Abstract

A simple, low-cost, and efficient online focusing method that combines a dynamic pH junction and sweeping by capillary electrophoresis with polymer solutions was developed and optimized for the simultaneous determination of benzoic acid (BA) and sorbic acid (SA). A sample solution consisting of 2.5 mM phosphate at pH 3.0 and a buffer solution containing 15 mM tetraborate (pH 9.2), 40 mM sodium dodecyl sulfate, and 0.100 % (w/v) poly(ethylene oxide) were utilized to realize dynamic pH junction–sweeping for BA and SA. Under the optimized conditions, the entire analysis process was completed in 7 min, and a 900-fold sensitivity enhancement was achieved with limits of detection (S/N = 3) as low as 8.2 and 6.1 nM for BA and SA, respectively. The linear ranges were between 20 nM and 20 μM for BA and 20 nM and 10 μM for SA, with correlation coefficients greater than 0.992. The recoveries of the proposed method ranged from 90 to 113 %. These satisfactory results indicate that this method has the potential to be an effective analytical tool for the rapid screening of BA and SA in different food products.

An online focusing strategy combining dynamic pH junction and sweeping for sensitive determination of benzoic and sorbic acid in food products using capillary electrophoresis wit polymer solutions

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Preservatives are typically used during the production and storage of foods to control the growth of undesirable microorganisms, thus maintaining the freshness of food commodities. Benzoic acid (BA), sorbic acid (SA), and their salts are commonly used as chemical preservatives in foodstuffs to inhibit the activity of a wide range of fungi, yeasts, molds, and bacteria [1–6]. However, the excessive addition of BA and SA may be harmful to human health [7–9]. The maximum allowable concentrations of these preservatives in foodstuffs are controlled by legislation. To assess their concentrations in foodstuffs and ensure food safety, it is important to develop convenient, inexpensive, and rapid analytical methods for these preservatives.

To date, several analytical methods for the determination of BA and SA in foodstuffs have been reported, including gas chromatography (GC) [10–12], high-performance liquid chromatography (HPLC) [13–15], and capillary electrophoresis (CE) [16–20]. GC and HPLC are the most powerful techniques for simultaneously detecting BA and SA, but they always require relatively long analysis times, consumption of large quantities of the mobile phase, and sample pretreatment. With its reduced sample and reagent consumption, fast separation speeds, and high separation efficiency, CE is becoming an attractive analytical method. Although CE is beneficial for obtaining high resolution and efficiency, due to the short optical path length for UV detection and low sample injection volumes, poor concentration sensitivity is a major disadvantage. Online preconcentration can be regarded as the most facile way to achieve CE sample enrichment. To date, various online focusing strategies for CE have been developed, such as large-volume sample stacking, field-amplified sample stacking, transient isotachophoresis, dynamic pH junction, and sweeping; all of these methods have been well reviewed [21–24]. Each strategy utilizes a distinct focusing mechanism that involves changing the mobilities of analytes during electrophoresis on the basis of the differences in the electrolyte properties of the sample solution and background electrolytes (BGE).

Dynamic pH junction is based on the creation of a pH discontinuity that is established by injecting the sample at a different pH than the BGE and can be used to concentrate weakly ionic analytes [25]. Sweeping utilizes the interactions between a pseudostationary phase or complexing agent, which is present only in the separation buffer, and the sample in the matrix [26]. The accumulation is based on chromatographic partitioning, complexation, or interactions between the analytes and the additives during the electrophoretic process. Recently, combining dynamic pH junction and sweeping during CE has been reported to lead to further improvements in sensitivity [27–29]. This approach integrates the merits of both dynamic pH junction and sweeping and improves separation selectivity and sensitivity. Thus, the dynamic pH junction–sweeping method can be used to focus both weakly ionic and neutral analytes. Britz-McKibbin et al. [27] first used dynamic pH junction–sweeping CE using laser-induced fluorescence for the determination of flavin derivatives with a picomolar detection limit. A dynamic pH junction–sweeping CE method for the analysis of toxic pyrrolizidine alkaloids in Chinese herbal medicines with a detection limit as low as 30 ppb was also demonstrated by Yu and Li [28]. In addition, Chen et al. [29] used dynamic pH junction–sweeping CE with laser-induced fluorescence for the determination of four dipeptides and achieved detection limits from 1.0 to 5.0 pM.

