Abstract

Phosphorus (P) rich ash from biomass incineration is a potential promising alternative for non-renewable phosphate rock. This study considered the P recovery potential of poultry manure ash, sewage sludge ash and meat and bone meal ash through wet chemical extraction. X-ray diffraction analysis showed that these three ash types had a distinct P mineralogy. If inorganic acids were used for the extraction, the P extraction efficiency was not or only slightly affected by the P mineralogy. Contrarily, for the organic acids, alkaline extraction liquid and chelating agents considered, the P extraction efficiency was highly affected by the P mineralogy, and was also affected by the elemental composition of the ash and/or the chemical characteristics of the extraction liquids. Alkaline extraction liquids showed in general low heavy metal co-extraction, in contrast to the inorganic acids. From an economic point of view, of all extraction liquids considered, sulfuric acid was the most interesting to extract P from all three ash types. Oxalic acid could be a more sustainable option for P extraction from sewage sludge ash. In addition, extraction of poultry manure ash with ethylenediaminetetraacetic acid showed a relatively high P extraction efficiency combined with relatively low heavy metal co-extraction.

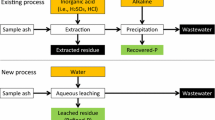

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

The present study is the first of its kind to evaluate and compare the efficiency of P and heavy metal extraction from different types of biomass ash considering various types of extraction liquids. Another novelty is the fact that the P (and heavy metal) extraction efficiency for the different types of biomass ash is linked to the ash mineralogy, elemental composition of the ash, and/or chemical characteristics of the extraction liquids.

Introduction

Globally, each year about 20 million tonnes of phosphorus (P) are extracted from phosphate rock to be used in fertilizers, animal feed and detergents [1,2,3]. However, phosphate rock is a non-renewable resource that is becoming scarce, while reserves are unevenly distributed over the world. Europe for instance, mainly depends on P and phosphate rock imports from other continents [4, 5]. To avoid a P shortage and to reduce Europe’s economic dependence, it is imperative to recover P from alternative sources.

After its use in different applications, a substantial part of the P extracted from phosphate rock eventually ends up in sewage sludge (SS) originating from wastewater treatment and in animal manure or animal by-products such as meat and bone meal (MBM) [3, 5, 6]. The application of SS as fertilizer to agricultural land is in most countries restricted or even prohibited because of its high concentrations of heavy metals and toxic organic compounds [7, 8]. The latter can be destroyed by incinerating the SS. However, the major fraction of the heavy metals remains in the resulting sewage sludge ash (SSA) and can pose, depending on local legislation, a regulatory constraint for direct application of the SSA as fertilizer [9,10,11]. On the other hand, animal manure is widely applied as fertilizer, although it is often present in excess in areas of intensive livestock farming [12,13,14]. Therefore, an alternative to direct land application is incineration of the animal manure, which reduces its volume whilst part of its energy content is recovered [14,15,16,17]. The power plant of BMC Moerdijk (the Netherlands) for instance, annually converts about 420,000 tonnes of poultry manure (PM) into green energy, producing about 55,000 tonnes of poultry manure ash (PMA). This PMA contains high concentrations of the essential fertilizer nutrients P and K, but its application as fertilizer is subject to legal constraints [18]. As for animal by-products, the outbreak of the mad cow disease (BSE) resulted in a ban on the use of MBM in animal feed from 2001 [13]. Since then, MBM, which has a high calorific value, is mainly mono-incinerated or co-incinerated with other waste in dedicated installations or in cement kilns [5, 13, 19, 20]. One of the advantages of biomass incineration in general is that P is not transferred to the gas phase but is largely retained in the ash [17, 21]. However, in the case of co-incineration in cement kilns, the P in the biomass is mixed with the cement components and is permanently lost for recovery [5, 10]. The P content in SSA, animal manure ash and meat and bone meal ash (MBMA) ranges between 3 and 20% [15, 19, 21,22,23]. Therefore, these ash types are a potential promising alternative for non-renewable (low grade) phosphate rock that contains between 2 and 18% P [24, 25].

Wet chemical extraction is the most proposed technique to recover P from incineration ash because of its high efficiency, low cost and because it is already applied on an industrial scale for P extraction from phosphate rock [9, 22, 26]. Various types of extraction liquids have been evaluated for P extraction, such as inorganic acids, organic acids, alkaline extraction liquids and chelating agents [9, 12, 22, 27,28,29]. A shown general disadvantage of wet chemical extraction is that heavy metals in the incineration ash are co-extracted. Subsequently, these heavy metals have to be separated from the valuable P by, for instance, cation exchange, pH adjustment or sulfide precipitation [25, 30,31,32]. As a consequence, an optimal extraction liquid combines a high P extraction efficiency with low heavy metal co-extraction, in this way reducing the downstream processing costs for heavy metal removal.

A first conclusion from a dedicated literature review was that the majority of studies on P recovery from incineration ash focused on only one type of incineration ash at a time. Indeed, researchers mainly focused on P recovery from SSA (e.g., [7, 9, 22, 25, 28, 32]) and to a lesser extent on P recovery from either animal manure ash (e.g., [12, 16, 26]) or MBMA (e.g., [16, 29]). However, to replace the major part of P that is currently extracted from phosphate rock, all different types of P rich incineration ash will have to be exploited since one ash type alone cannot supply the necessary amount of P [6]. The literature also shows that different ash types can have a distinct mineralogy [16, 33, 34], which can influence the P recovery process. However, to the authors knowledge, the link between ash mineralogy and P extraction efficiency has not been studied in dept in the literature. The best way to do so, would be to compare the ash mineralogy and P extraction efficiency for different types of biomass ash. Furthermore, most studies found in the literature only considered a limited set of extraction liquids for P recovery from incineration ash. Yet, different extraction liquids show different P and heavy metal extraction efficiencies [12, 22, 32]. Finally, the extraction settings (extraction liquid concentration, liquid/solid (L/S) ratio, contact time, etc.) and properties of the considered ash types (ash composition, ash mineralogy, etc.) differ for most studies found in the literature and hence a one-on-one comparison of literature data is almost impossible. Therefore, it is important to include a broad set of extraction liquids in comparative ash extraction studies.

Given the conclusions of the literature review discussed in the previous paragraph, the overall aim of this comprehensive study was to evaluate and compare the efficiency of P and heavy metal extraction from PMA, SSA and MBMA using a broad set of different types of extraction liquids. The experiments were set-up and the obtained results were in the first place interpreted from an engineering perspective. Yet, where possible, an attempt was made to link, based on fundamental chemical laws, the observed differences in P and heavy metal extraction efficiency to the ash mineralogy, elemental composition of the ash, and/or chemical characteristics of the extraction liquids.

