Abstract

This paper provides a capsule overview of recent experimental studies dealing with the drying of a large assortment of tropical and subtropical fruits, also called “exotic” fruits. The term exotic includes a number of tropical fruits that are not yet commonly found in global markets but do have the potential to do so in view of their appearance, taste, and textural and nutritional quality parameters. As the consumer is seeking diverse tastes and flavors without compromising on quality, it is logical to expect the market for dried exotic fruits to increase over the next decade. This review covers diverse drying techniques, drying kinetics, and key quality parameters of dried fruits.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, increasing attention has been paid to the role of natural active ingredients such as antioxidants in human health. The preservation of these compounds is important in the quality aspect of food preservation especially in drying. They are also regarded to be one of the important health-protecting factors. In fact, the active ingredients can reduce the content of toxic components in foods as well as supply the human body with exogenous antioxidants (Pokorny 1991; Fereidoon et al. 1992; Block and Langseth 1994; Halliwell et al. 1995; Ramarathnam et al. 1995).

Fruits are rich in antioxidants that help to lower the incidence of degenerative diseases such as acceleration of aging, cancer, arthritis, arteriosclerosis, heart disease, inflammation, brain dysfunction, etc. (Gordon 1996; Halliwell 1996; Feskanich et al. 2000). The most abundant antioxidants in fruits are polyphenols and vitamin C and vitamins A, B, and E. Carotenoids are present to a lesser extent in some fruits. These polyphenols, most of which are flavonoids, are present mainly in ester and glycoside forms (Fleuriet and Macheix 2003).

In preserving fruits for extending its shelf life, minimizing loss, and preventing growth of mold and microbes, it is important that the denaturation or damage of the active ingredients by the preservation methods is minimized as well (Santos and Silva 2008). As such, proper selection of dryer for the preservation of fruits is very important and vital to the process economics. Mujumdar (2007a) gave a comprehensive account on the classification of industrial dryers and selection of dryers based on different criteria such as physical form of feedstock, residence time, mode of heat input, methods of conveying of materials, etc. (Mujumdar and Menon 1995; Mujumdar and Passos 2000; Mujumdar 2000, 2001, 2006, 2007b, c, 2008a, b; Law et al. 2008).

Over the years, research on common fruit drying has been extensively carried out, for instance apples, grapes, berries, banana, etc. However, reports on other fruits especially some exotic and tropical fruits are rather scarce. This paper summarizes the research findings of the drying of some exotic fruits and comments on the type of dryers and drying methods for the drying of exotic fruits.

In quantifying the amount of antioxidant in fruits, many indexes and units are used. This paper focuses on three indexes: ascorbic acid equivalent antioxidant capacity (AEAC), ascorbic acid content (AAC), and total polyphenol content (TPC). AEAC is the total antioxidant capacity which is measured in terms of ascorbic acid equivalent, mg-AAE, per 100 g sample. TPC is the phenolic compound which is measured in terms of gallic acid equivalent, mg-GAE, per 100 g sample.

Table 1 lists the exotic fruits that are covered in this review paper. The list is comprehensive but probably misses some fruits. In some ways, it is an arbitrary selection. However, we hope that it includes most of the key fruits that are not commonly found around the globe but which may in the coming decade find new and cost-effective applications in processed foods, particularly snack foods, cereals, ice creams, and others. It also provides the amount of antioxidant namely L-AEAC, L-AAC, and TPC.

Values reported by researchers varied in a wide range which may be due to types of species and different maturation stages of the fruits when they were tested. For example, it has been reported that TPC of guava decreased throughout the immature stage to the full-ripe stage (Bashir and Abu-Goukh 2003). Besides, banana, mango, and date have also been reported to have decreasing TPC upon fruit ripening (Abu-Goukh and Abu-Sarra 1993; Ibrahim et al. 1994; Chong et al. 2009).

Exotic Tropical Fruits

Some exotic fruits contain higher antioxidant content compared to orange for instance. Leong and Shui (2002) found that some tropical fruits such as AEAC for ciku, guava, salak, and star fruit have higher antioxidant content compared to orange whose AEAC is 142 mg/100 g. The antiradical capacity (radical scavenging capacity) of seven tropical fruits from the Brazilian northeast (açaí, acerola, cashew apple, mangaba, murici, umbu, and uvaia) was studied using the diphenylpicryl-hydrazyl method. The study revealed that acerola contains a higher antiradical capacity than α-tocopherol, which is the best natural antioxidant that is commercially used as food additive. Extracts from açaí, cashew apple, mangaba, murici, umbu, and uvaia presented an antiradical capacity higher than butylated hydroxytoluene, which is one of the most employed commercial antioxidants (Rufino et al. 2009).

The following paragraphs briefly describe the exotic fruits covered within the scope of this paper as well as the active ingredients these fruits contain. Figure 1 presents the general aspect of the fruits covered by this review.

Acerola (Malpighia punicifolia L.) is also known as Barbados cherry and belongs to the family Malpighiaceae. The fruit is originated from the Caribbean and is cultivated in most countries of South America. The fruit is cherry-like (1.0–2.5 cm) and is an excellent source of vitamin C. Acerola is commercially used in the production of juices, toppings, and is added to foodstuffs as source of vitamin C.

African star apple or white star apple (Chrysophyllum albidum L.) belongs to the family Sapotaceae. The fruit grows in rainforest habitat and is well distributed along Africa and South America. Star apple is an excellent source of vitamins and iron. It is used in the production of homemade juices and jams. Commercial use of African star apple is scarce.

Aonla or Indian gooseberry (Phyllanthus emblica L.) or “Ma-khaam Pom” as known in Thailand (Chatchavalchokchai 1987) is indigenous in tropical Southeast Asia, including Thailand, and is known as a rich source of vitamin C. The fruit is commonly consumed as a health food in both fresh and various preserved forms such as pickles, dried fruits, and beverage products (Montri 1998). Indian gooseberry tea is an alternative product to instant beverage powder and pasteurized juice. It is usually consumed for thirst quenching.

Avocado (Persea americana Mill.) is also known as palta, aguacate, abacate, butter pear, or alligator pear and belongs to the family Lauraceae. The tree is native to Perú, Mexico, South America, and Central America. Avocado is a commercially valuable crop whose trees and fruits are cultivated in tropical climates throughout the world, producing a green-skinned, pear-shaped fruit that ripens after harvesting. Approximately 75% of an avocado’s calories come from fat, most of which is monounsaturated fat. They are rich in vitamins A, B, and E as well as in potassium. They have the highest fiber content of any fruit—including 75% insoluble and 25% soluble fiber (Dowling and Morton 1987). Avocados have been used in ice cream and pickle production as well as in guacamole powder.

Ber is cultivated all over the arid parts of India, Pakistan, Bangladesh, Sri Lanka, Central to Southern Africa, and in the northern part of Australia. Ber fruit is richer than apple in protein, phosphorous, calcium, carotene, and vitamin C (Bakshi and Singh 1974). Fully ripe fruits are dried to prepare a dehydrated product similar to dry dates. The dehydrated ber is consumed during off season and is relished as a dessert (Pareek 2001). The dehydrated ber has already generated a good demand and is expected to rise and become more popular.

Date palm (Phoenix dactylifera L.) is also known as tamara and belongs to the family Palmae. The tree is native to the Persian Gulf and is cultivated throughout the Middle East, Turkey, and Northern Africa. The fruit is rich in vitamin A and sugar (36 g/100 g). Date palm is used in the production of cookies, cakes, candy bars, ice cream, alcoholic beverages, sugar (date sugar), and syrup. It is also used as one of the ingredients in adulterate coffee.

Durian (Durio sp. L.) is the fruit of trees belonging to the family Malvaceae and is native to Thailand, Brunei, Indonesia, and Malaysia. The fruit is widely known and revered in Southeast Asia as the “king of fruits”; the fruit is distinctive for its large size, unique odor, and formidable thorn-covered husk. Durian contains a high amount of sugar, vitamin C, potassium, and the serotoninergic amino acid tryptophan and is a good source of carbohydrates, proteins, and fats. Dried durian from vacuum freeze drying is available in the Southeast Asia region, although not as popular as fresh durian. It is also sold as paste, sauce, and canned as syrup.

Fig (Ficus carica L.) is a fruit probably originated in Western Asia and spread to the Mediterranean. The fruit has a great importance in nutrition due its high carbohydrate content, essential amino acids, vitamins, and minerals. However, fresh figs are very sensitive to microbial spoilage, even stored in cold condition. Drying is the oldest way to preserve figs. Dried and crystallized figs are sold worldwide. Figs are used in the production of pies, puddings, cakes, bread or other bakery products, or added to ice cream mix. Dried cull figs have been roasted and ground as a coffee substitute. Alcoholic extract of dried figs has been used as flavoring for liqueurs and tobacco.

