Abstract

Transient isotachophoresis (tITP) is a universal online sample preconcentration technology. It uses ITP to focus electrically charged analytes during the initial stage of capillary electrophoresis (CE) analysis, which can effectively improve the sensitivity of CE. In this work, an approach of tITP under counter-electroosmotic flow was developed for capillary zone electrophoresis (CZE) determination of five trace food additives which include benzoic acid, sorbic acid, sunset yellow, allura red, and amaranth in beverage samples. The parameters that affect the preconcentration effect of the system, such as the type of terminating electrolyte and its injection time, the preconcentration time of ITP, and the sample injection time, have been investigated in detail. The mechanism of counterflow-tITP was explored preliminarily. Under optimal conditions, the sensitivity of five food additives was improved 11.9, 11.5, 13.04, 10.05, and 15.3 times. Their limits of detection (LODs, S/N = 3) reached 0.15, 0.10, 0.38, 0.33, and 0.11 μg/ml, with good repeatability (peak area RSDs ≤ 6.9%) and calibration graph linearity (r ≥ 0.9992). Recoveries of five food additives in spiked beverage samples ranged from 92.0 to 100.8% with RSDs between 1.38 and 2.95%. This method is simple, rapid, and sensitive. It has been successfully applied to the separation and detection of trace food additives in cocktails, orange juice, and carbonated beverages. The feasibility of determination of trace additives in beverages by tITP-CZE under the condition of counterflow has been confirmed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Food additives are added in foodstuffs to carry out certain technological functions, specifically to impart color, sweeten, or preserve the food product. According to the characteristics of food additives, it can be classified into various categories, such as colorants, preservatives, and sweeteners (Zhao et al. 2013; Nambiar et al. 2018). With the rapid development of food additive applications, a series of problems such as exceeding the limit control and scope of its use have appeared. Sunset yellow, allura red, and amaranth are artificial synthetic colors. They are widely used in beverages as they have greater stability and are relatively inexpensive. Nevertheless, when they are used beyond the permissible limits, they can cause adverse effects on the human body such as respiratory problems, allergy, thyroid tumors, chromosomal damage, hyperactivity, and abdominal pain (Jiang et al. 2020; Doguc et al. 2019, 2013). Benzoic acid and sorbic acid are commonly used preservatives in food. Their use beyond the permissible limits will also overload the human body, which in turn affects the normal catabolism of the human body (Singh and Gandhi 2015; Parke and Lewis 1992). Every country has specific directives to regulate the use of food additives and safety aspects. Hence, it becomes essential to monitor the added dose of these additives in various food substances to control their use and thereby reduce the health complications in consumers.

Due to the complex matrix of the food sample, the pretreatment process is tedious, and the content of the food additive to be tested is low, which places high requirements on the detection of food additives. Currently, the main analytical methods for food additives in food include gas chromatography (GC) (Abdol-Samad et al. 2014; Sun et al. 2013), high performance liquid chromatography (HPLC) (Sercan and Ahmet 2018; Rejczak and Tuzimski 2017; Pagacikova and Lehotay 2015; Zhang et al. 2015; Wang et al. 2015), and liquid chromatography-mass spectrometry (LC-MS) (Kim et al. 2018; Martin et al. 2016; Negrete et al. 2019), gas chromatography-mass spectrometry (GC-MS) (Sagandykova et al. 2017), and capillary electrophoresis (CE) (Wu et al. 2016, b; Tang et al. 2017). GC is only suitable for the detection of volatile components. HPLC has a wide range of applications and high sensitivity, but the sample pretreatment process is more time-consuming and tedious, and requires a large amount of organic solvents. Although GC-MS and LC-MS possess high throughput for simultaneous determination of multiple food additives in food with high sensitivity and selectivity, they are often not applicable in ordinary labs due to the need for expensive equipment.

