Abstract

Freezing is a very well established food preservation process that produces high-quality nutritious foods that offer the advantage of a long storage life. However, freezing is not suitable for all foods, and freezing does cause physical and chemical changes in many foods that are perceived as reducing the quality of the thawed material. Many innovative freezing processes are currently being researched and developed throughout the world to overcome these problems. One of these is dehydrofreezing. Dehydrofreezing is an adjunct to freezing in which a food is first dehydrated to a desirable moisture content and then frozen. It is particularly suited to fruits and vegetables. Since fresh fruits and vegetables contain more water than meat, and their cellular structure is less elastic, they are prone to more damage during freezing than meat. Removing some of the water prior to freezing theoretically allows the ice crystals to form and expand without damaging the cellular structure. Reducing the water content prior to freezing also has the potential to reduce the freezing time, the initial freezing point, and the amount of ice formed within the product. Despite being often cited as a new, novel or emerging technology, the concept of dehydrofreezing was developed in the 1940s. However, it has remained a niche process being commercially applied to products such as potatoes, carrots, and onions. In recent years there has been renewed interest in dehydrofreezing, and this review looks at the most recent innovations in dehydrofreezing research.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The process of freezing partially dehydrated foods is known as dehydrofreezing. If the drying/dehydrating pre-treatment is specifically osmotic, the whole process may also be termed osmodehydrofreezing. The process was developed, and term coined, at the Western Regional Research Laboratory of the US Department of Agriculture and first described by Howard and Campbell in 1946. The process was patented in 1949 (Howard et al. 1949). Full details of the process at the time are presented in Tressler and Evers’ Third Edition of The Freezing Preservation of Foods (1957). Dehydrofreezing of carrots, peas and potatoes are given as examples in the original patent (Howard et al. 1949). Work on apples, cherries, apricots and pimientos have also been cited (McGrath and Kerr 1963).

Despite being developed in the 1940s, and commercial products being available since the 1950s (McGrath and Kerr 1963), dehydrofreezing appears to have received limited interest in the scientific literature (beyond the initial series of articles and papers produced by the Western Regional Research Laboratory) until the 1990s. Since then, a wide range of fruits and vegetables has been studied (Table 1), with apple, kiwifruit and strawberry receiving the most interest.

It is claimed that dehydrofrozen fruits and vegetables have a better quality over conventionally frozen products (Li and Sun 2002), and that dehydrofreezing may be particularly suitable for sensitive fruits and vegetables, such as cucumber (Dermesonlouoglou et al. 2008).

In this review, we first address the different dehydration pre-treatments that have been studied and compare these methods. Freezing treatments and methods are then compared. Finally, current commercial production and developments are discussed, followed by an overall comparison of the effects of dehydrofreezing compared to conventional freezing.

Dehydration Pre-treatments

The original dehydrofreezing processes utilised air drying as the dehydration pre-treatment (Tressler and Evers 1957). However, most recent published studies have removed water from the fruits and vegetables prior to freezing by osmotic dehydration (Table 2). Osmotic dehydration is carried out by immersing the product in a hypertonic (osmotic) solution. The most commonly used osmotic solutes are sugars, such as sucrose, glucose, fructose, sorbitol, corn syrup, and salts, such as sodium chloride (Table 3). Osmotic dehydration methods have generally been preferred over air drying, since they are more adaptable to a wider variety of products and require less energy (Li and Sun 2002). However, some studies have shown quality advantages of air dehydration over osmotic dehydration (Ramallo and Mascheroni 2010).

The amount of dehydration required prior to freezing appears to depend on the product, the dehydration pre-treatment, and the freezing method. Many studies claim that at least 30 to 50 % of the water must be removed to improve texture after freezing and thawing (Torreggiani et al. 1987; Bolin and Huxsoll 1993; Spiazzi et al. 1998; Pham 2008; Ramallo and Mascheroni 2010; Rincon and Kerr 2010). This appears to be based on the original patented process (Howard et al. 1949). Other studies claim that only a 2 to 10 % loss by weight is required (Dermesonlouoglou et al. 2007c; Anmella 2010).

Physical Dehydration Pre-treatments

As previously stated, the original dehydrofreezing processes utilised air drying as the dehydration pre-treatment. Other physical dehydration pre-treatments that have been studied are vacuum drying (Wu et al. 2009; Uemura and Tagawa 2012) and vacuum-microwave drying (Uemura and Tagawa 2012). Given the wide range of physical drying methods (Sagar and Suresh Kumar 2010), it is surprising that few other methods appear to have been studied for pre-treatment of dehydrofrozen products. One method that does appear to warrant obvious investigation is infrared; since the feasibility of infrared heating for combined blanching and dehydration of fruits and vegetables has been demonstrated (Zhu et al. 2010; Wu et al. 2013). Since many dehydrofrozen products require blanching, a combined blanching-dehydration treatment would appear advantageous.

Relatively few published dehydrofreezing studies have compared different physical drying methods. In one of the few studies on different physical drying methods, Uemura and Tagawa (2012) compared three dehydration methods (vacuum drying, microwave drying and vacuum-microwave drying) on the physical properties of dehydrofrozen radish. The vacuum-microwave drying method was found to have the “least impact on the physical properties and loss of l-ascorbic acid (vitamin C) after freezing”. It has been recently reported that a commercial processor of frozen vegetables is looking to utilise a combined vacuum-microwave drying system for producing dehydrofrozen products (as will be discussed further in this review).

