Abstract

Physico-chemical, sensory and microbiological characteristics of plain yoghurt from bambara groundnut and soybean milks were studied. Milks were prepared from bambara and soybean and then fermented using Lactobacillus delbruieckii subspp. bulgaricus and Streptococcus salivarus subspp. thermophilus to produce yoghurt. The yoghurts were stored at 7 °C and 27 °C for 9 days and their quality monitored. Results showed that pH of soy and bambara yoghurts decreased during the storage period for both storage temperatures. This decrease in pH was accompanied by simultaneous increase in titratable acidity. Total solids and apparent viscosities of soy and bambara yoghurts increased at 7 °C, but decreased at 27 °C during storage period. Bambara yoghurt received higher sensory acceptability than soy yoghurt. Predominant microorganisms in the stored yoghurts were lactic acid bacteria (LAB). The LAB count in the yoghurts stored at 7 °C decreased but increased at 27 °C during the storage period. Similar trends were followed by total aerobic bacteria, yeast and moulds counts. Pathogenic bacteria such as Salmonella, Coliform and E. coli were absent in all the yogurt samples. Yoghurts of acceptable quality and safety were produced from bambara groundnut and soybeans.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Soybean (Glycine max) is one of the most important legumes of the tropics with high lysine content compared with other plant proteins (Ade-Omowaye et al. 2004). Soybean has gained increase in its utilization as a staple crop due to its high nutritional and excellent functional properties (Ren et al. 2006). It is rich in protein (39.4 %), carbohydrates (27.1 %) and oil (20.6 %) (Osundahunsi et al. 2007). Bambara groundnut (Vigna subterranea) is an indigenous African crop known to have been domesticated in West Africa from its presumed wild ancestor (Fery 2002). Bambara groundnut contains about carbohydrates (61.3 %), protein (20.7 %) and 6.0 % oil (Yusuf et al. 2008), and is used as main food, snacks, relish and medicine, and has high ceremonial value (Oluwole et al. 2007). Bambara groundnut flour has been used in bread production (Alozie et al. 2009).

Yoghurt is a fermented semi-fluid milk product prepared from fresh whole or skimmed milk, which is usually carried out by the addition of bacterial starter culture (Akpan et al. 2007). Streptococcus salivarus subspp. thermophilus and Lactobacillus delbrueckii subspp. bulgaricus are the major predominant cultures associated with the milk fermentation into yoghurt (Peterson and Johnson 1978; Gonçalves et al. 2009). The scarcity of milk supply in developing countries has led to the development of alternative milk sources from vegetable sources (Onweluzo and Nwakalor 2009). Also, vegetable milks could be used as vegetarian nutrition or for medical reasons, in cases of milk allergies and galactosemia (Obizoba and Egbuna 1992). Among the sources of vegetable milk, soybean has received a considerable research attention, and more research is still being done to improve the quality of soymilk (Onuorah et al. 2007) and soy-yoghurt (Osundahunsi et al. 2007; Cavallini and Rossi 2009; Osman and Razig 2010). Brough et al. (1993) noted that milk prepared from bambara groundnut gave preferred flavor compared to the milks from cowpea, pigeon pea and soybean. Although there were some reports on vegetable milk production from bambara (Obizoba and Egbuna 1992; Brough et al. 1993; Oluwole et al. 2007), relatively little research attention has been given to production of yoghurt from bambara groundnut milk. Also, yogurt quality during storage is very important, because shelf life of yoghurt will depend on its physical, chemical, sensory and microbiological characteristics (Salvador and Fiszman 2004). Different storage temperatures and times have been reported to influence the changes in the quality characteristics of yoghurt (Osman and Razig 2010; Obi et al. 2010). The objective of this study was to evaluate the physicochemical, sensory and microbiological characteristics of yoghurts produced from soymilk and bambara groundnut milk during storage.

Materials and methods

Materials

Soybeans (Glycine max) and Bambara groundnuts (Vigna subterranea) were obtained from a local market in Ibadan, Nigeria. Sodium bicarbonate (NaHCO3), glucose, sucrose, and lactose were equally purchased from a retail shop in Ibadan, Nigeria.