Materials and Methods

Chemical Characterization of the Different Ash Types

Three different ash types were investigated in this research, i.e., PMA, SSA and MBMA. The PMA sample was obtained from the fluidized bed power plant of BMC Moerdijk (the Netherlands), where PM is incinerated at a bed temperature of 765 °C. This PMA was a mixture of ash collected at the bottom of the fluidized bed, superheater, economizer, electrostatic precipitator and baghouse filter with a mass ratio of 26:6:5:58:5, which corresponds to the ratio of total ash production. A detailed description of the power plant of BMC Moerdijk and the sampling locations can be consulted in previous work of the authors [18]. The SSA sample was obtained from the electrostatic precipitator of the Aquafin fluidized bed incineration plant (Belgium), where SS is incinerated at bed temperatures between 840 and 850 °C. The MBMA was prepared by incinerating MBM, received from Indaver (Belgium), for 3 h at 850 °C in a muffle furnace after which it was cooled to room temperature in the ambient air. The PMA and MBMA were rather inhomogeneous in particle size and were grinded to a homogeneous particle size (< 40 µm). The SSA consisted already of a fine homogeneous powder (< 40 µm). All ash samples were homogenized by thorough mixing, after which subsamples were taken for the experiments.

The three ash types were digested with a combination of aqua regia and hydrofluoric acid. The method used in this paper was based on CMA/2/II/A.3 and the European standard EN 13656:2002 [35, 36]. For the digestion, 500 mg of dry (grinded) ash, 8 ml aqua regia and 6 ml hydrofluoric acid were mixed in a well‑sealed 100 ml HDPE digestion bottle. After 44 h of reaction and mixing in between, the content was transferred to a 100 ml PP volumetric flask containing about 5.6 g boric acid and diluted to the mark. This solution was further filtered over a syringe filter (0.45 µm) and analyzed for Al, Ca, Cd, Cr, Cu, Fe, K, Mg, Na, Ni, P, Pb, S, Si and Zn by Inductively Coupled Plasma Optical Emission Spectroscopy (ICP‑OES) (Varian 720‑ES ICP‑OES). No glassware was used for digestion and dilution. It should be noted that in this work the digestion was not microwave or temperature assisted. Previous experiments performed by the authors comparing microwave assisted digestion and the digestion described above indicated that for the ash types studied in this work similar composition data was obtained through both digestion methods.

To determine the ash mineralogy in the crystalline phase, the three ash types were mechanically grinded in the presence of ethanol and a corundum internal standard. Next, they were analyzed by quantitative X-ray diffraction (XRD) (D8 Bruker) with Cu Kα radiation and the data obtained was refined based on the Rietveld method.

Extraction Experiments

Eleven different extraction liquids were selected based on a literature review and own experience [7, 9, 12, 16, 21, 22, 25,26,27,28,29, 32, 37,38,39,40,41,42]. The different extraction liquids were tested at a concentration of 0.5 N, an L/S ratio of 50 ml/g ash and a contact time of 2 h for all three ash types. The same concentration (0.5 N) was used for all extraction liquids so that equivalent weights of reactive units (H+ or OH−) were present to obtain similar extraction conditions (see the first paragraph of section ‘P Extraction' for more detailed information on the influence of the reactive units on the P extraction efficiency). However, extraction liquids with equivalent weights of reactive units will not necessarily release the same amount of reactive units into solution to react with the P. For instance, weak acids do not completely dissociate in aqueous solutions, resulting in a lower amount of released reactive units (H+), which is reflected in higher pH values. In this way, the pH in the extraction experiments was intrinsically determined by the type and concentration of the extraction liquid and the specific ash type. The obtained pH was thus not actively controlled and was therefore different for the different extraction liquids and ash types.

The considered extraction liquids consisted of three inorganic acids, i.e., sulfuric acid, hydrochloric acid and nitric acid, and five organic acids, i.e., acetic acid, citric acid, formic acid, gluconic acid and oxalic acid. The organic acids provided both an acid and complexing extraction environment [12]. Furthermore, one alkaline extraction liquid, i.e., sodium hydroxide, and two chelating agents, i.e., ethylenediaminetetraacetic acid (EDTA) and nitrilotriacetic acid (NTA) were considered. Both chelating agents were dissolved in a sodium hydroxide solution, since their solubility in alkaline solutions is much higher than in water. For this, a 0.5 N sodium hydroxide solution was used, allowing to compare the results of the chelating agents with the results of the pure 0.5 N sodium hydroxide solution.

The extraction experiments were carried out at room temperature and all glassware was first rinsed with a 3% nitric acid solution. A well-sealed 50 ml PP falcon tube (HDPE flat cap) with 500 mg of dry (grinded) ash and 25 ml extraction liquid with a concentration of 0.5 N was placed horizontally on a reciprocating shaker (Heidolph Promax 2020) for 2 h at maximum speed (400 rpm). For each run, the pH of the extraction liquid was measured at the start and at the end of the extraction procedure (SenTix 21 electrode). Next, the solutions were filtered (0.45 μm) and analyzed for Cd, Cr, Cu, Ni, P, Pb and Zn by ICP-OES (Varian 720-ES ICP-OES). The extraction efficiency was calculated as the amount of element extracted according to Eq. (1):

Selection of Optimal Extraction Liquid

The selection of the most suited extraction liquid was based on the extraction efficiencies of both P and heavy metals. First, a high P extraction efficiency was desirable to recover as much P as possible for application as an essential nutrient in fertilizers. Moreover, a high P extraction efficiency results in a low P concentration in the solid extraction residue, which is desirable when using this solid residue as building material or in cement production [18].

Second, the extraction efficiencies of heavy metals had to be as low as possible to limit the costs of further processing the P extract to a final P fertilizer product that complies with legal limit values for heavy metals in fertilizers. This research focused on the heavy metals Cd, Cr, Cu, Ni, Pb and Zn for which limit values apply in the Flemish legislation for the use of waste materials as a fertilizer (VLAREMA, Annex 2.3.1.A) [43]. It should be noted that the concentration limit values for heavy metals laid down in the Flemish legislation do not directly apply to the extraction liquid but to the final fertilizer product. However, they serve as a relevant selection base since co-extraction of these heavy metals causes extra purification costs to prevent that they remain in the final fertilizer product.

Statistical Analysis

Digestions and extraction experiments were performed in triplicate with subsamples from the same ash sample. Average values and standard deviations were determined to assess statistical significance of trends and differences.

Results and Discussion

Chemical Characterization of the Different Ash Types

Table 1 gives the concentrations of the major elements (% of dry matter (DM)) and of the heavy metals of concern (mg/kg DM) in the PMA, SSA and MBMA. The average P concentration in these three ash types was 6.11%, 6.99% and 13.49% of DM, respectively, which is comparable to the P content in (low grade) phosphate rock (2–18%) [2, 24, 25]. Similar P concentrations were found in literature for these ash types: 4–11% P in PMA [15, 16, 23, 33], 4–12% P in SSA [3, 9, 21, 22, 25, 39], and 8–20% P in MBMA [16, 19, 21, 23].

The SSA showed higher levels of Al, Fe and Si compared to the PMA and MBMA (see Table 1). This is due to the presence of sand and the addition of Fe or Al containing chemicals for P precipitation during wastewater treatment. On the other hand, the PMA and MBMA showed higher concentrations of Ca compared to the SSA. The highest concentrations of heavy metals (Cd, Cr, Cu, Ni, Pb and Zn) were found in the SSA, while the MBMA was generally the least contaminated of the tree ash types (see Table 1).