A number of studies have compared air and osmotic dehydration pre-treatments. In a study of osmotic and air dehydration of pineapple, ascorbic acid (vitamin C) losses were less during air dehydration than with osmotic dehydration (Ramallo and Mascheroni 2010). In addition, after thawing, drip was less from hot air dehydrofrozen samples than osmotic dehydrofrozen samples. Drip loss was greater in frozen pineapple samples treated to 1 h of osmotic dehydration than those that had not been pre-treated. Robbers et al. (1997) reported that air dehydration always resulted in a firmer product after freezing of kiwifruit, but that a combination of a long air-drying period (at 30 °C) followed by dehydration in a 72 °Brix osmotic sucrose solution was best to maintain fruit firmness. Sormani et al. (1999) reported that air dehydration and a combination of osmotic and air dehydration gave the highest texture improvement of frozen strawberries after thawing. Conversely, Bolin and Huxsoll (1993) found that while hot-air drying, in combination with osmotic drying or alone, was more rapid than osmotic dehydration alone, it did not keep treated pears from darkening or from becoming soft on freezing and thawing. Osmotic dehydration has also been reported to be more advantageous than air dehydration for pre-treating frozen melon (Maestrelli et al. 2001). Air dehydration caused a significant increase of alcohols and these negative aroma compounds were stable in the osmotically treated samples. Osmotic pre-treatment also prevented an increase of alcohols during the freezing process. Osmotically pre-treated fruit had a higher sensory acceptability when compared with those which were air dehydrated. While Torreggiani et al. (1987) found that air drying was suitable for pears and peaches, it caused colour and texture defects in kiwifruit. Osmotic dehydration was found improve quality in this fruit in subsequent research (Crivelli et al. 1987a).

Osmotic Dehydration Pre-treatments

The principles of osmotic dehydration of fruits and vegetables have been recently reviewed by Falade and Igbeka (2007), Tortoe (2010) and Khan (2012). A wide range of sugars and salt have been utilised (Table 3). The most used sugar, unsurprisingly, has been sucrose. Trehalose, a non-reducing disaccharide, which has 45 % of the sweetness of sucrose, has recently received much attention, owing to its protective role during freezing of membranes and proteins (Ferrando and Spiess 2001; Mazzobre et al. 1997; Dermesonlouoglou et al. 2007a; Lowithun and Charoenrein 2009). Oligofructose, a non-digestible oligosaccharide, with exceptional dietary fibre properties and prebiotic activity has also been used (Giannakourou and Taoukis 2003; Dermesonlouoglou et al. 2007b; 2008). Another sugar investigated is maltitol, a type of polyol or sugar alcohol with a sweetness similar to sucrose that is widely used in food for diabetics because it is hydrolysed and absorbed more slowly than sucrose or glucose in humans (Lowithun and Charoenrein 2009).

A comparison of sucrose, trehalose and maltitol pre-treatments of rambutan by Lowithun and Charoenrein (2009) showed similar rates of water loss and solid gain for all treatments. However, osmodehydrofrozen rambutan pre-treated with sucrose had the highest firmness value after storage for 3 and 60 days. In a comparison of sucrose, sorbitol and maltose for pre-treating dehydrofrozen apricots (Forni et al. 1997), maltose was shown to have a higher protective effect on vitamin C retention and colour stability during frozen storage than the other two sugars. Forni et al. (1997) found that the water loss and solid gain of apricots pre-treated with 65 % sorbitol at atmospheric pressure were higher than that of samples treated with sucrose and maltose syrups. In sensory tests, the pre-treatment of watermelon with maltodextrin and oligofructose before freezing resulted in the most desirable sensory characteristics in comparison with sucrose (Dermesonlouoglou et al. 2007b). Osmotic pre-treatment increased colour intensity leading to higher sensory scores than untreated.

Osmotic dehydration, depending on the temperature and concentration of the solution, is a relatively fast process with most drying happening within the first hour (Tortoe 2010). In general, higher osmotic solution concentrations result in increased water loss and faster drying rates.

The ratio of osmotic solution to sample mass will affect the solid gain and water loss in osmotic dehydration (Tortoe 2010). To avoid significant dilution of the medium and subsequent decrease of the (osmotic) driving force during the process, a large ratio (at least 30:1) is required. Although some investigators use a much lower solution to product ratio (4:1 or 3:1) in order to control mass transfer.

Osmotic dehydration can be conducted at low temperatures and is therefore a less energy-intensive process than air or vacuum drying (Tortoe 2010). The most important variable affecting the kinetics of mass transfer during osmotic dehydration is temperature. Osmotic dehydration treatments have generally been carried out at 30 °C for 1 to 24 h. After investigating a range of conditions, Bunger et al. (2004) identified that the optimum treatment for apple was to be treated with a sucrose solution of 55 °Brix at 35 °C for 60 min followed by cryogenic freezing. While Moyano et al. (2002), using the same method to investigate process conditions, did not find that temperature was important in treating papaya. Treatment temperature may depend on whether the product is liable to enzymic browning. If the product is sensitive then higher temperatures have been shown to be advantageous (Bunger et al. 2004). However, high temperatures may affect the texture. Apple slices subjected to a 50 °C osmotic treatment were found to be less firm than untreated frozen samples (Tregunno and Goff 1996). High concentration of the osmotic medium has been shown to increase firmness and help to preserve colour, however it also increases the adsorption of the medium (sugar or salt). A small number of studies have investigated treatments at chilled temperatures (5 °C), usually for 24 h. Blanda et al. (2009) claimed that chilled treatment presented the highest weight loss to sucrose gain ratio, in comparison to treatments at higher temperatures, thus permitting a greater extent of dehydration without introducing excessive amounts of sucrose into the product.

A number of studies have supplemented sugar solutions with low concentrations of calcium salts to improve texture (Falade and Igbeka 2007; Dermesonlouoglou et al. 2007a, b). Calcium is able to interact with pectins and other cellular wall components modifying the structural and mechanical properties of plant cellular matrix (Gras et al. 2003; Izumi and Wtada 1995; Falade and Igbeka 2007). Calcium chloride is used as an economical processing aid in the fresh-cut produce industry to minimize tissue damage during processing. The concentration of the calcium dip depends on the fruit or vegetable being treated, and studies report that 1–2 % calcium salts are most effective for products such as diced tomatoes (Castaldo et al. 1996). The addition of ascorbic and citric acid as antioxidants in the osmotic solution has been shown to prevent browning and significant loss of ascorbic acid during osmotic drying (Robbers et al. 1997).

