Abstract

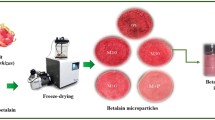

Different encapsulating agents from agroindustrial waste were tested to encapsulate betalains from red pitaya for use as natural pigments. Mucilage, extracted from the fruit peel, and gelatin from nutraceutical capsules were tested in combination with maltodextrin, and the microencapsulation was done by the spray drying method. The powders were characterized by their physicochemical properties, encapsulation yield and efficiency, morphology, betalain content, and glass transition temperature. The storage stability and the application in a food model system were also evaluated. The capsules presented low moisture and water activity, which is adequate for their safety and application. The encapsulation yields (16–25%) obtained were due to the low solid contents presented, and the combination of both wall materials increased the betalains retention by 7% in relation to liquid extract. Results for efficiency of encapsulation (above 90%) and glass transition temperature (around 85 °C) were highly satisfactory, indicating that the compounds remain well protected inside the capsule and a good storage stability of the powders. The morphology image and the results of particle size prove the obtained microcapsules, and the powder with mucilage was highlighted in relation to its stability under the studied storage conditions, retaining more than 80% of the pigment in 50 days. The microcapsules when added in yogurts corroborate the stability results and indicate the great potential of mucilage as an encapsulating agent for the food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Consumer’s demand for more natural and healthy products has challenged the industry to search new sources of pigments in order to replace the artificial colorants. The occurrence of intolerance and allergenic responses in recent years has alerted consumers and manufacturers of the importance of using natural ingredients like food dyes. However, the stability of natural pigments compared to artificial ones needs to be overcome (Celli and Brooks 2017; Downham and Collins 2000). Thus, researches in this area are necessary and of great interest to the food industry.

Studies on the use of betalains as a source of natural pigments in models of food systems are limited and essential to demonstrate their potentiality (Gengatharan et al. 2017). Cactus fruits with high contents of betalains, in contrast to red beets, can be used in food without causing a negative effect in flavor. Red-purple pitaya (Hylocereus polyrhizus) is native to Mexico, Central, and South America, and belongs to the family of Cactaceae (Leong et al. 2018). Betacyanins are responsible for its deep purple color, being betanin the most widely studied betacyanin, which has already shown several benefits to organism human (Choo et al. 2018). Betalains stability is affected by many factors, such as temperature, oxygen, pH, water activity, and presence of light (Castellar et al. 2003; Gonçalves et al. 2013; Pedreño and Escribano 2001; Tsai et al. 2010). The action of degradation parameters can be minimized with the use of technologies like microencapsulation. Among the encapsulation methods, spray drying is the most commonly used method for food. However, the quality and efficiency of the final product obtained may be influenced by the type of encapsulating agent and of the food matrix, being the choice of encapsulating agent important in the microencapsulation process (Méndez-Lagunas et al. 2013; Otálora et al. 2015).

Carbohydrates as maltodextrins and gums are widely applied as wall materials, and their use in combination with proteins has improved the properties of aggregation and emulsion formation of microcapsules (Augustin and Hemar 2009; Davidov-Pardo et al. 2013). Among proteins, gelatin has been used to improve the consistency and stability of food products (Sinthusamran et al. 2015). Compounds extracted from food wastes have received special attention due to its functional and beneficial properties. Besides that, the large quantity of residues generated by industries currently had been a significant problem of economic and environmental impact. So, the application of industrial wastes as ingredients for new products has grown to overcome this situation (Etxabide et al. 2017). The gelatin can be obtained from pharmaceutical industries that generate a residue-based on gelatin, glycerol, and water from nutraceutical gelatin capsules, which is usually wasted, and it has great potential to be used as an encapsulating material to deliver bioactive food compounds with active principles (Iahnke et al. 2015). The mixture of gelatin with other polysaccharides has been successfully used as wall material of carotenoid microcapsules due to its properties of film-formation, water solubility, edibility, and biodegradation, being an ecologically sustainable alternative (Wang et al. 2012).

In addition, pitaya peels are by-products of pulp processing which have high contents of dietary fibers, including mucilages (Jamilah et al. 2011; Utpott et al. 2020). It has been reported that mucilages obtained from cactus stems, which are generally discarded, have also a protecting effect during the encapsulating process (Gutiérrez et al. 2018; Otálora et al. 2015). Mucilages are polymers that have a complex chemical structure, and they are capable of forming large molecular aggregates. Thus, their addition in aqueous solutions can modify viscosity characteristics of the dispersion, but in high quantities may not be suitable for spray drying, so they should be used in combination with other encapsulating agents as maltodextrin (Espino-Díaz et al. 2010; Gutiérrez et al. 2018; Thanatcha and Pranee 2007). This kind of hydrocolloid proved to be a low-cost alternative for the food industry with potential applications as thickening agent, stabilizer, or emulsifiers (Dick et al. 2019).

Bakar et al. (2013) optimized the encapsulation of betalains of red pitaya peel by spray drying. However, the authors used only maltodextrin as wall material, and despite producing a powder with suitable characteristics, they did not evaluate its stability and application in any food matrix over the storage time. Other carrier materials like gums, polymers, peptides, sodium alginate, and chitosan had improved the efficiency of encapsulation and the retention of bioactive compounds of microencapsulated banana passionfruit pulp (Troya et al. 2018), tender coconut water (Nambiar et al. 2017), eggplant peel extract (Condurache et al. 2019), and elderberry extract (Ribeiro et al. 2019).

Until nowadays, the use of cited residues in combination with maltodextrin as encapsulating agents of the active compounds from pitaya pulp has not been reported in the literature. Thus, this work aimed at the microencapsulation of the betacyanins present in red pitaya (Hylocereus polyrhizus) by spray drying, using maltodextrin, gelatin, and mucilage from pitaya peel as wall materials, and the characterization and application of the obtained powders in yogurt.

Materials and Methods

Materials

Red pitaya (Hylocereus polyrhizus) fruits were provided by Pitaya do Brasil group, located in Novo Hamburgo city, state of Rio Grande do Sul, Brazil. Maltodextrin DE20 Vallens (Porto Alegre, Brazil), mucilage extracted from pitaya peel, and gelatin were used as wall materials. Gelatin capsule residue, derived from the production of linseed oil nutraceutical capsules, was supplied by the Chemical Pharmaceutical Tiaraju Laboratory (Rio Grande do Sul, Brazil). The gelatin used to produce the capsules was from a bovine source and molecular weight about 110 kDa. All reactants were of analytical grade and suitable for high-performance liquid chromatography (HPLC). The betanin standard was from Sigma-Aldrich.

