Abstract

Vitamin enrichment in fermented dairy products through the intervention of vitamin-producing probiotic strains during fermentation is a novel approach in the field of probioceuticals. In this study, riboflavin-enriched yogurt-based fermented milk was prepared by mixing 1% (v/v) riboflavin-producing strain [1.2 × 108 CFU/mL of Lactiplantibacillus plantarum MTCC 25432 or L. plantarum MTCC 25433 or L. plantarum MTCC 25434] with 2% (v/v) traditional yogurt cultures [Streptococcus thermophilus NCDC 295 and L. delbrueckii subsp. bulgaricus NCDC 293; each of 1.3 × 107 CFU/mL]. The yogurt-based fermented milk prepared with traditional yogurt cultures (2%, v/v) was served as a control. The prepared yogurt-based fermented milk samples were analyzed and compared for riboflavin content, antimicrobial activity, physicochemical, and functional properties. As a result, the yogurt-based fermented milk prepared with L. plantarum MTCC 25432 produced a significantly higher amount of riboflavin (2.49 mg/L) as compared with MTCC 25433 (2.33 mg/L), MTCC 25434 (2.14 mg/L), and control (1.70 mg/L). The probiotic supplementation to yogurt cultures maintained the pH and titratable acidity in the range of 4.1–4.4 and 1.0–1.05% (lactic acid/100 mL), as recommended by Indian yogurt standards. The rheological, texture, and antimicrobial properties of yogurt-based fermented milk were enhanced with the addition of riboflavin-producing probiotic strains. Moreover, all yogurt-based fermented milk samples prepared in this study were acceptable as per the sensory evolution scores. In conclusion, the use of riboflavin-producing L. plantarum strains along with standard yogurt cultures could be the best approach to enhancing riboflavin content in yogurt-based fermented milk and fulfilling the daily riboflavin requirement in humans.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, the production and consumption of fermented milk have increased due to its therapeutic potential. Yogurt is a functional dairy-based product that is consumed widely due to its delicious taste, texture, and health benefits, such as immunomodulation and gut health. It is produced from the fermentation of milk (cows, goats, and buffalos) [1]. Yogurt contains a significant amount of protein, calcium, minerals, and traces of vitamins (folic acid, riboflavin, and cobalamin). It is one of the promising strategies for the fortification of vitamins to mitigate vitamin deficiency in humans [2].

Riboflavin (vitamin B2) is an essential vitamin that undergoes modifications in a living cell to provide flavin mononucleotide (FMN) and flavin adenine dinucleotide (FAD) [3, 4]. FMN and FAD act as a substituent to flavoproteins which play a major role in several metabolic reactions such as the breakdown of carbohydrates, proteins, fats, photosensitization, oxidative stress response, and vitamin activation (folate and pyridoxine) [5, 6]. Flavins can transfer electrons in both one and two-electron transfer reactions [5, 6]. Besides this, flavoproteins are involved in DNA repair, circadian cycling, body development, light sensing, etc. [7]. This makes riboflavin an essential vitamin in nature. Plants, fungi, and bacteria can synthesize their riboflavin. However, higher animals and human lack this capacity [8]. Approximately 50% of the population of developing countries has mild riboflavin deficiency [9], which could be due to inadequate dietary intake and poor malabsorption [10]. Riboflavin deficiency, such as ariboflavinosis, comprises impaired vision, reduce growth rate, high level of homocysteine, liver and skin damage, and change in cerebral glucose metabolism [11].

Recently, vitamin-producing lactic acid bacteria (LAB) attracted much attention from researchers to enhance the level and bioavailability of vitamins in food [12]. Several studies reported the use of riboflavin overproducing strain for the manufacturing of riboflavin-enriched bread, pasta, soymilk, and soy curd [13,14,15,16]. However, their use to improve riboflavin levels in yogurt has not been reported so far. In this study, we investigated the ability of riboflavin-producing L. plantarum strains (MTCC 25432, 25433, and 25434) to improve riboflavin content in yogurt-based fermented milk and the techno-functional feasibility thereof. The strains reported here were previously been isolated based on riboflavin production ability [15] and reported for probiotic properties, safety [15, 16], and preparation of riboflavin-enriched soymilk and soy curd [15, 16].

