Abstract

With the rapid development of nanotechnology and multidisciplinary cross applications and the limitations of traditional materials, nanomaterials are being introduced for soil improvement. This paper describes and examines the potential benefits of nanotechnology for innovative solutions in the soil improvement sector. Studies on nanomaterials applied in geotechnical and geological engineering are reviewed to demonstrate how these nanoparticles work in soil improvement. Carbon nanotubes are used to reinforce soil by improving compressive strength. Nano bentonite is used as a drilling fluid additive and additive composite to improve the soil mechanic properties. Colloidal silica and laponite are used to mitigate or prevent the liquefaction of soils based on special rheological properties. Furthermore, this paper discusses the microscopic characteristics and mechanism of nanomaterials in soil improvement, and the advantages of nanomaterials compared with traditional grouting materials. Research on methods that apply nanomaterials for soil improvement is very promising and enhances our understanding of the relationship between nanotechnology and geotechnical engineering through innovative approaches.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Since the Earth summit in Rio de Janeiro in 1992, sustainable development has become one of the foremost issues facing the world. In 2000, 189 UN member countries signed the Millennium Development Goals, in which the seventh goal is related to environmental sustainability (UN 2000). In 2012, the United Nations Conference on Sustainable Development (Rio +20) proposed further measures to tackle forthcoming critical issues (Schlosser and Pfirman 2012). As the largest consumer of natural resources and a major consumer of energy, civil engineering activity is one of the primary contributors to unsustainable practices (Cuddihy et al. 2005; Lippiatt 1999). As Chong et al. (2009) pointed out, “Sustainable construction (SC) aims to achieve sustainable development (SD) objectives through the use of technology and knowledge to enhance the sustainability of production processes, operations and practices, and designs of infrastructures”; to comply with sustainable practices, traditional engineering must make transitions. Nano science and technology, considered to be the paramount science and technology field of the 21st century, can bring a revolutionary change to the traditional engineering industry and help to fulfil the sustainable development demand (Pacheco-Torgal and Labrincha 2013).

Nano science and technology, a new field that explores the nano-scale microscopic world, began to develop after physicist Richard Feynman (1960) announced “There’s plenty of room at the bottom” in a meeting of the American Physical Society at Caltech, California. A generalized description of “Nanotechnology” was established by the National Nanotechnology Initiative of the United States, which defines nanotechnology as the manipulation of matter with at least one dimension sized from 1 to 100 nm (NSTC 2007). Nanotechnology includes the study of the motion of atoms and the changes that occur in atoms; it examines molecules on the atomic scale, and molecular manipulation and processing in a range of scales to create materials with new fundamental properties and functions (Clement et al. 2012; Saini et al. 2010). This current definition of nanotechnology which is based on the nano-scale standard is so broad that nanotechnology research spans across almost all the natural science disciplinary areas. Therefore, we can also regard nanotechnology not as a new field but as an “enabling technology” that is an extension of existing science and technology. It makes the impossible become possible, the imperfect approach perfection, but it is not restricted to specific applications (Cacciatore et al. 2009). Thus, nanotechnology breaks the traditional boundaries between disciplines, and spans many fields: medicine, environment, energy, information and communication, and heavy industry (Finch et al. 2014; Hyung et al. 2007; Peng and Lee 2011).

In the field of civil engineering and construction, nanotechnology has increasingly played a role in improving the primary properties of materials. This role has the potential to reduce the environmental impact and energy consumption of structures, as well as improve the safety and decrease the costs associated with civil infrastructure (Halicioglu 2009; Hanus and Harris 2013; Ugwu et al. 2013). The main applications of nanotechnology can be in the following fields: (1) mitigating the surface roughness of steel with copper nanoparticles to promote the weldability and render the steel surface corrosion resistant (Ge and Gao 2008). (2) Using catalyst materials to improve the self-cleaning ability of concrete such as in the Dives in Misericordia church in Rome (Pacheco-Torgal and Jalali 2011). (3) Adding silicone dioxide nanoparticles to fill pores in concrete, reducing the segregation in self-compacting concrete to make it stronger, more durable, and more sustainable (Balaguru and Chong 2006). (4) Using nano-sensors to monitor structural health of concrete during the construction phase (Qureshi et al. 2009; Sanchez and Sobolev 2010).

With the growth of industrialization and urbanization, ground and structural reinforcement and environmental sustainability represent major challenges that traditional soil improvement methods are currently facing. Traditional materials such as cement and chemical grouts (sodium silicate, acrylate, and epoxy) used in soil strength improvement have limitation of full-field treatment and cause intensive disturbance. Moreover, they create environmental pollution and are costly to use; therefore, it is necessary to explore other novel materials that will reduce these problems. Currently, with the rapid development of nanotechnology and multidisciplinary cross applications, nanomaterials are being introduced as soil strength improvement materials. However, in the field of geotechnical and geological engineering, applications of nanotechnology are rare and the majority is still in the exploratory stage.

This paper reviews the main developments in the field of nano science and technology research and applications in soil improvement, along with their implications and key findings. The paper is divided into three main sections: the next section introduces the four types of nanomaterials used in soil improvement followed by a discussion on the microscopic characteristics and mechanism of nanomaterials that enhance the soil strength; the last section compares the advantages of nanomaterials to those of traditional grouts.