In this study, a dual dynamic pH junction–sweeping strategy was used for online focusing of BA and SA to improve the detection sensitivity. In addition, critical factors such as the pH and concentration of the sample phosphate solution and BGE, the amount of sodium dodecyl sulfate (SDS), and the use of poly(ethylene oxide) (PEO) in separation buffers were carefully examined to achieve the maximum focusing effect. This method was also tested for the simultaneous determination of nanomolar levels of BA and SA; therefore, it should be applicable for the direct analysis of common food samples using CE after only simple dilution.

Experimental

Chemicals and reagents

BA, PEO (M v = 8.0 × 106 g mol−1), SA, and SDS were purchased from Sigma-Aldrich (St. Louis, MO, USA). Sodium tetraborate was purchased from Acros Organics (Geel, Belgium). Sodium dihydrogen phosphate, disodium hydrogen phosphate, and sodium hydroxide were purchased from Riedel-de Haën (Seelze-Hannover, Germany). Phosphoric acid was purchased from J.T. Baker (Phillipsburg, NJ, USA). The standards were individually dissolved in deionized water at a stock concentration of 10 mM and stored in the dark at 4 °C. Various phosphate solutions were prepared daily, and stock sample standards were diluted to the desired concentration with the phosphate solution and used for different experiments. Deionized water was collected from a Barnstead Nanopure Ultrafiltration unit (Boston, MA, USA). PEO (0.0250–0.0625 g) was gradually added to each of the prepared tetraborate buffer solutions (50 mL). During the addition of PEO, the mixture was continuously stirred using a magnetic stirring rod to produce a homogeneous suspension. After the addition was completed, the solutions were stirred for at least 8 h. Prior to use for CE separation, the solutions were degassed with a vacuum system in an ultrasonic tank.

Apparatus

All experiments were performed using a laboratory-made CE unit similar to a previously described system [30] consisting of a 20-kV high-voltage power supply (ES20P-20W/DAM; Gamma High Voltage Research Inc., Ormond Beach, FL, USA) and a UV–Vis detector (SAPPHIRE 600 detector; ECOM, Prague, Czech Republic). Electropherograms were recorded and processed using DataApex Software (DataApex, Prague, Czech Republic). A fused-silica capillary with a 75-μm ID and 365-μm OD was purchased from Polymicro Technologies (Phoenix, AZ, USA). The total and effective lengths of each capillary were 50 and 40 cm, respectively. All measurements were repeated five times.

Electrophoretic conditions

New separation capillaries were conditioned before use by rinsing with 0.5 M NaOH for 30 min followed by deionized water for 1 min. The capillary was equilibrated with the separation buffer for 3 min before each run and rinsed with 0.5 M NaOH for 10 min followed by the separation buffer for 3 min after each run. Pre- and post-run conditioning steps were important for achieving a reproducible electro-osmotic flow (EOF). Samples were hydrodynamically injected for 150–360 s (approx. 343–824 nL) with a 20-cm height difference between the capillary inlet and outlet. The detection wavelength was set at 230 nm and the applied voltage was 15 kV. The capillary was filled with 15 mM tetraborate buffer (pH 9.2) containing 40 mM SDS; the same solution containing 0.100 % (w/v) PEO was used as the separation buffer. The shift of the baseline due to the absorbance difference between the sample solution and PEO solution was used to estimate the EOF mobility [31].

