Abstract

The study evaluates the effect of pulse milling pre-treatments such as moisture conditioning and mechanical scouring on the compositional (moisture, protein, ash), functional (water-holding capacity), and physical (L*a*b* color, particle size distribution) properties of pulse flours. Two different types of pulses of pure cultivars, lentil (Lens culinaris) and chickpea (Cicer arietinum), were milled into flour using a laboratory-scale roller mill. Prior to milling, pulse seeds were subjected to two types of seed pre-treatments—(1) moisture conditioning (0%, 0.5%, or 1% w/w) and (2) mechanical scouring. The green lentils and chickpeas showed distinctive differences in all of the studied properties with pre-treatments. Moisture contents were higher in the scoured green lentil flours, while in the scoured chickpea flours were often lower within moisture conditioning levels. For many of the scoured flours, protein content was lower compared to the unscoured flours within moisture conditioning levels. Scouring was associated with higher L*a*b* color in the green lentil flours; however, for the chickpea flours, L*a*b* were less influenced by scouring. Green lentil middling and straight grade (SG) flours were more refined with scouring. Ash content and water-holding capacity values were not significantly different between the pre-treatment conditions for both pulse types. Differences in flour property results between pre-treatment conditions were significantly different (P < 0.05) in the SG flours. These research findings could serve as a basis for the optimization and design of flour milling operations suitable for dry legumes and thereby improve the application of these high protein pulse flours in processed end-products to satisfy the desire for greater diversity in the food product market.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pulses are the dry seeds harvested from the pods of legume (Leguminosae) plants which are a common food source around the world. Commonly produced pulses include lentils (Lens culinaris), chickpeas (Cicer arietinum), dry peas (Pisum sativum), and dry beans (Phaseolus vulgaris). There have been significant increases in pulse crop production since the 1980s (Bekkering, 2014). Pulse production is widespread throughout the world (Siddiq & Uebersax, 2013). Most pulses produced in North America are exported to countries where they are processed for consumption as a staple food source or utilized in food processing (Asif et al., 2013; Bekkering, 2014). In recent years, good health and nutrition has been a high priority for consumers, resulting in increased demand for nutritionally balanced plant-based foods in the diet (Siddiq & Uebersax, 2013), and is compatible with the dietary contribution pulses provided. Pulses are a highly nutritious food source, rich in plant-based protein, carbohydrates, dietary fiber, vitamins, and minerals. Pulses are low in fat and the absence of gluten makes them suitable for consumers allergic/sensitive to foods that contain it (e.g., wheat, rye, barley). Regular consumption of pulses is associated with improved human health (Anderson & Major, 2002; Becerra-Tomás et al., 2017; Venn et al., 2010).

For household consumption, pulses are commonly available in whole, split, canned, and flour form, among which the canned and flours are gaining more popularity as ready-to-use ingredients for many recipes and processed products. Grinding whole pulses into flour greatly reduces their size and increases surface area, producing a pulse ingredient which can be used in flour-based food applications such as baked goods (breads, cookies, cakes), pastas, and noodles. Studies have found that the inclusion of pulse ingredients in wheat-based food products enhances nutritional content and lowers the glycemic index, often without negatively influencing the sensory qualities (Fujiwara et al., 2017; Marinangeli et al., 2009; Ringuette et al., 2018; Rizzello et al., 2014). This demonstrates that there is potential for producing good quality nutrient-rich food products that are high in plant-based protein, making pulse flours an excellent ingredient of choice for gluten-free products (Di-Cairano et al., 2021; Gularte et al., 2012). Pulse seed dehulling (removal of the outer seed coat) and splitting (cleavage of the cotyledon) are pulse milling processes that have been widely studied for many years. Effects (e.g., seed properties, pre-treatments, genotype, and location) of dehulling and splitting efficiency have been investigated (Black et al., 1998; Brar et al., 2021; Chidananda et al., 2014; Erskine et al., 1991a; Erskine et al., 1991b; Goyal et al., 2009; Jerish Joyner & Yadav, 2015; Phirke, et al., 1995; Reichert et al., 1984; Sunil et al., 2018; Wang, 2008). Pulse milling studies have also largely focused on dry fractionation, the process of grinding pulse seeds into flour, followed by separation and isolation of protein and starch fractions by air classification (Pelgrom et al., 2015; Wood & Malcolmson, 2011). Milling of whole seed pulse flours on the other hand has been studied less extensively. Limited research and understanding about pulse flour milling as compared to cereals hinders the development of benchmarking standards for pulse flour quality.

