Abstract

Polyethylene materials are a serious environmental concern as their nondegradable nature allows them to persist in the environment. Recent studies have shown that polyethylene can be degraded by microbes at a very slow rate, whereby detectable changes are evident after several years. In the present study, we report the degradation of low-density polyethylene by Pseudomonas sp. AKS2. Unlike the previous reports, degradation by Pseudomonas sp. AKS2 is relatively fast as it can degrade 5 ± 1 % of the starting material in 45 days without prior oxidation. This degradation can be altered by agents that modulate hydrophobic interaction between polythene and the microbe. As mineral oil promotes hydrophobic interactions, it enhances bacterial attachment to the polymer surface. This enhanced attachment results in increased biofilm formation and enhanced polymer degradation. In contrast, Tween 80 reduces bacterial attachment to the polymer surface by lowering hydrophobic interactions and thereby reduces polymer degradation. Thus, this study establishes a correlation between hydrophobic interaction and polymer degradation and also relates the biofilm formation ability of bacteria to polymer degrading potential.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyethylene represents up to 64 % of all the synthetic plastics produced and are mainly used for manufacturing plastic bags, bottles, and disposable containers (Byuntae et al.1991). Polyethylene remains in the environment for a long period of time as it lacks functional groups required for the microbial degradation. Thus, polyethylene-based plastic materials are accumulating in the environment at an alarmingly high rate of approximately 25 million tons per year (Soni et al. 2009; Zahra et al. 2010). Consistent with its inert nature, a polyethylene sheet that was kept in moist soil for a period of 12 years showed no evidence of weight loss (Potts 1978). In a separate study, only partial degradation of polyethylene film has been observed after a prolonged incubation of 32 years inside the soil (Otake et al. 1995). However, it is evident from the recent studies that the rate of biotic degradation of low-density polyethylene (LDPE) can be enhanced by its prior oxidation (Chatterjee et al. 2010; Albertsson et al.1998; Roy et al. 2008; Volke-Sepulveda et al. 2002). It is likely that the oxidation of polyethylene generates carbonyl groups that can be utilized by microorganisms for its degradation (Albertsson 1978, 1980; Cornell et al. 1984). All these reports indicate that polyethylene is highly recalcitrant with respect to natural degradation.

In our previous study, we have reported the isolation of a Pseudomonas strain (Pseudomonas sp. AKS2) capable of degrading a synthetic polymer polyethylene succinate (PES) (Tribedi et al. 2012). In the current study, we show that the same organism can degrade LDPE up to 5 ± 1 % at 30 °C in only 45 days without prior oxidation and discuss the role of hydrophobicity and the biofilm formation ability of the organism in this degradation process.

Materials and methods

Polyethylene

The LDPE films used in this study were collected from local markets (Kolkata) where they were sold as 20-μm-thick carrier bags. For the experiments, LDPE films were cut into small strips and sterilized with 70 % alcohol.

Bacterial strain and culture condition

Pseudomonas sp. AKS2 was previously isolated from the Kolkata municipal solid waste dumping ground soil (Kolkata, India) as a potential degrader of PES (Tribedi et al. 2012). This isolate was inoculated in 100 ml of basal media containing 100 mg yeast extract, 1 g (NH4)2SO4, 200 mg MgSO4·7H2O, 100 mg NaCl, 20 mg CaCl2·2H2O, 10 mg FeSO4·7H2O, 0.5 mg Na2MoO4·2H2O, 0.5 mg Na2WO4·2H2O, 0.5 mg MnSO4, 1.6 g K2HPO4, 200 mg KH2PO4 (per liter of distilled water), and 300 mg of sterile LDPE films and thereafter incubated at 30 °C for 45 days in shaking condition. In some experiments, mineral oil (a mixture of alkanes containing chain length ranging from C15 to C40) or Tween 80 (nonionic surfactant) was added to the media to test the effect of these substances on bacterial attachment to polymer and LDPE degradation by Pseudomonas sp. AKS2. Mineral oil and Tween 80 were made sterile by filtering through a 0.4-μm polycarbonate membrane filter.

