Abstract

This study evaluates the influence of nanomaterials (nano-copper and nano-alumina) on the suction and hydraulic conductivity of compacted soil-bentonite mixture with different plasticity indexes. The soil suction and hydraulic conductivity of the compacted soil-bentonite mixtures were measured before and after the addition of nanomaterials. Soil-water characteristic curves were then developed for compacted soil samples (with and without nanomaterial) using a pressure membrane apparatus. It was found that saturated water content was lower in the soil samples mixed with nanomaterials. The soil hydraulic conductivity also decreased with increasing nanomaterial content, except for S3 soil sample with nano-copper content. The decrease of hydraulic conductivity was possibly caused by the reduction of the effective porosity due to pore clogging. The results from testing samples after one to four drying times show that the largest rise in soil hydraulic conductivity occurred at first or second drying. Adding nanomaterials can reduce the soil hydraulic conductivity by as much as seven times for soil samples with high clay (bentonite) content.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The flow of water in soil is significantly influenced by the availability of continuous void spaces or continuous pores between soil grains. Flow through soil is very important in the design of earth dams, determination of seepage under hydraulic structures, and dewatering of foundations (Das 2008, 2010). Water flow in porous media is traditionally described by Darcy’s law in which water movement in aggregated soils largely depends on hydraulic conductivity. Investigators in the past have reported that soils with low hydraulic conductivity are commonly used as barriers in landfills, slurry walls, and similar structures to slow down the movement of contaminants because of their higher water absorption capacity (Cheung 1994; Craven et al. 1999; Peirce et al. 1987).

Hydraulic conductivity changes in landfills have serious environmental impacts. Landfills produce biogas and leachates as a result of the various biochemical reactions occurring within the waste body. This can be threatening to the overall pollution of surrounding soil and ground water if the hydraulic conductivity of the soil liner and cap is technically deficient. One of the most important factors that increase the hydraulic conductivity is the development of cracks in the soil. The cracks in clayey soils are due to volume changes that occur during desiccation and lead to increase of water flow (Daniel and Wu 1993).

Many studies have been published on the treatment of cracks occurring in soil using different materials i.e. cement, lime, fibre, fly ash, and silica fume (Akcanca and Aytekin 2012; Al-Rawas et al. 2005; Dash and Hussain 2012; Guney et al. 2007; Harianto et al. 2008; Kalkan 2009; Miller and Azad 2000; Nalbantoğlu 2004; Rifai 2000; Tastan et al. 2011; Walker 1995). In general, these studies have shown that the cracks in the soil can be suppressed but the soil hydraulic conductivity will increase. However, pervious researches have shown that nanomaterials can reduce the volume change in soil without increase of the hydraulic conductivity (Taha and Taha 2012). Nanomaterial is a material having particles or constituents of nanoscale dimensions, which can be naturally or produced by nanotechnology, whilst nanoparticles are particles with sizes between 1 and 100 nm (Auffan et al. 2009; Kreuter 2007). Nanoparticles can play an important role in the improvement of engineering properties of many materials i.e. concrete, pavement, and soil. For example, strength and water permeability of concrete can be improved by adding SiO2 nanoparticles in the cement paste (Nazari and Riahi 2011). In addition, nanomaterial can decrease loss of strength by reducing the moisture susceptibility in asphalt mixtures (Nejad et al. 2012). Similarly, the dry density and compressive strength of soils can increase with nanomaterial addition (Majeed and Taha 2012). Furthermore, the addition of some nanomaterial (i.e. SiO2 nanoparticles) reduces the soil plasticity index, which in turn reduces the heaviness in the soil sample (Bahmani et al. 2014).

The idea of using nanomaterials to improve soil volume changes without increasing the hydraulic conductivity comes from the concept of interference between particles. In addition, nanomaterials react more actively with other particles in the soil matrix due to their smaller dimensions (Majeed and Taha 2013). According to Montesh (2005). the difference between the particle sizes contributes to interparticle filling or interlayer filling, which reduce the void ratio. Moreover, flocculation and dispersion of clay particles can play an important role in hydraulic conductivity. One of the important factors that increase flocculation is the electrolyte concentration. A decrease in the diffused double layer due to increasing electrolyte concentration leads to a decrease in the electrostatic repulsion, which results in moving the clay particles towards each other and flocculates. This will cause an increase in hydraulic conductivity of the clay samples (Kodikara and Rahman 1997; Schmitz 2006; Schmitz et al. 2004a, 2004b). Moreover, when two different types of cations are present in an aqueous system, the mixing of cations in the interlayers can control the extent of swelling. This is due to the overlapping of diffused double layers of the particles (Laird 2006).

The research conducted herein examines the effect of two specific nanomaterials (nano-alumina and nano-copper) on the soil-water characteristic curves. In addition, the hydraulic conductivity of the four types of soils with different plasticity indexes was also studied to look into the beneficial results of using these nanomaterials for landfill liner.

