Abstract

This paper presents an experimental study performed on four types of soils mixed with three types of nano-material of different percentages. The expansion and shrinkage tests were conducted to investigate the effect of three type of nano-materials (nano-clay, nano-alumina, and nano-copper) additive on repressing strains in compacted residual soil mixed with different ratios of bentonite (S1 = 0 % bentonite, S2 = 5 % bentonite, S3 = 10 % bentonite, and S4 = 20 % bentonite). The soil specimens were compacted under the condition of maximum dry unit weight and optimum water content (w opt) using standard compaction test. The physical and mechanical results of the treated samples were determined. The untreated soil values were used as control points for comparison purposes. It was found that with the addition of optimum percentage of nano-material, both the swell strain and shrinkage strain reduced. The results show that nano-material decreases the development of desiccation cracks on the surface of compacted samples without decrease in the hydraulic conductivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Desiccation causes clayey soils to shrink. This occurs due to the loss of soil water content which developed matric suction in soil that increases the shrinkage strain in the soil and normally followed by cracks (Nahlawi and Kodikara 2006). According to the Albrecht and Benson (2001) the soil, for example in the area of landfill linear should be compacted at the maximum dry density (max. γd) and optimum water content (w opt), to achieve the lower shrinkage strain after saturation.

An important parameter related to desiccation is hydraulic conductivity. In general, for soil liner construction, the soil should be compacted to achieve a hydraulic conductivity of 1 × 10−9 m/s or less. So the acceptable zone of water content and dry unit weight that yielded lower hydraulic conductivity is the line of optimums and some parts of wet side of it. The volume change increase varied greatly between the dry and wet sides of the line of optimum where it increases towards the wet side and decreases on the dry side (Daniel and Wu 1993).

One of the methods to reduce the shrinkage strain and hydraulic conductivity is by increasing the compaction efforts. The increase in the compaction effort increases the dry density and decreases the w opt but for higher water content, the increase in the compaction effort does not reduce the shrinkage strain significantly (Osinubi and Nwaiwu 2008). Another method to reduce the shrinkage is to use additives. Mixing clayey soils with sand is one of the cheapest methods. The addition of sand effectively decreases the shrinkage while it increases the hydraulic conductivity. The same behavior was observed when lime was used as an additive material (Omidi 1993). Another material used to reduce the shrinkage strain is fibers. Mixing the soil with fiber can reduce the shrinkage strain up to 90 % and increase strength of soil up to 70 % (Kumar et al. 2006) but the fiber increase the hydraulic conductivity up to 50 times the hydraulic conductivity of the soil without fiber (Rifai 2000).

According to Nalbantoğlu (2004), fly ash is one of the treatment materials used to reduce soil swell pressure and soil cation exchange capacity with considerable environmental benefits, reducing land, air, and water pollution. However, treatment by fly ash bring the soil to a more granular nature and decrease the water absorption potential.

Omidi (1993) found out that cement decreases both shrinkage strain and hydraulic conductivity. Treatment by cement also provide some protection from the adverse effect of saturation on strength (Miller and Azad 2000). The ideal soil for cement treatment should have a plasticity index between 5 and 15 (Walker 1995). Soils with a plasticity index above 20–25 are not suited to cement stabilization due to problems with excessive drying shrinkage.

The difference between the particle size contributes to inter particle filling or interlayer filling, which reduce the void ratio. Based on Montesh (2005), Na-saturated bentonite has a swelling potential greater than Ca-saturated bentonite, while the raw bentonite has a swelling potential between Na and Ca because of the raw bentonite have mixed Na–Ca interlayer filling.

The development of nano-materials could result in considerable benefits since the material have shown to give significant advantages especially in concrete technology. According to Li et al. (2006), in cement composites nano-alumina (Al2O3) filled up the pores of loose net structure around the sand particle, and decreased the porosity and increased the density of the interfacial transition zone during the formation of C–H–S (C-CaO, S-SiO2, and H-H2O) gel. As a result, the elastic modulus of mortars increased. Figure 1 shows the hydration of mortars with and without nano-alumina. Around the aggregate, cracks can be observed at contact area between aggregate and cement paste (Fig. 1a). However, there is a dense zone with noticeable cracks around the aggregate upon the addition of 5 % mortars (Fig. 1b).