Determination of dry weight of residual LDPE

To facilitate accurate measurement of the dry weight of residual LDPE, LDPE films were recovered from the conditioned media, and adhered bacterial cells, if any, were washed off from the LDPE surface with 2 % (v/v) sodium dodecyl sulfate (SDS) solution and further washed with distilled water (Gilan et al. 2004). The residual LDPE containing mineral oil, if any, was treated with chloroform prior to washing with SDS to remove mineral oil from the LDPE surface. The washed LDPE was dried overnight at 60 °C before weighing. The weight difference between initial weight and final weight indicates the extent of polythene utilization by the bacteria.

Microscopic analysis of LDPE degradation

To examine the degradation of polythene film by the bacterium Pseudomonas sp. AKS2, polythene films were recovered from the conditioned media and washed with 2 % SDS to remove adhered organisms, if any. Thereafter, the films were air-dried overnight, and the surface morphology of the microbe-treated or untreated films was examined by both scanning electron microscopy (SEM) and atomic force microscopy (AFM). For SEM analysis, the polythene films were cut into small strips, coated with gold, and thereafter examined under SEM. For AFM analysis, all images were obtained with a scan speed of 1.0 Hz and a resolution of 512 × 512 pixels.

Tensile strength analysis of LDPE

Tensile strength of these pieces was measured using a tensometer as described previously (Tribedi et al. 2012).

Bacterial biomass estimation from LDPE film

The population density of Pseudomonas sp. AKS2 on the LDPE film surface was determined indirectly by determining the concentration of extractable protein as the amount of extractable protein is directly proportional to the number of adhered microorganisms. To extract the protein from microorganisms adhering to LDPE films, the films were taken out from conditioned media at different time intervals, washed with water, and then boiled for 30 min in 5 ml of 0.5 N NaOH. The suspension was centrifuged and the supernatant was collected. Protein concentration was determined by the Lowry method (Lowry et al. 1951).

Bacterial attachment on LDPE film

To examine the adherence of Pseudomonas sp. AKS2 on the LDPE surface, the LDPE film was recovered from the conditioned media with regular time interval, stained with acridine orange (4 μg ml−1), air-dried, and observed under a fluorescence microscope. For SEM analysis, LDPE films were fixed with 2.5 % glutaraldehyde for 1 h after its removal from the growth medium. Films were dried in vacuum and coated with gold. Adhered cells or the biofilm cells were examined under SEM (×6,000).

Viability of the bacterial biofilm

To check the metabolic activity of the biofilm on the polythene surface, the LDPE film was removed from the conditioned medium to a flask containing 60 ml of 60 mM sodium phosphate buffer, pH 7.6. Fluorescein diacetate (FDA) was added to a final concentration of 10 μg ml−1. The flask was shaken at 30 °C, and a 1-ml aliquot was withdrawn at various time points during the incubation. These samples were centrifuged at 8,000 rpm for 5 min, and the absorbance of the supernatant at 494 nm was measured. Samples without FDA served as blanks, and a sample of LDPE from a sterile basal medium served as a control.

Extraction and measurement of exopolysaccharides

The biofilm on LDPE surface was recovered by scrapping in sterile water. This biofilm suspension was centrifuged at 6,000 rpm for 20 min at 4 °C. The supernatant was collected. The pellet was treated with 10 mM EDTA, vortexed for 15 min, and recentrifuged to extract cell-bound exopolysaccharides (EPS). The supernatant was collected and mixed with the previous supernatant. The pooled supernatant was then mixed with 2.2 volume of chilled absolute ethanol, incubated at −20 °C for 1 h and centrifuged at 6,000 rpm for 20 min at 4 °C. The pellet containing EPS was dissolved in sterile water and measured by phenol sulfuric acid method (Dubois et al. 1956).

Statistical analysis

Experimental results were subjected to statistical analysis of one-way analysis of variance (ANOVA). Statistical analysis was carried out using the software SPSS-16. All experiments were performed three times.