Wheat flour production at the commercial level is commonly performed using roller mills (Fang et al., 1997; Sakhare et al., 2015), primarily because of the versatility of roller milling (Pagani et al., 2020) than other flour milling methods. Roller mills are designed to gradually reduce the particle size of the material through a series of grinding stages, producing multiple flour streams. Each roller-milled flour stream tends to vary in quality (e.g., moisture, protein, starch damage) (Sakhare et al., 2014). Unlike with single-stream flour mills (e.g., hammer mill, pin mill, stone mill) where only one type of flour is produced, roller-milled flour streams can be combined in various proportions to create flours with desirable quality levels. Within the roller milling process, large portions of the outer seed coat are removed during milling and collected separately from the flour streams, enabling the production of more refined flours. If a less refined, whole-meal flour is desired, the hull may be milled and later incorporated with the roller-milled flour streams. As was discussed in Cappelli et al. (2020), roller milling is widely adopted for grain milling because of its greater efficiency and flexibility (Doblado-Maldonado et al., 2012; Posner & Hibbs, 2005) in final product particle size; lower heat generation during milling which limits the degradation of chemical components (Prabhasankar & Rao, 2001); and better dough rheology and baking performance (Kihlberg et al., 2004). But this common milling method and different pre-treatments of milling are yet to be explored extensively for pulse milling. Unlike with cereal grains, the hull and cotyledon layers of pulses strongly adhere to each other with a strong bond which is the result of the presence of gums, pectin, lignin, etc. (Vishwakarma et al., 2018). These characteristics make milling of pulses or legumes different than that of the starchy cereal grains. Therefore, the aim of the present study is to examine the effects of seed moisture conditioning and mechanical seed scouring on the compositional, functional, and physical properties of whole green lentil and chickpea flours milled using a roller mill.

Materials and Methods

Pulse Samples

Whole green lentil (CDC Greeenstar) and chickpea (CDC Orion) were obtained from the 2018 harvest season grown in Limerick, Saskatchewan, Canada. Pulses were stored at ambient temperature (22 ± 2 °C) until use.

Pulse Seed Pre-Treatments and Experimental Design

Prior to applying seed pre-treatments, initial whole seed moisture content was determined using a Perten Inframatic 9500 near infrared grain analyzer (Perten Instruments NA, Inc., Springfield, IL). Prior to milling, the whole green lentil and chickpea seeds were treated with one of the two pre-treatments each with three levels as shown in Tables 1 and 2 (a combination of seed moisture conditioning and mechanical seed scouring) as discussed in detail in the following sections. A full factorial experimental design with two seed pre-treatments (independent variables), viz. (i) seed moisture conditioning with 3 levels (0% (no MC), 0.5%, and 1% w/w) (Table 2); and (ii) mechanical seed scouring with 2 levels (unscoured and scoured) (Table 1) for green lentils and chickpeas, was used in the study. In total, there were six (3 × 2) combinations of seed pre-treatments (Tables 1 and 2) and each of the combination pre-treatment and its respective milling trials were done in duplicates for each pulse type. The dependent variables (compositional, functional, and physical properties) were measured in duplicates for the two milling trials to yield 4 data replicates for each flour property measured for each pulse type and each combination of seed pre-treatment. The final dataset was carefully checked for outliers to ensure no experimental or human errors were present.

Moisture Conditioning

Three moisture conditioning (MC) levels chosen for the study were 0% (no MC), 0.5%, and 1% w/w. Initial seed moisture contents of the whole green lentil and chickpea seeds were determined using the Perten Inframatic grain analyzer. The amount of water to be added to the sample to obtain the desired seed MC level was calculated using the following formula:

where:

M1 = mass (g) of pulse sample;

M2 = mass (g) of water required for moisture tempering;

m1 = initial moisture content (%) of whole pulse seeds;

m2 = desired moisture content (%) after moisture tempering.

The calculated mass of water (M2) (water at room temperature) was added to the sample in a clear plastic bag, and manually shaken continuously until excess water was no longer visible. The bag of moistened whole pulse seeds was left to rest for 20 min for equilibration before application of mechanical seed scouring (if applicable) and roller milling. The moisture conditioning procedure was performed by the same technician for all pulse samples to ensure consistency in MC to avoid any subjective errors.

Mechanical Seed Scouring

The whole pulse seeds were mechanically scoured with a Buhler MHXA 50/70 (Buhler, Uzwil, Switzerland), a spring-loaded vertical scourer that operated at 620 rpm. The screen size openings were 5 mm and made of wire mesh material. The clearance size between the screen and beater was set to 15–20 mm to ensure optimal seed scouring with minimal breakage of the cotyledons.

Pre-Break

All pulses were pre-broken using the first break (B1) rolls of a Buhler MDDM 1000/250 pilot roller mill (Buhler, Uzwil, Switzerland) operating at 350 rpm, with a roll speed ratio of 2.5:1 (fast:slow).

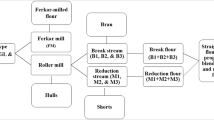

Flour Milling

Pre-broken pulses were milled using a Buhler MLU 202 laboratory mill (Buhler Group, Uzwil, Switzerland) operating at 1400 rpm at 5 kg/h feed rate. Break roll clearances were 0.1 mm for B1 and 0.01 mm for B2 and B3. Reduction roll clearances were set to 0.01 mm for 1M, 2M, and 3M. Screen sizes for the upper and lower levels of B1, B2, and B3 were 475 μm/132 μm, 475 μm/132 μm, and 375 μm/132 μm, respectively. All the screen sizes for the upper and lower levels of 1M, 2M, and 3M were 150 μm. Three break flour fractions (B1, B2, B3), three reduction (also known as middling) flour fractions (1M, 2M, 3M), and the milling by-products (bran and shorts) were produced for each milling trial of the roller mill. The milling by-products were not used or analyzed in this study. Duplicate millings trails were done for each pulse type and pre-treatment condition.

