Abstract

This work identified new treatments to develop red raspberries for baking applications for better consumer appeal. Fresh or frozen fruits are often incorporated in baked products such as muffins and pies. These baked products are very popular due to their fresh, fruity flavor. Raspberries are used as an ingredient in many foods due to their delicious flavor. However, the incorporation of red frozen raspberries turns the baked product red due to syneresis during baking. In this study, we developed baking-stable red raspberries to minimize syneresis during baking. We applied three treatments to the red raspberries: vacuum impregnation with low methoxyl pectin and calcium chloride at 20 °C and a vacuum level of 50.8 kPa, for 7 min; partial dehydration using hot air at a dry bulb temperature of 65 °C until the final water content of 0.65 g H2O/g fruit was reached; and edible coatings at different concentrations. Treated berries were stored in a freezer at − 35 °C for 2 months. We determined the mechanical properties, drip loss, and visual integrity of the frozen-thawed red raspberries before baking to select appropriate coatings. Raspberry muffins were then baked to 204 °C for 20 min. We determined the syneresis from the baked fruit using an image analyzer. Findings indicate that sodium alginate coating on red raspberries at 0.4% (w/v) resulted in minimal syneresis in baked muffins at 13.9%, while commercially frozen raspberries showed syneresis at 62.9%. The maximum force (FM) and gradient (GC) values as firmness indicators were improved from control berries (7.45 N and 2.06 N/mm, respectively) to treated berries (21.16 N and 7.06 N/mm, respectively).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Red raspberries (Rubus idaeus) continue to gain popularity with consumers. Neurological improvements in cognitive brain functions have been associated with the consumption of edible berries (Miller and Shukitt-Hale 2012). Additional health benefits are attributable to raspberry consumption, such as the lowered risk of cardiovascular disease (Basu et al. 2010). Raspberry juice has also been shown to protect against aortic fatty streaks (Bolling et al. 2016) and anti-inflammatory and anticancer properties (Bowen-Forbes et al. 2010). The food industry uses frozen fruit in its recipes according to availability, regardless of the season. Most textural changes in raspberries used in baking and dairy products occur during the handling and processing of frozen fruit. Cell lyses result from the formation of ice crystals during freezing, with an irreversible loss of firmness after thawing and syneresis from berries. This results in poor-quality baked products. The chemistry behind the syneresis lies in gel science. The gel would modify its structure during heat treatment, making the gel to shrink. As a result, the liquid exuded occurs after the gel network is contracted (Sherer 1989). Mizrahi (2010) described the term syneresis as the “liquid oozing out of a large number of foods such as jams, jellies, sauces, dairy products,” etc. This makes products less appealing to consumers. The higher the tendency for syneresis, the lesser the baking stability of a fruit during preparation possesses.

Baking-stable fruit preparation (BSFP) provides stability to fruit fillings during the baking process. In the production process of BSFP, the fruit is processed to withstand the type of baking to be conducted: thermally stable fruit filling and filling to be cold filled into a prebaked product (Pátkai 2012). Thermally stable fruit fillings provide shape stability and minimize the syneresis during baking. On the other hand, cold-fill fillings show a reasonably good capacity for pumping, injecting, or spreading in addition to acceptable flavor and texture properties. Edible coatings such as hydrocolloids have been used in bakery fillings to prevent syneresis and provide bake-stable functionality. Alginate, pectin, and carboxymethyl cellulose, among others, are examples of hydrocolloids used in the food industry to produce BSFP (Aditi et al. 2016; Jiang et al. 2016; Agudelo et al. 2014; Cropotova and Popel 2013a, 2013b; Basu and Shivhare 2010; Hernandez-Muñoz et al. 2008; de Vries 2004; Young et al. 2003).

We considered a different approach for providing stability to raspberry fillings before baking through the design and implementation of processes that improve structural integrity, such as vacuum impregnation (VI), partial drying (PD), and application of edible coating (EC). VI has been shown to improve firmness in raspberries. For example, in a previous study, we found that raspberries infused with low methoxyl pectin (LMP) and calcium are significantly firmer than infused raspberries with pectin methylesterase and calcium (Quintanilla et al. 2018). Yang et al. (2017) studied the effect of VI with calcium lactate and pectin methylesterase on fresh-cut papayas. The firmness of vacuum-impregnated papayas after 8 days stored at 4 °C was improved when compared with nontreated fruit. Improved thermal conductivity due to VI treatment on fruits and vegetables may reduce processing times during drying or freezing. This may also improve fruit integrity during baking. Martínez-Monzó et al. (2000) and Radziejewska-Kubzdela et al. (2014) reported an increase in thermal conductivity in vacuum-impregnated food products as a result of the replacement of gas with liquid into the porous tissue during the VI process.

