Abstract

An Australian hard wheat flour–water dough has been characterised using parallel plate and capillary rheometers over an extensive range of apparent shear rates (10 − 3–103 s − 1) relevant to process conditions. Torsional measurements showed that the shear viscosity of the dough increased with strain to a maximum value and then decreased, suggesting a breakdown of the dough structure. Both torsional and capillary experiments revealed the shear-thinning behaviour of the dough. The wall slip phenomenon in capillary rheometry was investigated and found to be diameter dependent and occurred at a critical shear stress of approximately 5–10 kPa. A two-regime power law behaviour was observed, with the power law index approximately 0.3 in the low shear rate range increasing to 0.67 in the high shear rate range. Pressure fluctuation was observed in the capillary data and increased with shear rate, in particular, at shear rates approaching 104 s − 1. The results demonstrate that capillary rheometry is a viable means of rheologically testing dough at high shear rates provided pressure fluctuation is carefully monitored and capillary rheometry corrections, including wall slip, are accounted for.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The wheat flour–water dough system is a rheologically complex material consisting of a polymeric network of gluten proteins with around 60% by volume starch filler particles (Tanner et al. 2008). The practical significance of studying the rheology of wheat flour–water doughs to the agricultural and food process industries would include (a) analysing the effect of growing conditions and wheat variety on processing and final product quality and (b) aiding the development of production techniques. Therefore, the characterisation and the subsequent modelling of wheat flour–water dough under processing conditions are critical to controlling bread quality and sustaining a cost-effective process.

Over the last 50 years, the breadmaking procedure has parted from tradition and has been transformed into a high throughput engineering process. In the present day, however, breadmaking remains, to some degree, an art or craft rather than a science or technology. This is particularly true for the areas of process control and quality optimisation that still rely heavily on experience to make necessary adjustments to the combination of raw materials, formula and process (Cauvain 2003). The majority of large throughput bakeries are highly automated but are primitively controlled. Experience gained from the polymer industry has shown the value of rheological data for quality control purposes (Bagley et al. 1998). However, the application of computer-based technology has just started to be applied to the breadmaking process and is yet to be fully developed and utilised (Young 1998). This is mainly due to complex raw materials and process interactions leading to products of different quality, making this class of material difficult to constitutively describe. The ingredients, wheat flour, water, yeast and salt (Sluimer 2005), are mixed into a dough that is heavily processed before the baking procedure to obtain the necessary properties for producing a high-quality loaf (Bloksma 1990).

A number of contributions have been made to understanding the rheological behaviour of wheat flour–water doughs. The reader is pointed to the reviews available (Bloksma 1972; Faridi and Faubion 1986, 1990; Dobraszczyk and Morgenstern 2003). The application of rheology to bread dough can be divided under two general strands: viscoelastic and flow characterisations. The bulk of research has focused on quality evaluation through the viscoelastic strand, with only a handful of literature on the flow characterisation of dough at shear rates relevant to high throughput process conditions (Bagley et al. 1998; Breuillet et al. 2002; Cuq et al. 2002; Dhanasekharan et al. 1999; Lindborg et al. 1997; Sharma 1990; Sharma and Hanna 1987; Sharma et al. 1993a, b; Sofou et al. 2008) despite a growing need for understanding in this area. Furthermore, throughout these investigations, important interactions between material and measurement system are often neglected. This includes fluctuations in data readings and the possibility of wall slip.

Two flow types are apparent in this type of breadmaking process: extension and shear, with shear behaviour predominant when in contact with solid boundaries, for example, in extrusion and cutting. In this work, we characterise the shear flow behaviour of an Australian hard wheat flour–water dough over an extensive range of shear rates, using both simple shear and capillary rheometry. In addition, we identify and discuss the experimental and conceptual problems associated with the capillary rheometry of bread dough, in particular, wall slip and pressure fluctuation.

The paper is structured as follows: “Materials and methods” describes the preparation of the dough and the experimental techniques used in the investigation. “Results and discussion” is next. First, we present the shear flow data obtained on a torsional rheometer and discuss the strain dependency of the bread dough response. Second, we explore the shear rate range up to 103 s − 1 using a capillary rheometer and investigate possible wall slip phenomenon. Third, a flow curve of the capillary data is presented, and both torsional and capillary data are combined on a shear viscosity curve. The shear thinning behaviour of the material is highlighted, and a two-regime power law behaviour is observed. Finally, high shear rate capillary rheometry of the dough (up to 104 s − 1) is explored and discussed in relation to findings in research on pastes. The paper finishes with “Conclusions”.

Materials and methods

Dough preparation

The material used for this study was the Janz variety commercial Australian hard wheat flour: moisture content, 12% (wet basis) and protein content, 12.9%. The dough was prepared by mixing 9.5 g of flour, 6.0 g of distilled water and 200 mg of salt in a 10-g mixograph. The mixograph consisted of a four-planetary pinhead revolving around three statutory pins in a mixing container. The dough was allowed to fully develop in the mixograph, a process taking approximately 3 min. The duration was determined by a mixing curve, with each sample judged to be mixed to peak consistency at the signal peak. After mixing, the dough was placed in a sealed plastic container inside a sealed wetted plastic bag to prevent moisture loss. Each sample was rested for approximately 45 min before use, following the procedure used by Phan-Thien et al. (1997), to allow the material to relax after the mixing process. The mixing operation was conducted under ambient humidity in an air-conditioned laboratory at 24°C.

