Abstract

Phosphorus, a limiting element, is essential for living organisms, but the total amount available is decreasing with its increasing use. This problem can be solved by studying the methods of phosphorus recovery from waste. Phosphorus (P2O5, 13.75%) is abundantly present in cattle manure bottom ash (CMBA), indicating its potential as a source for phosphorus recovery. Herein, phosphorus recovery from CMBA was investigated by acid extraction and precipitation methods. The optimum concentration of sulfuric acid for extraction was 1.4 M, which eluted approximately 90% of the phosphorus contained in CMBA. In the precipitation method, sodium hydroxide and calcium silicate hydrate (CSH, CaSiO3∙nH2O) were used to adjust the solution pH to 4 and 8, where more than 99% of the eluted phosphorus was recovered when the pH was adjusted to 8 using CSH alone. The chemical composition and crystal forms of the recovered precipitates were analyzed using X-ray fluorescence and an X-ray powder diffractometer. The results indicated monetite and brushite were the main crystal forms of precipitates at pH 4, and struvite, hydroxyapatite, and tricalcium phosphate were the main crystal forms at pH 8. The availability of phosphorus in the precipitates was also evaluated by quinoline gravimetric analysis using water and 2% citric acid, and the water-soluble precipitate was less than 35%, whereas it ranged from 65 to 97% in 2% citric acid. This study suggests that CMBA can be used as a promising source to recover phosphorus via acid extraction and precipitation processes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phosphorus is not only used for plating or surface polishing in the industries but is also used as an essential energy source by all living things, including humans (Adam et al. 2012; Sankara Narayanan 2005). It is present in triphosphate, which is an energy source for muscle movement. Phosphorus, with nitrogen, is an essential nutrient for plant growth. The demand for phosphorus and nitrogen has increased with the increase in crop cultivation caused by population growth (Krog 2003; Lee et al. 2018). In contrast to nitrogen fertilizer, which is obtained from the conversion of the atmospheric air (Bremner 1965; Smil 1999), the amount of phosphorus used as a fertilizer is obtained by mining P-rich deposits (Mayer et al. 2016). However, compared to the abundantly available nitrogen, phosphorus is a finite resource. According to Helin (Helin and Weikard 2019), the demand for mined phosphorus for use as fertilizers is expected to increase to 23 megatons by the end of this century (Gilbert 2009). Currently, most phosphates are stored in Morocco, followed by China, Algeria, and Syria. The total phosphorus in these countries accounts for more than 80% of the world’s phosphate reserves (Carrington 2019). Since phosphorus cannot be replaced by other elements, its use in the same proportion as before will soon lead to phosphate shortages in several countries of the world. Accordingly, methods of phosphorus recovery from various resources have been widely studied. Some have reported that using biomass ash can help recover phosphorus with high efficiency (Du et al. 2014; Wang et al. 2013; Xing et al. 2016). Table 1 shows the phosphorus content in various types of biomass ash. Among them, wood ash and sewage ash contain a substantial amount of phosphorus.

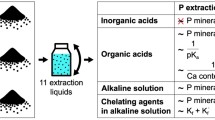

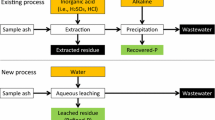

Typical methods of phosphorus extraction from biomass materials include chemical extraction and thermal extraction, which are frequently used. The chemical extraction method is relatively easy to operate, less expensive, and can efficiently extract phosphorus (Fang et al. 2020; Tan and Lagerkvist 2011), and consists of acid extraction and alkali extraction, wherein low-priced sulfuric acid is commonly used for extraction (Donatello and Cheeseman 2013; Liang et al. 2019; Ma and Rosen 2021). Since the chemical precipitation is straightforward and with efficient recovery, phosphorus dissolved in acid is mainly used for extraction by adjusting the pH, followed by precipitation and recovery (Ye et al. 2017). In this case, reagents used for precipitation include NaOH, MgO, Mg(OH)2, CaO, and Ca(OH)2 (Prazeres et al. 2020; Ye et al. 2017). Calcium silicate hydrate (CSH), a component of cement and concrete, is used as a precursor in the manufacturing of glass and filters (Ntafalias and Koutsoukos 2010). The high pH of CSH facilitates its use in precipitation, ion exchange, sorption, and lattice substitution (Gougar et al. 1996). In phosphorus recovery with chemical precipitation, CSH precipitates phosphorus in the form of hydroxyapatite (Guan et al. 2014; Zhang et al. 2018). Using CSH for phosphorus precipitation has several advantages (Law and Pagilla 2018; Lee et al. 2018; Okano et al. 2015): (1) calcium contained in CSH is used as seed material for phosphorus precipitation, (2) calcium hydroxide is formed by the release of calcium, so there is no need to add an additional chemical for pH control, (3) it has better settleability than other chemical compounds, and (4) phosphorus precipitation with CSH is less affected by coexisting anions.

