Abstract

Bacterial cellulose (BC) is a homopolymer and it is distinguished from plant-based cellulose by its unique properties such as high purity, high crystallinity, high water-holding capacity, and good biocompatibility. Microalgae are unicellular, photosynthetic microorganisms and are known to have high protein, starch, and oil content. In this study, Chlorella vulgaris was evaluated as source of glucose for the production of BC. To increase the starch content of algae the effect of nutrient starvation (nitrogen and sulfur) and light deficiency were tested in a batch assay. The starch contents (%) were 5.27 ± 0.04, 7.14 ± 0.18, 5.00 ± 0.08, and 1.35 ± 0.04 for normal cultivation, nitrogen starvation, sulfur starvation, and dark cultivation conditions, respectively. The performance of enzymatic and acidic methods was compared for the starch hydrolysis. This study demonstrated for the first time that acid hydrolysate of algal starch can be used to substitute glucose in the fermentation medium of Komagataeibacter hansenii for BC production. Glucose was used as a control for BC production. BC production yields on dry weight basis were 1.104 ± 0.002 g/L and 1.202 ± 0.005 g/L from algae-based glucose and glucose, respectively. The characterization of both BCs produced from glucose and algae-based glucose was investigated by scanning electron microscopy and Fourier transform infrared spectroscopy. The results have shown that the structural characteristics of algae-based BC were comparable to those of glucose-based BC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is found within the homopolysaccharides group of extracellular polysaccharides, and it is a widely used biopolymer in the world (Chawla et al. 2009; Zhong et al. 2013). While the main sources of cellulose are plants, bacteria are also able to produce cellulose. Bacterial cellulose (BC) is a microorganism-based homopolymer of β-(1,4) glucose with the formula ((C6H10O5)n) produced by various strains of the genera Komagataeibacter (formerly known as Gluconacetobacter, Acetobacter), Agrobacterium, Aerobacter, Achromobacter, Alcaligenes, Azotobacter, Rhizobium, Pseudomonas, Sarcina, Salmonella, etc. (Li et al. 2012; Huang et al. 2014).

Bacterial cellulose, BC, is distinguished from plant-based cellulose by its high purity, high crystallinity, high water-holding capacity, and good biocompatibility. It does not contain residual hemicellulose or lignin. Moreover, the unique properties of BC including high elasticity, high mechanical strength, high specific surface area, and high porosity have made BC a very potentially important material (Bielecki et al. 2005; Zhong et al. 2013).

Bacterial celluloses are of great research interests in many areas including enzyme immobilization, photocatalysis application, biosensor, dye decolorization, heavy metal removal, food and beverage processing, paper manufacturing, packaging, filtration material, membranes for separation, fuel cells, and pharmaceutical and medical applications (Indrarti and Yudianti, 2012; Katepetch et al. 2013; Kurniawan et al. 2013; Lin et al. 2013; Mohite and Patil 2013, Mondal, 2013).

The biosynthesis of BC is a biochemical network containing a large number of key enzymes, and the regulation of the enzymes controls the production of cellulose (Ha et al. 2011; Li et al. 2012; Huang et al. 2014). In addition to this, style of fermentation affects BC production. There are some types of culture methods used in BC production, named as static, and agitated. Under static culture conditions, a gelatinous membrane of BC is accumulated on the culture surface, and under agitated culture conditions, BC is produced as an irregular mass such as granule, pellet, and fibrous strand (Watanabe et al. 1998; Krystynowicz et al. 2002; Zhu et al. 2011). Watanabe et al. (1994) have compared BCs produced by static and agitated fermentation; they reported that agitated fermentation resulted with a lower degree of polymerization and crystallinity than static fermentation. Agitated cultivation can be chosen in terms of its high production rates of BC for commercial purposes; however, it is stated that there are Cel− mutants (cellulose nonproducers) that cause a decline in polymer synthesis under agitated culture conditions.

Incorporation with some ingredients to BC is also possible to attain a better yield of cellulose (Zhou et al. 2007; Sun et al. 2010; Lu, Guan and Wei, 2011; Lu, Zhang, et al., 2011; Liu et al. 2012; Katepetch et al. 2013; Ul-Islam et al. 2013). Krystynowicz et al. (2002) conducted both static and agitated conditions for BC production and reported that the addition of 1 % ethanol into stationary cultures increased the efficiency of BC production. Table 1 lists some of the studies which are carried out to improve BC production with the use of alternate carbon sources, supplementary materials, different cultivation periods, and various bacterial strains (Chawla et al. 2009; Shah et al. 2013). Of the microorganisms listed in Table 1, Komagataeibacter hansenii (formerly, Gluconacetobacter hansenii) use mainly pure sugars such as glucose and maltose in order to produce BC.