Materials and Methods

Bacterial Cultures

Lactiplantibacillus plantarum MTCC 25432, L. plantarum MTCC 25433, and L. plantarum MTCC 25434 were obtained from the Microbiology Laboratory, National Institute of Food Technology Entrepreneurship and Management (NIFTEM), India. All the cultures were deposited at Microbial Type Culture Collection (MTCC) (Chandigarh, India) under safe deposit. The cultures were activated in MRS (De Man, Rogosa, and Sharpe) broth (HiMedia, Mumbai, India) at 37 °C for 24 h. Standard yogurt starter cultures, i.e., Streptococcus thermophilus NCDC 295 and L. delbrueckii subsp. bulgaricus NCDC 293, were obtained from the National Collection of Dairy Cultures, India, and activated as per the standard procedures.

Milk Coagulation Activity

The milk coagulation activity of L. plantarum strains was determined as per the method described by Georgieva et al. [17] with minor modifications. The bacterial suspension (1.2 × 108 CFU/mL in PBS, pH 7.3) obtained from overnight grown cultures were each inoculated (1%, v/v) separately in 10% (w/v) reconstituted skim milk, 10% (w/v) skim milk supplemented with 1% (w/v) yeast extract and or 1% (w/v) glucose and incubated at 37 °C for 16–24 h. The strains able to coagulate milk ≤ 16 h were defined as fast coagulating strains, and ≥ 16 h were slow coagulating strains.

Preparation of Yogurt-Based Fermented Milk

A 1% (v/v) suspension (1.2 × 108 CFU/mL in PBS, pH 7.3) of overnight grown riboflavin-producing strain (Lactiplantibacillus plantarum MTCC 25432 or L. plantarum MTCC 25433 or L. plantarum MTCC 25434) was inoculated in lukewarm (~ 42 °C) full cream cow milk containing 2% (v/v) yogurt cultures (Streptococcus thermophilus NCDC 295 and L. delbrueckii subsp. bulgaricus NCDC 293; each of 1.3 × 107 CFU/mL in PBS, pH 7.3) and incubated at 42 °C for up to 20 h (Fig. 1). The pH and titratable acidity were determined at intervals of 0, 4, 8, 12, 16, and 20 h of fermentation. Simultaneously, the samples withdrawn at 8 h of fermentation were stored at 4 °C for further analysis. The yogurt-based fermented milk obtained by the addition of the starter culture (2%, v/v) served as a control.

Physicochemical Analysis of Yogurt-Based Fermented Milk

Moisture

The moisture content of the yogurt-based fermented milk samples was analyzed at 0-, 7-, and 14-day intervals by weight difference method [18] with slight modifications. In brief, a yogurt-based fermented milk sample of known weight was subjected to drying at 105 °C for 5 h. After drying, the weight was recorded, and moisture content was calculated as per the given formula. Moisture (%) = weight before drying – weight after drying / weight before drying × 100.

Titratable Acidity

The titratable acidity (TA) of the yogurt-based fermented milk samples was determined using a routine laboratory method. Briefly, a known quantity of yogurt-based fermented milk samples (0, 7, and 14 days) were mixed with 2–3 drops of phenolphthalein indicator and titrated using 0.1 N NaOH until the development of light pink color. The volume of NaOH consumed to change the color of yogurt-based fermented milk was recorded. Titratable acidity (lactic acid) was calculated using the following formula. Percentage of TA (lactic acid) = 90 × N × titer volume × 100 / sample volume × 1000 [16].

pH

The pH of the yogurt-based fermented milk samples (withdrawn at 0, 7, and 14 days) was measured with the help of calibrated digital pH meter (Model-MT 103, Manti Lab, India). The total soluble solids (TSS) of the yogurt-based fermented milk samples (withdrawn at 0, 7, and 14 days) were measured at 25 °C by using a digital refractometer (ATAGO RX-5000α, Tokyo, Japan) and expressed in terms of Brix.

Color

Color properties of yogurt-based fermented milk samples were measured by using a handheld chroma meter (CR-400, Konica Minolta, Japan) at 25 °C. The results were recorded in the L*, a*, and b* scales [18]. L* represents the lightness index (0 for black; 100 for white), a* represents greenness and redness (+ 100 for red and − 80 for green), while b* represents yellowness and blueness (+ 70 for yellow and − 80 for blue). ΔE* represents the total color difference based on L*, a*, and b* values. All of the samples were analyzed in triplicate, and average values were reported.

