Abstract

The mechanical properties as well antioxidant/antimicrobial effects of active packaging for beef produced from cornstarch, linear low-density polyethylene (LLDPE), and citric acid (CA) were evaluated. The addition of starch in the blends influenced the mechanical characteristics of the films, with reduced ultimate tensile strength (TS), elongation at break (E), and modulus of elasticity (ME) parameters for films with a higher starch concentration. Conversely, greater solubility and degree of swelling of the films were observed when the starch content was increased, with gradual release of the CA from the packaging to the product. Characterization by thermogravimetric analysis and Fourier transform infrared spectroscopy showed that the incorporation of starch affected the thermal stability and chemical composition of the blends. The "in vitro" biodegradability was shown by gravimetric evaluation, with weight loss and decrease of TS of the films. Meat samples packed with the active films and stored under refrigeration showed a significant reduction of the levels of thiobarbituric acid reactive substances (TBARSs) and a decrease of about 1 log in the total bacterial count in the beef, compared with the control film (nonactive). The color was also affected, with an increase in the a* (redness) parameter, which characterizes the desirable red color in beef. The biodegradable packaging of starch/LLDPE incorporating CA prevented oxidative and microbial processes, besides providing a more desirable color to the meat during storage. In this study, we hypothesized that the effects were related to CA presence.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Research and implementation of processes for achieve consumers’ requirements relating to convenience, quality, and practicality are not recent. In turn, they changed consumption patterns, boosting innovation in production technology and food preservation. On the other hand, the large volumes of food produced to meet the new standards of consumption negatively influence two important aspects: toxicological aspects relating to public health and aspects relating to the environment and sustainability.

Regarding public health, several diseases have been associated with excessive consumption of the chemical additives usually used in food preservation (Junqueira et al. 2009; Muriel-Galet et al. 2012), especially those chemical additives composed of allergenic and/or carcinogenic species. In order to minimize the consumption of conservative chemical additives and, therefore, the adverse health effects, the technology of active packaging presents itself as an alternative.

Active packaging can be described as auxiliary systems for food preservation, where one or more substances are released in a selective and controlled manner from the wrapping to the food surface with which they are in contact (Appendini and Hotchkiss 2002; Soares et al. 2010; Bodaghi et al. 2013). These substances should be able to control and/or inhibit reactions and/or undesirable processes, increasing the shelf life and safety of packaged food.

In parallel with conservation, active systems also offer advantages in the technological aspect, since they eliminate production stages, such as mixing, dipping, and spraying of chemical additives traditionally employed in the conservation. However, in some cases, they may influence the chemical safety aspects of food (Soares et al. 2010; Bolumar et al. 2011).

Packaging is activated by incorporation of several active compounds. An example is the silver ions released from inorganic salts, which stand out by effect; also, nano- and microparticulate silver and salts thereof are particularly efficient in microbiological control of pathogenic and spoilage species of importance in foods (Jokar et al. 2012). However, they are often criticized for their toxicological effect. Thus, the study of substances that do not exhibit problems relating to the chemical-toxicological aspect has been gaining attention in recent years (Basch et al. 2013; Foralosso et al. 2013; Espitia et al. 2012). Citric acid (CA), found among the compounds of lesser chemical-toxicological effect (International Numbering System, 330), is a multifunctional material that can be obtained by fermentative processes and also through extraction from natural sources. It is described in the listing of substances defined by the Food and Drug Administration (FDA) with affirmation as generally recognized as safe (GRAS) (Food and Drug Administration 2013).

Recent studies have shown that CA, besides showing antimicrobial (González-Fandos et al. 2009) and antioxidant (Dias et al. 2011; Doležalová et al. 2010; Ke et al. 2009) effects, also acts as a plasticizer and/or compatibilizer in the preparation of plastic films from polymers of different natures (Ning et al. 2007).

In the case of active packaging, in addition to factors relating to the active principles, the polymer used should be carefully evaluated, especially from the environmental point of view. The use of blends, hybrid polymer materials obtained by partial substitution of a fraction of polymers derived from petroleum (synthetic) by natural ones (Sionkowska 2011; Rahman et al. 2012), is becoming increasingly promising (Brito et al. 2011). Such materials aim to combine desirable properties of synthetic polymers (high impact and mechanical strength, high gas barrier, transparency, and flexibility) with properties of natural polymers (biodegradability, bioavailability, and renewable source). In addition, these important features, combined with the use of synthetic polymer and biopolymer matrix for impregnating substances as active packaging, provide favorable conditions for the release of active substances from the matrix and consequently improve the shelf life of the food (Bierhalz et al. 2012; Hwang et al. 2013; Kuorwel et al. 2013).

Films manufactured to attain higher biodegradability have attracted growing interest in the last decade. The literature is rich in data from researches on edible films, mainly made from cornstarch or through a combination of starch with synthetic polymers, about their physical, optical, and barrier properties (Basch et al. 2013; Cercléa et al. 2013; Jiménez et al. 2012; Garg and Jana 2011; Ruiz et al. 2011). However, only a few studies have addressed their potential application as food packaging.

Starch is one of the most promising and versatile materials for producing biodegradable blends (Maa et al. 2009; Brito et al. 2011), since it is produced in large quantities all around the world. As an inexpensive raw material, it can be used in the production of basic chemical inputs as well as directly in the composition of thermoplastic polymers (Carvalho et al. 2001). That is why the state of the art to prepare bioblends with these polymers, to be used in biodegradable packaging, has achieved a promising level (Thakore et al. 2001; Garg and Jana 2007, 2011; Ning et al. 2007; Santonja-Blasco et al. 2007; Vinhas et al. 2007; El-Naggara and Faragb 2010; Miranda and Carvalho 2011; Ruiz et al. 2011; Cercléa et al. 2013; Vieyra et al. 2013; Yua et al. 2013).

In this context, application of the active technology by incorporating CA in the biodegradable material (polyethylene-starch blend) could be an alternative for the beef industry. Since this food is highly perishable on microbiological aspects and oxidation of lipids (Sun and Holley 2012), CA addition may reduce the thickness of the conventional plastic materials used in the production chain.

Based on the above, the main objective of this work was to develop a biodegradable active film with two functional properties, antioxidant and antimicrobial functions, both provided by the addition of CA, as well as to study the effects of the film on quality parameters in beef. Additionally, a study on biodegradability of the films was performed.