Preparation of Flour Blends for Analysis

Flour blends (break, middling, straight grade) were made of representative proportions of the milled flour fractions (B1, B2, B3, 1M, 2M, 3M), proportional to the total yield of the milled flour product. Break flour samples were a blend of B1, B2, and B3 (referred to as B1 + B2 + B3) for both green lentil and chickpea. Middling flour samples for green lentil were a blend of 1M, 2M, and 3M (referred to as 1M + 2M + 3M) (Tables 1 and 2). For chickpea, there were two types of middling flours—1M only flour stream (referred to as 1M) and a blend of 2M and 3M flour streams (referred to as 2M + 3M) (Tables 1 and 2). Straight grade (SG) flours for both roller-milled green lentil and chickpea were made from a representative blend of B1, B2, B3, 1M, 2M, and 3M flour streams. Break, middling, and SG flour blends were prepared by placing proportional amounts of break and middling flour fractions into a plastic storage bag, twisting the bag closed leaving enough headspace in the bag for adequate blending, and manually shaking the bag for 2 min. Flour blends were then sealed with a twist tie and stored at room temperature.

Pulse Flour Analysis

Compositional Properties

Determination of Moisture Content

Moisture content was measured in duplicate using AACC International Method 44–15.02 (one-stage air-oven method) (AACCI, 1999c) for each pulse type for each pre-treatment condition (Tables 1 and 2). Average moisture content of each flour blend was calculated from a total of four moisture content values (two measurement trials each for the two milling replicates).

Determination of Protein Content

Nitrogen (N) content of the pulse flours was determined in duplicate by the Dumas (nitrogen combustion) method using a LECO FP-628 nitrogen/protein analyzer (LECO Corp., St. Joseph, MI) according to the AACC International Method 46–30.01 (AACCI, 1999d) for each milling replicate and pre-treatment condition (Tables 1 and 2). A nitrogen-to-protein conversion factor of 6.25 was used to calculate crude protein content of the pulse flours (% crude protein = % N \(\times\) 6.25). Crude protein was calculated on a dry weight basis. The four crude protein content values (two measurement trials each for the two milling replicates) for each flour blend were used to calculate average crude protein content.

Determination of Ash Content

Total ash content of the pulse flours was also determined in duplicates for each milling replicates using AACC Approved Method 08–01.01 (AACCI, 1999a). Pulse flours were weighed into crucible dishes dried for 1 h in a Fisher Scientific Isotemp 550–58 muffle furnace (Fisher Scientific Co., Pittsburgh, PA) at 600 °C, and then placed into a desiccator to cool before adding the flour sample. Pulse flour samples were incinerated in the muffle furnace at 600 °C, for a minimum of 16 h. Total ash content was calculated on a dry weight basis. The duplicate ash content values each for the two milling replicates were used to calculate average ash content.

Functional Properties

Determination of Water-Holding Capacity

Water-holding capacity (WHC) of the pulse flours was determined in duplicate for each milling replicate using AACC Approved Method 56–37.01 (AACCI, 2017). One modification made from the standardized method was the use of a 50.8 \(\times\) 101.6-mm piece of filter cloth instead of a 50.8 \(\times\) 50.8-mm piece. Average WHC was calculated from the four WHC values (two measurement trials each for the two milling replicates).

Physical Properties

Flour Color Measurement

Flour color was measured in duplicate using a Minolta CR-410 chroma meter with CR-A501 cell holder attachment and two CR-A502 glass cells (Konica Minolta Inc., Osaka, Japan). The chroma meter was set to D65 (wavelength of light that simulates normal daylight) with 2° standard observer angle and calibrated using a white ceramic calibration tile (L* = 93.97, a* = \(-\) 0.60, b* = 3.95). The CIELAB color parameters measured were L* (degree of darkness (0)/lightness (1)); a* (degree of greenness (\(-\))/redness (\(+\))); and b* (degree of blueness (\(-\))/yellowness ( +)). Flour color measurement method with respect to volume of water added and mixing and waiting times were performed according to AACC International Method 14–30.01 (AACCI, 1999b). For each duplicate, uniform flour slurries were prepared using 15 g samples of pulse flour corrected on a dry moisture basis (i.e., 0% moisture content). Following the 5-min resting time, two replicate color measurements were taken, one consecutively after the other. Average L*a*b* was calculated from four replicate color measurements (two measurement trials each for the two milling replicates) for each pulse flour sample analyzed.

Determination of Particle Size Distribution

Particle size was determined with laser diffraction spectroscopy using a Malvern Mastersizer 2000 optical bench instrument (Malvern Instruments, Malvern, UK) and Scirocco 2000 dry powder dispersion unit (Malvern Instruments, Malvern, UK). Air pressure of the compressed air tank was between 80 and 100 psi and feed rate was adjusted to 40%, 50%, or 60%, to ensure the fed flour samples would successfully pass through the optical bench instrument for measurement and ensure the obscuration range was less than 5%.