Manure is an inevitable by-product of livestock production, with approximately 1.9 × 105 tons of livestock manure produced in Korea per day, and cattle manure accounts for 44.1% of the total livestock manure produced (Lee et al. 2021). In particular, cattle manure has a high calorific value similar to that of sawdust and rice straw, and studies have been actively conducted on heat recovery (Hong et al. 2020; Yuan et al. 2017; Zhang et al. 2019a). Nonetheless, recovery of other inorganic resources from cattle manure bottom ash (CMBA) after heat recovery has not been researched. In particular, CMBA contains a substantial amount of phosphorus, but the hydrochloric acid insoluble content (58.9 ± 0.7%) exceeds the national standard for direct use as fertilizer (< 30%). Therefore, this study is the first study to investigate the recovery of phosphorus contained in CMBA using acid extraction and precipitation methods. The extraction efficiency of phosphorus from CMBA was evaluated, and precipitation experiments were performed under controlled pH conditions. To enhance phosphorus recovery, the pH was adjusted in two steps using a combination of sodium hydroxide and CSH. Characteristics such as chemical composition, crystal structure, and the efficacy of the final product according to the precipitation conditions were also evaluated.

Materials and methods

Materials and chemicals

CMBA was obtained from a local dairy farm in Anseong, South Korea, where cattle manure pellets were used as fuel to heat water (lower heating value: 2720 kcal/kg) (Hong et al. 2020). The cattle manure pellets were dried at 70 ℃ for 24 h and then pyrolyzed. After pyrolysis, the cattle manure bottom ash (CMBA) was used for phosphorus recovery. Sulfuric acid (H2SO4, ≥ 95.0%), L( +)-ascorbic acid (C6H8O6, ≥ 99.5%), and sodium hydroxide (NaOH, bead, ≥ 98.0%) were purchased from Samchun Chemical (Pyeongtaek, Korea). Calcium silicate hydrate (CaSiO3∙nH2O) and bis[( +)tartorato] diantimonate (III) dipotassium trihydrate (C8H4K2O12Sb2∙3H2O, ≥ 98.0%) were purchased from Junsei Chemical Co. Ltd. (Tokyo, Japan). Ammonium molybdate tetrahydrate ((NH4)6Mo7O24∙4H2O, powder, ≥ 98.0%) and ammonium sulfamate (H6N2O3S, ≥ 98.5%) were purchased from Daejung Chemicals & Metals (Shiheung, Korea).

Method of phosphorus extraction from cattle manure bottom ash

The phosphorus in the CMBA was eluted with varying concentrations of sulfuric acid (0.0, 0.5, 1.0, 1.2, 1.4, 1.6, 1.8, and 2.0 M) to facilitate leaching. The pH of the eluted solution was measured with a pH meter (Orion Star A211, Thermo Scientific Orion, Seoul, Korea). For phosphorus elution, a solution of ash (2 g) and each concentration of sulfuric acid (10 mL) at a 1:5 (w/v) ratio was mixed for 30 min. After measuring the pH, the phosphorus in each eluate was estimated using a standard method for the examination of water and wastewater (Federation and Association 2005). Briefly, the absorbance of the eluate samples treated with a combined reagent of ammonium molybdate and ascorbic acid was measured with a UV–Vis spectrophotometer at 665 nm (NEO-S2117, Neogen, Korea). To estimate the effect of retention time on phosphorus recovery, elution experiments were conducted at different retention times (30, 90, 120 min). The ashes that were washed with deionized water were used to estimate the influence of washing on phosphorus elution.

Precipitation of phosphorus under controlled pH

The eluate containing a mixture of sulfuric acid (1.4 M) and CMBA in a 1:5 (w/v) ratio was used for precipitation experiments. The precipitation test was performed using NaOH (2 M) and two different doses (10 and 15 g/L) of CSH for pH control. Overall, similar precipitation experiments were conducted using NaOH and CSH. For the NaOH precipitation test, only NaOH was used to adjust the solution pH. When the pH was controlled using 10 g/L CSH, NaOH was used in combination with CSH, but at 15 g/L CSH, the pH was controlled only using CSH. During the first precipitation, the leaching solution of varying concentrations was added to the sample, and the pH of the sample was maintained at 4. The solutions that were controlled using NaOH and CSH were mixed for 2 h at 100 rpm in a shaking incubator (SJ-808SF, Sejong Technology, Korea). The solutions were then centrifuged at 3000 rpm for 5 min (MF300, Hanil Science Medical, Korea) and filtered using a vacuum pump with a glass microfiber filter. The subsequent precipitation process was performed at pH 8 by adjusting with NaOH and/or CSH, and the mixing and separation procedures were the same. Then, the precipitates produced from the experiments were dried at 50 °C in a vacuum drying oven (FTVO-701, SB Environment Corporation, Japan) prior to further analysis. All experiments were conducted in duplicate, and a one-way analysis of variance (ANOVA) test was used to determine statistically significant differences between treatments at a 95% confidence level (p < 0.05).

Characterization methods

The surface of the precipitates and CMBA were analyzed using a field-emission scanning electron microscope (SEM–EDS; JSM-6700F, JEOL, Japan). The chemical composition of the precipitates was identified using X-ray fluorescence (XRF; ZSX Primus, Rigaku, Japan) and an X-ray powder diffractometer (XRD; D/max-2500 V/PC, Rigaku, Japan) covering a two-theta range of 5.0–90.0° in steps of 0.02°. Quinoline gravimetric analysis was performed to analyze water solubility and citric acid solubility, which are key properties of the precipitate (Lee et al. 2018). To analyze the water-soluble phosphorus, in a 250 mL flask, 1 g of the precipitate was dissolved in 150 mL of deionized water and placed on a shaker for 1 h, then filled with water and filtered. Similarly, in the citric acid-soluble phosphorus analysis, 150 mL of 2% citric acid solution was used instead.