Materials and Methods

Production of Multifunctional Films

Five blends, corresponding to the desired films, were formulated with cornstarch (Maizena®, Unilever, Brazil) and linear low-density polyethylene (LLDPE) (SLL 118/21), provided by BraskemPetroquimica (Triunfo, Brazil), in different proportions. Glycerol plasticizer (Sigma-Aldrich, Brazil) and CA (Sigma-Aldrich, Brazil) were added in different amounts (Table 1) to the mixtures of starch-LLDPE [mixture of starch (MS)].

Pellets of each formulation were obtained by direct extrusion using the following operating conditions: 140 °C (zone 1), 140 °C (zone 2), a screw speed of 36 rpm in a single screw extruder (AX Plasticos®, Brazil), and placing in vials protected from air and light. Films were produced by pellet extrusion via a single screw extruder (AX Plasticos®, Brazil), with a speed of 36 rpm and a temperature gradient programmed from 150 °C for zone 1, 150 °C for zone 2, and 145 °C for zone 3 (flat die/matrix). The feeding of the different mixtures was performed manually.

Characterization of the Films

Surface Morphology, Thickness, and Mechanical Properties of the Films

The surface morphology of the films was evaluated using a scanning electron microscope (SEM; EVO 50, Carl Zeiss) operating at 30 kV. Each sample was fixed in an aluminum sample holder without metallization. The thickness of the films was determined by averaging five points of each sample, in triplicate, immediately after extrusion using a micrometer Mainard® (model M 73011, Brazil).

Assays of mechanical properties were carried out according to ASTM E171-94 (American Society Standard Testing and Materials 1996a) and ASTM D681-95 (American Society Standard Testing and Materials 1996b) in a universal testing meter, Time Group® WDW 1E, 10KN (China). Tests of tension versus deformation were performed in triplicate, and values of high tensile strength (TS, MPa), elongation at break (E, %), and modulus of elasticity (ME, MPa) were obtained.

Optical Properties of the Films

Yellowness Index (YI), Whiteness Index (WI), and color difference (ΔE) were evaluated by Eqs. (1), (2), and (3), respectively (Ahmadi et al. 2012). The color parameters L, a*, and b* were determined instrumentally by a colorimeter (Minolta Color Reader®, CR-400, Japan), with a standardized light source. The films were laid on a smooth white surface, where five readings were made for each sample.

Water Solubility and Degree of Swelling

Samples of area of 6 cm2 were dried at 70 °C for 48 h in an oven with air circulation (Edutec, Brazil), and subsequently placed in a desiccator for 1 h; the initial masses were determined. Afterwards, each sample was mechanically stirred in 30 ml of distilled water in 125-ml Erlenmeyer flasks at 25 °C and 150 rpm for 24 h. Then, films were dried at 70 °C in an air-circulating oven for 48 h at 70 °C and were cooled in a desiccator (1 h) to determine the final mass. Water solubility (WS) was determined gravimetrically by the difference between the initial and final masses of each sample. The procedure was conducted twice, each time in triplicate.

Determination of WS and degree of swelling (DS) of the films was done in accordance with the techniques described in Lee et al. (2004), with some modifications. To determine DS, 6-cm2 samples of each film were weighed, soaked in 75 ml distilled water in 125-ml Erlenmeyer flasks, placed in an oven with air circulation, and replaced for 6 h at 25 °C. Excess water was subsequently removed from the films by contact with a piece of filter paper (weight of 80 g/m2 and porosity of 3 μm, Nalgon, Brazil) for 1 min. The film was then weighed again to calculate the amount of the water absorbed by every film during the 6-h analysis. The procedure was performed in triplicate with two repetitions.

Fourier Transform Infrared Spectroscopy Analysis

Chemical transformations of polymers were evaluated in the films through spectroscopy in the infrared region with Fourier transform infrared spectroscopy (FT-IR) in transmittance mode with 32 scans and 4-cm−1 resolution (IRPrestige-21, Shimadzu).

Thermal Studies

Weight loss in the thermal degradation of control film (CF) and blends of starch/LLDPE was determined by thermogravimetric analysis (TGA), using alumina pans under the following conditions: approximately 10 mg sample, atmosphere of nitrogen (flow 50.00 ml/min), and rate of 12 °C/min, temperature range of 0 to 600 °C for analysis, using TA Instruments (Q50, Castle, DE). Thermal degradation of CA was also determined by TGA. Results are presented as the mean of five repetitions.

Quality Evaluation of the Packed Beef

Preparation and Packaging of Samples

Hindquarter beef cuts (semimembranosus muscle), collected 24 h postmortem, were acquired directly from an inspected slaughter facility located in Concórdia, Santa Catarina, Brazil. The boned and sliced beef was transported packed in polyethylene bags inside isothermic boxes to the laboratory. The meat was ground and made into 5-mm disks, and individual samples, containing approximately 100 g, were vacuum packed (Selovac® model 3380) in CF and F30 films. The F30 film presented an ideal way to review the performance of the film as biodegradable active packaging for ground beef, due to some of its fundamental characteristics for this application. This film showed good homogeneity, as can be seen in the SEM micrographs and also satisfactory mechanical properties such as TS, E, and ME. In additional, F30 treatment showed a significant biodegradable property. In additional, F30 treatment was used to evaluate the activity like meat package, because it showed a significant biodegradable property among other properties for food packaging. All samples were stored under refrigeration at 5 °C in a biochemical oxygen demand (BOD) chamber (Eletrolab model 101/M3) for a period of 10 days.

Microbial Count of the Packaged Meat

Evaluation of total bacterial count (TBC) (Downes and Ito 2001) was carried out on the packed meat samples (25 ± 0.2 g) during 10 days of storage. To each specimen, 225 ml of 0.1 % peptone water was added, which was homogenized in a stomacher. The TBC was performed on plate count agar (PCA) with a pour plate after incubation at 36 °C for 48 h. The procedure was repeated.