Nanomaterials used in soil strength improvement

Nanomaterial is a new material level between atoms, molecules, and macroscopic materials, with at least one spatial dimension that does not exceed 100 nm. It has a special structure, a very large specific surface area, and high surface activity (Cao 2004). Soil is considered to be the most abundant and low-cost natural building material in various engineering applications. This natural material is particularly relevant to nanotechnology. The US National Research Council (NRC 2006) pointed out that studies of clay-sized particles (<0.002 mm) in the field of geotechnical engineering were the first steps in the field of nanotechnology. With the continuous development of science and technology, researchers began to apply nanoscale changes in geotechnical materials to make them more effective and economical. There are four typical nanomaterials that have been applied to soil improvement: carbon nanotube, colloidal silica, bentonite, and laponite.

Carbon nanotube

A carbon nanotube (CNT) is made of graphene, the world’s strongest known substance. Graphene is a super-thin sheet of carbon atoms arranged in a hexagonal “honeycomb” pattern. When rolled into a tube, graphene forms a CNT, a fiber 100 times stronger than steel and six times lighter (Chong 2003). Because of their exceptionally high elastic properties and high aspect ratios, CNTs are used as reinforcement fillers for metal to improve material strength (Sathurusinghe et al. 2012). In addition, nanotubes have the potential to act as filler within the cement grains to make composites denser (Fakhim et al. 2013). Therefore, CNT reinforcements have the ability to produce significantly stronger and tougher composites compared with traditional reinforcing fibers; Morsy et al. (2011) improved the compressive strength of metakaolin cement mortar by 11 % by adding 0.02 % CNTs. In the soil improvement sector, Arabania et al. (2012) mixed clayey sand with a range of 0.05–3 % CNTs by weight of the soil. The compressive strength of soil with 3 % CNTs increased about 120 % compared with the original clayey soil. Thus, very small amounts of CNT can significantly improve the compressive strength of soil. In addition, CNTs decrease the friction angle while increasing the cohesion between the soil grains. However, there is also a growing concern that this novel nanomaterial may have negative or unintended effects on organisms and the environment. For groundwater, CNTs are used in adsorption of contamination from water for its abundant nanometer void structure and huge specific surface area (Lu et al. 2005; Li et al. 2013). Tong et al. (2007) and Johansen et al. (2008) proved that carbon nanomaterials have little or no effect on microorganisms in soil. Hence, the validity and feasibility of CNTs used as a reinforcing material in soil have both been considered.

Colloidal silica

Colloidal silica is an aqueous dispersion of microscopic silica particles produced from saturated solutions of silicic acid. The particles are generally between 7 and 22 nm in size. Colloidal silica is nontoxic, biologically and chemically inert, and has excellent durability characteristics (Chang et al. 1994). Gelation is a process whereby a colloidal silica solution is transformed to a gel-like solid; the process can be induced by reducing the repulsive forces in a controlled manner (Dietler et al. 1986). The colloidal silica particles gel into chainlike structures and then into uniform three-dimensional networks, and continue to aggregate until the gelling process is complete. The gel time of colloidal silica is defined as the amount of time between mixing and the formation of a firm gel; this depends on the rate of particle interaction, which is related to several variables including the percentage of silica in the solution, the silica particle size, and the ionic strength, pH, and temperature of the solution (Liu et al. 2003; Martin et al. 1990).

Studies have shown that colloidal silica can effectively enhance the compressive strength of sand, and that the unconfined compressive strength of sand grouted with colloidal silica increases linearly with increasing percentage of colloidal silica (Yonekura and Miwa 1993). Persoff et al. (1999) reported that sands stabilized with 10 and 20 % colloidal silica had unconfined compressive strengths of 158 and 317 kPa, respectively. Similar trends were obtained in studies that showed that the unconfined compressive strength baseline of samples treated with 5–20 % colloidal silica varied from 32 to 222 kPa (Gallagher and Mitchell 2002). Kodaka et al. (2005) also observed the remarkable improvement of cyclic shear strength after colloidal silica treatment. Additionally, a passive site remediation using colloidal silica to mitigate liquefaction risk was proposed by Gallagher (2000) and the improvement of liquefaction resistance by colloidal silica was verified by multiple methods such as laboratory tests, model tests, and full-scale field tests. Different deformation properties were observed between treated and untreated sand samples under cyclic loading; the untreated samples collapsed within a few additional loading cycles while the grouted samples experienced very little strain during the cyclic loading and remained intact (Díaz-Rodríguez et al. 2008; Kodaka et al. 2005). The relationship between gel density, viscosity, and gel time was analyzed and the grouting process of colloidal silica was stimulated to verify the strength deformation of nano-sand composite under cyclic loading in model tests (Gallagher et al. 2007b). Meanwhile, to verify the practical validity of colloidal silica grouting and the mitigation of the liquefaction risk, full-scale field testing was conducted (Gallagher et al. 2007a). Mollamahmutoglu and Yilmaz (2010) discussed further the regularity of nano gel generation with time and its effects on the strength of the nano-sand composite.

