Abstract

This work evaluated the production of dehydrated papayas (Carica papaya L.) with low sugar content. The product was obtained applying ultrasonic waves to enhance the loss of sugar from the fruit. To achieve this goal, this paper examined the influence of the ultrasonic pre-treatment before air-drying on dehydration of papaya. Ultrasonic pre-treatment for air-drying of fruits was studied and compared with osmotic dehydration. This study allowed estimate of the effective diffusivity water in the air-drying process for papayas submitted to ultrasonic pretreatment. Results show that the water effective diffusivity increases after application of ultrasound causing a reduction of about 16% in the drying time. During ultrasonic treatment the papayas lost sugar (13.8% in 30 min), so such a pre-treatment stage can be a practical process to produce dried fruits with lower sugar content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Drying can reduce post-harvest losses of fruits. From a biological point of view, several tropical fruits, papayas (Carica papaya L.) included, present significant losses because of decomposition after harvesting because they are extremely perishable and do not allow the use of freezing for conservation. Papayas are largely produced in several countries with a production over 6.5 million tons in 2005 according to FAOSTAT (Food and Agriculture Organization 2005) and are sold both to internal and external markets. Some tropical countries such as Brazil, Nigeria, India, Mexico and Indonesia have large plantations that aim exportation of the fruit. Part of the production does not meet the minimal standard for exportation and is lost after harvesting. As such, these fruits can be dried to preserve part of the production that can not be consumed or exported, providing an extension of shelf-life, lighter weight for transportation, better return for the farmer, and less space for storage.

Conventional air-drying is a simultaneous heat and mass transfer process, accompanied by phase change being a high cost process. Usually, some form of pretreatment is used to reduce the initial water content or to modify the fruit tissue structure to reduce the total drying processing time (Madamba and Lopez 2002; Beaudry et al. 2004; Stojanovic and Silva 2006). Ultrasonic waves can cause a very rapid series of alternative compressions and expansions, in a similar way to a sponge when it is squeezed and released repeatedly (the so-called sponge effect). The forces involved in this mechanical mechanism can be much greater than those due to surface tension, which holds the moisture inside the capillaries of the fruit creating microscopic channels which may ease moisture removal. In addition, ultrasound produces cavitation which can be beneficial for the removal of moisture that is strongly attached to the solid. Deformation of porous solid materials, such as fruits, caused by ultrasonic waves is responsible for the creation of microscopic channels that reduces the diffusion boundary layer and increases the convective mass transfer in the fruit (Tarleton 1992; Tarleton and Wakeman 1998; Fuente-Blanco et al. 2006; Fernandes et al. 2007).

The use of ultrasound in the food industry is new; only a few studies have addressed the use of ultrasound pretreatment in drying processes (Tarleton 1992; Mason et al. 1996; Tarleton and Wakeman 1998; Gallego-Juárez et al. 1999; Fuente-Blanco et al. 2006; Zheng and Sun 2006; Rodrigues and Fernandes 2007; Fernandes et al. 2007; Rodrigues and Fernandes 2007), most of them dealing with ultrasound assisted osmotic dehydration and ultrasound assisted spray-drying.

The production of low sugar content papayas involves immersion of the pieces of fruit in water or in a hypertonic aqueous solution to which ultrasound is applied. The advantage of ultrasound is that the process can be carried out at ambient temperature as no heating is required, reducing the potential of thermal degradation (Mason 1998).

In this work, the use of ultrasound as a pretreatment to air-drying was investigated. The influence of time in ultrasound on water loss, sugar loss, and water diffusivity was evaluated. A comparison with the osmotic dehydration pretreatment was also carried out. The integrated process (ultrasound and air-drying) was optimized searching for the operating condition that minimizes total processing time.

Materials and Methods

Preparation of Samples

Papayas (Formosa cultivar) were bought from the producer (Fortaleza, Brazil). Papaya samples were cut to obtain cubes of same dimensions (0.02-m average side). The moisture content of the fruit was determined by heating in a drying oven (Marconi model MA-185) at 105 °C for 48 h according to the method of the Association of Official Analytical Chemists (1990). The initial soluble solids content of the fruit (°Brix) was determined by refractometry (Atago refractometer model 35B).

