Abstract

There is still considerable debate in the literature about the respective roles of starch and gluten in both the linear and non-linear rheology of wheat flour dough. Hence, to elucidate the individual contributions of gluten and starch to the overall dough behaviour, the rheological properties of dough and mixtures of different gluten-starch ratios were studied systematically in shear and extension, by means of an adequate rheological toolbox consisting of linear small amplitude oscillatory shear tests and non-linear tests such as creep-recovery in shear and uniaxial extension. The starch component plays a pivotal role in linear dough rheology. With increasing starch content, the linearity limit observed in oscillatory shear tests decreases as a power-law function. Starch also clearly affects the extensional viscosity at small strains. Consequently, in the linear region differences between different gluten systems may become obscured by the presence of starch. As breadmaking qualities are known to be intrinsically linked to the gluten network, it is imperative to probe the non-linear behaviour of dough in order to expose differences in flour quality. The quality differences between a strong and a weak flour type were revealed most clearly in the value of the strain-hardening index in uniaxial extension and the total recovery compliance in non-linear creep-recovery tests. Notwithstanding its earlier successful application to pure gluten gels, the accuracy of the critical gel model in predicting the linear rheological properties of dough was found to be limited, due to dough having a small linearity limit and a finite longest relaxation time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Among the cereal flours, only wheat flour has the ability to form a viscoelastic dough that is able to retain gas, which is crucial for the production of light, leavened products (Goesaert et al. 2005). Wheat flour dough is a composite material, consisting of a continuous protein phase, in which starch granules, lipids and gas cells are dispersed (Bloksma 1990). About 85 wt% of the proteins contained in wheat are gluten proteins (Jekle and Becker 2015). When mixed with water, these gluten proteins will swell and interact with each other, leading to the formation of a gluten network that gives wheat flour dough its distinct viscoelastic nature (Goesaert et al. 2005). Based on their extractability in aqueous alcohols, the gluten proteins can be subdivided into two categories, gliadins and glutenins, which occur in roughly equal amounts (Veraverbeke and Delcour 2002). The gliadins are single-chained proteins with a molar mass between 30,000 and 75,000 g/mol. The molar mass of the glutenin fraction ranges from about 50,000 g/mol upwards. In contrast to the gliadins, glutenins are multi-chain structures: a glutenin molecule can be regarded as an assembly of several polypeptide chains, held together by interchain disulfide (SS) bonds (Jekle and Becker 2015). The starch granules come in two types and sizes: the lenticular starch granules have a longest dimension of approximately 25 to 40 μm, whereas the spherical granules have a diameter of 5–10 μm (Delcour and Hoseney 2010).

The breadmaking performance of wheat flours is largely determined by the gluten network, and may differ significantly from one wheat variety to another. In addition to gluten quantity, gluten quality was also found to be an important factor (Veraverbeke and Delcour 2002). Differences in gluten quality are mostly related to differences in glutenin quality (Kontogiorgos 2011). An insufficient amount of high molecular weight glutenins will result in a loss of dough cohesiveness and elasticity, whereas a too high amount of these long protein chains will impede the expansion of the gas cells. In both cases, only very small bread volumes will be obtained. In addition, gluten quality may also be affected by the glutenin-gliadin ratio, which determines the balance between dough elasticity and viscosity (Veraverbeke and Delcour 2002).

It is widely recognised that the rheological properties of dough are somehow related to the final product quality (for a good overview of the commonly used rheological test methods for dough and some typical results, see Dobraszczyk and Morgenstern2003). Dough is known to behave as a relatively weak physical gel of a predominantly elastic nature (Gabriele et al. 2001). The complex dough microstructure also gives rise to highly non-linear, thixotropic behaviour. In uniaxial and biaxial extension, dough typically exhibits substantial strain-hardening, which is the main reason for the general belief that dough behaviour is primarily determined by the gluten network, even though several studies have hinted that starch (Amemiya and Menjivar 1992; Larsson and Eliasson 1997; Edwards et al. 2002; Uthayakumaran et al. 2002; Watanabe et al. 2002) and other, minor protein fractions (albumins, globulins) (Weegels et al. 1995; Tomić et al. 2013) may also play an important role. In addition, there is no consensus on the exact nature of the gluten network (Jekle and Becker 2015). In the past, it was often assumed that the entire gluten network (i.e. both the glutenin and the gliadin fractions) was mainly held together by covalent SS cross-links (Bloksma 1990). It has indeed been shown that the creation or disappearance of SS cross-links has an important effect on dough structure and properties (Veraverbeke and Delcour 2002). However, the ability of dough to flow under a constant stress in creep tests clearly indicates that either these cross-links are not permanent (Lefebvre 2006), or their contribution has been overestimated (Belton 1999). Authors adhering to the first view have suggested that SH/SS interchange reactions might allow for relative movement within the gluten matrix without compromising its stability (Bloksma 1975). The ability of the gluten network to incorporate compounds that contained either free thiol groups (Villegas et al. 1963) or disulfide bonds (Jones and Carnegie 1971) indicates that SH/SS interchange reactions do indeed occur in dough. On the contrary, the second school of thought suggests that the continuity of the gluten network also strongly depends on hydrogen bonds, hydrophobic interactions and chain entanglements (Jekle and Becker 2015; Kontogiorgos et al. 2016). The primary function of the SS cross-links would then be to hold the (unbranched) polypeptide chains together within each glutenin molecule (Bloksma 1990). According to this view, the SS cross-links are thus mainly intramolecular, whereas the glutenin molecules themselves tend to interact with each other and with the gliadin molecules mainly through non-covalent cross-links. The viscous deformation of dough can then be explained by the fact that, given the lack/low number of intermolecular covalent cross-links, the glutenin molecules are able to slide one along the other, temporarily breaking some of the non-covalent interactions (Bloksma 1990).

The glutenin molecules are certainly also largely responsible for the observed elasticity of wheat flour doughs, yet again the exact underlying mechanism is still under debate (Veraverbeke and Delcour 2002). Belton (1999) has developed an interesting molecular theory in line with the views of the second school of thought. His loop-and-train model attributes the observed elasticity of glutenin proteins to a combination of entropic and enthalpic changes associated with the creation and destruction of hydrogen bonds between the aligned glutenin subunits, thereby leading to an elastic restoring force. Edwards et al. (2003) observed that the globular gliadin proteins mainly act as a viscosity modifier, probably because they interfere with the alignment and movement of the glutenin proteins.

Finally, in view of their high concentration in the gluten network (60 vol% according to Bloksma (1990)), the starch granules can also be expected to contribute significantly to dough viscoelasticity. It has already been established that the starch particles do not merely act as an inert filler, but have the ability to interact with the gluten matrix (Yang et al. 2011). Indeed, altering the characteristics of the starch granular surface turned out to have a profound impact on the linear viscoelastic properties of dough (Larsson and Eliasson 1997; Edwards et al. 2002). Edwards et al. (2002) observed a significant reduction in dough elasticity following the partial replacement of starch granules by glass beads of similar size and shape. Dough reconstitution experiments using starches of different varietal origin revealed significant rheological differences, which highlight again the importance of the starch structure and surface characteristics (Petrofsky and Hoseney 1995). The starch-starch and starch-gluten interactions are typically of the van der Waals/hydrogen bond type, and will thus mostly be active at small distances and hence at small deformations (Amemiya and Menjivar 1992). Under large deformations, the addition of small quantities of starch to wheat flour was found to have a diluting effect on the gluten proteins, resulting in much lower shear and extensional viscosity values (Larsson et al. 2000; Uthayakumaran et al. 2002).

Although the viscoelastic properties of wheat flour doughs have already been studied by many researchers, numerous questions as well as contradictions remain. In this work, the behaviour of dough is studied with fundamental rheological techniques, rather than empirical ones. By developing a standardised rheological toolbox, the aim of this work is to contribute to the discussion on how the overall dough behaviour is influenced by the major flour constituents (gluten and starch). Although the effect of the minor protein fractions (albumins, globulins) on the dough behaviour is also still under debate (Tomić et al. 2013), this aspect is beyond the scope of the present study. As a representative example, the potential of different rheological tests to distinguish between two flours with different breadmaking performance, which is obviously of major interest for the industry, is studied. Small amplitude oscillatory shear measurements (SAOS) are used to obtain information on the dough structure in the linear region. However, from a practical point of view, these tests are not very relevant, as the deformations experienced by dough during mixing, sheeting and baking are far larger than those encountered in SAOS tests (Amemiya and Menjivar 1992). Consequently, the dough rheology is also studied under large deformations, by means of non-linear creep-recovery tests in shear, and extensional viscosity fixture (EVF) tests in uniaxial extension. As will be discussed below, the EVF setup is much more suited for applying a pure extensional flow field than the more commonly used Kieffer extensibility rig.

