Abstract

Colloidal silver nanoparticles with a size of 5.5 ± 1.1 nm were prepared by chemical reduction using polyethylene glycol (PEG). Silver nanoparticles were incorporated into low-density polyethylene (LDPE) by melt blending and subsequent hot pressing at 140 °C to produce nanocomposite film with an average thickness of 0.7 mm. PEG was added at 5% weight of polymer as a compatibilizer agent in order to prevent agglomeration and provide uniform distribution of nanoparticles in polymer matrix. Antimicrobial activity of silver nanocomposites against Escherichia coli ATCC 13706, Staphylococcus aureus ATCC12600, and Candida albicans ATCC10231 was evaluated by semi-qualitative agar diffusion test and quantitative dynamic shake flask test. Mechanical properties of nanocomposites were not significantly different from silver-free LDPE-containing PEG films (p > 0.05), and silver nanoparticles did not form chemical bonding with the polymer. LDPE-silver nanocomposite samples by more than 6.69 ppm silver nanoparticles showed considerable antimicrobial clear zone. LDPE-silver nanocomposite affected growth kinetic parameters of the examined bacteria and is more efficient on S. aureus than E. coli. Polyethylene-silver nanocomposites containing 22.64 ppm silver nanoparticles could reduce 57.8% growth rate and 23.3% maximum bacterial concentration and increase 35.8% lag time of S. aureus. This study shows the potential use of LDPE-silver nanocomposite as antimicrobial active film. Antimicrobial efficiency of silver nanocomposite depends on silver nanoparticles concentration; however, high level of silver nanoparticles may lead to weakening of mechanical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Active packaging is one of the innovative packaging that has been introduced due to current changes in distribution and market trends and consumer demands for improved product quality and safety (Vermeiren et al. 1999). Active packaging has been defined as a type of packaging that changes the condition of the packaging to extend shelf life or improve safety or sensory properties while maintaining the quality of the food (European FAIR-project CT 98-4170).

The antimicrobial packaging, an extensively interesting version of active packaging, is a packaging in which the food product, the package, and the environment interact to inhibit, reduce, or retard the growth of microorganisms in order to prolong shelf life and to maintain product quality and safety (Appendini and Hotchkiss 2002; Han 2000; Suppakul et al. 2003).

The antimicrobial packaging is based on the principle that active component can be released from the packaging material to the foodstuffs and is more efficient than incorporating directly into food formulation because of the controlled and slow migration of antimicrobial agent from the packaging material to the surface of the product (Quintavalla and Vicini 2002). Furthermore, antimicrobial packaging can effectively reduce the difficulties with direct addition of antimicrobials including loss of activity because of leaching into the food matrix and cross-reaction with other food components such as lipids or proteins (Han and Floros 1997; Mauriello et al. 2005), and result in extended activity of antimicrobials into the transport and storage phase of food distribution. Antimicrobial substance which incorporated to the packaging material can suppress microbial contamination by extending the lag phase and/or reducing the growth rate and maximum population or inactivating microorganism by contact (Appendini and Hotchkiss 2002; Quintavalla and Vicini 2002).

Antimicrobial substance could be incorporated directly into packaging material, coated onto polymer surface, or immobilized to polymers (Appendini and Hotchkiss 2002). Thermal processing such as melt blending, extrusion, and injection molding has been applied for incorporating the antimicrobials into polymers, but heat stability of active component and chemical compatibility of polymer matrix and antimicrobials, in order to evenly distribute antimicrobial substance, should be considered.