Methods

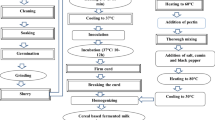

Production of bambara and soy milks

Bambara groundnuts and soybeans were sorted and cleaned to remove extraneous materials. About 200 g each of bambara nuts and soybeans were soaked in 2 L of distilled water with 0.5 % NaHCO3 (10 g) for 24 h. The soaked bambara groundnuts and soybeans were dehulled, thoroughly rinsed with distilled water and then blanched in 0.5 % NaHCO3 solution at 100 °C for about 20 min. The blanched and dehulled samples were rinsed with distilled water and milled into paste using a grinder (Excella, Kanchan International Limited unit III Dabhel Daman, India). Distilled water was then added in ratio 1:4 to give 12 % total solid. The slurry was then strained in a clean and sterile muslin cloth, followed by cooking of the recovered milk for 30 min at 82 °C, while stirring continuously with a wooden stirrer to prevent burning. The recovered milk was then mixed with blender (Excella, Kanchan International Limited unit III Dabhel Daman, India) and then allowed to cool to 45 °C (Nelson et al. 1975).

Production of bambara and soy yoghurts

Preparation of the starter cultures

Starter cultures (Lactobacillus delbruieckii subspp. bulgaricus and Streptococcus salivarus subspp. thermophilus) used for this research were stock cultures from the Department of Microbiology, University of Ibadan, Nigeria. The cultures were activated in MRS broth (Oxoid) incubated at 37 °C for 18 h to obtain cells at the stationary phase. The cells were then harvested by centrifugation (Selecta Medifridger centrifuge, Spain) and the pellet was washed once in sterile distilled water and re-suspended in 100 mL distilled water. The bacterial cells were then standardized using McFarland Standard ampule (bioMérieux, France) before inoculation into the homogenized, boiled and cooled Bambara groundnut and soy milks.

Fermentation process

Bambara and soy milks (n = 3) were homogenized using blender (Excella, Kanchan International Limited unit III Dabhel Daman, India), boiled for 15 min, 1 % glucose added and mixed thoroughly. The milks were then rapidly cooled in a water bath to 45 °C after having obtained homogenous mix (Tamime and Deeth 1980). The homogenized, boiled bambara and soy milks were inoculated with mixed culture at 106 cfu/mL. The inoculated milks were then incubated at 42 °C for 6 h after which the desired custard consistency was reached (Tamime and Deeth 1980). After fermentation, the yoghurt was cooled to 4 °C and then packaged into sterile Schott bottles.

Physico-chemical characteristics

Determination of milk yield

The percentage yield for soy and bambara milks was determined by weighing the slurry obtained after wet milling (Nwokolo 1996). Milk yields were determined by ratio of milk weight to the weight of slurry. Results were then expressed as percent yield.

pH of soy and bambara yoghurts

Fifty milliliters (50 mL) of each samples was measured in a beaker. The pH of the samples was determined using pH meter (Model 3520, Bibby Scientific Limited Dumow Essex, UK). The pH meter was calibrated with pH 4.0 and pH 7.0 buffer solutions before the measurement.

Titratable acidity of soy and bambara yoghurts

Twenty five milliliters (25 mL) of sample was pipetted into conical flasks and two drops of 0.1 N phenolphthalein indicator added. The mixture was titrated against 0.1 N NaOH until the first permanent pink colour appeared. The titratable acidity was then calculated and expressed as percent lactic acid (AOAC 1990).

Total solids of soy and bambara yoghurts

For each yoghurt sample, 20 mL was pipetted into already weighed petri dishes. The samples plus the petri dishes were then re-weighed. The samples were heated at 100 °C for 4 h in a hot air oven (S336RB, manufactured by carbolite parsons lane, Hope valley, England) until constant weights recorded. The dried samples with the petri dishes were then cooled in a desiccator. The weight of the petri dishes were then subtracted from the weight of the petri dishes plus sample before and after drying and the total solid content expressed in percentage (AOAC 1990).

Viscosity of soy and bambara yoghurts

The viscosity was measured using viscometer (Model 800, OFITE; OFI Testing Equipment, Inc., Houston, Texas, U.S.A). Samples were put in a stainless measuring cylinder and viscosity readings taken on the viscometer at 600 rev/min.