Materials and Methods

Materials

Two wheat flour types (Bilux and Bison) were used in this study, which were both provided by Dossche Mills (Deinze, Belgium). Compared to the Bison flour, the Bilux flour had a higher protein content (15.1 wt% vs. 12.4 wt% on a dry matter basis), a superior Farinograph mixing stability (10.8 vs. 1.0 min) and a better breadmaking potential (specific loaf volume 4.37 ± 0.19 vs. 3.27 ± 0.26 ml/g). Consequently, the Bilux flour was classified as a strong flour, and the Bison flour as a weak flour. Native wheat gluten and wheat starch were obtained from Tereos Syral (Aalst, Belgium). The commercial wheat gluten had a protein content of 77.8 wt% (dm), and the commercial wheat starch (type A) consisted mostly of lenticular particles (see Introduction). Even though the starch and gluten samples were not identical to the starch and gluten constituents in Bilux and Bison flour because of the difference in varietal origin and pretreatment, we expect their interactions to be representative. In all cases, the protein content (N × 5.7) was measured with an automated Dumas protein analysis system (EAS, VarioMax N/CN, Elt, Gouda, The Netherlands) following an adaptation of the AOAC method 990.03 (AOAC International 1995). In addition, the moisture content was determined according to AACC method 44–19.01 (AACC International 2000), and was found to be 13.4 wt%, 12.7 wt% and 6.53 wt% for Bilux, Bison and wheat gluten, respectively. All measurements were carried out in triplicate. Finally, for the breadmaking trials, commercial baker’s yeast from Algist Bruggeman (Ghent, Belgium) was used.

Dough Preparation

Apart from regular wheat flour dough, also gluten-starch mixtures were prepared to study the dough behaviour. The dough samples were formulated according to AACC method 10–10.03 using the following recipe: 9.90 g Bilux flour or 9.85 g Bison flour (equivalent to 8.6 g dry flour), 1.5 wt% sodium chloride, 6 wt% sucrose and 5.80 or 5.44 ml water for the Bilux and Bison flour, respectively. Optimal baking absorption and mixing time were determined using Farinograph (Brabender, Duisburg, Germany) and Mixograph (National Manufacturing, Lincoln, NE, USA) analyses according to AACC Methods 54-40.02 and 54-21.02 (AACC International 2000). As Amemiya and Menjivar (1992) already pointed out, comparing the properties of the different dough systems at the same consistency (torque of 500 FU) is rather arbitrary, but it is common practice in industry. All measurements were carried out in triplicate. The gluten-starch mixtures were prepared according to the same formula, but due to the excessive strength of the gluten network, it was not possible to determine the optimal water absorption with the Farinograph. Instead, for these mixtures, the amount of water needed to obtain a cohesive, well-developed sample had to be determined by trial-and-error. With increasing gluten concentration, this required higher levels of water. Furthermore, it was necessary to add some excess water to ensure that the gluten network would not become too strong for the pin bowl mixer. For 10.0 g of gluten-starch powder, the added amounts of water were as follows: 5.56 ml (for the 100 wt% starch sample); 6.06 ml (for the 10 wt%–90 wt% gluten-starch mixture); 7.26 ml (25 wt%–75 wt%); 9.86 ml (50 wt%–50 wt%); 12.36 ml (75 wt%–25 wt%) and 16.66 ml (100 wt% gluten sample).

To prepare the dough samples and the gluten-starch mixtures (with the exception of the pure gluten and pure starch samples), ingredients were mixed in a 10 g pin bowl mixer (National Manufacturing) for 3 min and 30 s. Conversely, the pure gluten samples only required 3 min of mixing, whereas the pure starch samples had to be mixed by hand (also for 3 min).

After mixing, the dough samples were shaped with a pasta machine to obtain a sample thickness of approximately 4 mm and a sample diameter larger than 40 mm. Because of the strong elastic nature of the gluten proteins, it was not possible to give the gluten-starch samples a lasting shape with the pasta machine. As an alternative, these samples were compressed in a plate press (Collin Presses Type P 200 E, Ebersberg, Germany) for 30 min (pure starch) or 2 h (pure gluten and gluten-starch combinations) to obtain a sample thickness of 4 mm.

Bread Making Trials

To evaluate the breadmaking performance of the Bilux and Bison flours, bread loaves were produced in triplicate at 10 g scale, according to the straight-dough method (Shogren and Finney 1984). Bilux and Bison doughs were prepared as described in the previous section, with the addition of 0.53 g of baker’s yeast. After mixing, the dough samples were fermented for 90 min in a fermentation cabinet (National Manufacturing) at 30 ∘C and 90 % relative humidity. Intermediate punching took place at 52, 77 and 90 min. Subsequently, the dough pieces were molded and proofed for 36 min (30 ∘C and 90 % relative humidity). Finally, baking was performed in a rotary oven (National Manufacturing) for 13 min at 232 ∘C. Immediately after baking, the bread was weighed, and the loaf volume was determined 120 min after baking with a Volscan Profiler (Stable Micro Systems, Godalming, UK).

Rheological Measurements

Shear Measurements

The shear tests were performed on a stress-controlled MCR501 rheometer (Anton Paar, Graz, Austria) with direct strain option (Läuger et al. 2002), using a 40-mm parallel plate system with a gap of approximately 3 mm. Despite of the non-homogeneous distribution of shear rates, the parallel plate system was selected rather than the cone-and-plate system. The latter setup only allows the use of a very small sample volume, which might lead to reproducibility issues, in view of the heterogeneous nature of dough. In addition, loading and compression of the sample in a cone-and-plate system will likely involve significant pre-test deformations, which may drastically alter the measured rheological properties (Tanner et al. 2013). For the same reason, care was taken to ensure that the samples did not experience normal forces higher than 1 N when loading them between the parallel plates. The temperature was kept constant at 25 ∘C by means of a peltier heating element. To prevent dehydration of the samples during the relatively long measurement times (1–2 h), a solvent trap combined with wet cotton wool was used to create a saturated atmosphere and to seal off the dough sample from the lab environment. Top and bottom plates were both coated with sand paper in order to eliminate slip effects.

In small amplitude oscillatory shear (SAOS) tests, the sample is subjected to a sinusoidal strain signal γ(t) with strain amplitude γ 0 [ −] and angular frequency ω [rad/s]. On the condition that γ 0 is sufficiently small, the material behaviour will be linear, and the resulting stress response signal σ(t) will also vary sinusoidally at the same frequency ω, but with a phase lag δ [rad]:

From the in-phase and out-of-phase parts of σ(t), the frequency-dependent dynamic moduli G ′(ω) and G ″(ω) [Pa] can be calculated. The storage modulus G ′(ω) is a measure for the elastic response of the material, whereas the loss modulus G ″(ω) represents the viscous behaviour. The two moduli can be combined to give the complex modulus G ∗(ω) ( = G ′(ω)+ i G ″(ω)) and their ratio defines the phase angle δ(ω) (tanδ(ω) = G ″(ω)/ G ′(ω)). The dynamic measurements on dough were performed at least three times on separately prepared batches, and good reproducibility (relative standard deviation less than 8 %, see also Phan-Thien and Safari-Ardi (1998), Sofou et al. (2008)) was obtained. Dynamic measurements on gluten-starch mixtures were only carried out in duplicate.

Creep-recovery experiments were performed using the same setup. In creep-recovery experiments, the dough sample is subjected to a constant shear stress σ [Pa], and the resulting deformation γ(t) [ −] is recorded over time. After a certain time, the shear stress is removed, and the sample is allowed to recover the elastic part of the deformation. Creep-recovery data are typically presented as the compliance J(t) [Pa −1] (which is defined as the ratio of the observed strain γ(t) to the applied shear stress σ) as a function of time (Steffe 1996). In dough literature, values for the creep and recovery times ranging from a few minutes (Edwards et al. 1999; Van Bockstaele et al. 2011) to a couple of hours (Edwards et al. 2001; Lefebvre 2006) can be found. The creep time t c should in principle be sufficiently long to ensure that the dough sample has reached a steady-state deformation rate (i.e. a linear increase in the creep compliance over time should be observed). Yet in practice, it is very difficult to reach this steady-state deformation rate with dough (Sofou et al. 2008). Instead, the time-dependent nature of dough behaviour will cause the slope of the compliance curve to slightly decrease over time, in accordance with the ever-increasing value of G ′(t) (see further). Consequently, the creep time t c was arbitrarily set to 30 min, even though a steady-state deformation rate had not yet been fully established after this time. For the same reason, dough cannot achieve a complete recovery in the recovery phase. To find an appropriate value for the recovery time t r , a representative creep test (σ=5 Pa; t c =30 min) with a very long recovery phase of 3 h was performed. After 1 h, the value of the recoverable compliance reached 90 % of the total recoverable compliance (obtained after 3 h). In all subsequent tests, a recovery time t r of 1 h was used. Creep-recovery measurements were performed at least in duplicate. Reproducibility was much less than for the dynamic measurements: especially for low stresses in the recovery phase, the relative standard deviation could become quite high (3–20 %). Creep-recovery tests also turned out to be extremely sensitive to deformation and loading history.