Results

Pseudomonas sp. AKS2 can utilize LDPE as sole source of carbon

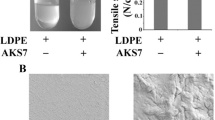

We have reported that Pseudomonas sp. AKS2 has the ability to degrade PES (Tribedi et al. 2012). Since PES is very similar in nature with LDPE (Tansengco and Tokiwa 1998), we have examined the degradation of LDPE by Pseudomonas sp. AKS2. Towards this, sterile LDPE films were added as sole carbon source to the basal medium, followed by inoculation with Pseudomonas sp. AKS2. In the control experiment, the inoculation step was omitted. After 45 days of incubation at 30 °C, we observed that the medium inoculated with Pseudomonas sp. AKS2 becomes turbid indicating the growth of the organism by utilizing LDPE as sole source of carbon (Fig. 1a). To further confirm the LDPE degradation ability of Pseudomonas sp. AKS2, the change in surface topography of the LDPE films was examined by both SEM and AFM. The SEM image showed an alteration in surface topology for those LDPE films that were treated with Pseudomonas sp. AKS2. The surface of the treated film became rough, and a number of cracks and grooves were also evident (Fig. 1b). In contrast, the film that was not treated with Pseudomonas sp. AKS2 retained a smooth surface even after 45 days of incubation under the same condition (Fig. 1b). Similar alterations in surface topology have also been observed from AFM image analysis (Fig. 1b). Consistent with these observations, we have also examined the tensile strength of the LDPE film, and it was found that the tensile strength was reduced significantly for the LDPE film that was treated with Pseudomonas sp. AKS2 (Fig. 1c).

Pseudomonas sp. AKS2 utilizes LDPE as sole source of carbon. a Pseudomonas sp. AKS2 survives in basal media containing LDPE. Equal numbers of cells from a saturated culture of Pseudomonas sp. AKS2 were inoculated in basal medium containing or not containing LDPE film and were incubated at 30 °C for 45 days. The appearance of turbidity indicates the growth of the organism. b Microscopic (SEM and AFM) observations of Pseudomonas sp AKS2-treated or untreated LDPE film. The image is representative of images obtained from 20 different fields for each group and from three independent experiments. The bar represents 1 μm. c Treatment of the LDPE film with Pseudomonas sp. AKS2 reduces tensile strength. The result represents the average of three independent experiments. Error bars indicate standard deviation (±SD). Statistical significance between the groups was evaluated by ANOVA at 5 % level. Mean values with different letters (a and b) are significantly different between treatments

To quantify the LDPE degradation efficiency of Pseudomonas sp. AKS2, the weight loss of the LDPE films was measured at different time points after incubating them with Pseudomonas sp. AKS2. The result showed a time-dependent weight loss of LDPE film. Over a period of 45 days, 5 ± 1 % of the starting material of LDPE was found to be degraded by Pseudomonas sp. AKS2 (Fig. 2). However, no weight loss was evident in the control experiment wherein incubation was carried out at the same temperature for a similar length of time but without Pseudomonas sp. AKS2 (data not shown). Therefore, this result shows that the weight loss of LDPE during the incubation with Pseudomonas sp. AKS2 was due to the utilization of the polyethylene by the bacteria as sole carbon source. Taken together, the above results indicate that Pseudomonas sp. AKS2 is capable of degrading LDPE.

Biodegradation of the LDPE film by Pseudomonas sp. AKS2. The dry weight of LDPE films were measured at different time points during the course of incubation. Weight loss was plotted against time of incubation. The result represents the average of three independent experiments. Error bars indicate standard deviation (±SD)

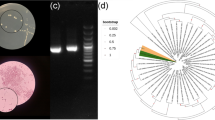

Mineral oil and nonionic surfactant Tween 80 modulate adherence of Pseudomonas sp. AKS2 to LDPE