Microbiological analysis

The microbial population (cfu/mL) of the total aerobic bacteria, lactic acid bacteria (LAB), total coliforms, E. coli and yeasts and moulds were determined using nutrient agar (NA) (Oxoid), MRS agar media (Oxoid), Mac Conkey and Eosin methylene blue agars (Oxoid) and acidified (using 10 % tartaric acid to a pH of 3.5) PDA (Merck, Darmstadt, Germany) respectively. One milliliter (1 ml) of each soy and bambara yoghurt samples was aseptically pipetted into a test tube containing 9 ml sterile 0.1 % buffered peptone water (Merck) solution and appropriate serial dilutions were made. The NA and Mac Conkey and eosin methylene blue agars (Oxoid) agar plates were incubated at 37 °C for 24 h while yeast and mould plates plates were incubated at 25 °C for 3–5 days. MRS agar plates were incubated anaerobically using anaerobic jars together with anaerocult system (Merck) at 37 °C for 2–3 days.

Sensory analysis

Sensory evaluation was carried out on the fresh prepared plain soy- yoghurt, plain bambara-yoghurt and commercial plain yoghurt (control). An organoleptic study was carried out to evaluate the overall acceptance of the samples. Thirty member panelists consisting of yoghurt consumers in Ibadan city evaluated the samples for aroma, colour, taste, consistency and overall acceptability, using a 7-point hedonic scale where 1 to 7 represent dislike extremely (1) to like extremely (7).

Storage study

The packaged yoghurt samples were stored at 7 °C and 27 °C for 0, 3, 6 and 9 days. Samples were monitored for pH, titratable acidity, total solids, apparent viscosity and microbial quality.

Statistical analyses

Mean (standard deviation) of the result of all the experiments conducted in triplicate were reported. Data was subjected to analysis of variance (ANOVA, means were separated using Tukey’s least significance difference (LSD) test ran with a MINITAB statistical software (Minitab® Release 14.13, Minitab Inc., USA). Significance was accepted at P ≤ 0.05.

Results and discussion

Yield of milk from soy and bambara

The percent yield of milk from soy and bambara groundnut is shown in Fig. 1. Milk yields from soy and bambara groundnut were 52.2 and 47.0 %, respectively. The yield of milk from soybean was significantly higher than Bambara groundnut (Fig. 1). This suggests that milk extraction from Soybean was more efficient than Bambara. Milk yield of 58.8 % has been reported for soymilk (Beddows and Wong 1987), while Brough et al. (1993) reported milk yield of 3.6 l/kg bambara seeds. In this study, however, the yield of milk was calculated based on the mass of the slurry prepared. It is possible that the slurry made from Bambara groundnut might have a lot of fibre compared to slurry made from soybean.

pH and titratable acidity of plain yoghurt from soy and bambara

The effects of storage temperature and time on pH and titratable acidity of soy and bambara plain yoghurts are shown in Fig. 2a and b, respectively. pH of Soy yoghurt stored at 7 °C decreased significantly (p ≤ 0.05) over the storage period from 4.97 (day 0) to 4.20 (day 9) (Fig. 2a) . Similarly, pH of plain yoghurt from Bambara groundnut stored at 7 °C decreased significantly (p ≤ 0.05) over the storage period from 5.21 (day 0) to 4.11 (day 9) (Fig. 2a). However, pH of yoghurt from bambara groundnut was significantly (p ≤ 0.05) higher than the plain Soy yoghurt (Fig. 2a). Similar pH trends were obtained over the storage period when plain yoghurt from Soy and Bambara were stored at 27 °C. However, pH values of plain soy and bambara yoghurts stored at 27 °C were significantly (p ≤ 0.05) lower than yoghurts stored at 7 °C (Fig. 2a). Osundahunsi et al. (2007) reported a decrease in pH of plain soy-yoghurt refrigerated and stored at 6 °C for 8 days, pH value of 4.7 and 4.3 was reported for day 1 and day 8, respectively. These values are similar to results obtained in the current study for plain Soy yoghurt. In contrast, Stijepić et al. (2013) reported stable pH value for probiotic yoghurt made from soymilk during storage (up to 20th day) at 4 °C. Murevanhema (2012) reported a fairly stable pH for fermented bambara milk beverage (probiotic yoghurt) during storage period at 5 °C, and a significant decrease in pH during storage at 15 and 25 °C.