Lipid Oxidation

The thiobarbituric acid (TBA) method, according to Raharjo et al. (1992), with some modifications, was used to evaluate the degree of lipid oxidation in the meat samples. Five grams of the sample was weighed, to which 18 ml of 5 % trichloroacetic acid (TCA) solution was added, together with 0.5 ml of a 0.15 % solution of the synthetic antioxidant butylated hydroxytoluene (BHT). The mixture was homogenized for 1 min and filtered through a qualitative filter paper into a 25-ml volumetric flask, and the volume was completed by 5 % (w/v) TCA. Posteriorly, a 2-ml aliquot of the filtrate was transferred into a test tube with 2 ml of 0.08 M TBA in 50 % (v/v) acetic acid, and this mixture was allowed to stand in a boiling water bath for 30 min before cooling in running water. Absorbance was read at 531 nm (SP-220 Spectrophotometer Biospectro, Brazil). A conversion factor of 7.8 was used to calculate the values of TBA reactive substances (TBARSs) (Yildiz-Turp and Serdaroglu 2010) and expressed as milligrams of malonaldehyde per kilogram of sample (TBARSs) according to Eq. 4. Analyses were performed in triplicate.

Color Parameters of the Meat

The color of the packaged meat in the films was evaluated by the parameters L*, a*, and b*, determined by direct reflectance (see procedure described in “Optical Properties of the Films”) at 0, 2, 4, 6, 8, and 10 days of storage. The color measurements for each time were repeated five times on different spots of each sample.

Migration Test in Simulant Medium

CF and F30 films were used to determine CA migration from the packaging to the meat. Samples of 10 × 15 cm were placed in 130 ml of distilled water simulant and stored under refrigeration at 5 °C in a BOD chamber (Eletrolab model 101/M3) for a period of 10 days. Each day, the CA (mg kg−1) migration from the control and active films into the water simulant was determined using the titration method described by Instituto Adolfo Lutz (2005). The procedure was performed in triplicate.

Study of Biodegradation

Determination of the biodegradability of the films was conducted according to Mani and Bhattacharya (1998), with some modifications. Film samples (25 cm2) were inoculated with Aspergillus niger (ATCC 9642) in potato dextrose agar (PDA) medium and were incubated at 25 °C. After 21 days of incubation, the films were examined for evidence of growth of colonies on the surface of the films, weight loss (see “Thermal Studies”), and determination of TS (see “Surface Morphology, Thickness, and Mechanical Properties of the Films”) to evaluate changes resulting from biodegradation by A. niger. The analytical procedures for weight loss and maximum TS were performed in triplicate.

Statistical Analyses

All data were statistically analyzed, and when necessary, analysis of variance (ANOVA) was used to estimate the significance of effects (p < 0.05). Tukey’s test was used to estimate the least significant difference between means at the 5 % level of significance with Statistica software version 8 (StatSoft).

Results and Discussion

Characterization of the Films

Morphology of Films

The images of film surfaces (Fig. 1) suggested alterations in the morphology with an increasing concentration of MS incorporated into LLDPE. The CF (Fig. 1a) appeared as a smoother, more homogeneous film than of starch blends, with a few areas of gel (small air gaps) like materials typically made of pure LLDPE. Films containing MS in the formulation showed two distinct behaviors regarding the homogeneity of the material: part of the film was homogeneous and consistent with the LLDPE portion and some kind of bubbles, probably undispersed starch particles, were clearly observable on the surface (F10 and F20, lighter areas of Fig. 1b, c). These agglomerates compromised the morphological integrity of the respective films. Irregularities in the surface topography of the films was proportional to the concentration of starch incorporated to the material, as can be seen in F30, F40, and F50 films; however, better dispersion between polymers was observed but without formation of visible clusters and holes. Because these films are a mix of polymer chains of different chemical natures, particularly regarding the polarity (Garg and Jana 2007), the surface tension tends to be high, and the resulting material is not always homogeneous (Silveira et al. 2007; Pires et al. 2008).

Physical Properties of Films

The thickness variations in active films are usually related proportionally to the mass amounts of the active principle incorporated into the polymer constitution. Versant et al. (1995) showed that the changes were even greater because of the addition of starch together with the antimicrobial and antioxidant active principle (CA). As shown in Table 2, the thickness of F20, F30, F40, and F50 films showed no significant difference from each other (p > 0.05), but this group, except for F20, differed in thickness from F10 and CF.

It was observed that the increasing the amount of MS added to the films directly influenced parameters of mechanical properties of the films intended to be used for food packaging. Concerning TS, adding 10 % of the starch polymer (F10) led to a slight decrease compared with CF, although the difference was not significant (p > 0.05). However, the films containing 20, 30, 40, and 50 % starch showed significant differences compared with the control, suggesting a loss in TS when starch levels greater than 10 % were incorporated into the LLDPE. According to Walker et al. (2007), irrespective of the manufacturing process used to increase the starch content in the formulation of a blend with polyethylene, the TS will decrease. In the evaluation of the mechanical properties of the blends, it was also demonstrated that the parameters E and ME also suffered a proportional decrease with the addition of starch, except for F10 regarding the parameter ME.

These results observed in the blends of LLDPE/starch may be related to poor homogeneity of the mixture during extrusion, and in this respect, the research highlights that in synthetic polymer blends, the addition of the second immiscible phase matrix usually results in a decrease in elongation (Pedroso and Rosa 2005). This property is considered highly sensitive to the interaction between the phases of a mixture of polymers of different natures (St-Pierre et al. 1997). Also, Versant et al. (1995) state that some particles may have different degrees of incompatibility with the polymer matrix, influencing the homogeneity against the added concentration, a fact that may explain the changes in the mechanical property of LLDPE/starch films.

It is very important to know the behavior of the films for packaging foods in contact with water because water acts as a plasticizer, modifying the mechanical properties of these materials. In the present work, such behavior was assessed by evaluation of the WS and DS. As shown in Table 2, all films with starch exhibited some solubility in water (WS > 0) compared with the CF. However, an increasingly difference was found with increasing addition of starch (p < 0.05 for 30 to 50 % starch). Water solubility of films with 10 and 20 % starch did not differ from each other in WS. Similar responses were observed for DS, where the smallest difference (p < 0.05) was for F10 compared with the other starch-containing films; increasing starch weight ratios increased DS (DSF20 = DSF30 < DSF40 = DSF50). This finding can be attributed to the greater formation of links of hydrophilic domains of starch (hydroxides) with the solvent which consequently provided higher rates of WS and DS. Solubility and swelling properties of films made from synthetic polymers and starch are expected, due to the hydrophilic characteristics of starch itself (Miranda and Carvalho 2011). As highlighted by Ghasemlou et al. (2011) and Ahmadi et al. (2012), often the water absorption can be further increased by addition of glycerol, which is a soluble fraction, as was used in this study as a compatibilizing agent.