Low-density polyethylene (LDPE) is widely used in food packaging because of acceptable flexibility, transparency, easy processability, thermal stability, environmentally recyclability, and inexpensive properties (Del Nobile et al. 2009; Marsh and Bugusu 2007). So, most of the researches of antimicrobial food packaging has been based on LDPE polymer matrix. Some examples of antimicrobials which incorporated into LDPE are sorbate compound (Han et al. 2007; Han and Floros 1997), imazalil (Vartianen et al. 2003), nisin (Mauriello et al. 2005), silver zeolite (Ishitani 1995), and natural extracts such as basil constituents (Suppakul et al. 2008), grapefruit seed extract (Lee et al. 1998), thymol and rosemary oleoresin (Han et al. 2007), and clove extract (Hong et al. 2000). Among all these, silver nanoparticles deserve special attention due to their unique properties, high thermal stability, and long-term activity, which differentiate from other antimicrobial additives. Silver nanoparticles represent one of the most interesting and developing area in recent nano-responding studies which can relate to their unique physicochemical characteristics such as catalytic activity, optical and electronic properties, and especially, strong antimicrobial activity and broad spectrum toxicity to microorganism (Kim et al. 2007), as well as radical scavenging biocompatibility (Jokar et al. 2009). Some mechanisms about inhibitory effects of silver nanoparticles have been reported such as reaction of silver ions released from surface of nanoparticles with cell membrane proteins by combining the thiol (SH)-containing amino acids which leads to inactivation of proteins (Cho et al. 2005; Liau et al. 1997), formation of pits in the cell wall of bacteria and change of membrane permeability (Sondi and Salopek-Sondi 2004), and generation of free radicals and subsequent free radical-induced membrane damage (Kim et al. 2007).

Studies on the antimicrobial effectiveness of polyethylene-silver nanocomposite prepared by several methods have been found in literature such as plasma depositing an Ag-containing polyethylene oxide-like coating on a polyethylene layer (Nobile et al. 2004), but little attention has been paid to antimicrobial efficiency of LDPE-silver nanocomposite produced by industrially thermal processing.

The objectives of this paper are to incorporate silver nanoparticles produced by chemical reduction using short chain polyethylene glycol (PEG) into LDPE film by melt processing and to address the antimicrobial effectiveness of LDPE-silver nanocomposite by qualitative and quantitative in vitro test. The effect of silver nanoparticles addition on mechanical properties of nanocomposite film has been studied. In particular, LDPE was used as a common polymeric matrix, and silver nanoparticles were used as an antimicrobial agent for the industrial thermal production of silver nanocomposite applicable in active food packaging systems.

Material and Methods

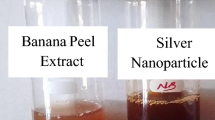

Preparation of Silver Nanoparticles

Silver nitrate (AgNO3) and PEG (molecular weight 200) were provided by Merck Company, Germany. Silver nanoparticles were prepared according to the procedure described by Popa et al. (2007). Briefly, AgNO3 (800 mg) was dissolved in 100 cm3 PEG 200 at room temperature (25 °C) and stirred until complete dissolution of silver nitrate. The transparent solution converted to gray-black colloid, which indicated the formation of silver nanoparticles. After 1 h, the colloidal dispersion was washed with acetone and then centrifuged at 14,000 rpm at 10 °C for 15 min for the separation of nanoparticles from PEG. Silver nanoparticles were dried by vacuum dryer (Binder, Germany) at 2.0 bar and 25 °C (Jokar et al. 2009).

Preparation of Silver Nanocomposite Film

LDPE 428043, melt index 25 g/10 min, was purchased from Sigma-Aldrich, USA. LDPE-silver nanocomposite was prepared by melt processing. Silver nanoparticles were incorporated into LDPE matrix using a Brabender Plasticorder EC, Germany. Different content of silver nanoparticles (0.1%, 0.3%, 0.5%, 3%, and 5% weight of polymer) was firstly dissolved in pure PEG 200 (5% weight of polymer) by the help of indirect sonication (water bath) for 15 min. PEG was used as a compatibilizer agent in order to prevent agglomeration of nanoparticles and to provide uniform distribution of polar silver nanoparticles into nonpolar LDPE matrix. The mixing chamber was filled with 20 g LDPE pellet at 60 rpm rotation speed. PEG containing silver nanoparticles was added after 5 min as filler and subsequently mixed for 10 min. The processing temperature was 140 °C. This temperature was chosen because of the optimum mechanical properties obtained by the LDPE film produced at 110 °C, 120 °C, 130 °C, 140 °C, and 150 °C. Melt-blended LDPE composite was subjected between two plates of Hot Press (HSIN-CHI Machinery Co., Ltd, Taiwan) at 140 °C for 10 min molding time under 50 bar pressing and subsequent 10 min cooling time (Del Nobile et al. 2009). From Hot Press, square specimens having dimensions of 140 × 140 × 0.7 mm were obtained.

