Greus A (2002) Biodegradation studies on LDPE filled with biodegradable additives: morphological changes. J Appl Polym Sci 83:1683–1691

da Luz JMR, Paes SA, Bazzolli DMS, Totola MR, Demuner AJ, Kasuya MCM (2014) Abiotic and biotic degradation of oxobiodegradable plastic bags by Pleurotus ostreatus. PLoS One. doi:10.1371/journal.pone.0107438

Das PM, Kumar S (2014) Microbial deterioration of low density polyethylene by Aspergillus and Fusarium sp. Int J Chem Tech Res 6(1):299–305

Das PM, Kumar S (2015) An approach to low-density polyethylene biodegradation by Bacillus amyloliquefaciens. doi: 10.1007/s13205-014-0205-1

Dey U, Mondal NK, Das K, Dutta S (2012) An approach to polymer degradation through microbes. IOSR J Pharm 2:385–388

Drímal P, Hoffmann J, Družbík M (2007) Evaluating the aerobic biodegradability of plastics in soil environments through GC and IR analysis of gaseous phase. Polym Test 26:729–741. doi:10.1016/j.polymertesting.2007.03.008

Duddu MK, Guntuku GS (2015) Isolation and screening of actinomycetes for biodegradation of low density polyethylene from mangrove sediment. Int J Pharma Res Rev 4(11):14–22

Esmaeili A, Pourbabaee AA, Alikhani HA, Shabani F, Esmaeili E (2013) Biodegradation of low-density polyethylene (LDPE) by mixed culture of lysinibacillus xylanilyticus and aspergillus niger in Soil. PLoS ONE 8(9):e71720. doi:10.1371/journal.pone.0071720

Gajendiran A, Krishnamoorthy S, Abraham J (2016) Microbial degradation of low-density polyethylene (LDPE) by Aspergillus clavatus strain JASK1 isolated from landfill soil. Biotech 6:52

Gilan I, Hadar Y, Sivan A (2004) Colonization, biofilm formation and biodegradation of polyethylene by a strain of Rhodococcus ruber. Appl Microbiol Biotechnol 65:97–104

Hadad D, Geresh S, Sivan A (2005) Biodegradation of polyethylene by the thermophilic bacterium Brevibacillus borstelensis. J Appl Microbiol 98(5):1093–1100. doi:10.1111/j.1365-2672.2005.02553.x

Hanaa A, El-Shafei, Nadia H, El-Nasser A, Kansoh AL, Ali AM (1998) Biodegradation of disposable polyethylene by fungi and Streptomyces species. Polym Degrad Stab. 62:361–365

Harper CA (2006) Handbook of plastics technologies: the complete guide to properties and performance: recycling-of-low-density-polyethylene-ldpe-and-linear-low-density-polyethylene-lldpe. Copyright The McGraw-Hill Companies

Jakubowicz I, Yarahmadi N, Petersen H (2006) Evaluation of the rate of abiotic degradation of biodegradable polyethylene in various environments. Polym Degrad Stab 91:1556–1562

Kannahi M, Sudha P (2013) Screening of polythene and plastic degrading microbes from Muthupet mangrove soil. J Chem Pharm Res 5(8):122–127

Kaseem M, Hamad K, Deri F (2012) Thermoplastic starch blends: a review of recent works. Polym Sci Ser A Chem Mat Sci 54:165–176. doi:10.1134/S0965545X1202006X

Kathiresan K (2003) Polythene and plastic degrading microbes from mangrove soil. Rev Biol Trop 51:629–633

Kurniawati T, Indrati R, Sardjono S (2014) Isolation of Rhizopus oryzae from rotten fruit and its potency forlactic acid production in glucose medium with and without addition of calcium carbonate. Agritech 34(2):170–176

Lee B, Pometto AL, Fratzke A, Bailey TB (1991) Biodegradation of degradable plastic polyethylene by Phanerochaete and Streptomyces species. Appl Environ Microbiol 57:678–685

Leja K, Lewandowicz G (2010) Polymer biodegradation and biodegradable polymers: a review. Pol J Environ Stud 19(2):255–266

León-Santiesteban H, Bernal R, Fernández JF, Tomasini A (2008) Tyrosinase and peroxidase production by Rhizopus oryzae strain ENHE obtained from pentachlorophenol-contaminated soil. J Chem Technol Biotechnol. doi:10.1002/jctb

Liyoshi Y, Tsutsumi Y, Nishida T (1998) Polyethylene degradation by lignin-degrading fungi and manganese peroxidase. J Wood Sci 44:222–229. doi:10.1007/BF00521967

Manzur A, Limón-González M, Favela-Torres E (2004) Biodegradation of physicochemically treated LDPE by a consortium of filamentous fungi. J Appl Polym Sci 92(1):265–271

Mathur G, Mathur A, Prasad R (2011) Colonization and degradation of thermally oxidized high-density polyethylene by (ITCC No. 6052) isolated from plastic waste dumpsite. Bioremediation J 15(2):69–76

Méndez CR, Vergaray G, Vilma R, Karina B, Cárdenas J (2007) Isolation and characterization of polyethylene-biodegrading mycromycetes. Rev Peru Biol 13:203–205

Moriyama Y, Kimura N, Inoue R, Kawaguchi A (1993) Examination of fungal deterioration on plasticized polyvinyl chloride by cryo-scanning electron microscopy. Int Biodeterior Biodegrad 31(3):231–239 doi:10.1016/0964-8305(93)90008-p

Mukherjee S, Roy Chowdhuri U, Kundu PP (2016) Bio-degradation of polyethylene waste by simultaneous use of two bacteria: Bacillus licheniformis for production of bio-surfactant and Lysinibacillus fusiformis for bio-degradation. RSC Adv 6:2982e2992. doi:10.1039/C5RA25128A

