Abstract

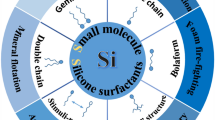

Silicone surfactants have been widely used in our daily life and many industrial fields on the basis of their unusual properties. Only in the past decades has the use of silicone as a hydrophobic building block for the preparation of surfactants become common. The recent trend to combine silicone, polyoxyalkylene and carbohydrate moieties in the same molecule has resulted in a plethora of new compounds with new properties. The generic structure and surface activity of silicone surfactants are reviewed in this article. Especially, the preparation, properties and application of carbohydrate-modified silicone surfactants such as glucosamide-containing and glycoside-containing silicone surfactants are described in detail. In addition, the future development of silicone surfactants is discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Silicone surfactants are a group of small-molecule and polymeric surfactants. They consist of a permethylated siloxane hydrophobic group (silicone-soluble group) coupled to one or more polar groups (water-soluble group) in the same molecule.

Silicone surfactants exhibit some unusual properties. The siloxane moiety is hydrophobic and oleophobic, which allows for application in both aqueous and nonaqueous media. They are often liquids even when their molecular weights are rather high. They are usually thermal stability, ultraviolet ray resistant, low toxicity and low surface tension [1–3].

The unique character is closely connected with bonding parameters. The difference of electronegativities of the Si–O bond is 1.76, according to Allred-Rochow. Nevertheless, this polar bond has little influence on the solubility of silicone oils. Evidently, these bonds are shielded by methyl groups that are exposed exclusively at the surface. The Si–O bond length is 0.165 nm compared to 0.140 nm of a C–C bond. The Si–O–Si bond angle of 130 ± 10° is much larger than the corresponding C–O–C bond angle of 110° in dimethyl ether.

Silicone surfactants have been widely used in our daily life and many industrial fields such as polyurethane foam, household, personal care, cosmetics, agricultural adjuvants, textiles and coatings as foam stabilizers, detergents, emulsifying agents, wetting agents and antifoaming/defoaming agents [4–8].

In contrast, carbohydrate surfactants such as N-alkyl glucosamides (NAGA) and alkyl polyglucosides (APG) have been known for many years and are particularly interesting because they are (partially) based on renewable resources. In recent years, they have begun to be produced on an industrial scale and their usage has been gradually increasing because of their valuable properties, such as good dermatological compatibility, excellent biodegradability, and the absence of toxic effects.

An increasing number of recent publications have described carbohydrate-modified silicone surfactants. The idea is to combine the extraordinary surface activity and wetting properties of siloxanes with the biodegradability of carbohydrates.

A summary of the synthesis and the properties of carbohydrate-modified silicone surfactants are given in this review paper.

General Information of Silicone Surfactants

Structure of Silicone Surfactants

Scheme 1 gives a general formula demonstrating organically modified polysiloxanes by substituting various organic groups for methyl moieties.

This generic structure describes the variety of organo-modified siloxanes. R and/or R′ represent various organic polar groups, which can be aliphatic and/or aromatic; monomers or polymers. They can be attached to a linear, grafted, or branched siloxane backbone via a Si–C bond (z = 0) or a Si–O–C bond (z = 1). In this way, it is possible to control solubility and compatibility. In general, the organically substituted silicones have relatively short siloxane chain lengths (x + y = 1–200). The organic substituents play a substantial role in the properties of such products.

According to the molecular structure, the grafted polysiloxane is more in the variety of organo-modified siloxanes. The advantage of using grafted copolymers is that they are more resistant to hydrolysis and chemical attack than linear types. According to the linkage of the siloxane backbone and organic groups, the organic groups are attached to the siloxane backbone through a series of hydrolytically stable Si–C bonds by the hydrosilylation reactions or through Si–O–C bonds by a condensation reaction. The latter offers limited resistance to hydrolysis under neutral or slightly basic conditions, but breaks down in strong acidic and basic condition.

The versatility of silicone surfactants comes from the many organic functional groups that can be incorporated into the molecule. Many types of polar groups have been described, but nonionic groups based on polyoxyethylene (PEO) and polyoxypropylene (PPO) have been the most extensively studied.

Surface Activity of Silicone Surfactants

Silicone surfactants have more excellent properties than the organic surfactants. These properties can be attributed to the strength and flexibility of the Si–O bond, its partial ionic character, and the low interactive forces between the nonpolar methyl groups, characteristics that are directly related to the comparatively long Si–O and Si–C bonds.

Siloxane surfactants significantly reduce the surface tension of the solution at low concentration, indicating that these molecules adsorb strongly at the air/water surface and that they are highly effective aqueous surfactants, reducing the surface tension of water to approximate 21 mN/m.