Ultrasound Pretreatment

An experimental set of four papaya samples was immersed in distilled water and submitted to ultrasonic waves for 10, 20, 30, 45, and 90 min. The experiments with ultrasound were carried out in separate 250-ml Erlenmeyer flasks to avoid interference between the samples and runs. The water to fruit ratio was maintained at 4:1 (weight basis), which also was used in the osmotic dehydration experiments. This ratio was used because previous works (Fernandes et al. 2006a,b; Teles et al. 2006; Oliveira et al. 2006) have shown that at this liquid medium to fruit ratio the dilution of the osmotic solution is negligible and the increase in soluble solids content observed in the ultrasound pretreatment was also small (less than 2.0 g/l).

The experiments were carried out under ambient water temperature (30 °C) in an ultrasonic bath (Marconi model Unique USC 25 kHz) without mechanical agitation. The ultrasound frequency was 25 kHz and the intensity was 4,870 or 100 kW/m3. The temperature increase during the experiments was not significant (less than 2 °C) after 30 min of ultrasonic treatment. The same procedure was carried out without applying ultrasound to evaluate the effect of ultrasound. The experiments were carried out in triplicate.

At the end of the ultrasonic pretreatment, a sample of the liquid medium was taken to determine its sugar content using the DNS method (Miller 1959). This procedure was carried out to quantify the amount of sugars that the fruit loses to the water.

Ultrasound-assisted Osmotic Dehydration

Each experimental group consisting of four papaya cubes was immersed in the osmotic solution for 10, 20, 30, 45, and 90 min. The osmotic dehydration was carried out in separate 250-ml Erlenmeyer flasks to avoid interference between the samples and runs. The osmotic solution used in each experiment was prepared by mixing food grade sucrose with distilled water to give a concentration of 35°Brix. To allow comparison with the ultrasonic experiments, the osmotic solution to fruit ratio was also maintained at 4:1 (weight basis) and the experiments were carried out under ambient water temperature (30 °C) without mechanical agitation. The ultrasound frequency was 25 kHz and the intensity was 4,870 W/m2. The same procedure was also carried out without applying ultrasound to evaluate the effect of ultrasound. The experiments were carried out in triplicate.

After removal from the solution, the dehydrated samples from each group were drained, blotted with absorbent paper to remove the excess solution. Weight and moisture content were measured individually. The concentration of the solution was monitored during the runs determining the osmotic solution soluble solids content (°Brix) using a refractometer.

Weight and moisture content of the samples were used to calculate the response variables of the experimental planning: water loss (WL) and solid loss (SL), according to the following equations:

Air Drying

At the end of the pretreatment, the dehydrated samples were drained, blotted with absorbent paper to remove the excess solution and transferred to a forced circulating air-drying oven (Marconi model MA-085) set at 60 °C. Air was injected at the sides of the dryer at 0.12 m3/s. The air relative humidity was 16% and was determined by psychrometry (dry and wet bulb temperature). The samples were weighed every 20 min.

The air-drying process was modeled assuming diffusion-controlled mass transfer with the liquid flow within the fruit conforming to Fick’s second law of diffusion. Only the falling-rate period (diffusion-controlled mass transfer period) was considered because during the experiments, the constant-rate period (heat transfer-controlled mass transfer period) was not observed. The equation used to model the falling-rate period was a simplification of Fick’s second law considering long drying times (Perry and Green 1999).

Experimental data were used to estimate the effective diffusion coefficient of the air-drying process. The parameter was adjusted using Eq. (3) with a parameter estimation procedure based on the minimization of the error sum of squares. The model equation was solved by numerical integration using the Runge–Kutta method. The F test was used as a criterion to validate the model. The level of significance of the model was established comparing the listed F values and the calculated F values for each operating condition. After validation, the model was used to optimize the total processing time required to dry the fruit. The optimization was done using the method of Levenberg–Marquardt, setting as objective function the minimization of the total processing time (pretreatment + air drying times). The computer programs were written in FORTRAN language.

Results and Discussion

The analysis of the fresh fruit showed that papayas had an initial moisture content of 0.883 ± 0.004 g water/g fresh fruit and a soluble solids content of 11.6 ± 0.4 °Brix.