Dehydrofreezing is a process of preserving food that combines the techniques of partial dehydration and freezing. Several studies have shown improvement in mechanical properties of dehydrofrozen fruits compared to conventionally frozen products (Quintanilla et al. 2020; Ben Haj Said et al. 2016; James et al. 2014; Ramallo and Mascheroni 2010; Maestrelli et al. 2001; Sormani et al. 1999). The addition of edible coatings to fruits and vegetables is considered an effective method in the preservation of food products. Edible coatings can inhibit the growth of microbes, providing structural stability that prevents mechanical damage during processing and controlling water migration that reduces respiration rates, and loss of components that stabilize organoleptic properties (Reyes-Avalos et al. 2019; Zhu et al. 2019; Yang et al. 2019; Nadim et al. 2015; Pavlath and Orts 2009; Tapia et al. 2008; Vargas et al. 2006).

In this study, we developed baking-stable red raspberries by improving the mechanical properties and minimizing the syneresis using vacuum impregnation, partial drying, and edible coatings before freezing. We hypothesized that edible coatings reduce moisture transfer and solute migration from the fruit, whose mechanical strength has been improved using vacuum impregnation and partial drying.

Materials and Methods

Materials

Fresh red raspberries (Rubus idaeus) were purchased from a local grocery store in Pullman, WA, USA. Upon arrival, the undamaged raspberries were screened visually. Uniformly sized raspberries were chosen. The fresh fruit was stored at 4 °C and kept under refrigeration no more than 3 days until the experiments were carried out. Frozen raspberries (Great Value Whole Red Raspberries, Walmart Stores, Inc., Bentonville, AR 72716, USA) were used as a reference to determine syneresis after baking. Deionized (DI) water was used to prepare all process solutions. All chemicals were of analytical grades: glycerol anhydrous and acetic acid glacial (J.T.Baker, Avantor Materials, Phillipsburg, NJ, USA), Tween 20 (Sigma-Aldrich, Inc., St. Louis, MO, USA), calcium chloride dihydrate (VWR International, LLC, Batavia, IL, USA), chitosan (Spectrum Chemicals and Laboratory Products, Gardena, CA, USA), Ticalose® CMC 2700 F NGMO cellulose gum, Ticaloid® 911 cellulose gum powder, TICA-algin® 400 sodium alginate, and low methoxyl pectin TIC Pretested® Pectin LM 35 powder. The last four chemicals were gifts from TIC Gums, White Marsh, MD, USA.

Process Description

This experimental study was divided into two stages. In the first stage, the performance of edible coatings was evaluated using only coated and partially dehydrated and coated berries (Fig. 1a and b). The effect of different coatings and solution concentrations on the mechanical properties, drip loss, and visual integrity of thawed raspberries was evaluated. Frozen and thawed berries without treatment were used as a control. Suitable edible coatings then were identified. In the second stage, fresh berries were subjected to vacuum impregnation before partial dehydration (Fig. 2). The selected coatings were applied to pretreated berries before freezing at − 35 °C. The berries were stored frozen for 2 months and then incorporated in muffins. The degree of syneresis in the resulting muffins was evaluated. Furthermore, the mechanical properties, visual integrity, and drip loss of berries were determined. Commercially frozen berries were also used in muffin baking for comparison.

First stage. a Performance evaluation of the edible coatings on nondried frozen-thawed raspberries. b Performance evaluation of the edible coatings on partially dried frozen-thawed raspberries. CMC, edible coated with carboxymethyl cellulose; SA, edible coated with sodium alginate; 911, edible coated with cellulose gum

Treatments

Edible Coatings

Four hydrophilic edible coatings at different concentrations were selected for this experiment. Sodium alginate TICA-algin® 400 (SA), sodium carboxymethyl cellulose gum Ticalose® CMC 2700 F NGMO (CMC), chitosan-based edible coating, and cellulose gum Ticaloid® 911 powder (911) were tested. The coatings were chosen, based on available information on their use as stabilizers in baking fillings, as inhibitors of moisture transfer, or as stabilizers during heating.

The edible coating solutions were prepared as follows: two SA coating solutions were prepared by adding 0.4% and 1.0% of SA (w/v) in DI water to 25% glycerol, and 0.15% Tween 20. These solutions were labeled in accordance with their level of concentration as SA L and SA H: two CMC coating solutions were prepared by adding 0.05% and 0.1% of CMC (w/v) in DI water to 25% glycerol, (and 0.15% Tween 20. These solutions were labeled in accordance with their level of concentration as CMC L and CMC H: 2% chitosan (w/v) was dissolved in DI water with 1% acetic acid, 25% glycerol, and 0.15% Tween 20). The edible coating solutions were homogenized for 2 min at 5000 rpm in a homogenizer (model Kinematica Polytron PT 2500E, Bohemia, NY, USA) and stored overnight at 4 °C before use. Two levels of 911 powder edible coatings were also used. The amount of powder deposited onto the raspberries surface was 1.5% and 3% based on the weight of raspberries. These levels of powder coatings were identified as 911 L and 911 H.