Rotational rheometry

The low shear rate range experiments were carried out on a Paar Physica MCR 301 rheometer. The parallel plate configuration was used with a top plate of 25-mm diameter and a gap width of 2 mm. Slippage was prevented during the test by gluing fine-grade sandpaper to each of the parallel plates, following the method of Tanner et al. (2008). Before testing, the rheometer was calibrated, and the temperature was set to 25°C. The sample was coated with Vaseline® petroleum jelly to prevent moisture loss. The sample was allowed to rest for 30 min before the experiment was commenced (Tanner et al. 2008). The experiments were performed in the shear rate range of 10 − 3–20 s − 1. Each experiment was repeated three times using dough from a freshly mixed batch. Good reproducibility of results was observed with an error of ±6% across experiments under the same conditions. The average result is presented. The same rheometer and sample preparation were used for small amplitude oscillatory tests.

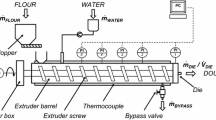

Capillary rheometry

The high shear rate range experiments were carried out on a dual barrel Göttfert Rheotester 2000 capillary rheometer. It comprises of a motor that drives two pistons at constant velocity through two corresponding barrels of 15-mm diameter and approximately 270-mm length. Round-hole dies of various length/diameter (L/D) ratios (30:1, 10:1, 5:1, 20:2 and 10:2), where the second value indicates the diameter in millimetres, were fixed at the end of the barrel. The temperature of the twin barrel system was set at 25°C and controlled by 3 heaters along the length of the barrel. Dough was carefully loaded into the barrel to avoid entrapped air and damage to the dough structure. Approximately 47 g of dough was required to fill each barrel. The rheometer was calibrated and the two pistons were brought into contact with the dough. The dough was allowed to rest in the unit for 10 min before starting the test. This allows the dough to relax from the filling process before significant drying of the sample can occur. The experiments were performed by increasing apparent shear rate in the range of 10–104 s − 1. The pressure at the entrance to each capillary was recorded by means of pressure transducers located just above the dies. Each experiment was repeated three times using fresh dough. Good reproducibility of data was observed in the shear rate range of 10–103 s − 1, with an error of up to ±8% for experiments under similar conditions. Results in this range only are considered in this work, and the average result is presented. A discussion will also be presented for behaviour observed at shear rates exceeding this range.

Results and discussion

Lower shear rate range experiments

The data for shear stress (τ) versus strain for the shear rate (\(\dot {\gamma })\) range 10 − 3–20 s − 1, obtained by the physica torsional rheometer, is plotted over six orders of magnitude of strain in Fig. 1. At strain values approaching 100, the test was stopped due to terminal fracture of the dough sample.

This dynamic behaviour has been previously reported in the literature (Lindborg et al. 1997; Phan- Thien et al. 1997; Tanner et al. 2008). The key characteristic of these curves is that the shear stress increases with strain to a maximum value and then decreases without the sample ever attaining a steady state of flow.

For the shear rate range studied, the maximum shear stress was observed at strain values of 10–24 in this work, with similar values (5–16) reported in the literature for hard wheat flour doughs (Lindborg et al. 1997; Phan-Thien et al. 1997; Tanner et al. 2008). The decrease in shear stress at higher strain values was interpreted by Phan-Thien et al. (1997) as a strain-dependent breakdown or rupture of the dough structure and a partial failure in the gluten network.

Since no steady state was observed, the material’s steady shear viscosity cannot be obtained. However, one can present a viscosity value (η, via \(\eta =\frac{\tau }{\dot {\gamma }}\)) for comparison with other rheological test methods by specifying the strain at which viscosity was calculated (Lindborg 1995). Figure 9 presents the strain-dependent viscosity data from the torsional measurements in comparison to data obtained from a capillary rheometer (details of the latter to be presented in the next section).

Higher shear rate range experiments

There is a limiting shear rate below which data can be confidently accepted as a reasonably accurate description of bread dough’s rheological properties in certain setups of capillary rheometer measurement systems (Bagley et al. 1998). The flow behaviour of bread dough at shear rates above this limit will be discussed later in the Section “Pressure fluctuation”. In this investigation, we have limited the apparent shear rate to 1,000 s − 1. This is somewhat above shear rates currently experienced in the bread industry, where shear rates of hundreds of reciprocal seconds are achieved (Bloksma 1990). Nonetheless, the elevated conditions (up to 1,000 s − 1) reported in this paper may well be present in dough processing in the future as companies strive for higher production rates to maximise profits and so remain worthwhile areas to investigate.

The Göttfert Rheotester 2000 capillary rheometer measurement process involves extruding a material through a die of finite aspect ratio at a specified volumetric flow rate and measuring the resulting pressure increase at the die entrance. All dies employ a 180° entrance angle. Figure 2 shows a typical transient pressure profile of the Janz variety bread dough at an apparent shear rate of 300 s − 1, calculated from Eq. 2, which will be explained below, for a 30:1 aspect ratio capillary die at 25°C.