Materials and methods

The experimental work performed in this study is designed to evaluate the effect of two different types of nanomaterials on the soil suction, hydraulic conductivity, and cyclic hydraulic conductivity for four types of soil. Initially, a natural soil was taken within the Universiti Kebangsaan Malaysia (UKM) campus then mixed with bentonite of different contents in order to obtain four soils with different plasticity indexes.

Materials

Bentonite

The bentonite used in the present investigation is a high-swell sodium containing sodium montmorillonite and its properties are listed in Table 1. In general, it has a specific gravity of 2.66, plasticity index of 394.6, and cation exchange capacity of 90 mEq/100 g. An electronic scanning microscope image of the bentonite sample is shown in the same table. It consists mostly of layered particles with thickness around 12 nm and different length sizes up to 15 μm.

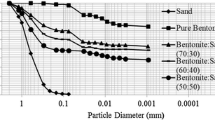

Soil

The soil is residual taken from Universiti Kebangsaan Malaysia (UKM) campus in Bangi, Selangor, Malaysia. This soil is termed as UKM. The soil was sampled from 0.5 to 1 m below the ground surface. According to the Unified Soil Classification System, the UKM soil is sandy with low plasticity index clay (i.e. CL). The other physical and chemical properties of UKM soil are listed in Table 1.

Nanomaterials

Two types of nanomaterials were used in this study, i.e. nano-alumina and nano-copper. Some properties of the nanomaterials are discussed below.

The nano-alumina material used in this study is Ultrapure Gamma-Alumina (γ-Al2O3) powder with a purity of 99.99 %, with high activity and low melting temperature. The gamma phase nano-alumina with large surface area and high catalytic activity can be made into microporous spherical structure or honeycomb structure of catalytic materials. From scanning electronic microscope image shown in Table 1, the particle size of gamma phase nano-alumina ranged between 20 and 50 nm. The gamma phase nano-alumina powder was supplied by Inframat Advanced Materials (Manchester, CT, USA). The general properties are shown in Table 1.

The other nanomaterial used in this study is copper oxide nanopowder with a purity of 99.99 %, also supplied by Inframat Advanced Materials (Manchester, CT, USA). The copper oxide nanopowder is insoluble in water. It dissolves slowly in alcohol or ammonia solution. It is also soluble in dilute acids, NH4Cl, (NH4)2CO3, and potassium cyanide solution under high temperature. Nano-copper oxide is a widely used material. It has been applied to the catalyst, superconducting materials, thermoelectric materials, sensing materials, glass, ceramics, and other fields. A scanning electronic microscope image for copper oxide nanopowder is shown in Table 1. The average particle diameter for copper oxide nanopowder is about 100 nm. The other properties for copper oxide nanopowder are also shown in Table 1.

Preparation of soil–nanomaterial mixtures

Initially, the UKM soil was mixed with three different bentonite contents to obtain soils with different plasticity index. Then the dry soil was mixed with nanomaterials before adding water to the mixture.

In this study, two mixing methods were examined. In the first method, the nanomaterials were mixed with required quantity of water and then the mixture was put in a beaker. The beaker was then placed in an ultrasonic bath of water for 2 h (sonication) by applying sound energy to agitate particles in the sample in order to loosen particles adhering to surfaces as was suggested by Bahmani et al. (2014) and Wei et al. (2002). After ultra-sonication, the suspension was mixed with the soil. However, it was too difficult to obtain a homogeneous mixture of the soil-nanomaterial mixture by this method.

In the second method, the dry soil was mixed with nanomaterials and then the water was added to the mixture. In this method, mixing was carried out into two stages. The quantity of soil, initially premixed or hand-mixed (To et al. 2011). was divided into ten portions and each portion was spread in a square pan (50 × 50 cm), then the required amount of nanomaterial was sprayed using sieve number 200 as shown in Fig. 1.

Each portion was mixed alone manually for 5 min then put in a bowl, and then the mixture was mixed by a horizontal cylindrical mixer machine at 139 rpm for 1, 3, 5, and 7 h (Jones and Parker 2007). It was found that 3 h mixing time achieved sufficient distribution for particles of the nanomaterial and no more change in the result after extended mixing time (Taha and Taha 2012).

In order to avoid the segregation problem, the soil-nanomaterial mixture was mixed with the required water content directly, then the entire mixture was placed in a sealed plastic bag and left for 24 h for hydration. This mixing method was repeated every time it is needed to prepare a new mixture. This procedure was found to be the best method to obtain homogeneous samples since homogeneous colour was obtained after compaction (Fig. 2). However, proper care was taken to prepare the homogeneous mixtures at each stage. The amount of bentonite and nanomaterials used in this study are given in Table 2 with the values of plasticity index (PI), optimum water content, and maximum dry density.