Table 2 gives the results of the XRD analysis of the PMA, SSA and MBMA. This table shows that about 22% of the MBMA consisted of amorphous material from which the mineralogy could not be determined, whereas the share of amorphous material was much higher for SSA (about 36%) and PMA (about 48%). The main crystalline minerals present in the PMA were apatite (Ca5(PO4)3(OH,Cl,F)), arcanite (K2SO4), quartz (SiO2), calcite (CaCO3) and KNaCa-phosphate (KNaCa2(PO4)2). The SSA mainly contained quartz, whitlockite (Ca9(Mg,Fe)(PO4)6(PO3OH)), hematite (Fe2O3) and magnetite (Fe3O4) in the crystalline phase. The crystalline phase in the MBMA mainly consisted of apatite, buchwaldite (NaCaPO4) and lime (CaO). The amount of P bound in the different crystalline minerals and in the amorphous phase was calculated based on the P and phosphates content in the crystalline phase in the three ash types (Tables 1 and 2, respectively). It was found that 52% of total P in the PMA was bound in the amorphous phase, whereas 30% of total P was bound as apatite and 18% of total P was bound as KNaCa-phosphate. For SSA, 59% of total P was bound in the amorphous phase, 39% of total P was bound as whitlockite and 2% of total P was bound as apatite. For MBMA, 67% of total P was bound as apatite, 18% of total P was bound as buchwaldite and 15% of total P was bound in the amorphous phase.

P Extraction

Figure 1 gives the solubility curves as function of pH for different P compounds (Al-, Ca-, Fe- and Mg-phosphates) calculated with Visual MINTEQ. From this figure, it is clear that P can be extracted from the ash in two different ways depending on the P mineralogy. On the one hand, in an acid solution, P can be extracted by protonation of \({\text{PO}}_{4}^{3-}\) in the ash resulting in \({\text{H}}{\text{PO}}_{4}^{2-}\), \({\text{H}}_{2}{{\text{PO}}}_{4}^{-}\) and finally \({\text{H}}_{3}{{\text{PO}}}_{4}\). This is for instance the case for some of the Ca-, Mg-, Al- and Fe-phosphates. However, high amounts of P can only be extracted if the pH of the extraction liquid is sufficiently low, for instance at pH < 1 for AlPO4 or at pH < 4 for Ca3(PO4)2 (see Fig. 1). On the other hand, in an alkaline solution, P can be extracted by formation of a hydroxide complexion with the phosphate counter ion (e.g., \({\text{Al}}{\left({\text{OH}}\right)}_{4}^{-}\)). This is for instance the case for some of the Al- and Fe-phosphates, which dissolve well at high pH (see Fig. 1). Most processes for P recovery from incineration ash that are implemented or still under development are based on the principle of P extraction in an acid solution. Some examples of processes are TetraPhos (dissolving P in SSA and MBMA by phosphoric acid), Phos4Life (dissolving P in SSA by sulfuric acid) and Ash2Phos (dissolving P in SSA by hydrochloric acid or sulfuric acid). On the other hand, P extraction in an alkaline solution has rarely been applied. An example is the Metawater process where P in SSA is mainly extracted from AlPO4 by sodium hydroxide [44, 45]. A more detailed description of these processes and other processes can be found in ESPP et al. [45] and Kabbe and Rinck-Pfieffer [44].

Solubility curves as function of pH for different P compounds calculated with Visual MINTEQ 3.1. AlPO4 belongs to the group of the Al-phosphates, Ca3(PO4)2 and Ca5(PO4)3OH belong to the group of the Ca-phosphates, FePO4 and Fe3(PO4)2 belong to the group of the Fe-phosphates, and Mg3(PO4)2 belongs to the group of the Mg-phosphates

Figure 2 gives the efficiency of P extraction from the PMA, SSA and MBMA for all extraction liquids considered (The P concentration in the three ash types differs. For the sake of completeness, the P extraction mass balance data can be consulted in the supplementary material, Fig. S1). The pH at the start and at the end of the extraction procedure for all extraction liquids considered can be consulted in Table 3. Figure 2 indicates that the P extraction efficiency was in general higher for the inorganic acids (sulfuric acid, hydrochloric acid and nitric acid) than for the other extraction liquids. There are two explanations for these higher P extraction efficiencies. First, this can be explained by the fact that the inorganic acids considered were all strong acids, whereas the organic acids considered (acetic acid, citric acid, formic acid, gluconic acid and oxalic acid) were all weak acids. In general, strong acids release more protons than weak acids and hence result in more protonation of \({\text{PO}}_{4}^{3-}\) and accordingly in a higher P extraction efficiency. Second, XRD analysis showed that at least part of the P in the three ash types was bound as Ca-phosphates (e.g. apatite and whitlockite, see Table 3). These Ca-phosphates are poorly soluble in an alkaline environment (see Fig. 1), explaining the lower P extraction efficiencies obtained with the alkaline extraction solutions (sodium hydroxide, EDTA and NTA) compared to the inorganic acids [28, 46]. It should, however, be noted that the P extraction efficiency in an alkaline environment increased considerably in the presence of chelating agents, except for the SSA (see Fig. 2). This might be due to the fact that chelating agents such as EDTA and NTA can form highly soluble complexes with the phosphate counter ions such as Al, Ca, Fe and Mg [47,48,49]. Hence, strong complex formation with for instance Ca will shift the Ca-phosphate dissolution reaction to the right, even if Ca-phosphates as such are poorly soluble in an alkaline environment. The latter is discussed in more detail in the last paragraph of section ‘P Extraction by Alkaline Extraction Liquid and Chelating Agents’.

Efficiency of P extraction from the PMA, SSA and MBMA for all extraction liquids considered (%). The error bars indicate plus and minus one standard deviation (n = 3, subsamples from the same sample). Extraction efficiencies of more than 100% can be attributed to slight interferences in ICP-OES measurements. IA inorganic acids; OA organic acids; Al alkaline solution; ChAl chelating agents in alkaline solution

P Extraction by Inorganic Acids

The P extraction efficiency was for all inorganic acids and for all ash types > 88% (see Fig. 2). This is in line with previously reported results, amongst others, by Darwish et al. [29], Fang et al. [22], Kootstra et al. [12] and Leng et al. [16]. However, as discussed in the introduction section, a one-on-one comparison with literature data is almost impossible due to differences in extraction settings and ash properties. These overall high P extraction efficiencies indicate that the P extraction efficiency for the inorganic acids was not or only slightly affected by the specific P mineralogy of the different ash types. This might be attributed to the low pH at the end of the extraction procedure, which was < 1 for all three inorganic acids and for all three ash types (see Table 3). According to Fig. 1, almost all phosphate compounds indeed show high solubility at pH < 1.

All extraction liquids other than the inorganic acids showed differences in P extraction efficiency between the three ash types and between the different extraction liquids (see Fig. 2). These differences are most likely due to differences in P mineralogy, elemental composition of the ash, and/or chemical characteristics of the extraction liquids. However, the fact that the ash types contained a considerable fraction of amorphous P from which the mineralogy could not be determined, especially the PMA and SSA (52% and 59% of total P, respectively), made it difficult to directly link the P mineralogy to the P extraction efficiency. Yet, below, an attempt is made to explain the differences in P extraction efficiency based on the P mineralogy, elemental composition of the ash and known chemical characteristics of the extraction liquids.