Effects of storage temperature and time on pH (a) and Titratable acidity (b) of plain Soy and Bambara yoghurts Soy at 7 °C = plain Soy yoghurt stored at 7 °C Soy at 27 °C = plain Soy yoghurt stored at 27 °C Bambara at 7 °C = plain Bambara yoghurt stored at 7 °C Bambara at 27 °C = plain Bambara yoghurt stored at 27 °C Error bars = ± standard deviations

As expected, decreased pH values of both soy and bambara yoghurts resulted in simultaneous increased titratable acidity values over the storage period (Fig. 2b). Titratable acidity of plain Soy and Bambara yoghurts stored at 7 °C increased significantly (p ≤ 0.05) from 1.63–2.02 % to 1.53–1.94 %, respectively. The titratable acidity of plain soy and bambara yoghurts stored at 27 °C showed similar significant (p ≤ 0.05) increases during the storage period (Fig. 2b). The titratable acidity of plain soy and bambara yoghurts stored at 27 °C were significantly (p ≤ 0.05) higher than yoghurts stored at 7 °C (Fig. 2b). Increase in titratable acidity (lactic acid) of plain soy-yoghurt refrigerated and stored at 6 °C for 8 days has been reported (Osundahunsi et al. 2007). These researchers reported titratable acidity (lactic acid) of 0.8 and 1.47 % for day 1 and day 8, respectively. These values are slightly lower than titratable acidity values for plain Soy yoghurt during the storage period obtained in our study. Stijepić et al. (2013) reported stable acidity value for probiotic yoghurt made from soymilk during storage (up to 20th day) at 4 °C. Murevanhema (2012) reported a gradual increase in titratable acidity of bambara groundnut milk beverage during storage at the 5 °C. In contrast, a faster increase in titratable acidity was reported when the samples were stored at 15 and 25 °C (Murevanhema 2012).

The decreased pH and simultaneous increased titratable acidity of the plain yoghurts during the storage period could be attributed to the starter culture’s activity, such as post acidification due to formation of lactic acid or growth of the bacteria used during fermentation (Osundahunsi et al. 2007; Murevanhema 2012). Growth rate of microbes has been associated with acidification and depended on the culture used (Zare et al. 2012). The relatively low pH and high titratable acidity of the plain Soy and Bambara yoghurts stored at 27 °C could be ascribed to the relatively higher microbial activities at the high storage temperature.

Total solids

The effects of storage temperature and time on total solids of soy and bambara plain yoghurts are shown in Table 1. The total solid contents of soy plain yoghurt stored at 7 °C increased significantly (p ≤ 0.05) from 10.4 % (day 0) to 14.3 % (day 9) over the storage period (Table 1). A similar trend was observed for bambara plain yoghurt stored at 7 °C over the storage period. Total solid contents increased significantly (p ≤ 0.05) from 9.7 % (day 0) to 12. 4 % (day 9) for bambara plain yoghurt (Table 1). However, total solid content decreased significantly (p ≤ 0.05) in soy and bambara plain yoghurts which were stored at 27 °C for 9 days (Table 1). Also, total solid content of the soy plain yoghurt was significantly (p ≤ 0.05) higher than values for Bambara plain yoghurt stored at 7 and 27 °C during the 9 days period (Table 1). Furthermore, total solid contents of Soy and Bambara plain yoghurts stored at 7 °C were significantly (p ≤ 0.05) higher than yoghurts stored at 27 °C (Table 1). Total solid contents varying from 10.62 to 11.49 % have been reported for soymilk-based yoghurts (Lee et al. 1990). Osundahunsi et al. (2007) also reported total solid content of 14.5 % for plain soy-yoghurt. Milk-based yoghurt has been reported to consist of about 14.5 % total solids (Lee et al. 1990). Decrease in soluble solid contents of some flavoured-yoghurts stored at 6 °C for 8 days have been reported (Osundahunsi et al. 2007). However, Muhammad et al. (2009) reported decreases in the total solid content of yoghurts from whole cow milk, powdered milk and soymilk stored in freezer (−4 °C), refrigerator (4 – 10 °C) and room temperature (26–32 °C) for 21 days period. Rasdhari et al. (2008) also reported that the total solid contents of some probiotic yoghurt samples decreased during storage at 4 °C for 7 days. Decreased total solid content of yoghurts from soy and Bambara groundnut milks with increased temperature during storage could be attributed to higher microbial activities at 27 °C than 7 °C (Rivkin et al. 1996).