Results and discussion

Characterization of cattle manure bottom ash

The characteristics of CMBA were analyzed to confirm their importance as a phosphorus resource. SEM images of CMBA coupled with EDS showed an irregular shape with distinctive peaks for C, O, Ca, P, Na, K, Cl, S, Mg, Si, Fe, and Al (Fig. 1(a) and 1(b)). Similar compositions were observed in iron-impregnated cattle manure biochar, mainly composed of C, followed by Fe, Cl, O, Ca, P, and Mg (Lee et al. 2021; Park et al. 2021). XRD was used to determine the mineralogical composition (Fig. 1(c)). According to Match software combined with Crystallography Open Database, CMBA mainly contained Ca10.08(PO4)5.94(OH)2.32 (#96–721-7895: 2θ = 25.84°, 31.70°, 32.14°, 32.84°, 46.62°), CaCO3 (#96–210-0190: 2θ = 29.38°, 47.50°, 48.46°), and Ca3(PO4)2 (#96–900-5866: 2θ = 34.02°, 46.62°, 53.18°). A more detailed chemical composition analyzed by XRF is shown in Table 2, and data for sewage sludge are also included for comparison (Lee et al. 2018). Sewage sludge is considered to be a phosphorus resource because it often contains a high content of P2O5. However, it also contains a considerable amount of heavy metals, such as Al, necessitating additional treatment in the phosphorus recovery process. CaO (66.08%), followed by P2O5 (13.75%), are the main components of CMBA. High CaO content was also observed in other bottom ash (Asokbunyarat et al. 2015), and its alkaline nature increases the pH (13.2 for CMBA). The P2O5 content in the bottom ash of cattle manure was comparable to that of other biomass-derived ash (Table 1), indicating its potential as a source of phosphorus for resource conservation. The contents of MgO and K2O in cattle manure bottom ash were similar to those in sewage sludge, whereas the contents of Al2O3 and Fe2O3 were considerably less than those in sewage sludge. These lower heavy metals content could cause less contamination during the phosphorus recovery process. Therefore, CMBA can be a suitable source for phosphorous recovery. After extraction with sulfuric acid (1.4 M), CaO (41.65%), and P2O5 (3.83%), contents in CMBA decreased while SO3 (50.05%) increased significantly (Table 2).

Effect of sulfuric acid dose on phosphorus elution and final solution pH

Wet chemical extraction, with high efficiency and low cost, is the most proposed technique for phosphorus recovery from various ash and has already been applied on an industrial scale to extract phosphorus from phosphate rocks (Donatello and Cheeseman 2013; Luyckx et al. 2021). In this ore processing technique, phosphate is eluted into concentrated sulfuric acid, and gypsum is abundantly generated during the process, as shown in Eq. (1):

The phosphoric acid product is separated from the calcium sulfate crystals using a filtration process. Similarly, various concentrations of sulfuric acid were added to check the degree of phosphorus elution from the bottom ash of cattle manure (Fig. 2(a)). Phosphorus elution was negligible (0.36%, 55.34 mg P/L) up to 0.5 M sulfuric acid concentration, which then increased to 42.77% (6560.27 mg P/L) for 1.0 M sulfuric acid, and gradually increased to 89.99% (13,804.57 mg P/L) for 1.4 M sulfuric acid. Similar phosphorus elution according to sulfuric acid concentration was also observed in a thermally gasified piggery waste ash about 80% of phosphorus was eluted as the sulfuric acid concentration increased to 1.0 M (Kuligowski and Poulsen 2010). The amount eluted was not statistically different (p > 0.05) for 1.4 M, 1.6 M, and 1.8 M sulfuric acid but increased slightly for 2.0 M sulfuric acid. Therefore, considering the economic feasibility, phosphorus was eluted using 1.4 M sulfuric acid concentration in subsequent experiments.

In contrast to phosphorus elution, the pH of the phosphorus eluate evidently decreased with increasing sulfuric acid concentration (Fig. 2(b)). The pH of the mixture decreased from 13.20 (solid–liquid ratio = 1:5 (w/v)) in distilled water to 6.77 in 0.5 M sulfuric acid. Phosphorus elution from sewage sludge containing Al generally proceeded below pH 3 (Monea et al. 2020a), whereas the elution of phosphorus from CMBA actively proceeded below pH 5. A substantial amount of phosphorus (42.77%) was eluted at pH 4.77 with 1.0 M sulfuric acid treatment because calcium phosphate can effectively dissolve below pH 5 (Monea et al. 2020b). Approximately 90% of the phosphorus was eluted when phosphorus eluate pH dropped to 1.79 after treating with 1.4 M sulfuric acid. This was consistent with the literature reporting that phosphorus elution from ash is generally most significant at pH < 2 (Monea et al. 2020a). The effect of retention time on phosphorus elution was not significantly different, and the elution equilibrium was estimated to be within 30 min (Fig. S1). This result is consistent with the literature examining the phosphorus eluted from incineration ash of chicken manure (Sugiyama et al. 2019). Therefore, a 30 min retention time was sufficient to elute phosphorus from CMBA. These results confirmed that phosphorus in CMBA could be effectively eluted with 1.4 M sulfuric acid.