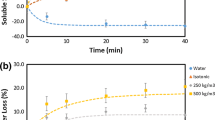

The fruit submitted to the ultrasonic pretreatment lost soluble solids to the liquid medium. The amount of sugars transferred to the liquid medium during the process was 13.8% after 30 min in ultrasonic bath and increased continuously reaching 30.6% after 90 min (Table 1). The amount of sugars lost to the liquid medium after 10 min, when ultrasound was applied, was 160.5% higher than the condition where the fruit was immersed in distilled water, showing that ultrasound has enhanced the removal of soluble solids from the fruit to the liquid medium. After 30 min, the enhancement obtained with ultrasound application fell to 55.1%. ANOVA and Tukey test were carried out to compare the results of the runs with and without application of ultrasound and showed that a statistical difference exists between these two runs, proving that the application of ultrasound enhances the loss of sugars from the fruit to the liquid medium.

In the ultrasonic-assisted osmotic dehydration the fruit gained 10.3% of sugar after 30 min and in the osmotic dehydration without ultrasound application the fruit gained 11.4% of sugar in the same period. Sugar gain increased significantly after 45 min under osmotic dehydration (with and without ultrasound application). In a previous study, Fernandes et al. (2006a) has shown that after 180 min under osmotic dehydration, papayas can gain from 144.1% of sugar when the osmotic dehydration is carried out at 50 °Brix and 50 °C to 189.6% of sugar when the process is carried out at 70 °Brix and 70 °C. The results show that ultrasonic treated papayas can have 13.8% less sugar than the dried fruit and at least 64.7% less sugar than the osmodehydrated fruit. As such, the ultrasonic treatment may be an interesting process to produce low sugar dried fruits.

At the end of the ultrasonic pretreatment, little change was observed in the fruit moisture content (Table 1). The fruit submitted to ultrasound in distilled water showed a water loss rather than a water gain which could be expected if only the mass transfer is considered. However, ultrasound application causes a series of rapid alternative compressions and expansion which can expel water from the fruit to the liquid medium, as observed for papayas. ANOVA and Tukey test were carried out to compare the results of the runs with and without application of ultrasound and showed that no statistical difference exists between these two treatments considering water loss.

The results obtained from the osmotic dehydration experiments showed higher water loss from the fruit as already expected, since the used of a hypertonic solution tends to increase the mass transfer of water from the fruit to the osmotic solution due to the high concentration gradient. The use of ultrasound-assisted osmotic dehydration showed similar results concerning water loss but slightly lower sugar gain. ANOVA and Tukey test were carried out to compare the results of the osmotic dehydration experiments with and without application of ultrasound and also showed that no statistical difference exists between these two treatments considering water loss and sugar loss.

The effect of the ultrasonic pretreatment on drying was also observed during the air-drying stage where an increase in water effective diffusivity was found. Water effective diffusivity during the air-drying process was found to be higher when the papayas were pretreated minutes under ultrasonic waves (Table 1 and Fig. 1). An increase by 28.8% in the effective water diffusivity was observed for papayas submitted to ultrasonic treatment for 20 min. Pretreating papayas using osmotic dehydration resulted in a mean water effective diffusivity of 2.10 10−9 m2 s−1, which was much lower than the water effective diffusivity of the fresh fruit (6.50 10−9 m2 s−1). The ultrasound-assisted osmotic dehydration also showed a lower water effective diffusivity (compared to the fresh fruit water diffusivity) for treatment periods up to 20 min and a slightly higher diffusivity for a treatment period of 30 min, however still lower than the effective diffusivity obtained with the ultrasonic process carried out with distilled water. As a consequence, the fruit submitted to 30 min of ultrasound pretreatment dried faster during the air-drying stage if compared to the fresh fruit with no pretreatment. This result may be caused by the cavitation and sponge effect caused by ultrasound and corroborates with the observations of Fuente-Blanco et al. (2006) that the ultrasonic pretreatment affects the fruit tissue making easier for water to diffuse during air-drying, most probably due to the formation of microscopic channels in the fruit. Microphotographs of the microscopic channels were shown by Fernandes et al. (2007) for melon pretreated with ultrasound application.

A significant change in the water effective diffusivity was observed after 45 min, in the experiments using an osmotic solution. The water effective diffusivity showed a rapid increase which may be caused by disruption of cell walls. Broken cells offers lower resistance for water flow within the fruit sample with consequent increase of the mass transfer of water. This effect was previously observed for melon (Fernandes et al. 2007) and for strawberry (Prinzivalli et al. 2006) and may be also affecting papaya.