Rheological Measurements

The rheological properties of yogurt-based fermented milk samples were determined as per the slightly modified procedure of Ferragut et al. [19]. In brief, yogurt-based fermented milk samples were investigated with Anton Paar Rheometer (MCR 302, Graz, Austria) using a parallel plate setup with a 2.5 mm gap at 20 °C. A small quantity of the yogurt-based fermented milk sample was placed in the center of the inset plate. First, a frequency of 1 Hz was used to determine the viscoelastic range (0.01–100 Pa), and then a frequency sweep test (0.1–10 Hz at a maximum strain of 0.06) was carried out. The instrument software was used to analyze the rheological measurement results. From the frequency sweep test, the dynamic module G’, G", G*, and eta (ὴ) values were calculated.

Texture Analysis

Texture analysis of yogurt-based fermented milk samples was measured using a TA-XT2i texture analyzer (Godalming, UK), equipped with a 25 kg load cell at 22 oC. Profile curves were used to calculate the hardness, cohesiveness, gumminess, adhesiveness, and springiness of the yogurt-based fermented milk samples [20].

Evaluation of Riboflavin Content in Yogurt-Based Fermented Milk

Extraction and Estimation of Riboflavin

Riboflavin from the yogurt-based fermented milk was extracted as per the method described by Jaurez et al. [21] and Singh et al. [16]. In brief, equal volumes (1:1) of sample and acetic acid (1%, v/v) were mixed and autoclaved at 121 °C for 20 min. After autoclaving, the mixture was cool at room temperature and centrifuged at 8000 × g for 20 min. The supernatant was collected and filtered using 0.22 µm cellulose acetate membranes (Merck, Germany) and stored at − 20 °C until further use. Extraction of riboflavin was performed in dark to prevent loss due to light.

The amount of riboflavin present in the extracted samples was analyzed using high-performance liquid chromatography (HPLC, Waters 2707, Kolkata, India) equipped with 250 × 4.6 mm (5 µm-100 Å) reverse-phase C18 column (Kromasil, MO, USA), auto-sampler, binary 515 pumps, and fluorescence detector with excitation wavelength 440 nm and emission wavelength 520 nm. All samples were eluted with isocratic elution at the flow rate of 1 mL/min. Methanol (36): water (65) (v/v) served as a mobile phase, and pure riboflavin was used as a control [14].

Antimicrobial Activity

The antimicrobial activity of the yogurt-based fermented milk was determined by agar-well diffusion assay. In brief, 100 µL overnight-grown pathogenic cultures (Staphylococcus aureus ATCC 6538, Escherichia coli ATCC 11229, Salmonella enterica ATCC 35664, and S. enterica ATCC 13 076) were each mixed separately in 25 mL molten semi-soft nutrient agar (0.8%, w/v) and poured into the plates. All the plates were kept at room temperature to solidify, and wells (6 mm) were prepared using a sterile 1 mL tip. An aliquot (100 µL) of supernatant (filtered sterilized) obtained from yogurt-based fermented milk samples was filled into the designated well and incubated at 4 °C for 20 min to diffuse. All the plates were incubated overnight at 37 °C and observed for a zone of inhibition.

Sensory Evaluation

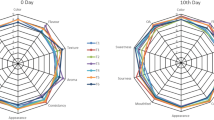

Yogurt-based fermented milk prepared in this study was evaluated for color, flavor, body texture, and overall acceptability by 30 volunteers (aged 22–45 years) at the NIFTEM campus in India. All the volunteers were instructed to use a 9-point hedonic scale (9-like extremely, 8-like very much, 7-like moderately, 6-like slightly, 5-neither like nor a dislike, 4-dislike slightly, 3-dislike moderately, 2-dislike very much, and 1-dislike extremely) to rate the yogurt-based fermented milk. To clear palates between samples, volunteers were asked to consume a cream cracker and a sip of water. Scores were presented as an average score of the records.

Statistical Analysis

Experimental results were designed as mean with standard deviation. The statistical analysis was performed using Microsoft Office Excel 2007. The differences between groups were analyzed by one-way analysis of variance (ANOVA) using SPSS base 19.0 statistical software. All tests were performed in triplicates, and differences were observed as statistically significant at p < 0.05.