In our previous study, we have shown that the cell surface hydrophobicity of Pseudomonas sp. AKS2 is very high (31 ± 2 %), and it plays an important role in PES degradation (Tribedi et al. 2012). It has also been reported that the agents such as mineral oil and Tween 80 that are modulators of hydrophobic interaction between the polymer and the organism can modulate the biodegradation of polyethylene (Gilan et al. 2004). Therefore, it is possible that these two agents will also be able to modulate the degradation of LDPE by Pseudomonas sp. AKS2. To examine this, we have added either mineral oil or Tween 80 to the basal media containing sterile LDPE prior to inoculation with Pseudomonas sp. AKS2. We observed reduced degradation of LDPE with increasing concentration of Tween 80 (Table 1). However, the degradation of LDPE by Pseudomonas sp. AKS2 was found to be increased with the increase in mineral oil concentration (Table 1). Mineral oil promotes hydrophobic interaction between the cell and polymer surface, whereas Tween 80 reduces it (Gilan et al. 2004). Therefore, it is expected that attachment of Pseudomonas sp. AKS2 to LDPE surface will be reduced with Tween 80, and on the other hand, mineral oil will facilitate attachment of Pseudomonas sp. AKS2 cells to the polymer surface. To test this hypothesis, we have monitored the adherence of Pseudomonas sp. AKS2 to the LDPE surface at different time points by staining bacteria with acridine orange. We have observed a steady increase in the adherence of Pseudomonas sp. AKS2 with time on the surface of LDPE (Fig. 3a). Consistent with our hypothesis, we also observed increased attachment of cells to the polymer surface when mineral oil was added to the medium while the addition of Tween 80 in the medium resulted in a reduced attachment of cells to LDPE, in comparison to films in media lacking either mineral oil or Tween 80 (compare Fig. 3a and b). Thus, the current study reveals that the agents like mineral oil and Tween 80 can modulate the biodegradation of LDPE by Pseudomonas sp. AKS2 by altering the bacterial adherence to LDPE.

Modulation of Pseudomonas sp. AKS2 adherence to LDPE by mineral oil and Tween 80. a Kinetics of Pseudomonas sp. AKS2 attachment to LDPE. Adherence of Pseudomonas sp. AKS2 to LDPE films recovered at different time points was examined by staining with acridine orange (4 μg ml−1) and observed under a fluorescence microscope. The figure is representative of images obtained from 20 different fields for each group and from three independent experiments. b Effect of mineral oil and Tween 80 on adherence of Pseudomonas sp. AKS2 to the LDPE film. The figure is representative of images obtained from 20 different fields for each group and from three independent experiments

Mineral oil enhances Pseudomonas sp. AKS2 biofilm formation on the surface of LDPE

The ability of an organism to form a biofilm improves its biodegradation potential significantly (Gilan et al. 2004; Balasubramanian et al. 2010). In agreement with this idea, we observed the formation of a biofilm on the LDPE surface by Pseudomonas sp. AKS2 both in the presence and absence of mineral oil in the growth medium (Fig. 3a and b). To further confirm biofilm formation, we have examined the surface of LDPE films by SEM. Figure 4a clearly shows the formation of a biofilm on the LDPE surface in both the presence and absence of mineral oil. However, the rate of biofilm formation was significantly enhanced in the presence of mineral oil as an extensive biofilm was formed in just 15 days, compared to the control sample in which biofilm formation was evident at 30 days (Fig. 4a). Even at the 45-day time point, the extent of biofilm formation did not reach the level achieved in 15 days in the presence of mineral oil. No biofilm formation was observed when Tween 80 was present (Fig. 3b). Secretions of EPS from organisms stabilize the network of biofilm, and thus, EPS measurement is considered as an important test for the biofilm formation. Consistent with our expectation, we observed that EPS secretion was markedly increased with the increase in incubation time both in the presence and absence of mineral oil (Fig. 4b). However, a higher amount of EPS secretion was observed when mineral oil was present. This result clearly indicates the formation of a biofilm on the LDPE surface by Pseudomonas sp. AKS2. To examine the bacterial viability and metabolic activity in a biofilm, we have measured the amount of fluorescein diacetate hydrolase enzyme activity on differentially treated LDPE films. Viable microbial cells produce a large array of hydrolytic enzymes, which can cleave fluorescein diacetate to produce fluorescein that can be detected spectrophotometrically, and this assay is widely used to measure cell metabolic activity and cell viability of the biofilm (Killham and Staddon 2002; Teng et al. 2010). Consistent with the biofilm formation, we have observed higher microbial activities from the surface of the LDPE films when mineral oil was added to the growth medium compared to the films either treated with Tween 80 or left untreated (Fig. 4c). To compare the bacterial population size on the different LDPE films quantitatively, we have determined the total extractable protein from LDPE films (see Materials and methods). As expected, we have obtained the highest amount of protein from the surface of the LDPE film in the mineral oil-containing growth medium (Fig. 4d).