A fine sieve basket with 0.8 mm mesh size was filled with eight stainless steel ball bearings and placed in the sample cone of the Scirocco 2000 dry powder feeder. The macro sample tray attachment was used for all pulse samples analyzed. For each particle size determination, approximately 2 g of well-mixed pulse flour sample was added using a lab spatula (without packing) to the securely fastened macro sample tray. The sample cone, sieve basket with ball bearings, and sample tray were cleaned between measurements using a ½ inch wide paint brush and compressed air duster. Particle size distribution was presented as three percentiles of a distribution curve (d), where d(0.1), d(0.5), and d(0.9) represent the flour particles in μm at the 10th, 50th, and 90th percentile, respectively. Volume weighted mean (μm), span, and uniformity were additional parameters that were measured and evaluated. All pulse flours were analyzed using four replicates (two measurement trials each for the two milling replicates).

Statistical Analysis

Statistical analysis was performed using SAS, Version 9.4 (SAS Institute Inc., Cary, NC). The data was analyzed using one-way analysis of variance (Welch ANOVA) to test the differences between the different pre-treatments within break, middling, and SG flours; mean differences were calculated at the 5% significance level (P < 0.05) using the Tukey HSD test. Significant effects of the pre-treatments were analyzed within break, middling, and SG flours of the appropriate pre-treatment conditions using Welch ANOVA (see Tables 1 and 2). Welch ANOVA statistical test procedure was selected for this study because it is appropriate for data with non-normal distributions and heterogeneous variances, while still having both very good control of type I error and statistical power (Jan & Shieh, 2014).

Results and Discussion

Flour Yield

Green lentils and chickpeas subjected to scouring had lower flour yields compared to their unscoured counterparts (Fig. 1). These are similar observations to a roller milling study on pearled barley flour, where lower flour yields were observed in the pearled barley flours compared to the unpearled barley flours (Izydorczyk et al., 2011). Conversely, higher flour yield was observed in roller-milled wheat cultivars subjected to scouring using a commercial scourer by Nagi and Bains (1983). However, the amount of difference in flour extraction between the scoured and control flours in that study varied between wheat cultivars.

Effects of Pre-Treatments

The results of compositional properties of green lentils and chickpeas with different levels of pre-treatments are given in Tables 3 and 4. MC had a significant effect (P < 0.05) on all the compositional properties (ash, protein, moisture) for the green lentil break flours that were not subjected to scouring (Table 5). When subjected to scouring, the protein content of the green lentil break and SG flours showed significant pre-treatment effects (P < 0.05) with MC (Table 5). Most of the green lentil flour fractions (mainly middling and SG) were significantly affected (P < 0.05) by the scouring pre-treatment at the three MC levels. Scouring is a processing step in flour milling that is performed to loosen and remove the dirt and hulls that are adhered on the outer surface of grains through abrasive action, which results in friction of the seed material when they make contact with each other or with the mesh screen (Kent & Evers, 1994; Willard & Swanson, 1911). The scoured particles that pass through the mesh screen are considered to be a dust fraction and get discarded at the end of the scouring process (Kent & Evers, 1994). The discarded dust fraction of the scoured green lentils in the present study was most likely comprised of a small proportion of protein, a factor that can explain the slightly lower protein contents in the scoured green lentil flours in comparison to the green lentil flours that did not undergo scouring. A similar trend was reported in a spelt pearling study, where pearled spelt grain that was associated with higher yields of pearling fines (similar product to the dust fraction produced in the scouring process) during a pearling cycle and had lower protein contents (Winterová et al., 2016).

In the chickpea break flours, significant MC effects (P < 0.05) were found for the majority of the compositional (Table 4), physical (Tables 6 and 7), and functional properties (Fig. 2) irrespective of scouring level (i.e., unscoured and scoured). Lower protein contents with scouring were observed in the chickpea flours (Table 4), only less consistently than the green lentil flours (Table 3). However, for both green lentil and chickpea flours, the differences in protein content between pre-treatments and their levels were infrequently significantly different. Ash contents of the green lentil and chickpea flours within flour blends were similar to one another (Tables 3 and 4). This is consistent with the ash content results reported for control and scoured roller-milled wheat flours in Nagi and Bains (1983).

MC had a significant effect (P < 0.05) on the WHC of the unscoured green lentil SG flours (Fig. 2). Significant effects (P < 0.05) of scouring on WHC of the green lentil SG flours were also observed at 0% MC (Fig. 2). The unscoured green lentil SG flours that were subjected to 0% MC had the highest mean WHC (0.75 ± 0.01 g/g) and was also significantly different (P < 0.05) than all other pre-treated green lentil SG flours, except for the 0.5% MC/unscoured condition (Fig. 2).

MC had a significant effect (P < 0.05) on the WHC of the scoured chickpea SG flours and, like the green lentil SG flours, was significantly affected (P < 0.05) by scouring at 0% MC level only (Fig. 2). WHC of the chickpea SG flours were also very similar between the pre-treatment conditions, with values ranging from 0.65 to 0.71 g/g (Fig. 2). The differences in WHC observed in the green lentil and chickpea SG flours may be too small to have any practical or observable effect in food processing applications.

