Abstract

Reduced elasticity and high stickiness of gluten-free bread doughs are major issues regarding the industrial breadmaking process. In this work, we compared traditional batch mixing with a revised continuous extrusion process and extensively study the rheological properties of both doughs. Shear viscosities were measured offline with a capillary rheometer and inline at the extruder die over a large range of apparent shear rates. Data were corrected for entrance effects, wall slip and non-Newtonian flow behaviour. Good agreement between inline and offline measured viscosities were supplemented by amplitude and frequency sweep tests. The results highlight that this extrusion process fostered the production of gluten-free bread dough. We demonstrated that extrusion processing support the combined mixing, kneading, and moulding of gluten-free dough in one single unit. This fundamental study linked physical dough characterization with applied engineering and yielded the understanding and processing of corresponding products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dough rheology plays a crucial role for the bakery industry since it strongly influences the quality of the final products. It is recognized as a valuable tool in terms of quality control, product development, process optimization and upscaling (Faridi and Faubion 1990; Cauvain 2015; Hesso et al. 2015). Many methods are available to rheologically describe the complex flow behaviour of conventional dough formulations. But still, it is a big task to link measurement data to relevant process applications or product properties (Dobraszczyk and Morgenstern 2003; Bagley et al. 1998). Particularly for gluten-free bread dough, it is challenging due to the different material properties (Arendt et al. 2008). Gluten-free doughs often contain a higher water content, cannot form a gluten network and have a reduced elasticity. On the one hand, this means that processes which are traditionally designed for gluten-containing products cannot simply be transferred to gluten-free products. On the other hand, novel processing technologies may be opened by this fact.

Dough preparation includes processes like mixing, kneading, rolling, fermenting, and extruding. During each step the material undergoes deformations at different strain rates, both in shear and elongational flow (Menjivar 1990; Poinot et al. 2008). In order to characterize the rheological properties at equivalent conditions, suitable instruments have to be selected. In the cereal industry empirical methods are frequently used to characterize the material. They serve descriptive information relevant to processing and quality control but are lacking in providing fundamental rheological data (Dobraszczyk and Morgenstern 2003).

One widely used and fundamental technique is dynamic oscillatory rheometry. A lot of studies are available applying this method to dough and batters for both, gluten-containing (Phan-thien et al. 1997; Uthayakumaran et al. 2002; Migliori et al. 2011) and gluten-free (Lazaridou et al. 2007; Pruska-Kedzior et al. 2008) formulations.

One disadvantage of oscillatory shear tests is that they are designed for small strain experiments in the order of 0.1–5%. But strains at different processes of bread making can vary a lot. During kneading and extrusion deformations up to 500,000% can occur. (Menjivar 1990; Dobraszczyk and Morgenstern 2003). Despite the obvious importance of linking rheological properties to particular process operations, there are only a few fundamental studies on large deformations in the non-linear viscoelastic regime. Recent research papers focused on large amplitude oscillatory shear LAOS tests providing useful information about the rheological properties at large strains (Hyun et al. 2011; Yazar et al. 2016).

Another very common method to measure the viscosity of highly viscous polymer melts at large deformations is capillary rheometry. This method yields fundamental information about the viscosity in shear and extensional flow and is closely related to industrial applications (Braun and Mennig 1996; Geiger 1989; Pabedinskas et al. 1991). Some publications proved a successful transfer of capillary rheometry to food materials, especially dough and starch based models (Corfield et al. 1999; Bagley et al. 1998; Aichholzer and Fritz 1998; Cuq et al. 2002; Singh and Smith 1999; Sharma et al. 1993). However, no study was found for gluten-free bread dough.