A number of pre-treatments have been investigated to improve osmotic dehydration, including vacuum treatments (in a series of linked studies by Chiralt et al. 2001, Talens et al. 2001, and Talens et al. 2003), pulsed electric fields (Ben Ammar et al. 2010), pre-freezing (Saurel et al. 1994; Falade and Adelakun 2007) and blanching (Falade and Igbeka 2007).

In pulsed vacuum osmotic dehydration (PVOD), a vacuum is applied at the beginning of the process for a short time, after which the osmotic process continues at atmospheric conditions (Falade and Igbeka 2007). During the vacuum pulse, expansion and subsequent compression of occluded gas in the product pores occurs due to the action of hydrodynamic mechanisms enhanced by pressure changes. This promotes the exchange of the pore gas/liquid for the external liquid (Fito et al. 1994). Vacuum impregnation of fruits and vegetables with an osmotic solution accelerates the mass transfer rate, thus reducing the temperature requirements and reducing process times (Falade and Igbeka 2007). The application of a vacuum for a short period at the beginning of an osmotic dehydration process has been reported to have beneficial effects on process kinetics and fruit quality in many fruits (Chiralt et al. 2001). However, Talens et al. (2001) found that the a pulsed vacuum treatment prior to osmotic dehydration had a negative effect on frozen kiwifruit, in terms of increasing drip loss and mechanical damage, and resulting in a darker less vivid product colour.

Freezing Treatments

Despite the wide range of drying methods covered in some studies, surprisingly few studies have looked at a range of freezing methods and rates (Table 4). The majority of studies have used air freezing, some using blast freezers, others using cabinet or chest storage freezers. The most common operating temperature is −40 °C, under both static and blast (air speeds up to 6.5 ms−1) conditions (Table 4). Only a few studies (Biswal and Bozorgmehr 1989; Biswal et al. 1991; Moyano et al. 2002; Bunger et al. 2004; Blanda et al. 2009) have utilised cryogenic freezing. No studies appear to have investigated combining dehydration pre-treatments with the many innovative rapid freezing technologies available, such as impingement, hydro-fluidisation, high pressure assisted, ultrasonic assisted, etc. (Li and Sun 2002; Sun 2012; James and James 2012). The potential advantages of combining osmotic dehydration with immersion freezing was highlighted by Lucas and Raoult-Wack (1998) in their review of immersion freezing. One of the few studies to look at this method has been Blanda et al. (2009). Mass transfer is much slower at lower temperatures, although osmotic dehydration at 5 °C has been shown to be effective (Blanda et al. 2009; Lucas and Raoult-Wack 1998).

Effect of Freezing Rate on the Quality of Dehydrofrozen Products

There is little published data on whether the quality of dehydrofrozen fruits or vegetables is affected by freezing rate or freezing method. The majority of published studies have utilised what the authors would consider to be relatively slow freezing methods. However, the studies that have compared different freezing rates appear to show that freezing rate is important. Moyano et al. (2002) reported that freezing rate had the most significant effect of all parameters (osmotic pre-treatment parameters) on sensory quality (flavour, texture and overall quality), instrumental texture (maximum strength and area) and water activity of papaya. Going from a slow to a fast freezing rate improved the overall quality of the product by 16.5 %.

The original work on the dehydrofreezing process did not indicate that freezing rates of dehydrofrozen products were “substantially slower or faster than those of comparable conventionally frozen fruits or vegetables” (Tressler and Evers 1957). However, there is evidence that the freezing time of dehydrofrozen products is faster than that of untreated product since there is less water to freeze (Pham 2008; Shizuka et al. 2008; Wu et al. 2009; Ramallo and Mascheroni 2010). Ramallo and Mascheroni’s (2010) data shows a clear relationship between water content of treated pineapple and freezing time (Fig. 1). The freezing time of dehydrofrozen pineapple pieces was almost half that of conventionally frozen samples.

Comparison of freezing time (time required to diminish product temperature from 0 to −18 °C) and moisture content of pineapple slices, untreated or dehydrated through hot air and through sucrose syrup (osmotic) for different process times prior to freezing (adapted from Ramallo and Mascheroni 2010)

Temperature Modelling of Dehydrofreezing

The suitability of a range of existing empirical and numerical freezing models for predicting freezing times of partially dehydrated produce has been compared by Ilicali and Icer (2010). The method proposed by Salvadori and Mascheroni (1991) gave the most accurate predictions for experimental fresh papaya puree freezing times. While the Pham (1984) method was generally the best performing method in predicting the experimental freezing times. A successive mass and heat transfer modelling approach was developed to describe the osmodehydrofreezing process by Goula and Lazarides (2012).

Commercial Applications of Dehydrofreezing

The authors have found very few details of current commercial dehydrofreezing systems. Currently, most manufacturers of dehydrofrozen vegetables and fruits appear to be North American (not surprisingly since the process was developed in the USA). While the companies give few details of the dehydrating pre-treatments used, given the types of product produced and product descriptions it is likely that most processors currently utilise physical drying methods rather than osmotic pre-treatments. Some drying equipment manufacturers do market their systems for dehydrofreezing applications (such as Bühler).

Commercially available dehydrofrozen products are mainly diced and sliced vegetables and fruits intended as food ingredients for use in soups, chowders, potato pies, stews, casseroles, salsas and salads, and as pizza toppings. The following products are advertised as commercially available (from companies such as the Oregon Potato Company (Boardman, Oregon, USA), Fruvemex (Mexicali, Mexico), and Gilroy Foods; Gilroy, California, USA): aubergine, courgettes (zucchini), hot peppers, onions, peppers (capsicums), potatoes, sweet corn, strawberries, and tomatoes. Most manufacturers describe their products as dehydrofrozen, although one (Gilroy Foods) describes their products as “Controlled Moisture™ (CM)” vegetables. Products such as diced and sliced potatoes are blanched and sodium acid pyrophosphate is used as a processing aid and chelating agent to prevent greying during storage.