Raspberries were weighed before and after treatments to determine the approximate coating weight. For berries coated with SA, CMC, and chitosan, the raspberries were placed on a stainless steel wired tray and manually sprayed until they were fully covered by the coating solution. A sprayer (model Continental Spray Pro Trigger 902RW9, China) was used for spraying the solution. After coating, the excess coating solution was removed by air drying at room temperature (24 °C) in an air-circulated drier for 30 min at 2 m/s.

The 911 powder was applied to raspberries as follows: frozen berries were randomly placed on a 3-in. stainless steel mesh (number 10, 2000 μm, ATM Corporation, Milwaukee, WI, USA), and the pan and berries were weighed. Second, the powder was sprinkled over the raspberries until the amount of remaining coating adhered to the surface of the raspberries. The adherence was confirmed by weighting the pan with the berries again. Between the mentioned steps, the sieve was carefully cleaned to remove the excess coating that adhered to the mesh.

Vacuum Impregnation

An infusion solution containing LMP at 1% (w/w) and calcium chloride (CaCl2·2H2O) at 35 mg of calcium per g of pectin, in DI water at 20 °C, was prepared. Fresh raspberries were placed in a container of the solution. The 1:4 (w/w) fruit-to-impregnation solution ratio was maintained. A vacuum level of 50.8 kPa for 7 min, followed by 5 more min of restoration time, was used to conduct the VI treatment. These optimal conditions were identified in our previous study. The experiment was performed by using a vacuum chamber (model No. 1410-2, Sheldon Manufacturing, Cornelius, OR, USA) connected to a vacuum pump (Edwards 12 two-stage, oil-sealed rotary vane, Hillsboro, OR, USA). Once the raspberries were infused, they were separated from the solution using a stainless steel strainer. Each berry was individually dried with paper tissue and swabs and then kept at room temperature (24 °C) for 1 h before further processing. Each experiment was performed three times, and each replicate involved ten raspberries.

Air-drying

The water content of fresh raspberries was previously determined using an oven (model ED-53L, Binder GmbH, Tuttlingen, Germany) at 105 ± 2 °C, over 24 h to achieve a constant weight. This procedure was performed 3 times, and each replicate involved ten raspberries. Raspberries were air-dried in an air-circulated drier (Armfield, UOP8, Hampshire, England) at 65 °C dry air temperature at an air velocity of 1.5 m/s. The raspberries were dried until the water content reached 0.65 g H2O/g fruit. The optimal conditions of partial drying were identified from our previous study (Quintanilla et al. 2020). The air velocity was measured with an anemometer (Extech AN300, Nashua, NH, USA). The raspberries were placed on sample trays inside the air drier. The sample trays were suspended from a scale connected to a computer, where the weight of the product and the dry bulb temperature were monitored. Once the berries were dried, they were ready to be coated or frozen.

Freezing

Next, the raspberries were carefully placed into glass jars. The jars were closed and cooled at 4 °C for 2 h and then transferred to an air blast freezer at − 35 °C and stored for 2 months. After storage, the berries were thawed. The berries were also used for baking. In general, a few berries were placed in each container during freezing to minimize their contact and avoid damage while handling.

Weight Loss and Drip Loss Analysis and Mechanical Properties

For weight loss analysis, the fresh and coated raspberries were placed on ventilated trays at 4 °C. Weight loss was measured by monitoring the weight changes of the fruit for 5 days. Weight loss was calculated as a percentage of initial weight. Three replicates were used. Ten berries were used for each measurement. For the drip loss analysis, the frozen berries were removed from jars after 6 h of thawing at 24 °C, and the jars were weighed again. The weight change before and after thawing was the drip loss result (Xie and Zhao 2004).

Frozen berries were allowed to thaw inside glass jars at 24 °C for 6 h before the analysis of mechanical properties. The mechanical properties of berries were determined with a texture profile analyzer (model TA-XT2, Stable Microsystems, Godalming, England) by measuring the maximum force (FM) and the gradient (GC). A compression test with 80% strain was performed with a 25-kg load cell and a flat cylinder probe of 50 mm diameter at a constant plunger speed of 0.5 mm/s. The berries were centrally placed, with their major axis perpendicular to the compression plate. Ten berries were used per experiment, and each experiment was performed three times.

Baking

Muffin batter containing the following ingredients was prepared: all-purpose enriched, bleached, and presifted wheat flour (General Mills, Inc., Minneapolis, MN, USA); fresh eggs (Wilcox Family Farm, Roy, WA, USA); pure cane sugar (Domino Foods, Inc., Yonkers, NY, USA); pure vegetable soybean oil (Long Life brand, Incobrasa Industries, Ltd., Gilman, IL, USA); nonfat instant dry milk (Great Value, Walmart Stores Inc., Bentonville, AR, USA); baking powder (Clabber Girl, Clabber Girl Corporation, Terre Haute, IN, USA); salt (IGA brand, IGA Inc., Chicago, IL, USA); and water (see Table 1). The ingredients were mixed at room temperature for 45 s using a hand mixer with a flat beater at speed level 2 (Hamilton Beach/Proctor Silex, Inc., Washington, NC, USA).