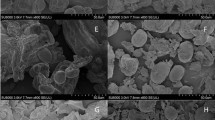

L*a*b* color values of the green lentil flours showed the most significant differences with scouring, irrespective of the MC levels for all three flour fractions. In most instances, higher L*a*b* color values were observed in the scoured green lentil flours compared to the unscoured green lentil flours (Table 8). Similarly, Izydorczyk et al. (2011) reported greater flour brightness (L* color) in pearled barley flours compared to unpearled barley flours produced at different grinding settings of a roller mill. Scouring in the present study may have aided in better removal of the outer seed coat layer which is darker in color than the cotyledon portion of green lentil seeds. It is uncertain if these differences in L*a*b* color values between the unscoured and scoured green lentil flours observed would be evident if these flours were used in end-products such as noodles, pasta, and bread. Therefore, food processing application studies utilizing green lentils pre-treated with MC and scouring used in the present study should be performed. Higher rates of pearling of roller-milled barley flours that are associated with increasing L* color were reported by Zhao et al. (2020). In that study, the barley flours were used to prepare barley-wheat flour noodles in a 1:1 proportion. From their sensory analysis, it was concluded that the noodles produced from barley flours pearled at higher rates were most acceptable for all factors assessed (color, flavor, surface smoothness, firmness, elasticity, overall acceptability).

Generally, L*a*b* color values were similar between the unscoured and scoured chickpea flours at the three different MC levels (Table 6). But unlike the green lentil flours, the significant differences (P < 0.05) observed in L*a*b* color values within the chickpea break, middling, and SG flours did not follow a clear trend between pre-treatment conditions and their levels. The seed coat and cotyledon of the chickpea cultivar used in this study are a similar color to one another which would likely result in small L*a*b* color differences between these flours pre-treated at different MC and scouring levels.

There are currently no regulated standards for pulse flour particle size. Statistical analysis of the effects of MC and scouring concluded that green lentil flour particle size distribution was more affected by scouring than MC (Tables 5 and 7). However, the significant differences (P < 0.05) in the green lentil flour particle size distribution properties that were observed between the pre-treatment conditions (within MC and scouring levels) were very minor (Table 9).

The majority of the particle size distribution properties for the chickpea break and SG flours were significantly affected (P < 0.05) by MC with and without scouring (Table 10). In the middling chickpea flours, MC had significant effects (P < 0.05) on mainly the unscoured flours (Table 10). Scouring had a significant effect (P < 0.05) on particle size distribution properties of primarily the chickpea break flours at 0% and 1% MC level, as well as the middling and SG flours at 0.5% and 1% MC (Table 11). Particle sizes at d(0.1) and d(0.5) of the particle size distribution curves within the chickpea break, middling, and SG flours were similar between the different pre-treatment conditions and their levels (Table 12). Greater disparities were observed at d(0.9) of the particle size distribution curves, along with VWM, span, and uniformity in the chickpea break flours and SG flours (to a lesser degree than the break flours) (Table 12). The values for these particle size distribution properties were the most different in the chickpea break flours pre-treated with 0% and 1% MC and scouring. Higher values were observed in these flours compared to the other pre-treatments; however, these differences were not always significantly different (Table 12).

Responses to the Pre-Treatments Based on Pulse Type and Their Milling Fractions

Compared to green lentil, the chickpea flour fractions exhibited more frequency of significant pre-treatment effects in their compositional (ash, protein, moisture) and particle size distribution properties with MC. Scouring more frequently affected ash and particle size distribution properties of the chickpea flours, and L*a*b* color values of the green lentil flours (Table 5). Due to the differences in physical properties (e.g., seed size, shape, color) and processing characteristics (downstream processing properties) of different pulse types, the pulse flour milling process varies based on the particular pulse type being milled, and therefore, requires the development of flour milling operations tailored to each pulse type (Sarkar & Subramaniam, 2016). The differences in seed size, composition, thickness, and hardness of the seed coat between different pulse types may have attributed to the pre-treatment effects observed in the milled fractions (Scanlon et al., 2018). Particle size uniformity of the SG flours as well as their greenness or redness (a* color value) of both green lentil and chickpea showed significant differences with the MC levels with and without scouring. For the chickpea break flours, MC had a significant effect on all of the compositional properties (ash, protein, moisture) and particle size distribution properties irrespective of the scouring level (Table 10). L*a*b* color values of the green lentil break and middling flours were significantly affected by scouring at all three MC levels, with exception to the green lentil middling flours pre-treated with 0% MC (Table 7). These observations lead to the conclusion that the color quality of the green lentil flours was primarily influenced by scouring. Both the green lentil and chickpea flours’ responses to MC and scouring in this study were mixed, meaning that these pre-treatment effects did not result in a clear pattern or trend in the findings.

Conclusion

The green lentil and chickpea flours responded differently to the MC and scouring pre-treatments in this study. Significant effects (P < 0.05) of the pre-treatments were frequently concluded for the pulse flours; however, the differences between the data values of the flour properties were quite small. Although infrequently concluded to be significantly different (P < 0.05), both the green lentil and chickpea flours were observed to have lower protein contents with scouring which was likely caused by some of the pulse material getting discarded during the scouring process. Scouring was also associated with higher L*a*b* color values in the green lentil flours. Better removal of the dark seed coat of green lentils during the scouring process enabled the production of green lentil flours with higher L*a*b* color values. The seed coat and cotyledon colors of chickpeas were similar; therefore, L*a*b* color values with and without scouring within the chickpea flour blends were similar to each other. The respective levels of MC and scouring did little to affect the particle size distribution properties of the green lentil flours. Differences in particle size properties between the pre-treatment conditions were more evident in the chickpea flours.