Apparent viscosity

The effects of storage temperature and time on apparent viscosity of soy and bambara plain yoghurts are shown in Table 2. The apparent viscosity of soy and bambara plain yoghurts stored at 7 °C increased significantly (p ≤ 0.05) with storage time. The apparent viscosity of plain soy yoghurt stored at 27 °C increased after the third day (day 3) of storage from 530 cP to 687 cP, and then decreased to 568.3 cP during storage day 9 (Table 2). The apparent viscosity of Bambara plain yoghurt stored at 27 °C decreased significantly (p ≤ 0.05) from 698.3 cP to 489 cP, immediately after production to day 9, respectively (Table 2). At the end of storage period, plain soy yoghurt had significant higher apparent viscosity than plain bambara yoghurt for both 7 and 27 °C storage temperatures (Table 2). Beal et al. (1999) reported increase in viscosity of stirred yoghurt stored at 4 °C between 1 and 7 days. This increase was attributed to a low but persistent metabolic activity at 4 °C until 7 days storage and could be related to post-acidification. Similar increase in viscosity of yoghurt between 1 and 14 days of storage has been reported (Kaytanli 1993).

Microbiological characteristics

The results of microbial profile of soy and bambara yoghurts after the fermentation, which represents time zero of the storage and during nine days of refrigerated (7 °C) and ambient storage (27 °C) conditions are presented in Figs. 3 & 4. The predominant microorganisms in all the fermented yoghurts were lactic acid bacteria (LAB). This may be due to the fact that defined starter cultures were used under proper conditions of fermentation for manufacture of the two yogurt samples. Similar trend was observed in LAB counts of both soy and bambara yoghurts after 9 days of storage at 7 °C. The counts of LAB decreased by 0.6 log10cfu/mL and 1.0 log10 cfu/mL in the plain soy and bambara yoghurt samples respectively, after 9 days of cold storage at 7 °C (Figs. 3a & 4a). Also, Aminigo et al. (2009) reported decrease in the lactic acid bacteria count in African yam bean yoghurt stored at refrigeration temperature for 4 weeks. Similarly, Laye et al. (1993) also reported a gradual decrease in Lactobacillus in plain non-fat yoghurt.

Microbial profile after the fermentation of the Soy bean milk with the starter cultures (Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus salivarus subsp. thermophilus) at 42 °C for 6 h (Day 0) and during 9 days of storage at 7 °C (a) and 27 °C (b) (n = 3) Error bars = ± standard deviation

Microbial profile after the fermentation of the Bambara milk with the starter cultures (Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus salivarus subsp. thermophilus) at 42 °C for 6 h (Day 0) and during 9 days of storage at 7 °C (a) and 27 °C (b) (n = 3). Error bars = ± standard deviation

A significant increase (P ≤ 0.05) in the LAB counts from 7.6 log10 cfu/mL to 8.8 log10 cfu/mL and from 7.6 log10 cfu/mL to 8.7 log10 cfu/mL were recorded for soy and bambara yoghurts respectively, after 9 days of storage at ambient temperature (27 °C) (Figs. 3b & 4b). This is similar to the findings of Sengupta et al. (2013) where they attributed the higher microbial load observed in the soy yoghurt stored at 37 °C than the yoghurt stored at cold temperature to the fact that low temperature of refrigeration inhibited the growth of the lactic acid bacteria which grow well at temperatures between 20 and 40 °C with an optimum temperature range of 30–32 °C. Furthermore, the studies of Muhammad et al. (2009) and Chacko et al. (2010) reported that soy yoghurt stored at 37 °C contained higher microbial load than those at refrigerated temperature after 7 days of storage.