Bentonite

Bentonite is composed mainly of montmorillonite. Nano bentonite is a processed clay mineral that is formed by the weathering of volcanic ash (Darvishi and Morsali 2011). Nano bentonite has higher purity than natural bentonite (Abdou et al. 2013) as well as moisture absorbency and swelling properties. When immersed in an aqueous medium, nano bentonite will disperse and form gelatinous or suspended solutions that have high viscosity, thixotropy, and lubricity (Teplitskiy et al. 2005). Because of these characteristics bentonite has been used as a drilling fluid additive to improve drilling mud properties and reduce fluid loss to the rock formation. In addition, the use of treated bentonite suspensions for permeation grouting to modify the pore fluid between sand grains to improve the liquefaction resistance is investigated as well. 10 % bentonite suspensions are proved to form gel, characterized by an elastic response even at large strains and this thixotropy of the gel helps improve the liquefaction resistances (El Mohtar et al. 2008). To lower the initial yield stress and viscosity of bentonite suspensions that can help improve the grouting permeation feasibility, 0.5–2 % Sodium pyrophosphate can be added to modify (Rugg et al. 2011; El Mohtar et al. 2013). Moreover, Witthoeft et al. (2012) verified bentonite suspension liquefaction mitigation and control effect at the field scale by using the finite difference method FLAC and furtherly presented the scope of reinforcement.

Laponite

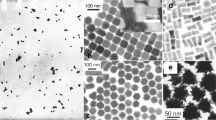

Laponite is a synthetic layered silicate nanoparticle with a thickness of 1 nm and a diameter of 25 nm, almost 10 times smaller than bentonite. Laponite is made from a synthetic sheet of silicate nanoparticles, with layered structures of two tetrahedral and one octahedral layers, similar to a natural montmorillonite structure (Kroon et al. 1998). It can quickly disperse in water into disc sheet-shape grain structures, forming a colorless transparent suspension. Because some of the bivalent magnesium ions are replaced on the particle surface by a lithium ion valence, its surface emits a large number of negative charges. Hydroxides on the edge such as Mg–OH and S–OH take a small amount of positive charge for protonation. Laponite is insoluble in water and some of the suspended material settles after a period, losing liquidity (Levitz et al. 2000). Tanaka et al. showed that when the ionic strength is low, electrostatic repulsion occurs between the particles, and the system is in a mutually exclusive glassy state. When the ionic strength is high, the electric double layer on the surface of the particles is compressed, the electrostatic interaction distance decreases, and the distance between the particles is shortened, forming a physical cross-linked gel (Tanaka et al. 2004). Because of the good rheological property of transparent gel along with its small-size scale, laponite can improve the liquefaction resistance of liquable sand and has better material properties and conductivity than nano bentonite (El Mohtar et al. 2008). Howayek et al. (2014) provided direct imagery of the structure of the sand–laponite suspension systems, highlighting their elongated cellular structure that affects their macro scale geotechnical properties.

Microscopic characteristics and mechanism of nanomaterials in soil strength improvement

Because the soil is a three-phase medium composed of soil grains, water, and air between the grains, pore water pressure has a great influence on the strength of the soil, especially under dynamic loading. At the macro level, nanomaterials improve soil strength by reinforcing the soil skeleton and modifying the pore fluid as “Nanomaterials used in soil strength improvement” discusses. At the micro level, nanomaterials have different characteristics to those of bulk materials including size, structure, surface functional groups, bond strength, and processes occurring that ultimately affect the engineering properties and performance of the bulk material (Ozin et al. 2009).

Micronization of particle size

Comparing the grain size of natural rock and soil mass with that of nanoparticles, the micronization process evolves as the grain size decreases from gravel to sand, fine particle, ultrafine particle, and finally, nanoparticle (Fig. 1). Because the type and characteristics of most materials will vary with their particle size, for example, from massive quartz and feldspar to sheet mica and clay, we see a decrease in particle size along with changes in the composition and shape of the soils. For example, adding mineral particles with a high surface area to clay liners and bases, the soils on a macroscopic scale demonstrate exceptional mechanical properties (such as high ductility) and unique chemical properties (such as specie-selective diffusion) (Srivastava and Singh 2011). Nanoparticles are smaller in size than clay particles on a nano scale. When the size of the particles is comparable to or shorter than the wavelength of light waves or De Broglie wave, the periodic boundary condition of the particle is destroyed and the surface atomic density will decrease; thus, the physical properties of the material will change. Meanwhile, the nanoparticles can easily disperse in the pore space between the soil grains, especially in fine soil that is not under high pressure.

Microstructure of nanomaterials

The special microstructure of nanomaterials will affect the soil strength when nanomaterials are added to soil. The four materials mentioned above can be classified into two categories: nano tubes and nano particles; the former has a two-dimensional nanometer-scale structure while the latter has a three-dimensional nanometer-scale structure. CNT belongs to the nanotube group, and is a type of one-dimensional quantum material with a special structure. The radial dimension of CNT is in nanometers while the axial dimension is in microns, with both ends of the tube sealed. The van der Waals force between carbon nanotubes is strong. Because of their large length–diameter ratio and special microstructure, CNTs can be used as a tough carbon fiber that is 100 times stronger than steel (Treacy et al. 1996). In nanoparticles such as colloidal silica, bentonite, and laponite, the nanoparticle-suspension microstructures play an important role in enhancing soil strength. According to cryo-SEM images (Howayek et al. 2014), nanoparticle suspension gel with special structures can be observed, where the gel microstructure is formed by elongated cells with the longest dimension over three orders of magnitude greater than the size of the individual nanoparticle. These elongated cells are arranged in layers that contribute to the cohesive bonding.