Capillary rheometers can be considered as small scale ram extruders due to the die entry flow. High-throughput extruders are widely applied in the food industry, particularly for breakfast cereals or pasta products (Luukkonen et al. 2001). In this study, a co-rotating twin-screw extruder was used as a continuous kneader mixing a gluten-free flour blend with water to form a dough. The optimal design of such a process is heavily dependent on the rheological properties of the gluten-free dough. Therefore the extruder was equipped with an inline rheometer mounted at the die. Viscosity was measured during processing over a large range of shear rates. Data were compared with measurements from a high pressure capillary rheometer for batch prepared dough.

The investigations on continuous dough preparation have a huge potential for process development, optimization, and upscaling. Especially for gluten-free dough formulations, this technology opens new possibilities for the product development of high quality bakery products. The design of related processes requires both, reliable experimental data and their transferability to the application. Accordingly, there is a big interest in linking dough rheology to dough processing from a scientific and applied engineering perspective.

In this study we characterized the rheological properties of a gluten-free bread dough with three different rheometers, namely a modular compact rheometer (MCR), a high pressure capillary rheometer (HPCR) and an inline extrusion rheometer (IER). The influence of (i) continuous preparation in a twin-screw extruder and (ii) a batch mixer on dough viscosity was compared.

Materials and methods

Dough formulation

The formulation of the model bread dough is based on a gluten-free flour blend from Zwicky Mill (E. Zwicky AG, CH) composed of rice-, corn- and buckwheat flour, glucose, corn starch, potato starch and guar gum. Based on 100 wt% of the flour blend, 1.5 wt% salt and 1.0 wt% sugar were added and remixed with the gluten-free flour blend in a drum hoop mixer. The water content of the dough formulation was 60 wt% based on 100 wt% flour.

Batch preparation

For the batch preparation water was tempered to 32 °C which allowed a constant dough temperature of 30 ± 1 °C for all trials. All ingredients, calculated for 1000 g of flour mix were mixed in a kneader (N50, Hobart GmbH, DE) for 1 min at level 1 and 3 min at level 2. Before the measurements, samples were allowed to rest for 10 min and were covered with a plastic bag to prevent moisture loss.

Continuous preparation

Dough was mixed and kneaded in a co-rotating twin-screw extruder (OEVB 30, Bühler AG, CH) with 11 heads, a barrel diameter D of 30 mm and a LS/DS ratio of 44. Each extruder head was equipped with a cooling/heating device, pressure transducers and sensors for barrel and product temperature. An end plate was mounted at the last head of the barrel which was temperature controlled by a water bath. The screw configuration was composed of conveying, mixing and kneading elements. The flour was loaded into the extruder via a gravimetric screw feeder (LWF D 5, K-Tron, CH) at LS/DS = 2. Water was injected by an eccentric screw pump (Nemo NM003BY11S12B, Netzsch, CH) at LS/DS = 10. The extruder was operated at 50 min−1. The total throughput was set to 7.3 kg/h. According to the dough formulation, the flow rates of the flour mix and water were set to 4.5 and 2.8 kg/h, respectively. The basic extrusion setup is illustrated in Fig. 1.

Oscillatory rheometer

Dynamic oscillatory measurements were performed using a Modular Compact Rheometer (MCR 300, Physica Messtechnik GmbH, Germany) with a rough plate-plate (PP 25) geometry. A dough sample of 5 g was placed immediately after dough preparation in the rheometer. The sample was compressed to a gap size of 2 mm. After the excess had been trimmed with a razor blade, a layer of liquid paraffin was brushed onto the edge of the sample to prevent moisture loss. Amplitude sweeps and frequency sweeps were carried out at 20 °C.

High pressure capillary rheometer (HPCR)

A High Pressure Capillary Rheometer (Rheograph 2002, Goettfert Werkstoff-Prüfmaschinen GmbH, Germany) was used to determine the viscosity of gluten-free bread dough at high shear rates as they appear in the twin-screw extruder die. About 70 g model dough was filled into a temperature controlled reservoir with a radius R of 10 mm. A cylindrical capillary die of known diameter D and length L was mounted at the bottom of the reservoir. A piston was used to extrude the sample with a constant velocity v through the die and the extrusion pressure p was measured at the die entrance with a pressure transducer (ECHO™ 0–100 bar, Dynisco Inc., USA). The volumetric flow rate was calculated as follows:

A set of capillary dies of different length to diameter ratios was used to perform Bagley, Mooney and Weissenberg–Rabinowitsch corrections as described in the results chapter. Steady shear stress was measured at 20 °C as a function of the shear rate.