P Extraction by Organic Acids

Of all organic acids considered, oxalic acid is the strongest acid (pKa1 = 1.25), followed by citric acid (pKa1 = 3.13), gluconic acid (pKa = 3.60), formic acid (pKa = 3.75) and acetic acid (pKa = 4.76). The lower the pKa value, the higher the dissociation constant (Ka) and hence the more the acid will dissociate in aqueous solutions, which is reflected in lower pH values. As discussed when comparing the strong and weak acids, lower pH values favor P extraction from the ash because of more protonation of \({\text{PO}}_{4}^{3-}\) [12, 21, 30]. Hence, it can be concluded that the pKa values of the organic acids are inversely proportional to the P extraction efficiency for SSA. Indeed, of all organic acids considered, oxalic acid showed the highest P extraction efficiency for SSA (92%), followed by citric acid (63%), gluconic acid (52%), formic acid (35%) and acetic acid (9%). Research by Atienza-Martinez et al. [7], Fang et al. [22] and Liang et al. [9] previously revealed that high P extraction efficiencies can indeed be obtained when extracting P from SSA by oxalic acid. However, differences in extraction settings impede the one-on-one comparison of literature data and the data in this research. Furthermore, for citric acid, a similar P extraction efficiency from SSA was previously obtained by Fang et al. [22], again taking into account other extraction settings. However, to the authors knowledge, P extraction from SSA by one of the other organic acids considered in this research (acetic acid, formic acid and gluconic acid) have not previously been under investigation.

Furthermore, Fig. 2 shows that the citric acid, formic acid and gluconic acid P extraction efficiency for PMA varied between 69 and 71%, whereas they varied between 33 and 39% for MBMA. These P extraction efficiencies may be linked to the P mineralogy. First, based on the work by Kratz et al. [34] it is hypothesized that buchwaldite and KNaCa-phosphate show a higher solubility than apatite, and that amorphous P shows a higher solubility than crystalline P. Second, the solubility curve of hydroxyapatiteFootnote 1 (Ca5(PO4)3OH) (see Fig. 1) indicates that this P mineral is highly soluble until a pH of about 2.5. The pH at the end of the extraction procedure for citric acid, formic acid and gluconic acid varied between 3.1 and 3.4 for PMA and between 2.7 and 3.0 for MBMA (see Table 3). Therefore, it is hypothesized that the 30% and 67% of total P bound as apatite in the PMA and MBMA did as good as not dissolve when extracted with citric acid, formic acid and gluconic acid. Indeed, the fraction of P bound as apatite corresponds rather well with the fraction of P not dissolving in these three extraction liquids (29–31% for PMA and 61–67% for MBMA, respectively). In addition, it was found that the acetic acid P extraction efficiency for PMA and MBMA was much lower than for all other organic acids (see Fig. 2), which might be related to the low pKa value of acetic acid.

It should be noted that the oxalic acid P extraction efficiency for SSA was within the same range as that of the inorganic acids (92%), whereas it was much lower for PMA and MBMA (70% and 40%, respectively). The pH at the end of the extraction procedure for oxalic acid varied between 1.0 and 1.3 for all three ash types. According to Fig. 1 and the discussion in the previous paragraph, it was expected that apatite and all other phosphates would totally dissolve at these pH values, resulting in P extraction efficiencies of about 100% for all three ash types. However, this was not the case and it is hypothesized here that this might be linked to the Ca concentration in the ash types. From Fig. 2 and Table 1 it can be concluded that the P extraction efficiency for oxalic acid is inversely proportional to the Ca concentration in the ash types (6.64% of DM for SSA, 21.12% of DM for PMA and 33.63% of DM for MBMA). During oxalic acid extraction, the Ca initially extracted from the ash binds with oxalate and forms poorly soluble Ca-oxalate [9, 12, 22]. Ca-oxalate precipitate formation might obstruct the acid penetration towards the core of the not yet dissolved ash particles. This Ca-oxalate precipitate formation will probably decrease the dissolution of P from the ash and most likely at some point P extraction will even stop due to the formation of a high amount of Ca-oxalate. Hence, it is expected that ash types with a higher Ca concentration will most likely reach the point of Ca-oxalate blocking already at a lower P extraction efficiency. It is worth noting that during sulfuric acid extraction a precipitate is also formed, i.e., gypsum [9, 21, 22, 25]. However, gypsum has a higher molar solubility than Ca-oxalate over the full pH range (for instance, at pH 1, s = 4.1 × 10−2 M for gypsum and 4.9 × 10−3 M for Ca-oxalate, respectively (data from Visual MINTEQ)). Therefore, less gypsum precipitate formation is expected compared to Ca-oxalate precipitate formation and hence less acid penetration obstruction is expected. For all other extraction liquids than oxalic acid, sulfuric acid and sodium hydroxide, it was found that the amount of Ca extracted was proportional to the amount of P extracted (data shown in supplementary material Fig. S2).

P Extraction by Alkaline Extraction Liquid and Chelating Agents

The P extraction efficiency with sodium hydroxide was 0% for PMA and MBMA, whereas it was 39% for SSA (see Fig. 2). The pH at the end of the extraction procedure with sodium hydroxide varied between 13.2 and 13.3. In Fig. 1 it can be seen that in this pH range some of the Al- and Fe-phosphates dissolve well, whereas Ca- and Mg-phosphates are in general poorly soluble [28, 46]. Hence, this indicates that hardly any Al- and or Fe-phosphates were present in the unknown amorphous phase of the PMA and MBMA. This might be related to the low Al and Fe content in PMA and MBMA compared to SSA. Furthermore, it can be concluded that at least part of the unknown amorphous P in the SSA consisted of Al- and/or Fe-phosphates since no Al- and/or Fe-phosphates were detected in the crystalline phase by the XRD analysis. Indeed, the presence of Al- and/or Fe-phosphates in SSA has been previously confirmed in studies by Lee and Kim [46], Liang et al. [9], Peplinski et al. [50] and Petzet et al. [28]. The presence of Al- and/or Fe-phosphates in SSA can be linked to the addition of soluble Al- and/or Fe-compounds such as alum or iron(III) chloride to the wastewater to precipitate the dissolved P that is subsequently removed with the SS.