SEM image of mortars hydrating for 28 days (after Li et al. 2006)

In addition, at nanometer scale, the contacting surfaces can be nearly ideal so that comparable effects are not partially averaged out by many differently oriented domains. It has been shown that friction can vary over an order of magnitude depending on the relative arrangement of the contacting surfaces. In some cases, the particle is restricted to move in one direction. In other cases, the particle rolls, rotates in-plane or slides, which can increase shear forces (Falvo and Superfine 2000).

The expansive and shrinkage strains in the soil causes cracks which increase the permeability of soil, and the soils with high permeability has less strength to resist sliding.

The main objectives from this research were to reduce the volumetric strains (shrinkage and expansive strains) and reduce the crack intensity factor (CIF) of the soil without increase in the hydraulic conductivity of the soil.

Materials

Bentonite

Bentonite used in the present investigation is a high swell sodium bentonite containing sodium montmorillonite and its properties are listed in Table 1. In general, it has a specific gravity of 2.655, plasticity index of 394.6, and cation exchange capacity of 90 meq/100 g.

Soil

The soil is a residual soil taken from National University of Malaysia campus in Bangi, Selangor, Malaysia. This soil is termed as UKM soil. The soil was sampled from 0.5 to 1 m below the ground surface. The UKM soil was mixed with different ratios of bentonite (S1 = 0 % bentonite, S2 = 5 % bentonite, S3 = 10 % bentonite, and S4 = 20 % bentonite) to produce four types of soil samples with different plasticity index. The physical and chemical properties of UKM soil (S1) and other type of mixed soil samples are listed in Table 2.

Nano-materials

Three types of nano-materials used in this study, i.e., nano-clay, nano-alumina, and nano-copper. Some properties of the nano-materials are discussed below.

Nano-clay

The nano-clay material was supplied by Southern Clay Products, Gonzales, TX, USA with the product known as Nanoclay Cloisite® Na+. The specification and all the information provided by the company is shown in Table 3. A scanning electronic microscope (SEM) shows the nano-clay layers (Fig. 2). The measured size was 5–15 nm thickness and 20 nm to 10 µm diameter.

Nano-copper and nano-alumina

The other nano-materials used in this study were ultrapure gamma-alumina (γ-Al2O3) powder with purity of 99.99 % and nano-copper oxide with purity of 99.99 %, supplied by Inframat Advanced Materials, Manchester, CT, USA. Its general properties are shown in Table 4.

Preparation of soil–nano-material mixtures

The amount of nano-alumina selected was 0, 0.05, 0.075, 0.1, 0.15, and 0.3 % of the total dry weight of the soil, while the amount of nano-copper was 0, 0.15, 0.3, 0.5, and 0.7 % of the total dry weight of the soil. The nano-clay was used only with UKM soil (S1) because the other type of soil already had montmorillonite (bentonite) as one of its constituents. The nano-clay content was 0.0, 0.05, 0.1, 0.15, 0.3, and 0.5 % of the total dry weight of the soil. The reason for using different amounts for different nano-materials was to take the advantages of different particle density and size of the nano-materials. The amount of nano-material was expressed by percent multiply by total dry weight of soil. Thus, the content of nano-copper was more than nano-alumina because the particle density and particle size of nano-copper was greater than nano-alumina (Table 4). Furthermore, the nano-alumina optimum content was less than 0.3 % while for nano-copper the optimum content was equal or greater than 0.3 % for all types of soil.

Two mixing methods were examined. In the first method, the nano-materials were mixed with required quantity of water and then the mixture was put in a beaker. The beaker was then placed in an ultrasonic bath of water for 2 h as was suggested by Wei et al. (2002). After ultra-sonication, the suspension was mixed with the soil. However, it was too difficult to obtain a homogeneous mixture of the soil–nano-material mixture by this method. In the second method, the dry soil was mixed with nano-materials and then the water was added to the mixture. In this method, mixing is carried out into two stages. Initially premix or hand mixed (To et al. 2011), the quantity of soil was divided into ten layers and each layer was sprayed with the required amount of nano-material. Each layer was mixed alone then put in the pot and then mixing the mixture by horizontal cylindrical mixer for at least 3 h (Jones et al. 2007). This procedure was found to be the best method to obtain homogeneous samples since homogeneous color was obtained after compaction as shown in Fig. 3.