The color of plastic materials used for packaging food, or even general use, is another important factor, especially from the commercial point of view, since the appearance of the product directly affects the decision of consumers. In this sense, increasing amounts of starch yellowed the films, with a significant increase (p < 0.05) in the YI of the F30, F40, and F50 films compared with the other treatments (Table 2). This can be associated with the transformations undergone by starch due to high temperature extrusion, such as the browning reaction that occurs with carbohydrates (Damodaran et al. 2010). However, visually, all films proved to be transparent.

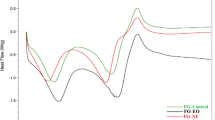

Thermal Characteristics

TGA curves were obtained in order to investigate the influence of incorporating starch on the thermal resistance of the films (Fig. 2), where the mass loss due to volatilization of degradation products was monitored as a function of temperature. It was observed that the incorporation of MS affected the thermal stability and, consequently, decomposition of the material. Unlike CF, which was composed only of LLDPE, that the decomposition occurred in one stage, the starch-containing films occurred in two stages. The first, mainly related to the loss of glycerol (contained in the mixture of MS) as well as water (Ma et al. 2005; Ma et al. 2008), occurred from 50 to 130 °C, causing a mass loss of 2.00 ± 0.88 % for films containing starch. In the second stage, the thermal decomposition occurred at temperatures around 335 °C, representing a mass loss of 20.8 ± 10.0 % for the abovementioned films (Aggarwal and Dollimore 1997; Mano et al. 2003; Garg and Jana 2011). The CF, composed only of LLDPE, showed the highest thermal stability, with degradation starting at approximately 400 °C (99.89 %). The CF, composed only of LLDPE, showed the highest thermal stability, with degradation starting at approximately 400 °C (99.89 %). These values are in agreement with those reported in the literature for decomposition of the carbon chains of this type of polyethylene (Dikobe and Luyt 2010). Similarly, a TGA curve was obtained for CA and showed a maximum decomposition temperature of 231.54 °C; this characteristic enables extrusion of CA, with good machinability at the extrusion temperatures adopted in this work.

Spectra in the Infrared Region (FT-IR)

FT-IR was used to verify and confirm the presence of characteristic bands of the components present in the composition of the blends as well as possible interactions between them during the manufacturing process of the films. Firstly, the prevalence of typical absorption bands of functional groups of LLDPE such as 2,852, 2,915, 1,472, and 719 cm−1 was seen (Fig. 3), indicating a symmetric and asymmetric axial deformation of CH2 of the polymer chain. However, with reduction of the LLDPE fraction compared with starch and other components of the mixture contained in the MS incorporated in the blends (F10, F20, F30, F40, and F50), we observed simultaneous variation in the frequency and intensity of the bands, mainly in the region between 1,472 and 719 cm−1. Additionally, with the gradual increase in the concentration of MS, an increase in the intensity of the characteristic peaks of starch was observed, being as follows: on the regions, 3,350 cm−1 for O–H stretching vibration (Kweon et al. 2000; Park et al. 2000), 1,026 cm−1 for C–O stretching, and 1,150 cm−1 for the glycosidic group (Pawlak and Mucha 2003). These variations may indicate an interaction, even a dipole moment between the CH2 radicals of LLDPE with –OH groups of fractions α 1–4 and α 1–6 of starch, which reinforces the gradual mass losses shown in the thermal study of each evaluated film. Due to the characteristic absorption of the starch in the ranges of 1,000–1,200 and 3,200–3,500 cm−1, it was not possible to identify characteristic bands related to other components incorporated into the MS in active packaging.

Evaluation of CA Migration and Duo-functional Effect of the Packaging

Migration Studies

The migration of active substances of a packaging must be assessed, primarily due to the toxic potential to which it is related, by way of confirmation of migration and, consequently, the expected effect of the substance in the food. CA is a substance with no toxicity, as defined by various regulatory agencies worldwide, and is on the list of substances defined by the Food and Drug Administration (2013) as GRAS. Thus, the primary purpose of determining CA migration in this study was to detect the presence of CA under the conditions tested. Figure 4 shows the migration of CA during the storage period. CA was detected from the second day of storage (CA mass concentration detected in the sample of simulate volume), representing an initial migrated dose of 0.0256 mg l−1, followed by values of 0.0384, 0.0427, 0.0485, and 0.0510 mg l−1 for days 4, 6, 8, and 10, respectively. It is known that the release of an active principle of a polymer to an environment can be influenced mainly by the polarity (Suppakul et al. 2003; López-De-Dicastillo et al. 2011; Kuorwel et al. 2013), which may explain the ease of migration of CA from the packaging into the water that was used as a simulant medium.

Evaluation of Antioxidant and Antimicrobial Effects

According to Sun and Holley (2012), the shelf life of fresh red meat is often determined by the activity of microorganisms, which results in the development of undesirable odors and formation of gas and slime. In addition, the influence of biochemical factors related to lipid oxidation and pigments, generation of undesirable flavors, and discoloration of the surface of the meat is observed.

As shown in Fig. 5, we observed a constant reduction of the TBC of meat packaged in F30 in comparison with that packaged in CF. A reduction of approximately 1 log of the microbial population at the end of the evaluation period [6.44 and 7.46 log colony-forming units (CFU) g−1] was observed exactly when the highest concentration of migrated CA from F30 (“Migration Studies”) was detected. Thus, CA had an antimicrobial effect on the chilled meat, as previously described in the literature (Doležalová et al. 2010; González-Fandos et al. 2009; Dias et al. 2011). Additionally, it is emphasized that the release of CA from the packaging provides a reduction of the microbial load during storage, which is related to the formation of undesirable meat characteristics. Normally, when changes to the viscosity and slime are detected, it means that populations of over 106 CFU g−1 are certainly present in the food. However, counts are necessary for 107 CFU g−1 or even 108 CFU g−1 to have noticeable changes compared to the viscosity, odor, and color of the meat (Jay 1992). For the CF, the TBC of the eighth day was more than 107 CFU g−1, while for F30, the microbial population remained at around 106 CFU g−1, with desirable characteristics of meat maintained, such as color and absence of slime and odor (data not shown).