Production of BC is an aerobic fermentation process, and carbon sources determine the cost of fermentation processes. So far with Acetobacter strains, generally pure sugars (glucose, fructose, etc.) have been used as carbon sources to produce BC. However, using pure sugars was found to be expensive (Zhong et al. 2013).

There are numerous applications of microalgae, as pharmaceutical chemicals, nutritional supplements, dyes for food, and cosmetics (Varfolomeev and Wasserman, 2011; Priyadarshani and Rath, 2012). Besides their lipid contents that could potentially be converted to practical biodiesel, the biomass of microalgae also contains many other valuable components, including carbohydrates, proteins, and pigments, all of which are worth to be used for various applications (Lammens et al. 2012). Yen et al. (2013) underlined the importance of microalgal biorefinery studies that are related with the use of components (carbohydrates, lipids, and proteins) of microalgae. Recently, the concept of “algorefinery/biorefinery” has been inspired from the petroleum refinery concept (Safi, 2013). It reflects a platform that integrates a process to fractionate the components of a biomass to produce multiple products. Thus, the production of microalgal biomass and other metabolic products through photosynthesis and the conversion of valuable components in the biomass into refined products for various applications represent additional benefits from the algae besides the contribution to the global carbon cycle and maximize profitability.

Starch is among the valuable components of microalgal biomass. It was reported that cheap enhanced starch biomass can be produced from highly productive Chlorella cultures grown in suitable outdoor photobioreactors (Doucha and Lívanský, 2009; Douskova et al., 2009; Mann et al., 2009). In line with this, there are some studies carried out to increase starch content of algal biomass under different conditions (sulfur limitation, nitrogen starvation, and different light intensities) (Branyikova et al. 2011; Ho et al. 2013).

Knowing that the freshwater algae Chlorella vulgaris has the ability to produce large amounts of starch (Dragone et al. 2011), it is noteworthy to show if algae-based glucose obtained from hydrolyzed starch could be used as a promising carbon source for the fermentation processes ending with BC.

The purpose of this study is to demonstrate if acid hydrolysate of algal starch can be used as a carbon source in the fermentation medium of Komagataeibacter hansenii for BC production; and also to optimize parameters such as pH, incubation type, and fermentation period using single-variable optimization method for obtaining the highest BC yield.

Materials and methods

Organisms and chemicals

Chlorella vulgaris was obtained from the Ecotoxicology and Chemometrics Laboratory, Institute of Environmental Sciences, Bogazici University, Istanbul, Turkey. Komagataeibacter hansenii was purchased from the German Collection of Microorganisms and Cell Cultures, Deutsche Sammlung von Mikroorganismen und Zellkulturen (DSMZ). All chemicals used in this study were analytical grade and purchased either from Sigma or Merck. The enzymes were obtained from Novozymes.

Cultivation of Chlorella vulgaris

Chlorella vulgaris was cultivated in modified Bold’s Basal medium, recipe was taken from CCAP (Culture Collection of Algae and Protozoa, Scottish Marine Institute, UK). Initial pH of the medium was 6.8. All of the solutions and glassware were sterilized by autoclaving at 121 °C, 20 min. Cultivation of algae was performed at 24.0 ± 0.6 °C, under continuous light (60 μmol photons m−2 s−1). All culture experiments were performed in 500 mL borosilicate glass containing 100 mL of medium in batch conditions. The details of test condition for the algal bioassay were given by Ertürk and Saçan (2013). All experiments have been carried out according to the algal growth inhibition test (OECD No.201) used for toxicity determination.

Determination of algal starch content

Cells were collected at the beginning of stationary phase. Algal biomass samples were harvested by centrifugation at 4500g for 15 min. Cells were double-washed with sterile ultrapure water and dried in an oven at 80 °C to a constant weight to determine the dry weight of algal cells. Sonication was performed on dried algal cells in order to destroy cell wall to release starch packages, at 45 °C, in sterile ultrapure water, for 15 min, as described by Jeon et al. (2013), and algal lysate was freeze-dried for further steps.

The starch content in algal lysate was assayed by the hydrolysis of starch to glucose with amylolytic enzymes (alpha-amylase, and amyloglucosidase) according to the procedure provided by Megazyme (Total Starch Assayprocedure, © Megazyme International Ireland 2011).