It is clear from this table that from S1 to S4, the (PI) of the soil increases. Based on results of Taha and Taha (2012). the optimum content of nanomaterial to achieve minimum shrinkage and swell strains in the soil was 0.05 % nano-alumina and 0.15 % nano-copper for soil sample S1, 0.075 % nano-alumina and 0.3 % nano-copper for soil sample S2, and 0.1 % nano-alumina and 0.5 % nano-copper for soil samples S3 and S4, respectively.

Test procedures

Suction measurements

The determination of soil-water characteristic curves was carried out according to the ASTM D 6836-02 standard method using Pressure Extractor Chamber apparatus. It consists of saturated porous ceramic plate inside a pressure chamber. Saturated soil samples were placed on top of the plate during testing. Suction was applied on the soil samples by controlling both pore air pressure and pore water pressure, and the difference between the two pressures is the matric suction. It is the most commonly used method for determining soil-water characteristic curves. The maximum differential pressure, which can be applied across the plate before cavitation, is constrained by the air entry value of the plate. Suctions of 10, 50, 100, 300, 500, 1000, and 1500 kPa were used to define the soil-water characteristic curves.

Hydraulic conductivity test

The soil was compacted according to the standard test method (ASTM D698) for both unamended soil and soil with nanomaterials. After compaction, cylindrical specimens with a diameter of 70 mm and a height of 35 mm were prepared from the mixtures compacted by standard compaction energy at optimum water content. Then its hydraulic conductivity was determined following ASTM D5084, i.e. using flexible membrane apparatus. Porous stones and filter paper were placed against the ends of the samples to distribute de-aired water to permeate across the entire end area of the sample. Once the sample has been prepared in the test cell, the cell was filled with water and the specimen was saturated by applying pressure gradually step by step in two directions i.e. back pressuring from the bottom and cell pressuring surrounding the sample to force water to enter the sample for saturation until the back pressure reaches 215 kPa and cell pressure reaching 240 kPa, giving the degree of saturation of more than 98 % (Black and Lee 1973; Head 1998). After the saturation was completed, 10 kPa pressure differences were applied (hydraulic gradient = 31), and the readings of inlet and outlet burette were taken until the measured hydraulic conductivity reached a relatively steady-state condition.

Cyclic hydraulic conductivity test

Samples that showed evidence of cracking when dried were subjected to hydraulic conductivity test after each dry cycle to determine how much the hydraulic conductivity increased due to cracking. Cyclic hydraulic conductivity tests were carried out only at samples mixed with optimum nanomaterial content. After the first hydraulic conductivity test, the samples were desiccated in the oven at 35 ± 2 °C for a period of approximately 5–10 days depending on the sample type. At the end of the drying period, each sample was weighed, and the diameter and height were measured. The samples were then placed back inside the flexible-wall membrane and permeated with water until saturation was achieved. Each sample was saturated at least for four times (including the initial saturation) and dried at least three times (Albrecht and Benson 2001).

Results and discussion

Effect of nano-alumina and nano-copper content on the soil-water characteristic curves

The soil-water characteristic curves (Figs. 3 and 4) show that the gravimetric water content decreases after mixing the soil with optimum value of nanomaterials. Looking at Fig. 3a, the red colour curve (the soil sample S1 without additive) is higher than the purple curve (the soil sample S1 with 0.075 nano-alumina), where 0.075 nano-alumina is the optimum value additive for S1 soil samples. A similar behaviour for other soil samples was noted. This reduction in water content indicates that the amount of water required for saturation also decreases, thus reducing the suction in soil samples. For soil sample S1 (100 % soil), there is no significant difference between the soil-water characteristic curves as shown in Figs. 3a and 4a. In addition, low amount of gravimetric water content was noted in soil samples S1 with and without nanomaterials. This is due to the amount of clay which is the lowest for sample S1 (Table 1).

Moreover, the same behaviour was noted for soil samples S2 (5 % bentonite) and S3 (10 % bentonite) after adding nano-alumina as shown in Fig. 3b, c. For soil sample S4 (20 % bentonite), the difference between the curves increases (Fig. 3d). However, there is some decrease in the gravimetric water content with certain nano-alumina content. The greatest drop was noted at 0.075 % nano-alumina content for soil samples S1 and S2 and at 0.10 % nano-alumina content for soil samples S3 and S4.

For soil samples with nano-copper, there is a significant decrease in the gravimetric water content for soil samples S2, S3, and S4. Moreover, the decrease in the gravimetric water content after mixing the soil samples with nano-copper was bigger than the decrease in the gravimetric water content when nano-alumina was used especially for soil samples S3 and S4. This may be due to the increase in dry density and the reduction in plasticity index. It can be observed from Fig. 4 that the highest reduction in the gravimetric water content occurs at 0.15 % nano-copper for soil sample S1 (Fig. 4a), 0.30 and 0.5 % nano-copper for soil sample S2 (Fig. 4b), and 0.5 % for soil samples S3 and S4 (Fig. 4c, d). In general, soils with high clay content (bentonite) have more water distributed in its many small size pores. Therefore, the required amount of nanomaterial to fill the pores to obtain best improvement will also increase.