Similar behavior was found for the antioxidant effect (Fig. 6). Meat samples packaged in F30 showed a significant reduction in the TBARS (p < 0.05) from the second day of storage to the end of the evaluation time compared with meat samples packed in CF. On the last day of evaluation, the difference in the TBARS content (mg malondialdehyde/kg meat) of F30 compared with that of CF was most significant, with an index about four times smaller (0.12 and 0.48 TBA, respectively). Ke et al. (2009) demonstrated the antioxidant effect of CA in cooled beef cuts by the TBA test. Sheard et al. (2000) pointed out the threshold for detection of rancidity by consumers as TBARS level of 0.5 mg kg−1 (Sheard et al. 2000). In this study, the antioxidant and antimicrobial effects were related only to the presence of CA, since the results showed a correlation between the rate of release (shown in “Migration Studies”) and the reduction in the TBARS index.

Coloration of Meat

Changes in meat color are closely related to the oxidation of lipids and pigments (Buckley et al. 1995; Morrissey et al. 1998). Meat color is mainly dependent on the chemical oxidation state of myoglobin pigment, which can take three distinct forms: deoxymyoglobin, metmyoglobin (MetMb), and oxymyoglobin (OMb) (Cornforth and Jayasingh 2004). Deoxymyoglobin assumes a purple-red color, which is responsible for the color of postmortem meat and of meat stored under vacuum, which is not well accepted by consumers (Renerre 1990). MetMb assumes a brown color and is usually associated with lack of freshness (Hood and Riordan 1973), whereas cherry-red meat, whose color is conferred by OMb, myoglobin in the complete oxidation/oxygenation state, shows the greatest acceptability (Faustman and Cassens 1990; Troy and Kerry 2010). However, if the OMb is oxidized to MetMb, the meat changes color from an acceptable cherry-red to an undesirable brown (Chan et al. 1995). The instrumental color parameters of the meat packaged in F30 and CF (Table 3) films were determined. The main change occurred in the parameter a* (which corresponds to red color). We observed the maintenance of the initial a* value for F30, as shown by the lack of significant difference in Tukey’s test (p < 0.05) along the storage time. Similar to the antioxidant effect previously shown, the parameter a* presented a significant difference between F30 and CF during the storage, and the same was not observed for the parameters L and b* (data not shown). This increase on parameter a* indicated the intensification of formation of OMb in the meat packed in F30 in relation to that packed in CF. On the contrary, CF showed lower a* values than F30, indicating color saturation and increased formation of MetMb. Red color is a critical factor for acceptability of red meats (Isdell et al. 2003), and the results obtained showed a significant increase in red color with F30 versus CF, which can be clearly seen in Fig. 7.

Figure 7 shows the meat samples packaged in CF and F30 on the last day of storage. The desirable cherry-red coloration of the beef packed in F30, characteristic of OMb, is highlighted. This significant result concerning the coloration of the meat is possibly related to the ability of CA in the active packaging to prevent oxidation of myoglobin and the consequent production of undesirable coloration of the meat.

Biodegradation Study

Biodegradable polymers are characterized by degradation through the action of enzymes produced by microorganisms such as fungi and bacteria (Tharanathan 2003). According to Tharanathan (2003), the biodegradation of polymers involves a few steps such as the attack of microorganisms on the surface of the polymer, the development of microorganisms using the polymer as a carbon source, and its subsequent degradation. Figure 8 shows the fungal growth (A. niger) on CF (LLDPE) and on films composed of starch/LLDPE blends. The results showed that there was no fungal growth on the surface of the CF film. This was due to the chemical structure of LLDPE, whose carbon–carbon bonds are not susceptible to microbial attack (Shah et al. 1995).

After 21 days of incubation, fungal growth was clearly visible on the surfaces of films composed of blends of LLDPE and starch, particularly with the formulations with higher proportions of starch, F30, F40, and F50 (Fig. 8). Blends of starch/PE show a continuous starch phase that, besides being hydrophilic, also increases the ease of access to the amylase produced by microorganisms to affect the degradation (El-Shafei et al. 1998; Bonhomme et al. 2003).

Corresponding to the higher superficial fungal growth observed, weight loss of the films (Fig. 9) due to deterioration was observed, which was 3.09, 9.56, and 12.83 % for F30, F40, and F50, respectively. This may be related to degradation by the A. niger amylase, which is able to attack the α 1–4 and α 1–6 linkages of the starch fraction of the blends, to use as an energy source for fungal growth and development (Pascoal et al. 2011).

It is well known that the shelf life of a product is mainly dependent on the mechanical properties of the film used for packaging. However, some microorganisms utilize the starch fraction in the packs as a preferred source of carbon, causing surface erosion and, consequently, reducing the TS (Nishida and Tokiwa 1993). Vieyra et al. (2011) took TS as a measure of biodegradation of blends after degradation conditions. Thus, it is important to assess the damage caused by A. niger to the blends of starch/LLDPE by measuring their mechanical properties (Sunilkumar et al. 2012).

Incubation of the biodegradable films for 21 days in a medium containing A. niger resulted in significant losses in TS (Fig. 10). While the CF presented a reduction of only 0.99 % in the TS parameter, the films of blends containing starch showed significantly decreases in TS (p < 0.05) by 27.16, 36.25, and 35.46 % for F10, F20, and F30, respectively, and even greater decreases for F40 and F50, which were 44.81 and 58.44 %, respectively. These results indicated that the blends became weaker with the biodegradation process. Sunilkumar et al. (2012), evaluating biodegradable blends, attributed this decrease of resistance to the presence of microcracks induced by degradation.

Conclusions

The active films prepared from mixtures of starch/LLDPE using CA as a compatibilizer proved to have potential application in the film extrusion to be used for food packaging. The morphological, physical, and thermal properties of the materials were modified by increasing concentrations of the natural polymer and additives, though machinability conditions were maintained. The films showed higher biodegradability compared with film made of pure LLDPE. The active agent, CA, was shown to be released from the polymer matrix, with a significant antioxidant effect. The evaluation of the duo-function of the active film in ground beef storage showed a reduction of the TBC and a beneficial effect on the color of the meat; maintenance of the cherry-red color of meat needed a minimum concentration of CA and is a critical factor for acceptability of meat. Effects of packaging systems with CA on sensory properties of meat products should be evaluated in the future work. The duo-functional biodegradable active films appear to be good alternatives for ground beef packaging, for the aspects of meat quality, lipid oxidation, microbial degradation, and coloration, as well as the necessary to reduce the use of conventional plastic materials in the beef supply chain.