The P extraction efficiency for PMA and MBMA in alkaline environment increased considerably in the presence of chelating agents. Figure 2 clearly shows that EDTA extraction resulted in higher P extraction efficiencies than NTA extraction. This might be due to the fact that EDTA can form more stable complexes than NTA with most metals because of higher formation constants (Kf). For instance, the Ca-EDTA complex (log Kf = 10.69) is more stable than the Ca-NTA complex (log Kf = 6.41). The more stable complexes ensured that the Ca or other metals bound to the P in the ashes more easily dissolved in the extraction liquid, simultaneously dissolving the P and thus resulting in higher P extraction efficiencies. Contrarily, the P extraction efficiency for SSA in alkaline environment decreased in the presence of chelating agents. This can probably be explained by the combination of the following two facts, both linked to the pH at the end of the extraction procedure. First, in Table 3 it can be seen that the pH at the end of the sodium hydroxide extraction procedure for SSA was 13.2, whereas this was 9.9 for EDTA and NTA extraction. Both AlPO4 and FePO4 show relatively low solubilities at pH 9.9 (< 25%), whereas they are completely soluble at pH 13.2 (see Fig. 1). Hence, it is likely that the amorphous Al- and/or Fe-phosphates that dissolved from the SSA when extracted with sodium hydroxide no longer dissolved or at least to a much lesser degree for EDTA and NTA extraction. Second, as for the PMA and MBMA, it was expected that phosphates in the SSA can dissolve through complex formation of chelating agents with the phosphate counter ion. However, the stability of EDTA and NTA complexes deteriorates with decreasing pH [49, 51, 52]. Hence, the complexes for the PMA and MBMA extraction were more stable than for the SSA extraction because of the higher pH at the end of the EDTA and NTA extraction procedure (11.9–12.2 for PMA and MBMA, and 9.9 for SSA, respectively). Indeed, the fraction of EDTA and NTA present in its fully deprotonated form, at which the metal complexes are most stable, depends on the pH of the solution [49, 51, 52]. For instance, at pH 10 only 37% of the EDTA is present in its fully deprotonated form, whereas this is almost 100% at pH 12 [51]. Hence, the pH-dependent conditional formation constant \(\left({\text{K}}_{\text{f}}^{^{\prime}}\right)\), considering the limited availability of fully deprotonated chelates, is lower at pH 10 than at pH 12 which explains the lower complex stability at lower pH. In short, the P extraction efficiency for SSA in alkaline environment decreased in the presence of chelating agents due to the lower pH at which both less Al- and Fe-phosphates dissolve and due to the presence of only little amounts of fully deprotonated EDTA and NTA for complexation of the phosphate counter ions.

Heavy Metal Extraction

Figures 3 and 4 give the efficiencies of Cd, Cr, Cu, Ni, Pb and Zn extraction from the PMA, SSA and MBMA for all extraction liquids considered (The heavy metal concentration in the three ash types differs. For the sake of completeness, heavy metal extraction mass balance data can be consulted in the supplementary material, Fig. S3 and Fig. S4). The concentration of Cd and Pb in the PMA and MBMA was below the detection limit value of the ICP-OES measurements (2 mg/kg DM, see Table 1) and therefore the Cd and Pb extraction efficiencies in Fig. 4 are only given for SSA.

Efficiency of Cr, Cu, Ni and Zn extraction from the PMA, SSA and MBMA for all extraction liquids considered (%). The error bars indicate plus and minus one standard deviation (n = 3, subsamples from the same sample). Extraction efficiencies of more than 100% can be attributed to slight interferences in ICP-OES measurements. IA inorganic acids; OA organic acids; Al alkaline solution; ChAl chelating agents in alkaline solution. a Cr extraction efficiency (%); b Cu extraction efficiency (%); c Ni extraction efficiency (%); d Zn extraction efficiency (%)

Efficiency of Cd and Pb extraction from the SSA for all extraction liquids considered (%). The error bars indicate plus and minus one standard deviation (n = 3, subsamples from the same sample). IA inorganic acids; OA organic acids; Al alkaline solution; ChAl chelating agents in alkaline solution. a Cd extraction efficiency (%); b Pb extraction efficiency (%)

Figure 3 shows that the Cr, Cu, Ni and Zn extraction efficiencies were in general higher for the PMA and MBMA than for the SSA. However, Table 1 shows that the heavy metal concentrations in the initial ash were in general highest in the SSA, followed by the PMA and MBMA. The mass balances in the supplementary material (Fig. S3) show that the extracted amount of Cu, Ni and Zn were in general highest for PMA, followed by SSA and MBMA, whereas the extracted amount of Cr was in general highest for MBMA, followed by PMA and SSA. This shows that there is no direct relationship between the concentration of the heavy metals in the three ash types and the amount of heavy metals that is extracted from these three ash types. This might be explained based on the differences in speciation of the heavy metals. Unfortunately, the mineralogy of the heavy metals could not be detected by XRD due to their low concentrations in the three ash types. However, based on the results obtained with the extraction experiments, it could be assumed that most of the heavy metals in the SSA were bound in poorly soluble silicates, aluminates or oxides due to the high contents of Si and Al in the SSA [53, 54]. In the PMA and MBMA, it is more likely that the heavy metals were bound in more soluble compounds such as chlorides or sulfates.

Overall, the alkaline extraction liquids (sodium hydroxide, EDTA and NTA) had the lowest heavy metal extraction efficiencies for all three ash types considered (see Figs. 3 and 4). This could mainly be explained by the high pH at the end of the extraction procedure (ranging between 9.9 and 13.3), since most heavy metal compounds show low solubility at high pH [55, 56]. However, the P extraction efficiency for these alkaline extraction liquids was also relatively low (< 39%), except for EDTA extraction of PMA (68%). Nonetheless, it was expected that extraction with complexing agents would result in relatively high heavy metal extraction efficiencies due to formation of highly soluble heavy metal complexes [47, 48]. However, the results in Figs. 3 and 4 showed a tendency opposite to the expectations. On the one hand, the limited heavy metal complexation might be attributed to competition for the complexion with major ash elements such as Ca, Al and Fe [47, 48]. On the other hand, it might be attributed to the fact that the formation of poorly soluble heavy metal oxides or hydroxides competes with the chelating agents at high pH [52, 57]. For instance, Zn(OH)2 is poorly soluble \(\left({\text{K}}_{\text{sp}}\text{ = 7.71 x }{10}^{-17}\right)\) and hence at high pH a substantial part of Zn may precipitate as hydroxide. As a result, less Zn is available for participating in the complex formation equilibrium and accordingly the formation constant (e.g., log Kf = 16.50 for Zn-EDTA) must be corrected with a factor that reflects the availability of the Zn ions. In addition, the formation constant has to be corrected for the availability of fully deprotonated chelates at a specific pH (see discussion in section ‘P Extraction by Alkaline Extraction Liquid and Chelating Agents'). Applying these two correction factors gives the conditional formation constant \(\left({\text{K}}_{\text{f}}^{^{\prime\prime} }\right)\) which is lower than the original formation constant and hence less stable complexes are formed [52].

In general, the highest heavy metal extraction efficiencies were obtained with the inorganic acids (sulfuric acid, hydrochloric acid and nitric acid) (see Figs. 3 and 4). As discussed in section ‘P Extraction by Inorganic Acids’, these extraction liquids also showed the highest P extraction efficiencies, indicating that a high P extraction efficiency coincides inevitably with high heavy metal co-extraction. Nevertheless, EDTA extraction of PMA resulted in a relatively high P extraction efficiency of 68%, combined with relatively low heavy metal co-extraction (12% Cr, 22% Cu, 13% Ni and 17% Zn extracted). Obviously, in this case, it must be considered whether the 32% P remaining in the PMA solid extraction residue outweighs the possibly lower downstream processing costs for heavy metal removal.

Selection of Optimal Extraction Liquid

The discussion in sections ‘P Extraction and Heavy Metal Extraction’ clearly indicates that the selection of the most suited extraction liquid for a specific ash type is affected by the ash mineralogy, elemental composition of the ash, and/or chemical characteristics of the extraction liquids. However, valorization on industrial scale might be facilitated when the same extraction liquid is used to treat several types of ash in the same P extraction installation. In this case, it is best to select one of the inorganic acids, since all inorganic acids showed good P extraction efficiencies regardless the difference in P mineralogy (at pH < 1). However, inorganic acid extraction resulted in relatively high heavy metal co-extraction implying further purification of the extract. From an economic point of view, it is in this case most interesting to use sulfuric acid because of the lower extraction liquid costs compared to the other inorganic acids considered (around 0.010 €/mol H+ for sulfuric acid, 0.023 €/mol H+ for hydrochloric acid and 0.030 €/mol H+ for nitric acid) [58]. Furthermore, sulfuric acid extraction is similar to the method applied most for P extraction from phosphate rock [5, 7]. Nonetheless, a suitable application for the gypsum and the solid extraction residue has to be found [8].