Compared to other separation methods described above, CE has the advantages of fastness, high efficiency, and minimum reagent and sample consumption. However, due to the small sample injection volume and the short light pathway, the sensitivity of CE with conventional UV detection is not sufficiently high. This limits the application of CE in the separation and detection of trace food additives. CE often needs to be combined with other preconcentration techniques to improve its detection sensitivity. Therefore, various online concentration procedures have been developed to improve the sensitivity such as field-amplified sample stacking (FASS), field-amplified sample injection (FASI) (Wang et al. 2018; Pawel and Rafal 2017; Wu et al. 2016a), large volume sample stacking (LVSS) (Shao et al. 2016; Bailon-Perez et al. 2007), dynamic pH junction (Hsu et al. 2014; Kitagawa et al. 2019), sweeping (Peng et al. 2020; Ma et al. 2019), electrokinetic supercharging (EKS) (Chu et al. 2020; Maddukuri and Gong 2020), and transient isotachophoresis (tITP) (Wu et al. 2019). Although FASS, FASI, and EKS are effective for low conductivity samples, they are inapplicable for analytes in high conductivity samples with complex matrices (Hattori et al. 2017). Due to the high ionic strength caused by more chemical components in the complex matrix, it is difficult to obtain effective stacking and enrichment effect. Therefore, the highly saline matrices significantly affect the sensitivity in CE, which increases the difficulty of sample pretreatment and makes things even more complicated. However, the ITP mode is a concentration method based on or unaffected by the highly saline matrices and is especially suitable for highly saline matrix sample. In tITP mode, analytes in high-salinity matrix samples can be preconcentrated without or with little pretreatment. This is very beneficial for food analysis with complex sample matrices.

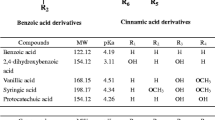

Generally, tITP is performed under conditions that suppress electroosmotic flow (EOF). A common strategy of suppressing EOF is to run tITP in a low pH background electrolyte (BGE) (Zhuo et al. 2006; Petr et al. 2006; Okamoto et al. 2005). However, the five food additives are anionic and cannot be effectively separated at low pH (the structural formulas of the five food additives are shown in Fig. 1).

In this paper, the counterflow-tITP-CZE technology was used to establish a rapid separation and detection method for five food additives which include benzoic acid, sorbic acid, sunset yellow, allura red, and amaranth red in beverages. This method took the advantages of counterflow to push the stacked analytes to the inlet end of capillary without the aid of hydrodynamic backpressure to preconcentration the analytes. Five food additives were then effectively separated by CZE at high pH. The parameters of terminating electrolyte type and injection time, preconcentration time of tITP, and sample injection time in the system were studied. The method has been successfully applied to the separation and detection of five food additives in a variety of beverages with satisfactory results.

Materials and Methods

Materials

Sunset yellow, benzoic acid, and sorbic acid were purchased from Aladdin (Shanghai, China). Allura red and amaranth were obtained from Shanghai Jinsui Technology Co., Ltd. (Shanghai, China). Sodium tetraborate and sodium dihydrogen phosphate (NaH2PO4) were obtained from Xilong Scientific Co., Ltd. (Guangdong, China). β-Cyclodextrin was from Tianjin Komeo Chemical Reagent Co., Ltd. (Tianjin, China). 2-(N-Morpholino)ethanesulfonic acid monohydrate (MES) and 2-[4-(2-hydroxyethyl) piperazin-1-yl]ethanesulfonic acid (HEPES) were purchased from Shandong Xiya Chemical Industry Co., Ltd. (Shandong, China). Methanol, hydrochloric acid, and sodium hydroxide were all obtained from Guangdong Guanghua Technology Co., Ltd. (Guangdong, China). The beverage samples of cocktails, orange juice, and carbonated beverages were purchased from local supermarket. All reagents were of analytical-reagent grade and were used as received. Deionized (DI) water at 18.2 MΩ cm was produced using a UPH-1V-20T Youpu series ultrapure water machine (Sichuan Youpu Super Pure Technology Co., Ltd., China) and used for all solution preparation. All reagents and solutions used in this experiment were filtered through a 0.22-μm microporous membrane and degassed by ultrasonication before use.