Mucilage Extraction

The mucilage extraction from red pitaya peels followed the procedure of Dick et al. (2019) with some modifications. The peels were cut into small pieces, crushed in a food processor (Philips Walita®, RI7762/91, Brazil), and homogenized in water in a proportion of 1:2 (pitaya peel to water). The mixture was mechanically stirred at 700 rpm and heated to 80 °C for 30 min. Then, it was submitted to centrifugation (10,000 g, 20 min, 20 °C) (Hitachi, CR 21GIII, Japan). The supernatant obtained was precipitated with ethanol 95% in the ratio of 1:3 v/v (supernatant to ethanol) and centrifuged again at the same conditions. The pellet was dried in an oven with airflow circulation at 40 °C for 24 h. The sample was ground by gentle grinding with a mortar and pestle and subsequently sieved through a 115 mesh (125 mm aperture) to obtain the mucilage powder with standard granulometry.

Preparation of Betalain Microcapsules

Pigment extraction was according to methods described by Tang and Norziah (2007) and Sandate-Flores et al. (2016) with adaptations. The pulp was homogenized with acidified water (1% v/v citric acid) in a proportion of 1:1 (pitaya pulp/solvent) for 30 min in a mechanical stirrer. Then the seeds, fibers, and mucilaginous material were separated from betalain extract by centrifugation at 3000 g for 15 min at 4 °C. The supernatant was collected, and the wall materials were added; the solution was shaken for more than 30 min before drying.

Three different solutions with encapsulating agents were used to obtain the microencapsulated powders, with the following composition: 10% maltodextrin (MC), 10% maltodextrin and 1% mucilage (MU), and 10% maltodextrin and 1% gelatin (MG). Preliminary tests showed that the use of larger amounts of maltodextrin did not significantly increase the yield of the capsules, and even decreased the reddish hue. The drying process was carried out using a laboratory-scale Spray Dryer MSDi 1.0 (LabMaq, Brazil), with dimensions of 1800 × 720 × 650 mm. The operation parameters were as follows: 0.4 L.h−1 of feed flow, 130 °C, and 75 °C of the inlet and outlet air temperatures, respectively. The internal nozzle diameter was 0.7 mm.

Microencapsulated Powder Characterization

Moisture and Water Activity

The content of moisture was determined according to the AOAC official methods (Association of Official Analytical Chemists 2005). The water activity (aw) was measured in a HygroPalm (Rotronic, Switzerland) water activity analyzer.

Encapsulation Yield (EY)

The powder yield was calculated following equation (Eq. 1), based on Lee et al. (2013):

where EY is encapsulation yield (%), Wp is powder weight (g), Xwb is the moisture content of the powders on a wet base (wb), Vs is the volume of sample fed into the dryer (L), and St is the total solids (g dry matter/L), determined by Eq. 2:

where W2 is the capsule weight with dry residue (g), W1 is the capsule weight (g), and V is the sample volume (cm3).

Color

The color was measured using a Minolta CR-400 colorimeter (Konica Minolta, Japan), with D65 as an illuminant, diffuse illuminating, and 2° observation angle. A granular attachment accessory was used to determine the color of the powders. The evaluated parameters from the CIELAB system were lightness (L*), red/green (a*), and yellow/blue (b*).

The other parameters, chroma (Cab*) and hue (hab), were calculated according to the following Eq. 3 and Eq. 4 (Otálora et al. 2015):

Identification of betalains by HPLC-DAD-MS/MS

The sample was purified by solid-phase extraction in C-18 cartridges (Phenomenex®, 1 g), according to Stintzing et al. (2002). The C18 cartridge was activated with 2 volumes (1 volume = 6 mL) of methanol and rinsed with 3 volumes of 1% (v/v) acetic acid in water (pH 3). The extract (2 mL) was applied with 3 volumes of acidified water into the cartridges. The fractionation was done with 1 volume of methanol 100%, followed by 1 volume of methanol/acidified water (95:5). The fractions were then concentrated in rotary evaporation at 30 °C and dissolved in purified water.

The betalain analysis was performed in a Shimadzu HPLC (Kyoto, Japan) equipped with two LC-20AD pumps, a degasser DGU-20A, an autosampler SIL20AHT, a CTO-20A column oven, and a diode array detection system SPD-M20A (DAD). The HPLC system was connected in series to a Brucker Daltonics mass spectrometer (micrOTOF-Q III, Bremen, Germany) fitted with an electrospray ionization source (ESI).

The betalains were separated in a C18 reversed-phase column (250 × 4 mm; Merck, Germany), at a flow rate of 0.9 mL.min−1 and column temperature at 29 °C. The mobile phase A consisted of 2% (v/v) acetic acid in water, and the mobile phase B was 0.5% acetic acid in water and acetonitrile (50/50, v/v). The elution was carried out following a linear gradient from 10% B in A to 27% B in A in 44 min. The UV-vis spectra were obtained between 200 and 600 nm, and the chromatograms were processed at 538 (betacyanins) and 476 nm (betaxanthins). The column eluate was split to allow only 0.45 mL.min−1 entering the ESI interface. The mass spectra were acquired with a scan range from m/z 100 to m/z 1000. The MS parameters were set as follows: ESI source in positive ionization mode; nitrogen was used as dry gas in a pressure of 30 psi; capillary voltage: 3.0 kV; temperature and gas flow of 310 °C and 8 L.min−1, respectively. MS2 was set in automatic mode.

Quantification of Betalains by HPLC-DAD

The quantification of betacyanins was performed at 538 nm by using a betanin standard (Sigma-Aldrich, USA) curve (0.05–20.14 mg.L−1, R2 = 0.9964, DL = 0.15 mg.L−1, QL = 0.53 mg.L−1). The total betanin of the microcapsules was determined according to the method described by Stoll et al. (2016) with some modifications. In total, 50 mg of each sample was extracted with 8 mL of acidified methanol/water (50:50), ultrasonicated (Unique, USC 1400A, Brazil) for 5 min, and centrifuged (Hitachi, model CR 21GIII, Japan) at 3500 g for 10 min. The process was made until the total loss of color. The supernatant was filtered in a 0.45-μm membrane before injection in HPLC.

Betacyanin retention was calculated according to Eq. 5:

where Bci is betacyanin concentration of the liquid extract, and Bcf is betacyanin concentration of the microcapsules.

The Efficiency of Encapsulation (EE)

The efficiency of encapsulation was calculated following the procedure of Stoll et al. (2016) as the equation below (Eq. 6). It was defined as the difference between the betacyanin retention (BR) and the betacyanin located in the microcapsule surface (BS). Betacyanin retention (BR) was considered as the percentage of pigment retained in powders in relation to pulp extract. The betacyanin surface (BS) was determined using 1 g of each sample extracted with 5 mL of a mixture of ethanol: methanol (1:1), stirred in a Vortex (Kasvi, K40-1020, Brazil) for 1 min and then centrifuged (Hitachi, model CR 21GIII, Japan) at 3500 g for 10 min. The supernatant was filtered in a 0.45-μm membrane before injection in HPLC.