Precipitation of phosphorus with NaOH and CSH at certain pH level

Phosphorus recovery from the eluent was investigated after eluting with 1.4 M sulfuric acid at certain pH values, which was adjusted using NaOH and CSH. As shown in Fig. 3(a), 37.39 ± 0.12% of the total phosphorous in the eluent was recovered by increasing the solution pH to 4 with NaOH and an additional 22.15 ± 0.71% of the phosphorus was precipitated when the solution pH was increased to 8. Thus, approximately half of the phosphorus could be recovered by increasing the solution pH to 8 with NaOH. In particular, phosphorus recovery from the eluent can be enhanced using CSH. In our previous study, over 90% phosphorus was recovered from sewage sludge at pH 6.93; CSH precipitated phosphorus in the eluent, which was eluted using sulfuric acid (Lee et al. 2018). When the solution pH was adjusted to 4 using NaOH after adding 10 g/L of CSH (Fig. 3(b)), the phosphorus recovery (37.04 ± 0.12%) did not significantly change compared to that when only NaOH was used. However, the final phosphorus recovery (82.04 ± 1.55%) was enhanced by adding 10 g/L of CSH and adjusting the solution pH to 8. An additional pH adjustment was unnecessary when 15 g/L of CSH was used to recover phosphorus from the eluent. More than half of the total phosphorus (62.99 ± 0.60%) in the eluent was recovered by the first CSH addition (15 g/L) at pH 4, and 99.55 ± 0.16% of phosphorous was recovered by the second CSH addition (15 g/L) at pH 8 (Fig. 3(c)). CSH can mostly act as a seed crystal during phosphorus precipitation, which increases the phosphorus recovery efficiency (Zhang et al. 2019b). In addition, CSH not only effectively increases the solution pH, but the Ca contained in CSH can also help in struvite and hydroxyapatite formations (Okano et al. 2013a). Therefore, phosphorus can be more effectively recovered from the eluent using CSH.

Characterization of precipitates

The surface morphology of the precipitates was measured using SEM (Fig. S4), and a significant change in the surface structure was not observed depending on the type of precipitates. The chemical composition of the precipitate was assessed using XRF analysis (Table 3). The components in the NaOH precipitate were mostly P2O5, followed by Na2O and K2O. In particular, Al2O3 and Fe2O3 were mostly precipitated at pH 4, whereas MgO was mostly precipitated at pH 8. These results indicated that the content of unnecessary metal components for using the final product as a fertilizer can be adjusted according to solution pH conditions. Therefore, the composition of the final precipitate can be possibly controlled by adjusting the pH conditions during precipitation (Kaikake et al. 2009; Kalmykova and Fedje 2013). In contrast, CaO was the most abundant in the CSH-derived precipitate, and the SiO2 content increased with the increasing doses of CSH from 10 to 15 g/L. The high content of CaO and SiO2 suggests that the precipitate can be reused as seed material for phosphorus recovery (Lee et al. 2018). Although the ratio of P2O5 was higher in NaOH precipitates than that in CSH precipitates, the actual mass of phosphorus precipitate recovered was higher with CSH because of the relatively higher mass of precipitate produced than that with NaOH (Fig. 4(a)). The actual recovered masses of P2O5 calculated from the P2O5 ratio and the mass of the precipitate produced via NaOH, CSH (10 g/L), and CSH (15 g/L) at pH 4 were 0.29 g, 0.30 g, and 0.62 g, respectively. The total recovered masses of P2O5 by NaOH, CSH (10 g/L), and CSH (15 g/L) up to pH 8 were 0.51 g, 0.79 g, and 0.98 g, respectively. An increase in CSH dose effectively recovered phosphorus from the eluted solution. This is because CSH can act as a nucleus for phosphorus precipitation and serve as an adsorption site for phosphorus (Okano et al. 2013b). The precipitation tendencies of Al2O3, Fe2O3, and MgO at pH 4 and pH 8 using CSH were the same as those obtained using NaOH.

Since calcium and phosphate are derived from CMBA, the types of crystals formed in the precipitant were assumed to be struvite (Eq. (2)), brushite (Eq. (3)), hydroxyapatite (Eq. (4)), monetite (Eq. (5)], tricalcium phosphate [Eq. (6)], and octacalcium phosphate [Eq. (7)) (Frost and Palmer 2011; Komlev et al. 2010b; Minh et al. 2014; Penn and Camberato 2019; Shi et al. 2019). Octacalcium phosphate, which is formed from brushite, can be used as a precursor material for hydroxyapatite (Komlev et al. 2010a). The corresponding reactions are presented in Eqs. (2)–(6):

A change in pH alters the degree of precipitation and the types of crystals contained in the precipitants (Bi et al. 2014; Huang et al. 2015; Liu et al. 2004). At a pH range of 5–6.5, H2PO4− is the dominant species in the solution, which is required for the formation of brushite and monetite (Mijangos et al. 2004). H2PO4− and HPO42− can be used as brushite precursors (Penn and Camberato 2019), and HPO42− can also be used as precursors of struvite (Hu et al. 2020). Octacalcium phosphate can be produced in the pH range of 5–6 (Komlev et al. 2010b). A pH above 7 increases the ratio of HPO42−, which increases the generation of hydroxyapatite and tricalcium phosphate compared to the other precipitates (Minh et al. 2014; Musvoto et al. 2000; Pastor et al. 2008). The precipitates were also influenced by the solubility of the crystals; a lower solubility at higher pH values may increase phosphorus recovery (Huang et al. 2015). The crystal formed with the lowest solubility is hydroxyapatite, followed by tricalcium phosphate, octacalcium phosphate, monetite, and brushite (Johnsson and Nancollas 1992; Musvoto et al. 2000).