Surface effect

As its particle size decreases, a nanoparticle’s specific surface area increases. This means the surface of the atom increases, leading to larger ion exchange capacity and increased interaction with other particles. Soil particles with a larger specific surface area will be surrounded by more water molecules. The existence of nanoparticles leads to an accumulation of pore water; thus, soil that contains nanoparticles usually has higher liquid and plastic limits. This helps non-plastic fine soils increase their liquefaction resistance (Ghahremani and Ghalandarzadeh 2006; Abedi and Yasrobi 2010). In coarse-grained soil, the surface charge is very weak and there is no connection between the grains. Such soil is characterized by gravity sedimentation in the process of deposition. Fine-grained soil has a high degree of dispersion and the distribution of surface charge is uneven; therefore, the forces between the soil grains are controlled by the attraction and repulsion of electrostatic forces in addition to gravity. However, on a nano scale, gravity is negligible, hence the electrostatic forces are dominant and random molecular motion is particularly significant. Thus, on a nano scale, it is appropriate to apply the quantum mechanics model rather than classical mechanics to describe the motion state and energy of particles.

Rheology of nanoparticle suspension

Because some nanoparticles are injected into the soil in the form of nanoparticle-water suspension, the rheological suspension properties affect the nanoparticle’s ability to enhance the soil strength. The nanoparticle suspension can have long induction periods during which the viscosity remains fairly low and exhibits Newtonian behavior. With time, the viscosity of the suspension will increase sharply and the fluid finally develops a gel structure at a controllable gelling moment. The solid-like gel can improve soil strength for the following reasons. Firstly, nanoparticles such as layered silicate can form a colloid in water suspension. The nanoparticle gel fills in the pores of the soil and transforms the pore fluid from a fluid state that has no shear resistance into a colloidal state that has shear resistance. Moreover, the gel can delay the pore pressure generation process, which will mitigate the liquefaction risk under dynamic loading. At the same time, the forming gel has high viscosity and can enhance the cementation between the sand matrixes, which can improve the shear strength of the soil mass. In addition, the gel in the sand pores appears denser and more concentrated in proximity to the particle contacts, and hydraulic conductivity decreases.

In conclusion, the microscopic characteristics of nanomaterials including size, microstructure, suspension properties, surface effect, and the rheology of nanoparticle suspension alter the soil composition, its structure, and the interaction between particles; this affects the plasticity, soil matrix connection, and pore fluid properties to improve soil strength.

Advantages of nanomaterials compared with traditional grout

The four above-mentioned nanomaterials can significantly improve soil strength including compressive strength and liquefaction resistance. Moreover, compared with traditional grout materials, the new nanomaterials exhibit advantages in terms of their environment effect and price/performance ratio.

Low environmental disturbance

Among soil improvement techniques, traditional mechanical reinforcements such as replacement, dynamic compaction, and other densification methods have some limitations such as cost and environment disturbance. Chemical grouting is a common method to improve soil strength; engineering slurries are pressed into the soil by a pressure transmission system, curing or forming gel, to reinforce the weak foundation. The traditional materials used in grouting are mainly cement and chemical solutions such as sodium silicate, acrylate, and epoxy. The grouting materials for soil strength improvement are likely to be applied into the soil as either solutions or particulate suspensions. For particulate suspensions such as cement, colloidal silica, bentonite, and laponite, the particle size of the suspension is the main controlling factor determining penetrability, and the rheological properties are also important. Ordinary Portland cement has an average particle size of about 20 microns. Cement slurry in a suspended particle state can only be inserted into soil pores that are three to five times larger than its own particle size; therefore it is difficult to use the slurry in fine soils. The cement suspension has a high initial viscosity so cement grouts are usually injected under pressure and often used to form grout columns rather than to permeate the entire area beneath the structure. Compared with traditional stabilizers, nanomaterials have particles of nano-scale size that can easily penetrate finer soils. The nanoparticle–water suspension has a lower initial viscosity, thus this new method can greatly reduce the disturbance effect on the surrounding environment as it does not require high-pressure infusion. The method is applicable to bare ground as well as to developed areas with buildings and construction.

Environmentally friendly

The traditional cement industry is generally an energy-intensive and highly polluting industry that consumes coal heavily in the process of production and releases harmful gases such as CO2, SO2, and NO x into the environment as well as using a significant amount of energy, water, and aggregate material (van Oss and Padovani 2003; Shafigh et al. 2014). This is not in line with sustainable development. For chemical solutions such as sodium silicate, acrylate, and epoxy, the viscosity of the stabilizer is the primary rheological parameter that determines penetrability into a soil formation. Though chemical solutions have advantages in terms of permeability over cement suspension, they present a big risk of damage to adjacent buildings and pollution of waterways if handled improperly (Vik et al. 2000). For example, epoxy is a nonaqueous solvent, soluble in aromatic hydrocarbon, ketone, alcohol, and other organic solvents. Organic solvents, however, are expensive and volatile; some polymer material solvents are toxic to the environment and are flammable and pose a high risk of explosion. Conversely, nanomaterials including CNT, colloidal silica, bentonite, and laponite are generally inert and non-toxic. When added to soil to improve its strength, they will not pollute and are environmentally friendly.