Raspberries commercially frozen or previously treated with at least one of the treatments were incorporated into the muffins and baked to evaluate the effects of vacuum impregnation, partial drying, and edible coating treatments. Twenty-five grams of batter was poured into each of seven paper muffin cups (63 mm top diameter × 30 mm depth; Reynolds Metals Company, Richmond, VA, USA), and one frozen-thawed berry was placed into the batter. Another 25 g of batter was added to complete the muffin preparation, and muffins were baked in an oven (Frigidaire, Pittsburgh, PA, USA) at 204 °C for 20 min. Three replicates were used. Each replicate involved ten samples of each fruit treatment. After baking, the muffins were loosely covered with aluminum foil and cooled at a temperature of 4 °C for 3 h. Then, the muffins were transversally cut in halves and photographed. The camera (Canon EOS 60D with 18.1 megapixels resolution, Japan) used had a Canon EF 100mm f/2.8 USM Macro lens with two lights (ALZO 27W, USA). The camera was connected to a computer. The images were analyzed through the image software program ImageJ 1.46r. Two methods to determine fruit and syneresis areas were selected: intensity threshold and line selection freehand.

Syneresis of the baked fruit for different treatments was determined using the following procedure: the area surrounding the skin of the fruit was measured in the image of muffins (A1), and then a second measurement by drawing a perimeter, including the area of the released liquid (A2) in the muffin (see Fig. 3). The difference between the areas divided by the area of the released liquid was the percentage of syneresis.

Statistical Analysis

Analysis of data was performed using SAS 9.2. A completely randomized factorial design with 3 replicates was used. Every replicate involved 10 raspberries. An analysis of variance (ANOVA) was carried out to establish the absence or presence of significant differences between means. The significance of differences was assessed using Tukey’s test at a level of significance of p ≤ 0.05.

Results and Discussion

Performance of Edible Coatings with Fresh and Partially Dried Berries

The drip loss of frozen-thawed control berries (4.27%) was significantly (p ≤ 0.05) higher than the drip loss of the frozen-thawed coated berries. This suggests that edible coatings can help maintain moisture in frozen and thawed berries. A decrease in drip loss was also observed with partially dried and coated berries in comparison to either control sample. In particular, the application of CMC at both concentrations and SA coatings at low concentration resulted in berries with better performance in terms of drip loss (see Table 2). Earlier studies have also shown improvement of postharvest-quality cold-stored fruits. Tapia et al. (2008) showed that water vapor resistance increased in alginate/gellan gum–coated fresh-cut papaya pieces, in comparison to nontreated fruit. The application of the edible coating on the strawberry fruit reduced loss of firmness at the end of storage compared with nontreated strawberries (Nadim et al. 2015).

The mechanical properties (FM and GC values) of the control raspberries (7.45 N and 2.06 N/mm, respectively) and the only coated berries with CMC at both concentrations and SA L were similar but significantly different (p ≤ 0.05). However, FM and GC values of partially dehydrated raspberries (16.76 N and 5.19 N/mm, respectively) were higher than the FM and GC values of control and only coated berries. Results show that an increase in maximum force and gradient was noticed in partially dried and coated fruit when compared with only coated berries. Again, CMC at both concentrations and SA coatings at a low concentration on partially dehydrated raspberries resulted in higher FM and GC values than those values at any other combination of treatments (Table 2). In a study by Vargas et al. (2006), chitosan combined with oleic acid promoted the reduction of the respiration rate protected strawberries against fungal infection and slowed down the changes in mechanical properties.

In addition, the use of chitosan and SA at high concentration and 911 at both concentrations on partially dehydrated and coated berries produced poor results in terms of mechanical properties and drip loss. Therefore, these latter four coating solutions were not considered in the following studies. The weight loss of both fresh and coated only berries increased with time during refrigerated storage. However, the fresh berries showed higher weight loss compared to other samples (Fig. 4). The data suggest that edible coatings can help reduce weight loss in berries during storage. Yang et al. (2019) reported reduced weight loss and improved the firmness of blueberry fruit coated with gum arabic–based coating enriched with roselle extracts.

Weight loss in fresh and coated raspberries during storage at 4 °C for 5 days. CMC L, coated with a low concentration of carboxymethyl cellulose; CMC H, coated with a high concentration of carboxymethyl cellulose; SA L, coated with a low concentration of sodium alginate. Means within the same day followed by the same letters are not significantly different at p ≤ 0.05