The measurement of the rheological properties of dough is hampered by the limited but continuous change of these properties with time. This time dependency is believed to stem from several factors such as enzymatic reactions ongoing in the flour, a continuous evolution in flour component interactions and the relaxation of the stresses induced during mixing, shaping and loading in the rheometer (Létang et al. 1999). To eliminate the contribution of the latter, dough should be allowed sufficient resting time before starting the rheological experiments (Kontogiorgos et al. 2016). It is, however, difficult to determine what a sufficient resting time would be, as the other physico-chemical factors will still induce time dependency. As a result, dough resting times reported in literature vary widely, from a few minutes to several hours (Edwards et al. 1999). Moreover, the dough samples can be allowed to rest either after mixing and shaping but before loading in the rheometer, or after loading. For all shear tests, a first resting period (30 min) was applied after the shaping step, and a second resting period (again 30 min) after sample loading. During this second resting period, the evolution of G ′ and G ″ at a fixed frequency (1 rad/s) and with a strain in the linear region was registered over time. Whereas G ′(t) exhibited a slight increase, G ″(t) remained more or less constant (results not shown). Dehydration can be an issue with dough, but fortunately it can be easily detected, as dehydration causes a sharp increase in both G ′(t) and G ″(t) (Létang et al. 1999). The fact that G ″(t) remained relatively constant over the entire measurement time is a clear indication that the measures taken to prevent dehydration are effective and that the observed time dependency is inherent to the material.

Extensional Measurements

Finally, extensional tests were carried out on a strain-controlled ARES-G2 rheometer (TA Instruments, New Castle, DE) equipped with the extensional viscosity fixture (EVF). The advantage of the EVF setup in comparison to the more widely used Kieffer extensibility rig is that the extensional deformations are much better defined and controlled. By contrast, the Kieffer extensibility rig also induces an important shear contribution, and consequently, it is impossible to obtain a truly uniaxial extension with this empirical setup (Dunnewind et al. 2004). The EVF add-on consists of two drums to which the dough strand can be attached by means of clips. With this setup, extension at a constant rate is obtained as one drum remains stationary, and the other drum moves in a circular orbit around it, while also rotating around its own axis. The dough strands were created by means of hollow stamps, and had to be positioned very carefully on the two drums using a spatula. Dough sample dimensions (length L 0=12.5 mm, height H 0=4 mm and thickness B 0=4 mm) were adjusted to ensure that the actual deformation approximates a homogeneous uniaxial extension. The latter was verified by video imaging with a Sentmanat extensional rheometer (SER) setup. The SER setup has a similar working principle as the EVF setup, but it keeps the centre of the extending sample stationary by rotating both drums, thereby allowing visualisation. For a more detailed description of the SER setup, the reader is referred to Sentmanat (2004) and Ng et al. (2006). To the best of our knowledge, the McKinley group at MIT was the first to use the SER setup in the rheological study of both gluten gels (Ng and McKinley 2008) and wheat flour dough (Ng et al. 2006). Subsequently, the SER setup has been used by Sofou et al. (2008) to obtain extensional viscosities as part of the input for their constitutive model of dough rheology. Using the SER setup, we could visualise the elongation of the dough samples by drawing mark lines on their frontal surface (see Fig. 1). Our video data indicated that the sample should have a B 0/ H 0 ratio close to unity to approximate uniaxial stretching, and so our study confirms the earlier findings of Ng and McKinley (2008). However, the values for the extension rate were observed to be roughly 10 % lower than the nominal values (Fig. 1) due to the occurrence of slip, which was compensated for by using higher values in the rheometer software. Excellent agreement between the extension curves obtained with the EVF and the SER add-on showed that the findings with the SER could be readily transferred to the EVF setup.

Video imaging of the stretching of dough samples with the SER setup. a The discrepancy between the nominal and observed extension rates in the horizontal, stretching direction (dark grey) and the vertical, contracting direction (light grey). b Mark lines were drawn on the dough sample (currently at rest) to visualise the deformation. c The deformed dough sample after stretching for 1.4 s at a nominal extension rate of 1 s −1

As a measure for extension, the Hencky strain ε(t) [ −] was used, which is defined as:

with L 0 the initial horizontal length of the dough strand, and L(t) the actual length during extension. The torque measured by the rheometer can be used to calculate the value for the longitudinal stress σ 11(t) [Pa] in the dough sample, from which the value of the transient extensional viscosity \(\eta _{e}^{+}(t)\) [Pa s] can be obtained (Macosko 1994):

in which σ 22(t) [Pa], the stress component in the transverse direction, is assumed to be zero. The extension rate \(\dot {\varepsilon }\) [s −1] was varied from 0.005 to 5 s −1. For the lowest extension rates, requiring relatively long measurement times (max. 10 min), the dough samples were coated with paraffin oil to prevent dehydration. The maximum achievable Hencky strain ε max with the EVF setup was only about 2.7, as the sample ends often touched each other well before the rotating drum had completed one full turn. After shaping, all samples were allowed to rest for 30 min before being loaded in the rheometer and tested. All experiments were carried out at ambient temperature. Results shown are always the average of at least six measurements on at least two separately prepared batches. As these six measurements only result from two different batches, they are not all independent, and consequently the pooled standard deviation s p was used to determine the data variability (McNaught and Wilkinson 1997):

In this expression, s 1 and s 2 are the standard deviations for the measurements of batch 1 and batch 2, respectively. The number of measurements obtained from each batch are denoted by n 1 and n 2. The relative standard deviation typically varied from 10 to 15 %.

Results and Discussion

Contributions of Gluten and Starch to the Overall Dough Behaviour

In the Linear Regime

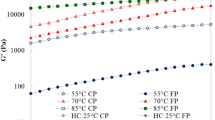

Frequency sweeps of Bilux dough, gluten and starch are given in Fig. 2. For all three materials, the storage modulus G ′(ω) is higher than the loss modulus G ″(ω) over the frequency range under investigation, which is a characteristic of highly structured materials (Létang et al. 1999). The G ′(ω) value is almost frequency independent for the starch sample, which suggests that starch behaves as a nearly close-packed or percolated suspension. Conversely, for dough and gluten the G ′(ω) curve shows a small, positive slope. It should be noted that, because of the differences in water content, it is difficult to compare the absolute values of G ′(ω) and G ″(ω) for the different systems, yet the slopes of G ′(ω) versus ω are known to be unaffected by small variations in the water content (data not shown). For Bilux dough, the values of G ′ and G ″ at ω=10 rad/s are about 104 Pa and 4×103 Pa, respectively, and are in good agreement with results previously reported in literature for wheat flour dough systems of similar water content (Létang et al. 1999).