According to the XRD data (Fig. 5(a)), the precipitates that were controlled by NaOH at pH 4 had two major peaks. The peak between 20 and 40° is assumed to belong to monetite, and the peak at 40° is presumably that of brushite (Djošić et al. 2009; Mirković et al. 2016). This is because both monetite and brushite can be produced at a relatively low pH range. According to the Minteq results (Fig. S2), the concentration of HPO42−, which is a precursor of both materials, is high when pH is between 4 and 6. Conversely, in the precipitate adjusted to pH 8, three major peaks appeared (Fig. 5(b)). The peak at lower than 20° presumably belongs to struvite (Lu et al. 2016), and the two peaks shown in part 20° represent the peaks of brushite and struvite (Lu et al. 2016; Mirković et al. 2016). Finally, the peaks shown in part 30° represents hydroxyapatite and tricalcium phosphate (Franca et al. 2014). Similarly, based on the results of Minteq, at pH 6 or higher, more HPO42− is present than that of the HPO4−, which generates more materials that use HPO42− as a precursor. In addition, hydroxyapatite, tricalcium phosphate, and struvite are produced at a high pH range and are more likely to be produced because of their lower solubility than the other phosphate crystals (Musvoto et al. 2000; Pastor et al. 2008; Recillas et al. 2012). The precipitate-adjusted pH using CSH showed similar patterns under the same pH conditions (Fig. 5(c–f)). Precipitates adjusted to pH 4 presented several peaks, where the peaks below 30° represented brushite and the peaks above 30° represented monetite (Djošić et al. 2009; Mirković et al. 2016). In contrast, the precipitate adjusted to pH 8 exhibited two peaks, which represented one of the peaks of hydroxyapatite, struvite, and tricalcium phosphate (Franca et al. 2014; Lu et al. 2016). In addition, a portion of the pH 8 precipitate graph observed a slight increase in intensity between 20 and 40°, which represents the peak of silicon dioxide contained in the precipitates (Musić et al. 2011).

Availability of phosphorus from the precipitates

In addition, the ratio of phosphate eluted from precipitates in water and 2% citric acid was evaluated by quinolone gravimetric analysis (Lee et al. 2018; Shaver 2008). Figure 4(b, c) shows the ratio of dissolved phosphate in water and citric acid. In water, the ratio of dissolved phosphate at pH 4 was higher than that at pH 8. Unlike the NaOH precipitates, the CSH precipitate at pH 8 did not contain significant amounts of water-soluble phosphorus. Overall, the phosphorus dissolved in citric acid was higher than that dissolved in water, and the CSH precipitates contained more citric acid-soluble phosphorus. Although CMBA also contained about 99% of citric acid-soluble phosphorus (167.7 ± 2.9 mg/L), the total amount of eluted phosphate was less than 40% of the CSH precipitate. Representative water-soluble phosphoric compounds are Ca(H2PO4)2•H2O and (NH4)H2PO4, and a typical citric acid-soluble phosphoric compound is NH4MgPO4•H2O (Tan et al. 2021; Weeks and Hettiarachchi 2019). The phosphorus eluted with water can easily desorb from the soil and permeate the groundwater, whereas phosphorus eluted with citric acid can be retained in the soil for a sufficient time and can be used as nutrients by the plants (Lee et al. 2018). Therefore, precipitants produced using CSH will be more beneficial to plants as fertilizers. In addition, the hydrochloric acid insoluble in the CSH precipitate were 16 and 27% at pH 4 and pH 8 (Fig. S3(a)), respectively, which satisfied the national regulation for fertilizer (< 30%), and the pH of the precipitate was also in the range of 4.6 to 9.4, which was suitable as an alternative fertilizer compared to CMBA (pH = 13.2) (Fig. 4(d)). However, in this study, the growth of crops using CSH precipitate as a fertilizer could not be evaluated, and future research on the amount of phosphorus accumulated in crops and growth should be conducted through crop growth experiments.

Conclusion

This study investigated phosphorus recovery methods using CMBA. The main components of CMBA were CaO (66.08%) and P2O5 (13.75%), and the pH was as high as 13.2. A wet chemical extraction method using sulfuric acid was applied to CMBA, and phosphorus was effectively eluted from CMBA using 1.4 M sulfuric acid (89.99%). The eluted phosphorus presented better recovery performance using CSH than that of NaOH at both pH 4 and pH 8, and 99.55 ± 0.16% of phosphorous was recovered by CSH-mediated precipitation at pH 8. Regardless of the use of NaOH or CSH, monetite and brushite were the main crystal forms of precipitates at pH 4, whereas struvite, hydroxyapatite, and tricalcium phosphate were the main crystal forms at pH 8. The chemical composition of the precipitates could also be controlled by adjusting the pH conditions. The phosphorus obtained from the water-soluble precipitate was less than 35%, whereas it ranged from 65 to 97% in 2% citric acid depending on the precipitation method. These results demonstrate the potential use of CMBA as a promising phosphorus resource and provide useful insights into phosphorus recovery methods from biomass ash.