All experiments were conducted using a CE instrument (Agilent Technologies, Waldbroon, Germany) equipped with UV diode-array detection (DAD). An uncoated fused-silica capillary (Yongnian Country Reafine Chromatography, Hebei, China) with 65 cm total length (57 cm effective length) and 75 μm I.D. (375 μm O.D.) was used. The detection wavelength was set at 214 nm for five additives. The temperature of the capillary was 25 °C in all experiments. The ChemStation software available in CE was used for CE control and data analysis, including peak area determination by manual selection of peak start and end points.

Methods

Solutions Preparation

Standard stock solutions with the concentration of 1000 μg/ml were prepared by dissolving the appropriate amount benzoic acid, sorbic acid, sunset yellow, allura red, and amaranth in methanol, respectively. The standard mixtures were prepared by diluting the corresponding stock solutions with methanol as required for the experiment. All standard solutions were stored at 4 °C.

Sample Preparation

Ten milliliters of cocktails, orange juice, and carbonated beverages was taken out separately. Ultrasonication was done for 20 min to remove carbon dioxide from the beverages, and they were placed in a 4 °C refrigerator for storage.

Counterflow-tITP Conditions

Before use, new capillary was flushed with methanol for 10 min, 1.0 M HCl for 20 min, and 1 M NaOH for 20 min. The capillary was then preconditioned daily prior to use by washing with 1 M NaOH for 10 min and water for 5 min. Before each sample injection, the capillary was rinsed with 1 M NaOH for 3 min followed by 3 min BGE. For CZE, the BGE consisted of 25 mM sodium tetraborate–12.5 mM sodium dihydrogen phosphate, and 8 mM β-cyclodextrin (the pH was adjusted to 11.0 with 0.1 M NaOH).

For the tITP experiments, the BGE was used as the lead electrolyte (LE), and 10 mM MES (was adjusted to pH 7.5 with 0.1 M Tris) was used as the terminating electrolyte (TE). First, sample solution was introduced into the capillary filled with LE using a pressure of 100 mbar for 10 s. Then, the sample vial at the capillary inlet end was replaced with a vial containing TE buffer. After TE was introduced into the capillary using a pressure of 50 mbar for 20 s (Fig. 2a), a voltage of − 23 kV was applied to complete the preconcentration of the analytes by tITP (Fig. 2b). Finally, the vial containing TE was replaced with a vial containing LE, and CZE analysis of the preconcentrated analytes was carried out with a constant voltage of 23 kV.

Results and Discussion

Schematic Representation of Counterflow-tITP

The experimental principle of tITP is shown in Fig. 2. First, the capillary inlet was inserted into the vial containing LE, and the capillary was filled with LE. The plug of sample was then introduced into the capillary at an injection pressure of 100 mbar for 10 s. Thereafter, to avoid the analytes migrating out of the capillary inlet during or after the preconcentration process, a short TE plug was injected (Fig. 2a). When a negative voltage of − 23 kV was applied, according to the principle of ITP, the leading ions, the sample ions, and the terminating ions would migrate with the same velocity. Meanwhile, preconcentration of the analytes was completed (Fig. 2b). In this process, the direction of EOF is always from the positive electrode to the negative electrode. When a negative voltage was applied, a strong counterflow was generated which flowed from the capillary outlet to the inlet. Therefore, the migration direction of the analytes was opposite to that of EOF. The counterflow acted as a pump, concentrating and pushing the analytes toward the capillary inlet end (Fig. 2c). After the preconcentration of analytes was completed, the separation and determination were immediately performed at a positive voltage of 23 kV, thereby achieving a smooth transition from the tITP state to the CZE state (Fig. 2d).

In the process of counterflow ITP-CZE, the most critical point in the process is the timing of the moment to switch off the ITP and to start the CZE. This is done at the moment the analytes are about to leave the capillary. If the ITP process is continued for too long, the sample zones will migrate out of the capillary into the inlet buffer vial, resulting in loss of the analytes. If the voltage is switched too early and the CZE run is started, there is still a plug of terminating buffer in the capillary. The mixing of the terminating buffer and the BGE will disturb the homogeneity of the electric field necessary for CZE, resulting in band broadening. Not only that, but it will also cause the analytes to reach the detector too early during the following CZE separation step and the resolution will be poor. Therefore, the sample zones have to be close to the inlet end of the capillary when the CZE separation step is started. The terminating electrolyte should be removed as much as possible to ensure that the field strength during CZE analysis is more homogeneous, to prevent band broadening, and to allow the analytes to be properly separated before reaching the detector.