Total aerobic bacteria counts, as well as yeast and mould counts decreased with days of storage in both soy and bambara yoghurts stored at 7 °C (Figs. 3a & 4a). The counts of total aerobic bacteria in soy and bambara yoghurts stored at 7 °C were similar, but the yeast counts was significantly higher (p ≤ 0.05) in the Bambara yoghurt (2.8 log10 cfu/ml) than in the Soy yoghurt (1.4 Log10 cfu/mL) after 9 days of cold storage at 7 °C. However, the counts of total aerobic bacteria increased from 6.1 log10 cfu/mL to 6.9 log10 cfu/mL and from 5.8 log10 cfu/mL to 7.2 log10 cfu/mL in soy and Bambara yoghurt respectively, after 9 days of storage at 27 °C (Figs. 3b & 4b). Similarly, the yeast counts increased significantly (P ≤ 0.05) by 1.2 log10 cfu/mL and 1.7 log10 cfu/mL in soy and Bambara yoghurt respectively, after 9 days of storage at 27 °C. The increase in the population of yeasts and moulds can be attributed to an increase in acidity or reduction in potential oxygen during fermentation process which possibly might have provided suitable conditions for growth of yeasts and moulds (Sengupta, et al. 2013). Several studies have reported contamination of processed yogurts by yeasts and molds (Dardashti et al. 2001; Dublin-Green and Ibe 2008; Eissa et al. 2010; Amakoromo et al. 2012). The growth of moulds and yeasts have been identified as primary contaminants in yoghurt (Lorentan et al. 1998; Dublin-Green and Ibe 2008).

It is worth noting that pathogenic bacteria such as Salmonella, coliforms, E. coli and feacal enterococci were not detected. This is in agreement with the study of Sengupta, et al. (2013), where absence of coliform, Escherichia coli and Salmonella spp were reported in fresh and fortified soy yogurts at zero time and on 7th day of storage. The absence of enterobacteria signifies the degree of safety of the yogurt samples as the presence of coliform in food is an indication of fecal pollution, which is of public health concern (Farinde et al. 2009). Furthermore, starter cultures are widely known for the production of organic acids and other secondary metabolites such as bacteriocins that act against the growth of spoilage and pathogenic bacteria during fermentation (Booregard and Arneborg 1998; Jayeola et al. 2010).

Sensory evaluation

The mean scores of sensory attributes of soy and bambara plain yoghurts in comparison with commercial (farm fresh) yoghurt are presented in Table 3. The mean aroma score for commercial plain yoghurt was greater but comparable to Bambara plain yoghurt (Table 3), meaning the aroma for both yoghurts were equally liked slightly. There was no significant (p > 0.05) difference between the aromas of both yoghurts. However, the aroma of plain soy yoghurt was neither like nor dislike, having a mean aroma score of 4.40 (Table 3). Similar trends were observed in the colour, taste, and consistency. In the case of overall acceptability, commercial plain yoghurt was most acceptable (5.77) followed by Bambara yoghurt (5.03) and then Soy plain yoghurt (4.30) by the sensory panelists. The overall acceptability of the commercial plain yoghurt could be attributed to the fact that the sensory panelists were familiar with the commercial plain yoghurt compared to the plain soy and bambara yoghurts. Also, the beany flavor of the soy and bambara plain yoghurts reduced their acceptability. Similar sensory results have been reported by Lee et al. (1990), when milk-based yoghurt was compared with soymilk-based yoghurt. Buono et al. (1990) and Shirai et al. (1992) also reported low acceptability of soymilk yoghurt when evaluated with cow milk yoghurt by sensory panels. The lower rating could be attributed to the off-beany flavour in soymilk yoghurt. According to Buono et al. (1990), the lower the beany flavour, the higher the probability of panelists accepting the yoghurt. Bambara milk yoghurt in this study was more acceptable compared to soy milk yoghurt.

Conclusion

Yoghurt with considerable quality was produced from soy and bambara groundnut. Total solids and apparent viscosities of soy and bambara yoghurts increased at 7 °C, but decreased during storage period. Bambara yoghurt was more acceptable compared to soy yoghurt. Soy and Bambara yoghurts exhibited similar microbial quality and profile. The absence of pathogenic bacteria such as Salmonella, Coliform and E. coli in all the yogurt samples confirmed the safety and acceptability of the products. However storage at ambient temperature encourages high proliferation of yeasts which is regarded as contaminant in dairy product. Yoghurt of acceptable quality and safety could be produced from Bambara and soybeans.

References

Ade-Omowaye BIO, Olajide JO, Otunola ET, Omotade VA (2004) Effect of some processing parameters on the quality characteristics of soya bean curd. Sci Focus 7:53–57

Akpan UG, Mohammed AD, Aminu I (2007) Effect of preservative on the shelf life of yoghurt produced from soya beans milk. Leonardo Elect J Pract Technol 6:131–142

Alozie YE, Mary AI, Olajumoke L (2009) Utilization of Bambara groundnut flour blends in bread production. J of Food Technol 7(4):111–114

Amakoromo ER, Innocent-Adiele HC, Njoku HO (2012) Shelf-life study of a yoghurt-like product from African Yam bean. Nature Sci 10(5):6–9

Aminigo ER, Metzger L, Lehtola PS (2009) Biochemical composition and storage of a yoghurt – like product from African yam bean (Sphenostylis stenocarpa). Int J Food Sci Technol 44:560–566

AOAC (1990). Official methods of analysis. Association of official analytica chemists. 15th Edition. Washington D.C.