Particle Morphology and Size

The morphology of the powders was evaluated by scanning electron microscopy (SEM) using the equipment JSM-6060 (JEOL, USA). The samples were attached in stubs with a two-sided metallic adhesive tape, and the stubs were coated with gold. The voltage used was 10 kV, and they were examined at × 250, × 500, and × 1500 magnifications.

The particle size distribution was determined by laser light scattering with a Mastersizer 2000 Malvern Instruments Ltd. (Worcestershire, UK). The data were analyzed by Mastersizer 2000® 5.61 software program, and span value was obtained by dividing the difference between d0.9 and d0.1 by d0.5, where d0.9, d0.1, and d0.5 are the diameters at 90, 10, and 50% of the cumulative size distribution curve, respectively.

Glass Transition Temperature

The glass transition temperature (Tg) was determined by a Differential Scanning Calorimeter (model DSC 8500, Perkin Elmer Corporation, Wellesley, USA), based on the methodology of Janiszewska-Turak (2017). The equipment was coupled with a cooling system of liquid nitrogen (Cryofab INC, USA) and calibrated with indium (melt temperature 156.60 °C, transition energy 28.45 J.g−1). Dry nitrogen was used as the purge gas (20 mL.min−1). A quantity between 5 and 10 mg of the microcapsules was scanned in a hermetically sealed aluminum pan, and an empty aluminum pan was used as a reference. The samples were heated at 10 °C.min−1 from 25 to 150 °C and then cooled to 25 °C at 50 °C.min−1.

Accelerated Storage Stability of Microencapsulated Powders

The powders were placed in Petri dishes (22 × 143 mm) and stored at 40 ± 1 °C with 55-60% RH and 1600 lx in a chamber with a photoperiod (NL-41-01, NewLab, Brazil) for 50 days. The stability was evaluated every 5 days by quantification of betacyanins, color analysis, and monitoring of water activity.

For betacyanin determination, about 0.05 g of each sample was dissolved in 2 mL of distilled water, and the betacyanin content was measured by absorbance at 538 nm using a spectrophotometer, according to the following Eq. 7 (Leong et al. 2018):

where BC is the betacyanin concentration in milligrams per 100 g dry matter, A is the absorption value at the absorption maximum (λ max = 538 nm), DF is the dilution factor, MW is the molecular weight of betanin (550 g.mol−1), V is the volume of extract (mL), ε is the molar extinction coefficient of betanin (ε = 65,000 L.mol−1.cm−1), L is the pathlength of the cuvette, and W is the weight of dry powder.

The color was determined with the Minolta CR-400 colorimeter (Konica Minolta, Japan), with D65 as an illuminant, using the same CIELAB system parameters.

Application in a Food Model System

Addition of Betalain Capsules in Yogurt

Quantities of 1 g of the more stable microcapsules (MC and MU) were added to a commercial natural yogurt (200 g) (Vigor®). The volume of 6.5 mL of liquid extract of pitaya was added to the same yogurt to compare the color stability during the shelf life of the product. The color standardization of the three products was performed by the parameters of the CIELAB colorimetric analysis system, with L*, a*, and b* values close to 45, 12, and − 3, respectively. Yogurt samples were evaluated through the determination of total betalains and color analysis by the colorimeter (Konica Minolta, Japan). A Glass Light Projection Tube was used for the color reading of the yogurts.

Determination of Betalains in Yogurt

The extraction of betalains was performed following the methodology of Güneşer (2015), with some adaptations. A volume of 5 mL of yogurt was mixed with 3 mL of a solution of 8% trichloroacetic acid in water. The mixture was homogenized in a vortex (Kasvi, K40-1020, Brazil) for 3 min and centrifuged at 6000 g for 10 min at 25 °C (Hitachi, CR 21GIII, Japan). Extraction was exhaustive. The supernatant was filtered through a 0.45-μm filter, and betacyanin content was measured in a spectrophotometer at 538 nm and calculated according to Eq. 7.

Statistical Analysis

The results were computed by analysis of variance (ANOVA) and the Tukey test, at the 5% level of significance, using Statistica 13.0 software.

Results and Discussion

Characterization of Microencapsulates

Moisture and Water Activity

The main characteristics of the encapsulated powders are presented in Table 1. The results found for moisture and water activity (aw) of the three microcapsules were adequate to a safe application; once moisture contents were low and values of aw were below 0.6, they reduce to a minimum the microbial deterioration in foods (Otálora et al. 2015). The higher value of water activity of the MC sample must be related to its higher moisture content.

Moisture contents of encapsulated powders were according to those reported by Bazaria and Kumar (2017a) (1.26–2.88%), who encapsulated beetroot juice with maltodextrin and Arabic gum as wall materials. This study shows that the combination of maltodextrin with other ingredients such as mucilage and gelatin reduced moisture and also water activity, due to the increase in the total solid content of the extract and to the moisture that needs to be evaporated in the drying process, which is in agreement with studies of Bazaria and Kumar (2016) and Otálora et al. (2015).

Encapsulation Yield

The betalain liquid extract had total solid content next to 3.8%, leading to low encapsulation yields (EY), and these values are proportional to the encapsulating agent concentration. The results are according to the work of Otálora et al. (2015) (16.4–25.4%) that studied the encapsulation of betalains from cactus fruit using cladode mucilage and maltodextrin as wall materials. The lowest value for the microcapsule with gelatin (MG) is probably due to gelatin sticking in the dryer wall of the equipment, which is not recovered, according to Kanwate et al. (2019). The addition of mucilage from pitaya peel did not change the final yield of the powder (MU), comparing to the control sample developed with only maltodextrin (MC).

A large difference in yield of microcapsules produced by spray drying can also be attributed to variations in the relative humidity during the drying process, to the escape of fine particles, or to their deposition in the collecting cone. Also, slow feed flows as 0.4 L.h−1 and high temperature gradients (130 °C inlet and 75 °C outlet) lead to low drying yields (Ceja-Medina et al. 2020). Delia et al. (2019) presented higher results, but with significant variability (42–82%) when betalain microcapsules were produced from cactus fruit of species Escontria chiotilla and Stenocereus queretaroensis using cladode mucilage of Opuntia fícus-indica.

Color and Betalain Content

The three different microcapsules produced presented color parameters L*, a*, and b* which are very similar (Table 1), indicating that the samples had a very close color tonality (Fig. 1). The use of gelatin (MG) caused a reduction in a* value and an increase in b* value in comparison to the control sample (MC), causing a decrease in chroma (Cab*). This may be due to the yellowish color of the gelatin residue. Parameters a* of powders produced were slightly lower than values found by authors who spray-dried dragon fruit juices with maltodextrin concentration of 30% (a* = 40.6) (Lee et al. 2013), and also than the powders obtained from other pitaya species (a* = 41.7–44) (García-Lucas et al. 2016). Results of the hue angle close to 340° were consistent with the magenta-purple ton, similar to pitaya powders with maltodextrin developed by Shaaruddin et al. (2017).