Inline extrusion rheometer (IER)

The measuring principle of the Inline Extrusion Rheometer is similar to the HPCR. Extrusion pressure and volumetric flow rate are measured and used to calculate shear stress and shear rate in the capillary die and to subsequently obtain viscosity data of the material. The experimental die assembly was manufactured in the institute’s workshop (IFNH, ETH Zurich, CH) and was mounted to the end plate to of the extruder. The inline produced dough was extruded through cylindrical dies differing in length and diameter. Extrusion pressure was measured at the end plate of the extruder with a pressure transducer (ECHO™ 0–100 bar, Dynisco Inc., USA). Right before the end plate a bypass with a valve was fixed at the extruder barrel. The valve was utilized to vary bypass and die flow. The mass flow rate was measured by weighing the material outflow during 5 min time intervals at steady state extrusion conditions. The volumetric flow rate was calculated as follows:

where ρ is the dough dennsity of 1200 g/L. Die pressure was recorded and averaged over 10 min for each measurement point. According to the HPRC measurements, dies with different L/D ratio were used for further flow corrections. Extruder barrel and end plate were cooled to ensure a product temperature of 20 °C at the exit.

Results and discussion

Oscillatory flow

Mixing and kneading are unit operations in dough processing where the structure is formed and final product quality is determined. Mixer design, mixing time, and mechanical energy input are crucial parameters influencing rheology, texture and baking performance of the dough (Dobraszczyk and Morgenstern 2003; Cuq et al. 2002). Dynamic oscillatory shear tests are commonly applied in cereal industry to assess flour and dough quality. They are useful for understanding the relationship between microstructure and rheological properties (Hyun et al. 2011; Phan-Thien et al. 1997). In this study, it is used for material characterization and quality control.

Region of linear viscoelasticity

Amplitude sweep tests were performed for batch and continuously prepared gluten-free bread dough. As the applied amplitude increases from small to large deformation at a fixed frequency, a transition between the linear and nonlinear viscoelastic regimes appears. In Fig. 2 the viscoelastic response is quantified by the elastic storage modulus G′ and the viscous loss modulus G″ at a frequency of 10 rad/s. In the linear viscoelastic regime (LVE regime), moduli are independent of strain amplitude. The plateau values in the LVE-regime were derived for the batchwise mixed dough (G′Batch = 9.2*104 Pa; G″Batch = 2.7*104 Pa) and the continuously mixed dough (G′Conti = 7.0*104 Pa; G″Conti = 1.9*104 Pa). Values for the storage modules are higher than those of the loss modules which indicate a viscoelastic, gel-like behavior of both dough types. With increasing strain amplitude the nonlinear regime appears, where the moduli are functions of the strain amplitude and a breakdown of the structure occurs. For batchwise and continuously prepared dough, the LVE regime ends at deformations of γBatch = 0.055% and γConti = 0.071%, respectively. Both values are in the same order of magnitude with indicates a high comparability of both dough types. Similar values were reported by Lazaridou et al. (2007) and Demirkesen et al. (2010) for wheat flour doughs that exhibit linear viscoelasticity at strain levels lower than 0.1 and 0.5%. The shear stress values for both doughs examined at the end of the LVE-regime are τBatch = 56 Pa and τConti = 52 Pa and were taken into account for the setting of successive frequency sweep tests.