Significant differences between the MC and scouring pre-treatments in this study were marginal, suggesting that the quality of the roller-milled green lentil and chickpea flours were not strongly influenced by seed MC and scouring. In order to draw stronger conclusions regarding the effects of pulse seed MC and scouring, these pre-treated pulse flours should be utilized as food ingredients to determine if quality differences can be observed in processed food products. This pulse study contributes insight into the direction flour milling research should take to continue advancing the knowledge of pulse flour milling technology for the food processing industry.

Availability of Data and Material

The authors declare that the data supporting the findings of this study are available within the article. The raw/derived data supporting the findings of this study are available from the corresponding author on request.

References

AACCI. (1999a). Approved methods of analysis. In AACC International Method 44–15.02. Moisture – Air-Oven Methods (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-44-15.02

AACCI. (1999b). Approved methods of analysis. In AACC Approved Method 08–01.01. Ash – Basic Method (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-08-01.01

AACCI. (1999c). Approved methods of analysis. In AACC International Method 46–30.01. Crude Protein – Combustion Method (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-46-30.01

AACCI. (1999d). Approved methods of analysis. In AACC International Method 14–30.01. Agtron Color Test for Flour (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-14-30.01

AACCI. (2017). Approved methods of analysis. In AACC Approved Method 56–37.01. Water-Holding Capacity of Pulse Flours and Protein Materials (11th ed.). St. Paul: AACC International. https://doi.org/10.1094/AACCIntMethod-56-37.01

Anderson, J., & Major, A. (2002). Pulses and lipaemia, short- and long-term effect: Potential in the prevention of cardiovascular disease. British Journal of Nutrition, 88(S3), 263–271. https://doi.org/10.1079/BJN2002716

Asif, M., Rooney, L. W., Ali, R., & Riaz, M. N. (2013). Application and opportunities of pulses in food system: A review. Critical Reviews in Food Science and Nutrition, 53(11), 1168–1179.

Becerra-Tomás, N., Díaz-López, A., Rosique-Esteban, N., Ros, E., Buil-Cosiales, P., Corella, D., Estruch, R., Fitó, M., Serra-Majem, L., Arós, F., Lamuela-Raventós, R., Fiol, M., Santos-Lozano, J., Díez-Espino, J., Portoles, O., & Salas-Salvadó, J. (2017). Legume consumption is inversely associated with type 2 diabetes incidence in adults: A prospective assessment from the PREDIMED study. Clinical Nutrition (Edinburgh, Scotland), 37(3), 906–913. https://doi.org/10.1016/j.clnu.2017.03.015

Bekkering, E. (2014). Pulses in Canada -Canadian Agriculture at a Glance. Statistics Canada, 1–12. https://publications.gc.ca/collections/collection_2014/statcan/96-325-x/CS96-325-2011-7-eng.pdf

Black, R., Singh, U., & Meares, C. (1998). Effect of genotype and pretreatment of field peas (Pisum sativum) on their dehulling and cooking quality. Journal of the Science of Food and Agriculture, 77(2), 251–258.

Brar, N. K., Ramachandran, R. P., Cenkowski, S., & Paliwal, J. (2021). Effect of superheated steam- and hot air-assisted processing on functional and nutritional properties of yellow peas. Food and Bioprocess Technology, 14, 1684–1699. https://doi.org/10.1007/s11947-021-02668-1

Cappelli, A., Oliva, N., & Cini, E. (2020). Stone milling versus roller milling: A systematic review of the effects on wheat flour quality, dough rheology, and bread characteristics. Trends in Food Science & Technology, 97, 147–155. https://doi.org/10.1016/j.tifs.2020.01.008

Chidananda, K. P., Chelladurai, V., Jayas, D. S., Alagusundaram, K., White, N. D. G., & Fields, P. G. (2014). Respiration of pulses stored under different storage conditions. Journal of Stored Products Research. 59: 42-47, https://doi.org/10.1016/j.jspr.2014.04.006

Di-Cairano, M., Condelli, N., Caruso, M. C., Cela, N., Tolve, R., & Galgano, F. (2021). Use of underexploited flours for the reduction of glycaemic index of gluten-free biscuits: Physicochemical and sensory characterization. Food and Bioprocess Technology, 14, 1490–1502. https://doi.org/10.1007/s11947-021-02650-x

Doblado-Maldonado, A. F., Pike, O. A., Sweley, J. C., & Rose, D. J. (2012). Key issues and challenges in whole wheat flour milling and storage. Journal of Cereal Science, 56(2), 119–126. https://doi.org/10.1007/s11947-021-02650-x

Erskine, W., Williams, P., & Nakkoul, H. (1991a). Splitting and dehulling lentil (Lens culinaris): Effects of genotype and location. Journal of the Science of Food and Agriculture, 57(1), 85–92. https://doi.org/10.1002/jsfa.2740570110

Erskine, W., Williams, P., & Nakkoul, H. (1991b). Splitting and dehulling lentil (Lens culinaris): Effects of seed size and different pretreatments. Journal of the Science of Food and Agriculture, 57(1), 77–84. https://doi.org/10.1002/jsfa.2740570109