Conversely, CNTs, bentonite and nano silica used to improve soil, which are discussed in this paper has been proved to be nontoxic to the soil and groundwater aquifers. For the CNTs, it will not affect the soil when added into the soil (Lam et al. 2006; Mauter and Elimelech 2008; Li et al. 2013); for bentonite and nano silica materials, their main component is silicon dioxide similar with natural clay, and they are generally inert and non-toxic. So it is safe and environmentally friendly to use CNTs, bentonite and nano silica in soil improvement. In addition, environmental scientists point out that there is currently a lot of attention being paid to the behavior, fate and effects of nanomaterials, but there is still only limited solid information. More quantitative measures are needed before ecological risk assessment can be conducted (Nowack and Bucheli 2007; Klaine et al. 2008).

Price/performance ratio

Another concern is the cost of strengthening materials applied in engineering practices. For the price/performance ratio, despite nanomaterials has relatively high unit price, only a small amount of nano materials is required for effective strengthening. Research has shown that the compressive strength of soil doubles after the introduction of 3 % CNT by weight of the soil. Colloidal silica suspension at 5 % by weight of the pore water between the soil grains can provide adequate stabilization; bentonite at 10 % by weight of the pore water can provide adequate stabilization and laponite can provide the same stabilization at about 3 % by weight of the pore water. The cost of colloidal silica and chemical solution grout (sodium silicate, acrylate, and epoxy) was reviewed in Gallagher (2000). The costs of sodium silicate, acrylate grout, and epoxy grout are about $180, $325, and $500 per cubic meter of treated soil, respectively, assuming a porosity of 35 %. However, the cost of colloidal silica is about $59 per cubic meter of treated soil at 5 % content. If based on the same grouting conditions and for soil porosity of 35 %, the pore formation could be completely filled by colloidal silica treatment without wasting any grout. The cost of cement, bentonite, and laponite can be estimated as follows. The unit price of each material is based on the market average price of typical products. Cement costs $0.1 per kg; the cost per cubic meter of soil treated is about $10. Bentonite costs $6 per kg at a sieving rate of 99 % and $2 per kg at a sieving rate of 85 %. For liquefaction mitigation, 10 % is acceptable, so the cost per cubic meter of soil treated will range between $80 and $240. Laponite RD costs $32 per kg; 3 % of laponite suspension can control the liquefaction risk, so the cost per cubic meter of soil treated is about $340. Comparing the costs per cubic meter of soil treated, the price/performance ratio of cement and colloidal silica is low (price <$100); the price/performance ratio of sodium silicate, acrylate, and laponite is medium ($100≤ price < $1000) and that of bentonite is between the low and medium levels; the price/performance ratio of epoxy grout is high ($1000 ≤ price). Thus, nanomaterials have a better price/performance ratio than traditional chemical grouting materials.

In the near future, the price of base nanomaterials may decrease with advanced production techniques and improved manufacturing (Holman 2007). Roco (2005) estimated $1 trillion worth of products worldwide will incorporate nanotechnology with average annual rate of increase about 25 %. Lucintel (2011).indicates the nanomaterials market develops rapidly and is expected to reach $6.1 billion with a 23 % CAGR (Compound Average Growth Rate) forecast from 2011 through 2016. According to this booming market development trend, even though the current research stage of nanomaterials in soil improvement is still in the experimental studies, it will be successful in the final commercial practice stage according to the trend. For example, CNT prices fell substantially, from over $150 per gram in 2000 to under $50 per gram in 2010 (Eden Energy, 2011).

The four types of nanomaterials mentioned in this review showed good performance in improving soil strength including compressive strength and liquefaction resistance. The soil strength improvement process based on nanomaterials causes only a slight disturbance in the surrounding ground and structures, and is an environmentally friendly and economical method. The disturbance, environmental friendliness, and price/performance ratio comparison between traditional materials and nanomaterials of treated soil are shown in Table 1.

Conclusions and prospects

Since the last century, a large number of multidisciplinary studies on nanometer-scale materials and technology have been published, containing comprehensive scientific research and potential applications. This field has become one of the most important sources of contemporary high-tech development. Based on current research, nanomaterials are being considered to be applied in soil improvement. The feasibility and effectiveness of nanomaterials, including CNT, colloidal silica, bentonite, and laponite were verified by various experimental studies. The research showed that the size, microstructure, surface functional groups, bond strength, and the rheology of the nanoparticle suspensions are the main factors affecting the improvement in soil strength. Soil improvement based on nanomaterials causes only slight ground disturbance, is environmentally friendly, and is economical compared with traditional grouting methods. The application of nanomaterials in geotechnical engineering has advantages both for the development of nanomaterials and the optimization of soil properties. Therefore, further research aimed at finding more appropriate nanomaterials for soil improvement and studying the improvement mechanism looks very promising.