Current manufacturers of dehydrofrozen products claim that their products offer numerous advantages in comparison with conventionally frozen products, including: lower water loss, better colour, better texture, more product per weight, quicker cooking times, better retention in particle cohesiveness during retorting and cooking, etc.

One innovation in commercial dehydrofreezing has just recently been announced. According to reports (Anon 2013; Durance 2013), Bonduelle, a Canada-based frozen vegetable producer, has been granted the exclusive global rights to develop and launch dehydrofrozen vegetables using EnWave Corporation’s Radiant Energy Vacuum (“REV™”) technology. This technology is a form of vacuum-microwave drying, this method has advantages over conventional air drying as in being rapid and operating at low temperatures (Anon 2014). The principles of combined vacuum-microwave drying have been described by Scaman and Durance (2005).

Comparison of the Effects of Dehydrofreezing with Conventional Freezing

When developed at the Western Regional Research Laboratory of the US Department of Agriculture in the 1940s, the chief advantage of dehydrofreezing was claimed to be the cost savings, “no other process offers a product of comparable quality at as low a cost to the user” (Tressler and Evers 1957). This claim was mainly based on the weight and volume saving in comparison with conventionally frozen products, which reduced the refrigeration and transport costs. Since then, more emphasis has been placed on quality advantages of dehydrofreezing versus conventional freezing.

It is clear from the published studies that dehydrofreezing of food potentially offers numerous advantages over conventional freezing, both in terms of product quality and processing efficiencies (Table 5), and may cause beneficial changes to the thermo-physical properties of treated food (Table 6).

Effects of Dehydrofreezing on Freezing Time

There is evidence that dehydrofreezing times are shorter than conventional freezing times for the same product, since there is less water to freeze (Pham 2008; Shizuka et al. 2008; Wu et al. 2009; Ramallo and Mascheroni 2010). Reduced freezing times of 20 to 30 %, and even 50 %, have been reported in comparison with freezing times of untreated products (Spiazzi et al. 1998; Ramallo and Mascheroni 2010).

Effects of Dehydrofreezing on Energy

Reducing the water load of the food through dehydrating pre-treatments will reduce the heat load and thus the amount of energy required to freeze it (Huxsoll 1982). Crivelli et al. (1987b) estimated energy savings of 27 % for dehydrofreezing as compared with conventional freezing. Such savings are significant and it is disappointing that there appear to have been no further studies into the energy saving potential of dehydrofreezing.

Effects of Dehydrofreezing on Thermo-physical Properties

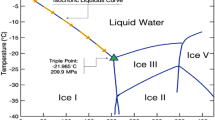

Dehydration pre-treatments may produce potentially advantageous changes to the thermal properties of the treated produce. Some of these are shown in Tocci and Mascheroni’s (2008) comparison of the thermal properties of fresh and osmotically dehydrated Kiwifruit. The water reduction reduces the enthalpy and heat capacity, and, combined with absorption of sugars and salts in the case of osmotic dehydration pre-treatments, leads to a lowering of the freezing point temperature (Table 7).

Osmotic pre-treatment of fruits and vegetables may also raise the glass transition temperature (T g). For frozen foods, as the temperature is reduced during freezing, the formation of ice results in an increase in the concentration of the water-soluble solutes and viscosity of the unfrozen matrix, this unfrozen matrix forms an amorphous glassy state (Lim et al. 2006). The temperature range at which this change takes place is the glass transition of the maximally concentrated phase, T g′ (Giannakourou and Taoukis 2003). Deterioration processes that are diffusion-controlled occur very slowly in a glassy state as opposed to a rubbery state, theoretically resulting in a longer stable frozen storage life. Storage close to or below T g′ for example has been shown to result in optimum colour and vitamin C retention in peas (Lim et al. 2006). In peas T g′ values are quite high, between −20 and −26 °C (Lim et al. 2006), however if the normal T g′ for a food is not practically achievable it may be possible to modify the food “formulation” by increasing this glass transition temperature above a practical storage temperature (Forni et al. 1997). Osmotic pre-treatment in carbohydrate solutions lead to tissue modification, due to partial water removal and solid uptake, that increases the value of T g′ (Forni et al. 1997; del Valle et al. 1998; Torreggiani et al. 1999; Giannakourou and Taoukis 2003; Lowithun and Charoenrein 2009). Increases in the glass transition temperature have been demonstrated in apple (del Valle et al. 1998; Table 8, Bunger et al. 2004), apricots (Table 9, Forni et al. 1997), peas (Giannakourou and Taoukis 2003), papaya (Table 8, Moyano et al. 2002) and rambutan (Lowithun and Charoenrein 2009). However, the glass transition temperatures for these fruits and vegetables in these studies are still generally very low, and the increase in T g′ less than 10 °C. None of these studies demonstrated practically whether storage in a glassy state of osmodehydrofrozen food was advantageous or practical.

Dehydrofreezing may also promote supercooling during freezing (Pham 2008) and this may potentially improve frozen food quality (Martins et al. 2011). However, we have identified no specific published data on the effect of dehydrofreezing on supercooling.

Effects of Dehydrofreezing on Product Quality

The protective effect of osmotic dehydrofreezing against freeze-thawing-induced texture softening has been reported to be effective in apples (Marani et al. 2007), aubergine (Wu et al. 2009), broccoli (Ohnishi and Miyawaki 2005), carrots (Ohnishi and Miyawaki 2005; Ando et al. 2012), cucumbers (Dermesonlouoglou et al. 2008) and peas (Giannakourou and Taoukis 2003). Giannakourou and Taoukis (2003) reported that parameters such as hardness and cohesiveness of osmotically pre-treated peas were 20 to 30 % higher than the respective non-treated samples when measured after they were thawed, and 10 % to 15 % when measured after cooking. However, this effect has not been observed in pears (Marani et al. 2007), potatoes (Ohnishi and Miyawaki 2005) and strawberries (Marani et al. 2007). Contradictory results have been reported for kiwifruit, with some studies reporting beneficial results (Talens et al. 2001) while others do not (Spiazzi et al. 1998; Marani et al. 2007). Ando et al. (2012) attributed these contradictory results to “an unclear understanding of the mechanisms of freezing and osmotic dehydration damage as it pertains to vegetable tissues”.