Data availability

Not applicable.

References

Adam C, Suhendra CV, Krueger O, Tetzlaff K (2012) Production of marketable multi-nutrient fertilisers from different biomass ashes and industrial by-products. In: ASH Utilisation 2012, pp 1–7

Asokbunyarat V, van Hullebusch ED, Lens PNL, Annachhatre AP (2015) Coal bottom ash as sorbing material for Fe(II), Cu(II), Mn(II), and Zn(II) removal from aqueous solutions. Water Air Soil Pollut 226 https://doi.org/10.1007/s11270-015-2415-5

Bi W, Li Y, Hu Y (2014) Recovery of phosphorus and nitrogen from alkaline hydrolysis supernatant of excess sludge by magnesium ammonium phosphate. Biores Technol 166:1–8. https://doi.org/10.1016/j.biortech.2014.04.092

Bremner J (1965) Total nitrogen methods of soil analysis: part 2 chemical and microbiological properties 9:1149–1178

Carrington D (2019) "Phosphate fertiliser 'crisis' threatens world food supply". Use of essential rock phosphate has soared, but scientists fear it could run out within a few decades

Djošić MS et al. (2009) Electrochemical synthesis of nanosized monetite powder and its electrophoretic deposition on titanium colloids and surfaces a: physicochemical and engineering aspects 341:110-117 https://doi.org/10.1016/j.colsurfa.2009.03.046

Donatello S, Cheeseman CR (2013) Recycling and recovery routes for incinerated sewage sludge ash (ISSA): a review Waste Manag 33:2328–2340 https://doi.org/10.1016/j.wasman.2013.05.024

Du S, Yang H, Qian K, Wang X, Chen H (2014) Fusion and transformation properties of the inorganic components in biomass ash fuel 117:1281-1287 https://doi.org/10.1016/j.fuel.2013.07.085

Fang L, Wang Q, Li J-s, Poon CS, Cheeseman CR, Donatello S, Tsang DCW (2020) Feasibility of wet-extraction of phosphorus from incinerated sewage sludge ash (ISSA) for phosphate fertilizer production: a critical review Critical Reviews in Environmental Science and Technology 51:939–971 https://doi.org/10.1080/10643389.2020.1740545

Federation WE, Association APH (2005) Standard methods for the examination of water and wastewater American Public Health Association (APHA): Washington, DC, USA

Franca R, Samani TD, Bayade G, Yahia L, Sacher E (2014) Nanoscale surface characterization of biphasic calcium phosphate, with comparisons to calcium hydroxyapatite and beta-tricalcium phosphate bioceramics. J Colloid Interface Sci 420:182–188. https://doi.org/10.1016/j.jcis.2013.12.055

Frost RL, Palmer SJ (2011) Thermal stability of the ‘cave’ mineral brushite CaHPO4·2H2O – mechanism of formation and decomposition. Thermochimica Acta 521:14–17. https://doi.org/10.1016/j.tca.2011.03.035

Gilbert N (2009) Environment: the disappearing nutrient. Nature News 461:716–718

Gougar M, Scheetz B, Roy D (1996) Ettringite and C• S• H Portland cement phases for waste ion immobilization: a review. Waste Manag 16:295–303

Guan W, Ji F, Chen Q, Yan P, Zhou W (2014) Phosphorus recovery using porous calcium silicate hydrate as seed crystal in form of hydroxyapatite. Mater Res Innovations 18:43–49

Helin J, Weikard H-P (2019) A model for estimating phosphorus requirements of world food production. Agric Syst 176:102666

Hong SH, Shin MC, Lee J, Lee CG, Song DS, Um BH, Park SJ (2020) Recycling of bottom ash derived from combustion of cattle manure and its adsorption behaviors for Cd(II), Cu(II), Pb(II), and Ni(II). Environ Sci Pollut Res Int. https://doi.org/10.1007/s11356-020-11719-7

Hu L, Yu J, Luo H, Wang H, Xu P, Zhang Y (2020) Simultaneous recovery of ammonium, potassium and magnesium from produced water by struvite precipitation. Chem Eng J 382:123001. https://doi.org/10.1016/j.cej.2019.123001

Huang H, Liu J, Ding L (2015) Recovery of phosphate and ammonia nitrogen from the anaerobic digestion supernatant of activated sludge by chemical precipitation. J Clean Prod 102:437–446. https://doi.org/10.1016/j.jclepro.2015.04.117

Johnsson MS-A, Nancollas GH (1992) The role of brushite and octacalcium phosphate in apatite formation. Crit Rev Oral Biol Med 3:61–82

Kaikake K, Sekito T, Dote Y (2009) Phosphate recovery from phosphorus-rich solution obtained from chicken manure incineration ash. Waste Manag 29:1084–1088. https://doi.org/10.1016/j.wasman.2008.09.008