Silver Filler Quantification

Because of losing a part of the silver filler during melt processing, real silver content determination of nanocomposite is necessary for better investigation. About 1.2 g of the dried nanocomposite material was kept at 600 °C in a furnace (ELF 11/14B, Carbolite, England) for 2 h in order to mineralize completely (Damm et al. 2008). The remaining ash was dissolved in 5 ml of nitric acid (65% v/v, Merck). The solution was diluted and analyzed by atomic absorption spectrometer (S4 AA systems, Thermo Scientific).

Morphology and Size Characterization

The morphology and size of the colloidal silver nanoparticles were characterized by transmission electron micrograph (TEM) using Philips HMG 400 transmission electron microscope operating at 400 kV and by placing the specimen onto a carbon-coated copper grid. Distribution of silver nanoparticles in LDPE nanocomposite was investigated using atomic force microscopy. X-ray diffraction measurements of nanocomposites and ultracentrifuged silver nanoparticles were executed using X'pert PANalytical diffractometer with Cu Ka radiation in 2θ range of 20–90°, and the size of the crystals were calculated using Scherrer equation (Zielinska et al. 2009).

where D p is dimension of the particle; 0.94 is the constant of the shape factor; λ is the x-ray wavelength, typically 1.54 Å; β 1/2 is peak width at half the maximum intensity; and θ is peak position (degree).

Infrared Spectroscopy and Mechanical Properties

Fourier transform infrared (FTIR) spectra of LDPE nanocomposites were obtained using PerkinElmer Spectrometer FTIR Model 1725 X and a KBr beam splitter within wavelength range of 400–4,000 cm−1.

Mechanical tests of the LDPE composite films were performed on an Instron Machine (Series IX version 8.31.00). The samples were tested according to ASTM D63M standard (Swapna Joseph et al. 2009). The tensile tests of the films were carried at a crosshead speed of 5 mm/min, 30 °C, and with a load capacity of 1 KN. Each test was repeated seven times, and results are expressed as means ± standard deviation and subjected to a one-way analysis of variance at 95% confidence intervals.

Microbiological Analysis

Escherichia coli ATCC 13706, Staphylococcus aureus ATCC12600, and Candida albicans ATCC10231 strains were obtained from MicroBioLogics Inc, USA. For recovery of lyophilized culture, the desired culture contained in plastic bead was aseptically transferred into a tube containing 5 mL of Nutrient Broth (Oxoid Ltd., England) and maintained in incubator at 37 °C for 24 h for bacteria and 25 °C for 72 h for mold. The working stock culture was maintained on tryptone soy agar and potato dextrose agar (Oxoid Ltd., England) slants for bacteria and mold, respectively, at 4 °C in a refrigerator (Kwakye-Awuah et al. 2008).

Antimicrobial efficiency of silver LDPE nanocomposites was evaluated using an agar diffusion method and a dynamic shake flask method as described by Appendini and Hotchkiss (2002).

In the agar diffusion test, a single bacterial colony for each microorganism was used to inoculate a 100-ml sterile nutrient broth, which was grown aerobically overnight at 37 °C for bacteria and 25 °C for fungi in a rotary shaker incubator (New Brunswick C24, USA) at 90 rpm to give a final concentration of 18.76 × 108 for E. coli, 23.36 × 107 for S. aureus, and 2.26 × 108 for C. albicans. Each film (about 0.5 × 0.5 cm) sample, sterilized by dipping in ethanol alcohol for 15 min, was placed on a tryptone soy agar and potato dextrose agar plate surface seeded with 1 mL of peptone water-diluted test culture. The tryptone soy agar plates were incubated for 1 day at 37 °C for bacteria cultures, and potato dextrose agar plates were incubated for 3 days at 25 °C for mold culture. The clear zone formed around the samples in the medium was recorded as an indication of inhibition of the microbial species (Suppakul et al. 2008).

For shake flasks test, eight specimens (2 × 1.5 cm) of the nanocomposite films were immersed in 100 mL of tryptone soy broth (TSB), and yeast and mold broth (YMB; Oxoid Ltd., England) created a ratio of 2.08 ml liquid/cm2 of exposed surface. A 200-ml flask containing TSB for bacteria, YMB for yeast, and 0.4 g of Tween 80 inoculated with 1 mL of E. coli (3.54 × 105) and S. aureus (22.30 × 106) and then incubated at 37 °C for bacteria and 25 °C for yeast with 150 rpm agitation. Evidence of microbial growth was acquired by reading the absorbance changes at 600 nm (Han et al. 2007) by using a spectrophotometer (Genesys 20, ThermoSpectronic, USA) at regular intervals (2 h). The absorbance data were modeled according to Gompertz equation as modified by Zwietering et al. (1990) to estimate microbial growth kinetic parameters:

where X(t) is the cell concentration of inoculated microorganism in the medium (absorbance at λ = 600 nm), X 0 is the initial value of absorbance, A is the maximum bacterial concentration attained at the stationary phase and its initial value, µ max is the maximum specific growth rate (h−1), λ is lag phase, and t is time (h).