The addition of nanomaterial increases the amount of fine particles. Generally, the increase in fine particles content increases the water content of samples possibly due to greater adsorption of water by fine particles (i.e. bentonite content) (Tay et al. 2001). On the other hand, the increase in soil density reduces the gravimetric water content in soil samples (Ahn and Jo 2009; Dixon et al. 1985; Komine 2008). Furthermore, the soil-water characteristic curves were more sensitive to changes in dry density (Miller et al. 2002). Thus, due to the high specific gravity, small quantity, and well distribution of nanomaterials, the nanomaterials can fill the microvoids leading to increase in soil density which in turn leads to lower gravimetric water content.

Effect of nano-alumina and nano-copper contents on the hydraulic conductivity

The hydraulic conductivity of the soil sample S1 (Fig. 5a) decreases when nano-alumina content increases to 0.05 %, whilst at 0.075 % nano-alumina content no significant change noted. Further increase in nano-alumina (0.1 % by dry weight) caused a slight increase in hydraulic conductivity. Then, a small decrease was noted at 0.15 % nano-alumina content. Finally, the hydraulic conductivity tends to increase with increasing the nano-alumina content to 0.3 %. However, there is a clear difference between the hydraulic conductivity of S1 soil sample without nano-alumina (0 % nano-alumina) and the hydraulic conductivity of the S1 soil sample with nano-alumina. In addition, the regression fit line for the hydraulic conductivity data of Fig. 5a shows slight decrease with increasing nano-alumina content which can consider insignificant decrease. In general, the results (Fig. 5) show that increase of nano-alumina content in soil sample S1 does not result in significant reduction in hydraulic conductivity, whilst for soil sample S2, the decrease in hydraulic conductivity was more notable than for soil sample S1 as nano-alumina contents were increased. Furthermore, the decrease in hydraulic conductivity for soil samples S3 and S4 was greater than that for soil samples S1 and S2 as shown in Fig. 5. This is due to the content of bentonite in S3 and S4 soil samples higher than that in S1 and S2 soil samples.

Similarly in Fig. 6a–d, the data show that the addition of nano-copper content in soil samples S1 and S2 results in a small reduction in hydraulic conductivity, whilst increasing in nano-copper content for soil sample S3 does not reduce hydraulic conductivity. However, there is significant drop in hydraulic conductivity for soil samples S4 as nano-copper content increases. This is possibly due to the increase in sample density as nano-copper content increases.

Generally, the hydraulic conductivity of soil decreases as the bentonite content increases due to the pore clogging caused by reduction in the effective porosity (Francisca and Glatstein 2010). Thus, the hydraulic conductivity of soil sample S4 is much less than that in soil samples S3, S2, and S1. Inversely, the soil suction of soil samples increases as the bentonite content is increased.

According to Ahn and Jo (2009). the maximum dry density decreased and the optimum water content increased with increasing cation exchange capacity of clay due to an increase in the swelling pressure, which in turn increases suction in soil. The hydraulic conductivity of soil reduced with increasing cation exchange capacity of clay possibly due to the larger double-layer thickness (Laird 2006). Thus, the increase in clay content increases the suction in soil, reducing its hydraulic conductivity. However, in this study, the use of nanomaterial can decrease the suction in soil at the same time reducing the hydraulic conductivity and the crack development in soil surface (Taha and Taha 2012).

Consequently, the idea behind the technique of using nanomaterial in soil is that the nanomaterial could fill up the space in between soil particles thus reducing the voids in soil samples. Furthermore, small-size nanoparticles aid in overlapping the nanomaterial between soil particles causing voids clogging as shown in Figs. 7 and 8, which in turn decreases the hydraulic conductivity. In addition, nanomaterial with high particle density can increase the maximum dry density of the soil causing decrease in soil voids and possibly increase soil strength (Taha and Taha 2012). However, as the nanoparticle size increased the soil hydraulic conductivity increased as well. A similar behaviour was noted by Bahmani et al. (2014).

From another standpoint, the Na bentonite has a pH of 9.9 (Table 1). However, the zero-point charge of copper oxide (CuO) and alumina oxide (Al2O3) is 9.5 and 8 to 9, respectively (Lewis 2000). Thus, the surface ions of nano-copper and nano-alumina have positive charge which possibly allows the bentonite particles to attract nano-copper and nano-alumina particles. In order to understand this in greater detail, the effect of nanomaterials on pH value was investigated. In addition, a zeta potential test was carried out on all types of soil before and after mixing with some specific nanomaterials. Zeta potential values can provide an indication on the swelling ability of the soil sample (Iwata et al. 1994). If all particles in suspension liquid have a large negative or positive zeta potential, then they tend to repel each other and there will be no tendency for the particles to come together. However, if the particles have low zeta potential values, then there will be no force to prevent the particles coming together and flocculating, and thus, the storage of water is reduced within the soil sample.