The signal variance of steady-state extrusion pressure, shown here at an apparent shear rate of 300 s − 1, is in agreement with observations by other authors who investigated bread dough (Bagley et al. 1998). These fluctuations observed in pressure will be extensively discussed in “Pressure fluctuation”. The apparent shear stress at the wall of a capillary die (τap) for a finite aspect ratio is calculated from extrusion pressure using the following equation (Dealy and Wissbrun 1999).

where ΔP (pascal) is the extrusion pressure and L (metres) and D (metres) are the respective length and diameter of the capillary die. The apparent shear rate (\(\dot {\gamma}_{\rm ap}\)) of the experiment can be expressed, assuming a flat velocity profile, in the form

where Q (cubic metre per second squared) is the volumetric flow rate. This expression is true for a Newtonian fluid. The correction for a non-Newtonian fluid is applied later and depends on the rheological nature of the fluid.

Figure 3 shows the apparent flow curves of bread dough, obtained using the above procedure, at 25°C for D = 1 mm and L/D ratios 5, 10 and 30.

Three curves are represented, one for each capillary length. These flow curves require the Bagley correction (Bagley 1957) for entrance pressure in order to obtain the correct value for shear stress at the wall of the capillary. This correction accounts for pressure associated with the material entering the die land. Extrusion pressure is corrected for by constructing a Bagley plot, which is displayed in Fig. 4.

Extrusion pressure (ΔP) is plotted against L/D of the three capillaries (5, 10 and 30) and extrapolated to L/D = 0, revealing the pressure correction (ΔP c) for several apparent shear rates. Using this pressure correction, the value of shear stress at the wall (τw) can be calculated by modifying Eq. 1 as follows:

The values for ΔP c are quite substantial, as expected for wheat flour–water dough (Bagley et al. 1998; Breuillet et al. 2002). This is likely due to the gluten network within the dough structure being subject to elongational flow at the entrance of the capillary. Subsequently, branched polymers with a high density of entanglement are known to generate high resistance to flow at the capillary entrance and also incur high ΔP c values (Liang and Ness 1997; White 1973). The data in Fig. 4 further suggests a linear relationship between the pressure and aspect ratio, indicating that disturbances in flow pattern are insignificant (Breuillet et al. 2002) and that pressure has a negligible effect on the properties of the dough. That is, the compression of the small amount of air contained in the dough during the mixing process under the conditions of the rheometer does not significantly change the density and viscosity of the material. It should be pointed out that the majority of authors have reported linear Bagley plots for dough (Cuq et al. 2002; Sharma and Hanna 1987; Sharma et al. 1993a; Sofou et al. 2008). Conversely, non-linear Bagley plots have also been reported (Breuillet et al. 2002) in which disturbances in flow pattern located at different positions in the rheometer could be considered as responsible (Cook et al. 1965). These tests were performed using a 45° (90° included) entrance angle, as opposed to the 180° entrance angle used in this study. A larger contraction angle induces greater elongational flow on the sample, offering a higher degree of structural orientation within the gluten network of the dough at the entrance to the die land. This limits subsequent deorientation during shear flow along the capillary, resulting in a reduced disturbance in flow pattern.

The Bagley corrected flow curves for bread dough using capillary dies 5:1, 10:1, 30:1, 10:2 and 20:2 can now be compared and are displayed in Fig. 5.

For a particular diameter, the data collapse in Fig. 5 onto a single flow curve is good; however, diameter dependence is observed. In capillary rheometry, a diameter dependence of the flow curve strongly suggests the presence of wall slip (Sharma et al. 1993a). This will now be discussed.

Wall slip phenomenon

Slip is a well-studied phenomenon in rheology. A detailed review of slip in rheological devices is presented by Barnes (1995).

The presence of slip when testing dough is well recognised in simple shear (Tanner et al. 2008) but was reported only once in capillary extrusion (Sofou et al. 2008). This is despite the fact that slip has been frequently reported in the capillary extrusion of other foodstuffs similar to dough: starch-based pastes (Corfield et al. 1999), coarse food suspensions (Chakrabandhu and Singh 2005), butter (Shukla and Rizvi 1995) and cheese (Muliawan and Hatzikiriakos 2008).

Our studies show that slip in testing dough can most likely be attributed to wall depletion effects at high shear rates, similar to other foodstuffs. Wall depletion is the displacement of the dispersed phase away from solid boundaries, leaving a lower-viscosity, depleted layer of liquid (Barnes 1995). This phenomenon occurs in dough when under shear near the solid boundary surface. The originally homogenous dough tends to separate into a protein phase (gluten) and starch areas, effectively lubricating the material at the wall, and so the material slips (Breuillet et al. 2002; Stephen 2006). This effect is generally confined quite close to the wall, with a typical thickness of 0.1–10 μm (Barnes 1995), which is much smaller than typical capillary die diameters.

Slip effects can be counteracted in shear rheometers using roughened surfaces (Barnes 1995; Buscall et al. 1993; Khan et al. 1988). For example, sand paper has been applied to the plates of a torsional rheometer to prevent slip when testing bread dough (Tanner et al. 2008) and in this paper. However, slip cannot be prevented in this way using a capillary rheometer as the geometry is so confined. This is exacerbated by the fact that rheometers with smooth walls that operate under high shear gradients, such as the capillary type, are the most vulnerable to slip effects (Barnes 1995).