The highest a* value, which is associated with redness, and chroma value, which means higher saturation of the color, however, are not related to the higher betacyanin content (Table 1). This difference may occur due to colorimeter measuring tonality of the surface of the powders, which allows better light reflection (Shaaruddin et al. 2017). The total betacyanin content differed between the capsules and was similar to the results of Otálora et al. (2015) (0.50 mg.g−1), but in this case, indicating that the type of encapsulating agent affected pigment retention. The amount of agent can also influence the pigment content of the final powder (Sharif et al. 2020). This is evidenced by the percentages of betanin retained in the capsules in relation to the liquid extract (Table 1), which were significantly affected by high exposure temperature during drying. And these retention values are comparable to those found by Ruíz-Gutiérrez et al. (2014) (40–57%), who encapsulated cactus pear betalains by spray drying using soluble fiber.

Betalains Identification

Six peaks were identified in the red pitaya extract by HPLC-DAD-MS/MS (Table 2). Figure 2 shows the chromatogram at 538 nm. The individual betacyanins were evaluated based on their UV-Vis detection, chromatic behavior, molecular mass, retention time, and reference authors who identified compounds of the same species of pitaya (Fathordoobady et al. 2016; Stintzing et al. 2002). According to them, the main betacyanin components of Hylocereus polyrhizus are betanin, phyllocactin, hylocerenin, and their corresponding isomers. The first peak was identified as betanin, followed by its isomer isobetanin.

The two subsequent peaks also had the same protonated molecular ions [M + H]+, meaning two additional isomers. A longer retention time indicates a compound with a more complex chemical structure in relation to betanin, and more difficult to separate in the column. According to Stintzing et al. (2002), the groupings connected to betacyanin structures are aliphatic acyl groups, corresponding to the phyllocactin compound and its isomer isophyllocactin. The compound hylocerenin was not detected, probably because it is present in not significant quantities, below the detection limit of the equipment. Peak number 5 was identified by retention time and molecular mass as iso-butyrylbetanin, the molecule also reported in this fruit species studied by other authors (Fathordoobady et al. 2016; Stintzing et al. 2002).

Efficiency of Encapsulation (EE)

High encapsulation efficiency results were found for the produced powders, as showed in Table 1, indicating that the highest amount of betalains was located inside the core of the capsules. Studies have reported that electrostatic interactions or hydrogen bondings induce a high betalain-polymer interaction, which should cause a good adhesion of the bioactive composite to some encapsulating materials (Kanner et al. 2001; Vergara et al. 2014). Furthermore, in the case of temperature-sensitive compounds, encapsulation efficiency decreases with increasing process temperature, mainly in temperatures above 150 °C (Sharif et al. 2020).

Vargas-Campos et al. (2018) obtained similar EE percentages (93.98%) using commercial starch to encapsulate betalains of pitaya fruit from species Stenocereus pruinosus. Still, they reached better results (96.7–97.6%) with modified starches as wall materials. The sample with mucilage presence (MU) had a higher efficiency of encapsulation in relation to the control (MC). This is explained by the molecular weight of the mucilage. Different molecular weights of compounds affect this characteristic of the capsules (Handayani et al. 2018). Studies have affirmed that cactus mucilages are heteropolysaccharides with high molecular weights, and it results in an improvement in efficiency. An excessive amount of core material, however, could even decrease the encapsulation potential of the agent (Handayani et al. 2018; Otálora et al. 2015). The use of gelatin residue did not affect the EE.

Particle Morphology and Size

Figure 3 shows that the microcapsules had a round shape, ranging from spherical to oval, with sizes between 15 and 30 μm, smooth surfaces, and no surface cracks. This format is typical in microencapsulation by the spray drying method (Bazaria and Kumar 2017b; Lee et al. 2013). According to Ceja-Medina et al. (2020), particles with spherical shape reflect adequate conditions of the spray drying process. Bazaria and Kumar (2017b) reported that a much round shape is due to a higher solid content, which can explain the format of the powder that was reached with the combination of maltodextrin and mucilage as encapsulating agents (3b). In addition, the integrity of microcapsules observed in the images increases microcapsule stability due to low oxygen permeability (Delia et al. 2019).

The particle size of samples ranged from 8 to 15 μm in diameter (Table 1), which allows them to be classified as microparticles. Fang and Bhandari (2010) evaluated that the inlet air temperature of the drying equipment influence the particle size of samples and that low temperatures around 120 °C resulted in larger capsules of size around 8–12 μm. Moreover, it has been reported that maltodextrin may allow air expansion inside the particle, causing an increase in its diameter and that the molecular size of wall material also is related to the size of the capsule, and can also increase it (Otálora et al. 2015).

Therefore, the control sample had the smallest size, and the others had higher diameters, probably due to the use of mucilage or gelatin with maltodextrin. The results found are in agreement with the study of Medina-Torres et al. (2019), which found maltodextrin particle size ranging from 18 to 20 μm. Larger sizes result in a reduction in the surface area of the particles, lower particle-particle interactions, and lower viscosity. Lee et al. (2013) found particle sizes of dragon fruit powders ranging between 3 and 7 μm.

Glass Transition Temperature

Compounds like sugars in spray-dried food powders are amorphous glassy components. They are thermodynamically unstable and can crystallize, becoming sticky (Tze et al. 2012). Therefore, the glass transition temperature is an essential parameter to determine the storage conditions of the powders. Under the process conditions studied, the encapsulated had high glass transition temperatures (Table 1), and the values were similar for all samples.

Generally, high drying temperatures lead to higher values of Tg due to the moisture evaporation being more efficient. Researchers who produced pitaya fruit powders using maltodextrin and different inlet air temperatures found values ranging from 59 to 74 °C (Tze et al. 2012). In this work, the inlet air temperature of 130 °C was sufficient to eliminate the moisture of the pitaya extracts, as previously described, leading to high glass transition temperatures. Besides that, maltodextrins with high dextrose equivalents (DE) provide higher glass transition temperatures, resulting in better stability of the dried powders (Sharif et al. 2020). Thus, the DE20 maltodextrin used must have improved this characteristic of the samples produced.

Analysis of Storage Stability

The graph of betacyanin retention of the powders over the 50 days of storage at 40 °C adjusted well to an exponential behavior, as shown in Fig. 4. Significant degradation of the pigment under the evaluated conditions can be observed, which was different for the three microcapsules, indicating a strong influence of the wall materials used in the betacyanin retention over storage time.

It has already been reported that the use of maltodextrin as an encapsulating matrix increases the stability of betalains, so it has been used alone or in combination with other polysaccharides. However, maltodextrin is a molecule of low mass and shorter chains, being more hygroscopic, so its use alone entails higher values of moisture, decreasing pigment retention. And its combination with other agents offers financial advantage, due to the low price and availability of maltodextrin. Some authors employed its combination with guar gum, Arabic gum, xanthan gum, and pectin to encapsulate betalains from red beet, and they achieved an increase in their stability (Cai and Corke 2000; Castro-Enríquez et al. 2020; Sharif et al. 2020).