Nanda S, Sahu SS, Abraham J (2010) Studies on the biodegradation of natural and synthetic polyethylene by Pseudomonas spp. J Appl Sci Environ Manag 14(2):57–60

Nayak P, Tiwari A (2011) Biodegradation of polythene and plastic by the help of microbial tools: a recent approach. IJBAR 2(9):344–355. doi:10.7439/ijbar.v2i9.47

Nowak B, Pająk J, Drozd-Bratkowicz M, Rymarz G (2011) Microorganisms participating in the biodegradation of modified polyethylene films in different soils under laboratory conditions. Int Biodeterior Biodegrad 65(6):757–767

Orhan Y, Buyukgungor H (2000) Enhancement of biodegradability of disposable polyethylene in controlled biological soil. Int Biodeterior Biodegrad 45:49–55. doi:10.1016/S0964-8305(00)00048-2

Potts JE (1978) Biodegradation. In: Jelinek HHG (ed) Aspects of degradation and stabilization of polymers. Elsevier, New York, pp 617–658

Premraj R, Doble M (2005) Biodegradation of polymers. Indian J Biotechnol 4:186–193

Priyanka N, Archana T (2011) Biodegradation of polythene and plastic by the help of microorganisms: a way for brighter future. J Environ Anal Toxicol 1:111. doi:10.4172/2161-0525.1000111

Raaman N (2012) Biodegradation of plastic by Aspergillus spp. isolated from polythene polluted sites around Chennai. J Acad Ind Res 1(6):313–316

Reddy RM (2008) Impact of soil composting using municipal solid waste on biodegradation of plastics. Indian J Biotechnol 7:235–239

Restrepo-Flórez J-M, Bassi A, Thompson MR (2014) Microbial degradation and deterioration of polyethylene—a review. Int Biodeterior Biodegrad 80:83–90. doi:10.1016/j.ibiod.2013.12.014

Salleh AB, Musani R, Basri M, Ampon K, Yunus WMZ, Razak CNA (1993) Extra- and intra-cellular lipases from a thermophilic and factors affecting their production. Can J Microbiol 39(10):978–981

Scott G (1999) Polymers in modern life. Polymers and the Environment. The Royal Society of Chemistry, Cambridge. doi: 10.1039/9781847551726-00001

Sen SK, Raut S (2015) Microbial degradation of low density polyethylene (LDPE): a review. J Environ Chem Eng 3:462–473. doi:10.1016/j.jece.2015.01.003

Shinkafi SA, Adamu US, Tanyi ST (2014) Production of laccases by fungi isolated from soil in sokoto. Niger J Microbiol Res. doi:10.5923/j.microbiology.20140401.05

Singh V, Dubey M, Bhadauria S (2012) Microbial degradation of polyethylene (low density) by Aspergillius Fumigatus and Penicillium sp. Asian J Exp Biol Sci 3(3):498–501

Sivan A, Szanto M, Pavlov V (2006) Biofilm development of the polyethylene- degrading bacterium Rhodococcus ruber. Appl Microbiol Biotechnol 72:346–352. doi:10.1007/s002530050259

Sonak S, Bhosle N (1995) Observations on biofilm bacteria isolated from aluminium panels immersed in estuarine waters. Biofouling 8:243–254

Sudhakar M, Doble M, Murthy PS, Venkatesan R (2008) Marine microbemediated biodegradation of low-and high density polyethylenes. Int Biodeter Biodegrad 61:203–213

Thompson RC, Olsen Y, Mitchell RP, Davis A, Rowland SJ, John AWG, Mc Gonigle D, Russell AE (2004) Lost at sea: where is all the plastic? Science 304:838

Tribedi P, Sil AK (2013) Low-density polyethylene degradation by Pseudomonas sp. AKS2 biofilm. Environ Sci Pollut Res Int 20(6):4146–4153. doi:10.1007/s11356-012-1378-y

Volke-Sepulveda T, Saucedo-Castaneda G, Gutierrez-Rojas M, Manzur A, Favela-Torres E (2002) Thermally treated low density polyethylene biodegradation by penicillium pinophilum and aspergillus niger. J Appl Polym Sci 83:305–314

Yamada OK, Mukumoto H, Katsuyaya Y, Saiganji A, Tani Y (2001) Degradation of polyethylene by a fungus, Penicillium simplicissmum YK. Polym Degrad Stab 72:323–327. doi:10.1016/S0141-3910(01)00027-1

Acknowledgements

Author S.A. acknowledges Ministry of Human Resource Development for the financial support through Department of Chemistry, Indian Institute of Technology (Banaras Hindu University), Varanasi, India. Author N.S. thankfully acknowledges DST, New Delhi, India for providing the Women Scientist-B fellowship (SEED/DISHA/WOSB/047/2012/G) and Department of Chemical Engineering and Technology, IIT (BHU), Varanasi for providing Institute PDF. Authors, S.A., N.S. and P.K.M. acknowledge the Department of Chemical Engineering and Technology, IIT (BHU), Varanasi, India for providing the research facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest between authors.

Ethical standards

There is no environment of human or animal cell in this work.

Funding

The funding agency has been duly acknowledged.

Additional information

Disclaimer

The article is not in consideration under any other journal in full or in part. No data or figures have been fabricated or manipulated.

Rights and permissions

About this article

Cite this article

Awasthi, S., Srivastava, N., Singh, T. et al. Biodegradation of thermally treated low density polyethylene by fungus Rhizopus oryzae NS 5. 3 Biotech 7, 73 (2017). https://doi.org/10.1007/s13205-017-0699-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0699-4