In general, slip effects in rheometers can be accounted for if they are confined to very fine layers and no gross changes occur in the bulk of the fluid (Barnes 1995). This is indeed the case for our measurement system below shear rates of approximately 1,000 s − 1. Above shear rates of 1,000 s − 1, gross changes in the material occur such that data is unreliable to quantify wall slip. This matter is discussed further in “Pressure fluctuation”. The overall flow can be split into slip flow operating in the near vicinity of the solid wall and bulk flow effectively running against the slip layer. The flow can then be resolved into separate, mathematically describable components with the introduction of the key quantity of slip velocity. The correction for wall slip in a capillary rheometer was first reported by Mooney (1931). A slip velocity can be quantitatively determined in capillary rheometry by comparing results of dies with the same aspect ratio but different diameter. In this case, it is possible to express apparent wall shear rate (\(\dot {\gamma}_{\rm ap} \)) as a function of wall shear stress (τw), slip velocity (V s) and die radius (R) through the following (Mooney 1931):

The main assumption made by Mooney is that the slip velocity is only dependent on the shear stress at the wall of the capillary. Therefore, for a given value of wall shear stress, the plot of apparent wall shear rate versus the inverse radius produces a straight line, with a slope equal to four times the value of the slip velocity and the y-intercept the apparent shear rate corrected for slip (\(\dot {\gamma }_{\rm ap, s} \)). This operation is repeated for a range of wall shear stresses to obtain a relationship between slip velocity and wall shear stress. This method has been successfully applied to several different materials: polyethylene (Blyler and Hart 1970; Lupton and Regester 1965), molten polymers (Worth et al. 1977) and elastomer (Knappe and Krumbock 1986).

Studies of wall slip in bread dough in capillary rheometry are scarce, such that only one recent publication could be found. Sofou et al. (2008) applied a modified Mooney method to their investigation. This modified method was first established by Geiger (1989) when experimenting with ethylene propylene diene monomer compounds. Here, the traditional Mooney method resulted in the apparent shear rate corrected for slip attaining a negative value, which in turn led to an unphysically high slip velocity. Geiger then introduced the idea of using curved Mooney plots to evaluate wall slip, whereby slip velocity is an exponential function of inverse die radius for different shear stresses of the form

where A(τw) and a(τw) are the respective y-intercept and slope of the fitted linear functions of log \(\dot{\gamma}_{\rm ap}\) and 1/R for different wall shear stresses, as seen here in Fig. 6. The value of A is then the apparent shear rate corrected for slip \((\dot {\gamma}_{\rm ap,s} )\).

This method has been successfully applied to other materials: styrene butadiene rubber (Mournaic et al. 1992), thermoplastic starch materials (Aichholzer and Frtiz 1998) and in bread dough measurements (Sofou et al. 2008), where all authors have reported linear modified Mooney plots. The regression lines where slip is present in Fig. 6 are practically close to parallel, as represented by the values of a, which suggests that the data are of reasonable value.

The resulting slip velocity for the Janz variety bread dough at 25°C as a function of wall shear stress for 1- and 2-mm dies is displayed in Fig. 7, which also shows how slip velocity is dependent on capillary diameter.

The slip velocity decreased slightly with increasing diameter, as expected for a shear-thinning fluid (Barnes 1995). Several other authors have also observed the dependence of slip velocity on capillary diameter for polymeric materials (Mournaic et al. 1992) and bread dough (Sofou et al. 2008). The critical shear stress at which wall slip occurs for bread dough is around 5–10 kPa, which is in the same range as reported by Sofou et al. (2008) where critical slip occurred at 5, 10 and 15 kPa for diameters 0.4, 0.8 and 2 mm, respectively. These values are relatively low when compared to critical slip values of shear stress of similar materials: around 50 kPa for a potato paste using 1- to 5-mm-diameter dies (Corfield et al. 1999) and 70 kPa for a mixture of polymer ethylene vinyl acetate and glass micro-spheres using a 1-mm diameter die (Lam et al. 2007).

Final flow curve

The corrected shear rate at the wall (\(\dot {\gamma }_{\rm w} \)) can now be found by applying the Rabinowitsch–Weissenberg correction (Eisenschitz et al. 1929), which assumes a power law fluid velocity profile, to the apparent shear rate corrected for slip (\(\dot {\gamma }_{\rm ap, s} \)).

where b is the slope of the curve log (\(\dot {\gamma}_{\rm ap, s} \)) versus log (τw). For the Janz bread dough at 25°C, b = 2.2. It is noted that \(\dot {\gamma}_{\rm ap, s} \equiv \dot {\gamma}_{\rm ap} \) under a no-slip condition.

The corrected flow curves for dough using 5:1, 10:1, 30:1, 10:2 and 20:2 dies are displayed in Fig. 8.

The data collapses well on a master curve to reveal the flow behaviour for the Janz variety bread dough at 25°C. This curve can be modelled empirically in the form

where K is the consistency coefficient and n is the power law index. For the Janz variety bread dough, K and n are estimated at values of 859 Pa s0.67 and 0.67, respectively. The exponent emphasises the shear thinning behaviour of the material and highlights the hardness of the wheat flour. Past capillary rheometry papers for hard wheat flour dough similar to the Janz variety have presented values of n ranging from 0.34–0.64 (Bagley et al. 1998; Breuillet et al. 2002; Cuq et al. 2002; Sharma et al. 1993a). These papers have not corrected for wall slip, thus making the Rabinowitsch–Weissenberg corrected shear rate appear as a higher value for a particular shear stress, acting to decrease the slope. Indeed, if the data from this study remained uncorrected for wall slip, an exponent of n = 0.42 is attained; however, it is clear that these results are diameter dependent; hence, wall slip is present, especially at high shear rates. In the low shear rate range, several authors have reported exponents for hard wheat flour doughs of n = 0.25–0.3 using torsional rheometry (Hicks et al. 2008; Phan-Thien et al. 1997; Tanner et al. 2008). This suggests two regimes of shear behaviour.