Real sample pretreatment

Food products including a juice, two soft drinks, two soy sauces, and a wine sample were purchased from local supermarkets (Taitung, Taiwan). Samples were prepared by dilution to a suitable volume ratio (400-fold for the juice, 1,000-fold for the soft drinks, 2,000-fold for the soy sauces, and 100-fold for the wine) before analysis and containing 2.5 mM phosphate at pH 3.0. The analytical recoveries were evaluated by spiking the real sample with a standard solution.

Results and discussion

Dynamic pH junction–sweeping for BA and SA with polymer solutions

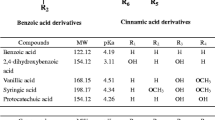

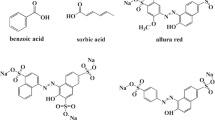

An online concentration technique combining sweeping and the use of polymer solutions was developed previously [32, 33]. In this study, dynamic pH junction, sweeping, and the use of polymer solutions were integrated for the online focusing of BA and SA. Figure 1 shows the focusing mechanism. The capillary is filled with BGE (tetraborate, pH 9.2) containing 40 mM SDS, and a long sample plug prepared in an acidic sample solution (phosphate, pH 2.5) is hydrodynamically injected into the capillary (Fig. 1A). BA and SA with pK a values of 4.20 and 4.76, respectively [34], are fully dissociated at pH 9.2 and neutral at pH 2.5. This behavior leads to BA and SA having mobilities close to zero at pH 2.5 and higher mobilities toward the anode at pH 9.2. Upon application of the separation voltage, the hydroxide ions (OH−) in BGE (pH 9.2, above the pK a values of BA and SA) migrate with rapid mobility into the sample zone, leading to an abrupt local pH increase at the front edge of the sample zone (Fig. 1B). Neutral BA and SA originally in the leading edge are suddenly dissociated and stopped when returned to the sample zone (phosphate, pH 2.5). As a result, the mobilities of BA and SA in the front edge experience a dramatic drop and become stacked. In the meantime, SDS micelles migrating from the BGE interact with BA and SA and thus sweep them into the sample zone (Fig. 1C). When aggregates of BA and SA with the SDS micelles migrate into the BGE with PEO, they get stacked again owing to an increase in the viscosity. Because the mobility of the EOF is larger than those of BA and SA (counter to the EOF), they still migrate toward the detector. Consequently, the injected large sample plug is concentrated into a sharp zone, and subsequently, the separation of BA and SA proceeds according to the normal micellar electrokinetic chromatography (MEKC) mode (Fig. 1D).

Schematic diagram of the online focusing of BA and SA by CE with a dynamic pH junction–sweeping strategy and the use of polymer solutions. A The capillary is conditioned with BGE and a large-volume sample plug is injected hydrodynamically. B Dynamic pH junction–sweeping is initiated. C Dynamic pH junction–sweeping is completed. D The analytes are separated according to the normal MEKC mode

Optimization of the online focusing conditions

Effect of the sample phosphate concentration

The enhancement factor (EF) for dynamic pH junction–sweeping was influenced by several factors, such as the pH and concentration of the sample phosphate solution and BGE and the concentration of SDS. The pH value influences the dissociation of BA and SA. Thus, the effect of the pH of the sample phosphate solution was investigated using 2.5 mM phosphate in the pH range from 2.0 to 6.0. As shown in Table 1, when the pH of the sample solution was 2.0, 5.0, and 6.0, the SA was not focused very well (peak widths were 0.07, 0.06, and 0.07, respectively). As the pH decreased from 4.0 to 3.0, the focusing effect was gradually improved and the absorbance signals were also found to be correspondingly enhanced (peak height increased from 2.05 to 2.17). BA always exhibits sharp peaks for the investigated pH range, but the absorbance signal gradually decreased as the pH increased. Thus, the optimum pH of the sample solution was determined to be 3.0. Because BA and SA were prepared in the sample solution, the effect of the phosphate concentration was also investigated over the concentration range from 0 to 3.0 mM. It was found that the phosphate concentration had a minimal effect on the focusing of SA, and the peak heights were only slightly increased as the concentrations varied from 0 to 2.5 mM. On the contrary, the focusing effect for BA was significantly influenced by the phosphate concentration. Therefore, a phosphate concentration of 2.5 mM was considered as the best concentration of sample solution.