Genipap (Genipa americana L.) is native to northern South America, the Caribbean, and southern Mexico, growing in rainforests. Genipap is also known as jagua, chipara, guayatil, maluco, and caruto. The tree belongs to the family Rubiaceae and the fruit is rich in phosphorus and calcium. The fruit is used mainly in beverage production (liquor), but the flesh is sometimes added as a substitute for commercial pectin to aid the jellying of low-pectin fruit juices.

Guava (Psidium guajava L.) belongs to the family Myrtaceae. The tree is native to Central America, northern South America, and parts of the Caribbean. Guava pulp may be sweet and deep pink with midline seeds of variable number and hardness depending on species. Guava is rich in vitamins A and C, omega-3 and -6 polyunsaturated fatty acids, and especially high levels of dietary fiber. A single guava contains over four times the amount of vitamin C as a single orange and also has good levels of the dietary minerals, potassium, magnesium, and an otherwise broad, low-calorie profile of essential nutrients. Guava is commercially used in the production of juice, jams, marmalade, ice cream, cookies, and several bakery products. Dried guava slice is also available in commercial markets in Southeast Asia.

Jackfruit (Artocarpus integrifolia L.) is also known as jaca and breadfruit. It belongs to the family Moraceae. Jackfruit is cultivated in Asia, Central Africa, and South America. Jackfruits turn brown and deteriorate quickly after ripening. The fruit is used in ice cream, chutney, jam, jelly, and paste or canned in syrup. Ripe bulbs may be dried, fried in oil, and salted for eating like potato chips. A pectin extract can be made from the peel. Jackfruit is rich in vitamin A and minerals such as phosphorus, potassium, and calcium. The seeds are rich in vitamins B1 and B2 and can be dried and used as vitamin supplement.

Malay apple (Syzygium malaccense L.) is also known as mountain apple, pomarosa, and jambu. Malay apple belongs to the family Myrtaceae. The fruit is native to Malaysia but has been introduced throughout the tropics, including many Caribbean countries such as Jamaica, Puerto Rico, and Trinidad and Tobago. The fruit is juicy and sold in fresh form. It is a good source of vitamin A. No commercial use of this fruit has been reported so far.

Salak (Salacca edulis) is a good food source due to its high values of dietary fibers and carbohydrate fractions (Lestari et al. 2003). In addition, salak contains valuable bioactive antioxidants such as pro-vitamin A, vitamin C, and phenolic compounds (Setiawan et al. 2001; Leong and Shui 2002; Leontowicz et al. 2006). However, salak has a short self life, not more than 1 week, due to its rapid ripening and degradation of bioactive ingredients in the fruit. Salak is sold in fresh form, and dried salak is still not sold in the market. As such, salak is not common to export market as its shelf life is rather short.

Star fruit (Averrhoa carambola L.), also known as carambola, is a species of tree native to Indonesia, India, and Sri Lanka and is popular throughout Southeast Asia, Trinidad, Malaysia, parts of East Asia, and South America. The tree belongs to the family Oxalidaceae. The fruit is rich in vitamin C, oxalic acid, and phosphorus. Star fruit is employed in puddings, tarts, stews, and curries.

Classification of Fruits

Fruits can be classified in several ways. They can be classified based on acidity, bearing, size, and seed type. Fruits are so diverse that it is difficult to devise a classification scheme that includes all known fruits.

The classification based on acidity comprises four sets of fruits: alkaline, subacidic, acid, and melons. Alkaline fruits are characterized by their sweet taste and high sugar content (apple, banana, peach, cherry, persimmon, fig, litchi). Acid fruits are characterized by their acid or sour taste and by high concentration of citric, malic, and oxalic acids (orange, pineapple, strawberry, lemon, kiwi, logan, star fruit, gooseberry). Subacidic fruits have a taste between sweet and sour (pear, papaya, mango, blueberry, mulberry, blackberry, cherimoya). Melons are characterized by their sweet taste and by high moisture content (watermelon, melon, cantaloupe).

Fruit-bearing plants are categorized in several ways. Among the tree fruits are the citrus fruits (orange, lemon), apple, pear, peach, fig, jambo, sapota, pitomba, avocado, and guava. Vine fruit are grapes and kiwi. Most berries are classified as bush fruits (currant, pitanga, gooseberries); however, some berries grow on cane-like shoots and are referred to as cane fruit (raspberry, blackberry, logan). Herbaceous fruits grow on plants that have little or no woody tissue (strawberry).

Fruits can also be classified as tender, nut, pome, and stone fruits. Tender fruits comprise pineapple, pomegranate, citrus fruits, pear, jackfruit, and fig. Nuts have a hard outer shell surrounding an inner edible tissue that can be eaten (pequi, cupuassu, pitomba). Pome fruits have a fleshy fruit surrounding a central core of seeds (apple, acerola, peach, papaya, guava, melon, jabuticaba, sapota, pinha). Stone fruits are characterized by a single pit or stone in the center (avocado, cherry, jambo).

Classifying fruits as tender, nut, pome, and stone fruits may be considered a good choice to select a dryer most suitable to dry a fruit. Also, fruits containing sugar are difficult to handle in dryers due to their stickiness, propensity to microbial attack, and potential for discoloring due to caramelization at higher temperatures. Thus, the choice of dryer to be used as well as the operating conditions is affected by the sugar content of the fruit.

Drying Techniques

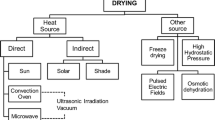

Mujumdar (2007a) has classified the industrial dryers into different categories according to diverse criteria. Detailed description of various drying technologies, including their classification and selection, can be obtained from various chapters in the “Guide to Industrial Drying” (Mujumdar 2008a) as well as the “Handbook of Industrial Drying” (Mujumdar 2007b). Mujumdar and Menon (1995) and Mujumdar (2000) have presented a comprehensive classification scheme for the numerous dryer types and their selection criteria in a general way. Suffice it to say that the choice of dryers for fruits is constrained mainly by the ability of the dryer to handle the material physically, while the choice of the operating conditions is determined by the thermal sensitivity of the material. Mujumdar and Passos (2000) and Mujumdar (2001, 2006, 2007c) have discussed the latest developments and innovation in drying. Law et al. (2008) have given overview and the recent developments and latest advancement in drying technology, drying of bio-origin products, etc. This paper, however, follows Law and Mujumdar’s (2008) classification method where these dryers are classified into four categories, namely, drying strategy, drying medium, method of handling of solids, and mode of heat input. Figure 2 shows the classification of dryers. Dryers can combine items listed in different categories and form a different variant. For instances, heat pump drying and tray dryer gives heat pump dryer; heat pump drying and fluidized bed dryer gives heat pump fluidized bed dryer; vacuum drying and fluidized bed gives low pressure fluidized bed dryer. Mujumdar (2008a) stated that there are more 400 dryers cited in the literature, and about 50 dryers are commonly found in practice.

Currently, most of the dehydrated fruits are produced by the technique of hot air drying, which is the simplest and most economical among the various methods. The dryers generally used for the drying of piece form fruits are cabinet, kiln, tunnel, belt-trough, bin, pneumatic, and conveyor dryers. Pretreatments can be used to reduce the initial water content of the fruit or to modify the tissue structure of the fruit in a way that the effective water diffusivity increases (Madamba and Lopez 2002; Pan et al. 2003; Cao et al. 2006; Fernandes et al. 2008c; Azuara et al. 2009; Cruz et al. 2010).

Osmotic Dehydration

Reis et al. (2007) showed that blanching and the addition of calcium lactate or ascorbic acid did not influence the uptake of sucrose by guavas subjected to an osmotic solution of 65ºBrix. During osmotic dehydration, blanching resulted in a greater loss of fructose and sucrose contained in the vacuoles of mango tissue due to the rupture of tonoplast and plasmalemma (Nieto et al. 2001). Vacuum osmotic dehydration of mango (60 mmHg for 10 min) showed a lower loss of fructose and sucrose than the traditional osmotic dehydration process.

Microscopic studies showed that the tissue structure of mangos underwent changes during the osmotic process. The fresh fruit tissue structure consisted mostly of thin-walled, polygonal parenchyma cells with few intercellular spaces. Round starch granules were present within many cells. After blanching, the cells became dense, most probably due to gelatinization of starch and to thermal denaturation of the mucilage. Cell interspaces at the corner of the cells increased. After osmotic dehydration, the tissue maintained its original arrangement of cells. An increase in intercellular spaces was observed (Nieto et al. 2001).