Results and Discussion

Milk Coagulation Activity

Milk coagulation ability is considered one of the prerequisites for the selection of adjunct cultures for the development of novel dairy products. In this study, we observed that Lactiplantibacillus plantarum MTCC 25432, 25433, and 25434 were capable of coagulating milk within 7.0, 7.7, and 8.0 h when supplemented with 1% (w/v) yeast extract. Moreover, when cultivated in the presence of 1% (w/v) glucose, L. plantarum MTCC 25432, 25433, and 25434 coagulated milk within 8.0, 8.5, and 18 h, respectively. These results are comparable with the milk coagulation ability showed by L. plantarum IMAU10216 (8.0 h), 80106 (8.5 h), and 70095 (9.3 h) in the presence of 1% (w/v) yeast extract [22]. Contrary to our results, L. plantarum IMAU strains failed to coagulate milk in the presence of 1% (w/v) glucose. It has been reported that nitrogen, vitamin, and growth factors of yeast extract accelerate the growth of bacteria, thus facilitating the coagulation of milk [23]. The milk coagulation in the presence of glucose could be a strain-dependent property. Moreover, probiotic strains MTCC 25432, 25433, and 25434 used in this study failed to coagulate milk without the supplementation of glucose or yeast extract. These results are corroborated well with the previous finding that L. plantarum strains are unable to coagulate milk without additional carbon and nitrogen sources [17].

Physicochemical Properties of Yogurt-Based Fermented Milk

Moisture and Total Soluble Solids

Yogurt-based fermented milk prepared with the supplementation of L. plantarum MTCC 25434 showed significantly lower moisture levels (70.85 ± 0.04%) as compared with MTCC 25433 (72.82 ± 0.06%), MTCC 25432 (73.11 ± 0.04%), and control (76.22 ± 0.11%) (Table 1). These results indicated strain-specific moisture level reduction in yogurt-based fermented milk samples. The mechanism by which strains reduce moisture in yogurt-based fermented milk was not explored. However, we hypothesized that the growth of yogurt cultures may ease the growth of L. plantarum strains to form better texture. Moreover, low-moisture yogurt has a prolonged shelf life. In this study, the moisture content of prepared yogurt-based fermented milk was within the limit (< 84%) as per the standard to maintain proper texture and mouth feel [24]. Besides this, no change in moisture content was observed after 14 days of storage at 4 °C (Table 1), and this could be ensuring the maintenance of yogurt-based fermented milk texture and mouth feel.

The total soluble solids (TSS) of different yogurt-based fermented milk samples were in the range of 5.05 to 5.92% (°Brix). The yogurt-based fermented milk prepared with L. plantarum MTCC 25434 supplementation showed significantly lower levels of TSS (5.05 ± 0.11%) as compared with MTCC 25433 (5.92 ± 0.17%), MTCC 25432 (5.46 ± 0.04%), and control (5.32 ± 0.49%) (Table 1). The percentage of TSS reflects the mass fraction of substances that remained after the completion of fermentation. The higher TSS is one of the reasons for the better rheology of yogurt-based fermented milk samples [25]. However, in this study, the variations and decrease in TSS (Table 1) observed during the storage could be due to the strain-specific activities in the presence of yogurt cultures.

pH and Titratable Acidity

The pH and titratable acidity (TA) are key indicators for assessing the acidity of yogurt [22]. As per the Indian standard of yogurt specification (IS12898:1989), the pH and TA of the yogurt should be between 3.8–4.6 and 0.8–1.2%. In this study, yogurt-based fermented milk prepared with and without supplementation of riboflavin-producing probiotic strains achieved recommended pH and TA (range: 4.1–4.4 and 1.0–1.05%) at 8 h of fermentation and remained stable up to 20 h of incubation (Fig. 2a, b). Besides this, the samples stored at 4 °C after 8 h of fermentation showed insignificant changes in pH and TA when analyzed at 0, 7, and 14th days (Table 1). These results are corroborated well with IS12898:1989 recommendations and ensure the long-term stability of probiotic-enriched yogurt-based fermented milk.

Color

Color is one of the factors which often contribute to consumers buying decisions. In this study, we observed that supplementation of riboflavin-producing strains (MTCC 25432, 25433, and 25434) in the fermentation of yogurt-based fermented milk significantly affected color properties (lightness and yellowness) as compared with the control (Table 2). However, the color difference recorded between yogurt-based fermented milk samples prepared with probiotic intervention remained insignificant.