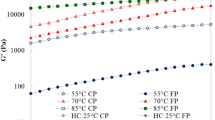

Frequency sweep tests

Based on the amplitude sweep tests, subsequent oscillatory measurements were performed at a constant shear stress of 50 Pa to ensure a linear viscoelastic response. In Fig. 3 moduli G′ and G″ and the complex viscosity |η*| are plotted as functions of the frequency for batchwise and continuously prepared dough. The complex viscosity decreases with increasing frequencies indicating a shear thinning flow behavior.

Both amplitude sweep and frequency sweep tests show similar curves for continuous and batch prepared gluten-free bread dough where the values for the continuous prepared dough are slightly lower. This finding indicates that the preparation mode only has small influence on the rheological properties of gluten-free dough. In turn, this means that the extrusion process does not alter the dough structure or changes its rheological properties. It is not self-evident since extrusion is a very complex process where structures might get modified due to different mechanical energy input.

Capillary flow

This section deals with the flow of gluten-free bread dough in axisymmetric capillary flow measured with a high pressure capillary rheometer and an inline rheometer. For the HPCR the dough was prepared in a batch mixer and for the IER the dough was prepared in an extruder. The measuring principle for both rheometers is the same.

Gluten-free bread dough is extruded through dies of various diameters and lengths. A pressure transducer measures the extrusion pressure p before the contraction between the reservoir barrel and the capillary die. In the HPCR, the volumetric flow rate is defined by the piston speed, whereas in the IER the flow rate is driven by throughput and screw speed.

The pressure drop is a function of die geometry, throughput, temperature and the rheological properties of the material (Pabedinskas et al. 1991).

Pressure drop and volumetric flow rate data were used to determine the wall shear stress and the wall shear rate in the capillary die. In order to secure a consistent dough quality it is important that formulation and process conditions are stable and reproducible. One measure for process stability in extrusion is the die pressure. Die pressure was measured over a time period of 10 min for different throughput rates. The volumetric flow rate through the die was set by a bypass valve. With increasing throughput, higher pressures can be observed. For the selected process conditions only minor pressure fluctuations were noticed. This indicates a stable process which is relevant for consistent dough quality. The maximum flow rate for this die configuration of 80 mm length and 20 mm diameter was 6 dm3/h. Throughputs higher than 6 dm3/h would pronounce pressure fluctuations and impede serious rheological measurements.

Of course, pressure fluctuations also occur in piston driven capillary rheometers as studied by several authors (Hicks and See 2010; Sofou et al. 2008). But in contrast to IER this phenomenon is less distinct in HPCR. This can be referred to the exact control of the volumetric flow rate by the specified ram velocity. By contrast, variations in the filling degree of the extruder screws may involve fluctuations in the die flow. Hence, the inline analysis in the extruder is more complex and limited to a certain range of flow rates.

For capillary flow, the apparent shear stress τ is calculated from the experimentally measured extrusion pressure difference Δp and the capillary die aspect ratio L/D:

The apparent shear rate for cylindrical pipe flow is defined as:

Figure 4 shows the apparent flow curves of gluten-free bread dough for 1 mm capillary dies with L/D ratios 10, 15, 20 and 30 measured with the HPCR. A dependency on the L/D ratio can be found. The shear stress decreases with increased L/D ratio. The same trend was observed for the IER measurements. For the IER the range of applied apparent shear rates are limited to 200–2000 s−1. This range is comparable to shear rates experienced in the bread industry (Bloksma 1990).

Corrections to capillary flow

Gluten-free dough is a viscoelastic, non-Newtonian fluid which undergoes elongational flow before it enters a capillary die. The contraction causes a funnel shaped entry flow. Due to the entrance pressure drop, wall slip phenomena, and non-Newtonian flow behaviour, the following three corrections to capillary flow were applied: Bagley, Mooney and Weissenberg–Rabinowitsch correction.