The results obtained by Andrade et al. (2007) showed that genipaps lost more water to the osmotic solution and incorporated less sucrose when a coating agent was applied (Table 2). A different result was obtained for star fruits. The use of sucrose and pectin as coating agent resulted in a lower loss of water and higher sugar gain than the fruit not subjected to coating. A slight increase in water loss was obtained when CaCl2 was applied as coating agent in star fruits (Shigematsu et al. 2005).

Solute impregnation processes, such as the osmotic dehydration, can benefit from process steps that cause tissue damage (i.e., freeze-thawing). Higher water loss in fresh fruit compared with frozen fruit was due to the intact structure that restricted solute infusion (Falade and Adelakun 2007).

Ultrasound Pretreatment

Ultrasound can be applied to modify the fruit tissue structure, increasing the effective water diffusivity in the fruit, therefore reducing air drying. Power ultrasound can produce chemical, mechanical, or physical changes on the processes or products where it is applied (Mason 1998). When low-frequency power ultrasound is applied, ultrasonic waves travel through the solid medium, causing a rapid series of alternative compressions and expansions in a similar way as a sponge when it is squeezed and released repeatedly (sponge effect; Fuente-Blanco et al. 2006). The sonication also causes cavitation in a liquid medium which forms bubbles that can explosively collapse and generate localized pressure and temperature increase (Wan et al. 1992; Simal et al. 1998). The rate of cavitation or alternate compressions and expansions depends on the frequency of the ultrasonic waves.

The forces involved by the sponge effect caused by ultrasonic waves can create microscopic channels that may ease moisture removal. These microscopic channels can be used by water molecules as a preferential pathway to diffuse toward the surface of the fruit, increasing its effective water diffusivity. The ultrasonic waves also reduce the diffusion boundary layer and increase the convective mass transfer in the sample (Tarleton 1992; Tarleton and Wakeman 1998; Fuente-Blanco et al. 2006). In addition, the cavitations produced by ultrasound are beneficial for the removal of moisture.

The pretreatment is generally carried out under ambient temperature because higher temperatures did not seem to enhance the effects of ultrasound application (Simal et al. 1998). The frequency of the ultrasonic waves that is used is between 25 and 40 kHz.

The continuous squeeze and release of the tissue of the fruit, on a microscopic level, have expelled water to the liquid medium despite the osmotic pressure gradient that tends to transfer water to the fruit. The loss of soluble solids for each fruit was very different, ranging from 1.5% to 52.9%. Fruits with high initial moisture content lost more soluble solids to the liquid medium than fruits with low initial moisture content. This behavior is explained by the diffusion of soluble solids in water. Fruits with high initial moisture content may ease the diffusion of soluble solids toward the liquid medium.

The loss of soluble solids was also influenced by the effects of ultrasound on the tissue structure of the fruit. The tissue structure of melon, papaya, pineapple, and sapota were very sensitive to ultrasound application, and several microscopic channels appeared in the tissue structure (Fernandes et al. 2008a, 2009; Rodrigues et al. 2009). These microscopic channels ease the diffusion of water and soluble solids in and out of the fruit. The number, length, and width of the microscopic channels affect the mass transfer between the fruit and the liquid medium. Microscopic channels were formed in all fruits during ultrasound application. The time required to form long channels, which increases the mass transfer rate, depended on the fruit (Fernandes and Rodrigues 2007a, b, 2008b).

The effect of the ultrasonic pretreatment was mainly observed during the air drying stage where a significant increase in effective water diffusivity was observed. Effective water diffusivity was affected by ultrasound application in some fruits, but no effect was observed in pineapples. The ultrasonic pretreatment had a positive effect on drying because the increase in the effective water diffusivity resulted in shorter air drying time if compared to the fresh fruit with no pretreatment. The ultrasonic pretreatment also showed positive effect of freezing of fruits (Delgado et al. 2009).

A higher water loss was observed when an osmotic solution was used as the liquid medium (ultrasound-assisted osmotic dehydration) if compared to the ultrasound pretreatment using distilled water as the liquid medium.

Vacuum Drying

Recently, a novel concept of low-pressure superheated steam drying (LPSSD) has been proposed as an alternative to drying heat-sensitive products since it can combine the advantages of drying at reduced temperature to those of conventional superheated steam drying (Mujumdar and Devahastin 2000).

Vacuum drying of dates (P. dactylifera L.) from moisture content 15% to 6% db produced satisfactory product quality in terms of color. No visual color change was observed (Amellal and Benamara 2008).

Microwave Drying

Microwave generates rapid volumetric heating of the material by altering the electromagnetic field to interact primarily with the water molecules and ions in food materials (Datta 2001). The advantage of microwave rapid heating is renowned for numerous applications such as heating (Karabulut and Baykal 2002; Sakia et al. 2005), thawing (Taher and Farid 2001), blanching (Chen et al. 1971), pasteurization and sterilization (Wang et al. 2003), and drying (Tulasidas et al. 1995; Adu and Otten 1996; Feng and Tang 1998; Feng et al. 1999; Krokida and Maroulis 1999; Piotrowski et al. 2004; Khraisheh et al. 2004; Goksu et al. 2005).

For drying purposes, microwave has been applied to dehydrate frozen strawberry (Piotrowski et al. 2004), banana, carrot, and potato (Krokida and Maroulis 1999). Microwave influences structure, optical porosity, viscosity, and elasticity of the dried product. The technology was also reported as able to reduce color damage. The right configuration of the equipment is an important aspect to assure good heat distribution and homogenization.

Sunjka et al. (2004) found that microwave power had a more positive effect than vacuum on the color of cranberries (Vaccinium macrocarpon) subjected to microwave drying.

Intermittent Drying

Intermittent drying can be applied in batch processing by varying with time the airflow rate, temperature, humidity, or operating pressure individually or in tandem. The idea is to match the drying condition to the instantaneous drying rate so as to obtain high energy efficiency without increasing the product temperature beyond its indicated level. One can also vary the mode of heat input (e.g., convection, conduction, radiation, or microwave/radio frequency heating). In view of the range of possible parameter variations including cycle time, a mathematical model is needed to develop optimal drying parameters intermittent drying. One can operate most batch dryers in intermittent mode, e.g., tray dryers, fluid bed, spouted bed, or vibrated bed dryers. Readers may refer to Mujumdar (2007a) for details.

Thomkapanich et al. (2007) investigated the intermittent low-pressure superheated steam drying of banana chips and found that the effective drying time of intermittent drying was significantly shorter than that of continuous drying, although the overall drying rates and color changes of both methods were similar. It was found that intermittent temperature drying led to a higher level of ascorbic acid retention, especially at longer tempering periods. On the other hand, intermittent pressure drying led to greater degradation of ascorbic acid.

Time-varying drying air temperature in batch drying of banana slices showed reduced color degradation and drying time. It was also found that a step-down air temperature profile with a longer holding time was able to induce higher drying rate, reducing color degradation (Chua et al. 2001). Proper selection of the temperature schedule such as cyclic temperature profile may minimize the degradation of ascorbic acid in isothermal drying of guava pieces (Chua et al. 2000).

Heat Pump Drying

Heat pump-assisted drying is particularly attractive for heat-sensitive materials since they can be dried at reasonable rates without exceeding their damage temperature when using dehumidified air. High coefficient of performance of heat pumps also helps enhance energy efficiency of such dryers.

Heat pump drying of sapota pulp to produce sapota powder was reported to be faster than hot air drying. Heat pump drying of sapota pulp at higher temperatures decreased the sugar content and rehydration ratio of sapota powder (Jangam et al. 2008). Heat pump drying of Australian nectarine slices showed that the dried product was better than that from cabinet and tunnel dryers in preserving lactones and terpenoids (Sunthonvit et al. 2007).

Hawlader et al. (2006a) investigated modified atmosphere heat pump drying of ginger (Zingiber officinale) Roscoe (Zingiberaceae) by using N2 and CO2 as drying media and concluded that modified atmosphere heat pump drying (HPD) improved not only drying characteristics but also retention of 6-gingerol. The effective diffusivity was observed to increase, resulting in better retention of flavor, even better than freeze drying.

Hawlader et al. (2006b) found improvement of dried product quality not only in color but also in rehydration ability. From the results of this study, modified air heat pump drying seems to offer a great potential, but related research is scarce. Hawlader et al. (2006c) investigated the effect of nitrogen and carbon dioxide on heat pump drying of guava and papaya. Both drying kinetics and quality of these dried fruits resulting from these two methods were compared with normal air HPD, vacuum dryer, and freeze dryer. When using CO2, the effective diffusivity during the drying process was 44% higher in guava and 16% higher in papaya. There was less browning, faster rehydration, and more vitamin C retention in the final products.