The pH values of the four examined samples are shown in Figs. 9 and 10. It can be seen from the figures that the pH value of S1 and S2 soil samples treated with nano-alumina and nano-copper increased when the percentage of nanomaterials increased due to low pH values of S1 and S2 soil samples (4.0 and 6.81, respectively). Moreover, the increase in pH value for samples treated with nano-copper was higher than nano-alumina because the content of nano-copper is more than that of nano-alumina. For S3 and S4 soil samples, the pH values were 9.05 and 9.83, respectively, at zero nanomaterial content, and the pH values for nano-alumina and nano-copper were 7.3 and 8.64, respectively. Therefore, a small increase in the pH value of S3 and S4 soil samples was noted after mixing with nano-copper because mixing two alkaline materials increases the concentration of hydroxide ions, i.e. OH−, or alkalinity (Pacheco-Torgal et al. 2008). A small reduction of pH values was instead noted in S3 and S4 soil samples after mixing with nano-alumina because the aluminium oxide is an amphoteric substance; it can react with both acids and bases, acting as an acid with a base and a base with an acid, neutralising the other (Doshi et al. 2008; Wilson 2011). However, one of the indications of increasing the cementation of colloidal particles is the increase in pH value (Muhunthan et al. 2008).

Some decrease in the absolute zeta potential values was noted in Fig. 11 for S1, S2, and S3 soil samples after mixing with nano-copper. The similar behaviour was noted for S1 and S2 soil samples after mixing with nano-alumina. Moreover, zeta potential values for S2, S3, and S4 soil samples are much more than that for S1 soil samples due to the presence of the bentonite. However, nano-alumina has high positive zeta potential value at pH less than 8 and nano-copper also has high positive zeta potential value at pH less than 9.5. Therefore, some reduction in zeta potential values occurred after mixing with the nanomaterial. For S3 and S4 soil samples mixed with nano-alumina, a small increase in zeta potential was noted. However, zeta potential increase was observed only when mixing nano-copper with S4 soil sample. Due to the increase of pH value of the mixtures beyond the zero point of charge of nano-alumina and nano-copper, the mixtures are expected to have larger negative zeta potential value. This is in addition to the fact that the soil sample is negatively charge. The zeta potential value of S3 soil sample (−48.06 mV) becomes more negative (−48.73 mV) after adding nano-alumina. Similarly, for S4 soil sample, the zeta potential value which was −47.4 mV becomes more negative (−47.6 and −47.7 mV) after adding nano-alumina and nano-copper, respectively. This behaviour was also noted on other materials by other researchers (Au and Leong 2013; Castellote et al. 2006; Grover et al. 2013; Hussain et al. 1996; Tunç and Duman 2008).

Effect of the number of drying cycles on soil

Since hydraulic conductivity tests require a long time, only the samples with optimum nanomaterial content were selected for the test. According to Taha and Taha (2012). the optimum contents of nano-alumina were 0.05, 0.075, 0.1, and 0.1 % for soil samples S1, S2, S3, and S4, respectively, whilst the optimum contents of nano-copper were 0.15, 0.3, 0.5, and 0.5 % for soil samples S1, S2, S3, and S4 respectively. The results in Fig. 12a show that there is no difference in soil sample S1 before and after adding nano-alumina possibly because of the low amount of nano-alumina content. However, there is a clear increase in hydraulic conductivity ratio (Kr) with nano-copper relative to soil sample S1. The Kr is the ratio between the hydraulic conductivity of soil at first, second, and third cycles to the zero cycle hydraulic conductivity, respectively. The increase in Kr for soil sample S1 after each drying cycle possibly comes from slow discharge of nano-copper during the water flow as indicated in Fig. 13, which shows that the sample surface colour had changed to black (colour of nano-copper) at the end of the hydraulic conductivity test. The nano-copper material actually gathered between the surface of the specimen and the filter paper at the top of the samples during hydraulic conductivity test leading to losses in nano-copper after every cycle of testing. However, discharging of the nanomaterials during the hydraulic conductivity is very low and can be considered safe for the environment. According to Varanasi et al. (2007). a nanoparticle can absorb persistent organic pollutants such as polychlorinated biphenyls (PCBs). In addition, the use of nanoparticles in the composition of cement results in significant reductions of CO2 pollution (Olar 2011). Thus, the use of nanoparticles in the contaminated soils can reduce soil pollution and enhance the engineering properties of soils.