Effect of the tetraborate and SDS concentrations

The effect of the tetraborate concentration was studied in solutions containing 5–25 mM tetraborate at pH 9.2 and containing 40 mM SDS and 0.100 % PEO (Fig. 2A). The highest peak height and narrowest peak width for SA were observed at a tetraborate concentration of 15 mM. As a result, the optimum concentration for tetraborate (pH 9.2) was determined to be 15 mM. The concentration of SDS is another important online focusing parameter. Without SDS in the buffer solution, the peak widths of BA and SA were broadened (0.11 and 0.09 min, respectively). It is well known that the SDS concentration is related to the pseudo-retention factors of the analytes because each one has a different hydrophobicity. The logK ow values for BA and SA are 1.87 and 1.33, respectively [34]. Thus, the migration order corresponds with the polarity of the analytes. Because the mobilities of the SDS micelles are less than that of the EOF, the analytes can be detected. Without adding SDS in the buffer solution, BA and SA can be separated, but the peak width was broad. Thus, the effect of SDS concentration was investigated over the concentration range from 20 to 60 mM, as shown in Fig. 2B. When the SDS concentration was increased from 20 to 60 mM, the migration time of EOF decreased from 6.29 to 4.64 min, mainly due to a decrease in the adsorption of the PEO molecules on the capillary wall. When compared to 0 mM SDS, a SDS concentration of 40 mM was chosen as the optimum concentration on the basis of the peak heights and widths observed for BA and SA.

A Effect of tetraborate concentration on the height and efficiency of BA and SA peaks at 230-nm absorbance. B Effect of SDS concentrations on the EOF, migration time, and peak widths of BA and SA. The sample (1.0 μM, prepared in 2.5 mM phosphate at pH 3.0) was hydrodynamically injected for 270 s. A 50-cm capillary (40-cm effective length) was filled with 15 mM tetraborate buffer (pH 9.2) containing 40 mM SDS prior to sample injection. A 0.100 % PEO solution was prepared in 5–25 mM tetraborate buffers (pH 9.2) containing 40 mM SDS (A) and 15 mM tetraborate buffer (pH 9.2) containing 20–60 mM SDS (B). The separation was conducted at 15 kV. Circles, BA; squares, SA; diamonds, EOF

Effect of the concentration of PEO

In previous studies, the separation efficiency and resolution were improved as a result of reduced analyte adsorption on the capillary wall when using a PEO solution at a concentration greater than 0.6 % [31]. The EOF was inhibited owing to an increase in the viscosity of the separation buffer containing PEO; a delayed migration time was also observed for each analyte. The effect of the PEO concentration in the range from 0 to 0.125 % in 15 mM tetraborate buffer (pH 9.2) containing 40 mM SDS was thus investigated (Fig. 3). In the absence or at lower concentrations of PEO (<0.05 %), the peaks were either broad or not well resolved. Upon increasing the PEO concentration (0.05–0.125 %), however, the separation efficiency and resolution for both BA and SA increased. The electropherograms depicted in Fig. 3A–E clearly demonstrate the role that PEO plays in determining the resolution and stacking efficiency. At 0.125 % PEO, the analysis time was slower than at a concentration of 0.100 %. Thus, a 0.100 % PEO solution was chosen for subsequent experiments. On the basis of all of the aforementioned experimental results, the optimum online focusing conditions were determined to be as follows: a solution containing 15 mM tetraborate buffer (pH 9.2) and 40 mM SDS was used to fill the capillary, BA and SA were prepared in 2.5 mM phosphate (pH 3.0) solution, and a 0.100 % PEO solution in 15 mM tetraborate buffer (pH 9.2) containing 40 mM SDS was used as the separation buffer. The separation current was 60 μA under these conditions.