Optimization of the Parameters in Counterfolw-tITP

Selection of Terminating Electrolyte Types

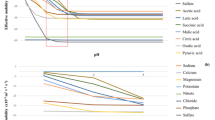

In order to increase the enrichment effect of counterflow-tITP and improve its sensitivity, it is crucial to choose appropriate TE. The choice of terminating ion is determined by the electrophoretic mobilities of some ions. In the ITP process, the mobility of the terminating ion is smaller than that of all analyte ions, so that the terminating ion can concentrate the sample plug together with the leading ion, thereby achieving the enrichment effect.

According to the reference (Huang et al. 2002), we selected the BGE used in CZE as LE, and examined the effects of HEPES, l-histidine, l-alanine, and MES as TE on the experimental. The experimental results showed that when HEPES was used as the terminating ion, the peak shapes of the five analytes overlap and have poor repeatability, while l-histidine and l-alanine are strong electrolytes. Excessive Joule heat will accelerate the dispersion of stacked analytes. When MES was used as TE, the five analytes have higher sensitivity enhancement factors (SEFs) and well separation. Therefore, in the counterflow-tITP process, MES was selected as TE.

Optimization of Counterflow-tITP Preconcentration Time

During the progress of counterflow-tITP, the analytes’ SEF is related to its preconcentration time. Within a short preconcentration time, the terminating ions were not completely pushed out of the capillary by counterflow. It will make the electric field distribution in the capillary uneven and affect the separation efficiency and migration time in the progress of CZE. It will also prevent the analytes from stacking sufficiently, so the analytes cannot be preconcentrated to the greatest extent or cannot be completely separated. If the preconcentration time is too long, part or even all of the analytes will be pushed out of the capillary inlet end by counterflow, resulting in a decrease in the analytes’ SEF. Therefore, the effects of preconcentration times of 6, 12, 18, 24, and 30 s on the preconcentration of analytes were investigated in this experiment. The results indicated that when the preconcentration time was 24 s, the analyte ions were stacked near the capillary inlet end, the SEF reached a maximum, and the analytes were completely separated (Fig. 3A). Consequently, the sample preconcentration time of 24 s was selected for further experiments.

Optimization of Sample Injection Time

The amount of sample injected determines the sensitivity enhancement of the tITP-CZE method. In order to examine the effect of injection time on counterflow-tITP stacking, a range of 5–15 s was investigated, applying an injection pressure of 100 mbar. As shown in Fig. 3B, the peak area increased as the injection time increased. However, interferences arose when the injection time was larger than 10 s. Therefore, an injection time of 10 s was for further experiments.

Effect of TE Injection Time on the Stacking and Separation Performance

Properly increasing the counterflow duration could minimize the movement of the ITP zone toward the detector during the ITP stage, thereby maximizing the remaining capillary length for separation the analytes, and improving the separation of the analytes. Meanwhile, the ITP occurred close to the capillary inlet during application of counterflow, allowing all analytes to migrate away from the ITP zone with improved resolution. Therefore, increased counterflow duration allowed for faster separation. However, due to the diffusion between zones when applying the counterflow, the sensitivity would decrease with counterflow duration (Aemi et al. 2014). In this paper, the length of the terminating ions’ zone determined the counterflow duration. Therefore, the length of the introduced terminating ions’ zone should be investigated. The effects of terminating ions’ injection time from 10 to 25 s on the analytes’ stacking and separation performance were studied at a pressure of 50 mbar. The peak area of the analytes increases with the increase of the TE injection time when the TE injection time is gradually increased from 10s to 20 s. However, the peak area started to decrease when the injection time exceeded 20 s. As shown in Fig. 4, when the TE injection time is 20 s, the five analytes can be separated. As a compromise between sensitivity and selectivity, the TE injection time of 20 s was selected for further experiments.