More can be learned by merging the torsional and corrected capillary data from both 1- and 2-mm die diameters as a combined shear viscosity curve, which is displayed in Fig. 9.

The data ranges of the two separate rheological test methods (torsional and capillary) are limited and consequently overlap only in the range 10–20 s − 1, including two out of four strain values presented in the torsional data. The data overlap is not quite matching, which may be explained by the strain-dependent nature of the material. Dough has been shown in this investigation; and others (Lindborg et al. 1997; Phan-Thien et al. 1997; Tanner et al. 2008), to be strain dependent under torsional measurements and so strain must be specified to obtain a value for viscosity. In capillary measurements, however, strain cannot be explicitly defined, so a value for viscosity is generated based on the material’s steady state in laminar tube flow using a pressure drop.

In Fig. 9, we observe a change in slope in the combined shear viscosity curve around a shear rate of 1–10 s − 1. Indeed, the same observation is made testing an identical sample under oscillation on the parallel plate torsional rheometer, as discussed below.

Results for the complex viscosity ∣ η * ∣, obtained on the Paar Physica MCR 301 rheometer, at a shear strain amplitude of 0.3% as a function of the applied frequency ω (radian per second) are shown in Fig. 10. Observe the clear change in slope as the frequency is increased.

∣η*∣ versus frequency measurements at a strain amplitude of 0.3% for the Janz bread dough at 25°C. n − 1 represents the slope of the corresponding torsional or capillary data presented in Fig. 9

The maximum strain that results in a linear viscoelastic response is very small for doughs (Uthayakumaran et al. 2002). A maximum shear strain of 0.003 (0.3%) was experimentally determined to be the limit of the linear viscoelastic region for the Janz variety dough at 25°C (obtained by an amplitude sweep test using the Paar Physica MCR 301 parallel plate rheometer), and this was the amplitude used in the investigation.

For comparison of shear and oscillatory rheometry, the Cox–Merz rule is often used, where \(\eta ( {\dot {\gamma }} )= {| {\eta *} |( \omega )} |_{\omega =\dot {\gamma }} \). Although ultimately useful for many polymers, this relationship has been shown to not apply to bread dough (Phan-Thien et al. 1997; Sofou et al. 2008). However, we observe that the viscosity and oscillatory curves have similar characteristics: both Figs. 9 and 10 suggest that the material becomes less shear thinning, with a lower exponent observed at higher deformation rates. In addition, in Fig. 9, there is an obvious difference in slope of the low shear rate data (n − 1) = 0.74, which is consistent with the literature (Tanner et al. 2008; Uthayakumaran et al. 2002), and the high shear rate data (n − 1) = 0.33. This is replicated in Fig. 10 when we look at the oscillatory data as a function of frequency, where similarity in the slopes of the two curves can be observed. This confirms the two regime power law behaviour of the Janz variety bread dough.

In the past, results from both methods have been empirically modelled on the basis that the data collapses onto a straight line of a log–log plot, a simple power law correlation. Therefore, any change in slope in the data at the limit of the data range would have been neglected on the basis of simplifying the model. In this work, the low deformation rate regime portrays the stability of the structural element of the dough, whereas the higher rate regime represents the breakdown of this element and a phase separation at the shearing boundary, effectively influencing the rheological properties of the dough. Increasing the shear rate further acts to severely break down the dough to the point where data cannot be confidently accepted as a representation of material properties. More can be learned by analysing the fluctuations in pressure when testing dough at high shear rates, which will be discussed in the next section.

Pressure fluctuation

Establishing replicate data on the Göttfert capillary rheometer presents a challenge in the high shear rate range (in our case, above 1,000 s − 1) since gross changes are occurring in the bulk flow of the fluid. First, pressure fluctuations are so intense that a relatively steady state of flow cannot be identified, and second, wall slip, which is prominent in such conditions, is more difficult to account for.

The typical variance in steady state extrusion pressure at acceptable conditions, shown earlier in Fig. 2, was significant but accountable. Pressure fluctuation in the testing of dough is an issue that often gets overlooked or ignored. This is despite the fact that understanding how a material interacts with a measuring system is paramount in characterising that material (Dobraszczyk and Morgenstern 2003).

A statistical analysis has not been carried out on dough, but it would prove very useful in future research to combine with qualitative observations. However, the cause and statistical analysis of pressure fluctuation in solid–liquid pastes, a material with some similarities to bread dough, is well recognised (Amarasinghe and Wilson 1998; Benbow and Bridgwater 1993; Russell et al. 2003; Wilson and Rough 2006). After making observations during rheological experiments and analysing the raw data, it is clear that similarities exist between bread dough and solid–liquid pastes in the cause of pressure fluctuation. Bread dough consists of particles in a viscoelastic matrix, and similarly, solid–liquid pastes are particles in a viscous matrix (usually water). However, since capillary experiments involve a steady flow, the elastic component of the dough does not play an explicit role.