The addition of a polysaccharide of high molecular weight as pitaya peel mucilage decreased powder moisture. Consequently, it ensured betacyanin stability for a longer time, as reported by Otálora et al. (2015). However, the functional properties and molecular structure of gelatin are affected by technological processes. Studies demonstrated that protein degradation occurred in gelatin submitted to spray drying, increasing the number of small peptides. This may lead to higher aggregation between proteins, and also higher moisture absorption, or even cause permeability and allow oxygen entrance, accelerating color degradation (Kanwate et al. 2019; Shaaruddin et al. 2017; Vergara et al. 2014).

Storage stability of betalain capsules from pitaya with commercial and modified starches was also evaluated at 40 °C during 39 days, and the authors had lower betacyanin losses (22–23%) than the powder with only maltodextrin (MC) of this study (Fig. 4). The researchers still found that the use of commercial starch resulted in higher pigment loss (65%), which was higher than the value found for the microcapsule with gelatin in this work (Fig. 4). The combination of mucilage with maltodextrin (MU) overcame the modified starches used by the same authors since it corresponded to betacyanin retention around 85% (Vargas-Campos et al. 2018). Delia et al. (2019) obtained high results of pigment retention (85–99%) in betalain powders from cactus fruit pulps with mucilage as wall material after 3 months of storage in vacuum conditions at room temperature.

In the study of Lee et al. (2013), who submitted the betalain capsules to different relative humidity, the physical appearance of the powders changed at 55% RH, with structural deformation and formation of agglomerates. The same happened in this work; there were changes in the color and format of the particles, which became sticky. The water activity of all samples remained at values of 0.55 to 0.65 during the storage period, in keeping with the ambient humidity conditions, and indicating that the use of different encapsulating materials did not affect this parameter.

Values of the coefficient of determination (Table 3) confirmed the good exponential fit to the curves and that degradations followed first-order kinetics. Shaaruddin et al. (2017) reported that the kinetics of degradation had the same behavior for powders with maltodextrin. Still, the values of rate constants (5.1–5.3 × 10−3) were lower, probably due to a higher concentration of the material and to the lower moisture of samples. The results found for kt also confirmed that the stability of encapsulated betalains during storage depends on the type of encapsulating material and probably on the temperature and related humidity, such as reported by Otálora et al. (2015).

Rate constants were used to estimate the half-life time of the capsules, the time that betacyanin degradation reaches 50% of its initial value. Sample MU had a half-time significantly higher than the others, equivalent to more than 5 months under these conditions, and it was higher than values found by Otálora et al. (2015), evidencing the great potential of mucilage as an encapsulating agent together with other materials such as maltodextrin. Previous researches had already indicated that the protective effect of microcapsules depends on their initial encapsulation efficiency, particle integrity after spray drying, and also on the strength of wall materials (Ding et al. 2020).

A significant change in color parameters of powders after 50 days of storage at 40 °C and 55–60% RH may be perceived in Table 4. Decreasing in L* values indicated a darkening of samples. The decrease in lightness may be derived from the oxidation of the incorporated compounds (Rubio et al. 2020). It was more pronounced in the first 5 days, with a subsequent mild increase in the luminosity of the samples over the other days of storage.

The decrease of a* coordinate (redness) corroborates the loss in pigmentation due to betacyanin degradation, as previously discussed. It was possible to verify that the high temperature and relative humidity already demonstrate their great influence on the powder stability in the initial days of storage due to the significant reduction of redness. Furthermore, this parameter in the sample with mucilage remained higher during all days in relation to the sample with gelatin, suggesting higher retention of betacyanins. The increase in b* parameter (yellowness) indicate a lower tendency to purple tonality. The positive b* coordinate indicates a more yellowish color trend, leading to an orange tonality when combined with the reduction of a* parameter.

The behavior of the three microparticles, in this case, was very similar because the color measurement was performed on the surface of the capsules, this analysis being indicative of the perception of change in color through the human eye. Lee et al. (2013) also observed physical and structural changes in betalain capsules stored at high relative moisture, above 50%, due to water migration to the environment into the powder samples.

Application of the Microencapsulated Powders in Yogurts

Betalain microcapsules produced from red pitaya pulp extract that showed the highest stability and the pure liquid extract (control) were applied in a food model system in order to evaluate its behavior in the shelf life of yogurt. The loss of pigmentation in this case also followed first-order kinetics with adequate exponential fits (0.94 < R2 < 0.97) (Fig. 5).

As expected, the higher betacyanin degradation occurred in yogurt added of liquid extract (YE), which reached less than 60% of retention in 28 days. The microcapsule obtained with 10% maltodextrin (YMC) and microcapsule with 10% maltodextrin and 1% mucilage (YMU) reached higher retention (> 80%) corroborating with stability results. Gengatharan et al. (2017) compared the pigment degradation obtained from pitaya and red beet in yogurt and observed higher stability of pitaya extract pigment. In another study, microencapsulated anthocyanins when applied to yogurt showed higher retention compared to the liquid extract, which maintained only values of up to 4%, and the microparticles obtained by atomization reached 21% retention after 36 days of storage at 5 °C (de Moura et al. 2019).

A significant increase in lightness (L*) of stored yogurts was observed, indicating a higher loss of color intensity of samples from day 14 (Table 5). But the values were still lower than those found by Obón et al. (2009) (70–72), which produced a colorant from Opuntia stricta fruits with glucose and also applied at the same product. These authors evaluated by color parameters and had close hue angles (335°), as well as an increase of them over time, meaning a deviation from purple to red color.

The best pigmenting potential was obtained in samples with lower hab°, and the yogurt with pitaya extract had the highest angle at the last day and a weak pink final appearance, as in work of Vargas-Campos et al. (2018), where the refined extract added to the yogurt caused a final hue angle of 40.73°. Chroma values did not show significant variations; they just had lower results for the sample YE, suggesting a weaker color tonality for it. The parameters and color retention obtained indicate that the developed microcapsules can be used as natural additives to color foods since it maintains much of its coloring power over their shelf life.

Conclusion

The pigments extracted from the red pitaya pulp in encapsulated form were shown as potential natural dyes with characteristics suitable for application in foods. The color tonality, the efficient encapsulation, and the low values of moisture and water activity of the obtained powders indicated its easy and excellent applicability in several branches of the industry. The use of mucilage extracted from fruit peel combined with maltodextrin as encapsulating agents improved some properties, including encapsulation efficiency, betalain content and retention, and also the stability of the powders under accelerated storage conditions, becoming this formulation the most effective for betalain encapsulation. The gelatin residue, however, did not prove to be a suitable material for use in encapsulation processes by the spray drying method. The application of the capsules in a food matrix as yogurt confirmed the effectiveness of the technique and of the materials used to decrease color degradation when exposed to specific conditions. The dyes would be used in powder form and could also be applied in other matrices, such as candies, soft drinks, ice creams, and bakery products, for example. The results suggest that natural wastes could be an excellent source of wall materials to improve the production of encapsulated pigments and should be better explored.