Dynamic moduli for Bilux dough (black), gluten (grey) and starch (white) versus frequency. For Bilux dough and gluten a strain amplitude γ 0 of 0.06 % was applied, for starch γ 0 was lowered to 0.04 % to account for the very small linearity limit. Dashed lines represent the \(G^{\prime }(\omega )\) and \(G^{\prime \prime }(\omega )\) curves as given by the critical gel model with gel stiffness S=5100 Pa s 0.22 and gel exponent n=0.22

In Fig. 2, the G ′(ω) and G ″(ω) curves of Bilux dough essentially seem to run parallel, a feature that can be captured with the critical gel model. Originally, Winter and Chambon (1986) developed this model for describing the linear viscoelastic properties of a polymeric system at its gel point, but the model was found to be also applicable to many food systems (including wheat flour dough), as they may also contain supramolecular structures comprised of subunits (droplets, particles, etc.) that have the ability to interact at various length scales (Gabriele et al. 2001). The great asset of the critical gel model is that only two parameters, the gel stiffness S and the gel exponent n, are required to describe the linear behaviour of the material:

with Γ(1−n) the gamma function. Fitting these equations to the strong Bilux dough curves in Fig. 2 over the 1–10 rad/s frequency range, yields S=5100 Pa s 0.22 and n=0.22. These values indicate that dough behaves as a relatively weak (physical) gel. For the weak Bison dough S=6140 Pa s 0.19 and n=0.19. In general, the values for the gel stiffness S may vary considerably for different flour types and water contents, whereas the values of n are always very similar (Ng 2007). At high frequencies, the G ′(ω) and G ″(ω) curves typically start to deviate from the predicted critical gel response; this deviation is generally attributed to relaxation processes in the Rouse regime (Ng and McKinley 2008). However, even at ω=100 rad/s, the slope of G ′(ω) is still far lower than the value predicted by the Rouse relaxation regime (G ′(ω)∼ω 0.5). Also at low frequencies, dough does not behave exactly as a critical gel, since the G ″(ω) values tend to deviate from the straight line, exhibiting a subtle upward bend (Ng 2007; Tanner et al. 2008). Ng (2007) attributed this deviation to sample relaxation following the loading step in the rheometer. Yet even after prolonged resting times (1.5 h), the G ″(ω) curve will still show this upward trend, and we therefore conclude that this feature results from the material itself. At sufficiently long times, all physical gels should flow, which implies that the G ′(ω) and G ″(ω) curves should intersect at a very low frequency. In other words, as opposed to real critical gels, wheat flour dough does have a finite relaxation time, albeit a very large one (Gabriele et al. 2001). It is clear that the intersection of the G ′(ω) and G ″(ω) curves is situated well outside the frequency range that is accessible by the rheometer, but nevertheless the onset towards this intersection can already be discerned in the upward bending of the G ″(ω) curve for ω smaller than 1 rad/s. Our attempts to extend the frequency range towards lower values have proven unsuccessful for several reasons. Firstly, the time temperature superposition principle could only be applied to dough over a relatively small temperature range (Gabriele et al. 2001). Secondly, the strain-rate frequency superposition principle (Wyss et al. 2007) failed due to the small linearity limit of dough. And finally, linear creep tests indicated that even after 4 h, a steady-state deformation rate had not yet been fully achieved, which implies that the intersection is to be situated at a frequency value smaller than 10 −4 rad/s. Lefebvre (2006) used a similar approach to locate the intersection point, and also found ω intersection to be of the order of 10 −4 rad/s for his dough system.

The strain sweep data at a frequency of 1 rad/s are presented in Fig. 3. The linearity limit γ c can be defined as the strain amplitude at which the value of G ′(γ 0) drops to 95 % of the plateau value \(G^{\prime }_{0}\). From this definition, it follows that for the strong Bilux dough γ c is only about 0.09 %, while for the weak Bison dough the linearity limit is even smaller (0.06 %; data not shown). Similar values for the linearity limit have been reported by other research groups (Amemiya and Menjivar 1992; Berland and Launay 1995). Above the linearity limit, the dough undergoes strain-softening, which can most likely be attributed to the breakdown of starch aggregates (Smith et al. 1970) and a loss of adhesion between the gluten proteins and the starch granules (Watanabe et al. 2002). Figure 3 also shows that the starch component has a very small linearity limit (0.042 %), above which both dynamic moduli decrease substantially. By contrast, for the pure gluten, the linearity limit is much larger (around 3.2 %), and the dynamic moduli essentially remain constant up until the largest strain amplitudes.

It is known that the starch component is responsible for the small linearity limit of dough (Smith et al. 1970; Larsson et al. 2000; Khatkar and Schofield 2002a; Watanabe et al. 2002; Uthayakumaran et al. 2002). Figure 4a shows the linearity limit as a function of starch content. With the addition of starch, the linearity limit of gluten-starch mixtures decreases substantially. Although all mixtures were prepared with different water amounts, it is still possible to compare the linearity limits, as γ c was verified to be only weakly dependent on water content (data not shown). Above starch contents of approx. 75 wt%, γ c evolves as a power law with respect to the starch content (in wt%; Fig. 4a). For colloidal gels well above the gelation concentration, Shih et al. (1990) argumented that the linearity limit should scale with the volume fraction as a power law. Consequently, dough can be viewed as a concentrated dispersion of starch granules in a gluten protein matrix, at least as far as its linear behaviour is concerned (Uthayakumaran et al. 2002). In some instances (Smith et al. 1970; Phan-Thien and Safari-Ardi 1998), this suspension behaviour becomes apparent in the dough strain sweep, as the G ″(γ 0) curve occasionally shows a shallow maximum close to the linearity limit, reflecting the breakup of the particle network. While this local maximum in G ″(γ 0) appears to be absent in both our dough systems, it does become visible in the 10 wt% gluten–90 wt% starch mixture (results not shown) and evidently also in the 100 wt% starch sample (Fig. 3). Although the effect is partially masked by the differences in water content, the addition of starch also seems to result in an increase in G ′ (Fig. 4b). Uthayakumaran et al. (2002) reached the same conclusion when using optimal water levels for each of the gluten-starch mixtures. Yet, at constant water level (10.0 ml water added to 10.0 g gluten-starch powder) their ranking of G ′ values became inverted. Conversely, Watanabe et al. (2002) have reported a significant increase in G ′ with increasing starch content, even at constant water level (5.95 ml water added to 10.0 g gluten-starch powder). Finally, our SAOS tests on gluten-starch mixtures indicate that with increasing gluten-starch ratio, G ′(ω) exhibits a stronger frequency dependence (Fig. 4b), which has also been reported by Hibberd (1970) and Smith et al. (1970), and which is in line with our earlier observation that G ′(ω) is more dependent on frequency for dough and gluten, than for starch (see Fig. 2).

The linearity limit γ c (a), the value of \(G^{\prime }(\omega = 10\) rad/s ) and the gel exponent n of \(G^{\prime }(\omega )\) (b) as a function of the starch content [wt%]. The \(G^{\prime }(\omega = 10\) rad/s ) value was measured in the linear region, and the gel exponent n was determined for the interval ω=1–10 rad/s (see Eq. 6). The white symbols represent the gluten-starch mixtures, whereas the black and grey symbols correspond roughly to the compositions of Bilux and Bison dough, respectively. The dashed lines were added to guide the eye. Error bars have the length of one standard deviation

In the Non-linear Regime

While the SAOS tests are very useful for obtaining information on the time and strain sensitivity of dough, their practical relevance is rather limited as the applied deformation does not correspond to the type of deformations encountered in the breadmaking process. During mixing, fermentation and oven rise, dough will mostly experience large-strain, extensional deformations, rather than small-strain, shear flows. It is therefore imperative to study dough behaviour under extension. The EVF setup constitutes a well-established technique to characterise materials under uniaxial extension. The results of the uniaxial extensional tests on Bilux dough and gluten are shown in Fig. 5. It is clear from this figure that there is a striking resemblance in behaviour between dough and gluten under extensional deformation (Schofield and Scott Blair 1937). At sufficiently large strains, both materials exhibit strain-hardening, i.e. the stress increases more than proportionally with strain at constant strain rate. Figure 5 also shows that at small strains all the gluten curves more or less coincide to form the so-called linear viscoelastic envelope (LVE), but the dough curves do not.

Uniaxial extension of Bilux dough (circles) and gluten (squares) at different extension rates (1 - 0.5 - 0.1 - 0.05 - 0.01 - 0.005 s −1). Colour shifts gradually from white to black with increasing extension rate. Dashed lines indicate the LVE predictions for Bilux dough and gluten, according to the critical gel model. For clarity, the extensional viscosity values of gluten (and the predicted LVE of gluten) have been rescaled with a factor 1/50

In the limit of small Hencky strains (ε<<1), the extensional viscosity \(\eta _{e}^{+}(t)\) is given by Ng and McKinley (2008):

The dashed lines in Fig. 5 are predictions of the LVE for gluten and dough, with S=652 Pa s 0.24 and 5100 Pa s 0.22, and n=0.24 and 0.22, respectively. For the gluten, as also reported by Ng and McKinley (2008), we observe a fairly good qualitative agreement, up until the onset of strain-hardening. By contrast, the extensional viscosity curves of dough show a dependency with respect to extension rate, and strongly deviate from the predicted linear viscoelastic envelope. The absence of a clear LVE region for dough can be attributed to its very small linearity limit, as shown in Fig. 3. The latter stems from the strain-dependent complex interplay between gluten and starch. Tanner et al. (2011) have shown that the critical gel model can be improved to yield a more accurate prediction of the extensional behaviour of dough by considering a damage function. However, this damage function can only be obtained by additional fitting of non-linear data and is beyond the scope of the present work.