Table 2 shows that the total processing time (air-drying + pretreatment) to remove 90 and 95% of the initial moisture content of the fresh fruit was lower when the ultrasound pretreatment was applied. When ultrasound was applied for 20 min, the total processing time to dehydrate papayas removing 95% of the initial moisture content was 263.7 min, 50 min less than air-drying without using a pretreatment. The result obtained for ultrasound-assisted osmotic dehydration showed that applying this technique for 30 min the total processing time to dehydrate papayas removing 95% of the initial moisture content was 308.7 min, 5 min less than air-drying without using a pretreatment, but still higher than using ultrasound with the fruit immersed in distilled water.

The use of osmotic dehydration at ambient temperature increased the total processing time. This was most probably due to the formation of a sucrose layer in the surface of the fruit which acts as an additional resistance to mass transfer, resulting in a much lower effective diffusivity of water (Table 1). A previous work (Fernandes et al. 2006a) showed that process temperature is an important factor for osmotic dehydration of papayas. Temperatures above 50 °C should be used in osmotic dehydration of papayas as to increase the mass transfer coefficients and effective diffusivity of water in the process, reducing the total processing time.

The drying process of fruits considered in this study comprises the pretreatment process followed by air-drying. Total processing time can be optimized to reduce the drying process to a minimum, which can reduce costs and increase the overall productivity.

Previous studies (Fernandes et al. 2006a,b; Teles et al. 2006; Oliveira et al. 2006; Rodrigues and Fernandes 2007) have shown that in a process consisting of osmotic dehydration followed by air-drying, the optimum processing time is obtained when the osmotic dehydration is used while the water loss rate of the fruit is higher than the rate that would be obtained by the air-drying process. When the water loss rate in the osmotic dehydration becomes lower than the rate that would be obtained in the air-drying process, then the fruit is transferred from the osmotic dehydration to the air-drying equipment, where the fruit stays till drying is completed. The optimization of the process consisting of ultrasonic treatment and air-drying is obtained in a different way. The ultrasonic treatment should be carried out while the increase in water diffusivity it provokes leads to a continuous reduction of total processing time (Fig. 2). One of the main effects of the ultrasonic treatment is to produce microchannels inside the fruit structure. The number of microchannels produced may increase with time but this increase may be limited to a certain number or may not be constant through time. Thus, up to a certain period, the effect of these microchannels in reducing the air-drying period halts and after that period the time spent under ultrasonic period could be considered void (the total processing time increases as the ultrasonic time increases).

Table 3 shows that to remove 95% of the water content of the fresh fruit the best operating condition is found when ultrasound is submitted for 20 min, which reduces the total processing time to 263.7 min. To achieve the same dried fruit specification, the ultrasound-assisted osmotic dehydration should be carried out for 30 min, condition which will reduce the total processing time to 308.7 min.

Conclusion

The use of ultrasound as a pretreatment in the conditions applied in this study caused loss of sugar to the liquid medium decreasing the amount of sugar of the fruit and producing a dried low sugar fruit.

The use of ultrasound pretreatment also increased the water effective diffusivity of the fruit leading to faster air-drying of the fruit. The increase in effective water diffusivity was estimated in 28.8% after 20 min of ultrasound. This phenomenon may happen due to the process of formation of microchannels during the application of ultrasound. The increase in water effective diffusivity at the air-drying stage makes the use of ultrasound as a pretreatment an interesting methodology complementary to classical air-drying.

Abbreviations

- D :

-

effective diffusivity (m2/h)

- H :

-

moisture content of the fruit (gwater/g)

- H eq :

-

equilibrium moisture content of the fruit (gwater/g)

- t :

-

time (h)

- WL:

-

water loss (%)

- SL:

-

solid loss (%)

- X i :

-

initial fruit moisture on wet basis (gwater/g)

- X f :

-

final fruit moisture on wet basis (gwater/g)

- w i :

-

initial fruit mass (g)

- w f :

-

final fruit mass (g)

- δ :

-

bed height of the fruit (m)

References

Association of Official Analytical Chemists (1990). Moisture in dried fruits. In Official methods of analysis (16th edition). Washington, USA: Association of Official Analytical Chemists.