The similar behaviour occurred for soil sample S2 with less discharge of nanomaterial (Fig. 12b). Generally, as the bentonite content increases, the nanomaterial becomes a more effective material for improvement, especially for nano-copper particles. It can be seen from Fig. 12c that the Kr decreased after adding nano-alumina and nano-copper for soil sample S3. The reduction in Kr was much better for soil sample S4 after adding the nanomaterials (Fig. 12d). The maximum reduction in hydraulic conductivity of the treated samples exposed to drying cycle was observed in the soil sample S3 by as much as two times using nano-alumina and nano-copper. However, in soil sample S4, the reduction in hydraulic conductivity is about five times when using nano-alumina and seven times for nano-copper. For all of the specimens, the hydraulic conductivity of cracked specimens increased by as much as ten times. The most significant increase in the hydraulic conductivity took place after the first or second drying cycle because most cracks in the specimens occurred during the initial drying cycles. It was also observed that a few additional cracks were formed during subsequent drying cycles. Therefore, a slight increase in hydraulic conductivity was observed. The similar behaviour was noted by Albrecht and Benson (2001).

Conclusions

This work provides an insight into the role of nanomaterials (nano-alumina and nano-copper) on the improvement of soil-water characteristic curves and hydraulic conductivity behaviour of the four types of soils with different plasticity indexes. Compacted soil specimens with optimum nanomaterials content subjected to cyclic hydraulic conductivity test were also examined.

The results showed that the gravimetric water content in soil retention curves decreases measurably after mixing with the optimum nanomaterials (nano-alumina and nano-copper) content due to the increase in dry density, especially for soil samples with the highest plasticity index. The soil-water retention curves for nano-copper were lower than that of nano-alumina. Otherwise, the hydraulic conductivity of samples mixed with nano-alumina was less than hydraulic conductivity of samples mixed with nano-copper. In general, the hydraulic conductivity of compacted samples decreased as the nanomaterial (nano-alumina and nano-copper) content was increased, except for S3 soil sample with nano-copper content. This is due to the pore clogging and interparticle interaction by the nanomaterials. Thus, a potential method to reduce soil hydraulic conductivity without increase in soil suction is by the use of nanomaterials. Moreover, the results show that the nanomaterials are more appropriate for soils with high clay content (bentonite).

The pH value of S1 and S2 soil samples increased as nano-alumina and nano-copper increased. The pH value of S3 and S4 soil samples increased slightly after mixing with nano-copper. Conversely, the pH value of S3 and S4 soil samples decreased slightly after mixing with nano-alumina. The zeta potential value is a direct relation to pH value. The value of zeta potential become less negative after mixing with nanomaterial as the pH value reaches below the point of zero charge of the nanomaterial. However, when the mixture of soil nanomaterials has pH value greater than the point of zero charge of the particular nanomaterial, then the zeta potential value of the mixtures becomes more negative. This behaviour is similar for the other additives as well.

Testing of cracked specimens after drying indicated that the hydraulic conductivity increased by as much as ten times, and the largest increases in hydraulic conductivity occurred after the first or second drying cycles. Thus, two drying cycles appear enough to damage the compacted clay severely. Nano-copper was discharged during the water flow after first or two drying cycles in low bentonite content soil samples, leaving more continuous voids which in turn increase the hydraulic conductivity. Nano-alumina and nano-copper reduced the increase in hydraulic conductivity from drying cycle for highly bentonite content soil samples by as much as five times and seven times, respectively.

References

Ahn H-S, Jo HY (2009) Influence of exchangeable cations on hydraulic conductivity of compacted bentonite. Appl Clay Sci 44:144–150. doi:10.1016/j.clay.2008.12.018

Akcanca F, Aytekin M (2012) Effect of wetting–drying cycles on swelling behavior of lime stabilized sand–bentonite mixtures. Environmental Earth Sciences 66:67–74. doi:10.1007/s12665-011-1207-5

Al-Rawas AA, Hago AW, Al-Sarmi H (2005) Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman. Build Environ 40:681–687. doi:10.1016/j.buildenv.2004.08.028

Albrecht BA, Benson CH (2001) Effect of desiccation on compacted natural clays. J Geotech Geoenviron 127:67–75

Au P-I, Leong Y-K (2013) Rheological and zeta potential behaviour of kaolin and bentonite composite slurries. Colloid Surface A 436:530–541. doi:10.1016/j.colsurfa.2013.06.039

Auffan M, Rose J, Bottero J-Y, Lowry GV, Jolivet J-P, Wiesner MR (2009) Towards a definition of inorganic nanoparticles from an environmental, health and safety perspective. Nat Nano 4:634–641

Bahmani SH, Huat BBK, Asadi A, Farzadnia N (2014) Stabilization of residual soil using SiO2 nanoparticles and cement. Construct Build Mater 64:350–359. doi:10.1016/j.conbuildmat.2014.04.086

Black DK, Lee KL (1973) Saturating laboratory samples by back pressure. J Soil Mech Found Div ASCE 99:75–93

Castellote M, Llorente I, Andrade C (2006) Influence of the composition of the binder and the carbonation on the zeta potential values of hardened cementitious materials. Cem Concr Res 36:1915–1921. doi:10.1016/j.cemconres.2006.05.033

Cheung SCH (1994) Modeling of inorganic contaminant transport in dense bentonite. Journal of Soil Contamination 3:137–157. doi:10.1080/15320389409383459