Four causes for pressure fluctuation are identified in the case of solid–liquid pastes: rupture of large agglomerates, release of entrapped gas, inhomogeneity (poor mixing) and surface fracture. The rupture of large agglomerates causes spikes to a higher extrusion pressure, a release of entrapped gas is accompanied by a sharp decrease in extrusion pressure, poor mixing results in a small alternating noisy signal, and the exact mechanisms of surface fracture are not yet fully understood (Russell et al. 2003).

Attempts to explain pressure fluctuation in the extrusion of dough in previous literature were made by Cuq et al. (2002), who described the variations in pressure as a result of the dough structure sensitivity during the filling of the barrel, and by Bagley et al. (1998) who attributed part of the fluctuation in dough to sample heterogeneity by directly observing significant fluctuations in extrudate diameter. The phenomenon observed by Bagley et al. was seen occurring in the current investigation at high shear rates, along with several additional observations. Upon extruding the dough, irregular surface fracture patterns could be visually observed on the sample extrudate typically above shear rates of 800 s − 1 in a 1-mm-diameter die and 1,000 s − 1 in a 2-mm-diameter die and became more noticeable with an increased shear rate. This can partly be explained by the sharp change in tensile stresses the dough experiences upon exit from the die land into the surrounding atmosphere. Alternatively, this fracture may also be a result of the material breaking down or rupturing under the high strains experienced close to the wall of the capillary as showed by the low shear rate range rheometry in Fig. 1 or the release of entrapped air at higher shear rates.

A further observation was that what sounded like exploding air pockets could be clearly heard during the tests at shear rates above around 2,000 s − 1 in 1-mm-diameter dies and 4,000 s − 1 in 2-mm-diameter dies. This is not surprising since bread dough contains about 8% vol/vol air after the mixing stage (Wang et al. 2006). The air expands rapidly as the materials flows out of the die land to atmospheric pressure and ruptures the extrudates, promoting surface fracture. This is an important consideration in designing a high throughput breadmaking process since the presence of air in the mixture is a key factor in fulfilling the requirements of a quality, high-volume and structured loaf (Sluimer 2005). However, a reassuring trend is that the release of gas is seemingly exacerbated by smaller diameter dies, and so in large-scale operation of a high throughput breadmaking process, where dimensions are much larger, the dough may not be affected.

In solid–liquid pastes, the extrusion process acts to break down agglomerates and cause significant pressure fluctuation (Bohm and Blackburn 1994). Agglomerates are formed in the dough during the mixing process when starch particles coalesce amongst proteins with the addition of water and the application of mechanical energy. Torsional experiments in this investigation (Fig. 1) and previous literature (Phan-Thien et al. 1997; Tanner et al. 2008) have shown that high strain levels act to break down or rupture bread dough, such as those reached in the capillary experiments in this investigation.

Pressure fluctuation can be further investigated by displaying extrusion pressure versus time for a range of shear rates with 30:1 and 5:1 capillary dies. This is shown in Fig. 11.

Figure 11 shows that pressure fluctuations increase with shear rate and die length. In capillary rheometry, the use of longer dies is recommended to reduce the need for standard capillary corrections. In this case, however, the strain on the material is much larger in a longer die that acts to intensify pressure fluctuation. Therefore, the data suggests that the rupture of large agglomerates is a significant contributor to pressure fluctuation. That is, it would be expected that the pressure displays larger fluctuations as the rate of de-agglomeration increases (Bohm and Blackburn 1994). This agrees with the suggestion by Bagley et al. (1998) that pressure fluctuation is associated with sample heterogeneity.

One proposed solution to minimise pressure fluctuation would be to over-mix the dough. Over-mixing has indeed been shown to significantly reduce pressure fluctuation, invoking a higher level of con fidence in the data (Bagley et al. 1998), and has been adopted by Sofou et al. (2008) in their investigation on bread dough. Furthermore, it is consistent with the work of Amarasinghe and Wilson (1998) using solid–liquid pastes that demonstrated that the reduction in number and size of agglomerates was matched by a reduction in pressure spikes to a higher extrusion pressure. Experiments on over-developed dough we have undertaken using the capillary rheometer suggest that over-mixing the dough significantly reduces pressure fluctuations to approximately ±2%, compared to ±8% observed using bread dough mixed to peak consistency. However, characterising over-mixed dough is of less use from an application viewpoint since mixing the dough past its peak consistency results in a poor quality loaf as the structural element (proteins) cannot support itself due to terminal damage (Zheng et al. 2000).

In summary, it is clear that dough mixed to peak consistency will contain agglomerates that cause pressure fluctuation. Bagley et al. (1998) suggested that larger sample sizes and die diameters could be used to identify a relatively steady state of flow and therefore that pressure output be confidently extracted from the test to derive parameters that are then used to model the flow behaviour of the dough. A further option is to limit the data range of the study, as in this report.

Conclusions

The breadmaking procedure is becoming further industrialised concurrent with a growing demand for bread. Quality and process control in this industry, as well as advances in agricultural and processing methods, have been limited by a deficit in understanding the complex rheology of wheat flour–water doughs.