Over the last 10 years, scholars have carried out preliminary experimental exploration on soil strength improvement by using nanomaterials; valuable results were obtained, but there are still many themes that need to be explored in future research:

-

Systemic research approaches that can integrate nanomaterial science and geotechnical engineering approaches should be established to further investigate soil improvement using nanomaterials. Current research deals mostly in experimental studies on the mechanics of soil-nanomaterial mixtures to verify their reinforcement effect. Nanomaterial science methods should be combined with quantum physics rather than focus entirely on classical physics to explain the mechanics of soil improvement.

-

Nanomaterial has complex characteristics, and its structure characterization, chemical composition, microstructure, and the interface reaction between nanoparticle and matrix are key factors that determine the performance and application in bulk materials. Deeper research into the material properties of nanomaterials suitable for improving soil properties is needed. Moreover, the physicochemical interaction between nanomaterials and natural materials such as soil and groundwater is not clear, and a good understanding of the process at the material interface is necessary.

-

Engineering applications should progress from the scientific experimental research stage to the commercial practice stage (Roco et al. 2011), lowering the cost of nano materials. Meanwhile, corresponding applied technology and industry standards should be proposed. Each new generation of nanomaterial applied in geotechnical engineering improves the economic and social outcomes of this new technology.

-

Extreme caution in the field of nanomaterial toxicity must be used when using nanomaterials, especially for nanomaterials of unknown toxicity, to prevent environmental pollution both in the manufacturing and use stages. Though the four materials discussed in this paper have shown no toxic risk, research has found that some nanomaterials such as TiO2 particles can cause lung inflammation or produce nano wastes (Grassian et al. 2007). As new materials are brought into engineering use, it is important to understand their potential effects on the environment (e.g., pH, salinity, microbes, and natural organic matter) and their reactivity, mobility, bioavailability, and toxicity, to guarantee sustainable development in the field of nano materials.

References

Abdou MI, Al-sabagh AM, Dardir MM (2013) Evaluation of Egyptian bentonite and nano-bentonite as drilling mud. Egypt J Pet 22:53–59

Abedi M, Yasrobi SS (2010) Effects of plastic fines on the instability of sand. Soil Dyn Earthq Eng 30:61–67

Arabania M, Haghib AK, Moradic Y (2012) Evaluation of mechanical properties improvement of clayey sand by using carbon nanotubes. In: Proceedings of the 4th International Conference on Nanostructures (ICNS4), Kish Island, I.R. Iran, 1567–1569

Balaguru P and Chong K (2006) Nanotechnology and concrete: research opportunities. In: Proceedings of ACI Session on “Nanotechnology of Concrete: Recent Developments and Future Perspectives”, Denver, 15–28

Cacciatore MA, Scheufele DA, Corley EA (2009) From enabling technology to applications: The evolution of risk perceptions about nanotechnology. Public Underst Sci 20(3):385–404

Cao G (2004) Nanostructures and nanomaterials-synthesis, properties and applications. Imperial College Press, London

Chang SY, Liu L, Asher SA (1994) Preparation and properties of tailored morphology, monodisperse colloidal silica cadmium-sulfide nanocomposites. J Am Chem Soc 116(15):6739–6744

Chong KP (2003) Nano science and engineering in mechanics and materials. Rev Adv Mater 5:110–116

Chong WK, Kumar S, Haas CT, Beheiry SA, Coplen L, Oey M (2009) Understanding and interpreting baseline perceptions of sustainability in construction among civil engineers in the United States. Manage Eng 25:143–154

Clement K, Iseli A, Karote D, Cremer J, Rajagopalan S (2012) Nanostructured materials industrial applications. Handbook of industrial chemistry and biotechnology. Springer, Berlin, pp 265–306

Cuddihy J, Kennedy C, Byer P (2005) Energy use in Canada: environmental impacts and opportunities in relationship to infrastructure systems. Can J Civ Eng 32:1–15

Darvishi Z, Morsali A (2011) Synthesis and characterization of nano-bentonite by sonochemical method. Ultrason Sonochem 18:238–242

Díaz-Rodríguez JA, Antonio-Izarraras VM, Bandini P, López-Molina JA (2008) Cyclic strength of a natural liquefiable sand stabilized with colloidal silica grout. Can Geotech J 45(10):1345–1355

Dietler G, Aubert C, Cannell DS et al (1986) Gelation of colloidal silica. Phys Rev Lett 57(24):3117

Eden Energy (2011) Eden sells carbon nanomaterials for second electrical application. http://www.edenenergy.co.in/UploadedPDF/16-May-2011.pdf. Accessed 27 Aug 2014

El Mohtar CS, Clarke J, Bobet A, Santagata M, Drnevich V, Johnston C (2008) Cyclic response of a sand with thixotropic pore fluid. In: Zeng D, Manzari MT, Hiltunen DR (eds) Geotechnical earthquake engineering and soil dynamics IV, vol 181. Geotechnical Special Publication, pp 1–10

El Mohtar CS, Bobet A, Santagata MC, Drnevich VP, Johnston CT (2013) Liquefaction mitigation using bentonite suspensions. J Geotech Geoenvironmental Eng 139(8):1369–1380

Fakhim B, Hassani A, Rashidi A, Ghodousi P (2013) Predicting the impact of multiwalled carbon nanotubes on the cement hydration products and durability of cementitious matrix using artificial neural network modeling technique. The Scientific World Journal