References

AOAC (Association of Official Analytical Chemists) (2005). Official Methods of Analysis of the Association of Analytical Chemists International, 18th ed. Gathersburg, MD U.S.A Official methods, 2005.08.

Augustin, M. A., & Hemar, Y. (2009). Nano- and micro-structured assemblies for encapsulation of food ingredients. Chemical Society Reviews, 38(4), 902–912. https://doi.org/10.1039/B801739P.

Bakar, J., Ee, S. C., Muhammad, K., Hashim, D. M., & Adzahan, N. (2013). Spray-drying optimization for red pitaya peel (Hylocereus polyrhizus). Food and Bioprocess Technology, 6(5), 1332–1342. https://doi.org/10.1007/s11947-012-0842-5.

Bazaria, B., & Kumar, P. (2016). Effect of whey protein concentrate as drying aid and drying parameters on physicochemical and functional properties of spray dried beetroot juice concentrate. Food Bioscience, 14, 21–27. https://doi.org/10.1016/j.fbio.2015.11.002.

Bazaria, B., & Kumar, P. (2017a). Comparative analysis of bio-polymers addition on structural and physical properties of spray dried beetroot juice concentrate. Journal of Food Processing and Preservation, 41(6), 1–8. https://doi.org/10.1111/jfpp.13232.

Bazaria, B., & Kumar, P. (2017b). Effect of dextrose equivalency of maltodextrin together with Arabic gum on properties of encapsulated beetroot juice. Journal of Food Measurement and Characterization, 11(1), 156–163. https://doi.org/10.1007/s11694-016-9382-4.

Cai, Y. Z., & Corke, H. (2000). Production and properties of spray-dried Amaranthus betacyanin pigments. Journal of Food Science, 65(3600), 1248–1252.

Castellar, R., Obónn, J. M., Alacid, M., & Fernández-López, J. A. (2003). Color properties and stability of betacyanins from Opuntia fruits. Journal of Agricultural and Food Chemistry, 51(9), 2772–2776. https://doi.org/10.1021/jf021045h.

Castro-Enríquez, D. D., Montaño-Leyva, B., Del Toro-Sánchez, C. L., Juaréz-Onofre, J. E., Carvajal-Millan, E., Burruel-Ibarra, S. E., et al. (2020). Stabilization of betalains by encapsulation—a review. Journal of Food Science and Technology, 57(5), 1587–1600. https://doi.org/10.1007/s13197-019-04120-x.

Ceja-Medina, L. I., Ortiz-Basurto, R. I., Medina-Torres, L., Calderas, F., Bernad-Bernad, M. J., González-Laredo, R. F., et al. (2020). Microencapsulation of Lactobacillus plantarum by spray drying with mixtures of Aloe vera mucilage and agave fructans as wall materials. Journal of Food Process Engineering, (April), 1–12. https://doi.org/10.1111/jfpe.13436

Celli, G. B., & Brooks, M. S. L. (2017). Impact of extraction and processing conditions on betalains and comparison of properties with anthocyanins — A current review. Food Research International, 100(Pt 3), 501–509. https://doi.org/10.1016/j.foodres.2016.08.034.

Choo, K. Y., Kho, C., Ong, Y. Y., Thoo, Y. Y., Lim, R. L. H., Tan, C. P., & Ho, C. W. (2018). Studies on the storage stability of fermented red dragon fruit (Hylocereus polyrhizus) drink. Food Science and Biotechnology, 1–7. https://doi.org/10.1007/s10068-018-0367-4

Condurache, N. N., Aprodu, I., Crăciunescu, O., Tatia, R., Horincar, G., Barbu, V., Enachi, E., Râpeanu, G., Bahrim, G. E., Oancea, A., & Stănciuc, N. (2019). Probing the functionality of bioactives from eggplant peel extracts through extraction and microencapsulation in different polymers and whey protein hydrolysates. Food and Bioprocess Technology, 12(8), 1316–1329. https://doi.org/10.1007/s11947-019-02302-1.

Davidov-Pardo, G., Arozarena, I., & Marín-Arroyo, M. R. (2013). Optimization of a wall material formulation to microencapsulate a grape seed extract using a mixture design of experiments. Food and Bioprocess Technology, 6(4), 941–951. https://doi.org/10.1007/s11947-012-0848-z.

de Moura, S. C. S. R., Schettini, G. N., Garcia, A. O., Gallina, D. A., Alvim, I. D., & Hubinger, M. D. (2019). Stability of hibiscus extract encapsulated by ionic gelation incorporated in yogurt. Food and Bioprocess Technology, 12(9), 1500–1515. https://doi.org/10.1007/s11947-019-02308-9.

Delia, S. C., Chávez, G. M., León-Martínez Frank, M., Araceli, S. G. P., Irais, A. L., & Franco, A. A. (2019). Spray drying microencapsulation of betalain rich extracts from Escontria chiotilla and Stenocereus queretaroensis fruits using cactus mucilage. Food Chemistry, 272(April 2018), 715–722. https://doi.org/10.1016/j.foodchem.2018.08.069.

Dick, M., Dal Magro, L., Rodrigues, R. C., Rios, A. d. O., & Flôres, S. H. (2019). Valorization of Opuntia monacantha (Willd.) Haw. cladodes to obtain a mucilage with hydrocolloid features: Physicochemical and functional performance. International Journal of Biological Macromolecules, 123, 900–909. https://doi.org/10.1016/j.ijbiomac.2018.11.126.

Ding, Z., Tao, T., Wang, X., Prakash, S., Zhao, Y., Han, J., & Wang, Z. (2020). Influences of different carbohydrates as wall material on powder characteristics, encapsulation efficiency, stability and degradation kinetics of microencapsulated lutein by spray drying. International Journal of Food Science and Technology, 55(7), 2872–2882. https://doi.org/10.1111/ijfs.14544.

Downham, A., & Collins, P. (2000). Colouring our foods in the last and next millennium. International Journal of Food Science and Technology, 35(1), 5–22. https://doi.org/10.1046/j.1365-2621.2000.00373.x.

Espino-Díaz, M., De Jesús Ornelas-Paz, J., Martínez-Téllez, M. A., Santillán, C., Barbosa-Cánovas, G. V., Zamudio-Flores, P. B., & Olivas, G. I. (2010). Development and characterization of edible films based on mucilage of Opuntia ficus-indica (L.). Journal of Food Science, 75(6), 347–352. https://doi.org/10.1111/j.1750-3841.2010.01661.x.