A number of studies have examined tissue structure of dehydrofrozen fruits and vegetables in detail (Tregunno and Goff 1996; Sormani et al. 1999; Ohnishi and Miyawaki 2005; Ben Ammar et al. 2010; Ando et al. 2012). Tregunno and Goff (1996) observed that the type of solute used for osmodehydrofreezing may affect where ice crystals are formed during freezing. Cryo-scanning electron microscopy showed that ice formation in sucrose and sorbitol treated apples was mainly intracellular, while it was extracellular in corn syrup solids treated samples. The authors postulated that the solute may act as a nucleating agent and that since corn syrup solids molecules are large, they remain outside of cells, causing ice to preferentially form there. The light photomicrographs of freeze-thawed strawberry tissue by Sormani et al. (1999) clearly indicated a reduction of freezing damage in air dried samples. Ohnishi and Miyawaki’s (2005) light photomicrographs of treated and untreated carrot, broccoli and potato showed that although there was some shrinkage of the cell wall in carrot and broccoli samples the cellular structure was much better than untreated samples after freezing; however, potato samples were shown to be affected by the osmotic process. In particular, the researchers noted that “the broccoli tissue after dehydration-rehydration seemed almost the same as fresh tissue”. Ando et al. (2012) evaluated cell membrane damage in carrot tissue as a result of osmodehydrofreezing using water permeability, as determined by pulsed field gradient-nuclear magnetic resonance (PFG-NMR) measurement. They also observed cell structure using light microscopy. Their study showed that although dehydrofreezing protected texture from freezing damage, the effect was only observed with respect to fracture stress, with exhibited values close to those for raw tissue. However, there was no protective effect on initial modulus and water permeability, in which values did not differ from those of cell membrane-free tissue. More specifically, osmotic dehydrofreezing had no effect on the cell membrane changes induced by freeze-thawing.

Dehydrofreezing has been reported to reduce drip loss in a range of fruits and vegetables, such as apples (Marani et al. 2007), aubergine (Wu et al. 2009), broccoli (Ohnishi and Miyawaki 2005), carrots (Ohnishi and Miyawaki 2005), kiwifruit (Talens et al. 2001; Marani et al. 2007), melon (Spiazzi et al. 1998; Maestrelli et al. 2001), pears (Marani et al. 2007), rambutan (Lowithun and Charoenrein 2009) and strawberries (Xie et al. 2004; Moraga et al. 2006; Marani et al. 2007). For example, drip loss in fresh strawberries without pre-treatment was 38 %, while drip loss in strawberries impregnated with 50 % w/w high-fructose corn syrup solutions was about 20 % (Xie et al. 2004). However, osmodehydrofreezing of pineapple has been reported to increase drip loss (Ramallo and Mascheroni 2010).

There are a number of claims of improved nutrient retention, usually vitamin C, in comparison with conventionally frozen samples (Giannakourou and Taoukis 2003; Dermesonlouoglou et al. 2007a; 2007b; Rincon and Kerr 2010). The absorption of sugars during osmotic dehydration pre-treatments has been shown to have a protective effect on l-ascorbic acid/vitamin C retention during frozen storage. Forni et al. (1997) reported maltose to be more effective than sucrose and sorbitol. Improved retention of vitamin C content (Fig. 2) in dehydrofrozen tomato has also been reported (Dermesonlouoglou et al. 2007a). The rate of l-ascorbic acid loss (vitamin C) in dehydrofrozen peas has been reported to have been reduced by as much as threefold (Giannakourou and Taoukis 2003). Osmotic pre-treatment improved nutrient retention (lycopene, an antioxidant) in frozen watermelon (Dermesonlouoglou et al. 2007b). However, some osmotic pre-treatments may have an adverse effect on vitamin C content. The use of salt has also been reported to accelerate the oxidisation of ascorbic acid (Biswal and Bozorgmehr 1989).

Retention of vitamin C content in untreated and dehydrofrozen (DHF) tomato (adapted from Dermesonlouoglou et al. 2007a)

There is evidence that dehydrofreezing retains and improves colour in aubergine (Wu et al. 2009), melon (water) (Dermesonlouoglou et al. 2007b), pear (Bolin and Huxsoll 1993) and peas (Giannakourou and Taoukis 2003; Talens et al. 2001). It may also decrease enzymic browning in some produce, such as apples (Marani et al. 2007).

Few studies have addressed the importance of ripeness or cultivar. Maestrelli et al. (2001) found that the cultivar of muskmelon used was of crucial importance. Fruits of the Rony cultivar had higher acceptability scores and proved to be more suitable for both freezing and dehydrofreezing than those of the Mirado cultivar. Studies (Rincon and Kerr 2010) have shown that less ripe fruit may be softened somewhat by osmotic treatment, with firmness and cohesiveness being maintained through frozen storage. In their study of mango slices, treated less ripe fruit had a lower acid content and higher vitamin C levels than more mature fruit.

Finally, it has been postulated that the impregnation of solutes, through osmotic dehydration pre-treatment processes, may be used as a method to improve overall quality of frozen foods and develop functional frozen foods through the enrichment of fruit and vegetable products with physiologically active components such as pre-biotics, vitamins and minerals, dietary fibre, fish oils and plant sterols (Chiralt et al. 2001; Fito et al. 2001).