Beal C, Skokanova J, Latrille E, Martin N, Corrieu G (1999) Combined effects of culture conditions and storage time on acidification and viscosity of stirred yogurt. J Dairy Sci 82(4):673–681

Beddows C, Wong J (1987) Optimization of yield and properties of silken tofu from soybeans. Int J Food Sci Technol 22:15–21

Booregard DE, Arneborg N (1998) Interaction between Lactococcus lactis subspp. Lacti and Issatchenkia orientalis at milk fermentation. Food Technol Biotechnol 36:75–78

Brough SH, Azam-Ali SN, Taylor AJ (1993) The potential of bambara groundnut (Vigna subterranea) in vegetable milk production and basic protein functionality systems. Food Chem 47(3):277–283

Buono MA, Setser C, Erickson LE, Fung DYC (1990) Soymilk yogurt: sensory evaluation and chemical measurement. J Food Sci 55:528–531

Cavallini DCU, Rossi EA (2009) Soy yogurt fortified with iron and calcium: stability during the storage. Aliment Nutr Araraquara 20:7–13

Chacko A, Muraleedharan H, Sastry PS (2010) Effect of storage conditions on the microbial quality of fermented foods. World Appl Sci J 9(12):1365–1369

Dardashti AD, Akhndzadeh A, Bokaei S (2001) Study of coliform, yeast and mold contamination of yogurt in Ghaemshahr in Iran. Period Biol 103:183–186

Dublin-Green M, Ibe SN (2008) Quality evaluation of yogurts produced commercially in Lagos, Nigeria. Afr J Appl Zool Environ Biol 7(1):78–82

Eissa EA, Ahmed IM, Yagoub AEA, Babiker EE (2010) Physicochemical, microbiological and sensory characteristics of yoghurt produced from goat milk. Livest Res Rural Dev 22(8)

Farinde EO, Adesetan TO, Obatolu VA, Oladapo MO (2009) Chemical and microbial properties of yogurt processed from cow’s milk and soymilk. J Food Proc Preserv 33(2):245–254

Fery RL (2002) New opportunities in vigna. In Trends in new crops and new uses, Eds J.

Gonçalves MM, Freitas R, Nero LA, Carvalho AF (2009) Enumeration of starter cultures during yogurt production using Petri film TM AC plates associated with acidified MRS and M17 broths. J Dairy Res 76:229–233

Jayeola CO, Yahaya LE, Igbinadolor RO (2010) Cocoa powder supplementation in yoghurt production. J Food Technol 3:82–85

Kaytanli M (1993) Effect of the different heat treatments on rheological and organoleptical properties of yoghurt. J Dairy Foods Home Sci 12:8–16

Laye I, Karleskino D, Morr CV (1993) Chemical, microbial and sensory properties of plain non-fat yoghurt. J Food Sci 58:991–995

Lee SY, Morr CV, Seo A (1990) Comparison of milk-based and soymilk-based yogurt. J Food Sci 55(2):532–536

Lorentan T, Viljoen BC, Mostert JF, Vogel AM, Jordaan HF, Du P (1998) A preliminary study on the diversity and technological study of indigenous traditional south Africa fermented milk (Note). In: Jakobsen M, Viljoen BC (eds) Yeasts in the dairy industry: positive and negative aspects. proceedings of the symposium organized by group F47(2–3), september 1996. Brussels, Belgium, pp 178–182

Muhammad BF, Abubakar MM, Adegbola TA (2009) Effect of period and conditions of storage on properties of yoghurt produced from cow milk and soy milk materials. J Dairy Sci 3(2):18–24

Murevanhema YY (2012) Evaluation of bambara groundnuts (Vigna subterrenea (L.) Verdc.) milk fermented with lactic acid bacteria as a probiotic beverage. M. Tech. Dissertation. Cape Peninsula University of Technology, South Africa, p 183