Beaudry, C., Raghavan, G. S. V., Ratti, C., & Rennie, T. J. (2004). Effect of four drying methods on the quality of osmotically dehydrated cranberries. Drying Technology, 22, 521–539.

FAOSTAT (2005). Core production data database, Food and Agriculture Organization of the United Nations.

Fernandes, F. A. N., Gallão, M. I. & Rodrigues, S. (2007). Effect of osmotic dehydration and ultrasound pre-treatment on cell structure: melon dehydration. Food Science and Technology - LWT, DOI 10.1016/j.lwt.2007.05.007.

Fernandes, F. A. N., Rodrigues, S., Gaspareto, O. C. P., & Oliveira, E. L. (2006a). Optimization of osmotic dehydration of papaya followed by air-drying. Food Research International, 39, 492–498.

Fernandes, F. A. N., Rodrigues, S., Gaspareto, O. C. P., & Oliveira, E. L. (2006b). Optimization of osmotic dehydration of bananas followed by air-drying. Journal of Food Engineering, 77, 188–193.

Fuente-Blanco, S., Sarabia, E. R. F., Acosta-Aparicio, V. M., Blanco-Blanco, A., & Gallego-Juárez, J. A. (2006). Food drying process by power ultrasound. Ultrasonics Sonochemistry, 44, e523–e527.

Gallego-Juárez, J. A., Rodríguez-Corral, G., Gálvez-Moraleda, J. C., & Yang, T. S. (1999). A new high intensity ultrasonic technology for food dehydration. Drying Technology, 17, 597–608.

Madamba, P. S., & Lopez, R. I. (2002). Optimization of the osmotic dehydration of mango (Mangifera indica L.) slices. Drying Technology, 20, 1227–1242.

Mason, T. J. (1998). Power ultrasound in food processing - the way forward. In Povey & Mason (eds), Ultrasounds in Food Processing (pp. 104–124). Glasgow, United Kingdom: Blackie Academic and Professional.

Mason, T. J., Paniwnyk, L., & Lorimer, J. P. (1996). The use of ultrasound in food technology. Ultrasonics Sonochemistry, 3, S253–S256.

Miller, G. L. (1959). Use of dinitrosalicilic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428.

Oliveira, I. M., Fernandes, F. A. N., Rodrigues, S., Sousa, P. H. M., Maia, G. A., & Figueiredo, R. W. (2006). Modeling and optimization of osmotic dehydration of banana followed by air-drying. Journal of Food Processing Engineering, 29, 400–413.

Perry, R. H., & Green, D. W. (1999). Perry’s Chemical Engineer’s Handbook. 5th Edition. New York, USA: McGraw Hill.

Prinzivalli, C., Brambilla, A., Maffi, D., Scalzo, R. L., & Torreggiani, D. (2006). Effect of osmosis time on structure, texture and pectic composition of strawberry tissue. European Food Research and Technology, 224, 119–127.

Rodrigues, S., & Fernandes, F. A. N. (2007). Dehydration of melons in a ternary system followed by air-drying. Journal of Food Engineering, 80, 678–687.

Stojanovic, J., & Silva, J. L. (2006). Influence of osmoconcentration, continuous high-frequency ultrasound and dehydration on properties and microstructure of rabbiteya blueberries. Drying Technology, 24, 165–171.

Tarleton, E. S. (1992). The role of field-assisted techniques in solid/liquid separation. Filtration Separation, 3, 246–253.

Tarleton, E. S., & Wakeman, R. J. (1998). Ultrasonically assisted separation process. In Povey & Mason (eds) Ultrasounds in Food Processing (pp. 193–218). United Kingdom: Blackie Academic and Professional, Glasgow.

Teles, U. M., Fernandes, F. A. N., Rodrigues, S., Lima, A. S., Maia, G. A., & Figueiredo, R. W. (2006). Optimization of osmotic dehydration of melons followed by air-drying. International Journal of Food Science and Technology, 41, 674–680.

Zheng, L., & Sun, D. W. (2006). Innovative applications of power ultrasound during food freezing processes—A review. Food Science and Technology, 17, 16–23.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fernandes, F.A.N., Oliveira, F.I.P. & Rodrigues, S. Use of Ultrasound for Dehydration of Papayas. Food Bioprocess Technol 1, 339–345 (2008). https://doi.org/10.1007/s11947-007-0019-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-007-0019-9