Mineral oil enhances biofilm formation of Pseudomonas sp. AKS2 on the LDPE surface. a Comparison of biofilm formation of Pseudomonas sp. AKS2 on the LDPE surface in the presence and absence of mineral oil in the growth medium assessed by SEM analysis. The figure is representative of images obtained from 20 different fields for each group and from three independent experiments. The bar represents 3 μm. EPS secretion is indicated by an arrow. b Mineral oil increases EPS secretion. EPS produced by Pseudomonas sp. AKS2 under different experimental conditions were measured by the conventional phenol sulfuric acid method. The result represents the average of three independent experiments. Error bars indicate standard deviation (±SD). Statistical significance between the groups was evaluated by ANOVA at 5 % significance level. Mean values with different letters (a, b, c, and d) are significantly different among treatments. c Microbial activity profile. The extent of microbial activity of Pseudomonas sp. AKS2 biofilm on the LDPE recovered from different growth media was monitored by FDA hydrolysis assay. Squares indicate medium with mineral oil, triangles indicate medium with Tween 80, and diamonds indicate medium without mineral oil or Tween 80. The result represents the average of three independent experiments. Error bars indicate standard deviation (±SD). d Effect of mineral oil and Tween 80 on bacterial biomass on the LDPE surface. The extent of Pseudomonas sp. AKS2 biomass on LDPE films under different treatments was quantified by measuring total protein extracted from the biofilm. Squares indicate medium with mineral oil, triangles indicate medium with Tween 80, and diamonds indicate medium without mineral oil or Tween 80. Three replicates have been used for each treatment. The result represents the average of these three replicates. Error bars indicate standard deviation (±SD)

Taken together, our results show that the addition of mineral oil results in a higher level of bacterial attachment to the LDPE surface and induces the formation of a biofilm that eventually results in enhanced degradation of LDPE. Thus, the formation of a biofilm may be a major contributing factor in the increased efficiency of LDPE degradation by Pseudomonas sp. AKS2 in the presence of mineral oil in the medium. It is also known that bacteria changed their size and shape when they form a biofilm. Consistent with it, we have also observed that Pseudomonas sp. AKS2 underwent a significant reduction in their size and shape in a biofilm (Fig. 4a).

Discussion

In this study, we report the degradation of LDPE by mesophilic bacteria Pseudomonas sp. AKS2. We have observed that Pseudomonas sp. AKS2 can degrade LDPE up to 5 ± 1 % after 45 days of incubation without any prior oxidation of LDPE by thermal treatment, acids, and/or UV irradiation, and this degradation can be increased up to 14 ± 1 % with the addition of mineral oil to the growth medium. This is in contrast to the previously published reports showing very slow degradation of LDPE and an enhancement of this degradation only after LDPE was subjected to prior oxidation (Chatterjee et al. 2010; Albertsson et al. 1998; Roy et al. 2008). Thus, compared to previous reports, the rate of LDPE degradation by Pseudomonas sp. AKS2 is very high, even without the use of prior oxidation. This higher rate of degradation can partly be attributed to the high surface hydrophobicity of Pseudomonas sp. AKS2. In general, hydrophobicity of polyethylene prevents bacterial adhesion to its surface as most bacterial surfaces are hydrophilic. However, in a previous report, we have shown that the cell surface of Pseudomonas sp. AKS2 is highly hydrophobic (Tribedi et al. 2012). This cell surface hydrophobicity results in increased attachment of Pseudomonas sp. AKS2 to the surface of the hydrophobic polymer LDPE. Consistently, we have also observed that agents like mineral oil and Tween 80, capable of modulating hydrophobic interaction between polythene and organism, influence both the bacterial adherence and the degradation of polymer.