The velocity variations in the direction of the flow cannot be neglected and the pressure drop over the length of steady fully developed flow in the capillary is unknown. The Bagley correction is a common method to correct the measured pressure drop across the capillary die due to the die entrance and exit flow of the material (Bagley 1957; Bagley et al. 1998). Bagley plots for HPCR and IER dough are constructed by plotting the extrusion pressure against the L/D ratio for different apparent shear rates (Fig. 5).

According to Bagley (1957) linear functions of L/D ratio were chosen and extrapolated to L/D = 0. Experimental data are well described for both types of dough, which indicates a negligible effect of pressure on dough viscosity. Linear correlations for wheat flour bread dough were reported by other authors (Kieffer et al. 1982; Cuq et al. 2002), where a non-linear correlation was assumed by Breuillet et al. (2002). So far no data was found for gluten-free bread dough.

The intercept of the ideally line corresponds to the sum of entrance and exit pressure loss and represents the corrected end pressure Δpc. With this, the wall shear stress τw can be calculated by a modified equation:

One common phenomenon in capillary flow is the occurence of wall slip. Wall slip effects can be described as discontinuities in the velocity profile close to the wall. For flow processes with wall slip effects the total volumetric flow rate can be divided into parts of shearing and slipping (Mooney 1931; Aichholzer and Fritz 1998). For the determination of the true viscosity, the apparent shear rate has to be corrected. For slip correction according to Mooney (1931), measurements with dies of the same L/D ratio and various diameters are needed. Such Mooney plots were plotted for various dies with a length to diameter ratio L/D = 10 measured with the HPCR. The apparent shear rate was plotted against the reciprocal capillary radius 1/R, wherein the values correspond to a constant wall shear stress. The traditional Mooney plot is based on a linear correlation between the apparent shear rate and 1/R. It is assumed that the slip velocity vs is only dependent on the wall shear stress τw. In this case, the slope of of the plot is equal to four times the value of the slip velocity (Mooney 1931; Mourniac et al. 1992). As previously reported by different authors (Aichholzer and Fritz 1998; Sofou et al. 2008; Hicks and See 2010) a linear plot would lead to negative apparent shear rates for dough-like materials. Therefore a modified, semi-logarithmic Mooney plot was applied according to Geiger (1989). Accordingly, slip velocities were derived from the Mooney corrections and were implemented into the corrected viscosity functions for both rheometer types.

As mentioned earlier in this paper, gluten-free bread dough is a non-Newtonian fluid with a shear thinning flow behaviour. Applying the Weissenberg–Rabinowitsch correction (Eisenschitz et al. 1929) the non-parabolic flow behaviour is taking into account and the wall shear rate τw can be determined as follows:

where \( \dot{\varvec{\gamma }}_{{\varvec{a},\varvec{s}}} \) is the slip-corrected, apparent shear rate and b is defined as:

In Fig. 6 the calculated and corrected viscosity is plotted against the wall shear rate for both rheometers at two different length to diameter ratios. For the range of 1–4000 s−1 the shear thinning flow behaviour of gluten-free dough can be approximated with a power law model, which can be written as:

where K and n are the consistency and the power-law indices. R2 describes the coefficient of determination. The indices were determined as follows: KHPCR = 2378, nHPCR = 0.28, R 2 HPCR = 0.99. KIER = 1335, nIER = 0.33, R 2 IER = 0,99. The power-law index emphasizes the shear thinning behaviour. These values are lower compared to results from capillary rheometry on gluten-containing dough (Cuq et al. 2002; Hicks and See 2010). However, in this study measurements were carried out at 20 °C, while other researchers did their measurements at 25 °C. Two possible reasons were identified for the lower values. Firstly, some of these papers did not correct the data for wall slip, thus resulting in higher values for n. Secondly, gluten-free bread dough has a less strong connected network due to the absence of the gluten protein.