Method Validation

In this paper, the sensitivity enhancement factor (SEF) was used to evaluate the enrichment effect of the presented method. The sensitivity enhancement factor can be calculated from formula (1):

where AtITP and ACZE represent the peak areas of the analytes obtained by tITP and CZE, respectively. CtITP and CCZE represent the analyte concentrations corresponding to AtITP and ACZE, respectively. The corresponding typical electropherograms of counterflow-tITP and CZE are shown in Fig. 5A ((a) and (b)). According to formula (1), the SEFs of benzoic acid, sorbic acid, sunset yellow, allura red, and amaranth were 11.9, 11.5, 13.04, 10.05, and 15.3.

Typical electropherograms of the standards, cocktail, orange juice, and carbonated beverage. Na+ served as the LE of counter-EOF-tITP. TE was 10 mM MES (pH 7.5) and was injected with 50 mbar for 20 s. Sample was injected at 100 mbar for 10 s. A The standards with CZE (a) and with counterflow-tITP (b). B The standards and cocktail sample with counterflow-tITP (a, cocktail samples; b, real cocktail sample spiked with amaranth). C The standards and orange juice sample with counterflow-tITP (a, orange juice samples; b, real orange juice sample spiked with sorbic acid and sunset yellow). D The standards and carbonated beverage sample with counterflow-tITP (a, carbonated beverage sample; b, real carbonated beverage sample spiked with allura red). 1, benzoic acid; 2, sorbic acid; 3, sunset yellow; 4, allura red; 5, amaranth

Linear Range and Limit of Detection

The prepared standard stock solution was serially diluted with methanol to prepare a series of mixed standard solutions of five analyte standards. The concentrations of five analytes in serially diluted mixed standard solution were analyzed under the optimized counterflow-tITP-CZE conditions. The peak areas of five analytes at different concentrations were measured to fit the calibration curve. The results indicated that the five analytes had good linearity in a certain concentration range (r > 0.9992). The limits of detection (LODs) were calculated as three times the signal-to-noise ratio. The obtained linear range, regression curve, correlation coefficient, LOD, and relative standard deviation (RSD) are shown in Table 1.

Application of Counterflow-tITP-CZE Method to Beverage Sample

In order to clearly demonstrate the applicability of this method, we applied it to the detection of five food additives in cocktails, orange juice, and carbonated beverages. Cocktail sample was spiked with 50 μg/ml amaranth, orange juice sample was spiked with 50 μg/ml sorbic acid and 50 μg/ml sunset yellow, and carbonated beverage was spiked with 50 μg/ml allura red. The three beverages were then analyzed by counterflow-tITP-CZE. The electropherograms of cocktail sample, orange juice sample, and carbonated beverage sample are shown in Fig. 5B–D. As can be seen from Fig. 5B–D, among the three beverages without additional spiked with additives, only benzoic acid and sorbic acid were detected in the cocktail samples and orange juice samples. The remaining three food additives are not detected in these three samples. The contents of benzoic acid and sorbic acid are shown in Table 2.

Addition and recovery tests were performed in three beverage samples at three different concentrations of analytes. Cocktail sample was spiked with benzoic acid and amaranth. The spiking levels of benzoic acid were 5.0, 15.0, and 25.0 μg/ml, and the spiking levels of amaranth were 8.0, 24.0, and 48.0 μg/ml. Orange juice sample was spiked with sorbic acid and sunset yellow, and the spiking levels were all 5.0, 15.0, and 25.0 μg/ml. Carbonated beverage was spiked with allura red, and the spiking levels were 8.0, 24.0, and 48.0 μg/ml. The above levels of each addition were measured in parallel three times. The quantitative results and the recoveries of the method, which were determined by adding different amounts of the analytes to the sample, are listed in Table 3. The results proved that the detection method was accurate and reproducible. It is suitable for the determination of five food additives in actual samples.