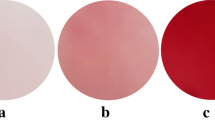

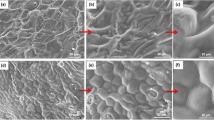

Results show no difference between the visual appearance and integrity of the nondried control and the coated nondried raspberries. No noticeable change in color was observed in the partially dried control and the partially dried coated berries. A change in raspberry structure caused by drying was evident (Fig. 5a). Results also show that partial dehydration of berries before coating created changes in color and visual integrity compared to only coated berries. James et al. (2014) showed that dehydrofrozen fruits and vegetables have better quality than conventionally frozen products. Ben Haj Said et al. (2016) investigated the effects of dehydrofreezing of apples to improve its firmness. Sormani et al. (1999) reported that predehydrated strawberry slices have significantly better textural characteristics than nondried strawberry slices after thawing. Ramallo and Mascheroni (2010) found that in dehydrofrozen pineapple, drip loss after thawing decreases compared to that of fresh fruit. Maestrelli et al. (2001) studied the effects of the dehydrofreezing treatment in muskmelon spheres. Moisture reduction before freezing reduced exudate loss at thawing when compared with not air-dried muskmelons.

a Visual integrity of color of frozen-thawed raspberries. First row, nondried berries with and without coatings. Second row, dried berries to a water content of 0.65 g of H2O/g of fruit with and without coatings. b Visual integrity of color of frozen-thawed raspberries. Control, without any treatment; vacuum impregnated with LMP and calcium chloride at 20 °C and a vacuum level of 50.8 kPa, for 7 min; dried to a water content of 0.65 g H2O/g of fruit

In general, all dehydration processes showed degradation of color and structural changes. The effect of high temperature upon the sensitivity of anthocyanins leads to a noticeable change in the color of dried fruit. Structural changes during drying cause stress in the cellular structure collapsing the drupelets allowing the loss of water (Rodriguez et al. 2019; Sette et al. 2016).

Performance of Edible Coatings with Vacuum Impregnated and Partially Dehydrated Berries

This study compared the performance indices of VI, PD, VI-PD, and VI-PD-EC and also compares the benefits of applying PD-EC vs VI-PD-EC treatment. There was no difference in visual integrity and color between frozen-thawed control and VI berries. The visual quality of both control and VI berries was better than the partially dehydrated berries (Fig. 5b). Once again, some changes in berry color and structure were apparent due to the drying process. In a previous study, the thawed and previously infused raspberries with LMP and calcium, followed by dehydrofreezing, showed an increase in firmness and visual integrity compared to untreated frozen-thawed berries (Quintanilla et al. 2020).

Each treatment, e.g., VI, PD, and VI-PD-EC, individually improved the mechanical properties compared to control berries. The combination of VI-PD further improved firmness in thawed berries (FM = 20.29 N and GC = 7.06 N/mm). Overall, even the application of the VI-PD-EC did not improve the mechanical properties further (Figs. 6 and 7), which still have a significant difference (p ≤ 0.05). However, treated berries with VI, PD, VI-PD, and VI-PD-EC reduced drip loss significantly (p ≤ 0.05) compared to control berries (Fig. 8). Results indicate the benefits of impregnation, drying, and coating in reducing the syneresis and improving mechanical properties when compared with partially dried and coated frozen-thawed berries (Table 3).

Maximum force (FM) in treated red raspberries after thawing. VI, vacuum impregnated; PD, partially dried; VI-PD, vacuum impregnated and partially dried; CMC L, vacuum impregnated, partially dried, and edible coated with a low concentration of carboxymethyl cellulose; CMC H, vacuum impregnated, partially dried, and edible coated with a high concentration of carboxymethyl cellulose; SA L, vacuum impregnated, partially dried, and edible coated with a low concentration of sodium alginate. Results reported are mean ± SD. Values with different letters are significantly different (p ≤ 0.05)

Gradient (GC) in treated red raspberries after thawing. VI, vacuum impregnated; PD, partially dried; VI-PD, vacuum impregnated and partially dried; CMC L, vacuum impregnated, partially dried, and edible coated with a low concentration of carboxymethyl cellulose; CMC H, vacuum impregnated, partially dried, and edible coated with high a concentration of carboxymethyl cellulose; SA L, vacuum impregnated, partially dried, and edible coated with a low concentration of sodium alginate. Results reported are mean ± SD. Values with different letters are significantly different (p ≤ 0.05)

Drip loss in treated red raspberries after thawing. VI, vacuum impregnated; PD, partially dried; VI-PD, vacuum impregnated and partially dried; CMC L, vacuum impregnated, partially dried, and edible coated with a low concentration of carboxymethyl cellulose; CMC H, vacuum impregnated, partially dried, and edible coated with a high concentration of carboxymethyl cellulose; SA L, vacuum impregnated, partially dried, and edible coated with a low concentration of sodium alginate. Results reported are mean ± SD. Values with different letters are significantly different (p ≤ 0.05)

Evaluation of the Tendency to Syneresis in Baked Stable Raspberries Preparations

Different approaches have been performed to provide baking-stable fillings. Hydrocolloids such as alginates, pectin, and chitosan to provide bake stability and syneresis-free products have been used traditionally. The effect on microstructure in fruit fillings with or without hydrocolloids upon freezing was investigated (Cropotova et al. 2016). Results showed the degree of syneresis in fruit fillings without gellan gum was higher than the degree of syneresis in fruit fillings containing the hydrocolloid. Cropotova and Popel (2013a) reported that carboxymethyl cellulose and low methoxyl pectin improved heat stability while maintaining textural characteristics of the apple fillings after baking for 10 min at 200 °C. Cropotova and Popel (2013b) investigated the effectiveness of incorporating amylopectin starch with gellan gum in fruit composition to provide bake stability and syneresis-free products after baking fruit fillings at 220 °C for 20 min. The fruit fillings were prepared according to the procedure presented by Basu and Shivhare (2010). Chitosan has been suggested as a potential food preservative (Jiang et al. 2016). Furthermore, chitosan on coated fruits has been proved to delay changes in weight loss and firmness. Hernandez-Muñoz et al. (2008) observed that the use of chitosan or chitosan combined with calcium gluconate on strawberries delayed changes in weight loss and firmness.