The significantly lowest average lightness (L*) value was recorded with the yogurt-based fermented milk prepared with L. plantarum MTCC 25,432 (63.21 ± 0.81) as compared with the control (66.80 ± 0.52). Similarly, lightness recorded for MTCC 25433 (64.86 ± 0.87) and MTCC 25434 (64.14 ± 0.59) was significantly less as compared with the control (66.80 ± 0.52) (Table 2). These results indicated that riboflavin production may responsible for the lightness difference between test and control samples. The significantly highest yellowness (b*) observed with yogurt-based fermented milk prepared with MTCC 25432 (9.64 ± 0.26) as compared with control (8.67 ± 0.13) (Table 2) suggested the influence of the amount of riboflavin present in yogurt-based fermented milk on color properties. The yellowness differences observed between MTCC 25433 (9.05 ± 0.51), MTCC 25434 (8.52 ± 0.69), and control (8.67 ± 0.13) were insignificant. No significant changes were observed in green and redness (a*) properties between tests and control (Table 2). The L*, a*, and b* values observed in this study are coordinated well with the values (L*: 86.2 ± 11.0; a*: − 1.1 ± 4.9; b*: 9.0 ± 5.3; a number of studies: 34) given for yogurt in a recent systematic review on the color of milk and milk products [26]. Overall, no significant change in total color difference (ΔE*) among yogurt-based fermented milk prepared in this study may not negatively affect consumers buying decisions.

Rheological Analysis

In this study, the yogurt-based fermented milk samples prepared with and without supplementation of probiotics strains were investigated to understand the way yogurt gel flows and deforms when subjected to normal and/or tangential forces. The force delivered perpendicularly or tangentially to the product cross-section is known as shear stress, and the rate at which it is applied is known as shear rate. The apparent viscosity (ὴ), consistency index, storage modulus (G′), loss modulus (G″), and loss tangent (or G″/G′) are rheological characteristics used to define yogurt [27]. The resistance to flow caused by the internal friction of moving fluid particles under force is known as viscosity. The yogurt is typically non-Newtonian, while the water is Newtonian (shear stress is precisely proportional to shear rate). The normal characteristics of yogurt gels are mild viscoelastic, shear-thinning, or pseudoelastic activity, where a higher shear rate or shear stress causes the viscosity to decrease. The rheological measure of the milk after fermentation is most commonly altered by the Lactobacillus and Bifidobacterium [28]. In this study, in frequency sweep test, yogurt-based fermented milk prepared with supplementation of Lactiplantibacillus plantarum MTCC 25432, MTCC 25433, and MTCC 25434 had lower G′ (2.12 × 102, 5.41 × 102, and 6.29 × 102 Pa), G″ (1.32 × 102, 2.56 × 102, and 2.86 × 102 Pa), and G* (2.49 × 102, 5.98 × 102, and 6.90 × 102 Pa) values as compared with control G′ (8.36 × 102 Pa), G″ (4.0 × 102 Pa), and G* (9.30 × 102 Pa) (Table 3). Similarly, the lowest angular frequency was observed for MTCC 25432 (0.48 rad/s) and the highest for control yogurt-based fermented milk (1.26 rad/s). These results indicated that the control had a better semi-solid, unbroken structural network as compared with test (riboflavin-enriched yogurt-based fermented milk) samples. In the stress sweep test, yogurt-based fermented milk prepared with MTCC 25432 showed the highest shear stress (8.61 Pa), shear rate (2.57 1/s), viscosity (3, 56 Pa s), speed (2.44 1/min), and torque (248 µNm) as compared with control and other test yogurt-based fermented milk (Table 4). Overall, these results indicated that the observed rheological variations could be due to exopolysaccharide (EPS) production or interactions between probiotic and traditional yogurt cultures during the fermentation. A similar finding was reported when riboflavin-producing L. plantarum strains (MTCC 25432 and 25433) were used to prepare soy curd [16].