Effect of PEO concentration on the online focusing of BA and SA. PEO solutions of 0 % (A), 0.050 % (B), 0.075 % (C), 0.100 % (D), and 0.125 % (E) were prepared in 15 mM tetraborate buffer (pH 9.2) containing 40 mM SDS. Other conditions were the same as those in Fig. 2

Performance of the online focusing method

Table 2 lists the linear ranges, correlation coefficients, and limits of detection (LODs) and quantification (LOQs) of the method under optimal conditions. The LODs and LOQs were calculated for S/N = 3 and S/N = 10, respectively. The EFs were calculated as the ratio of the LODs obtained using the stacking method (360 s) to those obtained by normal injection (10 s) without polymers in separation solutions. The calculated results indicate that the stacking method enhanced the analyte detection sensitivity by approximately 930-fold (BA) and 920-fold (SA) compared to the normal MEKC mode. In addition, the LODs of BA and SA were reduced to 8.2 and 6.1 nM, respectively, using the stacking method. The performance of the proposed method was also compared with that of recent online focusing methods for BA and SA (Table 3) and was found to be generally superior with respect to the LOD, analysis time, and EF.

Applications

To demonstrate the applicability of the proposed method, six commercially available food products were analyzed (Fig. 4). The concentrations and recoveries of BA and SA are shown in Table 4 and are found to be satisfactory. According to the analytical results, it can be concluded, in all food products examined, that the actual levels of BA and SA found are significantly lower than the maximum authorized levels. The matrix effect of a real sample was investigated by calculating the LODs and LOQs of BA and SA spiked in the wine sample (60 s injection). The LODs for BA and SA were 47.9 and 38.0 nM, respectively; the LOQs were 159.2 and 126.7, respectively. When compared to the aqueous sample solution, the LODs and LOQs of BA and SA were similar, indicating that no matrix effect was observed. The analytical performance of the method, particularly the short analysis time, low cost, and simple sample pretreatment, verifies its potential applicability for the routine analysis of BA and SA in the quality control of food samples.

Electropherograms of BA and SA in food products: standard (2.0 μM BA and SA) (A), juice (B), soft drink 1 (C), soft drink 2 (D), soy sauce 1 (E), soy sauce 2 (F), and wine (G). Unidentified peak was marked as *. Samples were hydrodynamically injected for 60 s. Other conditions were the same as those in Fig. 3D

Conclusions

A dynamic pH junction–sweeping focusing method was successfully demonstrated to be effective for the determination of BA and SA in food samples using CE with polymer solutions. BA and SA present in food products such as juice, soft drinks, soy sauces, and wine can be rapidly analyzed after simple dilution. In this method, dynamic pH junction plays a more important role in focusing the BA and SA than sweeping. In addition, it was found that the pH and concentration of phosphate solution and the concentration of tetraborate, SDS, and PEO were critical for achieving greater sensitivity enhancement, a shorter analysis time, and better resolution. Sensitivity enhancements of 930-fold for BA and 920-fold for SA were achieved, and the LODs were reduced to 8.2 and 6.1 nM for BA and SA, respectively. Finally, the use of the proposed method for the analysis of BA and SA in real food samples provided satisfactory recoveries and reproducibility.

References

Han P, Jia Z, Liu M, Li Y, Liu H, Yang H, Wang X, Ban F, Zhang S (2007) Electrophoresis 28:4114–4119

Farahani H, Ganjali MR, Dinarvand R, Norouzi P (2009) J Agric Food Chem 57:2633–2639

Lino CM, Pena A (2010) Food Chem 121:503–508

Jangbai W, Wongwilai W, Grudpan K, Lapanantnoppakhun S (2012) Food Anal Methods 5:631–636

Alizadeh N, Saburi N, Hosseini SE (2012) Food Control 28:315–320

Berger TA, Berger BK (2013) Chromatographia 76:393–399

Zengin N, Yüzbaşıoğlu D, Ünal F, Yılmaz S, Aksoy H (2011) Food Chem Toxicol 49:763–769