References

Aggarwal, P., & Dollimore, D. (1997). The combustion of starch, cellulose and cationically modified products of these compounds investigated using thermal analysis. Thermochimica Acta, 291, 65–72.

Ahmadi, R., Kalbasi-Ashtari, A., Oromiehie, A., Yarmand, M. S., & Jahandideh, F. (2012). Development and characterization of a novel biodegradable edible film obtained from psyllium seed (Plantago ovata Forsk). Journal of Food Engineering, 109(4), 745–751.

American Society Standard Testing and Materials (ASTM) (1996a). Standard specification for standard atmosphere for conditioning and testing flexible barriers materials—E171-94. Philadelphia.

American Society Standard Testing and Materials (ASTM) (1996b). Standard practice for conditioning plastics and electrical insulating materials form testing—D618-95. Philadelphia.

Appendini, P., & Hotchkiss, J. H. (2002). Review of antimicrobial food packaging. Innovative Food Science and Emerging Technologies, 3, 113–126.

Basch, C. Y., Jagus, R. J., & Flores, S. K. (2013). Physical and antimicrobial properties of tapioca starch-HPMC edible films incorporated with nisin and/or potassium sorbate. process Technology, 6(9), 2419–2428.

Bierhalz, A. C. K., da Silva, M. A., & Kieckbusch, T. G. (2012). Natamycin release from alginate/pectin films for food packaging applications. Journal of Food Engineering, 110, 18–25.

Bodaghi, H., Mostofi, Y., Oromiehie, A., Zamani, Z., Ghanbarzadeh, B., Costa, C., et al. (2013). Evaluation of the photocatalytic antimicrobial effects of a TiO2 nanocomposite food packaging film by in vitro and in vivo tests. LWT – Food Science and Technology, 50(2), 702–706.

Bolumar, T., Andersen, M. L., & Orlien, V. (2011). Antioxidant active packaging for chicken meat processed by high pressure treatment. Food Chemistry, 129, 1406–1412.

Bonhomme, S., Cuer, A., Delort, A.-M., Lemaire, J., Sancelme, M., & Scott, G. (2003). Environmental biodegradation of polyethylene. Polymer Degradation and Stability, 81, 441–452.

Brito, G. F., Agrawal, P., Araújo, E. M., & Mélo, T. J. A. (2011). Biopolímeros, polímeros biodegradáveis e polímeros verdes. Revista Eletrônica de Materiais e Processos, 6, 127–139.

Buckley, D. J., Morrissey, P. A., & Gray, J. I. (1995). Influence of dietary vitamin E on the oxidative stability and quality of pig meat. Journal of Animal Science, 73, 3122–3130.

Carvalho, A. J. F., Curvelo, A. A. S., & Agnelli, J. A. M. (2001). A first insight on composites of thermoplastic starch and kaolin. Carbohydrate Polymers, 45, 189–194.

Cercléa, C., Sarazinb, P., & Favisa, B. D. (2013). High performance polyethylene/thermoplastic starch blends through controlled emulsification phenomena. Carbohydrate Polymers, 92, 138–148.

Chan, W. K. M., Hakkarainen, K., Faustman, C., Schaeffer, D. M., Scheller, K. K., & Liu, Q. (1995). Color stability and microbial growth relationships in beef as affected by endogenous α-tocopherol. Journal of Food Science, 60, 966–971.

Cornforth, D. P., & Jayasingh, P. (2004). Chemical and physical characteristics of meat: colour and pigment. Amsterdam: Elsevier. In Encyclopedia of meat sciences.

Damodaran, S., Parkin, K. L., & Fennema, O. R. (2010). Química de alimentos de fennema (4th ed.). Porto Alegre: Artmed.

Dias, F. S., Ávila, C. L. S., & Schwan, R. F. (2011). In situ inhibition of Escherichia coli isolated from fresh pork sausage by organic acids. Journal of Food Science, 76(9), 605–610.

Dikobe, D. G., & Luyt, A. S. (2010). Comparative study of the morphology and properties of PP/LLDPE/wood powder and MAPP/LLDPE/wood powder polymer blend composites. Polymer Letters, 4(11), 729–741.

Doležalová, M., Molatová, Z., Buñka, F., Brezina, P., & Marounek, M. (2010). Effect of organic acids on growth of chilled chicken skin microflora. Journal of Food Safety, 30, 353–365.

Downes, F. P., & Ito, K. (Eds.). (2001). Compendium for the microbiological examination of foods (4th ed.). Washington: American Public Health Association (APHA).

El-Naggara, M. M. A., & Faragb, M. G. (2010). Physical and biological treatments of polyethylene-rice starch plastic films. Journal of Hazardous Materials, 176, 878–883.

El-Shafei, H. A., El-Nasser, N. H. A., Kansoh, A. L., & Ali, A. M. (1998). Biodegradation of disposable polyethylene by fungi and Streptomyces species. Polymer Degradation and Stability, 62, 361–365.

Espitia, P. J. P., Soares, N. F. F., Coimbra, J. S. R., Andrade, N. J., Cruz, R. S., & Medeiros, E. A. A. (2012). Zinc oxide nanoparticles: synthesis, antimicrobial activity and food packaging applications. Food and Bioprocess Technology, 5(5), 1447–1464.

Faustman, C., & Cassens, R. G. (1990). The biochemical basis for discoloration in fresh meat: a review. Journal of Muscle Foods, 1, 217–243.

Food and Drug Administration (FDA) (2013). Code of federal regulations. Part 184—direct food substances affirmed as generally recognized as safe sec. 184.1033: citric acid. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=184.1033. Accessed 23 July 2013.

Foralosso, F. B., Fronza, N., dos Santos, J. H., Capeletti, L. B., & Quadri, M. G. N. (2013). The use of duo-functional PVC film for conservation of minimally processed apples. Food and Bioprocess Technology. doi:10.1007/s11947-013-1233-2.

Garg, S., & Jana, A. K. (2007). Studies on the properties and characteristics of starch-LDPE blend films using cross-linked, glycerol modified, cross-linked and glycerol modified starch. European Polymer Journal, 43, 3976–3987.

Garg, S., & Jana, A. K. (2011). Effect of propylation of starch with different degrees of substitution on the properties and characteristics of starch-low density polyethylene blend films. Journal of Applied Polymer Science, 122, 2197–2208.