Feynman R (1960) There´ s plenty of room at the bottom (reprint from the speech given at the annual meeting of the West Coast section of the American Physical Society). Eng Sci 23:22–36

Finch G, Havel H, Analoui M, Barton RW, Diwan AR, Hennessy M et al (2014) Nanomedicine drug development: a scientific symposium entitled “Charting a Roadmap to Commercialization”. AAPS J 16(4):698–704

Gallagher PM (2000) Passive site remediation for mitigation of liquefaction risk. PhD thesis, Virginia Polytechnic Institute and State University, Virginia

Gallagher PM, Mitchell JK (2002) Influence of colloidal silica grout on liquefaction potential and cyclic undrained behavior of loose sand. Soil Dyn Earthq Eng 22:1017–1026

Gallagher PM, Conlee CT, Rollins KM (2007a) Full-scale field testing of colloidal silica grouting for mitigation of liquefaction risk. Geotech Geoenviron Eng 133(2):186–196

Gallagher PM, Pamuk A, Abdoun T (2007b) Stabilization of liquefiable soils using colloidal silica grout. J Mater Civ Eng 19(1):33–40

Ge Z and Gao Z (2008) Applications of nanotechnology and nanomaterials in construction. First International Conferernce on Construction in Developing Countries, 235–240

Ghahremani M and Ghalandarzadeh A (2006) Effect of plastic fines on cyclic resistance of sands. In: Proceedings of GeoShanghai International Conference, Shanghai, China, 406–412

Grassian V, O’Shaughnessy PT, Adamcakova-Dodd A, Pettibone JM, Thorne PS (2007) Inhalation exposure study of titanium dioxide nanoparticles with a primary particle size of 2–5 nm. Environ Health Perspec 115:397–402

Halicioglu FH (2009) The potential benefits of nanotechnology for innovative solutions in the construction sector. Nanotechnology in construction 3. Springer, Heidelberg, 209–214

Hanus MJ, Harris AT (2013) Nanotechnology innovations for the construction industry. Prog Mater Sci 58:1056–1102

Holman M (2007) Nanomaterial forecast: Vol. s and applications. ICON nanomaterial environmental health and safety research needs assessment. Lux Research, Houston

Howayek AE, Bobet A, Johnston CT, Santagat MV, Sinfield J (2014) Microstructure of Sand-Laponite-Water Systems using Cryo-SEM. Geo-Congress 2014 Technical Papers, ASCE, 693–702

Hyung H, Fortner JD, Hughes JB, Kim JH (2007) Natural organic matter stabilizes carbon nanotubes in the aqueous phase. Environ Sci Technol 41(1):179–184

Johansen A, Pedersen AL, Jensen KA et al (2008) Effects of C60 fullerene nanoparticles on soil bacteria and protozoans. Environ Toxicol Chem 27(9):1895–1903

Klaine SJ, Alvarez PJJ, Batley GE et al (2008) Nanomaterials in the environment: behavior, fate, bioavailability, and effects. Environ Toxicol Chem 27(9):1825–1851

Kodaka T, Ohno Y, Takyu T (2005) Cyclic shear characteristics of treated sand with colloidal silica grout. Proceedings of the International Conference on Soil Mechanics and Geotechnical Engineering, Aa Balkema Publishers, 16(2): 401

Kroon M, Vos WL, Wegdam GH (1998) Structure and formation of a gel of colloidal disks. Phys Rev E 57:1962–1970

Lam CW, James JT, McCluskey R et al (2006) A review of carbon nanotube toxicity and assessment of potential occupational and environmental health risks. Crit Rev Toxicol 36(3):189–217

Levitz P, Lecolier E, Mourhid A (2000) Liquid-solid transition of laponite suspensions at very low ionic strength: long-range electrostatic stabilization of anisotropic colloids. Europhys Lett 49(5):672–677

Li S, Anderson TA, Green MJ, Maul JD, Canas-Carrell JE (2013) Polyaromatic hydrocarbons (PAHs) sorption behavior unaffected by the presence of multi-walled carbon nanotubes (MWNTs) in a natural soil system. Environ Sci Process Impacts 15:1130–1136

Lippiatt B (1999) Selecting cost-effective green building products BEES approach. Constr Eng Manage 125:448–455

Liu YL, Hsu CY, Wei WL et al (2003) Preparation and thermal properties of epoxy-silica nanocomposites from nanoscale colloidal silica. Polymer 44(18):5159–5167

Lu CY, Chung YL, Chang KF (2005) Adsorption of trihalomethanes from water with carbon nanotubes. Water Res 39:1183–1189

Lucintel (2011) Nanocomposites: breakthrough applications or will the cost outweigh the benefits. http://www.materialstoday.com/composite-industry/features/composites-europe-2011-show-preview/. Accessed 10 Mar 2016

Martin JE, Wilcoxon JP, Schaefer D et al (1990) Fast aggregation of colloidal silica. Phys Rev A 41(8):4379

Mauter MS, Elimelech M (2008) Environmental applications of carbon-based nanomaterials. Environ Sci Technol 42:5843–5859