Freeze Drying

Jangam et al. (2008) found that freeze-dried sapota powder from sapota pulp has brighter color than raw sapota; its rehydration ability is higher than heat pump and hot air-dried sapota powders. Hu et al. (2006) found that freeze-dried edamame (Glycine max L.) gave maximum retention of vitamin C and chlorophyll and maximum rehydration capacity. The color of the freeze-dried products was closer to the fresh samples.

Marques et al. (2006) reported that freeze-dried pineapple, Barbados cherry, guava, papaya, and mango conserved their color, flavor, and taste. Freeze drying of Barbados cherry and guava fruits resulted in a hygroscopic product due to the transition from a crystalline structure of the soluble carbohydrates (sugars) present in pulps to an amorphous structure, causing a softened appearance, but the other product characteristics were maintained. Based on nutritional analysis (vitamin C, calcium, and phosphorus), the freeze drying of tropical fruit pulps seems to provide products with high nutritive value. However, freeze-dried products are expensive, and with rising energy costs, they will be less competitive.

Fluidized Bed Drying

Fluidized bed drying of aonla (Emblica officinalis or P. emblica) from initial moisture content of 82% to 12% gave better retention of ascorbic acid than sun drying and hot air drying (Murthy and Joshi 2007). This type of dryer can operate in batch as well as continuous mode.

Spouted Bed Drying

Cunha et al. (2006) found that spouted bed drying of mango pulp (Mangifera indica L.) to produce mango powder at high temperatures gave better drying performance and product quality in terms of color, vitamin C, and carotenoid content.

Spray Drying

Gong et al. (2008) conducted spray drying of bayberry (Myrica rubra Sieb. et Zucc) juice to form powder. It was found that color parameter a value of the spray-dried powder decreased, agglomeration increased wet ability, decreased bulk density, and slightly increased the angle of repose. After agglomeration, the reconstitution properties of bayberry powder were found greatly improved.

Combined/Hybrid Drying

Osmotic microwave drying of mango (M. indica L.) reduced the drying time and energy requirement. Microwave power influences the drying kinetics. It may also produce charred pieces (Andrés et al. 2007).

Study of pulse vacuum osmotic dehydration of mango slices found that temperature and solution concentration have positive effects on the drying kinetics. Vacuum time affected the solids gain and water loss effective diffusivity. Osmotic solution recirculation and vacuum pressure had no effect on drying kinetics and product quality (Ito et al. 2007).

Hu et al. (2006) found that vacuum microwave drying of edamame (G. max L.) accelerated the drying rate and enhanced the quality of dried samples. They also found that air drying coupled with vacuum microwave drying produced a porous structure and improved retention of vitamin C and chlorophyll, color, and microstructural changes and rehydration capacity. These authors recommend a combination of air drying and vacuum microwave drying judging from the drying performance as well as product quality.

Xu et al. (2006) claimed that combination of freeze drying followed by air drying is a good alternative to vacuum freeze drying. This method produced dried strawberry (Fragaria ananassa Duch.) that has similar product quality as freeze-dried products in terms of color and bacterial count. In addition, the total capital and operating costs for the two-stage freeze drying followed by air drying process are estimated to be about half of those of freeze drying.

Sunjka et al. (2004) conducted microwave convective drying and microwave vacuum drying of cranberries (V. macrocarpon). It was found that color parameters for products of both methods are quite similar. Microwave vacuum-dried cranberries had softer texture. It was noted that microwave (MW) power level and MW mode have more influence on the product color than application of vacuum or hot air.

Selection of Dryer

Figure 3 shows the selection tree for selecting a dryer for fruit drying according to the feedstock’s physical form. Fruits appear in three forms, namely, liquid suspension, paste, and particulate solids. New techniques classified under each category are rather new to the industry but are currently under extensive research and development. It should be noted that not all new techniques necessarily produce better quality than conventional dryers. Proper selection must be conducted with preliminary experimental work as selection of dryer is also labor cost-, weather-, and geographical location-dependent. In general, many different types of dryers can carry out given drying equally well and at similar cost.

Freeze drying typically yields best product but at very high cost. Vacuum drying is also a good method to preserve nutritional value, color, and rehydration capability, but again at higher cost than normal atmospheric pressure air drying. Low pressure superheated steam drying has been attracting much attention recently as it can provide higher quality as well.

Drying Characteristics and Kinetics

Research on drying of exotic fruits has been carried out by many researchers worldwide. Most research focused on air drying in tray dryers and on pretreatments, such as osmotic dehydration. However, only a few studies have been carried out using different pretreatments and non-conventional dryers, for instance spray dryer and fluidized bed dryer.

The drying kinetics of exotic fruits displays the same behavior as most common fruits, such as apples, bananas, pineapple, and pears. The effective diffusivity of water increased with the increase of temperature, as expected for drying processes. All studies reported that the drying kinetics followed Fick’s second law of diffusion. Constant drying rate period was not observed in the drying curves for most fruits, for instance kiwi (Simal et al. 2005; Kaya et al. 2008), date fruit (Falade and Abbo 2007), mangos (Corzo et al. 2008), pinha (Fernandes and Rodrigues 2008a), Malay apple (Fernandes and Rodrigues 2008a), and sapota (Fernandes and Rodrigues 2008b).

Table 2 presents some literature data on water effective diffusivity for several exotic fruits reported in the literature. Note that there are variations in values reported by different researchers. Most are not corrected for shrinkage. Effects of operating condition such as application of microwaves are often lumped into an effective diffusivity.

Effect of Drying Parameters

An increase in the velocity of the drying air resulted in decreasing drying times as a result of increasing convective heat and mass transfer coefficients between the drying air and the fruit, as observed for kiwis. However, the reduction in drying times was only slight (<10% change) by increasing the velocity of the drying air from 0.3 to 0.9 m/s in a convective drier (Kaya et al. 2008). Mangos were also only slightly influenced by the velocity of the drying air from 0.4 to 1.6 m/s (Dissa et al. 2008).

For kiwi fruit, increase of air temperature from 25 °C to 60 °C reduced the processing time to reach the equilibrium moisture content from approximately 60 to 19 h (at an air velocity of 0.3 m/s; Kaya et al. 2008).

Moisture transport in some fruits is controlled by inherent internal factors of maturity as observed by the drying curves for mangos where the moisture content change was lowest for green mango than for half-ripe mango (Corzo et al. 2008).

The use of osmotic dehydration, in general, decreased the water diffusivity because of the saturation of the outer layer of the fruit with sugar (Nieto et al. 2001; Fernandes et al. 2008b; Rodrigues and Fernandes 2007a, b). The use of ultrasound pretreatment increased the water diffusivity during air drying on sapota, Malay apple, pinha, and other fruits.

Quality Aspects

The first quality judgment made by a consumer on a food at the point of sale is its visual appearance. Appearance analyses of foods (color, taste, odor, and texture) are used in maintenance of food quality throughout and at the end of processing. Color is one of the most important appearance attributes of food materials since it influences consumer acceptability. Abnormal colors, especially those associated with deterioration in eating quality or with spoilage, cause the product to be rejected by the consumer (Rhim et al. 1989; Lopez et al. 1997; Avila and Silva 1999). Therefore, many food producers utilize the psychological effect of color to enhance their products (Waliszewski et al. 1999).

It has been reported that many reactions can affect color during thermal processing of fruits and their derivatives. Among them, the most common are pigment degradation, especially carotenoids and chlorophyll, and browning reactions such as Maillard condensation of hexoses and amino components and oxidation of ascorbic acid (Barreiro et al. 1997; Lozano and Ibarz 1997; Lee and Coates 1999). Other factors affecting color include fruit pH, acidity, processing temperature and duration, fruit cultivar, pretreatments, and heavy metal contamination (Abers and Wrolstad 1979; Skrede 1985; Garcia-Viguera et al. 1999; Guan et al. 2010).

Drying of Exotic Fruits

Although a greater number of studies have been carried out on the dehydration of fruits that have high global-scale commercial interest, such as mango and guava, drying of exotic fruits have received rather limited attention over the years. However, this is changing with growing interest from Brazil, India, China, etc. in these fruits. Report and literature on drying of many exotic fruits with potential commercial interest such as açaí, annona, cupuassu, babassu, buriti, caja, cajarana, guaraná, mangaba, umbu, tamarind, pequi, and pitaya are not available in the public domain. This includes some regional exotic fruits such as breadfruit, cagaita, noni, opuntia, pitanga, pitomba, lucuma, and murici.