Current contributions from the scientific community in this field fail to completely address the conceptual problems associated with the determination of the rheological properties of wheat flour doughs at these conditions, specifically, the interaction between material and measuring system. For example, Sofou et al. (2008) have incorporated wall slip into their empirical model for bread dough at high shear rates; however, to overcome expected pressure fluctuations, they employed an over-mixed dough, which has limited practical application to breadmaking.

In this paper, the flow behaviour of an Australian hard wheat flour–water dough was characterised over an extensive range of shear rates by employing both torsional and capillary rheometry techniques. Torsional measurements showed that no steady shear viscosity could be attained and revealed the strain-dependent breakdown of the dough structure. In capillary rheometry tests, the shear rate range was limited to 1,000 s − 1 to avoid terminal pressure fluctuations typically observed in capillary rheometry of doughs at high shear rates. The wall slip phenomenon in the capillary rheometry of dough was discussed, and the wall slip velocity was quantified to produce a flow curve, which highlighted the shear thinning behaviour of the material.

Combining the torsional and capillary data on a single curve over an extensive range of shear rates revealed a two-regime power law behaviour, which was confirmed by oscillatory measurements. This was explained by the breakdown in the dough’s structure under high shear gradients. Identifying the two-regime power law behaviour exercised by bread dough is significant to breadmaking since previous literature recognises only a single-regime behaviour. A future direction in this area would be to understand the mechanisms and develop a suitable rheological model for bread dough over the two regimes.

This paper shows that capillary rheometry is a viable method for testing bread dough provided that pressure fluctuation is accounted for. This can be achieved by limiting the shear rate range and selecting shorter dies with a larger diameter. In addition, wall slip should be accounted for in future investigations when testing doughs in capillary rheometry.

References

Aichholzer W, Frtiz H-G (1998) Rheological characterisation of thermoplastic starch materials. Starch-Starke 50:77–83

Amarasinghe ADUS, Wilson DI (1998) Interpretation of paste extrusion data. Chem Eng Res Des 76:3–8

Bagley EB (1957) End corrections in the capillary flow of polyethylene. J Appl Phys 28:624–627

Bagley EB, Dinitzis FR, Chakrabarti S (1998) Experimental and conceptual problems in the rheological characterization of wheat flour doughs. Rheol Acta 37:556–565

Barnes HA (1995) A review of the slip (wall depletion) of polymer solutions, emulsions and particulate suspensions in viscometers: its cause, character, and cure. J Non-Newton Fluid Mech 56:221–251

Benbow J, Bridgwater J (1993) Paste flow and extrusion. Oxford University Press, Oxford

Bloksma AH (1972) Rheology of wheat flour doughs. J Texture Stud 3:3–17

Bloksma AH (1990) Rheology of the breadmaking process. Cereal Foods World 35:228–236

Blyler LL, Hart AC (1970) Capillary flow instability of ethylene polymer melts. Polym Eng Sci 10:193

Bohm H, Blackburn S (1994) Agglomerate breakdown in fine alumina powder by multiple extrusion. J Mater Sci 29:5779–5786

Breuillet C, Yildiz E, Cuq B, Kokini JL (2002) Study of the anomalous capillary Bagley factor behaviour of three types of wheat flour doughs at two moisture contents. J Texture Stud 33:315–340

Buscall R, Mcgowen JI, Morton-Jones A (1993) The rheology of concentrated dispersions of weakly attracting colloidal particles with and without wall slip. J Rheol 37:621–641

Cauvain SP (2003) Breadmaking. In: Cauvain SP (ed) Bread making: improving quality. Woodhead Publishing Limited, Cambridge

Chakrabandhu K, Singh RK (2005) Wall slip determination for coarse food suspensions in tube flow at high shear rates. J Food Eng 70:73–81

Cook NP, Furno FJ, Eirich FR (1965) Polymer melt flow behaviour in the barrel of a capillary rheometer. Trans Soc Rheol 9:405–420

Corfield GM, Adams MJ, Briscoe BJ, Fryer PJ, Lawrence CJ (1999) A critical examination of capillary rheometry for foods (exhibitng wall slip). Food Bioprod Process 77:3–10

Cuq B, Yildiz E, Kokini J (2002) Influence of mixing conditions and rest time on capillary flow behaviour of wheat flour dough. Cereal Chem 79:129–137

Dealy JM, Wissbrun KF (1999) Melt rheology and its role in plastics processing. Kluwer Academic Publishers, Dordrecht, The Netherlands

Dhanasekharan M, Huang H, Kokini JL (1999) Comparison of observed rheological properties of hard wheat flour dough with predictions of the Giesekus–Leonov, White–Metzner and Phan–Thien–Tanner models. J Texture Stud 30:603–623

Dobraszczyk BJ, Morgenstern MP (2003) Rheology and the breadmaking process. J Cereal Sci 38:229–245

Eisenschitz R, Rabinowitsch B, Weissenberg K (1929) Mitt Dtsch Mat-Prtif-Anst, Sonderheft 9:91

Faridi H, Faubion JM (eds) (1986) Fundamentals of dough rheology. American Association of Cereal Chemists, St Paul

Faridi H, Faubion JM (eds) (1990) Dough rheology and baked product texture. Van Nostrand Reinhold, New York

Geiger K (1989) Rheologische characterisierung von EPDM kautschukmischungen mittels kapillar-rheometer systemen. Kautsch Gummi Kunstst 42:273–283