Bacterial biofilm formation can be influenced by the cellular surface hydrophobicity (Gilan et al. 2004; Balasubramanian et al. 2010). Consistently, in the present study, we have found the formation of a dense layer of biofilm and concomitant enhancement of biodegradation in the presence of mineral oil in the medium. The link between biofilm formation and enhanced degradation is further supported by our observation that Tween 80, which prevents bacterial attachment to the polymer surface, prevents biofilm formation and lowers the rate of LDPE degradation. The formation of a biofilm provides the organism a milieu conducive for better execution of biodegradation. Thus, mineral oil not only helps the bacterium to better attach to the polymer film but also accelerates the formation of a biofilm on the polymer surface and thus contributes to a great extent to the higher degradation of the polymer. In our previous study, we have shown that the rate of degradation of another polymer, PES, decreases by a different Pseudomonas with lower surface hydrophobicity (Tribedi et. al. 2012). Taken together, it can be concluded that hydrophobic interactions between Pseudomonas sp. AKS2 and the synthetic polymers play an important role in the degradation of the latter.

It is known that the shape and size of bacteria undergo alteration upon biofilm formation. Consistently, we have observed a reduction in the size of Pseudomonas sp. AKS2 in the biofilm. This change in size could be a cellular response to the change in surface topography of the LDPE film during degradation whereby pits are formed on the film surface due to enzymatic digestion. The reduction in bacterial size is likely to facilitate the access of Pseudomonas sp. AKS2 to the grooves and patches on the polymer that would otherwise be inaccessible to it in its original size. Thus, the observed size reduction may be a cellular adaptation that provides this bacterium a better access to the available nutrients in its surroundings and contributes to better degradation of the polymer.

The AFM micrographs demonstrate localized degradation of the polyethylene around the bacterial cells in the biofilm, resulting in the formation of grooves in the treated polyethylene after the incubation with Pseudomonas sp. AKS2. It is likely that Pseudomonas sp. AKS2 produces unique enzymes capable of degrading polyethylene, and such enzymatic activities result in the formation of grooves. Since Pseudomonas sp. AKS2 can degrade LDPE even without prior oxidation, it is possible that Pseudomonas sp. AKS2 harbors enzyme(s) capable of oxidizing alkene bonds to carbonyls and/or carboxylic acids and thus eliminates the requirement of prior oxidation. Such an enzyme has already been reported by Yoon and coworkers wherein they showed that alkane hydroxylase enzyme (alkB) from Pseudomonas played an important role in LDPE degradation (Yoon et al. 2012). Further investigation is required to elucidate the underlying mechanism of LDPE degradation by Pseudomonas sp. AKS2.

Conclusion

In conclusion, the current study demonstrates degradation of LDPE by a mesophilic microbe, Pseudomonas sp. AKS2, that does not require prior oxidation. It indicates the presence of unique enzymatic activities in Pseudomonas sp. AKS2. Apart from the enzymatic activities, the better degradation of LDPE by Pseudomonas sp. AKS2 can also be attributed to its ability to form a biofilm wherein the hydrophobicity of the cell surface may play an important role.

References

Albertsson AC (1978) Biodegradation of synthetic polymers: 2. Limited microbial conversion of C-14 in polyethylene to (CO-2)-C-14 by some soil fungi. J Appl Polym Sci 22:3419–3433

Albertsson AC (1980) The shape of the biodegradation curve for low and high density polyethylenes in prolonged series of experiments. Eur Polym J 16:623–630

Albertsson AC, Erlandsson B, Hakkarainen M, Karlsson S (1998) Molecular weight changes and polymeric matrix changes correlated with the formation of degradation products in biodegraded polyethylene. J Environ Polym Degrad 6:187–195

Balasubramanian V, Natarajan K, Hemambika B, Ramesh N, Sumathi CS, Kottaimuthu R, Rajash KV (2010) High-density polyethylene(HDPE)-degrading potential bacteria from marine ecosystem of Gulf of Mannar, India. Lett Appl Microbiol 51:205–211