Conclusions

In this work, a counterflow-tITP method was developed as an online concentration procedure for CZE determination of food additives in beverages, including benzoic acid, sorbic acid, sunset yellow, allura red, and amaranth. The tITP feature of the system allowed analytes to be preconcentrated under counterflow conditions, and thus their improved detection sensitivity. Moreover, it simultaneously maintained excellent CZE resolution, peak shapes, and separation efficiencies of the analytes. The sensitivity of benzoic acid, sorbic acid, sunset yellow, allura red, and amaranth red was improved 11.9, 11.5, 13.04, 10.05, and 15.3 times compared to those obtained using the conventional CZE method. The method was validated and showed satisfactory analytical performance. The LOD, linearity, recovery, and repeatability were determined to confirm that the method has sufficient detection ability and precision to be used for the determination of five food additives in beverages.

References

Abdol-Samad A, Abdorreza M, Ebrahim A, Mohammad MA, Ramin K (2014) Simultaneous determination of sorbic and benzoic acids in milk products using an optimised microextraction technique followed by gas chromatography. Food Addit Contam A 31:21–28. https://doi.org/10.1080/19440049.2013.859742

Aemi SAK, Rosanne MG, Christopher JSB, Michael CB (2014) Transient isotachophoresis- capillary zone electrophoresis with contactless conductivity and ultraviolet detection for the analysis of paralytic shellfish toxins in mussel samples. J Chromatogr A 1364:295–302. https://doi.org/10.1016/j.chroma.2014.08.074

Bailon-Perez MI, Garcia-Campana AM, Cruces-Blanco C, Del Olmo IM (2007) Large- volume sample stacking for the analysis of seven beta-lactam antibiotics in milk samples of different origins by CZE. Electrophoresis 28:4082–4090. https://doi.org/10.1002/elps.200700305

Chu C, Lian LM, Liu CJ, Li J, Mao H, Jiang LY, Yan JZ (2020) Online preconcentration by electrokinetic supercharging for sensitive determination of berberine and jatrorrhizine in biological samples. Biomed Chromatogr 34:e4824. https://doi.org/10.1002/bmc.4824

Doguc DK, Ceyhan BM, Ozturk M, Gultekin F (2013) Effects of maternally exposed colouring food additives on cognitive performance in rats. Toxicol Ind Health 29:616–623. https://doi.org/10.1177/0748233712436638

Doguc DK, Deniz F, İlhan İ, Ergonul E, Gultekin F (2019) Prenatal exposure to artificial food colorings alters NMDA receptor subunit concentrations in rat hippocampus. Nutr Neurosci. https://doi.org/10.1080/1028415X.2019.1681065

Hattori T, Okamura H, Asaoka S, Fukushi K (2017) Capillary zone electrophoresis determination of aniline and pyridinein sewage samples using transient isotachophoresis with a system-induced terminator. J Chromatogr A 1511:132–137. https://doi.org/10.1016/j.chroma.2017.07.009

Hsu SH, Hu CC, Chiu TC (2014) Online dynamic pH junction-sweeping for the determination of benzoic and sorbic acids in food products by capillary electrophoresis. Anal Bioanal Chem 406:635–641. https://doi.org/10.1007/s00216-013-7481-1

Huang HY, Shih YC, Chen YC (2002) Determining eight colorants in milk beverages by capillary electrophoresis. J Chromatogr A 959:317–325. https://doi.org/10.1016/S0021-9673(02)00441-7

Jiang LL, Li K, Yan DL, Yang MF, Ma L, Xie LZ (2020) Toxicity assessment of 4 azo dyes in zebrafish embryos. Int J Toxicol 39:115–123. https://doi.org/10.1177/1091581819898396

Kim HJ, Lee MJ, Park HJ, Kim HJ, Cho SK, Jeong MH (2018) Simultaneous determination of synthetic food additives in kimchi by liquid chromatography-electrospray tandem mass spectrometry. Food Sci Biotechnol 27:877–882. https://doi.org/10.1007/s10068-018-0308-2

Kitagawa F, Tanigawa-Joh K, Terashita S, Fujiki R, Nukatsuka I, Sueyoshi K, Otsuka K (2019) On-line sample preconcentration by polarity switching in floating electrode-integrated microchannel. Electrophoresis 40:2478–2483. https://doi.org/10.1002/elps.201800501