Effect of stress parameters on algal starch content

In order to investigate the effect of growth conditions on the starch content of algae, Chlorella vulgaris was exposed to different stress conditions. The stress parameters used in this study were nitrogen starvation, sulfur starvation, and dark cultivation conditions as indicated in Table 2. For the nitrogen starvation experiments, to omit nitrogen content, NaNO3 was replaced by NaOH in the modified Bold’s Basal medium. Then, to test the sulfur starvation response of algae, MgCl2 was added to the modified Bold’s Basal medium instead of MgSO4 7H2O. pH values were kept at 6.8 for both media. Starch content of algae exposed to different stress conditions was determined as mentioned above.

The initial algal cell density in each test vessel was about 1 × 104 cells mL−1. All experiments were carried out in triplicate.

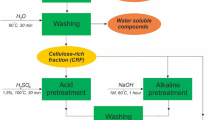

Hydrolysis of algal starch and determination of glucose concentration

Starch hydrolysis was carried out on algal lysates by enzymatic and acidic methods to compare their efficiencies in terms of glucose yields. In the enzymatic method, alpha-amylase (Liquozyme SC 4X) and glucoamylase (Spirizyme Excel) enzymes were used following the manufacturer’s instructions (Novozymes, Denmark). The acidic method was applied using H2SO4 in two steps. In the first step, 72 % (w/w) H2SO4 was used and hydrolysate was kept at 30 °C, for 1 h. In the second step, hydrolysate was treated with 4 % (w/w) H2SO4 at 121 °C, for 1 h (Laurens et al. 2012). After cooling to room temperature, hydrolysates were neutralized by 0.1 N NaOH. These hydrolysates were filtered (TPP syringe filter, pore size 0.22 μm) prior to their introduction into the high performance liquid chromatography (HPLC) system. Glucose concentrations were determined by HPLC system Class LC 10 (Shimadzu, Japan) using refraction index detector equipped with a MetaCarb 87H column 300 × 7.8 mm (Agilent Technologies, USA). As a mobile phase, 0.01 N sulfuric acid was used with a flow rate of 0.4 mL min−1, and column temperature was 35 °C. Calibration was carried out using glucose as a standard.

Culture medium and fermentation conditions

Komagataeibacter hansenii culture was used for the production of BC. In order to maintain Komagataeibacter hansenii culture, Gluconobacter oxydans (GO) medium taken from DSMZ was used (Table 3). A single colony of Komagataeibacter hansenii from GO agar plate was taken with a sterile loop and inoculated into 5 mL of GO medium under aseptic conditions. This culture tube was incubated at 28 °C and 180 rpm, for 24 h.

The efficiency of different growth media was tested to increase the yield of BC production by K .hansenii. The first medium used was a modified nutrient broth with the addition of glucose and NaCl, and it was called as Fermentation medium (FM), (Table 4). The second medium tested (Table 4) was Hestrin and Schramm (1954).

One hundred microliters of 24-h old culture was inoculated into culture tube which contains FM. Then, culture tubes were incubated in orbital shaker at 28 °C and 180 rpm, for 48-h. 2.5 mL of these 48-h old culture were used as inoculum for each of 50 mL FM and HS medium to compare their efficiency for BC yield, in static incubation at 28 °C, for 7 days. To increase the BC yield 0.5 % ethanol was added to the FM medium as a supplementary material.

Determination of optimal conditions for BC production

A variety of parameters including incubation type, glucose percentage, ethanol percentage which is used as a supplementary material (additive), pH, and fermentation period were tested to obtain the highest BC yield. All of the optimization parameters were considered by single-variable optimization method. pH was adjusted by using 0.1 N NaOH and/or 0.1 N HCl. All experiments were carried out in triplicate.

The use of algae-based glucose in BC production and characterization of BCs

After the optimization of BC production conditions, glucose at the selected medium for bacterial growth was replaced by hydrolysate of algae (algae-based glucose) for the production of BC. As a control, glucose (Merck) was used for BC production.

Once BC synthesized, it was treated with 0.1 N NaOH, at 80 °C, for 20 min to remove bacterial cells and medium components, then washed with sterile ultrapure water until neutrality. BC yields were given as g bacterial cellulose/L fermentation medium. The microfibrillated structure of the previously lyophilized bacterial celluloses was investigated under scanning electron microscope (SEM) by taking micrographs of gold-coated (Polaron Emitech SC7640 Sputter Coater) samples with a JEOL/JSM 6510LV. Additionally, analyses for the structural differences were recorded by a Thermo Scientific Nicolet™ 6700 Fourier Transform Infrared (FT-IR) spectrometer equipped with a Smart Orbit high performance diamond attenuated total reflectance accessories, in the transmittance mode with a resolution of 1 cm−1 in the range of 4000–400 cm−1. Microcrystalline cellulose (Merck), MCC, was used as a reference in the FT-IR study.