Ghasemlou, M., Khodaiyan, F., & Oromiehie, A. (2011). Physical, mechanical, barrier, an thermal properties of polyol-plasticized biodegradable edible film made from kefiran. Carbohydrate Polymers, 84(1), 477–483.

González-Fandos, E., Herrera, B., & Maya, N. (2009). Efficacy of citric acid against Listeria monocytogenes attached to poultry skin during refrigerated storage. International Journal of Food Science and Technology, 44, 262–268.

Hood, D. E., & Riordan, E. B. (1973). Discoloration in pre-packaged beef: measurement by reflectance spectrophotometry and shopper discrimination. Journal of Food Technology, 8, 333–343.

Hwang, S. W., Shim, J. K., Selke, S., Soto-Valdez, H., Matuana, L., Rubino, M., & Auras, R. (2013). Migration of α-tocopherol and resveratrol from poly(l-lactic acid)/starch blends films into ethanol. Journal of Food Engineering, 116, 814–828.

Instituto Adolfo Lutz (2005). Ministério da Saúde. Agência Nacional de Vigilância Sanitária. Métodos físico-químicos para análise de alimentos. Brasília.

Isdell, E., Allen, P., Doherty, A., & Butler, F. (2003). Effect of packaging cycle on the colour stability of six beef muscles stored in a modified atmosphere mother pack system with oxygen scavengers. International Journal of Science and Technology, 38, 623–632.

Jay, J. M. (1992). Modern food microbiology (4th ed.). New York: Chapman & Hall.

Jiménez, A., Fabra, M. J., Talens, P., & Chiralt, A. (2012). Edible and biodegradable starch films: a review. Food and Bioprocess Technology, 5(6), 2058–2076.

Jokar, M., Rahman, R. A., Ibrahim, N. A., Abdullah, L. C., & Tan, C. P. (2012). Melt production and antimicrobial efficiency of low-density polyethylene (LDPE)-silver nanocomposite film. Food and Bioprocess Technology, 5(2), 719–728.

Junqueira, M. S., Soares, N. F. F., Reis, R. C., Carneiro, J. D. S., Benicio, R. T., & Yokota, S. R. C. (2009). Efeito de embalagens ativas no escurecimento enzimático de batatas (Solanum tuberosum) fatiadas e minimamente processadas. Semina: Ciências Agrárias, 30(3), 613–618.

Ke, S., Huang, Y., Decker, E. A., & Hultin, H. O. (2009). Impact of citric acid on the tenderness, microstructure and oxidative stability of beef muscle. Meat Science, 82, 113–118.

Kuorwel, K. K., Cran, M. J., Sonneveld, K., Miltz, J., & Bigger, S. W. (2013). Migration of antimicrobial agents from starch-based films into a food simulant. LWT – Food Science and Technology, 50, 432–438.

Kweon, D.-K., Cha, D.-S., Park, H.-J., & Lim, S.-T. (2000). Starch-g-polycaprolactone copolymerization using diisocyanate intermediates and thermal characteristics of the copolymers. Journal of Applied Polymer Science, 78(5), 986–993.

Lee, K. Y., Shim, J., & Lee, H. G. (2004). Mechanical properties of gellan and gelatin composite films. Carbohydrate Polymers, 56, 251–254.

López-De-Dicastillo, C., Catala, R., Gavara, R., & Hernandez-Munoz, P. (2011). Food applications of active packaging EVOH films containing cyclodextrins for the preferential scavenging of undesirable compounds. Journal of Food Engineering, 104, 380–386.

Ma, X. F., Yu, J. G., & Ma, Y. B. (2005). Urea and formamide as a mixed plasticizer for thermoplastic wheat flour. Carbohydrate Polymers, 60, 111–116.

Ma, X., Chang, P. R., Yu, J., & Wang, N. (2008). Preparation and properties of biodegradable poly(propylene carbonate)/thermoplastic dried starch composites. Carbohydrate Polymers, 71(2), 229–234.

Maa, X., Chang, P. R., Yang, J., & Yu, J. (2009). Preparation and properties of glycerol plasticized-pea starch/zinc oxide-starch bionanocomposites. Carbohydrate Polymers, 75, 472–478.

Mani, R., & Bhattacharya, M. (1998). Property’s injection moulded starch/synthetic polymer blends—III. Effect of amylopectin to amylase ratio in starch. European Polymer Journal, 34, 1467–1475.

Mano, J. F., Koniarova, D., & Reis, R. L. (2003). Thermal properties of thermoplastic starch/synthetic polymer blends with potential biomedical applicability. Journal of Materials Science: Materials in Medicine, 14(2), 127–135.

Miranda, V. R., & Carvalho, A. J. F. (2011). Blendas compatíveis de amido termoplástico e polietileno de baixa densidade compatibilizadas com ácido cítrico. Polímeros, 21(5), 353–360.

Morrissey, P. A., Sheehy, P. J. A., Galvin, K., Kerry, J. P., & Buckley, D. J. (1998). Lipid stability in meat and meat products. Meat Science, 49, 73–86.

Muriel-Galet, V., Cerisuelo, J. P., López-Carballo, G., & Lara, M. (2012). Development of antimicrobial films for microbiological control of packaged salad. International Journal of Food Microbiology, 157, 195–201.

Ning, W., Jiugao, Y., Xiaofei, M., & Ying, W. (2007). The influence of citric acid on the properties of thermoplastic starch/linear low-density polyethylene blends. Carbohydrate Polymers, 67, 446–453.

Nishida, H., & Tokiwa, Y. (1993). Distribution of poly(β-hydroxybutirate) and poly(-caprolactone) aerobic degrading microorganisms in different environments. Carbohydrate Polymers, 59, 1–9.

Park, J. W., Im, S. S., Kim, S. H., & Kim, Y. H. (2000). Biodegradable polymer blends of poly(l-lactic acid) and gelatinized starch. Polymer Engineering & Science, 40(12), 2539–2550.

Pascoal, A. M., Mitidieri, S., & Fernandes, K. F. (2011). Immobilisation of α-amylase from Aspergillus niger onto polyaniline. Food and Bioproducts Processing, 89(4), 300–306.

Pawlak, A., & Mucha, M. (2003). Thermogravimetric and FTIR studies of chitosan blends. Thermochimica Acta, 396, 153–166.

Pedroso, A. G., & Rosa, D. S. (2005). Mechanical, thermal and morphological characterization of recycled LDPE/corn starch blends. Carbohydrate Polymers, 59, 1–9.