Fang, Q., Bölöni, I., Haque, E., & Spillman, C. K. (1997). Comparison of energy efficiency between a roller mill and a hammer mill. Applied Engineering in Agriculture, 13(5), 631–635. https://doi.org/10.13031/2013.21636

Fujiwara, N., Hall, C., & Jenkins, A. (2017). Development of low glycemic index (GI) foods by incorporating pulse ingredients into cereal-based products: Use of in vitro screening and in vivo methodologies. Cereal Chemistry, 94(1), 110–116. https://doi.org/10.1094/CCHEM-04-16-0119-FI

Goyal, R. K., Vishwakarma, R. K., & Wanjari, O. D. (2009). Optimization of process parameters and mathematical modelling for dehulling of pigeonpea. International Journal of Food Science & Technology, 44(1), 36–41. https://doi.org/10.1111/j.1365-2621.2007.01630.x

Gularte, M. A., Gómez, M. & Rosell, C. M. (2012). Impact of legume flours on quality and in vitro digestibility of starch and protein from gluten-free cakes. Food and Bioprocess Technology, 5, 3142–3150. https://doi.org/10.1007/s11947-011-0642-3

Izydorczyk, M. S., McMillan, T. L., Kletke, J. B., & Dexter, J. E. (2011). Effects of pearling, grinding conditions, and roller mill flow on the yield and composition of milled products from hull-less barley. Cereal Chemistry, 88(4), 375–384. https://doi.org/10.1094/CCHEM-10-10-0147

Jan, S. & Shieh, G. (2014). Sample size determinations for Welch’s test in one-way heteroscedastic ANOVA. British Journal of Mathematical & Statistical Psychology, 67(1), 72–93. https://doi.org/10.1111/bmsp.12006

Jerish Joyner, J. & Yadav, B. (2015). Optimization of continuous hydrothermal treatment for improving the dehulling of black gram (Vigna mungo L). Journal of Food Science and Technology, 52(12), 7817–7827. https://doi.org/10.1007/s13197-015-1919-8

Kent, N. L. & Evers, A. D. (1994). Kent’s technology of cereals – An introduction for students of food science and agriculture (4th ed.). Oxford, UK: Elsevier Science Ltd.

Kihlberg, I., Johansson, L., Kohler, A., & Risvik, E. (2004). Sensory qualities of whole wheat pan bread – Influence of farming system, milling and baking technique. Journal of Cereal Science, 39(1), 67–84. https://doi.org/10.1016/S0733-5210(03)00067-5

Marinangeli, C., Kassis, A., & Jones, P. (2009). Glycemic responses and sensory characteristics of whole yellow pea flour added to novel functional foods. Journal of Food Science, 74(9), S385–S389. https://doi.org/10.1111/j.1750-3841.2009.01347.x

Nagi, H. P. S. & Bains, G.S. (1983). Effect of scouring and conditioning variables on milling, rheological and baking properties of Indian wheats. Journal of Food Science and Technology, 20(3), 122–124.

Pagani, M. A., Giordano, D., Cardone, G., Pasqualone, A., Casiraghi, M. C., Erba, D., Blandino, M., & Marti, A. (2020). Nutritional features and bread-making performance of wholewheat: Does the milling system matter? Foods, 9(8), 1035–1052. https://doi.org/10.3390/foods9081035

Pelgrom, P., Boom, R., & Schutyser, M. (2015). Method development to increase protein enrichment during dry fractionation of starch-rich legumes. Food and Bioprocess Technology, 8(7), 1495–1502. https://doi.org/10.1007/s11947-015-1513-0

Phirke, P., Bhole, N., & Adhaoo, S. (1995). Shear forces for dehulling, splitting and breaking raw and pretreated pigeonpeas. International Journal of Food Science & Technology, 30(4), 485–491. https://doi.org/10.1111/j.1365-2621.1995.tb01395.x

Posner, E. S., & Hibbs, A. N. (2005). Wheat flour milling (2nd ed.). St. Paul, Minnesota, U.S.A.: American Association of Cereal Chemists, Inc.

Prabhasankar, P., & Rao, P. H. (2001). Effect of different milling methods on chemical composition of whole wheat flour. European Food Research & Technology, 213(6), 465–469. https://doi.org/10.1007/s002170100407

Reichert, R., Oomah, B., & Youngs, C. (1984). Factors affecting the efficiency of abrasive-type dehulling of grain legumes investigated with a new intermediate-sized, batch dehuller. Journal of Food Science, 49(1), 267–272. https://doi.org/10.1111/j.1365-2621.1984.tb13723.x

Ringuette, C., Finley, J., Prinyawiwatkul, W., & King, J. (2018). Development of reduced glycemic load/high fiber ravioli using bean flour. Journal of Culinary Science & Technology, 16(4), 336–356. https://doi.org/10.1080/15428052.2017.1391147

Rizzello, C., Calasso, M., Campanella, D., De Angelis, M., & Gobbetti, M. (2014). Use of sourdough fermentation and mixture of wheat, chickpea, lentil and bean flours for enhancing the nutritional, texture and sensory characteristics of white bread. International Journal of Food Microbiology, 180, 78–87. https://doi.org/10.1016/j.ijfoodmicro.2014.04.005

Sakhare, S. D., Inamdar, A. A., Gaikwad, S. B., Indrani, D., & Rao, G. V. (2014). Roller milling fractionation of green gram (Vigna radiata): Optimization of milling conditions and chemical characterization of millstreams. Journal of Food Science and Technology, 51(12), 3854–3861. https://doi.org/10.1007/s13197-012-0903-9

Sakhare, S. D., Inamdar, A. A., Indrani, D., Madhu Kiran, M. H., & Venkateswara Rao, G. (2015). Physicochemical and microstructure analysis of flour mill streams and milled products. Journal of Food Science and Technology, 52(1), 407–414. https://doi.org/10.1007/s13197-013-1029-4

Sarkar, A., & Subramaniam, M. (2016). Processing of pulses for nutrition, product diversification and profitability in the milling industry. International Miller, 2Q, 34–43.