The dry mixtures were mixed with the required amount of water to obtain the optimum standard Proctor moisture content and maximum dry density. All mixing was done manually, and proper care was taken to prepare homogeneous mixtures at each stage. Moreover, the type of water used for preparing samples was distilled water.

Test procedures

Initially the soil–nano-material mixture was mixed with water and left for curing then the X-ray diffraction (XRD) test was carried out to check if there is a chemical reaction for nano-material on the soil or not. SEM image indicated that there was no gel or fume inside the sample. The same observation was obtained by XRD test as shown in Fig. 4. The curves of sample S2 and sample S2 + 0.5 % nano-alumina were both identical. This is because of the nano-material used in this study was insoluble material, and cannot react with soil material by just mixing with water.

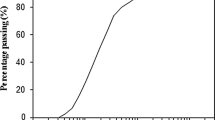

The experimental procedures involved determining compaction behavior of unamended soil and soil mixed with nano-materials. The compaction behavior curves were determined according to the standard test method (ASTM D698) for both unamended soil and soil with nano-materials. The soil used for compaction was dried in an oven and crushed with a rubber hammer until it passed the US No. 4 sieve. The soils were moisten with tap water using a spray bottle, and stirred with a trowel during mixing to ensure an even distribution of water. Then the soils were sealed in plastic bags and allowed to hydrate for at least 24 h prior to compaction.

Compacted samples were used for the shrinkage strain, expansive strain, and hydraulic conductivity tests. Volume change measurement was made to evaluate shrinkage and expansive behavior. For hydraulic conductivity tests, the specimens were either immediately placed in permeameters for saturation or wrapped in plastic to prevent drying until they could be saturated.

After compaction, the soil samples were divided into two group. The first group was saturated with water to measure the expansive strain and the second group was left to dry in an oven temperature ~34 ± 2 °C to measure shrinkage strain.

Saturation procedure for hydraulic conductivity and expansive strain measurement

Saturation was conducted by soaking the specimens in flexible-wall permeameters using a hydraulic gradient of 10 and an average effective stress of 10.5 kPa following ASTM D 5084. The specimens were permeated with tap water until the ratio of inflow to the outflow was between 0.75 and 1.25, and the hydraulic conductivity was steady. This procedure resulted in specimens saturated close to field condition. When the specimen was removed from the permeameter, measurements were made of its height, diameter, and weight.

Test method for volumetric strain and crack intensity factor

For the desiccation crack test, soil specimens were prepared at max. γd and w opt. The drying process was conducted for a period of more than 10 days depending on the sample type. The weight, height, and diameter of each specimen was then measured. The volume change was used to determine the volumetric shrinkage strain of the soil specimens. The volumetric shrinkage strain is defined as the change in volume (ΔV) to the total volume of the soil specimens (V, %), expressed by

The surficial dimensions of cracks were measured in order to find the CIF to evaluate the magnitude of desiccation cracks developed in the soils, expressed by (Harianto et al. 2008)

where A c is the desiccation crack area and A t is the total surface area of soils.

Results and discussion

The effect of nano-clay on UKM soil

The influence of nano-clay on the max. γd and w opt are shown in Fig. 5. There is a slight decrease in w opt and slight increase in max. γd, which indicated that the optimum percentage of nano-clay is 0.1 %. Figure 6 shows that the increase in nano-clay causes an increase in plasticity index and linear shrinkage. This happened because the nano-clay material is an expansive clay. The shrinkage strain slightly decreased at 0.05, 0.1, and 0.15 % nano-clay content then increases beyond this amount. While there was no increase in expansive strain for the nanoparticle contents mentioned. When nano-clay content is increased the expansive and shrinkage strain increases. However, the total volume change was also observed to increase. The total shrinkage strain after saturation was measured relative to the final volume of sample when become fully dry. The total shrinkage strain is the total volume change and approximately equal to the shrinkage volume change and expansive volume change. The increase in nano-clay content of more than 0.3 % gives an increase in total volume change as shown in Fig. 7.

The effect of nano-alumina and nano-copper on the plasticity index

A small positive effect can be observed on the plasticity index of the soil mixture. The addition of nano-alumina causes a small decrease in the plasticity index while an increase in nano-copper content gives higher decrease in the plasticity index (Figs. 8, 9). This happened because of the nano-alumina and nano-copper particles have higher density than clay particles, as well as the surface area of nano-alumina is less than bentonite particles (nano-clay) surface area.