Pires, A. C. S., Soares, N. F. F., Andrade, N. J., Silva, L. H., Camilloto, G., & Campos, B. P. (2008). Development and evaluation of active packaging for sliced mozzarella preservation. Packaging Technology & Science, 7, 375–383.

Raharjo, S., Sofos, J. N., & Schmidt, G. R. (1992). Improved speed, specificity and limit of determination of an aqueous acid extraction thiobarbituric acid-C18 method for measuring lipid peroxidation in beef. Journal of Agricultural and Food Chemistry, 40(12), 2182–2185.

Rahman, M. M., Karim, R., Mustafa, A. I., & Khan, M. A. (2012). Preparation and characterization of bioblends from gelatin and linear low density polyethylene (LLDPE) by extrusion method. Journal of Adhesion Science and Technology, 26, 1281–1294.

Renerre, M. (1990). Review: factors involved in the discoloration of beef meat. International Journal of Food Science and Technology, 25, 613–630.

Ruiz, H. V., Martín-Martínez, E. S., & Aguilar Méndez, M. A. (2011). Biodegradability of polyethylene-starch blends prepared by extrusion and molded by injection: evaluated by response surface methodology. Starch, 63, 42–51.

Santonja-Blasco, L., Contat-Rodrigo, L., Moriana-Torro, R., & Ribes-Greus, A. (2007). Thermal characterization of polyethylene blends with a biodegradable masterbatch subjected to thermo-oxidative treatment and subsequent soil burial test. Journal of Applied Polymer Science, 106, 2218–2230.

Shah, P. B., Bandopadhyay, S., & Bellare, J. R. (1995). Environmentally degradable starch filled low density polyethylene. Polymer Degradation and Stability, 47, 165–173.

Sheard, P. R., Enser, M., Wood, J. D., Nute, G. R., Gill, B. P., & Richardson, R. I. (2000). Shelf life and quality of pork products with raised n-3 PUFA. Meat Science, 55, 213–221.

Silveira, M. F. A., Soares, N. F. F., Geraldine, R. M., Andrade, N. J., Botrel, D. A., & Gonçalves, M. P. J. (2007). Active film incorporated with sorbic acid on pastry dough conservation. Food Control, 18, 1063–1067.

Sionkowska, A. (2011). Current research on the blends of natural and synthetic polymers as new biomaterials: review. Progress in Polymer Science, 36, 1254–1276.

Soares, N. F. F., Sa, S. C. A., Santiago-Silva, P. Espitia, P.J.P., Gonçalves, M.P.J.C., Lopez, M.J.G., et al. (2010). Active and intelligent packaging for milk and milk products. In: J. S. R. Coimbra, J. A. Teixeira (Eds.), Engineering aspects of milk and dairy products (pp 175–199). Taylor & Francis Group

St-Pierre, N., Favis, B. D., Ramsay, B. A., Ramsay, J. A., & Verhoogt, H. (1997). Processing and characterization of thermoplastic starch/polyethylene blends. Polymer, 38, 648–655.

Sun, X. D., & Holley, R. A. (2012). Antimicrobial and antioxidative strategies to reduce pathogens and extend the shelf life of fresh red meats. Comprehensive Reviews in Food Science and Food Safety, 11, 340–354.

Sunilkumar, M., Francis, T., Thachil, E. T., & Sujith, A. (2012). Low density polyethylene-chitosan composites: a study based on biodegradation. Chemical Engineering Journal, 204–206, 114–124.

Suppakul, P., Miltz, J., Sonneveld, K., & Bigger, S. W. (2003). Active packaging technologies with an emphasis on antimicrobial packaging and its applications. Journal of Food Science, 68(2), 408–420.

Thakore, I. M., Desai, S., Sarawade, B. D., & Devi, S. (2001). Studies on biodegradability, morphology and thermomechanical properties of LDPE/modified starch blends. European Polymer Journal, 37, 151–160.

Tharanathan, R. N. (2003). Biodegradable films and composite coatings: past, present and future. Trends in Food Science & Technology, 14, 71–78.

Troy, D. J., & Kerry, J. P. (2010). Consumer perception and the role of science in the meat industry. Meat Science, 86, 214–226.

Versant, E. F., Van, D. E. R., Voort, P., & Vrancken, K. C. (1995). Characterization and chemical modification of the silica surface (p. 93). Amsterdam: Elsevier Science BV. In Studies in surface science and catalysis.

Vieyra, H., Martín-Martínez, E. S., & Aguilar-Méndez, M. A. (2011). Biodegradability of polyethylene-starch blends prepared by extrusion and model by injection: evaluated by response surface methodology. Starch, 63, 42–51.

Vieyra, H., Aguilar-Méndez, M. A., & Martín-Martínez, E. S. (2013). Study of biodegradation evolution during composting of polyethylene-starch blends using scanning electron microscopy. Journal of Applied Polymer Science, 127(2), 845–853.

Vinhas, G. M., Lima, S. M., Santos, L. V., Lima, M. A. G. A., & Almeida, Y. M. B. (2007). Evaluation of the types of starch for preparation of LDPE/starch blend. Brazilian Archives of Biology and Technology, 50, 361–370.

Walker, A. M., Tao, Y., & Torkelson, J. M. (2007). Polyethylene/starch blends with enhanced oxygen barrier and mechanical properties: effect of granule morphology damage by solid-state shear pulverization. Polymer, 48, 1066–1074.

Yildiz-Turp, G., & Serdaroglu, M. (2010). Effects of using plum puree on some properties of low fat beef patties. Meat Science, 86, 896–900.

Yua, F., Prashanthaa, K., Soulestina, J., Lacrampea, M.-F., & Krawczaka, P. (2013). Plasticized-starch/poly(ethylene oxide) blends prepared by extrusion. Carbohydrate Polymers, 91, 253–261.

Acknowledgments

This work was supported by the Federal Institute of Santa Catarina (IFC); Federal University of Santa Catarina (UFSC); the Institute of Chemistry, Federal University of Rio Grande do Sul (UFRGS); and Videplast. A. V. Junior appreciates all their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Júnior, A.V., Fronza, N., Foralosso, F.B. et al. Biodegradable Duo-functional Active Film: Antioxidant and Antimicrobial Actions for the Conservation of Beef. Food Bioprocess Technol 8, 75–87 (2015). https://doi.org/10.1007/s11947-014-1376-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1376-9