The baking trials in our study indicated that berries subjected to VI-PD-EC with CMC at two concentrations and SA at low concentration had lower syneresis compared to berries treated with VI or PD alone or a combination of these two treatments (Table 4). These observations are consistent with reports in the literature. Alginate is an excellent gel former in the presence of multivalent cations, a formation that is almost independent of temperature (Draget et al. 1997; de Vries 2004). The bake stability of dry figs and date fillings added with sodium alginate was studied (Aditi et al. 2016). Texture and spreadability of fruit fillings were used as bake stability indicators. The addition of sodium alginate stabilized and further improved the bake stability of the dry fruit fillings. Young et al. (2003) analyzed syneresis of fruit fillings with added low methoxyl pectin and high M alginate and a blend food grade stabilizer. High M alginates are products with a higher percentage of mannuronic acid blocks with relevant gelling properties. Syneresis as a function of the baking stability was evaluated by measuring the inner and outer diameters of the baked fruit filling on Marie biscuits. Tests were conducted in a hot air oven at 200 °C for 10 min. Results show that a mix of pectin and alginate had beneficial effects in fruit fillings concerning bake stability. Agudelo et al. (2014) studied fruit fillings added with a mixture of low methoxyl pectin, native tapioca starch, and calcium. The product showed bake stability with no syneresis when compared with a modified waxy corn starch system normally used in the fruit filling industry.

In the absence of soluble solids, the importance of gelation from the interaction with calcium ions in bakery fillings has been reported (Draget et al. 2006). CMC is also an excellent hydrocolloid derivative from cellulose. The major applications of CMC are in the area of water binding. CMC is a good contributor to the stabilization of frozen products, inhibiting ice crystal formation and resisting dripping (Murray 2009). In our study, the commercially frozen berries showed higher syneresis than the treated berries (Fig. 9).

Syneresis in baked red raspberries muffins. a Commercially frozen. b VI, vacuum impregnated. c PD, partially dried. d VI-PD, vacuum impregnated and partially dried. e VI-PD-EC CMC L, vacuum impregnated, partially dried, and coated with a low concentration of carboxymethyl cellulose. f VI-PD-EC CMC H, vacuum impregnated, partially dried, and coated with a high concentration of carboxymethyl cellulose. g VI-PD-EC SA L, vacuum impregnated, partially dried, and coated with a low concentration of sodium alginate

Conclusions

The findings of this study demonstrate that combining different processes and technologies such as vacuum impregnation, partial drying, and edible coating may be beneficial for the development of baking-stable red raspberries. Both SA and CMC at low concentrations were found to be effective in minimizing the syneresis in raspberries during baking. Vacuum impregnation, partial drying, and edible coating alone improved the mechanical properties and reduced the drip loss. However, combining all three pretreatments resulted in a synergetic effect in producing the baking-stable berries. The optimal treatment conditions were as follows: an infusion solution at 20 °C containing a LMP concentration of 1% (w/w) and 0.035 mg of CaCl2·2H2O per g of pectin, at 50.8 kPa abs, for 7 min and 5 min, vacuum and restoration times, respectively; air-drying at 65 °C and air velocity at 1.5 m/s until the water content of 0.65 g of H2O/g of fruit; and coating with SA at a low concentration of alginate at 0.4% (w/v). The developed red raspberries may find application in baked products.

References

Aditi, M., Shashirekha, M. N., & Sudha, M. L. (2016). Characterization and bake stability of dry fruits fillings in dehydrated chiku (Manilkara zapota L.P. Royen) incorporated biscuit. Journal of Texture Studies, 48(3), 231–240. https://doi.org/10.1111/jtxs.12232.

Agudelo, A., Varela, P., Sanz, T., & Fiszman, S. (2014). Formulating fruit fillings. Freezing and baking stability of a tapioca starch-pectin mixture model. Food Hydrocolloids, 40, 203–213.

Basu, A., Rhone, M., & Lyons, T. (2010). Berries: emerging impact on cardiovascular health. Nutrition Reviews, 68(3), 168–177.

Basu, S., & Shivhare, U. S. (2010). Rheological, textural, micro-structural and sensory properties of mango jam. Journal of Food Engineering, 100(2), 357–365.