In spite of the absence of a proper LVE, we can still draw a quasi-LVE for dough, by taking the tangent to all the dough curves corresponding to different extension rates. This way it is possible to define a strain-hardening index (SHI) for gluten and dough alike, similar to that defined by Laguna-Gutierrez et al. (2015) for polypropylene blends:

with the maximum strain ε max here being 2.7. In this expression, \(\eta _{e}^{+}(\varepsilon _{\max })\) represents the actual value of the transient extensional viscosity at the maximum strain, and \(\eta _{e0}^{+}(\varepsilon _{\max })\) is the value of the extrapolated LVE at maximum strain. The SHI values for Bilux dough and gluten are given in Table 1. With increasing extension rate, the SHI value also increases, until a plateau value is reached around 0.1 s −1. At higher extension rates, the SHI value for Bilux dough seems to drop again, but this could simply be due to inevitable inaccuracies in the data analysis as for these high extension rates the dough viscosity curves have only a very short straight part, and consequently it is difficult to obtain the correct LVE reference for the calculation of the SHI. As the gluten curves have a well-defined LVE, their SHI values can be determined more accurately, and these values appear to remain constant at high extension rates. Uthayakumaran et al. (2002) also reported that with increasing extension rate, the degree of strain-hardening will decrease, yet the authors merely used the maximum extensional viscosity value as a measure of strain-hardening, and did not take the differences in the linear part of the viscosity curves into account. In any case, the highest extension rates are not very relevant with regard to breadmaking as the (biaxial) extension rates found in the fermentation and baking stage are typically only about 10 −3 s −1 (van Vliet 2008).

The gluten curves in Fig. 5 have been rescaled to increase visibility, but their absolute \(\eta _{e}^{+}(\varepsilon _{\max })\) is almost twice as large as the corresponding value for dough. Since the gluten samples had to be prepared with an excess of water, it is safe to state that gluten in general exhibit much higher extensional viscosities than standard dough. The SHI values for gluten are also higher than those for dough, yet the SHI turns out to be very sensitive to changes in water content. For dough the SHI at \(\dot {\varepsilon } = 0.1\) s −1 increases by almost 50 % just by using an additional 1 ml of water in the sample preparation. For that reason, the higher SHI values for gluten as compared to dough seem to reflect merely the use of a much higher amount of water in their preparation.

In order to elucidate the contributions of both gluten and starch to the extensional behaviour of dough, gluten-starch mixtures were also characterised in extension (see Fig. 6). Pure starch could not be tested, as these samples turned out to be too brittle. Figure 6 reveals that with increasing starch content, the viscosity curves gradually shift from gluten-like to dough-like behaviour, as the slope of the initial part of the curves systematically decreases. This observation suggests that starch substantially affects dough behaviour at small strains. Because of the change in the LVE’s inclination, the presence of starch granules leads to an increase in the value of the SHI, even though the absolute value of \(\eta _{e}^{+}(\varepsilon _{\max })\) decreases with increasing starch content (Fig. 6). The latter evolution has also been noted by Uthayakumaran et al. (2002).

Our findings further substantiate the framework originally developed by Amemiya and Menjivar (1992), which aims to explain the interplay between gluten and starch in determining the behaviour of dough in start-up shear and extensional flows. Amemiya and Menjivar (1992) distinguish four regions in the stress-strain relationship for dough in these flow types. At very small strains, starch-starch and starch-gluten interactions (i.e. the short-range interactions) determine the dough response. In this pre-yield region, the gluten-gluten interactions are probably only of minor importance. Upon increasing the strain, the short-range interactions start to break down, and the gluten molecules acquire some mobility. This yield region corresponds to the straight part in the curves of Fig. 5, and is followed by the strain-hardening region, in which the longer-range gluten-gluten interactions play a pivotal role. At sufficiently large strains, the stress reaches a maximum, and the gluten network finally ruptures. With our EVF setup, it is not possible to reach this post-fracture region: most of our samples did not yet experience failure at the maximum attainable strain ε max of 2.7. In tensile tests, Uthayakumaran et al. (2002) obtained rupture strains varying from 2.2 to 2.9 for dough, with similar values for gluten. They also found the rupture strain to increase with increasing extension rate.

Finally, it is important to note that gluten-starch mixtures cannot fully account for the extensional behaviour of dough, as there remains some difference between the dough curve and the 10 wt% gluten–90 wt% starch curve shown in Fig. 6. Obviously, the gluten and starch are commercial products, and are consequently not identical to the gluten and starch in the dough (see ‘Materials and Methods’ section). Dough also contains many minor components, which are (partially) absent in the gluten-starch mixtures, but might yet have a significant effect on dough behaviour.

Distinguishing Strong from Weak Flour Dough

In the Linear Regime

The discussion in the previous section revealed that the gluten network primarily determines dough behaviour under large, non-linear deformations, whereas for small, linear deformations the starch-starch and starch-gluten interactions also play a pivotal role, and are likely to even dominate the gluten-gluten interactions. As the breadmaking performance of wheat flours is largely determined by the gluten network (Veraverbeke and Delcour 2002), we can anticipate that SAOS tests will not be suitable for distinguishing strong from weak flour dough, at least not within the accessible frequency range.

Figure 7 gives the values of |G ∗| at a fixed frequency of 10 rad/s and a strain amplitude of 0.06 % for both strong (Bilux) and weak (Bison) dough as a function of water content, including the optimal water content data. It is obvious that at optimal water content, SAOS tests fail to distinguish between strong and weak flour dough. The value of |G ∗| for weak Bison dough at 5.4 ml water is even a bit higher than the corresponding value for strong Bilux dough at 5.8 ml water. Doughs with the same Farinograph consistency yield very similar but not identical values for |G ∗|; in general, weak flours tend to show slightly higher |G ∗| values than strong flours (Navickis et al. 1982; Amemiya and Menjivar 1992; Kokelaar et al. 1996; Safari-Ardi and Phan-Thien 1998; Keentok et al. 2002; Khatkar and Schofield 2002b). Strong flours having a high protein content typically require more water to achieve the same Farinograph consistency (Meredith 1966), and it appears that this small difference in water content is already sufficient to mask differences in the gluten network between strong and weak flours. By contrast, at equal water contents, |G ∗| is consistently higher for the strong Bilux dough, and the relative difference with respect to the weak Bison dough seems to increase with increasing water content, which is in agreement with the earlier findings of Navickis et al. (1982). Hibberd (1970) and Smith et al. (1970) both studied gluten-starch mixtures with widely differing gluten-starch ratios and water levels, and they found the water dependency of the dynamic moduli to decrease with increasing gluten content. As changes in water content mostly affect the starch component rather than the gluten network, flours with a higher protein content will have a |G ∗| that is less sensitive to water content. Conversely, at the highest water content (6.6 ml/10 g flour), the Bison sample already started to disintegrate, and was no longer suitable for testing. Safari-Ardi and Phan-Thien (1998) have also performed SAOS tests on different flour types, but even at equal water contents they did not observe significant differences between strong and weak flour dough systems. We have to conclude, therefore, that SAOS tests are not able to distinguish between strong and weak flour doughs. Nor can different wheat flour types be distinguished on the sole basis of their linearity limit. Even though in the previous section we found the linearity limit γ c to vary from one dough to another, in general these differences are too small to allow an unambiguous distinction (Keentok et al. 2002).

In the Non-linear Regime

As dynamic measurements in the linear region are unable to differentiate between different flours and consequently fail to predict their breadmaking performance, dough has to be subjected to larger deformations, in order to pick up variations in gluten content and quality in the mechanical response. Rheological methods that involve large deformations are for example extensional tests and non-linear creep-recovery tests.

Figure 8 shows the transient extensional viscosity of both strong and weak flour dough at a fixed extension rate of 0.1 s −1. It is clear from this figure that extensional tests are indeed able to distinguish strong from weak flour dough, even at optimal water contents. At first sight, the two dough systems seem to behave in a similar manner, but their absolute viscosity values are actually quite different (\(\eta _{e}^{+}(\varepsilon _{\max }) = 9.9 \cdot 10^{5}\) and 5.3⋅105 Pa s, respectively). This difference is also reflected in the strain-hardening index: the SHI values for the strong dough are systematically higher than those for the weak dough (Table 1). The SHI has already been acknowledged as an excellent indicator of the breadmaking performance of a given dough (van Vliet 2008). Strain-hardening behaviour will impede coalescence of the gas cells, by stabilising the dough film between expanding gas cells against premature rupture. Furthermore, strain-hardening may also avert excessive disproportionation and ensure an equal growth of the gas cells during fermentation and baking (van Vliet 2008). Differences in the degree of strain-hardening displayed by different types of flour may reflect differences in the glutenin-gliadin ratio of the gluten network, but the properties of the separate fractions also seem to play an important role (Kokelaar et al. 1996). Furthermore, we observed that for the strong Bilux flour the onset of strain-hardening tends to occur at a smaller strain than for the weak Bison flour. For instance, at \(\dot {\varepsilon } = 0.1\) s −1, the viscosity curve for Bilux shows a 10 % deviation from the extrapolated baseline already at ε=0.43, whereas for Bison this transition point occurs only at ε=0.58.