Park H-W, Park EH, Yun H-M, Rhim H (2011) J Food Biochem 35:1034–1046

Mamur S, Yüzbaşıoğlu D, Ünal F, Aksoy H (2012) Cytotechnology 64:553–562

Jurado-Sánchez B, Ballesteros E, Gallego M (2011) Talanta 84:924–930

Kokya TA, Farhadi K, Kalhori AA (2012) Food Anal Methods 5:351–358

Sun Y, Wang X, Huang Y, Pan Z, Wang L (2013) J Sep Sci 36:2268–2276

Mahboubifar M, Sobhani Z, Dehghanzadeh G, Javidnia K (2011) Food Anal Methods 4:150–154

Can NO, Arli G, Lafci Y (2011) J Sep Sci 34:2214–2222

Kamankesh M, Mohammadi A, Tehrani ZM, Ferdowsi R, Hosseini H (2013) Talanta 109:46–51

Han F, He Y-Z, Li L, Fu G-N, Xie H-Y, Gan W-E (2008) Anal Chim Acta 618:79–85

Costa ACO, da Silva PL, Tavares MFM, Micke GA (2008) J Chromatogr A 1204:123–127

Ling DS, Xie H-Y, He Y-Z, Gan W-E, Gao Y (2010) J Chromatogr A 1217:7807–7811

Wang P, Ding X, Li Y, Yang Y (2012) J AOAC Int 95:1069–1073

Xue Y, Chen N, Luo C, Wang X, Sun C (2013) Anal Methods 5:2391–2397

Chen Y, Lü W, Chen X, Teng M (2012) Cent Eur J Chem 10:611–638

Šlampová A, Malá Z, Pantůčková P, Gebauer P, Boček P (2013) Electrophoresis 34:3–18

Breadmore MC, Shallan AI, Rabanes HR, Gstoettenmayr D, Keyon A, Gaspar ASA, Dawod M, Quirino JP (2013) Electrophoresis 34:29–54

Chiu T-C (2013) Anal Bioanal Chem 405:7910–7930

Kazarian AA, Hilder EF, Breadmore MC (2011) J Sep Sci 34:2800–2821

El Deeb S, Iriban MA, Gust R (2011) Electrophoresis 32:166–183

Britz-McKibbin P, Otsuka K, Terabe S (2002) Anal Chem 74:3736–3743

Yu L, Li SFY (2005) Electrophoresis 26:4360–4367

Chen Y, Zhang L, Cai Z, Chen G (2011) Analyst 136:1852–1858

Hsu C-H, Hu C-C, Chiu T-C (2012) J Sep Sci 35:1359–1364

Chiu T-C, Chang H-T (2007) J Chromatogr A 1146:118–124

Kao Y-Y, Liu K-T, Huang M-F, Chiu T-C, Chang H-T (2010) J Chromatogr A 1217:582–587

Wu C-W, Lee J-Y, Hu C-C, Chiu T-C (2013) J Chin Chem Soc (in press)

NIH. http://sis.nlm.nih.gov/chemical.html. Accessed 13 Nov 2013

Horáková J, Petr J, Maier V, Znaleziona J, Staňová A, Marák J, Kaniansky D, Šervčík J (2007) J Chromatogr A 1155:193–198

Zhang X, Xu S, Sun Y, Wang Y, Wang C (2011) Chromatographia 73:1217–1221

Wei R, Li W, Yang L, Jiang Y, Xie T (2011) Talanta 83:1487–1490

Acknowledgments

This study was supported by the National Science Council of Taiwan under contract no. NSC 102-2113-M-143-001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, SH., Hu, CC. & Chiu, TC. Online dynamic pH junction–sweeping for the determination of benzoic and sorbic acids in food products by capillary electrophoresis. Anal Bioanal Chem 406, 635–641 (2014). https://doi.org/10.1007/s00216-013-7481-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-7481-1