The low surface tension of silicone surfactants has been attributed to both the preponderance of highly surface active methyl substituent and a flexible polymer backbone. The length of the Si–O and Si–C bonds allows an unusual freedom of rotation, which enables the molecules to adopt the lowest energy configuration at interfaces. By comparison, hydrocarbon surfactants generally have many methylene groups in their hydrophobic portions, which have an intrinsically higher surface energy than methyl groups. The surface tension values of these surfactants suggest that the siloxane portion lies flat on the water surface, exposing the methyl groups to the air.

A dramatic change in slope of the surface tension versus log surfactant concentration curves is generally interpreted as the onset of surfactant aggregation into micelles in bulk aqueous solution. Micelle formation by siloxane surfactants in aqueous solution has not been extensively investigated. Most of the studies to date report critical micelle concentrations (CMC) values from surface tension versus log surfactant concentration plots. Although the structure of the micelles formed has been investigated in the past few years, no conclusion has been drawn on the tendency of these surfactants to form well-defined micelles [9–15].

Glucosamide-Modified Silicone Surfactants

Prepared by Reacting the Aminosilicone with Aldoniolactone

Wagner et al. [16, 17] reported a synthetic sequence of reaction of aldoniolactones with primary amino functions of polysiloxanes. A series of carbohydrate-modified silicone surfactants (Scheme 2) were synthesized and their properties such as spreading and wetting on a low energy surface (tetrafluoraoethylene-hexafluoropropylene copolymer; FEP) were determined.

von Braunmühl et al. [18] synthesized aldonamide siloxanes (Scheme 3) in a broad variety of molecular weight and composition by the hydrosilylation reaction of polymethylhydrosiloxane (PMHS) with O-acetylated N-allylaldonamides of various sugars using different transition metal complexes as catalyst.

Han et al. [19–25] reported the synthesis of a series of glucosamide-modified silicone surfactants such as glucosamide-based trisiloxane surfactants, glucosamide-based trisiloxane surfactants of substitution in the oxyethylene units, and glucosamide-based trisiloxane gemini surfactants (Scheme 4). The properties of these glucosamide-based trisiloxane surfactants were determined by the surface tension, critical aggregation concentration (CAC), the spread abilities on hydrophobic surface (paraffin wax, sterile polystyrene, wheat and cabbage leaf) and the hydrolyzations.

These trisiloxane surfactants significantly reduced the surface tension of the solution to approximately 21 mN/m at low concentration and possessed advantageous spread properties.

Du et al. [26] synthesized carbohydrate-modified siloxane surfactants (Scheme 5) by an analogous method. Their surface activities, adsorption, and aggregation behavior in aqueous solution were investigated by surface tension measurements, dynamic light scattering (DLS) and transmission electron microscopy (TEM).

Prepared by Reacting the Aminosilicone with Glucose

Ma [27] prepared a group of glucosamide gemini surfactants (Scheme 6) by the catalytic hydrogenation reaction between glucose and α,ω-diaminopropylsiloxane in the presence of the Pd/C as a catalyst.

Members of this kind of surfactant reduced the surface tension of water to 25–35 mN/m at concentration levels of 10−4–10−5 mol/L.

Moreover, the shapes of molecular aggregates of gemini surfactants in water were studied by transmission electromicroscopy. In the dilute solution, the product displayed unprecedented aggregation behavior with a thread-like micelle-to-vesicle transition. The stability of vesicle was increased as the length of spacer chain grew.

Prepared by Reacting the Epoxy-Silicone with Amino-Sugar

Dietz et al. [28] prepared the siloxane-polyether-sugar ternary copolymers (Scheme 7) by reacting polyether-epoxy-siloxane with N-methylglucamine.

Polyether silicones belong to the class of nonionic surfactants which show inverse solubility behavior in water. In other words, they decrease in solubility as the temperature rises. This behavior is defined by what is known as the inverse cloud point. Sugar silicones are likewise nonionic surfactants that exhibit a “normal” solubility behavior. In other words, their solubility in water improves constantly as the temperature climbs. Therefore, through an appropriate balance of polyether groups and sugar groups at the molecular level, it is possible to prepare silicone surfactants with custom-tailored solubility parameters as emulsifiers for use in microemulsions.

The sugar radicals increase as a proportion of the sum of the sugar and polyether radicals and there is likewise an increase in the cloud point. With a relatively short siloxane chain and an approximately constant number of functional groups per molecule, the cloud point is raised for a comparable proportion of the sugar radicals to the polyether radicals.