However, if only one specific ash type is treated in a P extraction installation, EDTA extraction could be an interesting option for the PMA and oxalic acid extraction for the SSA. On the one hand, EDTA extraction of PMA is interesting because of the relatively high P extraction efficiency (68%) combined with relatively low heavy metal co-extraction (12–22%), possibly decreasing downstream processing costs. Yet, further research should indicate if in this case the economic loss, due to the 32% of P that in not extracted from the ash, outweighs these lower downstream processing costs. On the other hand, oxalic acid extraction of SSA is interesting since the P extraction efficiency (92%) was within the same range as that of the inorganic acids. Furthermore, the use of oxalic acid is interesting because of the fact that the production of organic acids is overall more sustainable than the production of inorganic acids [12].

Conclusion

PMA, SSA and MBMA are promising alternatives for P recovery because they are renewable sources with a P content comparable to that of (low grade) phosphate rock. XRD analysis showed that PMA, SSA and MBMA had a distinct P mineralogy. The efficiency of P extraction with inorganic acids was very similar for the different ash types, indicating that it was not or only slightly affected by the specific P mineralogy. This can be explained by the fact that the applied concentration of 0.5 N, which was equal for all considered inorganic acids, resulted in pH values < 1 at which almost all P minerals in the ash show high solubility. Contrarily, for the organic acids, alkaline extraction liquid and chelating agents considered, the P extraction efficiency was highly affected by the specific P mineralogy. For these extraction liquids, the extraction of P from PMA, SSA and MBMA in the considered systems showed to be complex, since the ash composition, ash mineralogy and chemical characteristics of the extraction liquids indirectly influence (1) the pH of the solution which on its turn affects the solubility of the P minerals and (2) the type and the concentration of ions in the solution that can interact.

Heavy metal extraction efficiencies were in general higher for PMA and MBMA than for SSA. Alkaline extraction liquids showed in general low heavy metal extraction efficiencies, in contrast to the inorganic acids, indicating that a high P extraction efficiency coincides inevitably with high heavy metal co-extraction.

From an economic point of view, it is most interesting to extract P with sulfuric acid since all three ash types could be treated in the same installation, regardless the difference in P mineralogy. However, further downstream processing to separate the co-extracted heavy metals from the P in the extract remains necessary in this case. Oxalic acid could be a more sustainable option than sulfuric acid, but only showed a good P extraction efficiency for SSA. EDTA extraction could be an alternative for P extraction from PMA, since it showed a relatively high P extraction efficiency combined with relatively low heavy metal co-extraction. The optimal extraction procedure for industrial scale applications, however, will also depend on economic considerations such as the cost of the extraction liquids and the tradeoff between P extraction efficiency (increasing the revenue) and heavy metal co-extraction (increasing the downstream processing cost).

Availability of Data and Materials

Research data is stored and documented in a safe, secure and sustainable way and can be retrieved or accessed when needed.

Notes

Visual MINTEQ databases do not contain data on the chlorapatite (Ca5(PO4)3Cl) and fluorapatite (Ca5(PO4)3F) solubility. However, in the literature, it was found that for the ash types studied, apatite mainly occurs in the form of hydroxyapatite and only to a lesser extent in the form of chlorapatite and fluorapatite [19, 20, 26, 34]. Therefore, the conclusions in this paragraph are only based on the hydroxyapatite solubility.

Abbreviations

- MBM:

-

Meat and bone meal

- MBMA:

-

Meat and bone meal ash

- PM:

-

Poultry manure

- PMA:

-

Poultry manure ash

- SS:

-

Sewage sludge

- SSA:

-

Sewage sludge ash

References

U.S. Geological Survey (USGS): Phosphate rock. In: Mineral Commodity Summaries 2020, pp. 122–123. U.S. Geological Survey, Washington, D.C. (2020). https://doi.org/10.3133/mcs2020

Desmidt, E., Ghyselbrecht, K., Zhang, Y., Pinoy, L., Van der Bruggen, B., Verstraete, W., et al.: Global phosphorus scarcity and full-scale P-recovery techniques: a review. Crit. Rev. Environ. Sci. Technol. 45(4), 336–384 (2015). https://doi.org/10.1080/10643389.2013.866531

Mayer, B.K., Baker, L.A., Boyer, T.H., Drechsel, P., Gifford, M., Hanjra, M.A., et al.: Total value of phosphorus recovery. Environ. Sci. Technol. 50(13), 6606–6620 (2016). https://doi.org/10.1021/acs.est.6b01239

Cordell, D., White, S.: Sustainable phosphorus measures: strategies and technologies for achieving phosphorus security. Agronomy 3(1), 86–116 (2013). https://doi.org/10.3390/agronomy3010086

Takhim, M., Sonveaux, M., de Ruiter, R.: The Ecophos process: highest quality market products out of low-grade phosphate rock and sewage sludge ash. In: Ohtake, H., Tsuneda, S. (eds.) Phosphorus Recovery and Recycling, pp. 209–219. Springer, Singapore (2019). https://doi.org/10.1007/978-981-10-8031-9_14

Nättorp, A., Kabbe, C., Matsubae, K., Ohtake, H.: Development of phosphorus recycling in Europe and Japan. In: Ohtake, H., Tsuneda, S. (eds.) Phosphorus Recovery and Recycling, pp. 3–27. Springer, Singapore (2019). https://doi.org/10.1007/978-981-10-8031-9_1

Atienza-Martínez, M., Gea, G., Arauzo, J., Kersten, S.R.A., Kootstra, A.M.J.: Phosphorus recovery from sewage sludge char ash. Biomass Bioenerg. 65, 42–50 (2014). https://doi.org/10.1016/j.biombioe.2014.03.058

Donatello, S., Cheeseman, C.R.: Recycling and recovery routes for incinerated sewage sludge ash (ISSA): a review. Waste Manag. 33(11), 2328–2340 (2013). https://doi.org/10.1016/j.wasman.2013.05.024

Liang, S., Chen, H., Zeng, X., Li, Z., Yu, W., Xiao, K., et al.: A comparison between sulfuric acid and oxalic acid leaching with subsequent purification and precipitation for phosphorus recovery from sewage sludge incineration ash. Water Res. 159, 242–251 (2019). https://doi.org/10.1016/j.watres.2019.05.022

Adam, C., Peplinski, B., Michaelis, M., Kley, G., Simon, F.-G.: Thermochemical treatment of sewage sludge ashes for phosphorus recovery. Waste Manag. 29(3), 1122–1128 (2009). https://doi.org/10.1016/j.wasman.2008.09.011

Van de Velden, M., Dewil, R., Baeyens, J., Josson, L., Lanssens, P.: The distribution of heavy metals during fluidized bed combustion of sludge (FBSC). J. Hazard. Mater. 151(1), 96–102 (2008). https://doi.org/10.1016/j.jhazmat.2007.05.056