Studies on the effects of drying operating conditions on the quality of the dried product are rather scarce. Most papers reported the effects of drying conditions on color change and some on the retention of vitamins. As such, this area remains as one of the challenging areas in the dehydration and preservation of agricultural products and food. Extensive studies and research works are required to understand the effects of drying conditions as well as pretreatments on texture, reduction of enzymatic browning, and preservation of vitamins and antioxidants. The following paragraphs summarize some research findings on the drying of some exotic fruits. Table 3 also summarizes the most important effects of drying conditions on several parameters: water loss and sugar gain during pretreatment, drying rate, color change, textural change, and ascorbic acid loss.

Acerola

Alves et al. (2005) studied the osmotic dehydration of whole frozen acerolas. Water loss increased with the increase of temperature, but it was not significantly affected by sugar concentration (from 30 to 60ºBrix). However, addition of 10% of salt in the osmotic solution increased the water loss by 50%. It was also found that sugar gain was not affected by the sugar concentration as well.

Investigations carried out by Marques et al. (2007) showed that when acerola was rapidly frozen, the fruit preserved its original porous structure during freeze drying. The preservation of its porous structure made acerola powder less susceptible to degradation reactions. Cryogenic freezing using liquid nitrogen was recommended for freezing acerolas before freeze drying. The rehydration capacity of freeze-dried acerola was high because the samples did not suffer from cellular rupture.

Acerola is a small fruit that can be dried as whole fruit or cut into pieces. The peel is edible; thus, peeling is not necessary. Drying of whole fruit may be carried out in spouted bed dryer or fluidized bed dryer. Further studies are needed to evaluate the preservation and retention of vitamin C in dried acerolas.

Aonla

Study on vacuum drying of aonla revealed that increasing of drying temperature from 65 °C to 75 °C decreased the dehydration time by approximately 20%. If superheated steam is used in the vacuum drying, drying time is even longer. It was found that LPSSD required relative long drying time to complete the drying of aonla. This is caused by the existence of the condensation period and the lower evaporation rate in LPSSD than that of vacuum drying (Methakhup et al. 2005).

The retention of ascorbic acid in dried aonla was highest in osmo-air-dried aonla (243.74 mg/100 g), followed by oven-dried (189.10 mg/100 g), direct solar-dried (170.17 mg/100 g), and indirect solar-dried aonla (159.08 mg/100 g). Ascorbic acid content of dehydrated aonla decreased further when stored for 3 months. The reduction was highest in osmo-air-dried fruit followed by oven-dried and then direct and indirect solar-dried aonla. The reduction in ascorbic acid content might be due to oxidation during storage at high ambient temperature (Pragati and Dhawan 2003). The retention of ascorbic acid in the samples dried in fluidized bed drying was greater compared to those dried under sun and hot air tray drying (Murthy and Joshi 2007). In all driers, volatile chemical compounds, along with moisture, were lost to some extent. But the fluidized bed drying proved to be better than the other methods for aonla drying.

Avocado

Thus far, literature on the drying of avocado is rather scarce and limited despite its high commercial value. Ceylan et al. (2007) have reported the drying curves of air drying of avocados.

Ber

Kingsly et al. (2007) studied the shrinkage of ber during solar drying. The drying time for drying from initial moisture content of 470% to the final desirable moisture content of 38% (dry basis) was 58 h. Ber fruit contains a thick outer skin; thus, the moisture loss was slow. The moisture–time relationship was nonlinear and the drying rate decreased along with time, but constant rate period was not observed with the whole drying in the falling rate period. It was observed that the percentage shrinkage was higher radially than in lengthwise direction. This may be due to the faster movement of moisture from the pulpy portion of ber fruits. The volumetric shrinkage was faster in the high-moisture regime, and the observations indicated relation of moisture content and volumetric shrinkage. However, ber fruits did not follow the pattern of shrinkage of other fruits and vegetables like apple, grapes, strawberry, and potato. It was found that during drying, after reaching the moisture content of 47% (dry basis), the changes in relative dimensions were non-significant. It could be interpreted that 47% moisture content is the transition moisture of ber fruits.

Cashew Apple

Osmotic dehydration of cashew apples was very effective. A water loss higher than 40% was observed by using an osmotic solution of 50% and temperature of 40 °C. Under ambient temperature, cashew apples may lose up to 35% of its initial water. The use of corn syrup instead of sucrose reduced the water loss, especially at higher solution concentrations. The use of corn syrup, however, decreased significantly the sugar gain (up to 66%; Azoubel and Murr 2003).

Osmotic dehydration has reduced the vitamin C content of cashew apples by 35% to 45% depending on the condition applied (temperatures from 30 °C to 45 °C and osmotic solution consisting of 44 to 60ºBrix of sucrose or corn syrup). At low temperatures (below 45 °C), the ascorbic acid losses during osmotic dehydration might be attributed to the leaching of the vitamin from the product to the osmotic solution. At high temperatures, chemical degradation as well as diffusion seemed to be the most significant phenomena (Vial et al. 1991; Azoubel and Murr 2003). Further studies are required to preserve the high amount of vitamin C and to reduce the non-enzymatic browning on dried cashew apples.

Chempedak

Chong et al. (2008a, b) reported that dried chempedak using sun drying and hot air drying has significant total color change and textural change from the fresh fruit (p < 0.05). Total color change for sun-dried chempedak slabs was 23.64 compared to hot air-dried chempedak at 50–70 °C of 17.6–28.4. Hardness, cohesiveness, and chewiness except springiness were significantly changed (p < 0.05) after the chempedak slabs were dried by sun drying. Whereas hardness and chewiness in hot air drying increased with increasing temperature, cohesiveness and springiness remained unchanged with reference to the fresh chempedak.

Ciku/Sapota

Under ultrasound-assisted osmotic dehydration, sapota presented low water loss, which was related to the starch content of the fruit (16 ± 5%, dry basis), because high amount of starch favors water uptake (Witrowa-Rajchert and Lewicki 2006). Expressive water loss (13.2% after 30 min) was observed only when an osmotic solution of 70ºBrix was employed (Fernandes and Rodrigues 2008b). Sapotas showed a different behavior regarding sugar gain. In the first 10 min under ultrasound-assisted osmotic dehydration, sapotas lost 12.1% and 11.2% of its soluble solid to the osmotic solution, respectively, for osmotic solutions of 35 and 70ºBrix. After 30 min, the pretreatment carried out with an osmotic solution of 35ºBrix still showed a slight reduction in sugar loss, whereas when the pretreatment was carried out with an osmotic solution of 70ºBrix, the fruit showed a sugar gain of 10.0%. The behavior observed for sapotas might be explained by the physical–chemical composition of the fruit, which contain high amounts of sugar and starch (85% dry basis; Morton 1987b; Brito and Narain 2002).

Sun drying of ciku, whose temperature fluctuated at 28–32 °C, reduced significantly the retention of antioxidant content. This is due to long exposure to heat during sun drying. It was found that total polyphenol content of sun-dried ciku was 28% lower than that of fresh ciku (Chong et al. 2009). In addition, textural attributes of sun-dried ciku slabs are significantly different (p < 0.05) from fresh ciku. This is because of the formation of shrunken structure after drying. It was found that hardness of sun-dried ciku increased significantly (p < 0.05) as compared to fresh ciku. On the other hand, total color change of sun-dried ciku is also significant; Chong et al. (2009) reported that the total color change was 30. High total color change is owing to pigment degradation and long drying duration.

The presence of fibers and hardened phenolic cells of sapotas makes it suitable to be dried in a wide range of dryers, from tray driers to fluidized bed driers.

Date Palm Fruit

Drying of date palm carried out in a tray dryer showed that water diffusivity ranged from 0.59 to 1.78 × 10−9 m/s (Falade and Abbo 2007). Although the commercial use of dried date palm fruit is well developed, study on the drying of date palm fruit is not well documented in literature, especially optimization of the drying process drying kinetics and characteristics of date palm fruit in other types of dryers.

The sorption isotherm of three Tunisian cultivars, Allig, Kentichi, and Deglet Nour, were studied by Bellagha et al. (2008). The sorption isotherms were obtained at 40 °C, 60 °C, and 80 °C and were best fitted by a Brunauer–Emmett–Teller isotherm. Sugars were considered the determining factor of water sorption in dates, and the dissolution of sugars increased significantly as temperature was raised, offsetting the opposite effect of temperature on the sorption of non-sugar solids.

Dragon Fruit (Pitaya)

Yong et al. (2006) found that mechanical pretreatment such as application of pinholes and drilled holes improved the drying rate of dragon fruit drying in a convective dryer.

Nordin et al. (2008) found that microwave drying of pitaya consists of an initial transient period followed by a falling rate period. Rapid microwave penetration caused the internal and surface temperature to rise rapidly during drying. The color change was higher at higher power density and temperature because of fast browning rate. The commencement of the color change corresponded closely to the beginning of the falling rate period. The changes in a values were very small compared to the L and b values, which indicates that the variation in red-green spectrum is minimal whereas the lightness and blue-yellow spectrum were affected by drying significantly. It was reported that the internal structure collapsed during the microwave drying (Nordin et al. 2008).