The values for both rheometers and both L/D ratios are in the same order of magnitude and are showing the same trend. For the HPCR the influence of the L/D ratio on the viscosity function is negligibly small whereas a lower viscosity is found for increased L/D for the IER measurements. In general, the inline prepared dough in the extruder seems to have a slightly lower viscosity than the batch prepared dough.

Conclusion

Batch and continuously prepared gluten-free bread doughs are rheologically investigated in oscillatory and capillary shear flow. The influence of the preparation mode on dough viscosity is examined using a high pressure capillary rheometer (HPCR) and an inline extrusion rheometer (IER). Shear viscosities of continuously and batchwise mixed bread doughs are in good agreement. This shows that the rheological properties are largely independent of the selected kneading process. It can be summarized that under given process conditions, the mechanical treatment in the screws does not negatively alter the dough. This information is of high importance with regard to the industrial processing of gluten-free dough as it supports design and implementation of related processes. Concluding, the HPCR can be regarded as a small scale ram extruder in order to predict the flow behaviour of gluten-free bread dough in the extruder die. It serves fundamental rheological data over a wide range of deformations and can be closely linked to extrusion applications. The advantage of the IER is the possibility to measure the viscosity without any delay. The extrusion process can be directly controlled and tuned via throughput and pressure measurements. The outcome of the combined analysis supports optimization, development, and upscaling of related processes, such as the continuous production of gluten-free bread dough using extrusion technology.

References

Aichholzer W, Fritz HG (1998) Rheological characterization of thermoplastic starch materials. Starch Stärke 50:77–83

Arendt EK, Morrissey A, Moore MM, Dal Bello F (2008) Gluten-free breads. In: Arendt EK (ed) Gluten-free cereal products and beverages. Academic Press, USA, pp 110–119

Bagley EB (1957) End corrections in the capillary flow of polyethylene. J Appl Phys 28:624–627

Bagley EB, Dintzis FR, Chakrabarti S (1998) Experimental and conceptual problems in the rheological characterization of wheat flour doughs. Rheol Acta 37:556–565

Bloksma A (1990) Rheology of the breadmaking process. Cereal Foods World 35:228–236

Braun P, Mennig G (1996) In-line-Rheometrie durch direkte Wandschubspannungsermittlung. Die Angew Makromol Chem 238:73–86

Breuillet C, Yildiz E, Cuq B, Kokini JL (2002) Study of the anomalous capillary Bagley factor behavior of three types of wheat flour doughs at two moisture contents. J Texture Stud 33:315–340

Cauvain SP (2015) Breadmaking Processes. In: Cauvian SP, Young LS (eds) Technology of Breadmaking. Springer, Berlin, pp 23–55

Corfield G, Adams M, Briscoe B, Fryer P, Lawrence C (1999) A critical examination of capillary rheometry for foods (exhibiting wall slip). Food Bioprod Process 77:3–10

Cuq B, Yildiz E, Kokini JL (2002) Influence of mixing conditions and rest time on capillary flow behavior of wheat flour dough. Cereal Chem 79:129–137

Demirkesen I, Mert B, Sumnu G, Sahin S (2010) Rheological properties of gluten-free bread formulations. J Food Eng 96:295–303

Dobraszczyk B, Morgenstern M (2003) Rheology and the breadmaking process. J Cereal Sci 38:229–245

Eisenschitz R, Rabinowitsch B, Weissenberg K (1929) Zur Analyse des Formänderungswiderstandes. Mitteilungen der deutschen Materialprüfungsanstalten. Springer, Berlin, pp 91–94

Faridi H, Faubion JM (1990) Dough rheology and baked product texture. Van Nostrand Reinhold, New York

Geiger K (1989) Rheological characterization of EPDM rubber compounds with high-pressure capillary rheometer systems. Kautsch Gummi Kunstst 42:273–283

Hesso N, Loisel C, Chevallier S, Marti A, Le-Bail P, Le-Bail A, Seetharaman K (2015) The role of ingredients on thermal and rheological properties of cake batters and the impact on microcake texture. LWT Food Sci Technol 63:1171–1178