Conclusions

On reviewing the published literature on dehydrofreezing, whilst it is clear that dehydrofreezing of fruits and vegetables potentially offers numerous advantages over conventional freezing, it is a little disappointing from a refrigeration aspect to see so few studies address the freezing process itself, and the dearth of studies that have investigated the importance of freezing rate, or method, on dehydrofrozen foods. Many studies have investigated a range of dehydrating pre-treatment parameters while ignoring key freezing parameters and whether there is any interaction between the two. The freezing methods employed have often been very perfunctory and not representative of standard commercial freezing methods. Given the vast literature on the importance of freezing rate on the quality of frozen fruits and vegetables it is also surprising that so few dehydrofreezing studies have utilised cryogenic freezing methods, or other more novel rapid freezing methods, such as impingement, hydro-fluidisation, high pressure assisted, ultrasonic assisted, etc. It is to be hoped that these issues will be addressed in future studies.

References

Agnelli, M. E., Marani, C. M., Spiazzi, E. A., & Mascheroni, R. H. (2001). Modelling of heat and mass transfer during (osmo) dehydrofreezing. Application to apple cubes processing. Rapid Cooling of Food, Meeting of IIR Commission C2, Bristol (UK), Section 3, 253–261

Agnelli, M. E., Marani, C. M., & Mascheroni, R. H. (2005). Modelling of heat and mass transfer during (osmo) dehydrofreezing of fruits. Journal of Food Engineering, 69, 415–424.

Ando, H., Kajiwara, K., Oshita, S., & Suzuki, T. (2012). The effect of osmotic dehydrofreezing on the role of the cell membrane in carrot texture softening after freeze-thawing. Journal of Food Engineering, 108, 473–479.

Anmella, J.M.N. (2010). Process for the production of frozen foods, particularly vegetables or fruits. US Patent 2010/0143564A1.

Anon. (2013). Bonduelle signs commercial royalty-bearing license with EnWave. Refrigerated & Frozen Foods. http://www.refrigeratedfrozenfood.com/articles/87491. Accessed 6 February 2014.

Anon. (2014). Dehydration technology for discrete food pieces. EnWave Corporation. http://www.enwave.net/nutrarev.php. Accessed 5 February 2014.

Ben Ammar, J., Lanoisellé, J.-L., Lebovka, N. I., Hecke, E., & Vorobiev, E. (2010). Effect of a pulsed electric field and osmotic treatment on freezing of potato tissue. Food Biophysics, 5(3), 247–254.

Biswal, R. N., & Bozorgmehr, K. (1989). Intermediate moisture frozen vegetables through osmotic dehydration. Technical innovations in freezing and refrigeration of fruits and vegetables, Proceedings of meeting of IIF-IIR Commissions C2 and D, Davis, USA, (IIR, Paris), 259–264.

Biswal, R. N., Bozorgmehr, K., Tompkins, F. D., & Liu, X. (1991). Osmotic concentration of green beans prior to freezing. Journal of Food Science, 56(4), 1008–1012.

Blanda, G., Cerretani, L., Cardinali, A., Barbieri, S., Bendini, A., & Lercker, G. (2009). Osmotic dehydrofreezing of strawberries: polyphenolic content, volatile profile and consumer acceptance. LWT - Food Science and Technology, 42, 30–36.

Bolin, H. R., & Huxsoll, C. C. (1993). Partial drying of cut pears to improve freeze/thaw texture. Journal of Food Science, 58(2), 357–360.

Bunger, A. (2004). Osmotic dehydration and freezing as combined processes on apple preservation. Food Science and Technology International, 10, 163–170.

Castaldo, D., Villari, G., Laratta, B., Impembo, M., Giovane, A., Fasanaro, G., & Servillo, L. (1996). Preparation of high-consistency diced tomatoes by immersion in calci-frying solutions: A pilot study. Journal of Agricultural and Food Chemistry, 44, 2600–2607.

Chiralt, A., Martínez-Navarrete, N., Martínez-Monzó, N., Talens, P., Moraga, G., Ayala, A., & Fito, P. (2001). Changes in mechanical properties throughout osmotic processes cryoprotectant effect. Journal of Food Engineering, 49, 129–135.

Crivelli, G., Torregiani, D., Bertolo, G., Forni, E., & Maestrelli, A. (1987a). Research on dehydrofreezing of fruit. Part 2: utilization for the preparation of fruit salad. XVIIth International Congress of Refrigeration, IIR, Paris, C, 468–471.

Crivelli, G., Torregiani, D., Bertolo, G., Forni, E., & Maestrelli, A. (1987b). Research on dehydrofreezing of fruit. Part 1: utilization for the preparation of fruit salad. Annales Istituto Sperimentale Valorizzazione Tecnologica dei Prodotti Agricoli, 18, 63–67.

Del Valle, J. M., Cuadros, T. R. M., & Aguilera, J. M. (1998). Glass transitions and shrinkage during drying and storage of osmosed apple pieces. Food Research International, 31, 191–204.

Dermesonlouoglou, E. K., Giannakourou, M. C., & Taoukis, P. (2007a). Stability of dehydrofrozen tomatoes pretreated with alternative osmotic solutes. Journal of Food Engineering, 78, 272–280.

Dermesonlouoglou, E. K., Giannakourou, M. C., & Taoukis, P. (2007b). Kinetic modelling of the degradation of quality of osmo-dehydrofrozen tomatoes during storage. Food Chemistry, 103, 985–993.

Dermesonlouoglou, E., Giannakourou, M., & Taoukis, P. (2007c). Kinetic modelling of the quality degradation of frozen watermelon tissue: effect of the osmotic dehydration as a pre-treatment. International Journal of Food Science & Technology, 42, 790–798.

Dermesonlouoglou, E. K., Pourgouri, S., & Taoukis, P. S. (2008). Kinetic study of the effect of the osmotic dehydration pre-treatment to the shelf life of frozen cucumber. Innovative Food Science & Emerging Technologies, 9, 542–549.

Durance, T. (2013). EnWave signs commercial royalty-bearing license with Bonduelle. EnWave Corporation. http://www.enwave.net/news.php?id=478. Accessed 5 February 2014.

Falade, K. O., & Adelakun, T. O. (2007). Effect of pre-freezing and solutes on mass transfer during osmotic dehydration and colour of oven-dried African star apple during storage. International Journal of Food Science and Technology, 42, 394–402.