Etxabide, A., Uranga, J., Guerrero, P., & de la Caba, K. (2017). Development of active gelatin films by means of valorisation of food processing waste: a review. Food Hydrocolloids, 68, 192–198. https://doi.org/10.1016/j.foodhyd.2016.08.021.

Fang, Z., & Bhandari, B. (2010). Encapsulation of polyphenols - a review. Trends in Food Science and Technology, 21(10), 510–523. https://doi.org/10.1016/j.tifs.2010.08.003.

Fathordoobady, F., Mirhosseini, H., Selamat, J., Yazid, M., & Manap, A. (2016). Effect of solvent type and ratio on betacyanins and antioxidant activity of extracts from Hylocereus polyrhizus flesh and peel by supercritical fluid extraction and solvent extraction. Food Chemistry, 202, 70–80. https://doi.org/10.1016/j.foodchem.2016.01.121.

García-Lucas, K. A., Méndez-Lagunas, L. L., Rodríguez-Ramírez, J., Campanella, O. H., Patel, B. K., & Barriada-Bernal, L. G. (2016). Physical properties of spray dryed Stenocereus griseus pitaya juice powder. Journal of Food Process Engineering, (August), 1–9. https://doi.org/10.1111/jfpe.12470

Gengatharan, A., Dykes, G. A., & Choo, W.-S. (2017). The effect of pH treatment and refrigerated storage on natural colourant preparations (betacyanins) from red pitahaya and their potential application in yoghurt. LWT - Food Science and Technology, 80, 437–445. https://doi.org/10.1016/j.lwt.2017.03.014.

Gonçalves, L. C. P., Di Genova, B. M., Dörr, F. A., Pinto, E., & Bastos, E. L. (2013). Effect of dielectric microwave heating on the color and antiradical capacity of betanin. Journal of Food Engineering, 118(1), 49–55. https://doi.org/10.1016/j.jfoodeng.2013.03.022.

Güneşer, O. (2015). Pigment and colour stability of beetroot betalains in cow milk during thermal running head : Thermal stability of beetroot betalains in milk. Food Chemistry, (September). https://doi.org/10.1016/j.foodchem.2015.09.033

Gutiérrez, M. C., Utrilla-Coello, R. G., & Soto-Castro, D. (2018). Effect of Opuntia ficus-indica mucilage in the ecological extraction, drying, and storage of eggplant anthocyanins. Journal of Food Processing and Preservation, 42(2), 1–8. https://doi.org/10.1111/jfpp.13439.

Handayani, M. N., Khoerunnisa, I., Cakrawati, D., & Sulastri, A. (2018). Microencapsulation of dragon fruit (Hylocereus polyrhizus) peel extract using maltodextrin. IOP Conference Series: Materials Science and Engineering, 288(1), 1–8. https://doi.org/10.1088/1757-899X/288/1/012099.

Iahnke, A. O.e S., Costa, T. M. H., Rios, A. d. O., & Flôres, S. H. (2015). Residues of minimally processed carrot and gelatin capsules: Potential materials for packaging films. Industrial Crops and Products, 76, 1071–1078. https://doi.org/10.1016/j.indcrop.2015.08.025.

Jamilah, B., Shu, C. E., Kharidah, M., Dzulkifly, M. A., & Noranizan, A. (2011). Physico-chemical characteristics of red pitaya (Hylocereus polyrhizus) peel. International Food Research Journal, 18(1), 279–286. https://doi.org/10.1163/156856103321645176.

Janiszewska-Turak, E., Dellarosa, N., Tylewicz, U., Laghi, L., Romani, S., Dalla Rosa, M., & Witrowa-Rajchert, D. (2017). The influence of carrier material on some physical and structural properties of carrot juice microcapsules. Food Chemistry, 236, 134–141. https://doi.org/10.1016/j.foodchem.2017.03.134.

Kanner, J., Harel, S., & Granit, R. (2001). Betalains - A new class of dietary cationized antioxidants. Journal of Agricultural and Food Chemistry, 49(11), 5178–5185. https://doi.org/10.1021/jf010456f.

Kanwate, B. W., Ballari, R. V., & Kudre, T. G. (2019). Influence of spray-drying, freeze-drying and vacuum-drying on physicochemical and functional properties of gelatin from Labeo rohita swim bladder. International Journal of Biological Macromolecules, 121, 135–141. https://doi.org/10.1016/j.ijbiomac.2018.10.015.

Lee, K. H., Wu, T. Y., & Siow, L. F. (2013). Spray drying of red (Hylocereus polyrhizus) and white (Hylocereus undatus) dragon fruit juices: Physicochemical and antioxidant properties of the powder. International Journal of Food Science and Technology, 48(11), 2391–2399. https://doi.org/10.1111/ijfs.12230.

Leong, H. Y., Ooi, C. W., Law, C. L., Julkifle, A. L., Pan, G. T., & Show, P. L. (2018). Investigation of betacyanins stability from peel and flesh of red-purple pitaya with food additives supplementation and pH treatments. Lwt, 98(September), 546–558. https://doi.org/10.1016/j.lwt.2018.09.021.

Medina-Torres, L., Núñez-Ramírez, D. M., Calderas, F., González-Laredo, R. F., Minjares-Fuentes, R., Valadez-García, M. A., Bernad-Bernad, M. J., & Manero, O. (2019). Microencapsulation of gallic acid by spray drying with aloe vera mucilage (Aloe barbadensis miller) as wall material. Industrial Crops and Products, 138(June), 111461. https://doi.org/10.1016/j.indcrop.2019.06.024.

Méndez-Lagunas, L., García-Lucas, K., Rodríguez-Ramírez, J., Campanella, O. H., Patel, B. K., & Sandoval-Torres, S. (2013). Physical properties of spray dried pitaya. Researchgate.Net, (February 2015), 2–4.

Nambiar, R. B., Sellamuthu, P. S., & Perumal, A. B. (2017). Microencapsulation of tender coconut water by spray drying: effect of moringa oleifera gum, maltodextrin concentrations, and inlet temperature on powder qualities. Food and Bioprocess Technology, 10(9), 1668–1684. https://doi.org/10.1007/s11947-017-1934-z.

Obón, J. M., Castellar, M. R., Alacid, M., & Fernández-López, J. A. (2009). Production of a red–purple food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. Journal of Food Engineering, 90(4), 471–479. https://doi.org/10.1016/j.jfoodeng.2008.07.013.

Otálora, M. C., Carriazo, J. G., Iturriaga, L., Nazareno, M. A., & Osorio, C. (2015). Microencapsulation of betalains obtained from cactus fruit (Opuntia ficus-indica) by spray drying using cactus cladode mucilage and maltodextrin as encapsulating agents. Food Chemistry, 187, 174–181. https://doi.org/10.1016/j.foodchem.2015.04.090.