The parameters were determined by using Statistica 7.0 for Windows (StatSoft Inc, Tulsa, OK, USA) to describe microbial growth kinetics.

Results and Discussion

Morphology and Size

TEM showed relatively uniformly distributed spherical silver nanoparticles in colloid solution with size of 5.5 ± 1.1 nm (Fig. 1). The image of TEM also demonstrated the stabilization effect of PEG in order to favor silver nanoparticles formation which can attribute to numerous ether bonds (–O–) present in PEG avoiding nanoparticles growth and agglomeration (Popa et al. 2007; Wang et al. 2006). Separation of PEG by ultra centrifuge at 14,000 rpm resulted in increasing size up to 29.55 nm according to x-ray diffraction data using Scherer formula as shown in Table 1.

The real silver content of nanocomposites was less than the added amount of ultracentrifuged silver nanoparticles because some part of the silver nanoparticles was lost due to melt processing. The silver content of composites was 1.19, 2.21, 6.69, 11.23, and 22.64 mg/kg determined by atomic absorbance spectroscopy.

X-ray diffraction data of ultracentrifuged silver nanoparticles and LDPE-silver nanocomposites was shown in Table 1, which revealed four main peaks in cubic structure, which are confirmed to silver 3C reference by the code 01-087-0717 in accordance with ICSD file. Results indicated that PEG is a crucial key of crystal size. Ultracentrifuged silver nanoparticles have the biggest size because of the removal of PEG from the colloidal solution. The crystal size of nanocomposites is lower than that of ultracentrifuged silver nanoparticles because of the dispersal of silver nanoparticles in 5% (w/w) PEG before adding to polymer as filler in melt blender. PEG prevents agglomeration of nanoparticles in polymer and facilitates uniform distribution of polar silver nanoparticles into unpolar LDPE matrix. The more concentrated the silver nanoparticles are in the composite, the lower the ratio of PEG/nanoparticles and the lower the function of PEG, which caused increase in crystal size, especially for the main peak at 2θ = 38° (1 1 1 pattern) as shown in Table 1.

Atomic force micrograph of nanocomposite (Fig. 2) indicated that the silver nanoparticles are well distributed in the polymer, which could be attributed to the presence of PEG as solvent of silver nanoparticles and compatibilizer agent of polymer composite as described above.

Mechanical Properties

The mechanical properties of the LDPE composite films were given in Table 2. The results of the mechanical tests indicated that the addition of PEG decreases tensile stress and elongation of LDPE films (p < 0.05) and did not affect the young' modulus significantly (p > 0.05). These findings are in agreement with that of Xie and Li (2008) who found small size of PEG additives less declined tensile strength of the PE/PP blend while maintaining toughness at high level.

An increase in Young's modulus and decrease in tensile stress and elongation of LDPE-silver nanocomposites with an increase in silver concentration were observed; however, the effect of silver content was not significant (p > 0.05), except of nanocomposite containing 22.64 ppm silver nanoparticle. Young' modulus was increased at high silver nanoparticles concentration of 22.64 ppm that can be attributed to poor bonding between silver nanoparticles and LDPE polymer. Overall, considering the significant differences between the values that are shown in Table 2, it is concluded that silver concentration did not quiet affect the mechanical properties of the LDPE nanocomposites, which further support the findings of Pehlivan et al. (2005), who studied on silver exchanged zeolite polypropylene composite, and Damm et al. (2008), who studied on polyamide 6-silver nanocomposites.

FTIR spectra of LDPE nanocomposites containing different concentration of silver were shown in Fig. 6. Distribution of silver nanoparticles in the LDPE matrix is physical due to the same FTIR pattern. The same FTIR spectra of different silver concentration nanocomposites refuse bonding between silver nanoparticles and LDPE polymer. The new peak at wavenumber 1,722 cm−1 for the 22.64-ppm silver nanocomposite indicated a weak chemical bonding at high concentration of silver nanoparticle, which can relate to significant higher Young' modulus value of the nanocomposite containing 22.64 ppm of silver nanoparticle.