Kalmykova Y, Fedje KK (2013) Phosphorus recovery from municipal solid waste incineration fly ash. Waste Manag 33:1403–1410. https://doi.org/10.1016/j.wasman.2013.01.040

Komlev V, Fadeeva I, Fomin A, Shvorneva L, Ferro D, Barinov S (2010a) Synthesis of octacalcium phosphate by precipitation from solution. In: Doklady Chemistry. vol 2. SP MAIK Nauka/Interperiodica, pp 178–182

Komlev VS, Fadeeva IV, Fomin AS, Shvorneva LI, Ferro D, Barinov SM (2010b) Synthesis of octacalcium phosphate by precipitation from solution. Dokl Chem 432:178–182. https://doi.org/10.1134/s0012500810060066

Krog N (2003) Biomasses central heating units burning animal biomasses or rest products making ‘‘green el-and heat production” for small and medium power plant. From ORC-Scandinavia IS, Publications, 2003

Kuligowski K, Poulsen TG (2010) Phosphorus and zinc dissolution from thermally gasified piggery waste ash using sulphuric acid. Bioresour Technol 101:5123–5130

Law KP, Pagilla KR (2018) Phosphorus recovery by methods beyond struvite precipitation. Water Environ Res 90:840–850

Lee C-G et al (2018) Phosphorous recovery from sewage sludge using calcium silicate hydrates. Chemosphere 193:1087–1093

Lee N, Hong SH, Lee CG, Park SJ, Lee J (2021) Conversion of cattle manure into functional material to remove selenate from wastewater. Chemosphere 278:130398. https://doi.org/10.1016/j.chemosphere.2021.130398

Liang S et al (2019) A comparison between sulfuric acid and oxalic acid leaching with subsequent purification and precipitation for phosphorus recovery from sewage sludge incineration ash. Water Res 159:242–251. https://doi.org/10.1016/j.watres.2019.05.022

Liu Y, Shelton R, Barralet J (2004) Homogeneous octacalcium phosphate precipitation: effect of temperature and pH. In: Key Engineering Materials. Trans Tech Publ, pp 79-82

Lu X, Shih K, Li XY, Liu G, Zeng EY, Wang F (2016) Accuracy and application of quantitative X-ray diffraction on the precipitation of struvite product. Water Res 90:9–14. https://doi.org/10.1016/j.watres.2015.12.014

Luyckx L, Sousa Correia DS, Van Caneghem J (2021) Linking phosphorus extraction from different types of biomass incineration ash to ash mineralogy, ash composition and chemical characteristics of various types of extraction liquids waste and biomass valorization 12:5235–5248 https://doi.org/10.1007/s12649-021-01368-3

Ma P, Rosen C (2021) Land application of sewage sludge incinerator ash for phosphorus recovery: a review. Chemosphere 274:129609. https://doi.org/10.1016/j.chemosphere.2021.129609

Mayer BK et al (2016) Total value of phosphorus recovery. Environ Sci Technol 50:6606–6620

Mijangos F, Kamel M, Lesmes G, Muraviev DN (2004) Synthesis of struvite by ion exchange isothermal supersaturation technique. React Funct Polym 60:151–161. https://doi.org/10.1016/j.reactfunctpolym.2004.02.019

Minh DP et al (2014) Hydroxyapatite starting from calcium carbonate and orthophosphoric acid: synthesis, characterization, and applications. J Mater Sci 49:4261–4269

Mirković MM, Pašti TDL, Došen AM, Čebela MŽ, Rosić AA, Matović BZ, Babić BM (2016) Adsorption of malathion on mesoporous monetite obtained by mechanochemical treatment of brushite RSC. Advances 6:12219–12225. https://doi.org/10.1039/c5ra27554g

Monea MC et al (2020) Comparing the leaching behavior of phosphorus, aluminum and iron from post-precipitated tertiary sludge and anaerobically digested sewage sludge aiming at phosphorus recovery. J Clean Prod 247:119129. https://doi.org/10.1016/j.jclepro.2019.119129

Monea MC, Meyer C, Steinmetz H, Schonberger H, Drenkova-Tuhtan A (2020) Phosphorus recovery from sewage sludge - phosphorus leaching behavior from aluminum-containing tertiary and anaerobically digested sludge. Water Sci Technol 82:1509–1522. https://doi.org/10.2166/wst.2020.414

Musić S, Filipović-Vinceković N, Sekovanić L (2011) Precipitation of amorphous SiO2 particles and their properties. Braz J Chem Eng 28:89–94

Musvoto E, Wentzel M, Ekama G (2000) Integrated chemical–physical processes modelling—II. simulating aeration treatment of anaerobic digester supernatants. Water Res 34:1868–1880

Ntafalias E, Koutsoukos P (2010) Spontaneous precipitation of calcium silicate hydrate in aqueous solutions Crystal Research and Technology. J Exp Indus Crystallogr 45:39–47

Okano K et al (2015) Amorphous calcium silicate hydrates and their possible mechanism for recovering phosphate from wastewater. Sep Purif Technol 144:63–69. https://doi.org/10.1016/j.seppur.2015.01.043

Okano K et al (2013) Novel technique for phosphorus recovery from aqueous solutions using amorphous calcium silicate hydrates (A-CSHs). Water Res 47:2251–2259. https://doi.org/10.1016/j.watres.2013.01.052