Texture Analysis

The texture is one of the most essential quality parameters of yogurt-based fermented milk. In this study, we observed significantly higher values for hardness (MTCC 25432: 237.67 ± 1.08 g), adhesiveness (MTCC 25433: − 153.03 ± 1.06 g s), springiness (MTCC 25433: 0.74 ± 0.65), gumminess (MTCC 25433: 106.21 ± 1.05 g), and chewiness (MTCC 25433: 79.18 ± 1.87) with yogurt-based fermented milk samples prepared with riboflavin-producing probiotic strains as compared with control, except cohesiveness (Table 5). These results indicated a stronger gel structure and greater structural integrity of probiotic yogurt-based fermented milk as compared with the control. Overall, the texture profile of probiotic yogurt-based fermented milk was much improved as compared with the control, which could be due to the rate of acid and EPS production and the type of strain [29]. Recently, Singh and coworkers [16] reported improved texture quality of soy curd prepared by using L. plantarum MTCC 25432 and 25433 strains.

Riboflavin Estimation

The yogurt-based fermented milk prepared with supplementation of riboflavin-producing probiotic strains had an enhanced level of riboflavin as compared to the control. HPLC analysis of extracted samples showed characteristic riboflavin peak at 6–8 min (Fig. 3a–d), which was coordinated well with previous studies [16]. The quantitative analysis indicated a significantly highest level of riboflavin in yogurt-based fermented milk prepared with L. plantarum MTCC 25432 (2.49 mg/L) supplementation as compared with MTCC 25433 (2.33 mg/L), MTCC 25434 (2.14 mg/L), and control (1.70 mg/L) yogurt (Fig. 3e). In previous studies, L. plantarum MTCC 25432 (0.190 mg/L) and 25433 (0.195 mg/L) are reported to enhance riboflavin content in soy curd [16]. Moreover, previous and present studies assert that our riboflavin-producing probiotic L. plantarum strains can effectively be employed for the riboflavin bio-enrichment in dairy and nondairy products.

HPLC analysis of riboflavin extracted from yogurt-based fermented milk samples prepared with standard starter cultures (a) and in combinations with the different strains of Lactiplantibacillus plantarum (b, c, d). quantification of riboflavin (e). C: Streptococcus thermophilus NCDC 295 and L. delbrueckii subsp. bulgaricus NCDC 293

Antibacterial Activities

Yogurt is known to inhibit pathogenic bacteria, which could be due to antimicrobial compounds and organic acids produced by starter cultures [30]. In this study, we observed improved antimicrobial activity when L. plantarum strains were supplemented with standard yogurt cultures (Table 6). The significantly highest antimicrobial activity was observed with yogurt-based fermented milk prepared with supplementation of MTCC 25432 against tested pathogens (Staphylococcus aureus ATCC 6538:16 mm; Escherichia coli ATCC 11229: 19 mm; Salmonella enterica ATCC 35664: 15 mm; S. enterica ATCC 13076: 13 mm) as compared to control and rest of the samples (Table 6). These results corroborated well with the previous study that L. plantarum MTCC 25432 supplementation enhanced the antimicrobial activity of soy curd [16]. Moreover, the antimicrobial activity showed by the riboflavin probiotic strains could be due to the acid or antimicrobial peptide production. However, strains were not yet investigated for the production of antimicrobial peptides. Overall, strains antimicrobial activity is the added benefit apart from riboflavin enrichment in yogurt-based fermented milk.

Sensory Evaluation

Product acceptance of their sensory evolution is very important for the consumer’s preferences. The yogurt-based fermented milk prepared in this study had an overall rating in the range of 8.96–6.13 (Table 7), indicating like very much, moderately, and slightly. The sensory evaluation score for body and texture, color, and overall acceptability was similar to the test and control samples, except for flavor, which was significantly higher with MTCC 25432 yogurt-based fermented milk as compared to control and other test samples (Table 7). Enhanced flavor with MTCC 25432 yogurt-based fermented milk could be due to the highest riboflavin or other metabolites produced by the strain. Moreover, all samples with good overall acceptability may positively affect consumers buying decisions.