Strain-hardening is probably not the only factor explaining breadmaking performance. The extensional data of Kokelaar et al. (1996) and Keentok et al. (2002) seem to indicate that breadmaking performance is related to strain-hardening and rupture strain ε b in a complex relationship triangle, and that a high rupture strain can offset a rather low degree of strain-hardening, and vice versa. In our EVF tests, neither the strong nor the weak dough experienced complete failure within the attainable range of strains, indicating that the rupture strains of both systems must be higher than 2.7. Finally, van Vliet (2008) has argued that the absolute value of the dough strength (defined as the value of the stress or viscosity at the point of sample rupture) is most likely only of minor importance compared to the degree of strain-hardening in determining the breadmaking performance. In Kieffer rig experiments, Kindelspire et al. (2015) indeed found the degree of strain-hardening to be much stronger correlated to bread volume than the dough strength.

In the fermentation and baking step, dough experiences primarily extensional deformations, and consequently, extensional tests seem to be the appropriate choice for studying the breadmaking potential of dough (Kokelaar et al. 1996). As the response of the gluten network can also be probed with large, non-linear shear deformations, non-linear creep-recovery tests in shear can also be expected to provide useful information about the breadmaking performance. The results of our creep-recovery experiments on Bilux and Bison dough are presented in Fig. 9. Both dough systems were subjected to shear stresses ranging from 5 to 500 Pa. For low values of the shear stress (Fig. 9a), the compliance curves corresponding to different stress values essentially superimpose, which means that a stress of 10 Pa is still below the linearity limit. Similar stress values for the linearity limit have been reported by several other authors (Edwards et al. 2001; Lefebvre 2006; Van Bockstaele et al. 2011). In Fig. 9b, much higher stress values were applied, and consequently the dough samples have entered the non-linear region. Under these high stresses, the weak Bison dough flows more readily than the strong Bilux dough, and after stress removal the latter can recoil to a much larger extent than the former. By contrast, in the linear region, the weak Bison dough clearly displays more resistance to flow than the strong Bilux dough (see below for a further discussion).

Creep-recovery tests on the strong Bilux dough (black symbols) and the weak Bison dough (white symbols). a In the linear region: σ=5 Pa (circles) and σ=10 Pa (diamonds). b In the non-linear region: σ=250 Pa (downward triangles) and σ=500 Pa (upward triangles). c The critical gel model (grey squares) nicely predicts the recovery curve in the linear region (Bilux dough, 5 Pa, downward triangles), whereas with the Burgers model (dashed lines), both the creep (upward triangles) and the recovery curves can be fitted

Similarly to the linear dynamic moduli in oscillatory shear tests, the critical gel model can also be used to predict the creep compliance J c (t) in linear creep-recovery experiments (Ng and McKinley 2008):

According to the critical gel model, J c (t) will show a power-law dependence, growing without bound over time, and the material will lack a steady-state viscosity. A real critical gel will thus never attain a steady-state flow regime, and the material does not have a finite longest relaxation time. However, our SAOS tests indicated that wheat flour dough does have a finite longest relaxation time (Fig. 2). Likewise, in linear creep tests, dough seems to approach a steady-state flow regime after 1800 s, so we can determine a finite, (quasi-)steady-state viscosity. Consequently, for dough, the critical gel model will only be able to describe the elastic part (but not the viscous part) of the linear creep curve. This elastic part of J c (t) equals J r (t), as the recovery curve only contains the elastic response of the material. Figure 9c shows that J r (t) indeed follows closely the critical gel model prediction, whereas J c (t) strongly deviates from that prediction due to the significant viscous contributions to the overall dough response. In fact, a good fit of J c (t) can only be obtained if the viscous contribution t/η (with the value of η given by the Burgers model, see further) is explicitly added to the critical gel prediction (results not shown). Conversely, for pure gluten gels, Ng and McKinley (2008) did obtain a very good prediction of the linear creep curve J c (t) (for 0<t<2000 s) with the critical gel model. This apparent discrepancy can be explained by the fact that for pure gluten gels the longest relaxation time is much longer than for dough (see again Fig. 2). As a consequence, pure gluten gels will attain a steady-state flow regime only after much longer creep times (t c >> 1800 s), whereas for t c =2000 s, the viscous contributions to the overall material response will not be significant yet.

The compliance curves can also be modelled with the Burgers model, which allows quantifying the elastic and viscous contributions to the overall flow behaviour. Although this model has originally been developed for the linear region only, it can also be used to examine creep-recovery curves obtained outside the linear region, provided that the non-Newtonian viscosity does not depend too strongly on time (Lefebvre 2006). For the creep phase, the compliance J c (t) can be written as:

in which J 0 is the instantaneous compliance, J 1 and J 2 are the retarded elastic compliances, r 1 and r 2 the corresponding retardation times and η the steady-state viscosity. The value of J c (t) at the end of the creep phase is called the maximum creep compliance \(J_{c}^{\max }\).

The recovery compliance J r (t) is given by a similar expression:

The sum of J 0, J 1 and J 2 represents the total recovery compliance \(J_{r}^{\max }\). Figure 9c shows that with this two-mode Burgers model, it is indeed possible to obtain a good fit for the creep as well as the recovery curves, despite the fact that in reality dough behaviour is characterised by a continuous distribution of relaxation times, as illustrated by the fit with the critical gel model. The values of \(J_{c}^{\max }\), \(J_{r}^{\max }\), r 2 in creep (r 2 being the longest of the two retardation times) and η are given in Table 2 for Bilux and Bison dough. In the linear regime, the elastic contribution to the material response should be the same in the creep and the recovery phase. Consequently, the recovery parameters were used to fit the creep data in the linear regime. In the non-linear regime, the creep and recovery curves had to be fitted independently from each other.

From the creep curves, we can obtain values for the steady-state viscosity η(σ) corresponding to different stress levels. It is important to note that the ability of dough to flow implies that the gluten proteins in dough do not form a permanently cross-linked network (see Introduction). From Table 2, we find that for stress values up to 50 Pa, the steady-state viscosity η(σ) remains essentially stress-independent. At optimal water contents, the plateau viscosity of the weak Bison dough is somewhat higher than that of the strong Bilux dough. Edwards et al. (2001) and Lefebvre (2006) also observed similar Newtonian viscosities for flours of different quality, but the plateau values they reported are slightly higher (3.5–7.6 ⋅ 10 6 Pa s) than our values. At higher stress values, η(σ) decreases sharply, and becomes lower for the weak dough than for the strong dough. By contrast, Van Bockstaele et al. (2011) still observed higher viscosities for low-quality flours even in the non-linear region. It thus appears that the shear viscosity does not correlate well with flour strength, regardless of the magnitude of the applied creep stress.

From Table 2, we can also deduce that with increasing creep stress, the values of the maximum creep compliance \(J_{c}^{\max }\) as well as the total recovery compliance \(J_{r}^{\max }\) both increase. Yet at the same time, the fraction of the total creep deformation that can be recovered tends to decrease, indicating that the dough structure experiences a progressively increasing amount of damage with increasing shear stress (Van Bockstaele et al. 2008). In the non-linear region, Bilux dough has a smaller maximum creep compliance, but at the same time higher total (and relative) recovery values than Bison dough. The total recovery compliance \(J_{r}^{\max }\) in the non-linear region has already been found to correlate well with the breadmaking performance (Van Bockstaele et al. 2011). There is, however, much disagreement on how \(J_{c}^{\max }\) is related to breadmaking performance. For durum wheat flours in the non-linear region, Edwards et al. (1999) found the maximum creep compliance of strong flours to be lower than those of weak flours. In a later publication, Edwards et al. (2001) observed the same trend for common wheat doughs, but their creep experiments were performed in the linear region. Our findings seem to indicate, however, that strong flours do not necessarily display lower maximum creep compliances as compared to weak flours. Figure 9a shows that in the linear region, the weak Bison dough has a slightly smaller \(J_{c}^{\max }\) than the strong Bilux dough, which agrees well with the fact that the value of |G ∗| was also found to be somewhat higher for Bison than for Bilux dough at optimal water content (see Fig. 7). In addition, a reverse order in the value of \(J_{c}^{\max }\) with respect to flour strength has already been observed in the non-linear region as well (Van Bockstaele et al. 2008). Finally, Wang and Sun (2002) did not find any correlation between \(J_{c}^{\max }\) and the bread volume in compression creep tests. Hence, we have to conclude that differences in flour strength are not always reflected in the maximum creep compliance. In contrast to the total recovery compliance \(J_{r}^{\max }\), the maximum creep compliance \(J_{c}^{\max }\) contains information on both the elastic and the viscous response of the material. The shear viscosity, however, cannot be trusted to correlate well with flour strength (see previous discussion). Furthermore, the relative importance of differences in the elastic response tends to diminish sharply as t c is increased (since more viscous creep will occur), and the ranking of flours is thus also affected by the amount of time the dough sample has been subjected to the creep stress.