Hicks C, See H (2010) The rheological characterisation of bread dough using capillary rheometry. Rheol Acta 49:719–732

Hyun K, Wilhelm M, Klein CO, Cho KS, Nam JG, Ahn KH, Lee SJ, Ewoldt RH, McKinley GH (2011) A review of nonlinear oscillatory shear tests: analysis and application of large amplitude oscillatory shear (LAOS). Prog Polym Sci 36:1697–1753

Kieffer R, Kim J, Kempf M, Belitz HD, Lehmann J, Sprößler B, Best E (1982) Untersuchung rheologischer Eigenschaften von Teig und Kleber aus Weizenmehl durch Kapillarviscosimetrie. Zeitschrift für Lebensmittel-Untersuchung und Forschung 174:216–221

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis C (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in glutenfree formulations. J Food Eng 79:1033–1047

Luukkonen P, Newton JM, Podczeck F, Yliruusi J (2001) Use of a capillary rheometer to evaluate the rheological properties of microcrystalline cellulose and silicicated microcrystalline cellulose wet masses. Int J Pharm 216:147–157

Menjivar J (1990) Fundamental aspects of dough rheology. In: Faridi H, Faubion JM (eds) Dough rheology and baked product texture. Van Nostrand Reinhold, New York, pp 1–29

Migliori M, Gabriele D, Baldino N, Lupi FR, De Cindio B (2011) Rheological properties of batter dough: effect of egg level. J Food Process Eng 34:1266–1281

Mooney M (1931) Explicit formulas for slip and fluidity. J Rheol 2:210–222

Mourniac P, Agassant JF, Vergnes B (1992) Determination of the wall slip velocity in the flow of a SBR compound. Rheol Acta 31:565–574

Pabedinskas A, Cluett WR, Balke ST (1991) Development of an in-line rheometer suitable for reactive extrusion processes. Polym Eng Sci 31:365–375

Phan-Thien N, Safari-Ardi M, Morales-Patiño A (1997) Oscillatory and simple shear flows of a flour-water dough: a constitutive model. Rheol Acta 36:38–48

Poinot P, Arvisenet G, Grua-Priol J, Colas D, Fillonneau C, Le-Bail A, Prost C (2008) Influence of formulation and process on the aromatic profile and physical characteristics of bread. J Cereal Sci 48:686–697

Pruska-Kedzior A, Kedzior Z, Goracy M, Pietrowska K, Przybylska A, Spychalska K (2008) Comparison of rheological, fermentative and baking properties of gluten-free dough formulations. Eur Food Res Technol 227:1523–1536

Sharma N, Hanna M, Chen Y (1993) Flow behavior of wheat flour-water dough using a capillary rheometer. I. effect of capillary geometry. Cereal Chem 70:59–63

Singh N, Smith AC (1999) Rheological behaviour of different cereals using capillary rheometry. J Food Eng 39:203–209

Sofou S, Muliawan E, Hatzikiriakos S, Mitsoulis E (2008) Rheological characterization and constitutive modeling of bread dough. Rheol Acta 47:369–381

Uthayakumaran S, Newberry M, Phan-Thien N, Tanner R (2002) Small and large strain rheology of wheat gluten. Rheol Acta 41:162–172

Yazar G, Duvarci O, Tavman S, Kokini JL (2016) Non-linear rheological properties of soft wheat flour dough at different stages of farinograph mixing. Appl Rheol 26:1–11

Acknowledgements

The financial support by Swiss Commission of Technology and Innovation (CTI) under contract number 13615.1 PFFLR-LS is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lammers, V.R.G., Wolf, P. & Windhab, E.J. The rheology of batch and continuously prepared gluten-free bread dough in oscillatory and capillary shear flow. J Food Sci Technol 55, 3077–3084 (2018). https://doi.org/10.1007/s13197-018-3231-x

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3231-x