Nelson AI, Steinberg MP, Wei LS (1975) Illinois process for preparation of soymilk. J Food Sci 41:57–61

Nwokolo E (1996) Peanut (Arachis hypogeal): Legumes and oil seeds in nutrition.(Ed. E. Nwokolo and J. Small). Chapman and Hall Publishers. Pp. 49

Obi TE, Henshaw FO, Atanda OO (2010) Quality evaluation of plain-stirred probiotic yoghurt produced from skim and whole milk powder during refrigerated storage. Electron J Environ Agric Food Chem 9(7):1203–1213

Obizoba IC, Egbuna HI (1992) Effect of germination and fermentation on the nutritional quality of bambara nut (Voandzeia subterranea L. Thouars) and its product (milk). Plant Foods Hum Nutr 42:13–23

Oluwole FA, Abdulrahim AT, Olalere RK (2007) Effect of moisture content on crackability of bambara groundnut using a centrifugal cracker. Interl Agrophysics 21:179–184

Onuorah CE, Adejare AO, Uhiara NS (2007) Comparative physico-chemical evaluation of soymilk and soya cake produced by three different methods. Nigerian Food J 25(2):32

Onweluzo JC, Nwakalor C (2009) Development and evaluation of vegetable milk from Treculia Africana (decne) seeds. Pak J Nutr 8:233–238

Osman MM, Razig KA (2010) Quality attributes of soy yoghurt during storage period. Pak J Nutr 9(11):1088–1093

Osundahunsi OF, Amosu D, Ifesan BOT (2007) Quality evaluation and acceptability of soy-yoghurt with different colours and fruit flavours. Am J Food Technol 2(4):273–280

Peterson M S, Johnson AH (1978) Encyclopedia of food technology and food science series. Vol. 3. Encyclopedia of food science, AVI Publishing Company, Inc

Rasdhari M, Parekh T, Dave N, Patel V, Subhash R (2008) Evaluation of various physico-chemical properties of Hibiscus sabdariffa and L. casein incorporated probiotic yoghurt. Pak J Biol Sci 11:2101–2108

Ren H, Liu H, Endo H, Takag Y, Hayashi T (2006) Anti-mutagenic and anti-oxidatives activities found in Chinese traditional soybean fermented products furu. Food Chem 95:71–76

Rivkin RB, Anderson MR, Lajzerowicz C (1996) Microbial processes in cold oceans. I. Relationship between temperature and bacterial growth rate. Aquat Microb Ecol 10(3):243–254

Salvador A, Fiszman SM (2004) Textural and sensory characteristics of whole and skimmed flavored Set-type yoghurt during long storage. J Dairy Sci 87:4033–4041

Sengupta S, Bhowal J, Bhattacharyya DK (2013) Development of new kinds of soy yogurt containing functional lipids as superior quality food. Annals Biol Res 4(4):144–151

Shirai K, Gutierrez-Durán M, Marshall VME, Revah-Moiseev S, García-Garibay M (1992) Production of a yogurt-like product from plant foodstuffs and whey. sensory evaluation and physical attributes. J Sci Food Agric 59(2):205–210

Stijepić M, Glušac J, Đurđević-Milošević D, Pešić-Mikulec D (2013) Physicochemical characteristics of soy probiotic yoghurt with inulin addition during the refrigerated storage. Rom Biotechnol Lett 18(2):8077–8085

Tamime AY, Deeth HC (1980) Yoghurt technology and biochemistry. J Food Prot 43(12):939–977

Yusuf A, Ayedun H, Sanni L (2008) Chemical composition and functional properties of raw and roasted Nigerian benniseed (Sesamum indicum) and bambara groundnut (Vigna subterranean). Food Chem 111:277–282

Zare F, Champagne CP, Simpson BK, Orsat V, Boye JI (2012) Effect of the addition of ingredients to milk on acid production by probiotic and yoghurt starter culture. LWT – Food Sci Technol 45:155–160

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Falade, K.O., Ogundele, O.M., Ogunshe, A.O. et al. Physico-chemical, sensory and microbiological characteristics of plain yoghurt from bambara groundnut (Vigna subterranea) and soybeans (Glycine max). J Food Sci Technol 52, 5858–5865 (2015). https://doi.org/10.1007/s13197-014-1657-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1657-3