For the retardation time r 2 (as well as for r 1), a significant decrease can be observed with increasing shear stress (in both the creep and the recovery phase). This means that in the creep phase steady-state deformation will be attained faster, and in the recovery phase the recovery will be completed faster, as the stress level is increased. Overall, the retardation times for Bilux and Bison dough appear to be quite similar, and thus cannot be used as a differentiating tool. The creep-recovery data of Edwards et al. (2001) and Van Bockstaele et al. (2011) seem to suggest that higher bread volumes can be obtained from doughs which show higher retardation times, but in the end no correlation between the retardation times and the bread volume could be established. Conversely, an inverse relationship of the retardation time with the bread volume has been reported by Kawai et al. (2006).

Conclusions

The long-held view in literature that the behaviour of dough is primarily determined by the gluten network is only valid when we consider large deformations. In the linear region, by contrast, the starch granules also have a clear impact on dough rheology, both in shear and extensional flow, and may mask differences in gluten content and quality. Only non-linear creep-recovery and extensional tests are therefore able to distinguish clearly between strong and weak flour doughs. The total recovery compliance and the strain-hardening index turn out to be very promising quality indicators. However, as only two flour types were used in this study, additional research is required to verify their applicability for other flour types as well.

The uniaxial extensional data were determined with an EVF or SER setup on a rotational shear rheometer. Both setups generate a pure extensional flow in contrast to the often used empirical Kieffer extensibility rig. Hence, the obtained data allow to determine true material parameters, which can be used to develop and validate constitutive equations for dough rheology.

With linear oscillatory data as the starting point, the critical gel model can be used to estimate the linear dough response in both creep and uniaxial extension. However, in light of the highly non-linear elements and significant liquid contributions that characterise dough behaviour, the predictiveness of the critical gel model was shown to be rather limited. By contrast, the two-mode Burgers model was successful in modelling both the linear and the non-linear creep-recovery behaviour of dough, despite the fact that dough has a very broad relaxation spectrum.

References

AACC International. (2000). Approved methods of analysis. St Paul: American Association of Cereal Chemists International.

Amemiya, J. I., & Menjivar, J. A (1992). Comparison of small and large deformation measurements to characterize the rheology of wheat flour doughs. Journal of Food Engineering, 16(1–2), 91–108.

AOAC International. (1995). Official methods of analysis of AOAC international. Washington: Association of Official Analytical Chemists International.

Belton, P. S. (1999). On the elasticity of wheat gluten. Journal of Cereal Science, 29(2), 103–107.

Berland, S., & Launay, B (1995). Shear softening and thixotropic properties of wheat flour doughs in dynamic testing at high shear strain. Rheologica Acta, 34(6), 622–625.

Bloksma, A.H. (1975). Thiol and disulfide groups in dough rheology. Cereal Chemistry, 52(3s), 170r–183r.

Bloksma, A. H. (1990). Dough structure, dough rheology and baking quality. Cereal Foods World, 35(2), 237–244.

Delcour, J. A., & Hoseney, R. C. (2010). Principles of Cereal Science and Technology, (pp. 1–270). St Paul: American Association of Cereal Chemists International.

Dobraszczyk, B., & Morgenstern, M. P. (2003). Rheology and the breadmaking process. Journal of Cereal Science, 38(3), 229–245.

Dunnewind, B., Sliwinski, E. L., Grolle, K., & van Vliet, T. (2004). The Kieffer dough and gluten extensibility rig—an experimental evaluation. Journal of Texture Studies, 34(5–6), 537–560.

Edwards, N. M., Dexter, J. E., Scanlon, M. G., & Cenkowski, S. (1999). Relationship of creep-recovery and dynamic oscillatory measurements to durum wheat physical dough properties. Cereal Chemistry, 76(5), 638–645.

Edwards, N. M., Peressini, D., Dexter, J. E., & Mulvaney, S. J. (2001). Viscoelastic properties of durum wheat and common wheat dough of different strengths. Rheologica Acta, 40(2), 142–153.

Edwards, N. M., Dexter, J. E., & Scanlon, M. G. (2002). Starch participation in durum dough linear viscoelastic properties. Cereal Chemistry, 79(6), 850–856.

Edwards, N. M., Mulvaney, S. J., Scanlon, M. G., & Dexter, J. E. (2003). Role of gluten and its components in determining durum semolina dough viscoelastic properties. Cereal Chemistry, 80(6), 755–763.

Gabriele, D., de Cindio, B., & D’Antona, P. (2001). A weak gel model for foods. Rheologica Acta, 40(2), 120–127.

Goesaert, H., Brijs, K., Veraverbeke, W. S., Courtin, C. M., Gebruers, K., & Delcour, J. A. (2005). Wheat flour constituents: how they impact bread quality, and how to impact their functionality. Trends in Food Science & Technology, 16(1–3), 12–30.

Hibberd, G. E. (1970). Dynamic viscoelastic behaviour of wheat flour doughs III. The influence of the starch granules. Rheologica Acta, 9(4), 501–505.

Jekle, M., & Becker, T. (2015). Wheat dough microstructure: the relation between visual structure and mechanical behavior. Critical Reviews in Food Science and Nutrition, 55(3), 369–382.

Jones, I. K., & Carnegie, P. R. (1971). Binding of oxidised glutathione to dough proteins and a new explanation, involving thiol-disulphide exchange, of the physical properties of dough. Journal of the Science of Food and Agriculture, 22(7), 358–364.

Kawai, H., Tanaka, F., Takahashi, H., Hashimoto, N., & Yamauchi, H. (2006). Relationship between physical properties of dough and expansion ability during breadmaking. Food Science and Technology Research, 12 (2), 91–95.

Keentok, M., Newberry, M. P., Gras, P., Bekes, F., & Tanner, R. I. (2002). The rheology of bread dough made from four commercial flours. Rheologica Acta, 41(1), 173–179.

Khatkar, B. S., & Schofield, J. D. (2002a). Dynamic rheology of wheat flour dough. I. Non-linear viscoelastic behaviour. Journal of the Science of Food and Agriculture, 82(8), 827–829.

Khatkar, B. S., & Schofield, J. D. (2002b). Dynamic rheology of wheat flour dough. II. Assessment of dough strength and bread-making quality. Journal of the Science of Food and Agriculture, 82(8), 823–826.

Kindelspire, J. Y., Glover, K. D., Caffé-Treml, M., & Krishnan, P. G. (2015). Dough strain hardening properties as indicators of baking performance. Cereal Chemistry, 92(3), 293–301.

Kokelaar, J. J., van Vliet, T., & Prins, A. (1996). Strain hardening properties and extensibility of flour and gluten doughs in relation to breadmaking performance. Journal of Cereal Science, 24(3), 199–214.

Kontogiorgos, V. (2011). Microstructure of hydrated gluten network. Food Research International, 44(9), 2582–2586.

Kontogiorgos, V., Shah, P., & Bills, P. (2016). Influence of supramolecular forces on the linear viscoelasticity of gluten. Rheologica Acta, 55(3), 187–195.

Laguna-Gutierrez, E., Van Hooghten, R., Moldenaers, P., & Rodriguez-Perez, M. A. (2015). Understanding the foamability and mechanical properties of foamed polypropylene blends by using extensional rheology. Journal of Applied Polymer Science, 132(33), 42430/1–42430/14.

Larsson, H., & Eliasson, A.-C. (1997). Influence of the starch granule surface on the rheological behaviour of wheat flour dough. Journal of Texture Studies, 28(5), 487–501.