Durian

It was reported that fresh durian pulp contains 30 volatile constituents. According to Chin et al. (2008), four esters disappeared after freeze drying and 14 volatile constituents diminished after spray drying. However, new volatiles were formed in spray-dried powder, comprising aldehydes, ketone, furan, and pyrrole compounds. During drying, aroma loss is significant as the volatile compounds that contribute to the aroma are lost due to exposure to heat. It was reported that major durian aroma such as propanethiol, ethyl propanoate, propyl propanoate, ethyl 2-methylbutanoate, and diethyl disulfide vanished, from 70–100%, during freeze drying.

Hot air drying normally gives poorer product quality in terms of appearance and color. Jamradloedluk et al. (2007) found that superheated steam drying produced dried durian chip that has better quality in terms of color and rehydration ratio, but gave lower drying rate and required longer drying time. SEM image obtained by Jamradloedluk et al. (2007) revealed that superheated steam-dried product has less uniform, fewer but larger, pores than hot air-dried products.

Fig

Doymaz (2006) studied the sun drying behavior of figs and found that the entire drying process of figs occurred in falling rate period which is controlled by diffusion. Figs have a soft consistency and may be damaged or deformed when dried. Tray driers may be the most suitable drier to dry figs.

Xanthoupoulos et al. (2007, 2009) have tested several thin-layer drying models to simulate convective drying of figs. The drying model assessment revealed that the logarithmic model exhibited the best performance in fitting data for drying of figs.

Genipap

The results obtained by Andrade et al. (2007) showed that genipaps lost more water to the osmotic solution and incorporated less sucrose when a coating agent was applied. When ultrasound pretreatment was applied, genipaps gained 14.9% of water after 30 min, which is relatively higher than other fruits (Fernandes and Rodrigues 2008a). The use of coatings (alginate and pectin) was studied by Andrade et al. (2007), and it was found that coatings can reduce the water loss significantly but not the sugar gain during osmotic dehydration. Genipaps have a hard consistency and thus may be dried in several kinds of driers without damaging the fruit.

Gooseberry

Reduction of total acidity and also ascorbic acid content was also observed for gooseberry dried using vacuum drying and LPSSD (Methakhup et al. 2005). The retention of ascorbic acid was in the range of 64–94% for vacuum drying and 93–96% for LPSSD. Retentions increased with increasing drying temperature and may be due to the shorter drying time. Pressure showed little influence on the retention of ascorbic acid.

Guava

The acidity of guavas decreased by 21.7% to 51.0% after osmotic dehydration with a sucrose solution of 30 to 50ºBrix (Queiroz et al. 2007). This result, however, is not due to the osmotic process but due to blanching of the samples. Reis et al. (2007) showed that the osmotic dehydration treatment did not change the acidity of guava. The use of calcium lactate decreased the acidity of guava by 10%. In addition, the blanching and the addition of calcium lactate or ascorbic acid did not influence the uptake of sucrose by guavas subjected to an osmotic solution of 65ºBrix.

The red color of guavas was intensified during air drying when osmotic dehydration was applied as pretreatment. No color change was verified when blanching was applied to guavas (Queiroz et al. 2007). The L value and a value increased during vacuum drying and LPSSD, while the b value stayed similar to that of fresh sample. These results implied in the intensification of the red color because of browning reaction and pigment destruction. Color change was milder applying vacuum drying at 65 °C and an absolute pressure of 7 kPa (lower temperature and pressure; Methakhup et al. 2005).

The texture of guavas was severely influenced by the pretreatment. Penetration tests showed that osmotic dehydrated guavas presented required 109% more force than air-dried guavas. Blanching previous to osmotic dehydration decreased the penetration force by 15%, while the addition of ascorbic acid and calcium lactate in the osmotic solution increased the penetration force by 14.6% and 87.9%, respectively (Reis et al. 2007).

The effect of blanching on the peroxidase activity and color changes in seedless guava was studied by Ganjloo et al. (2010) over a temperature range of 80–95 °C. Thermal inactivation data showed monophasic behavior that was only resulted from inactivation of heat-labile fraction of the enzyme. Color change during blanching increased with increasing temperature and immersion time. For a 90-s immersion time, total color change increased by 400% between a processing temperature of 80 °C and 95 °C.

Sensory analysis of guavas showed that the guavas pretreated with osmotic dehydration were more accepted by consumers than guavas air-dried with any pretreatment. Rating for osmotic dehydrated guavas were more than double the air-dried guavas for appearance, flavor, and texture, while the results for aroma were only slightly influenced by the pretreatment (Queiroz et al. 2007).

Jackfruit

Saxena et al. (2008) reported that preservation of jackfruit slices can be accomplished by using osmotic dehydration at 5.9°Brix as osmotic concentration, 68.5 °C temperature, 180.6 min of immersion time, followed by in-pack pasteurization which could extend the shelf life of jackfruit with low carotenoid loss, minimal color changes, minimal chroma changes, as well as high retention of tissue integrity. In a related work, Saxena et al. (2010) have reported second-order polynomial models to describe the firmness, browning index, color, and acceptability of minimally processed jackfruit during storage.

In the production of jackfruit powder, emulsifiers are used to ensure uniform quality. In a study investigating the effect of emulsifiers such as soy lecithin and gum arabic on color and sensory attributes of jackfruit powder, Pua et al. (2007) revealed that high concentration of soy lecithin tends to produce darker drum-dried jackfruit, whereas gum arabic has positive effect on the lightness. It was also found that low concentration of both emulsifiers tends to give better sensory quality.

Giraldo-Zuñiga et al. (2006) reported that jackfruit has presented the highest water effective diffusivity among all exotic fruits, with diffusivity 100 times higher than the mean water effective diffusivity of other fruits.

Kiwi

Maskan (2001) studied the kinetics of color changes of kiwifruits due to drying by hot air, MW, and hot air–microwave drying (HAMW). The drying process changed all three color parameters (L, a, b), causing a color shift toward the darker region. Parameters L and b decreased and a value increased during drying. The Hunter parameters were more influenced by MW drying. Changes in L, a, and b values took place according to two apparent consecutive reactions. The parameters tended to change faster during the 10 min subjected to MW and during the 50 min subjected to hot air drying processes, after which the rate of change became rather slower. The authors stated that this behavior was possibly due to the presence of heat-sensitive reactions in the first phase of the curve involving the degradation of thermolabile pigments, which in turn resulted in the formation of dark compounds that reduced luminosity, while in the second phase, more thermostable pigments were involved. As a whole, the development of discoloration of samples during drying by any technique may be related to pigment destruction, ascorbic acid browning, and non-enzymatic Maillard browning (Abers and Wrolstad 1979; Skrede 1985; Salunkhe et al. 1991; Ibarz et al. 1999).

The L, a, and b values revealed that the color of kiwifruits was affected regardless of the drying method. The L value decreased with drying time. The time, for example, to reach an L value of about 40 was 5 min for MW and about 325 min for hot air drying. Therefore, MW would give a destruction rate 65 times faster than hot air at 60 °C.

When combining hot air with MW drying, the decrease in L value accelerated. The time to reach an L value of 40 decreased to 138 min. A similar trend was observed in a value and in b value, probably because of high temperatures generated by MW in the samples. The hot air drying had little influence on the color of kiwifruits as compared to MW and HAMW drying. All parameters were influenced by drying conditions. Introduction of MW increased the rate of color deterioration.

In a related work, Fathi et al. (2010) have studied the changes in the color of kiwis subjected to osmotic dehydration. Their result showed that higher changes in color were observed when kiwis were processed at higher temperatures (60 °C). Although solid gain and water loss have increased significantly with increasing temperature, osmotic solution concentration, and immersion time, the concentration and immersion time had little influence on color change.

Langsat

Literature on the drying of Langsat (Lansium domesticum) is rather scarce and not available in major journals. Some researchers have reported the findings on antimalarial tetranortriterpenoids from langsat seeds (Nishizawa et al. 1988; Saewan et al. 2006) and isolation of cycloartanoid triterpene from langsat leaves (Nishizawa et al. 1989). Judging from the physical form of the fruit and seeds, most common dryers are suitable to be employed to dry langsat and its seeds.

Longan

Unpeeled longan fruit requires longer drying time than peeled longan fruit, for instance 48 to 52 h at 75 °C for unpeeled longan fruit compare to peeled longan for 12 to 15 h at 70 °C to reach final moisture of 22% (dry basis; Attabhanyo et al. 1998). As such, the drying efficiency is rather low, and hence, further studies on the application of pretreatment is required to enhance the drying performance.