Conclusion

Our study investigated the effect of riboflavin-producing probiotic strains of Lactiplantibacillus plantarum on riboflavin content and other physicochemical properties during fermentation and post-fermentation storage of the yogurt-based fermented milk. Among the L. plantarum-supplemented yogurts-based fermented milk, the sample prepared with L. plantarum MTCC 25432 was found highest riboflavin content (2.49 mg/L). In comparison with plain yogurt-based fermented milk, bio-fortified yogurt-based fermented milk has better riboflavin content, techno-functional properties, and enhanced antimicrobial potential that may increase the value of the product. Moreover, the use of riboflavin-producing L. plantarum strains along with standard yogurt cultures could be the best approach to enhancing riboflavin content in yogurt-based fermented milk and fulfilling the daily riboflavin requirement in humans.

References

Savaiano DA, Hutkins RW (2021) Yogurt, cultured fermented milk, and health: a systematic review. Nutr Rev 79:599–614. https://doi.org/10.1093/nutrit/nuaa013

El-Abbadi NH, Dao MC, Meydani SN (2014) Yogurt: role in healthy and active aging. Am J Clin Nutr 99:1263–1270. https://doi.org/10.3945/ajcn.113.073957

Vikram MV, Ananya R, Ahire JJ (2022) Riboswitch-mediated regulation of riboflavin biosynthesis genes in prokaryotes. Biotech 3:1–14. https://doi.org/10.1007/s13205-022-03348-3

Liu S, Hu W, Wang Z, Chen T (2020) Production of riboflavin and related cofactors by biotechnological processes. Microb Cell Fact 19:1–16. https://doi.org/10.1186/s12934-020-01302-7

Udhayabanu T, Karthi S, Mahesh A et al (2018) Adaptive regulation of riboflavin transport in heart: effect of dietary riboflavin deficiency in cardiovascular pathogenesis. Mol Cell Biochem 440:147–156. https://doi.org/10.1007/s11010-017-3163-1

García-Angulo VA (2017) Overlapping riboflavin supply pathways in bacteria. Crit Rev Microbiol 43:196–209. https://doi.org/10.1080/1040841X.2016.1192578

Henriques BJ, Katrine Jentoft Olsen R, Gomes CM, Bross P (2021) Electron transfer flavoprotein and its role in mitochondrial energy metabolism in health and disease. Gene. https://doi.org/10.1016/j.gene.2021.145407

Averianova LA, Balabanova LA, Son OM et al (2020) Production of vitamin B2 (riboflavin) by microorganisms: an overview. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2020.570828

Sherwood RA (2018) Methods for assessment of vitamin B2. Elsevier Inc.

Mosegaard S, Dipace G, Bross P et al (2020) Riboflavin deficiency—implications for general human health and inborn errors of metabolism. Int J Mol Sci. https://doi.org/10.3390/ijms21113847

Thakur K, Tomar SK, De S (2016) Lactic acid bacteria as a cell factory for riboflavin production. Microb Biotechnol 9:441–451. https://doi.org/10.1111/1751-7915.12335

Zhang J-R, Ge Y-Y, Liu P-H et al (2021) Biotechnological strategies of riboflavin biosynthesis in microbes. Engineering. https://doi.org/10.1016/j.eng.2021.03.018

Capozzi V, Menga V, Diges AM et al (2011) Biotechnological production of vitamin B2-enriched bread and pasta. 8013–8020

Russo P, Capozzi V, Arena MP et al (2014) Riboflavin-overproducing strains of Lactobacillus fermentum for riboflavin-enriched bread. Appl Microbiol Biotechnol 98:3691–3700. https://doi.org/10.1007/s00253-013-5484-7

Bhushan B, Kumkum CR, Kumari M et al (2020) Soymilk bio-enrichment by indigenously isolated riboflavin-producing strains of Lactobacillus plantarum. LWT 119:108871. https://doi.org/10.1016/j.lwt.2019.108871

Narayan KS, Gaurkhede S, Sharma V et al (2021) Technological and functional assessment of riboflavin enriched probiotic soy curd. Fermentation. https://doi.org/10.3390/fermentation7020047

Georgieva R, Iliev I, Haertlé T et al (2009) Technological properties of candidate probiotic Lactobacillus plantarum strains. Int Dairy J 19:696–702. https://doi.org/10.1016/j.idairyj.2009.06.006

Sanett Matela K, Karuppiah Pillai M, Matebesi-Ranthimo P, Ntakatsane M (2019) Analysis of proximate compositions and physiochemical properties of some yoghurt samples from Maseru, Lesotho. J Food Sci Nutr Res 02:245–252. https://doi.org/10.26502/jfsnr.2642-11000023