Pure sugar siloxanes, despite the large number of OH groups, are of poor solubility in water, probably owing to the formation of aggregates as a consequence of strong hydrogen bonds. The additional polyether radicals in the sugar siloxanes prevent the aggregation of sugar radicals and hence raise the solubility of sugar siloxanes. The sugar-polyether-siloxane features a greatly increased stability in water in comparison with corresponding binary sugar siloxanes.

Wagner et al. [29] synthesized sulfobetain amphoteric surfactants (Scheme 8) by means of the reaction of siloxanylpropyl-2,3-epoxypropylether with glucamine or N-methylglucamine, respectively, followed by the addition of butanesultone.

The biodegradability, as determined by the OECD test, was 60% higher than that of a common polydimethylsiloxane. But the value of degradability was much lower than it is for hydrocarbon surfactants.

The very high surface activity of this type of siloxane was expressed by the low critical micelle concentration and the maximum surface tension depression. And they were very good emulsifiers.

Wagner et al. [30] further reported quaternization of tertiary amino functions containing aminoalkylamides yields polyhydroxylated ammonium salts (Scheme 9).

The reactions between primary and tertiary amino functions containing polyamines and polyhydroxylated lactones were carried out and yielded the corresponding amides. The quaternary ammonium salts were synthesized by using epoxy-silicone as an alkylating agent. An essential precondition for a quantitative alkylation is a sufficiently long alkylene bridge (n ≥ 3) to insulate the tertiary amino function from electronic (amide structure) influences.

Glycoside-Modified Silicone Surfactants

Prepared by Protective Groups

Jonas et al. [31, 32] followed a multistep procedure on the route to carbohydrate-polysiloxane graft copolymers. Peracetylation, glycosidation, hydrosilylation and finally deacetylation yield, mainly β-glycosides of polysiloxanes. Haupt et al. [33] prepared carbohydrate-modified polydimethylsiloxanes (Scheme 10) by an analogous method.

Wagner et al. [16] also synthesized glycoside-modified siloxanes in a four-step sequence which includes peracetylation, glycosidation, deacetylation and hydrosilylation.

Prepared by Directly Glycosidation

Glycosides bearing siloxanyl moieties have been claimed by Greber [34] and Sejpka et al. [35]. In both cases, acid catalyzed Fischer glycosidations were described, despite the known tendencies of unprotected reducing carbohydrates to oligomerize and of siloxanes to equilibrate under such conditions.

O’Lenick [36, 37] provided a series of novel silicone containing glycoside polymers (Scheme 11), which were prepared by the reaction of a dimethicone copolyol with a saccharide or saccharide source in the presence of an acid catalyst. They were substantive to skin and hair and possessed outstanding emoliency properties when applied to the skin. In addition, unlike the alkyl products previously known, these materials were exceptionally well tolerated by the skin and eye and were essentially non-irritating. The compounds were very mild surface active agents which were ideally suited for use in personal care compositions like hair and skin care products.

Sejpka et al. [38] reported that glycoside polysiloxanes (Scheme 12) could be prepared by two various processes. In the first process, the compound whereas synthesized by the hydrosilylation reaction of polymethylhydrosiloxane (PMHS) with allyl polyoxyethylene ether glycosides. The latter was synthesized by the glycosidation reaction of saccharide with allyl polyoxyethylene ether. The excess allyl polyoxyethylene ether can be removed by distillation in the glycosidation. In the second process, the glycoside silicone polymers were prepared by the reaction of a dimethicone copolyol with a saccharide in the presence of an acid catalyst. The excess polyethyleneoxide-modified silicone to lower the polymerization degree of glucoside was not easy to remove. The polysiloxane chain could be equilibrated again by the acid catalyst.

Afriat et al. [39] prepared the siloxane-alkyl-glycoside ternary copolymers (Scheme 13) as a moisturizing agent in a cosmetic or dermatological composition. They were especially effective for treating human skin and the scalp, and were particularly effective for moisturizing the skin and treating dry skin. The composition had long-lasting skin moisturization properties.

Wagner et al. [40] prepared the anion trisiloxane surfactant (Scheme 14) by the hydrosilylation of ally1 glycidyl ether with H-siloxanes followed by the reaction of the product with the sodium salt of glucose maleate. The compound was a nearly white solid with good solubility in water and some alcohols.

Using the same reaction path, a number of compounds with polymeric siloxane groups were synthesized. However, they were not soluble in water.