Antimicrobial Activity

LDPE-silver nanocomposites were subjected to an evaluation of their antimicrobial efficiency by agar diffusion and shake flasks test.

LDPE nanocomposite samples containing more than 6.69 ppm silver nanoparticle exhibited an interesting antimicrobial activity against E. coli, S. aureus, and C. albicans in the agar disc diffusion test (Table 3 and Fig. 3). Colonies of E. coli (Gram-negative), S. aureus (Gram-positive), and C. albicans (yeast) could not be viewed in the clear zone directly above the nanocomposites film samples; however, the clear zone for nanocomposites containing less than 6.69 mg/kg silver was not observed. The microbial inhibition indicates release of silver ion from the nanocomposite sample and diffusion into the agar layer, preventing the development of microbial colonies in the agar. The results revealed more inhibitory effect on yeast than bacteria and more inhibitory effect on Gram-positive S. aureus than Gram-negative E. coli. These findings are consistent with other studies (Cho et al. 2005; Liau et al. 1997); they indicated that Gram-positive strains are more sensitive to silver compounds than Gram-negative bacteria, which attributed to binding of silver ions to peptidoglycan layer. In fact, inhibitory effects of silver compounds may be associated with characteristics of specific bacterial species. Gram-positive and Gram-negative bacteria have differences in their membrane structure, the most distinctive of which is the thickness of the peptidoglycan layer. Peptidoglycan layer, also known as murein, is a mesh-like layer with specific membrane feature of bacterial species. Gram-positive bacteria having thicker peptidoglycan layer than Gram-negative bacteria result in attraction of more silver ions. However, further study should be undertaken to distinguish the effect of silver ions on Gram-negative and -positive bacteria.

Growth profile of E. coli and S. aureus was shown by plotting absorbance (600 nm) of inculcated solutions as a function of time in contact with the silver-free LDPE film (control) and LDPE films containing silver nanoparticles and fitting according to modified Gomertz equation (Eq. 2) and was shown in Figs. 4 and 5. Results from fitting process to determine the parameters of lag time (λ), maximum growth rate (µ max), and maximum bacterial concentration (A), along with corresponding R 2 (adj.), are listed in Tables 4 and 5.

The growth curves result from fitting Eq. 2 to the experimental data for Escherichia coli

The growth curves result from fitting Eq. 2 to the experimental data for Staphylococcus aureus

The results indicated that a modified Gompertz equation (Eq. 2) was fitted to all experimental absorbance data. The R 2 (adj.) values, ranging from 0.9916 to 0.9995, were obtained for predicted values to experimental values and the lack of fit (p value = 0.000), which measure the fitness of the model for all samples, indicating the proposed model was sufficiently accurate and significant (p < 0.05) for describing the examining data (Del Nobile et al. 2009; Zwietering et al. 1990). Silver nanocomposites influenced growth kinetics of E. coli and S. aureus. The lag time (λ) parameter extended for about an hour (ranged from 3.52 to 4.38 h) for E. coli and 3 h (ranged from 7.49 to 10.17 h) for S. aureus, as contacted with LDPE-silver nanocomposite. The antimicrobial efficacy of the composite-containing silver is a function of the filler content, and the amounts of silver nanoparticles content are in a range in which antimicrobial efficacy was found (Damm et al. 2008). Silver nanocomposites containing 22.4 ppm silver could increase lag time up to 24.4% and 35.8%, reduce maximum growth rate to 30.4% and 57.95%, and decrease maximum bacterial concentration to 27.3% and 23.3% for E. coli and S. aureus, respectively. Results indicated that the nanocomposites containing low concentration of silver nanoparticles did not change the growth kinetics of target microorganisms to a great extend as compared to control. In fact, no statistically significant differences were found between the model parameter values by the nanocomposites containing less than 6.69 ppm silver nanoparticles, with an exception of lag time (λ) parameter of the S. aureus, showing an increase ranged from 7.49 to 9.76 h. The results revealed that the antimicrobial activity of LDPE-silver nanocomposites is more efficient on S. aureus than E. coli, which is consistent with the agar diffusion results. The maximum growth rate parameter (µ max) decrease from 0.23 to 0.16 h−1 for E. coli and from 0.57 to 0.24 h−1 for S. aureus, indicating Gram-positive S. aureus is more susceptible to silver ion released from the nanocomposites compared to Gram-negative E. coli due to lack of peptidoglycan layer of Gram-positive membrane structure (Kim et al. 2007; Liau et al. 1997). In contrast, some other researchers reveled that Gram-negative bacteria are more sensitive to silver compounds, which attributed to thinner murein cell wall of Gram-negative bacteria (Cho et al. 2005). Further study should be undertaken to distinguish the effect of silver nanoparticles on Gram-negative and -positive bacteria. However, it is important to note that risk assessment of silver ion migration from silver nanoparticles and silver nanocomposites in food contact systems should be considered (Bouwmeester et al. 2009), which is under research (Fig. 6).