Ben Haj Said, L., Bellagha, S., & Allaf, K. (2016). Dehydrofreezing of apple fruits; freezing profiles, freezing characteristics, and texture variation. Food and Bioprocess Technology, 9(2), 252–261.

Bolling, B. W., DiMarco, D. M., Lainas, K., & Kranz, S. (2016). Raspberry juice. In F. Shahidi & C. Alasalvar (Eds.), Handbook of functional beverages and human health (pp. 527–534). Boca Raton: CRC Press Taylor & Francis Group.

Bowen-Forbes, C., Zhang, Y., & Nair, M. (2010). Anthocyanin content, antioxidant, anti-inflammatory and anticancer properties of blackberry and raspberry fruits. Journal of Food Composition and Analysis, 23(6), 554–560.

Cropotova, J., Tylewicz, U., Dellarosa, N., Laghi, L., Romani, S., & Dalla Rosa, M. (2016). Effect of freezing on microstructure and degree of syneresis in differently formulated fruit fillings. Food Chemistry, 195, 71–78.

Cropotova, J., & Popel, S. (2013a). Influence of different hydrocolloids on physicochemical and heat-stable properties of fruit fillings. The Annals of the University Dunarea De Jos of Galati. Fascicle VI. Food Technology, 37, 59–67.

Cropotova, J., & Popel, S. (2013b). A way to prevent syneresis in fruit fillings prepared with gellan gum. Scientific Papers, Series D. Animal Science, 56, 326–329.

de Vries, J. (2004). Hydrocolloid gelling agents and their applications. In P. A. Williams & G. O. Phillips (Eds.), Gums and stabilizers for the food industry 12 (pp. 23–31). Cambridge: Royal Society of Chemistry.

Draget, K., Skjåk-Bræk, G., & Smidsrød, O. (1997). Alginate based new materials. International Journal of Biological Macromolecules, 21(1-2), 47–55.

Draget, K., Moe, S., Skjak-Broek, G., & Smidsrød, O. (2006). Alginates, In: Food polysaccharides and their applications. In A. Stephen, G. Phillips, & P. Williams (Eds.), Food Science and Technology (Vol. 1995, 2nd ed., pp. 245–286). Boca Raton: CRC/Taylor & Francis.

Hernandez-Muñoz, P., Almenar, E., Del Valle, V., Velez, D., & Gavara, R. (2008). Effect of chitosan coating combined with postharvest calcium treatment on strawberry (Fragaria x ananassa) quality during refrigerated storage. Food Chemistry, 110(2), 428–435. https://doi.org/10.1016/j.foodchem.2008.02.020.

James, C., Purnell, G., & James, S. (2014). A critical review of dehydrofreezing of fruits and vegetables. Food and Bioprocess Technology, 7(5), 1219–1234.

Jiang, H., Sun, Z., Jia, R., Wang, X., & Huang, J. (2016). Effect of chitosan as an antifungal and preservative agent on postharvest blueberries. Journal of Food Quality, 39(5), 516–523.

Maestrelli, A., Lo Scalzo, R., Lupi, D., Bertolo, G., & Torreggiani, D. (2001). Partial removal of water before freezing: cultivar and pre-treatments as quality factors of frozen muskmelon (Cucumis melo, cv reticulatus Naud.). Journal of Food Engineering, 49(2-3), 255–260.

Martínez-Monzó, J., Baret, J. M., González-Martínez, C., Chiralt, A., & Fito, P. (2000). Changes in thermal properties of apple due to vacuum impregnation. Journal of Food Engineering, 43(4), 213–218.

Miller, M., & Shukitt-Hale, B. (2012). Berry fruit enhances beneficial signaling in the brain. Journal of Agricultural and Food Chemistry, 60(23), 5709–5715.

Mizrahi, S. (2010). Syneresis in food gels and its implications for food quality. In L. H. Skibsted, J. Risbo, & M. L. Andersen (Eds.), Chemical deterioration and physical instability of food and beverages (pp. 324–348). Cambridge: Woodhead Publishing, Ltd..

Murray, J. C. (2009). Cellulosics. In G. O. Phillips & P. A. Williams (Eds.), Handbook of hydrocolloids (2nd ed., pp. 710–722). Boca Raton: Publishing Limited.

Nadim, Z., Ahmadi, E., Sarikhani, H., & Amiri Chayjan, R. (2015). Effect of methylcellulose-based edible coating on strawberry fruit’s quality maintenance during storage. Journal of Food Processing and Preservation, 39(1), 80–90.

Pátkai, G. (2012). Fruit and fruit products as ingredients. In N. Sinha, J. Sidhu, J. Barta, J. S. Wu, & M. Cano (Eds.), Handbook of fruits and fruit processing (2nd ed., pp. 270–274). Hoboken: John Wiley & Sons.

Pavlath, A., & Orts, W. (2009). Edible films and coatings: why, what and how? In K. C. Huber & M. E. Embuscado (Eds.), Edible films and coatings for food applications (pp. 16–19). Springer New York: New York.