Craven W, Townsend T, Vogel K, Laux S (1999) Field investigation of landfill leachate collection system clogging. Pract Period Hazard Toxic Radioact Waste Manage 3:2. doi:10.1061/(ASCE)1090-025X(1999)3:1(2)

Daniel DE, Wu Y-K (1993) Compacted clay liners and covers for arid sites. J Geotech Eng 119:223–237

Das BM (2008) Advanced soil mechanics, 3rd edn. Taylor & Francis, New York

Das BM (2010) Principles of foundation engineering, 7th edn. Cengage Learning, Stamford

Dash S, Hussain M (2012) Lime stabilization of soils: reappraisal. J Mater Civ Eng 24:707–714. doi:10.1061/(ASCE)MT.1943-5533.0000431

Dixon DA, Gray MN, Thomas AW (1985) A study of the compaction properties of potential clay—sand buffer mixtures for use in nuclear fuel waste disposal. Eng Geol 21:247–255. doi:10.1016/0013-7952(85)90015-8

Doshi R, Braida W, Christodoulatos C, Wazne M, O’Connor G (2008) Nano-aluminum: transport through sand columns and environmental effects on plants and soil communities. Environ Res 106:296–303. doi:10.1016/j.envres.2007.04.006

Francisca FM, Glatstein DA (2010) Long term hydraulic conductivity of compacted soils permeated with landfill leachate. Appl Clay Sci 49:187–193. doi:10.1016/j.clay.2010.05.003

Grover IS, Singh S, Pal B (2013) The preparation, surface structure, zeta potential, surface charge density and photocatalytic activity of TiO2 nanostructures of different shapes. Appl Surf Sci 280:366–372. doi:10.1016/j.apsusc.2013.04.163

Guney Y, Sari D, Cetin M, Tuncan M (2007) Impact of cyclic wetting–drying on swelling behavior of lime-stabilized soil. Build Environ 42:681–688. doi:10.1016/j.buildenv.2005.10.035

Harianto T, Hayashi S, Du Y-J, Suetsugu D (2008) Effects of fiber additives on the desiccation crack behavior of the compacted Akaboku soil as a material for landfill cover barrier. Water, Air, and Soil Pollution 194:141–149. doi:10.1007/s11270-008-9703-2

Head KH (1998) Manual of soil laboratory testing: effective stress tests. Wiley, New York

Hussain SA, Demirci S, Ozbayogu G (1996) Zeta potential measurements on three clays from Turkey and effects of clays on coal flotation. J Colloid Interface Sci 184:535–541. doi:10.1006/jcis.1996.0649

Iwata S, Tabuchi T, Warkentin BP (1994) Soil-water interactions: mechanisms applications, second edition, revised expanded. Taylor & Francis, New York

Jones JR, Parker DJ, Bridgwater J (2007) Axial mixing in a ploughshare mixer. Powder Technology 178:73–86. doi:10.1016/j.powtec.2007.04.006

Kalkan E (2009) Influence of silica fume on the desiccation cracks of compacted clayey soils. Appl Clay Sci 43:296–302. doi:10.1016/j.clay.2008.09.002

Kodikara J, Rahman MF (1997) Clay hydraulic conductivity and permeant electrolyte concentration. Paper presented at the Environmental geotechnics: proceedings of the 1st Australian-New Zealand conference geoenvironment, 26–28 November, Melbourne

Komine H (2008) Theoretical equations on hydraulic conductivities of bentonite-based buffer and backfill for underground disposal of radioactive wastes. J Geotech Geoenviron 134:497–508. doi:10.1061/(ASCE)1090-0241(2008)134:4(497)

Kreuter J (2007) Nanoparticles—a historical perspective. International Journal of Pharmaceutics 331:1–10. doi:10.1016/j.ijpharm.2006.10.02

Laird DA (2006) Influence of layer charge on swelling of smectites. Appl Clay Sci 34:74–87. doi:10.1016/j.clay.2006.01.009

Lewis JA (2000) Colloidal processing of ceramics. J Am Ceram Soc 83:2341–2359. doi:10.1111/j.1151-2916.2000.tb01560.x

Majeed ZH, Taha MR (2012) Effect of nanomaterial treatment on geotechnical properties of a Penang soft soil. Journal of Asian Scientific Research 2:587–592

Majeed ZH, Taha MR (2013) A review of stabilization of soils by using nanomaterials. Australian Journal of Basic and Applied Sciences 7:576–581

Niller C, Yesiller N, Yaldo K, Merayyan S (2002) Impact of soil type and compaction conditions on soil water characteristic. J Geotech Geoenviron 128:733–742. doi:10.1061/(ASCE)1090-0241(2002)128:9(733)

Miller GA, Azad S (2000) Influence of soil type on stabilization with cement kiln dust. Construct Build Mater 14:89–97. doi:10.1016/s0950-0618(00)00007-6

Montesh G (2005) Swelling–shrinkage measurements of bentonite using coupled environmental scanning electron microscopy and digital image analysis. J Colloid Interface Sci 284:271–277. doi:10.1016/j.jcis.2004.09.025

Muhunthan B, Sariosseiri F, Washington State Department of Transportation, Office of Research & Library Services (2008) Interpretation of geotechnical properties of cement treated soils.