Mollamahmutoglu M, Yilmaz Y (2010) Pre- and post-cyclic loading strength of silica-grouted sand. Proc ICE Geotechn Eng 163:343–348

Morsy MS, Alsayed SH, Aqel M (2011) Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar. Constr Build Mater 25:145–149

Nowack B, Bucheli TD (2007) Occurrence, behavior and effects of nanoparticles in the environment. Environ Pollut 150:5–22

NRC (2006) Geological and geotechnical engineering in the new Millennium: opportunities for research and technological innovation. National Academies Press, Washington

NSTC (2007) The National Nanotechnology Initiative—Strategic Plan, December 2007. Executive Office of the President of the United States

Oss HG, Padovani AC (2003) Cement manufacture and the environment, Part II:e nvironmental challenges and opportunities. J Ind Ecol 7(1):93–126

Ozin GA, Arsenault AC, Cademartiri L (2009) Nanochemistry: a chemical approach to nanomaterials. Royal Society of Chemistry, London

Pacheco-Torgal F, Jalali S (2011) Nanotechnology: advantages and drawbacks in the field of construction and building materials. Constr Build Mater 25(2):582–590

Pacheco-Torgal F, Labrincha JA (2013) The future of construction materials research and the seventh UN Millennium development goal: a few insights. Constr Build Mater 40:729–737

Peng KQ, Lee ST (2011) Silicon nanowires for photovoltaic solar energy conversion. Adv Mater 23(2):198–215

Persoff P, Apps J, Moridis G, Whang JM (1999) Effect of dilution and contaminants on sand grouted with colloidal silica. J Geotechn Geoenviron Eng 125(6):461–469

Qureshi A, Kang WP, Davidson JL, Gurbuz Y (2009) Review on carbon-derived, solid-state, micro and nano sensors for electrochemical sensing applications. Diam Relat Mater 18(12):1401–1420

Roco MC (2005) International perspective on government nanotechnology funding in 2005. J Nanopart Res 7:707–712

Roco MC, Mirkin CA, Hersam MC (2011) Nanotechnology research directions for societal needs in 2020: summary of international study. J Nanopart Res 13:897–919

Rugg DA, Yoon J, Hwang H, Mohtar CSE (2011) Undrained shearing properties of sand permeated with a bentonite suspension for static liquefaction mitigation. In: Proceedings of the Geofrontiers, Dallas, 677–686

Saini R, Saini S, Sharma S (2010) Nanotechnology: the future medicine. J Cutan Aesthet Surgy 3(1):32–33

Sanchez F, Sobolev K (2010) Nanotechnology in concrete: a review. Constr Build Mater 24:2060–2071

Sathurusinghe S, Herath W, Subhashini H, Herath K (2012) Stress concentrations in single walled carbon nanotube reinforced metal and polymer composites under uniaxial loading. I J Adv Struct Geotechn Eng 1(2):58–60

Schlosser P, Pfirman S (2012) Earth science for sustainability. Nat Geosci 5:587–588

Shafigh P, Bin Mahmud H, Jumaat MZ, Zargar M (2014) Agricultural wastes as aggregate in concrete mixtures: a review. Constr Build Mater 53:110–117

Srivastava A and Singh K (2011) Nanotechnology in civil engineering and construction: a review on state of the art and future prospects. In: Proceedings of Indian Geotechnical Conference, Kochi, 1077–1080

Tanaka H, Meunier J, Bonn D (2004) Nonergodic states of charged colloidal suspensions: repulsive and attractive glasses and gels. Phys Rev E 69(3):031404

Teplitskiy A, Gee R, Kourmaev R (2005) Application of physical-chemical properties of bentonite utilized in construction, as viewed through the TRIZ Prism. http://www.triz-journal.com/archives/2005/10/05.pdf. Accessed 30 July 2014

Tong Z, Bischoff M, Nies L et al (2007) Impact of fullerene (C60) on a soil microbial community. Environ Sci Technol 41(8):2985–2991

Treacy MMJ, Ebbesen TW, Gibson JM (1996) Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nat Geosci 381:678–680

Ugwu OO, Arop JB, Nwoji CU, Osadebe NN (2013) Nanotechnology as a Preventive Engineering Solution to Highway Infrastructure Failures. J Constr Eng Manag 139:987–993

UN (2000) United Nations millenium declaration. http://www.un.org/millennium/declaration/ares552e.pdf. Accessed 27 Aug 2014

Vik EA, Sverdrup L, Kelley A, Storhaug R, Beitnes A, Boge K, Grepstad GK, Tveiten V (2000) Experiences from environmental risk management of chemical grouting agents used during construction of the Romeriksporten tunnel. Tunn Undergr Space Technol 15(4):369–378

Witthoeft AF, Santagata MC, Bobet A (2012) Numerical study of the effectiveness of bentonite treatment for liquefaction mitigation. Proc GeoCongress 2012:1958–1967

Yonekura R and Miwa M (1993) Fundamental properties of sodium silicate based grout. Eleventh Southeast Asia Geotechnical Conference, Singapore, 439–444

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 41372355 and 41511130069).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, Y., Wang, L. Experimental studies on nanomaterials for soil improvement: a review. Environ Earth Sci 75, 497 (2016). https://doi.org/10.1007/s12665-015-5118-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-015-5118-8