Conclusion

LDPE-silver nanocomposites prepared by cost-effective and industrial method described here proved to be capable of rendering antimicrobial polymer. Application of LDPE-silver nanocomposites based on these findings may lead to valuable active packaging. PEG can be used as appropriate additive for well distribution of silver nanoparticles into LDPE polymer matrix. Results suggest that proposed active film can be successfully used for inhibiting or reducing Gram-negative E. coli and Gram-positive S. aureus bacteria. Antimicrobial efficiency of silver nanocomposite depends on silver nanoparticles concentration; however, high level of silver nanoparticles may lead to weakening of mechanical properties.

References

Appendini, P., & Hotchkiss, J. H. (2002). Review of antimicrobial food packaging. Innovative Food Science & Emerging Technologies, 3, 113–126.

Bouwmeester, H., Dekkers, S., Noordam, M. Y., Hagens, W. I., Bulder, A. S., Heer, C., et al. (2009). Review of health safety aspects of nanotechnologies in food production. Regulatory Toxicology and Pharmacology, 53(1), 52–62.

Cho, K. H., Park, J. E., Osaka, T., & Park, S. G. (2005). The study of antimicrobial activity and preservative effects of nanosilver ingredient. Electrochimica Acta, 51, 956–960.

Damm, C., Munstedt, H., & Rosch, A. (2008). The antimicrobial efficacy of polyamide 6/silver-nano- and microcomposites. Materials Chemistry and Physics, 108, 61–66.

Del Nobile, M. A., Conte, A., Buonocore, G. G., Incoronato, A. L., Massaro, A., & Panza, O. (2009). Active packaging by extrusion processing of recyclable and biodegradable polymers. Journal of Food Engineering, 93, 1–6. doi:10.1016/j.jfoodeng.2008.12.022.

Han, J. H. (2000). Antimicrobial food packaging. Food Technology, 54(3), 56–65.

Han, J. H., & Floros, J. D. (1997). Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. Journal of Plastic Film and Sheeting, 13, 278–298.

Han, J., Castell-Perez, M. E., & Moreira, R. G. (2007). The influence of electron beam irradiation of antimicrobial-coated LDPE/polyamide films on antimicrobial activity and film properties. LWT, 40, 1545–1554.

Hong, S. I., Park, J. D., & Kim, D. M. (2000). Antimicrobial and physical properties of food packaging films incorporated with some natural compounds. Food Science Biotechnology, 9(1), 38–42.

Ishitani, T. (1995). Active packaging for food quality preservation in Japan. In P. Ackerman, M. Jägerstad, & T. Oglsson (Eds.), Food and food packaging materials—chemical interactions (pp. 177–188). Cambridge: The Royal Society of Chemistry.

Jokar, M., Abdul Rahman, R., Ibrahim, N. Z., Chuah Abdullah, L., & Chin Ping, T. (2009). Characterization and biocompatibility properties of silver nanoparticles produced using short chain polyethylene glycol. Journal of Nano Research, 9, 29–37.

Kim, J. S., Kuk, E., Nam Yu, K., Kim, J. H., Park, S. J., Lee, H. J., et al. (2007). Antimicrobial effects of silver nanoparticles. Nanomedicine, 3, 95–101.

Kwakye-Awuah, B., Williams, C., Kenward, M. A., & Redecka, I. (2008). Antimicrobial action and efficiency of silver-loaded. Journal of Applied Microbiology, 104(5), 1516–1524.

Lee, D. S., Hwang, Y. I., & Cho, S. H. (1998). Developing antimicrobial packaging film for curled lettuce and soybean sprouts. Food Science and Biotechnology, 7(2), 117–121.