Ferragut V, Cruz NS, Trujillo A et al (2009) Physical characteristics during storage of soy yogurt made from ultra-high pressure homogenized soymilk. J Food Eng 92:63–69. https://doi.org/10.1016/j.jfoodeng.2008.10.026

Kumar P, Mishra HN (2004) Mango soy fortified set yogurt: effect of stabilizer addition on physicochemical, sensory and textural properties. Food Chem 87:501–507. https://doi.org/10.1016/j.foodchem.2003.12.022

Juarez del Valle M, Laiño JE, Savoy de Giori G, LeBlanc JG (2017) Factors stimulating riboflavin produced by Lactobacillus plantarum CRL 725 grown in a semi-defined medium. J Basic Microbiol 57:245–252. https://doi.org/10.1002/jobm.201600573

Li C, Song J, Kwok L, yu, et al (2017) Influence of Lactobacillus plantarum on yogurt fermentation properties and subsequent changes during postfermentation storage. J Dairy Sci 100:2512–2525. https://doi.org/10.3168/jds.2016-11864

Hekmat S, Soltani H, Reid G (2009) Growth and survival of Lactobacillus reuteri RC-14 and Lactobacillus rhamnosus GR-1 in yogurt for use as a functional food. Innov Food Sci Emerg Technol 10:293–296. https://doi.org/10.1016/j.ifset.2008.10.007

Farinde EO, Adesetan TO, Obatolu VA, Oladapo MO (2009) Chemical and microbial properties of yogurt processed from cow’s milk and soymilk. J Food Process Preserv 33:245–254. https://doi.org/10.1111/j.1745-4549.2008.00336.x

Falade KO, Ogundele OM, Ogunshe AO et al (2015) Physico-chemical, sensory and microbiological characteristics of plain yoghurt from bambara groundnut (Vigna subterranea) and soybeans (Glycine max). J Food Sci Technol 52:5858–5865. https://doi.org/10.1007/s13197-014-1657-3

Milovanovic B, Djekic I, Miocinovic J et al (2020) What is the color of milk and dairy products and how is it measured? Foods 9:1–17. https://doi.org/10.3390/foods9111629

Donkor ON, Henriksson A, Vasiljevic T, Shah NP (2007) Rheological properties and sensory characteristics of set-type soy yogurt. J Agric Food Chem 55:9868–9876. https://doi.org/10.1021/jf071050r

Ozturkoglu-Budak S, Akal HC, Buran İ, Yetişemiyen A (2019) Effect of inulin polymerization degree on various properties of synbiotic fermented milk including Lactobacillus acidophilus La-5 and Bifidobacterium animalis Bb-12. J Dairy Sci 102:6901–6913. https://doi.org/10.3168/jds.2019-16479

Pandit P, Prajapathi DM, Shrigod NM, PrajapathiI RJ (2020) Textural and rheological properties of yoghurt : a review. Adv life Sci 5:18

Prabhurajeshwar C, Chandrakanth K (2019) Evaluation of antimicrobial properties and their substances against pathogenic bacteria in-vitro by probiotic Lactobacilli strains isolated from commercial yoghurt. Clin Nutr Exp 23:97–115. https://doi.org/10.1016/j.yclnex.2018.10.001

Funding

The work was funded by the National Institute of Food Technology Entrepreneurship and Management (NIFTEM), Sonepat, India.

Author information

Authors and Affiliations

Contributions

Taneja NK and Vikram contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Vikram and Amrutha. The first draft of the manuscript was written by Vikram. Ahire JJ edited the manuscript extensively and wrote the final draft. Taneja NK reviewed and approved the draft. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

This study does not contain any work related to the participation of humans and/or animals.

Competing Interests

Ahire JJ was employed by Advanced Enzyme Technologies Limited. Advanced Enzyme Technologies had no direct and in-direct role in the study design/analysis/writing of this article. Other authors have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, V., R., A., Ahire, J.J. et al. Techno-Functional Assessment of Riboflavin-Enriched Yogurt-Based Fermented Milk Prepared by Supplementing Riboflavin-Producing Probiotic Strains of Lactiplantibacillus plantarum. Probiotics & Antimicro. Prot. 16, 152–162 (2024). https://doi.org/10.1007/s12602-022-10026-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12602-022-10026-6