Quintanilla, A., Mencia, A., Powers, J., Rasco, B., Tang, J., & Sablani, S. S. (2018). Vacuum impregnation of firming agents in red raspberries. Journal of the Science of Food and Agriculture, 98(10), 3706–3714. https://doi.org/10.1002/jsfa.8878.

Quintanilla, A., Mencia, A., Powers, J., Rasco, B., Tang, J., & Sablani, S. S. (2020). Developing vacuum-impregnated dehydrofrozen red raspberries with improved mechanical properties. Drying Technology Journal, 1–11. https://doi.org/10.1080/07373937.2020.1789654.

Radziejewska-Kubzdela, E., Bieganska-Marecik, R., & Kidon, M. (2014). Applicability of vacuum impregnation to modify physico-chemical, sensory and nutritive characteristics of plant origin products–A review. International Journal of Molecular Sciences, 15(9), 16577–16610.

Ramallo, L. A., & Mascheroni, R. H. (2010). Dehydrofreezing of pineapple. Journal of Food Engineering, 99(3), 269–275.

Reyes-Avalos, M. C., Minjares-Fuentes, R., Femenia, A., Contreras-Esquivel, J. C., Quintero-Ramos, A., Esparza-Rivera, J. R., & Meza-Velazquez, J. A. (2019). Application of an alginate-chitosan edible film on figs (Ficus carica): Effect on bioactive compounds and antioxidant capacity. Food and Bioprocess Technology, 12(3), 499–511.

Rodriguez, A., Bruno, E., Paola, C., Campaoñe, L., & Mascheroni, R. (2019). Experimental study of dehydration processes of raspberries (Rubus idaeus) with microwave and solar drying. Ciência e Tecnologia de Alimentos, 39(2), 336–343.

Sette, P., Salvatory, D., & Schebor, C. (2016). Physical and mechanical properties of raspberries subjected to osmotic dehydration and further dehydration by air- and freeze-drying. Food and Bioproducts Processing, 100, 156–171.

Sherer, G. W. (1989). Mechanics of syneresis I. Theory. Journal of Non-Crystalline Solids, 108(1), 18–27.

Sormani, A., Maffi, D., Bertolo, G., & Torreggiani, D. (1999). Textural and structural changes of dehydrofreeze-thawed strawberry slices: Effects of different dehydration pretreatments/Cambios texturales y estructurales de rodajas de fresa deshidratadas y descongeladas: efectos de diferentes pretratamientos de deshidratación. Food Science and Technology International, 5, 479–485.

Tapia, M., Rojas-Graü, M. A., Carmona, A., Rodriguez, F. J., Soliva-Fortuni, R., & Martin-Belloso, O. (2008). Use of alginate-and gellan-based coatings for improving barrier, texture and nutritional properties of fresh-cut papaya. Food Hydrocolloid, 22(8), 1493–1503.

Vargas, M., Albors, A., Chiralt, A., & González-Martinéz, C. (2006). Quality of cold-stored strawberries as affected by chitosan-oleic acid edible coatings. Postharvest Biology and Technology, 41(2), 164–171. https://doi.org/10.1016/j.postharvbio.2006.03.016.

Xie, J., & Zhao, Y. (2004). Use of vacuum impregnation to develop high quality and nutritionally fortified frozen strawberries. Journal of Food Processing and Preservation, 28(2), 117–132.

Yang, H., Wu, Q., Ng, L. Y., & Wang, S. (2017). Effects of vacuum impregnation with calcium lactate and pectin methylesterase on quality attributes and chelate-soluble pectin morphology of fresh-cut papayas. Food and Bioprocess Technology, 10(5), 901–913.

Yang, Z., Zou, X., Li, Z., Huang, X., Zhai, X., Zhang, W., Shi, J., & Haroon, E. (2019). Improved postharvest quality of cold stored blueberry by edible coating based on composite gum arabic/roselle extract. Food and Bioprocess Technology, 12(9), 1537–1547.

Young, N. W., Kappel, G., & Bladt, T. (2003). A polyuronan blend giving novel synergistic effects and bake-stable functionality to high soluble solids fruit fillings. Food Hydrocolloids, 17(4), 407–418. https://doi.org/10.1016/S0268-005X(03)00032-8.

Zhu, D., Guo, R., Li, W., Song, J., & Cheng, F. (2019). Improved postharvest preservation effects of Pholiota nameko mushroom by sodium alginate-based edible composite coating. Food and Bioprocess Technology, 12(4), 587–598.

Acknowledgments

The first author gratefully acknowledges the support and generosity of CONACYT, without which the present study could not have been completed.

Funding

This research was funded in part by the Washington State Department of Agriculture Specialty Crop Block Grant Program #K1772.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Quintanilla, A., Zhang, H., Powers, J. et al. Developing Baking-Stable Red Raspberries with Improved Mechanical Properties and Reduced Syneresis. Food Bioprocess Technol 14, 804–816 (2021). https://doi.org/10.1007/s11947-021-02599-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-021-02599-x