Ma HF, Liu T, Li J, Ding MY, Gao XM, Chang YX (2019) The in-capillary-2,2-azinobis-(3- ethylbenzothiazoline-6-sulfonic acid)-sweeping micellar electrokinetic chromatography-diode array detector method for screening and quantifying trace natural antioxidants from Schisandra chinensis. J Chromatogr A 1593:147–155. https://doi.org/10.1016/j.chroma.2019.01.050

Maddukuri N, Gong MJ (2020) Vacuum-assisted electrokinetic supercharging in flow-gated capillary electrophoresis for rapid analysis of high-salt cerebrospinal fluid samples. Anal Methods-UK 12:25–32. https://doi.org/10.1039/C9AY02143D

Martin F, Oberson JM, Meschiari M, Munari C (2016) Determination of 18 water- soluble artificial dyes by LC-MS in selected matrices. Food Chem 197:1249–1255. https://doi.org/10.1016/j.foodchem.2015.11.067

Nambiar AP, Sanyal M, Shrivastav PS (2018) Simultaneous densitometric determination of eight food colors and four sweeteners in candies, jellies, beverages and pharmaceuticals by normal-phase high performance thin-layer chromatography using a single elution protocol. J Chromatogr A 1572:152–161. https://doi.org/10.1016/j.chroma.2018.08.059

Negrete MAA, Kazimierz W, Barrientos EY, Escobosa ARC, Aguilar FJA, Katarzyna W (2019) Determination of sulfonated azo dyes in chili powders by MALDI-TOF MS. Anal Bioanal Chem 411:5833–5843. https://doi.org/10.1007/s00216-019-01965-1

Okamoto H, Andrei RT, Hirokawa T (2005) Simultaneous determination of metal ions, amino acids, and other small biogenic molecules in human serum by capillary zone electrophoresis with transient isotachophoretic preconcentration. J Sep Sci 28:522–528. https://doi.org/10.1002/jssc.200400070

Pagacikova D, Lehotay J (2015) Determination of synthetic colors in meat products using high-performance liquid chromatography with photodiode Array detector. J Liq Chromatogr R T 38:579–583. https://doi.org/10.1080/10826076.2014.922473

Parke DV, Lewis DF (1992) Safety aspects of food preservatives. Food Addit Contam 9:561–577. https://doi.org/10.1080/02652039209374110

Pawel K, Rafal G (2017) Determination of lipoic acid in human urine by capillary zone electrophoresis. Electrophoresis 38:1800–1805. https://doi.org/10.1002/elps.201700002

Peng LQ, Dong X, Zhen XT, Yang J, Chen Y, Wang SL, Xie T, Cao J (2020) Simultaneous separation and concentration of neutral analytes by cyclodextrin assisted sweeping-micellar electrokinetic chromatography. Anal Chim Acta 1105:224–230. https://doi.org/10.1016/j.aca.2020.01.037

Petr J, Gerstmann S, Frank H (2006) Determination of some heavy metal cations in molten snow by transient isotachophoresis/capillary zone electrophoresis. J Sep Sci 29:2256–2260. https://doi.org/10.1002/jssc.200600022

Rejczak T, Tuzimski T (2017) Application of high-performance liquid chromatography with diode array detector for simultaneous determination of 11 synthetic dyes in selected beverages and foodstuffs. Food Anal Method 10:3572–3588. https://doi.org/10.1007/s12161-017-0905-3

Sagandykova GN, Alimzhanova B, Nurzhanova YT, Kenessov B (2017) Determination of semi-volatile additives in wines using SPME and GC-MS. Food Chem 220:162–167. https://doi.org/10.1016/j.foodchem.2016.09.164

Sercan Y, Ahmet Y (2018) A core-shell column approach to fast determination of synthetic dyes in foodstuffs by high-performance liquid chromatography. Food Anal Method 11:1581–1590. https://doi.org/10.1007/s12161-017-1138-1

Shao YX, Chen GH, Fang R, Zhang L, Yi LX, Meng HL (2016) Analysis of six beta-lactam residues in milk and egg by micellar electrokinetic chromatography with large-volume sample stacking and polarity switching. J Agr Food Chem 64:3456–3461. https://doi.org/10.1021/acs.jafc.6b00482