Liau, S., Read, D., Pugh, W., Furr, J., & Russell, A. (1997). Interaction of silver nitrate with readily identifiable groups :relationship to the antibacterial action of silver ions. Letters in Applied Microbiology, 25, 279–283.

Marsh, K., & Bugusu, B. (2007). Food packaging—roles, materials, and environmental issue. Journal of food science, 72(3), 39–55.

Mauriello, G., De Luca, E., La Storia, A., Villani, F., & Ercolini, D. (2005). Antimicrobial activity of a nisin-activated plastic film for food packaging. Letters in Applied Microbiology, 41, 464–469.

Nobile, M. A. D., Cannarsi, M., Altieri, C., Sinigaglia, M., Favia, P., Iacoviello, G., et al. (2004). Effect of Ag-containing Nano-composite active packaging system on survival of Alicyclobacillus acidoterrestris. Journal of Food Science, 9(8), 379–383.

Pehlivan, H., Balkose, D., Ulku, S., & Tihminlioglu, F. (2005). Characterization of pure and silver exchanged natural zeolite filled polypropylene composite films. Composite Science and Technology, 65, 2049–2058.

Popa, M., Pradell, T., Crespo, D., & Calderon-Moreno, J. M. (2007). Stable silver colloidal dispersions using short chain polyethylene glycol. Colloids and Surfaces. A, Physicochemical and Engineering Aspects, 303, 184–190.

Quintavalla, S., & Vicini, L. (2002). Antimicrobial food packaging in meat industry. Meat Scienc, 62, 73–380.

Sondi, I., & Salopek-Sondi, B. (2004). Silver nanoparticles as antimicrobial agent: A case study on E. coli as a model for Gram-negative bacteria. Journal of Colloids and Interface Science, 275, 177–182.

Suppakul, P., Milts, J., Sonneveld, K., & Bigger, S. W. (2003). Active packaging technologies with an emphasis on antimicrobial packaging and its application. Journal of Food Science, 68, 408–420.

Suppakul, P., Sonneveld, K., Bigger, S. W., & Miltz, J. (2008). Efficacy of polyethylene-based antimicrobial films containing principal constituents of basil. LWT, 41, 779–788.

Swapna Joseph, C., Harish Prashanth, H. V., Rastogi, N. K., Indiramma, A. R., Yella Reddy, S., & Raghavarao, K. S. M. S. (2009) Optimum blend of chitosan and poly-(ε-caprolactone) for fabrication of films for food packaging applications. Food Bioprocess Technology. doi:10.1007/s11947-009-0203-1.

Vartianen, J., Skytta, E., Ahvenainen-Rantala, R., & Enqvisit, J. (2003). Antimicrobial and barrier properties of LDPE films containing Imazalil and EDTA. Journal of Plastic Film and Sheeting, 19, 249–261.

Vermeiren, L., Devlieghere, F., Beest, M. V., Kruijf, N. D., & Debever, J. (1999). Developments in the active packaging of foods. Trends in Food Science and Technology, 10, 77–86.

Wang, A. L., Yin, H. B., Ren, M., Cheng, X. N., Zhou, Q. F., & Zhang, X. F. (2006). Effects of different functional group-containig organics on morphology-controled synthesis of silver nanoparticles at room temperature. Acta Metallurgica Sinica, 19(5), 362–370.

Xie, M., & Li, H. (2008). Mechanical properties of an ultrahigh-molecular-weight polyethylene/polypropylene blend containing poly(ethylene glycol) additives. Journal of Applied Polymer Science, 108(5), 3148–3153.

Zielinska, A., Skwarek, E., Zaleska, A., Gazda, M., & Hupka, J. (2009). Preparation of silver nanoparticles with controlled particle size. Procedia Chemistry, 1, 1560–1566.

Zwietering, M., Jongenberger, I., Roumbouts, F. M., & Riet, K. V. (1990). Modeling of bacterial growth curve. Applied and Enviromental Microbiology, 56(6), 1875–1881.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jokar, M., Abdul Rahman, R., Ibrahim, N.A. et al. Melt Production and Antimicrobial Efficiency of Low-Density Polyethylene (LDPE)-Silver Nanocomposite Film. Food Bioprocess Technol 5, 719–728 (2012). https://doi.org/10.1007/s11947-010-0329-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-010-0329-1