Kootstra, A.M.J., Brilman, D.W.F., Kersten, S.R.A.: Dissolution of phosphate from pig manure ash using organic and mineral acids. Waste Manag. 88, 141–146 (2019). https://doi.org/10.1016/j.wasman.2019.03.038

Langeveld, K.: Phosphorus recovery into fertilizers and industrial products by ICL in Europe. In: Ohtake, H., Tsuneda, S. (eds.) Phosphorus Recovery and Recycling, pp. 235–252. Springer, Singapore (2019). https://doi.org/10.1007/978-981-10-8031-9_16

Nusselder, S., de Graaff, L.G., Odegard, I.Y.R., Vandecasteele, C., Croezen, H.J.: Life cycle assessment and nutrient balance for five different treatment methods for poultry litter. J. Clean. Prod. 267, 121862 (2020). https://doi.org/10.1016/j.jclepro.2020.121862

Komiyama, T., Kobayashi, A., Yahagi, M.: The chemical characteristics of ashes from cattle, swine and poultry manure. J. Mater. Cycles Waste Manag. 15, 106–110 (2013). https://doi.org/10.1007/s10163-012-0089-2

Leng, L., Bogush, A.A., Roy, A., Stegemann, J.A.: Characterisation of ashes from waste biomass power plants and phosphorus recovery. Sci. Total Environ. 690, 573–583 (2019). https://doi.org/10.1016/j.scitotenv.2019.06.312

Billen, P., Costa, J., Van der Aa, L., Van Caneghem, J., Vandecasteele, C.: Electricity from poultry manure: a cleaner alternative to direct land application. J. Clean. Prod. 96, 467–475 (2015). https://doi.org/10.1016/j.jclepro.2014.04.016

Luyckx, L., de Leeuw, G.H.J., Van Caneghem, J.: Characterization of poultry litter ash in view of its valorization. Waste Biomass Valoriz. 11, 5333–5348 (2020). https://doi.org/10.1007/s12649-019-00750-6

Coutand, M., Cyr, M., Deydier, E., Guilet, R., Clastres, P.: Characteristics of industrial and laboratory meat and bone meal ashes and their potential applications. J. Hazard. Mater. 150(3), 522–532 (2008). https://doi.org/10.1016/j.jhazmat.2007.04.133

Deydier, E., Guilet, R., Sarda, S., Sharrock, P.: Physical and chemical characterisation of crude meat and bone meal combustion residue: “Waste or raw material?” J. Hazard. Mater. 121(1–3), 141–148 (2005). https://doi.org/10.1016/j.jhazmat.2005.02.003

Cohen, Y.: Phosphorus dissolution from ash of incinerated sewage sludge and animal carcasses using sulphuric acid. Environ. Technol. 30(11), 1215–1226 (2009). https://doi.org/10.1080/09593330903213879

Fang, L., Li, J., Guo, M.Z., Cheeseman, C.R., Tsang, D.C.W., Donatello, S., Poon, C.S.: Phosphorus recovery and leaching of trace elements from incinerated sewage sludge ash (ISSA). Chemosphere 193, 278–287 (2018). https://doi.org/10.1016/j.chemosphere.2017.11.023

Sarabèr, A.J.: Co-combustion and its impact on fly ash quality; Full-scale experiments. Fuel Process. Technol. 128, 68–82 (2014). https://doi.org/10.1016/j.fuproc.2014.06.026

European Sustainable Phosphorus Platform (ESPP). ESPP phosphorus fact sheet. Retrieved from https://phosphorusplatform.eu/images/download/ESPP-Phosphorus-fact-sheet-v21-4-19.pdf (2019)

Donatello, S., Tong, D., Cheeseman, C.R.: Production of technical grade phosphoric acid from incinerator sewage sludge ash (ISSA). Waste Manag. 30(8–9), 1634–1642 (2010). https://doi.org/10.1016/j.wasman.2010.04.009

Kaikake, K., Sekito, T., Dote, Y.: Phosphate recovery from phosphorus-rich solution obtained from chicken manure incineration ash. Waste Manag. 29(3), 1084–1088 (2009). https://doi.org/10.1016/j.wasman.2008.09.008

Ekpo, U., Ross, A.B., Camargo-Valero, M.A., Fletcher, L.A.: Influence of pH on hydrothermal treatment of swine manure: impact on extraction of nitrogen and phosphorus in process water. Bioresour. Technol. 214, 637–644 (2016). https://doi.org/10.1016/j.biortech.2016.05.012

Petzet, S., Peplinski, B., Cornel, P.: On wet chemical phosphorus recovery from sewage sludge ash by acidic or alkaline leaching and an optimized combination of both. Water Res. 46(12), 3769–3780 (2012). https://doi.org/10.1016/j.watres.2012.03.068

Darwish, M., Aris, A., Puteh, M.H., Jusoh, M.N.H., Kadir, A.A.: Waste bones ash as an alternative source of P for struvite precipitation. J. Environ. Manag. 203(2), 861–866 (2017). https://doi.org/10.1016/j.jenvman.2016.02.033

Franz, M.: Phosphate fertilizer from sewage sludge ash (SSA). Waste Manag. 28(10), 1809–1818 (2008). https://doi.org/10.1016/j.wasman.2007.08.011

Schaum, C., Cornel, P., Jardin, N.: Phosphorus recovery from sewage sludge ash—a wet chemical approach. In: Proceeding of the IWA Conference, pp. 583–590, June 24–27. Moncton, Canada (2007)

Xu, H., He, P., Gu, W., Wang, G., Shao, L.: Recovery of phosphorus as struvite from sewage sludge ash. J. Environ. Sci. 24(8), 1533–1538 (2012). https://doi.org/10.1016/S1001-0742(11)60969-8

Bogush, A.A., Stegemann, J.A., Williams, R., Wood, I.G.: Element speciation in UK biomass power plant residues based on composition, mineralogy, microstructure and leaching. Fuel 211, 712–725 (2018). https://doi.org/10.1016/j.fuel.2017.09.103

Kratz, S., Vogel, C., Adam, C.: Agronomic performance of P recycling fertilizers and methods to predict it: a review. Nutr. Cycl. Agroecosyst. 115, 1–39 (2019). https://doi.org/10.1007/s10705-019-10010-7

EMIS. CMA/2/II/A.3: Ontsluitingsmethode voor de bepaling van elementen in bodem, vaste en pasteuze materialen. Belgisch Staatsblad (2016)

European Committee for Standardization. EN 13656:2002 Characterization of waste—microwave assisted digestion with hydrofluoric (HF), nitric (HNO3) and hydrochloric (HCl) acid mixture for subsequent determination of elements (2002)

Azuara, M., Kersten, S.R.A., Kootstra, A.M.J.: Recycling phosphorus by fast pyrolysis of pig manure: concentration and extraction of phosphorus combined with formation of value-added pyrolysis products. Biomass Bioenerg. 49, 171–180 (2013). https://doi.org/10.1016/j.biombioe.2012.12.010

Luyckx, L.: Fosforherwinning uit pluimveemestverbrandingsassen en uit beendermeel. Masterproef ingediend tot het behalen van de graad van Master of Science in de Industriële Wetenschappen: Chemie: Sustainable Process and Materials Engineering, Faculteit Industriële Ingenieurswetenschappen, Campus Groep T, KU Leuven (2016)