The effect of nano-alumina and nano-copper on the compaction conditions

There is no significant effect of nano-alumina on the w opt for S1, S2, and S3 soils for the amount of nano-alumina tested (Fig. 10). However, some measurable changes occurred for S4 soil (20 % bentonite) with a decrease in w opt at 0.1 % and increasing w opt beyond this. For tested specimens with nano-copper, minimal changes occurred on the w opt as the amount of nano-copper increases (Fig. 11). For the max. γd, a greater increase was observed with the addition of nano-copper compared to nano-alumina (Figs. 12, 13). This is because the particle density of nano-copper is greater than the particle density of nano-alumina. However, beyond the peak, increase in nano-materials results in decrease in density and increase in the w opt.

The increase of nano-material more than the optimum limit may possibly result from agglomeration in nano-material particles which in turn causes an increase in the void ratio then decrease in density and increase in water content. According to Ferkel and Hellmig (1999), the agglomeration of nanoscaled powders increase the amount of necks between particles and therefore decreases the density of green bodies. Figures 14 and 15 show the soil samples S3 which was mixed with 0.5 and 0.7 % nano-copper. The nano-copper particle agglomerated when the nano-copper content was increased. Soil sample S4 shows similar behavior (Figs. 16, 17).

The effect of nano-alumina and nano-copper on the shrinkage and expansive strains

Total strain in soil occurred into two stages. First, expansive strain took place when soil samples were exposed to water until saturation, and the second when soil samples were exposed to drying. The summation of the expansive and shrinkage strains give the total strain in soil samples. Nano-alumina was observed to reduced both the amount of expansive and shrinkage strains. This is because the increase in dry density and the reduction in w opt. However, when the nano-alumina content increases the density reduces because the particle becomes agglomerated which normally increases the void ratio and decreases the density which in turn leads to increase in the soil strain (Figs. 18, 19, 20).

Similar behavior was also observed using nano-copper. However, the nano-copper content is more than nano-alumina and the improvement from using nano-copper is better than nano-alumina (Figs. 21, 22, 23). In addition, the reduction in strain by nano-copper of soil samples S3 and S4 are more than the soil samples S1 and S2, especially the shrinkage strain (Fig. 21).

The effect of nano-alumina and nano-copper on the CIF and hydraulic conductivity

The effect of nano-material on the desiccation crack development is shown in Fig. 24. The test results showed that the nano-materials causes some decrease in the desiccation cracks on the surface of S3 and S4 samples. For S1 and S2, however, the cracks cannot be measured. The reduction in CIF when nano-copper is used is more than the soil samples with nano-alumina. This is because the total strain of soil with nano-copper is less than the total strain of soil with nano-alumina. Furthermore, from Table 5, the hydraulic conductivity with and without nano-material are very close to each other for soils with low bentonite content (low plasticity index), i.e., samples S1 and S2. This means that the nano-materials can be used as a treatment material for cracks without any significant effect on the hydraulic conductivity of soil. Furthermore, the addition of nano-materials in high bentonite soils content causes a reduction in hydraulic conductivity. This differs from other treatment materials which reduces the cracks in soil and increase the hydraulic conductivity, for example, polypropylene fiber and other type of fiber (Rifai 2000).

Conclusions

The mixtures of soil and nano-materials enhance the engineering properties of soils (i.e., compaction characteristics, volumetric shrinkage strain, volumetric expansive strain, and the CIF). Insoluble nano-material does not give chemical reaction with soil by just mixing with water. The addition of some type of nano-material such as nano-clay does not produce significant improvement in soil. However, nano-clay content exceeding certain limits has a negative effect. The improvement by nano-copper was more positive than nano-alumina in terms of expansive and shrinkage strain. This is possibly because the particle density of nano-copper is greater than nano-alumina which increases the specific gravity of the soil–nano-material mixture leading to increase in the maximum dry density of the mixture. The increase in the dry density subsequently leads to decrease in the soil shrinkage and expansive strains. Moreover, the increase in the content of agglomerated particles leads to decrease in the dry density and increase in voids which increase the water content. Therefore, the shrinkage and swell strain also increases. Since the size of nano-copper particles is more than two times size of nano-alumina particles, the nano-copper less agglomeration than nano-alumina thus improving the soil better than nano-alumina. The addition of nano-materials more than the optimum value causes agglomeration of particles that produce negative side effects on the mechanical properties of the soil. The additive of nano-materials does not reduce the hydraulic conductivity of soils. This different from other stabilizer materials which decrease the crack development and increase the hydraulic conductivity (i.e., fiber).