Sahoo et al. [41] synthesized glycoside-modified siloxane (Scheme 15) by esterification between organosilicon carboxylic diacids and a C1-O-alkylated sugar by using Novozyme 435 as a catalyst under mild reaction conditions (i.e., low temperature, neutral pH, solventless). Specifically, the acid-functionalized organosilicones reacted with the primary hydroxyl group at the C6 position of α,β-ethyl glucoside during the regioselective esterification. The pure organosilicon-sugar conjugates were prepared in a one-step reaction without protection–deprotection steps and without activation of the acid groups with the integrity of the siloxane bonds.

Further Work

A great variety of silicone derivatives with different structure and functional properties is now available to the formulator. These derivatives permit great formulation latitude and make possible the creation of products which are optimized for specific applications.

The modification of siloxanes with carbohydrate moieties led to a new class of surface active silicone compounds with improved biodegradability. This advance can expand the application of siloxane surfactants into new fields.

Future work on silicone surfactants needs to continue to develop new materials that are able to deliver multiple performance capabilities. A series of surfactants, based on silicone as a hydrophobe and containing other functional groups similar to those in conventional surfactants, have been and continue to be developed. These surfactants are silicone functional analogs of conventional surfactants.

References

Hill RM (1999) Silicone surfactants. Marcel Dekker, New York

Hill RM (2002) Silicone surfactants-new development. Curr Opin Colloid Interface Sci 7(5–6):255–261

Stürmer A, Thunig C, Hoffmann H, Gruening B (1994) Phase behaviour of silicone surfactants with a comblike structure in aqueous solution. Tenside Surf Deterg 31:90–98

Kobayashi R, Yabe S, Nomura T (1997) Polysiloxane gel with low crosslinking density for make-up cosmetics. Polym Adv Technol 8(6):351–354

Krupers MJ, Bartelink CF, Grunhauer HJM, Moeller M (1998) Formation of rigid polyurethane foams with semi-fluorinated diblock copolymeric surfactants. Polymer 39:2049–2053

Bonner MP, Wilson JIB, Burnside BM, Reuben RL, Gengenbach TR, Crisser HJ, Beamson G (1998) X-ray photoelectron spectroscopic investigation of the durability of siloxane plasma polymer coatings in a steam atmosphere. J Mater Sci 33:4843–4855

Lin Y, Smith TW, Alexandridis P (2002) Adsorption of a rake-type siloxane surfactant onto carbon black nanoparticles dispersed in aqueous media. Langmuir 18:6147–6158

Purohit P, Somasundaran P, Kulkarni R (2006) Study of properties of modified silicones at solid–liquid interface: fabric-silicone interactions. J Colloid Interface Sci 298:987–990

Snow SA, Fenton WN, Owen MJ (1990) Synthesis and characterization of zwitterionic silicone sulfobetaine surfactants. Langmuir 6:385–391

Snow SA, Fenton WN, Owen MJ (1991) Zwitterionic organofunctional siloxanes as aqueous surfactants: synthesis and characterization of betaine functional siloxanes and their comparison to sulfobetaine functional siloxanes. Langmuir 7:868–871

Snow SA (1993) Synthesis, characterization, stability, aqueous surface activity, and aqueous solution aggregation of the novel, cationic siloxane surfactants (Me3SiO)2Si(Me)-(CH2)3 +NMe2(CH2)2ORX−(R = H, C(O)Me, C(O)NH(Ph);X = Cl, Br, I, NO3, MeOSO3). Langmuir 9:424–430

Gentle TE, Snow SA (1995) Absorption of small silicone polyether surfactants at the air/water surface. Langmuir 11:2905–2910

Rosen MJ, Song L (1996) Superspreading, skein wetting, and dynamic surface tension. Langmuir 12:4945–4949

Svitova T, Hoffmann H, Hill RM (1996) Trisiloxane surfactants: surface/interfacial tension dynamics and spreading on hydrophobic surfaces. Langmuir 12:1712–1721

Zhu S, Miller WG (1994) Superspreading of water–silicone surfactant on hydrophobic surfaces. Colloids Surf A 90:63–78

Wagner R, Richter L, Wersig R, Schmaucks G, Weiland B, Weißmüller J, Reiners J (1996) Silicon-modified carbohydrate surfactants I: synthesis of siloxanyl moieties containing straight-chained glycoside and amides. Appl Organomet Chem 10:421–435

Wagner R, Richter L, Weiland B, Reiners J, Weißmüller J (1996) Silicon-modified carbohydrate surfactants II: siloxanyl moieties containing branched structures. Appl Organomet Chem 10:437–450

von Braunmühl V, Stadler R (1998) Synthesis of aldonamide siloxanes by hydrosilylation. Polymer 39:1617–1629