Okano K et al (2013) Novel technique for phosphorus recovery from aqueous solutions using amorphous calcium silicate hydrates (A-CSHs). Water Res 47:2251–2259. https://doi.org/10.1016/j.watres.2013.01.052

Park S-J, Lee Y-J, Kang J-K, Lee J-C, Lee C-G (2021) Application of Fe-impregnated biochar from cattle manure for removing pentavalent antimony from aqueous solution. Appl Sci 11:9257. https://doi.org/10.3390/app11199257

Pastor L, Mangin D, Barat R, Seco A (2008) A pilot-scale study of struvite precipitation in a stirred tank reactor: conditions influencing the process. Biores Technol 99:6285–6291. https://doi.org/10.1016/j.biortech.2007.12.003

A critical review on soil chemical processes that control how soil pH affects phosphorus availability to plants agriculture 9:120 https://doi.org/10.3390/agriculture9060120

Prazeres AR, Luz S, Fernandes F, Jerónimo E (2020) Cheese wastewater treatment by acid and basic precipitation: application of H2SO4, HNO3, HCl, Ca(OH)2 and NaOH. J Environ Chem Eng 8:103556. https://doi.org/10.1016/j.jece.2019.103556

Recillas S, Rodríguez-Lugo V, Montero M, Viquez-Cano S, Hernandez L, Castano V (2012) Studies on the precipitation behaviour of calcium phosphate solutions. J Ceram Process Res 13:5–10

Sankara Narayanan T (2005) Surface pretretament by phosphate conversion coatings-a review Reviews in Advanced. Mater Sci 9:130–177

Shaver LA (2008) Determination of phosphates by the gravimetric quimociac technique. J Chem Educ 85:1097

Shi H, Zhang J, Ye X, Wu T, Yu T, Ye J (2019) Formation and stability of well-crystallized metastable octacalcium phosphate at high temperature by regulating the reaction environment with carbamide. CrystEngComm 21:5174–5184

Smil V (1999) Nitrogen in crop production: an account of global flows. Global Biogeochem Cycles 13:647–662

Sugiyama S, Wakisaka K, Imanishi K, Kurashina M, Shimoda N, Katoh M, Liu J-C (2019) Recovery of phosphate rock equivalents from incineration ash of chicken manure by elution-precipitation treatment. J Chem Eng Jpn 52:778–782. https://doi.org/10.1252/jcej.19we030

Tan Y, Zou Z, Qu J, Ren J, Wu C, Xu Z (2021) Mechanochemical conversion of chrysotile asbestos tailing into struvite for full elements utilization as citric-acid soluble fertilizer. J Clean Prod 283:124637

Tan Z, Lagerkvist A (2011) Phosphorus recovery from the biomass ash: a review. Renew Sustain Energy Rev 15:3588–3602. https://doi.org/10.1016/j.rser.2011.05.016

Wang L, Skjevrak G, Hustad JE, Skreiberg Ø (2013) Investigation of biomass ash sintering characteristics and the effect of additives. Energy Fuels 28:208–218. https://doi.org/10.1021/ef401521c

Weeks JJ Jr, Hettiarachchi GM (2019) A review of the latest in phosphorus fertilizer technology: possibilities and pragmatism. J Environ Qual 48:1300–1313

Xing P et al (2016) A comparative assessment of biomass ash preparation methods using X-ray fluorescence and wet chemical analysis. Fuel 182:161–165. https://doi.org/10.1016/j.fuel.2016.05.081

Ye Y et al (2017) Insight into chemical phosphate recovery from municipal wastewater. Sci Total Environ 576:159–171. https://doi.org/10.1016/j.scitotenv.2016.10.078

Yuan X, He T, Cao H, Yuan Q (2017) Cattle manure pyrolysis process: kinetic and thermodynamic analysis with isoconversional methods. Renew Energy 107:489–496. https://doi.org/10.1016/j.renene.2017.02.026

Zhang Z, Wang X, Wang H, Zhao J (2018) Removal of Pb (II) from aqueous solution using hydroxyapatite/calcium silicate hydrate (HAP/CSH) composite adsorbent prepared by a phosphate recovery process. Chem Eng J 344:53–61

Zhang J, Liu J, Evrendilek F, Xie W, Kuo J, Zhang X, Buyukada M (2019a) Kinetics, thermodynamics, gas evolution and empirical optimization of cattle manure combustion in air and oxy-fuel atmospheres. Appl Therm Eng 149:119–131. https://doi.org/10.1016/j.applthermaleng.2018.12.010

Zhang Z, Wang X, Zhao J (2019b) Phosphate recovery from wastewater using calcium silicate hydrate (C-S-H): sonochemical synthesis and properties. Environ Sci Water Res Technol 5:131–139. https://doi.org/10.1039/c8ew00643a

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MIST) [grant no. NRF-2021R1F1A1063535].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Heejin Yang. The first draft of the manuscript was written by Heejin Yang and Chang-Gu Lee, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, H., Kang, JK., Park, SJ. et al. Phosphorus recovery from cattle manure bottom ash by extraction and precipitation methods. Environ Sci Pollut Res 29, 39567–39577 (2022). https://doi.org/10.1007/s11356-022-18934-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-18934-4