Pedreño, M. A., & Escribano, J. (2001). Correlation between antiradical activity and stability of betanine from Beta vulgaris L roots under different pH, temperature and light conditions. Journal of the Science of Food and Agriculture, 81(7), 627–631. https://doi.org/10.1002/jsfa.851.

Ribeiro, A. M., Estevinho, B. N., & Rocha, F. (2019). Spray drying encapsulation of elderberry extract and evaluating the release and stability of phenolic compounds in encapsulated powders. Food and Bioprocess Technology, 12(8), 1381–1394. https://doi.org/10.1007/s11947-019-02304-z.

Rubio, F. T. V., Windson Isidoro Haminiuk, C., Martelli-Tosi, M., Palazzolli da Silva, M., Yasuo Figueiredo Makimori, G., & Sílvia Favaro-Trindade, C. (2020). Utilization of grape pomaces and brewery waste Saccharomyces cerevisiae for the production of bio-based microencapsulated pigments. Food Research International, 136(April), 109470. https://doi.org/10.1016/j.foodres.2020.109470.

Ruiz-Gutiérrez, M. G., Amaya-Guerra, C. A., Quintero-Ramos, A., de Jesús Ruiz-Anchondo, T., Gutiírrez-Uribe, J. A., Baez-González, J. G., et al. (2014). Effect of soluble fiber on the physicochemical properties of cactus pear (Opuntia ficus indica) encapsulated using spray drying. Food Science and Biotechnology, 23(3),755–763. https://doi.org/10.1007/s10068-014-0102-8.

Sandate-Flores, L., Rodríguez-Rodríguez, J., Calvo-Segura, S., Mayorga-Martínez, A., Parra-Saldívar, R., Chuck-Hernández, C. (2016). Evaluation of different methods for betanin quantification in pitaya (Stenocereus spp.). Agro Food Industry Hi-Tech, 27(1), 20–24.

Shaaruddin, S., Ghazali, H. M., Hamed Mirhosseini, S., & Muhammad, K. (2017). Stability of betanin in pitaya powder and confection as affected by resistant maltodextrin. LWT - Food Science and Technology, 84, 129–134. https://doi.org/10.1016/j.lwt.2017.05.031.

Sharif, N., Khoshnoudi-Nia, S., & Jafari, S. M. (2020). Nano/microencapsulation of anthocyanins; a systematic review and meta-analysis. Food Research International, 132(October 2019), 109077. https://doi.org/10.1016/j.foodres.2020.109077.

Sinthusamran, S., Benjakul, S., & Kishimura, H. (2015). Molecular characteristics and properties of gelatin from skin of seabass with different sizes. International Journal of Biological Macromolecules, 73(1), 146–153. https://doi.org/10.1016/j.ijbiomac.2014.11.024.

Stintzing, F. C., Schieber, A., & Carle, R. (2002). Betacyanins in fruits from red-purple pitaya, Hylocereus polyrhizus (Weber) Britton & Rose. Food Chemistry, 77(1), 101–106. https://doi.org/10.1016/S0308-8146(01)00374-0.

Stoll, L., Costa, T. M. H., Jablonski, A., Flôres, S. H., & de Oliveira Rios, A. (2016). Microencapsulation of anthocyanins with different wall materials and its application in active biodegradable films. Food and Bioprocess Technology, 9(1), 172–181. https://doi.org/10.1007/s11947-015-1610-0.

Tang, C. S., & Norziah, M. H. (2007). Stability of betacyanin pigments from red purple pitaya fruit (Hylocereus polyrhizus) : influence of pH, temperature, metal ions and ascorbic acid. Indian Journal of Chemistry, 7(3), 327–331. https://doi.org/10.14499/IJC-V7I3P327-331.

Thanatcha, R., & Pranee, A. (2007). Extraction and characterization of mucilage in Opuntia spp. Journal of Arid Environments J, 68(4), 534–545. https://doi.org/10.1016/j.jaridenv.2006.08.001.

Troya, D., Tupuna-Yerovi, D. S., & Ruales, J. (2018). Effects of wall materials and operating parameters on physicochemical properties, process efficiency, and total carotenoid content of microencapsulated banana passionfruit pulp (Passiflora tripartita var. mollissima) by spray-drying. Food and Bioprocess Technology, 11(10), 1828–1839. https://doi.org/10.1007/s11947-018-2143-0.

Tsai, P. J., Sheu, C. H., Wu, P. H., & Sun, Y. F. (2010). Thermal and pH stability of betacyanin pigment of djulis (Chenopodium formosanum) in Taiwan and their relation to antioxidant activity. Journal of Agricultural and Food Chemistry, 58(2), 1020–1025. https://doi.org/10.1021/jf9032766.

Tze, N. L., Han, C. P., Yusof, Y. A., Ling, C. N., Talib, R. A., Taip, F. S., & Aziz, M. G. (2012). Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Science and Biotechnology, 21(3), 675–682. https://doi.org/10.1007/s10068-012-0088-z.

Utpott, M., Ramos de Araujo, R., Galarza Vargas, C., Nunes Paiva, A. R., Tischer, B., de Oliveira Rios, A., & Hickmann Flôres, S. (2020). Characterization and application of red pitaya (Hylocereus polyrhizus) peel powder as a fat replacer in ice cream. Journal of Food Processing and Preservation, 44(5), 1–10. https://doi.org/10.1111/jfpp.14420.

Vargas-Campos, L., Valle-Guadarrama, S., Martínez-Bustos, F., Salinas-Moreno, Y., Lobato-Calleros, C., & Calvo-López, A. D. (2018). Encapsulation and pigmenting potential of betalains of pitaya (Stenocereus pruinosus) fruit. Journal of Food Science and Technology, 55(7), 2436–2445. https://doi.org/10.1007/s13197-018-3161-7.

Vergara, C., Saavedra, J., Sáenz, C., García, P., & Robert, P. (2014). Microencapsulation of pulp and ultrafiltered cactus pear (Opuntia ficus-indica) extracts and betanin stability during storage. Food Chemistry, 157, 246–251. https://doi.org/10.1016/j.foodchem.2014.02.037.

Wang, Y., Ye, H., Zhou, C., Lv, F., Bie, X., & Lu, Z. (2012). Study on the spray-drying encapsulation of lutein in the porous starch and gelatin mixture. European Food Research and Technology, 234(1), 157–163. https://doi.org/10.1007/s00217-011-1630-6.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Utpott, M., Assis, R.Q., Pagno, C.H. et al. Evaluation of the Use of Industrial Wastes on the Encapsulation of Betalains Extracted from Red Pitaya Pulp (Hylocereus polyrhizus) by Spray Drying: Powder Stability and Application. Food Bioprocess Technol 13, 1940–1953 (2020). https://doi.org/10.1007/s11947-020-02529-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-020-02529-3