References

Albrecht BA, Benson CH (2001) Effect of desiccation on compacted natural clays. J Geotech Geoenviron Eng 127(1):67–75

Daniel DE, Wu Y-K (1993) Compacted clay liners and covers for arid sites. J Geotech Eng 119(2):223–237

Falvo MR, Superfine R (2000) Mechanics and friction at the nanometer scale. J Nanopart Res 2(3):237–248. doi:10.1023/a:1010017130136

Ferkel H, Hellmig RJ (1999) Effect of nanopowder deagglomeration on the densities of nanocrystalline ceramic green bodies and their sintering behaviour. Nanostruct Mater 11(5):617–622. doi:10.1016/s0965-9773(99)00348-7

Harianto T, Hayashi S, Du Y-J, Suetsugu D (2008) Effects of fiber additives on the desiccation crack behavior of the compacted Akaboku soil as a material for landfill cover barrier. Water Air Soil Pollut 194(1–4):141–149. doi:10.1007/s11270-008-9703-2

Jones JR, Parker DJ, Bridgwater J (2007) Axial mixing in a ploughshare mixer. Powder Technol 178(2):73–86. doi:10.1016/j.powtec.2007.04.006

Kumar A, Walia B, Mohan J (2006) Compressive strength of fiber reinforced highly compressible clay. Constr Build Mater 20(10):1063–1068. doi:10.1016/j.conbuildmat.2005.02.027

Li Z, Wang H, He S, Lu Y, Wang M (2006) Investigations on the preparation and mechanical properties of the nano-alumina reinforced cement composite. Mater Lett 60(3):356–359. doi:10.1016/j.matlet.2005.08.061

Miller GA, Azad S (2000) Influence of soil type on stabilization with cement kiln dust. Constr Build Mater 14(2):89–97. doi:10.1016/s0950-0618(00)00007-6

Montesh G (2005) Swelling–shrinkage measurements of bentonite using coupled environmental scanning electron microscopy and digital image analysis. J Colloid Interface Sci 284(1):271–277. doi:10.1016/j.jcis.2004.09.025

Nahlawi H, Kodikara JK (2006) Laboratory experiments on desiccation cracking of thin soil layers. Geotech Geol Eng 24(6):1641–1664. doi:10.1007/s10706-005-4894-4

Nalbantoğlu Z (2004) Effectiveness of class C fly ash as an expansive soil stabilizer. Constr Build Mater 18(6):377–381. doi:10.1016/j.conbuildmat.2004.03.011

Omidi G (1993) Desiccation shrinkage and cracking in soil liner. Texas A & M University, Austin

Osinubi KJ, Nwaiwu CMO (2008) Desiccation-induced shrinkage in compacted lateritic soils. Geotech Geol Eng 26(5):603–611. doi:10.1007/s10706-008-9193-4

Rifai SM (2000) Impact of polypropylene fibers on desiccation cracking and hydraulic conductivity of compacted clay soils. Wayne State University, Detroit

To D, Sundaresan S, Dave R (2011) Nanoparticle mixing through rapid expansion of high pressure and supercritical suspensions. J Nanopart Res 13(9):4253–4266. doi:10.1007/s11051-011-0369-0

Walker PJ (1995) Strength, durability and shrinkage characteristics of cement stabilised soil blocks. Cem Concr Compos 17(4):301–310. doi:10.1016/0958-9465(95)00019-9

Wei D, Dave R, Pfeffer R (2002) Mixing and characterization of nanosized powders: an assessment of different techniques. J Nanopart Res 4(1):21–41. doi:10.1023/a:1020184524538

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Taha, M.R., Taha, O.M.E. Influence of nano-material on the expansive and shrinkage soil behavior. J Nanopart Res 14, 1190 (2012). https://doi.org/10.1007/s11051-012-1190-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-012-1190-0