Larsson, H., Eliasson, A.-C., Johansson, E., & Svensson, G. (2000). Influence of added starch on mixing of dough made with three wheat flours differing in high molecular weight subunit composition: rheological behavior. Cereal Chemistry, 77(5), 633–639.

Läuger, J., Wollny, K., & Huck, S. (2002). Direct strain oscillation: a new oscillatory method enabling measurements at very small shear stresses and strains. Rheologica Acta, 41(4), 356–361.

Lefebvre, J. (2006). An outline of the non-linear viscoelastic behaviour of wheat flour dough in shear. Rheologica Acta, 45(4), 525–538.

Létang, C., Piau, M., & Verdier, C. (1999). Characterization of wheat flour-water doughs I. Rheometry and microstructure. Journal of Food Engineering, 41(2), 121–132.

Macosko, C. W. (1994). Viscous liquid. In Macosko, C. W. (Ed.) Rheology: Principles, Measurements and Applications (pp. 65–108). New York: Wiley-VCH.

McNaught, A. D., & Wilkinson, A. (1997). Compendium of Chemical Terminology. Oxford: Blackwell Scientific Publications.

Meredith, P. (1966). Dependence of water absorption of wheat flour on protein content and degree of starch granule damage. New Zealand Journal of Science, 9(2), 324–330.

Navickis, L. L., Anderson, R. A., Bagley, E. B., & Jasberg, B. K. (1982). Viscoelastic properties of wheat flour doughs: variation of dynamic moduli with water and protein content. Journal of Texture Studies, 13(2), 249–264.

Ng, T. S. K. (2007). Linear to Nonlinear Rheology of Bread Dough and its Constituents. Ph.D. Thesis. Cambridge: Massachusetts Institute of Technology.

Ng, T. S. K., & McKinley, G. H. (2008). Power law gels at finite strains: the nonlinear rheology of gluten gels. Journal of Rheology, 52(2), 417–449.

Ng, T. S. K., McKinley, G. H., & Padmanabhan, M. (2006). Linear to non-linear rheology of wheat flour dough. Applied Rheology, 16(5), 265–274.

Petrofsky, K., & Hoseney, R. (1995). Rheological properties of dough made with starch and gluten from several cereal sources. Cereal Chemistry, 72(1), 53–58.

Phan-Thien, N., & Safari-Ardi, M. (1998). Linear viscoelastic properties of flour-water doughs at different water concentrations. Journal of Non-Newtonian Fluid Mechanics, 74(1–3), 137–150.

Safari-Ardi, M., & Phan-Thien, N. (1998). Stress relaxation and oscillatory tests to distinguish between doughs prepared from wheat flours of different varietal origin. Cereal Chemistry, 75(1), 80–84.

Schofield, R. K., & Scott Blair, G. W. (1937). The relationship between viscosity, elasticity and plastic strength of a soft material as illustrated by some mechanical properties of flour dough IV. The separate contributions of gluten and starch. Proceedings of the Royal Society of London Series A, 160(900), 87–94.

Sentmanat, M. L. (2004). Miniature universal testing platform: from extensional melt rheology to solid-state deformation behavior. Rheologica Acta, 43(6), 657–669.

Shih, W.-H., Shih, W. Y., Kim, S.-I., Liu, J., & Aksay, I. A. (1990). Scaling behavior of the elastic properties of colloidal gels. Physical Review A, 42(8), 4772–4780.

Shogren, M. D., & Finney, K. F (1984). Bread-making test for 10 grams of flour. Cereal Chemistry, 61(5), 418–423.

Smith, J. R., Smith, T. L., & Tschoegl, N. W (1970). Rheological properties of wheat flour doughs III. Dynamic shear modulus and its dependence on amplitude, frequency, and dough composition. Rheologica Acta, 9(2), 239–252.

Sofou, S., Muliawan, E. B., Hatzikiriakos, S. G., & Mitsoulis, E. (2008). Rheological characterization and constitutive modeling of bread dough. Rheologica Acta, 47(4), 369–381.

Steffe, J. F. (1996). Rheological Methods in Food Engineering, (pp. 1–418). East Lansing: Freeman Press.

Tanner, R. I., Qi, F., & Dai, S. (2008). Bread dough rheology and recoil I. Rheology. Journal of Non-Newtonian Fluid Mechanics, 148(1–3), 33–40.

Tanner, R. I., Qi, F., & Dai, S. (2011). Bread dough rheology: an improved damage function model. Rheologica Acta, 50(1), 75– 86.

Tanner, R. I., Qi, F., Uthayakumaran, S., & Dai, S. C. (2013). The effect of pre-test deformation on dough rheology. Rheologica Acta, 52(1), 33–38.

Tomić, J., Torbica, A., Popović, L., Strelec, I., Vaštag, ž., Pojić, M., & Rakita, S. (2013). Albumins characterization in relation to rheological properties and enzymatic activity of wheat flour dough. Journal of Agricultural Science and Technology, 17(4), 805– 816.

Uthayakumaran, S., Newberry, M., Phan-Thien, N., & Tanner, R. I. (2002). Small and large strain rheology of wheat gluten. Rheologica Acta, 41(1), 162–172.

Van Bockstaele, F., De Leyn, I., Eeckhout, M., & Dewettinck, K. (2008). Rheological properties of wheat flour dough and the relationship with bread volume. I. Creep-recovery measurements. Cereal Chemistry, 85 (6), 753–761.

Van Bockstaele, F., De Leyn, I., Eeckhout, M., & Dewettinck, K. (2011). Non-linear creep-recovery measurements as a tool for evaluating the viscoelastic properties of wheat flour dough. Journal of Food Engineering, 107(1), 50–59.

van Vliet, T. (2008). Strain hardening as an indicator of bread-making performance: a review with discussion. Journal of Cereal Science, 48(1), 1–9.

Veraverbeke, W. S., & Delcour, J. A. (2002). Wheat protein composition and properties of wheat glutenin in relation to breadmaking functionality. Critical Reviews in Food Science and Nutrition, 42(3), 179–208.

Villegas, E., Pomeranz, Y., & Shellenberger, J. (1963). Effects of thiolated gelatins and glutathione on rheological properties of wheat doughs. Cereal Chemistry, 40(6), 694–703.

Wang, F. C., & Sun, X. S. (2002). Creep-recovery of wheat flour doughs and relationship to other physical dough tests and breadmaking performance. Cereal Chemistry, 79(4), 567–571.

Watanabe, A., Larsson, H., & Eliasson, A.-C. (2002). Effect of physical state of nonpolar lipids on rheology and microstructure of gluten-starch and wheat flour doughs. Cereal Chemistry, 79(2), 203–209.

Weegels, P. L., Orsel, R., van de Pijpekamp, A. M., Lichtendonk, W. J., Hamer, R. J., & Schofield, J. D. (1995). Functional properties of low M r wheat proteins. II. Effects on dough properties. Journal of Cereal Science, 21(2), 117–126.

Winter, H. H., & Chambon, F. (1986). Analysis of linear viscoelasticity of a crosslinking polymer at the gel point. Journal of Rheology, 30(2), 367–382.

Wyss, H. M., Miyazaki, K., Mattsson, J., Hu, Z., Reichman, D. R., & Weitz, D. A. (2007). Strain-rate frequency superposition: a rheological probe of structural relaxation in soft materials. Physical Review Letters, 98 (23), 238303.

Yang, Y., Song, Y., & Zheng, Q. (2011). Rheological behaviors of doughs reconstituted from wheat gluten and starch. Journal of Food Science and Technology, 48(4), 489–493.

Acknowledgments

MM and RC are indebted to the Research Foundation - Flanders (FWO) for a doctoral and postdoctoral fellowship at KU Leuven, respectively. In addition, financial support was obtained from the Research Fund KU Leuven (IDO/12/011). The authors also wish to thank Nore Struyf and Mohammad Naser Rezaei for determining the protein and moisture content of both flours and gluten, as well as the optimal mixing times and water absorptions, and Sarah Van Engeland for providing assistance with the rheological measurements. Equally, we would like to express our gratitude to Prof. Em. Jan Mewis for the many fruitful discussions and insights. Finally, DSM Ahead B.V. is gratefully acknowledged for lending us their SER add-on.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meerts, M., Cardinaels, R., Oosterlinck, F. et al. The Interplay Between the Main Flour Constituents in the Rheological Behaviour of Wheat Flour Dough. Food Bioprocess Technol 10, 249–265 (2017). https://doi.org/10.1007/s11947-016-1810-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1810-2