Varith et al. (2007) developed and evaluated the performance of peeled longan drying in a hybrid microwave–hot air (MWHA). At low MW power of 100 and 180 W, drying curves were similar for all temperatures of hot air. It was found that MW power significantly affect the drying curve of longan drying in a hybrid MWHA, and it is the dominant factor affecting the drying kinetics of longan. Drying rate for peeled logan during hot air drying at 65 °C exhibited three falling rate periods, while the constant rate period did not exist. Stepwise MWHA exhibited faster drying rates than that of regular MWHA and hot air drying at 65 °C, respectively. Longan contains medium-high sugar (25ºBrix), and a rapid heating of microwave tends to cause desirable color change. It is desirable to produce dried longan that has a “golden brown” color. It was found that microwave hot air drying with the setting of 300 W microwave and air temperature of 60 °C yielded the best product color.

Janjai et al. (2009) and Román et al. (2009) have studied solar drying of longan. A simulation program for a flat-plate solar air heater was used to estimate the potential to preheat drying air given the conditions of several longan drying facilities. Results showed that solar collectors can replace up to 19.6% of the thermal energy demand during the drying season.

Litchi

Litchis have presented a steep reduction in ascorbic acid content during storage after pulsed vacuum osmotic dehydration (PVOD). The reduction was slightly lower when litchis were dipped in a mixture of cysteine (0.49%, w/w), ascorbic acid (0.2%, w/w), and 4-hexyl resorcinol (0.013%, w/w) prior to PVOD (Shah and Nath 2008).

Malay Apple

Report on the drying of Malay apple (S. malaccense) is rather scarce in major journals. The red color degradation of Malay apple in refrigerated storage has been report by Sankat et al. (2000). Fernandes and Rodrigues (2008a) applied ultrasound as a pretreatment technique prior to osmotic dehydration to dry jambu (another name of Malay apple) and found that ultrasound could reduce the drying significantly. Thus far, there is no report on the quality of dried Malay apple.

The fresh of Malay apple is porous but the skin is coated with a layer of wax. Thus, drying of whole Malay apple requires long drying time. However, if it is cut into half or pieces, the drying time should be reduced noticeably. Since the fruit is in tens of centimeters in size, selection of dryer is important in optimizing the drying of Malay apple. Readers are to refer to the “Handbook of Industrial and Guide to Industrial Drying” for the selection of dryer.

Mango

Corzo et al. (2008) reported that half-ripe mangoes showed higher water diffusivity than green mangoes (approximately 4% higher). The water effective diffusivity observed in thin-layer dryers was similar to the results obtained in tray dryers (Goyal et al. 2006). Blanching with 1% KMS, however, increased the water effective diffusivity by 38%.

Osmotic dehydration of mango showed that the temperature and osmotic solution concentration were the dominant process variables that affected the loss of water in mangos (Almeida et al. 2005). Osmotic dehydration with glucose solution reduced the effective diffusivity in mango drying by 67%. It was reported that the use of osmotic dehydration under vacuum (60 mmHg) increased the water effective diffusivity during air drying (Nieto et al. 2001).

During osmotic dehydration, blanching resulted in a greater loss of fructose and sucrose contained in the vacuoles of mango tissue due to the rupture of tonoplast and plasmalemma (Nieto et al. 2001). Vacuum osmotic dehydration of mango (60 mmHg for 10 min) showed a lower loss of fructose and sucrose than the traditional osmotic dehydration process.

Touré and Kibangu-Nkembo (2004) studied the solar drying of mangos in a hurdle-dryer with a wire net bottom. Final moisture of 27.6% (wet basis) was reached after 15 h of drying for mango with an initial moisture content of 84% (wet basis). It was observed that during the constant rate period, the product temperature was lower than the ambient air temperature with average difference of 2.3 °C. Thus, the surface of mango was wet and acted like free water so that the cooling produce by evaporation was important. The authors reported the following drying parameters for sun drying of mango: mass transfer coefficient, h c = 9.47 Jm−2 s−1 °C−1; specific rate, R sp = 2.2 × 10−3 kg−1 s−1 °C−1; overall resistance to diffusion, R ds = 6361 m2s kg−1; sorption velocity, V sor = 0.5045 moisture/min; and desorption velocity, V des = 0.7738 moisture/min.

Chen et al. (2007) have studied the effect of hot air drying and freeze drying on the stability of carotenoids in mango. The results from their study showed that carotenoids were better preserved when mangos were soaked in NaHSO3 and then freeze-dried. Freeze-dried mangos contained 24.4% more carotenoids then air-dried mangos.

A deep orange appearance was observed for air-dried mango, and no significant difference was found when mangos were previously soaked in NaHSO3 or in ascorbic acid. However, the soaking treatments affected freeze-dried mangos, which exhibited higher a and b values, and a yellow color was shown for both treatments. Air drying has generated a darker appearance of mango than freeze drying, probably because of a more intense browning reaction during air drying. Freeze drying produced a pale yellow color of mango, which was related to a less intense browning reaction. From the commercial point of view, air drying produced a more desirable color for dried mango (Chen et al. 2007).

Mulberry

As an attempt to enhance solar drying of mulberry fruit, Doymaz (2004) have studied the use of ethyl oleate as coating agent during sun drying. Ethyl oleate coating has been reported as an alternative to accelerate drying of vegetables and fruits. Ethyl oleate solution is applied to the surface of the fruit by dipping, resulting in a coat, which may break down the cuticular fruit surface, resulting in a reduced resistance to moisture loss (Williams 1989). To increase the water permeability of mulberry skin, samples were dipped into ethyl oleate solution at room temperature for 1 min. Dipping solution was prepared by mixing water, K2CO3 (5 %), and ethyl oleate (2%).

In the experiments with sun drying of mulberries, the variation of ambient air temperature from 9:00 a.m. to 17:00 p.m. ranged from 26 °C to 34 °C, presenting a maximum at 13:00 p.m. Effective drying time of mulberries treated by ethyl oleate alkaline solution was reduced by 45%. The drying time of untreated samples was 213 h, while drying time for treated samples was 98 h. The overall appearance of the pretreated dried fruit was better than the untreated. Mulberries treated with ethyl oleate were dried 2.7 times faster than the untreated samples. Consequently, treatment with ethyl oleate might be considered effective in mulberry drying.

Pinha

During ultrasound pretreatment, pinha rapidly lost soluble solids to the liquid medium because of the low cohesion between the cells in its tissue structure (Fernandes and Rodrigues 2008a). The application of pretreatments with pinha is not advisable because of the significant loss of soluble solids (higher than 52%). Drying of pinha can be carried out in spray dryer, especially for powder production, as loss of solids is inevitable even using a tray dryer.

Rambutan

Thus far, no literature on the drying of rambutan is reported in major journals, but there are a few reports on the findings of rambutan shelf life during storage and the effect of controlled storage atmosphere on the shelf life (O’Harea et al. 1994; O’Harea 1995).

Star Fruit

Sensory analysis of star fruit showed that star fruits pretreated with osmotic dehydration were more accepted by consumers regarding appearance, texture, and flavor than air-dried star fruits and star fruits that were pretreated with a mixture of sucrose and CaCl2. Air-dried star fruits had the lowest scores for appearance, texture, and flavor. Acceptance was also higher when air drying was carried out at 60 °C rather than at 70 °C (Shigematsu et al. 2005).

Star Apple

Frozen white star apple showed a steady increase in water loss and solid gain. In addition to the initial rapid water loss and solid gain in freeze fruits, fresh star apple showed a higher water loss and solid gain after 2–3 h of immersion. Solute impregnation processes, such as the osmotic dehydration, can benefit from process steps that cause tissue damage (i.e., freeze-thawing). Higher water loss in fresh fruit compared with frozen fruit was due to the intact structure that restricted solute infusion (Shigematsu et al. 2005; Falade and Adelakun 2007). In addition, the use of coatings (pectin and calcium chloride) during osmotic dehydration reduces the sugar gain.

The a and b values of white star apple pretreated using osmotic dehydration with sucrose and glucose solutions at 60ºBrix were higher than the fruit pretreated using osmotic dehydration with 52 and 44ºBrix solutions. The results show that the osmotic solution concentration has a strong influence on the a and b values of star apple during storage. Increase in L value and decrease in a and b values of osmo-dehydrated white star apple during the storage period is an indication that lightness increased while redness and yellowness decreased during storage. The changes in color parameters supported the visual loss of redness and development of a dull, darker color. The browning of star fruit may be related to the oxidation of carotenoid during air drying and storage, which resulted in color loss of the products (Falade and Adelakun 2007).