Hicks CI, See H, Arabo EYM (2008) Capillary rheometry of microstructured fluids. Proc. Chemeca, Newcastle

Khan SA, Schnepper CA, Armstrong RC (1988) Foam rheology: III. Measurement of shear flow properties. J Rheol 32:69

Knappe W, Krumbock E (1986) Slip flow in non-plasticized PVC-compounds. Rheol Acta 25:296–307

Lam YC, Wang ZY, Chen X, Joshi SC (2007) Wall slip of concentrated suspension melts in capillary flows. Powder Technol 177:162–169

Liang JZ, Ness JN (1997) Studies on melt flow properties of low density and linear low density polyethylene blends in capillary extrusion. Polym Test 16:173–184

Lindborg KM (1995) Rheological studies of wheat flour doughs: the development of structure during mixing. Dissertation, University of Lund, Sweden

Lindborg KM, Tragardh C, Eliasson A-C, Dejmek P (1997) Time-resolved shear viscosity of wheat flour doughs—effect of mixing, shear rate, and resting on the viscosity of doughs of different flours. Cereal Chem 74:49–55

Lupton JM, Regester WJ (1965) Melt flow of polyethylene at high rates. Polym Eng Sci 5:235

Mooney M (1931) Explicit formulas for slip and fluidity. J Rheol 2:210–222

Mournaic PH, Agassant J-F, Vergnes B (1992) Determination of the wall slip velocity in the flow of a SBR compound. Rheol Acta 31:565–574

Muliawan EB, Hatzikiriakos SG (2008) Rheology of mozzarella cheese: extrusion and rolling. Int Dairy J 18:615–623

Phan-Thien N, Safari-Ardi M, Morales-Patino A (1997) Oscillatory and simple shear flows of a flour-water dough: a constitutive model. Rheol Acta 36:38–48

Russell BD, Lasenby J, Blackburn S, Wilson DI (2003) Characterising paste extrusion behaviour by signal processing of pressure sensor data. Powder Technol 132:233–248

Sharma N (1990) Modelling flow behaviour of flour water doughs. Dissertation, University of Nebraska, Lincoln

Sharma N, Hanna MA (1987) Flow characterization of wheat flour dough using an extruder. Unpublished laboratory work on cold extrusion of flour–water dough, Department of Agricultural Engineering, University of Nebraska, Lincoln

Sharma N, Hanna MA, Chen YR (1993a) Flow behaviour of wheat flour–water dough using a capillary rheometer: I. Effect of capillary geometry. Cereal Chem 70:59–63

Sharma N, Hanna MA, Chen YR (1993b) Flow behaviour of wheat flour–water dough using a capillary rheometer: II. Effects of water, protein, mix, and rest time. Cereal Chem 70:63–67

Shukla A, Rizvi SSH (1995) Measurement of flowability of butter by capillary rheometry. J Texture Stud 26:299–311

Sluimer P (2005) Principles of breadmaking: functionality of raw materials and process steps. American Association of Cereal Chemists, Inc

Sofou S, Muliawan EB, Hatzikiriakos SG, Mitsoulis E (2008) Rheological characterization and constitutive modelling of bread dough. Rheol Acta 47:369–381

Stephen AM (2006) Phase behaviour in mixed polysaccharide systems. In: Stephen AM, Phillips GO, Williams PA (eds) Food polysaccharides and their applications. CRC Press, Boca Raton, FL

Tanner RI, Qi F, Dai S-C (2008) Bread dough rheology and recoil I. Rheology. J Non-Newton Fluid Mech 148:33–40

Uthayakumaran S, Newberry M, Phan-Thien N, Tanner RI (2002) Small and large strain rheology of wheat gluten. Rheol Acta 41:162–172

Wang C, Dai S-C, Tanner RI (2006) On the compressibility of bread dough. Korea–Australia Rheol J 18:127–131

White JL (1973) Critique on flow patterns in polymer fluids at the entrance of a die and instabilities leading to extrudate distortion. Appl Polym Symp 20

Wilson DI, Rough SL (2006) Exploiting the curious characteristics of dense solid–liquid phases. Chem Eng Sci 61:4147–4154

Worth RA, Parnaby J, Helmy HAA (1977) Wall slip and its implications in the design of single screw melt-fed extruders. Polym Eng Sci 17:257–265

Young LS (1998) The application of knowledge-based systems. In: Cauvain SP, Young LS (eds) Technology of breadmaking. Blackie Academic & Professional London, UK

Zheng H, Morgenstern MP, Campanella OH, Larsen NG (2000) Rheological properties of dough during mechanical dough development. J Cereal Sci 32:293–306

Acknowledgements

Christopher I. Hicks acknowledges the support of the Postgraduate Scholarship in Rheological Research made available for this study, and the authors acknowledge the support of the Australian Research Council (ARC). The authors also thank Professor Roger Tanner and Dr. Shao Cong Dai for their assistance and valuable comments

Dedication

This work is dedicated to the memory of Associate Professor Howard See. A valued member of the international Rheology community, an inspirational teacher and great friend.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hicks, C.I., See, H. The rheological characterisation of bread dough using capillary rheometry. Rheol Acta 49, 719–732 (2010). https://doi.org/10.1007/s00397-010-0441-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-010-0441-1