Scanlon, M. G., Thakur, S., Tyler, R. T., Milani, A., Der, T., & Paliwal, J. (2018). The critical role of milling in pulse ingredient functionality. Cereal Foods World, 63(5), 201–206. https://doi.org/10.1094/CFW-63-5-0201

Siddiq, M., & Uebersax, M. A. (2013). Dry beans and pulses production and consumption – An overview. In M. Siddiq, & M. A. Uebersax (Eds.), Dry Beans and Pulses Production, Processing and Nutrition (1st ed., pp. 1–22). Oxford: John Wiley & Sons, Inc. https://doi.org/10.1002/9781118448298.ch1

Sunil, C., Chidanand, D., Manoj, D., Choudhary, P., & Rawson, A. (2018). Effect of ultrasound treatment on dehulling efficiency of blackgram. Journal of Food Science and Technology, 55(7), 2504–2513. https://doi.org/10.1007/s13197-018-3168-0

Venn, B., Perry, T., Green, T., Skeaff, C., Aitken, W., Moore, N., Mann, J., Wallace, A., Monro, J., Bradshaw, A., Brown, R., Skidmore, P., Doel, K., O’Brien, K., Frampton, C., & Williams, S. (2010). The effect of increasing consumption of pulses and wholegrains in obese people: A randomized controlled trial. Journal of the American College of Nutrition, 29(4), 365–372. https://doi.org/10.1080/07315724.2010.10719853

Vishwakarma, R. K., Shivhare, U. S., Gupta, R. K., Yadav, D. N., Jaiswal, A., & Prasad, P. (2018). Status of pulse milling processes and technologies: A review. Critical Reviews in Food Science and Nutrition, 58(10), 1615–1628. https://doi.org/10.1080/10408398.2016.1274956

Wang, N. (2008). Effect of variety and crude protein content on dehulling quality and on the resulting chemical composition of red lentil (Lens culinaris). Journal of the Science of Food and Agriculture, 88(5), 885–890. https://doi.org/10.1002/jsfa.3165

Willard, J. T., & Swanson, C.O. (1911). Milling tests of wheat and baking tests of flour. Manhattan, Kansas, U.S.A.: Kansas State Agricultural College, Experiment Station, Bulletin 177. http://www.ksre.k-state.edu/historicpublications/pubs/SB177.PDF. Accessed 22 October 2021.

Winterová, R., Holasová, M., & Fiedlerová, V. (2016). Effect of spelt pearling on the contents of total dietary fibre, wet gluten, protein and starch fractions. Czech Journal of Food Sciences, 34(1), 61–67. https://doi.org/10.17221/453/2015-CJFS

Wood, J. A., & Malcolmson, L. (2011). Pulse milling technologies. In B. K. Tiwari, A. Gowen, & B. McKenna (Eds.), Pulse foods: Processing, quality and nutraceutical applications (1st ed., pp. 193–221). London: Academic Press. https://doi.org/10.1016/B978-0-12-382018-1.00008-3

Zhao, B., Wang, L., Shang, J., Liu, L., Tong, L., Zhou, X., Wang, S., Zhang, Y., & Zhou, S. (2020). Application of pearling in modified roller milling of hull‐less barley and effect on noodles quality. Journal of Food Processing and Preservation, 44(11). https://doi.org/10.1111/jfpp.14838

Acknowledgements

We thank Canada Foundation for Innovation for infrastructural support and Canadian International Grains Institute for milling of samples. Sincere thanks to Ms. Lindsey Boyd (Technologist, Pulse Science Cluster, Cereals Canada, Winnipeg, Canada), Dr. Ning Wang (Research Scientist, Grain Research Laboratory, Canadian Grain Commission, Winnipeg, Canada), Mr. Ashok Sarkar (Senior Advisor, Technology, Cereals Canada, Winnipeg, Canada), and Dr. Mohammad Nadimi (University of Manitoba, Winnipeg, Canada) for their input.

Funding

The authors acknowledge the Pulse Cluster of the Canadian Agricultural Partnership’s AgriScience Program and Natural Sciences and Engineering Research Council of Canada’s Discovery Grant program for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choo, K., Ramachandran, R.P., Sopiwnyk, E. et al. Effects of Seed Moisture Conditioning and Mechanical Scouring Pre-Treatments on Roller-Milled Green Lentil (Lens culinaris) and Chickpea (Cicer arietinum) Flours. Food Bioprocess Technol 15, 1311–1326 (2022). https://doi.org/10.1007/s11947-022-02816-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02816-1