White Star Apple

Falade and Adelakun (2007) have reported the effects of osmotic dehydration on frozen white star apple. In addition to the initial rapid water loss and solid gain in freeze fruits, fresh star apple showed a higher water loss and solid gain after 2–3 h of immersion. The use of glucose instead of sucrose as osmotic agent increased the water loss during osmotic dehydration. The sugar gain, however, increased significantly. The increase in the osmotic solution concentration (from 44 to 60ºBrix) increased the water loss and sugar gain by 73% and 210% (mean values after 2 h of immersion). Tray driers were satisfactory for white star apple drying, and osmotic dehydration may be used to reduce total drying time.

White star apple color during storage was affected by the osmotic dehydration condition. The osmotic solution concentration had a strong influence on the a and b values of star apple during storage. Increasing the solution concentration has increased the a and b color parameter values. Increase in L value and decrease in a and b values of osmo-dehydrated white star apple during the storage period was an indication that lightness increasing while redness and yellowness decreasing during storage. The changes in color parameters supported the visual loss of redness and development of a dull, darker color. The browning of star fruit may be related to the oxidation of carotenoid during air drying and storage, which resulted in color loss of the products (Falade and Adelakun 2007).

Conclusions

A comprehensive and selective overview is presented on recent studies of drying characteristics including kinetics and quality parameters for a wide assortment of exotic fruits with significant global market potential. Such fruits can be excellent nutritional snacks and as additives to cakes, ice cream, candy, cereals, etc. Exotic fruits in this coverage include those with sugar and those without. It is clear that diverse drying techniques have been employed to dry fruits in various physical forms. Most studies have been done on small-scale equipment, but they are readily scalable. In general, techniques used to drying heat-sensitive materials are suited for drying fruits; this allows retention of color, appearance, and textural and nutritional quality in the dried product. In this respect, exotic fruits behave similarly to conventional fruits.

This review attempts to cover a very broad topic of increasing interest. It covers a number of fruits that have attracted limited attention so far due to smaller global market. We believe this will change in the next decades as consumers will seek high-quality nutritional foods with diverse flavors, taste, and appearance. We have not considered dryer selection and optimization in this review since the methodologies for this aspect are common to all fruits and even foods. We have also not considered novel drying techniques in any detail, e.g., superheated steam drying, pulse combustion drying, pressure/vacuum drying, microwave drying, etc. We have also excluded drying techniques used to produce fruit powders, fruit leather, etc. Readers are encouraged to refer to the literature cited for details.

References

Abers, J. E., & Wrolstad, R. E. (1979). Causative factors of colour deterioration in strawberry preserves during processing and storage. Journal of Food Science, 44, 75–78.

Abu-Goukh, A. A., & Abu-Sarra, A. F. (1993). Compositional changes during mango fruit ripening. University of Khartoum Journal of Agricultural Sciences, 1, 33–51.

Adu, B., & Otten, L. (1996). Effect of increasing hygroscopicity on themicrowave heating of solid foods. Journal of Food Engineering, 27, 35–44.

Almeida, F. A. C., Ribeiro, C. F. A., Tobinaga, S., & Gomes, J. P. (2005). Otimização do processo de secagem osmótica na obtenção de produtos secos da manga Tommy Atkins. Revista Brasileira de Engenharia Agrícola e Ambiental, 9, 576–584.

Alves, D. G., Barbosa, J. L., Jr., Antonio, G. C., & Murr, F. E. X. (2005). Osmotic dehydration of acerola fruit (Malpighia punicifolia L.). Journal of Food Engineering, 68, 99–103.

Amellal, H., & Benamara, S. (2008). Vacuum drying of common date pulp cubes. Drying Technology, 26, 378–382.

Andrade, S. A. C., Barros Neto, B., Salgado, S. M., & Guerra, N. B. (2007). Influência de revestimentos comestíveis na redução de ganho de sólidos em jenipapos desidratados osmoticamente. Ciência e Tecnologia de Alimentos, 27, 39–43.

Andrés, A., Fito, P., Heredia, A., & Rosa, E. M. (2007). Combined drying technologies for development of high-quality shelf-stable mango products. Drying Technology, 25, 1857–1866.

Attabhanyo, R., Ngramsomsut, K., Attabhanyo, A., Arrayarungsarit, S., Chaowanapoonpon, Y., & Kitchaijaroon, J. (1998). Longan process industry. Faculty of Agriculture, Chiang Mai University.

Avila, I. M. L. B., & Silva, C. L. M. (1999). Modelling kinetics of thermal degradation of colour in peach puree. Journal of Food Engineering, 39, 161–166.

Azoubel, P. M., & Murr, F. E. X. (2003). Optimisation of osmotic dehydration of cashew apple (Anacardium occidentale L.) in sugar solutions. Food Science and Technology International, 9, 427–433.

Azuara, E., Flores, E., & Beristain, C. I. (2009). Water diffusion and concentration profiles during osmodehydration and storage of apple tissue. Food and Bioprocess Technology, 2, 361–367.

Bakshi, J. C., & Singh, P. (1974). The ber—A good choice for semi-arid and marginal soils. Indian Horticulture, 19, 27–30.

Barreiro, J. A., Milano, M., & Sandoval, A. J. (1997). Kinetics of colour change of double concentrated tomato paste during thermal treatment. Journal of Food Engineering, 33, 359–371.

Bashir, H. A., & Abu-Goukh, A. A. (2003). Compositional changes during guava fruit ripening. Food Chemistry, 80, 557–563.

Bellagha, S., Sahli, A., & Farhat, A. (2008). Desorption isotherms and isosteric heat of three Tunisian date cultivars. Food Bioprocess Technol, 1, 270–275.

Block, G., & Langseth, L. (1994). Antioxidant vitamins and disease prevention. Food Technology, 48, 80–84.

Brito, E. S., & Narain, N. (2002). Physical and chemical characteristics of sapota fruit at different stages of maturation. Pesquisa Agropecuária Brasileira, 37, 567–572.

Cao, H., Zhang, M., Mujumdar, A. S., Du, W. H., & Sun, J. C. (2006). Optimization of osmotic dehydration of kiwifruit. Drying Technology, 24, 89–94.

Ceylan, I., Aktas, M., & Dogan, H. (2007). Mathematical modeling of drying characteristics of tropical fruits. Applied Thermal Engineering, 27, 1931–1936.

Chatchavalchokchai, N. (1987). Effect of some ruminants on seed quality of Phyllanthus emblica L., Elaeocarpus madopetalous P., Spondias pinnata K. and Terminalia chebula R. MSC thesis, Kasetsart University, Thailand.

Chen, S. C., Colins, J. L., McCarty, I. E., & Young, M. R. (1971). Blanching of white potatoes by microwave energy followed by boiling water. Journal of Food Science, 36, 742–743.

Chen, J. P., Tai, C. Y., & Chen, B. H. (2007). Effects of different drying treatments on the stability of carotenoids in Taiwanese mango (Mangifera indica L.). Food Chemistry, 100, 1005–1010.

Chin, S. T., Nazimah, S. A. H., Quek, S. Y., Che Man, Y., Rahman, R. A., & Mat Hashim, D. (2008). Changes of volatiles’ attribute in durian pulp during freeze- and spray-drying process. LWT–Food Science and Technology, 41, 1899–1905.

Chong, C. H., Law, C. L., Cloke, M., Luqman Chuah, A., & Daud, W. R. W. (2008a). Drying kinetics, texture, color, and determination of effective diffusivities during sun drying of chempedak. Drying Technology, 26, 1286–1293.

Chong, C. H., Law, C. L., Cloke, M., Luqman Chuah, A., & Daud, W. R. W. (2008b). Drying kinetics and product quality of dried chempedak. Journal of Food Engineering, 88, 522–527.

Chong, C. H., Law, C. L., Cloke, M., Luqman Chuah, A., & Daud, W. R. W. (2009). Drying models and quality analysis of sun-dried ciku. Drying Technology, 27, 985–992.

Chua, K. J., Chou, S. K., Ho, J. C., Mujumdar, A. S., & Hawlader, M. N. A. (2000). Cyclic air temperature drying of guava pieces: Effects on moisture and ascorbic acid contents. Transactions IChemE, 78, Part C, pp. 72–78.

Chua, K. J., Mujumdar, A. S., Hawlader, M. N. A., Chou, S. K., & Ho, J. C. (2001). Batch drying of banana pieces—Effect of stepwise change in drying air temperature on drying kinetics and product colour. Food Research International, 34, 721–731.

Corzo, O., Bracho, N., & Alvarez, C. (2008). Water effective diffusion coefficient of mango slices at different maturity stages during air drying. Journal of Food Engineering, 87, 479–484.