Wang, Q., Li, J., Tang, P., Fang, L., Poon, C.S.: Sustainable reclamation of phosphorus from incinerated sewage sludge ash as value-added struvite by chemical extraction, purification and crystallization. J. Clean. Prod. 181, 717–725 (2018). https://doi.org/10.1016/j.jclepro.2018.01.254

Biswas, B.K., Inoue, K., Harada, H., Ohto, K., Kawakita, H.: Leaching of phosphorus from incinerated sewage sludge ash by means of acid extraction followed by adsorption on orange waste gel. J. Environ. Sci. 21(12), 1753–1760 (2009). https://doi.org/10.1016/S1001-0742(08)62484-5

Li, J., Chen, Z., Wang, Q., Fang, L., Xue, Q., Cheeseman, C.R., et al.: Change in re-use value of incinerated sewage sludge ash due to chemical extraction of phosphorus. Waste Manag. 74, 404–412 (2018). https://doi.org/10.1016/j.wasman.2018.01.007

Szögi, A.A., Vanotti, M.B., Hunt, P.G.: Phosphorus recovery from pig manure solids prior to land application. J. Environ. Manag. 157, 1–7 (2015). https://doi.org/10.1016/j.jenvman.2015.04.010

VLAREMA - Besluit van de Vlaamse Regering tot vaststelling van het Vlaams reglement betreffende het duurzaam beheer van materiaalkringlopen en afvalstoffen. Retrieved from https://navigator.emis.vito.be/mijn-navigator?woId=43991 (2018)

Kabbe, C., Rinck-Pfieffer, S.: Global compendium on phosphorus recovery from sewage/sludge/ash. Global Water Research Coalition (2019)

European Sustainable Phosphorus Platform (ESPP), German Phosphorus Platform (DPP), & Netherlands Nutrient Platform (NNP). Phosphorus recovery technology catalogue. Retrieved from https://phosphorusplatform.eu/images/download/ESPP-NNP-DPP_P-recovery_tech_catalogue_v_25_2_2020.pdf (2020)

Lee, M., Kim, D.-J.: Identification of phosphorus forms in sewage sludge ash during acid pre-treatment for phosphorus recovery by chemical fractionation and spectroscopy. J. Ind. Eng. Chem. 51, 64–70 (2017). https://doi.org/10.1016/j.jiec.2017.02.013

Fang, L., Li, J., Donatello, S., Cheeseman, C.R., Wang, Q., Poon, C.S., Tsang, D.C.W.: Recovery of phosphorus from incinerated sewage sludge ash by combined two-step extraction and selective precipitation. Chem. Eng. J. 348, 74–83 (2018). https://doi.org/10.1016/j.cej.2018.04.201

Li, J., Tsang, D.C.W., Wang, Q., Fang, L., Xue, Q., Poon, C.S.: Fate of metals before and after chemical extraction of incinerated sewage sludge ash. Chemosphere 186, 350–359 (2017). https://doi.org/10.1016/j.chemosphere.2017.08.012

Liu, J., Li, K., Wang, H., Zhu, M., Xu, H., Yan, H.: Self-assembly of hydroxyapatite nanostructures by microwave irradiation. Nanotechnology 16, 82–87 (2005). https://doi.org/10.1088/0957-4484/16/1/017

Peplinski, B., Adam, C., Michaelis, M., Kley, G., Emmerling, F., Simon, F.-G.: Reaction sequences in the thermochemical treatment of sewage sludge ashes revealed by X-ray powder diffraction—a contribution to the European project SUSAN. In: Zeitschrift für Kristallographie Supplemente, vol. 30, pp. 459–464. September 19–22. Warsaw, Poland (2009). https://doi.org/10.1524/zksu.2009.0068

Harvey, D.: Complexation titrations. Retrieved May 15, 2020, from https://chem.libretexts.org/Bookshelves/Analytical_Chemistry/Book%3A_Analytical_Chemistry_2.1_(Harvey)/09%3A_Titrimetric_Methods/9.03%3A_Complexation_Titrations (2020)

Deutsche Forschungsgemeinschaft (DFG): Nitrilotriacetic acid and its sodium salts. In: The MAK-Collection for Occupational Health and Safety. Wiley, Hoboken (2014). https://doi.org/10.1002/3527600418.mb13913vere4514

Nowak, B., Aschenbrenner, P., Winter, F.: Heavy metal removal from sewage sludge ash and municipal solid waste fly ash—a comparison. Fuel Process. Technol. 105, 195–201 (2013). https://doi.org/10.1016/j.fuproc.2011.06.027

Liu, J., Fu, J., Ning, X., Sun, S., Wang, Y., Xie, W., et al.: An experimental and thermodynamic equilibrium investigation of the Pb, Zn, Cr, Cu, Mn and Ni partitioning during sewage sludge incineration. J. Environ. Sci. 35, 43–54 (2015). https://doi.org/10.1016/j.jes.2015.01.027

Li, J., Xue, Q., Fang, L., Poon, C.S.: Characteristics and metal leachability of incinerated sewage sludge ash and air pollution control residues from Hong Kong evaluated by different methods. Waste Manag. 64, 161–170 (2017). https://doi.org/10.1016/j.wasman.2017.03.033

Zhang, Y., Cetin, B., Likos, W.J., Edil, T.B.: Impacts of pH on leaching potential of elements from MSW incineration fly ash. Fuel 184, 815–825 (2016). https://doi.org/10.1016/j.fuel.2016.07.089

Yang, T., Rao, S., Zhang, D., Wen, J., Liu, W., Chen, L., Zhang, X.: Leaching of low grade zinc oxide ores in nitrilotriacetic acid solutions. Hydrometallurgy 161, 107–111 (2016). https://doi.org/10.1016/j.hydromet.2016.01.024

Chembid. (n.d.). Prices for chemicals from different suppliers. Retrieved May 4, 2020, from https://www.chembid.com

Acknowledgements

This study was financially supported by BMC Moerdijk BV (Industrial Park M349, Middenweg 36a, 4782 PM Moerdijk, The Netherlands) and Fonds Wetenschappelijk Onderzoek Vlaanderen (FWO) (Lorien Luyckx is a SB PhD fellow at FWO, Project Number 1S08418N – 1S08420N). Furthermore, we want to thank BMC Moerdijk, Aquafin and Indaver for supplying the PMA, SSA and MBM samples. In addition, we want to thank Antoinette Deschuytere for carefully revising the manuscript.

Funding

This study was financially supported by BMC Moerdijk BV (Industrial Park M349, Middenweg 36a, 4782 PM Moerdijk, The Netherlands) and Fonds Wetenschappelijk Onderzoek Vlaanderen (FWO) (Project Number 1S08418N – 1S08420N).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Luyckx, L., Sousa Correia, D.S. & Van Caneghem, J. Linking Phosphorus Extraction from Different Types of Biomass Incineration Ash to Ash Mineralogy, Ash Composition and Chemical Characteristics of Various Types of Extraction Liquids. Waste Biomass Valor 12, 5235–5248 (2021). https://doi.org/10.1007/s12649-021-01368-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01368-3