Byuntae L, Anthony LP, Alfred F, Theodore BB (1991) Biodegradation of degradable plastic polyethylene by Phanerocheate and Streptomyces species. Appl Environ Microbiol 57:678–688

Chatterjee S, Roy B, Roy D, Banerjee R (2010) Enzyme-mediated biodegradation of heat treated commercial polyethylene by staphylococcal species. Polym Degrad Stab 95:195–200

Cornell JH, Kaplan AM, Rogers MR (1984) Biodegradation of photooxidized polyalkylenes. J Appl Polym Sci 29:2581–2597

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Gilan I, Hadar Y, Sivan A (2004) Colonization, biofilm formation and biodegradation of polyethylene by a strain of Rhodococcus ruber. Appl Microbiol Biotechnol 65:97–104

Killham K, Staddon WJ (2002) Bioindicators and sensors of soil health and the application of geostatistics. In: Burns RG, Dick R (eds) Enzymes in the environment: activity, ecology and applications. Marcel Dekker, New York, pp 391–405

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Otake Y, Kobayashi T, Ashbe H, Murakami N, Ono K (1995) Biodegradation of low density polyethylene, polyvinyl-polyvinyl-chloride and urea-formaldehyde resin buried under soil for over 32 years. J Appl Polym Sci Symp 56:1789–1796

Potts JE (1978) Biodegradation. In: Jelinek HHG (ed) Aspects of degradation and stabilization of polymers. Elsevier, New York, pp 617–658

Roy PK, Titus S, Surekha P, Tulsi E, Deshmukh C, Rajagopal C (2008) Degradation of abiotically aged LDPE films containing pro-oxidant by bacterial consortium. Polym Degrad Stab 93:1917–1922

Soni R, Kapri A, Zaidi MGH, Goel R (2009) Comparative biodegradation studies of non-poronized and poronized LDPE using indigenous microbial consortium. J Environ Polym Degrad 17:233–239

Tansengco ML, Tokiwa Y (1998) Thermophilic microbial degradation of poly (ethylene succinate). World J Microbiol Biotechnol 14:133–138

Teng Y, Luo Y, Sun M, Liu Z, Li Z, Christie P (2010) Effect of bioaugmentation by Paracoccus sp. strain HPD-2 on the soil microbial community and removal of polycyclic aromatic hydrocarbons from an aged contaminated soil. Bioresour Technol 101:3437–3443

Tribedi P, Sarkar S, Mukherjee K, Sil AK (2012) Isolation of a novel Pseudomonas sp from soil that can efficiently degrade polyethylene succinate. Environ Sci Pollut Res 19:2115–2124

Volke-Sepulveda T, Saucedo-Castaneda G, Gutierrez-Rojas M, Manzur A, Favela-Torres E (2002) Thermally treated low density polyethylene biodegradation by Penicillium pinophilum and Aspergillus niger. J Appl Polym Sci 83:305–314

Yoon GM, Jeon JH, Kim NM (2012) Biodegradation of polyethylene by a soil bacterium and AlkB cloned recombinant cell. J Bioremed Biodegrad 3:145. doi:10.4172/2155-6199.1000145

Zahra S, Abbas SS, Mahsa MT, Mohsen N (2010) Biodegradation of low-density polyethylene (LDPE) by isolated fungi in solid waste medium. Waste Manag 30:396–401

Acknowledgments

The authors would like to thank Dr. Srimonti Sarkar for critical reading of the manuscript. PT is supported by CSIR-Senior Research Fellowship, Government of India. AFM facility was availed at central instrumental facility under DBT-IPLS program at University of Calcutta. This work is supported partly by a grant in aid for scientific research from the Department of Biotechnology, Government of West Bengal, India.

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Robert Duran

Rights and permissions

About this article

Cite this article

Tribedi, P., Sil, A.K. Low-density polyethylene degradation by Pseudomonas sp. AKS2 biofilm. Environ Sci Pollut Res 20, 4146–4153 (2013). https://doi.org/10.1007/s11356-012-1378-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-012-1378-y