Falade, K. O., & Igbeka, J. C. (2007). Osmotic dehydration of tropical fruits and vegetables. Food Reviews International, 23, 373–405.

Ferrando, M., & Spiess, W. E. L. (2001). Cellular response of plant tissue during the osmotic treatment with sucrose, maltose and trehalose solutions. Journal of Food Engineering, 49, 115–127.

Fito, P., Andres, A., Pastor, R., & Chiralt, A. (1994). Vacuum osmotic dehydration of fruits. In R. P. Singh & F. A. R. Oliveira (Eds.), Minimal processing of foods and process optimization and process assessment (pp. 107–121). Boca Raton: CRC.

Fito, P., Chiralt, A., Betoret, N., Gras, M., Cháfer, M., Martínez-Monzó, J., Andrés, A., & Vidal, D. (2001). Vacuum impregnation and osmotic dehydration in matrix engineering. Application in functional fresh food development. Journal of Food Engineering, 49, 175–183.

Floury, J., Le Bail, A., & Pham, Q. T. (2008). A three-dimensional numerical simulation of the osmotic dehydration of mango and effect of freezing on the mass transfer rates. Journal of Food Engineering, 85, 1–11.

Forni, E., Sormani, A., Scalise, S., & Torreggiani, D. (1997). The influence of sugar composition on the colour stability of osmodehydrofrozen intermediate moisture apricots. Food Research International, 30, 87–94.

Giannakourou, M. C., & Taoukis, P. S. (2003). Stability of dehydrofrozen green peas pretreated with nonconventonal osmotic agents. Journal of Food Science, 68, 2002–2010.

Goula, A. M., & Lazarides, H. N. (2012). Modeling of mass and heat transfer during combined processes of osmotic dehydration and freezing (osmo-dehydro-freezing). Chemical Engineering Science, 82, 52–61.

Gras, M. L., Vidal, D., Betoret, N., Chiralt, A., & Fito, P. (2003). Calcium fortification of vegetables by vacuum impregnation interactions with cellular matrix. Journal of Food Engineering, 56, 279–284.

Howard, L. B., & Campbell, H. (1946). Dehydrofreezing—a new way of preserving food. Food Industries, 18, 674–676.

Howard, L. B., Ramage, W. D., & Rasmussen, C. L. (1949). Process for preserving foods. US Patent, 2, 477,605.

Huxsoll, C. C. (1982). Reducing the refrigeration load by partial concentration of foods prior to freezing. Food Technology, 36(5), 98–102.

Ilicali, C., & Icier, F. (2010). Freezing time prediction for partially dried papaya puree with infinite cylinder geometry. Journal of Food Engineering, 100, 696–704.

Izumi, H., & Wtada, A. E. (1995). Calcium treatment to maintain quality of zucchini squash slices. Journal of Food Science, 60, 789–793.

James, S. J., & James, C. (2012). Innovative freezing technologies for foods. New Food, 15(4), 21–24.

Khan, M. R. (2012). Osmotic dehydration technique for fruits preservation—a review. Pakistan Journal of Food Sciences, 22, 71–85.

Li, B., & Sun, D. W. (2002). Novel methods for rapid freezing and thawing of foods—a review. Journal of Food Engineering, 54, 175–182.

Lim, M., Wu, H., Breckell, M., & Brich, J. (2006). Influence of the glass transition and storage temperature of frozen peas on the loss of quality attributes. International Journal of Food Science and Technology, 41, 507–512.

Lowithun, N., & Charoenrein, S. (2009). Influence of osmodehydrofreezing with different sugars on the quality of frozen rambutan. International Journal of Food Science & Technology, 44, 2183–2188.

Lucas, T., & Raoult-Wack, A. (1998). Immersion chilling and freezing in aqueous refrigerating media: review and future trends. International Journal of Refrigeration, 21, 419–429.

Maestrelli, A., Scalzo, R. L., Lupi, D., Bertolo, G., & Torreggiani, D. (2001). Partial removal of water before freezing: cultivar and pre-treatments as quality factors of frozen muskmelon (Cucumis melo, cv reticulatus Naud.). Journal of Food Engineering, 49, 255–260.

Marani, C. M., Agnelli, M. E., & Mascheroni, R. H. (2001). Quality of osmo-frozen products. Rapid Cooling of Food, Meeting of IIR Commission C2, Bristol (UK), Section 2,187-196

Marani, C. M., Agnelli, M. E., & Mascheroni, R. H. (2007). Osmo-frozen fruits: mass transfer and quality evaluation. Journal of Food Engineering, 79, 1122–1130.

Martins, R. C., Castro, C. C., & Lopes, V. V. (2011). The influence of geometrical and operational factors on supercooling capacity in strawberries: a simulation study. Food Bioprocess Technology, 4, 395–407.

Mazzobre, M. F., Del Pilar, B. M., & Chirife, J. (1997). Protective role of trehalose on thermal stability of lactase in relation to its glass and crystal forming properties and effect of delaying crystallization. LWT - Food Science and Technology, 30, 324–329.

McGrath, E. J., & Kerr, H. W. (1963). Dehydrofrozen apple slices: their potential in selected markets. Marketing Research Report No 578. Washington, D.C.: U.S. Dept. of Agriculture, Economic Research Service, Marketing Economics Division.

Moraga, G., Martínez-Navarrete, N., & Chiralt, A. (2006). Compositional changes of strawberry due to dehydration, cold storage and freezing–thawing processes. Journal of Food Processing and Preservation, 30, 458–474.

Moyano, P. C., Vega, R. E., Bunger, A., Garretón, J., & Osorio, F. A. (2002). Effect of combined processes of osmotic dehydration and freezing on papaya preservation. Food Science and Technology International. Vol., 8, 295–301.

Ohnishi, S., & Miyawaki, O. (2005). Osmotic dehydrofreezing for protection of rheological properties of agricultural products from freezing-injury. Food Science and Technology Research, 11, 52–58.