Singh P, Gandhi N (2015) Milk preservatives and adulterants: processing, regulatory and safety issues. Food Rev Int 31:236–261. https://doi.org/10.1080/87559129.2014.994818

Sun Y, Wang XQ, Huang YL, Pan ZF, Wang LL (2013) Derivatization following hollow-fiber microextraction with tetramethylammonium acetate as a dual-function reagent for the determination of benzoic acid and sorbic acid by GC. J Sep Sci 36:2268–2276. https://doi.org/10.1002/jssc.201300239

Tang W, Tian XY, Zhang YH, Yin D, Zhao WD, Zhang WF, Zhang SS (2017) Determination of benzoic acid and sorbic acid in seasoning by capillary electrophoresis with a new triethylamine aminated polychloromethyl styrene nanolatex coated capillary column. Anal Methods- UK 9:6280–6285. https://doi.org/10.1039/C7AY01930K

Wang ZY, Guo HT, Chen M, Zhang GB, Chang RM, Chen AJ (2018) Separation and determination of corynoxine and corynoxine B using chiral ionic liquid and hydroxypropyl- beta-cyclodextrin as additives by field-amplified sample stacking in capillary electrophoresis. Electrophoresis 39:2195–2201. https://doi.org/10.1002/elps.201800129

Wang N, Liao Y, Wang JM, Tang S, Shao SJ (2015) Solid-phase extraction using bis(indolyl) methane-modified silica reinforced with multiwalled carbon nanotubes for the simultaneous determination of flavonoids and aromatic organic acid preservatives. J Sep Sci 38:4111–4118. https://doi.org/10.1002/jssc.201500913

Wu ML, Chen WJ, Wang G, He PG, Wang QJ (2016a) Analysis of acrylamide in food products by microchip electrophoresis with on-line multiple-preconcentration techniques. Food Chem 209:154–161. https://doi.org/10.1016/j.foodchem.2016.04.065

Wu YC, Li J, Zhao S, Ding XJ (2016b) Simultaneous determination of 11 food additives by micellar electrokinetic capillary chromatography. Food Anal Method 9:589–595. https://doi.org/10.1007/s12161-015-0225-4

Wu HM, Yi L, Roza W, Shi TJ, Tang KQ (2019) A separation voltage polarity switching method for higher sample loading capacity and better separation resolution in transient capillary isotachophoresis separation. Analyst 144:454–462. https://doi.org/10.1039/c8an01779d

Zhang Y, Zhou H, Wang YG, Wu XL, Zhao YG (2015) Simultaneous determination of seven synthetic colorants in wine by dispersive micro-solid-phase extraction coupled with reversed- phase high-performance liquid chromatography. J Chromatogr Sci 53:210–218. https://doi.org/10.1093/chromsci/bmu042

Zhao YG, Cai MQ, Chen XH, Pan SD, Yao SS, Jin MC (2013) Analysis of nine food additives in wine by dispersive solid-phase extraction and reversed-phase high performance liquid chromatography. Food Res Int 52:350–358. https://doi.org/10.1016/j.foodres.2013.03.038

Zhuo H, Andrei RT, Bernhard KK, Takeshi H (2006) Determination of cisplatin and its hydrolytic metabolite in human serum by capillary electrophoresis techniques. J Chromatogr A 1106:75–79. https://doi.org/10.1016/j.chroma.2005.09.042

Funding

This work was financially supported by the Natural Science Foundation of Guangxi (Grant No. 2016GXNSFAA 380108) and the High Levels of Innovation Team and Excellence Scholars Program in Colleges of Guangxi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Jun Feng declares that he has no conflict of interest. Jinxia Li declares that she has no conflict of interest. Wenyi Huang declares that he has no conflict of interest. Hao Cheng declares that he has no conflict of interest. Zhiyong Zhang declares that he has no conflict of interest. Lijun Li declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, J., Li, J., Huang, W. et al. Capillary Zone Electrophoresis Determination of Five Trace Food Additives in Beverage Samples Using Counterflow Transient Isotachophoresis. Food Anal. Methods 14, 380–388 (2021). https://doi.org/10.1007/s12161-020-01894-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-020-01894-1