Han F, Zhang G (2003) New family of siloxane surfactants having glucosamide. Tenside Surf Deterg 40:332–337

Han F, Zhang G (2004) Synthesis and characterization of glucosamide-based trisiloxane gemini surfactants. J Surf Deterg 7:175–180

Han F, Zhang G (2004) New family of Gemini surfactants with glucosamide-based trisiloxane. Colloids Surf A 237:79–85

Han F (2004) Synthesis and properties of novel trisiloxane surfactants. Wuhan University, Wuhan

Zhang Y, Zhang G, Han F (2007) Spreading mechanism of new glucosamide-based trisiloxane surfactant on low-energy surface. Acta Chim Sin 65:465–469

Zhang Y, Zhang G, Han F (2006) The spreading and superspeading behavior of new glucosamide-based trisiloxane surfactants on hydrophobic foliage. Colloids Surf A 276(1–3):100–106

Zhang Y, Han F (2009) The spreading behavior and spreading mechanism of new glucosamide-based trisiloxane on polystyrene surface. J Colloid Interface Sci 337:211–217

Wang G, Du Z, Li Q, Zhang W (2010) Carbohydrate-modified siloxane surfactants and their adsorption and aggregation behavior in aqueous solution. J Phys Chem B 114:6872–6877

Ma Q (2006) Synthesis and properties in solution of carbohydrate-modified polysiloxanes. Shandong University, Shandong

Dietz T, Grüning B, Lersch P, Weitemeyer C (1999) organopolysiloxanes comprising polyhydroxyorganyl radicals and polyoxyalkylene radicals. US Patent 5,891,977

Wagner R, Wersig R, Schmaucks G, Weiland B, Richter L, Hennig A, Jänicke A, Reiners J, Krämer W, Weiβmüller J, Wirth W (1994) siloxanyl group-containing cationic polyhydroxy compounds for use as surfactants. DE Patent 4,318,537

Wagner R, Richter L, Weiland B, Weißmüller J, Reiners J, Krämer W (1997) Silicon-modified carbohydrate surfactants III: cationic and anionic compounds. Appl Organomet Chem 11:523–538

Jonas G, Stadler R (1994) Carbohydrate modified polysiloxanes II. Synthesis via hydrosilation of mono-, di- and oligosaccharide allylglycosides. Acta Polymer 45:14–20

Loos K, Jonas G, Stadler R (2001) Carbohydrate modified polysiloxanes, 3. Solution Properties of Carbohydrate-polysiloxane Conjugates in Toluene. Macromol Chem Phys 202:3210–3218

Haupt M, Knaus S, Rohr T, Gruber H (2000) Carbohydrate modified polydimethylsiloxanes. Part 1. Synthesis and characterization of carbohydrate silane and siloxane building blocks. J Macromol Sci, A: Pure Appl Chem 37:323–341

Greber G, Gruber H, Moessl E (1991) Preparation of hydrophilic silanes and siloxanes by hydrosilylation. Austrian Patent 393,509

Sejpka J, Wimmer F (1994) Preparation of glycoside containing organosilicon compounds. European Patent 612,759

O’Lenick A Jr (1995) Preparation of glycoside-containing dimethicone polyols for use in skin and hair products. US Patent 5,428,142

O’Lenick A Jr (1996) Silicone glycoside polymer surfactants for mild hair and skin products. US Patent 5,550,219

Sejpka J, Wimmer F (1998) Preparation of glycoside containing organosilicon compounds. European Patent 5,831,080

Afriat I, Gagnebien D (2000) Use of a polydimethylsiloxane containing glucoside groups as a moisturizing agent in a cosmetic or dermatological composition. US Patent 6,066,326

Wagner R, Wersig R, Schmaucks G, Weiland B, Richter L, Hennig A, Jänicke A, Reiners J, Krämer W (1994) Siloxanyl group-containing anionic polyhydroxy compounds for use as surfactants. DE Patent 4,318,539

Sahoo B, Brandstadt KF, Lane TH, Gross RA (2005) “Sweet silicones”: biocatalytic reactions to form organosilicon carbohydrate macromers. Org Lett 7:3857–3860

Acknowledgments

The financial support of the Natural Science Foundation of China (No. 20976003) and the Research Program of Beijing Municipal Commission of Education (No. KM201010011003) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Han, F., Deng, Yy., Zhou, Yw. et al. Carbohydrate-Modified Silicone Surfactants. J Surfact Deterg 15, 123–129 (2012). https://doi.org/10.1007/s11743-011-1290-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-011-1290-3