Pham, Q. T. (1984). An extension to Plank’s equation for predicting the freezing times for foodstuffs of simple shapes. International Journal of Refrigeration, 7, 377–383.

Pham, Q. (2008). Advances in food freezing/thawing/freeze concentration modelling and techniques. Japan Journal of Food Engineering, 9(1), 21–32.

Ramallo, L. A., & Mascheroni, R. H. (2010). Dehydrofreezing of pineapple. Journal of Food Engineering, 99, 269–275.

Rincon, A., & Kerr, W. L. (2010). Influence of osmotic dehydration, ripeness and frozen storage on physicochemical properties of mango. Journal of Food Processing and Preservation, 34, 887–903.

Robbers, M., Singh, R. P., & Cunha, L. M. (1997). Osmotic-convective dehydrofreezing process for drying kiwifruit. Journal of Food Science, 62, 1039–1042.

Sagar, V. R., & Suresh Kumar, P. (2010). Recent advances in drying and dehydration of fruits and vegetables: a review. Journal of Food Science and Technology, 47, 15–26.

Salvadori, V. O., & Mascheroni, R. H. (1991). Prediction of freezing and thawing time of foods by means of a simplified analytical method. Journal of Food Engineering, 13, 67–78.

Saurel, R., Raoult-Wack, A. L., Rios, G., & Guilbert, S. (1994). Mass transfer phenomena during osmotic dehydration of apple II: frozen plant tissue. International Journal of Food Science and Technology, 29, 543–550.

Scaman, C. H., & Durance, T. D. (2005). Combined microwave vacuum drying. In D.-W. Sun (Ed.), Emerging technologies for food processing (pp. 507–533). Oxford: Elsevier.

Shizuka, J., Ogawa, Y., & Tagawa, A. (2008). Effects of freezing and thawing on the physical and electrical properties of dehydrated radish. Journal of the Japanese Society for Food Science and Technology, 55, 158–163.

Sormani, A., Maffi, D., Bertolo, G., & Torreggiani, D. (1999). Textural and structural changes of dehydrofreeze-thawed strawberry slices: effects of different dehydration pretreatments. Food Science and Technology International, 5, 479–485.

Spiazzi, E. A., Raggio, Z. I., Bignone, K. A., & Mascheroni, R. H. (1998). Experiments in dehydrofreezing of fruits and vegetables: Mass transfer and quality factors. Advances in the Refrigeration System, Food Technologies and Cold Chain, Proceedings of meeting of IIF-IIR Commissions B2 & C2, with D1 & D2/3, Sofia, Bulgaria, IIR, Paris, 401–408.

Sun, D. W. (2012). Handbook of frozen food processing and packaging. Boca Raton: CRC.

Talens, P., Martínez-Navarrete, N., Fito, P., & Chiralt, A. (2001). Changes in optical and mechanical properties during osmodehydrofreezing of kiwi fruit. Innovative Food Science & Emerging Technologies, 3, 191–199.

Talens, P., Escriche, I., Martínez-Navarrete, N., & Chiralt, A. (2003). Influence of osmotic dehydration and freezing on the volatile profile of kiwi fruit. Food Research International, 36, 635–642.

Tocci, A. M., & Mascheroni, R. H. (2008). Some thermal properties of fresh and osmotically dehydrated kiwifruit above and below the initial freezing temperature. Journal of Food Engineering, 88, 20–27.

Torreggiani, D., Forni, E., Guercilena, I., Maestrelli, A., Bertolo, G., Archer, G. P., Kennedy, C. J., Bone, S., Blond, G., Contreras-Lopez, E., & Champion, D. (1999). Modification of glass transition temperature through carbohydrates additions: effect upon colour and anthocyanin pigment stability in frozen strawberry juices. Food Research International, 32, 441–446.

Torregiani, D., Forni, E., Crivelli, G., Bertolo, G., & Maestrelli, A. (1987). Research on dehydrofreezing of fruit. Part 1: influence of dehydration levels on the products quality. XVIIth International Congress of Refrigeration, IIR, Paris, C, 461–467.

Tortoe, C. (2010). A review of osmodehydration for food industry. African Journal of Food Science, 4, 303–324.

Tregunno, N. B., & Goff, H. D. (1996). Osmodehydrofreezing of apples: structural and textural effects. Food Research International, 29, 471–479.

Tressler, D. K., & Evers, C. F. (1957). The freezing preservation of foods: volume 1—freezing of fresh foods. Westport: AVI.

Uemura, T., & Tagawa, A. (2012). Effect of dehydration method on the physical properties of fresh-cut radish after freezing and after post-thaw rehydration in the dehydro-freezing technique. Journal of the Japanese Society for Food Science and Technology, 59, 115–121.

Wu, L., Orikasa, T., Tokuyasu, K., Shiina, T., & Tagawa, A. (2009). Applicability of vacuum-dehydrofreezing technique for the long-term preservation of fresh-cut eggplant: effects of process conditions on the quality attributes of the samples. Journal of Food Engineering, 91, 560–565.

Wu, B., Pan, Z., Qu, W., Wang, B., Wang, J., & Ma, H. (2013). Effect of simultaneous infrared dry-blanching and dehydration on quality characteristics of carrot slices. LWT—Food Science and Technology. doi:10.1016/j.lwt.2013.11.035.

Xie, J., & Zhao, Y. (2004). Use of vacuum impregnation to develop high quality and nutritionally fortified frozen strawberries. Journal of Food Processing and Preservation, 28, 117–132.

Zhu, Y., Pan, Z., McHugh, T. H., & Barrett, D. M. (2010). Processing and quality characteristics of apple slices processed under simultaneous infrared dry-blanching and dehydration with intermittent heating. Journal of Food Engineering, 97, 8–16.

Acknowledgments

The authors would like to thank Air Products for funding the work required to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

James, C., Purnell, G. & James, S.J. A Critical Review of Dehydrofreezing of Fruits and Vegetables. Food Bioprocess Technol 7, 1219–1234 (2014). https://doi.org/10.1007/s11947-014-1293-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1293-y