Nalbantoğlu Z (2004) Effectiveness of class C fly ash as an expansive soil stabilizer. Construct Build Mater 18:377–381. doi:10.1016/j.conbuildmat.2004.03.011

Nazari A, Riahi S (2011) The effects of SiO2 nanoparticles on physical and mechanical properties of high strength compacting concrete. Compos Part B 42:570–578. doi:10.1016/j.compositesb.2010.09.025

Nejad FM, Azarhoosh AR, Hamedi GH, Azarhoosh MJ (2012) Influence of using nonmaterial to reduce the moisture susceptibility of hot mix asphalt. Construct Build Mater 31:384–388. doi:10.1016/j.conbuildmat.2012.01.004

Olar R (2011) Nanomaterials and nanotechnologies for civil engineering. Bulletin of the Polytechnic Institute of Iasi 61:109–117

Pacheco-Torgal F, Castro-Gomes J, Jalali S (2008) Alkali-activated binders: a review. Part 2. About materials and binders manufacture. Construct Build Mater 22:1315–1322. doi:10.1016/j.conbuildmat.2007.03.019

Peirce J, Sallfors G, Peel T, Witter K (1987) Effects of selected inorganic leachates on clay permeability. J Geotech Eng 113:915–919. doi:10.1061/(ASCE)0733-9410(1987)113:8(915)

Rifai SM (2000) Impact of polypropylene fibers on desiccation cracking and hydraulic conductivity of compacted clay soils. Wayne State University

Schmitz R (2006) Can the diffuse double layer theory describe changes in hydraulic conductivity of compacted clays? Geotech Geol Eng 24:1835–1844. doi:10.1007/s10706-005-3365-2

Schmitz R, Schroeder C, Thorez J, Charlier R (2004a) Using the complete nano engineering geological spectrum to assess the performance of clay barriers. In: Hack R, Azzam R, Charlier R (eds) Engineering geology for infrastructure planning in Europe, vol 104, Lecture Notes in Earth Sciences. Springer, Berlin Heidelberg, pp 236–243. doi:10.1007/978-3-540-39918-6_28

Schmitz RM, Schroeder C, Charlier R (2004b) Chemo–mechanical interactions in clay: a correlation between clay mineralogy and Atterberg limits. Appl Clay Sci 26:351–358. doi:10.1016/j.clay.2003.12.015

Taha M, Taha O (2012) Influence of nano-material on the expansive and shrinkage soil behavior. J Nanoparticle Res 14:1–13. doi:10.1007/s11051-012-1190-0

Tastan E, Edil T, Benson C, Aydilek A (2011) Stabilization of organic soils with fly ash. J Geotech Geoenviron 137:819–833. doi:10.1061/(ASCE)GT.1943-5606.0000502

Tay YY, Stewart DI, Cousens TW (2001) Shrinkage and desiccation cracking in bentonite–sand landfill liners. Eng Geol 60:263–274. doi:10.1016/s0013-7952(00)00107-1

To D, Sundaresan S, Dave R (2011) Nanoparticle mixing through rapid expansion of high pressure and supercritical suspensions. Journal of Nanoparticle Research 13:4253–4266. doi:10.1007/s11051-011-0369-0

Tunç S, Duman O (2008) The effect of different molecular weight of poly(ethylene glycol) on the electrokinetic and rheological properties of Na-bentonite suspensions. Colloid Surface A 317:93–99. doi:10.1016/j.colsurfa.2007.09.039

Varanasi P, Fullana A, Sidhu S (2007) Remediation of PCB contaminated soils using iron nano-particles. Chemosphere 66:1031–1038. doi:10.1016/j.chemosphere.2006.07.036

Walker PJ (1995) Strength, durability and shrinkage characteristics of cement stabilised soil blocks. Cem Concr Compos 17:301–310. doi:10.1016/0958-9465(95)00019-9

Wei D, Dave R, Pfeffer R (2002) Mixing and characterization of nanosized powders: an assessment of different techniques. J Nanoparticle Res 4:21–41. doi:10.1023/a:1020184524538

Wilson RW (2011) 2 - Aluminum. In: Chris M. Wood APF, Colin JB (eds) Fish physiology, vol 31, Part B. Academic, pp 67–123. doi:http://dx.doi.org/10.1016/S1546-5098(11)31024-2

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Taha, O.M.E., Taha, M.R. Soil-water characteristic curves and hydraulic conductivity of nanomaterial-soil-bentonite mixtures. Arab J Geosci 9, 12 (2016). https://doi.org/10.1007/s12517-015-2038-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-015-2038-6