Results and discussion

The algal starch content

Starch contents were determined for algal culture exposed to different stress conditions, and given in Table 2. According to Total Starch Assay procedure, the algae had a starch content of 5.27 ± 0.04 % (DW) under the normal cultivation conditions. The results obtained in our study were remarkable when compared with previously reported data (Rodrigues and Silva Bon, 2011). All experiments have been carried out according to the algal growth inhibition test (OECD No.201) used for toxicity determination. The purpose was to search the suitability of the control algal cultures of the toxicity experiments to be used in BC production. Chlorella vulgaris cells were affected by various stress conditions. The relative content of starch decreased during the dark interval to low levels (1.35 ± 0.04 % of DW). Nitrogen starvation made about a 35 % increase in the starch content compared to that of the normal cultivation condition. This can be explained by algae metabolism as described by Scott et al. (2010). The main principle is, if there is not enough N for protein synthesis required for growth, excess carbon from photosynthesis is directed into storage molecules such as triacylglycerol or starch. On the other hand, starch percentage of algae was 5.00 ± 0.08 (DW) for sulfur starvation stress. Nitrogen starvation medium which has the highest yield of starch has been selected to obtain algae-based glucose for fermentation of BC.

Glucose concentration (% DW)

Under the nitrogen starvation conditions, after the hydrolyses of starch, glucose concentrations were given as percentage dry weight (% DW) yielded 10.2 ± 0.2 and 6.6 ± 0.1 for acidic and enzymatic methods, respectively. Results have shown that algae hydrolysate contained high amounts of glucose, and the detected maltose percentage was negligible (data not shown).

Optimal fermentation conditions for BC production

The parameters tested to obtain high yield of BC were summarized in Table 5, all experiments were carried out in triplicate. When FM and HS media were compared in terms of their efficiencies in producing higher yield of BC, FM medium was selected, because the BC yields were 0.620 ± 0.005 and 0.422 ± 0.007 g/L for FM and HS media, respectively. Of the agitated and static incubation, 7-day static incubation resulted in 0.612 ± 0.003 g/L BC, whereas 7-day agitated (shaking at 180 rpm) incubation resulted in 0.176 ± 0.004 g/L BC. Therefore, the static incubation was found to be better for the fermentation of BC.

For BC fermentation, 7-, 14-, and 21-day incubation periods were studied with the static method. The highest BC yield was 0.707 ± 0.002 g/L after 14-day fermentation period. pH was also known as one of the most important parameter for microbial fermentation processes. pH 6 was selected regarding the results of tested pH range (4–7) (Table 5). The effect of pH on BC production is well documented by Lin et al. (2013).

The percentage of glucose in the fermentation medium was also studied. 0.886 ± 0.006 g/L BC was obtained in the presence of 1.0 %(w/v) glucose within the FM medium, and this BC yield increased to 1.207 ± 0.004 g/L with the addition of 0.5 % (v/v) ethanol as a supplementary material. Other supplementary materials such as organic compounds, polymers, and inorganic substances have been applied to influence the assembly and microstructure of BC including the crystallinity, crystalline polymorphism, crystallite size, and ribbon width (Hu et al. 2014).

Finally, the replacement of glucose in FM medium with algae-based glucose gave promising and comparable result regarding the yield of BC. BC yields on dry weight basis were 1.104 ± 0.002 and 1.202 ± 0.005 g/L from algae-based glucose and glucose, respectively.

Scanning electron microscopy

SEM micrographs for BCs produced from glucose (Fig. 1a), and from algae-based glucose (Fig. 1b) by Komagataeibacter hansenii in FM medium were given. SEM images were taken at the same magnification. Fibrillated structure was not visible because of the produced BCs were covered by K.hansenii cells.

Removal of the bacterial cell debris was achieved by NaOH treatment. Hence, after alkaline wash of BCs, three dimensional web-like structures and microfibrils became visible in Fig. 1c, d, BCs from glucose, and algae-based glucose, respectively. Reticulated fibril arrangement with size and density variations can be easily observed by SEM micrographs. Both BC samples showed highly fibrous network-like structures consisting of ultra fine cellulose microfibrils. As seen on Fig. 1d, majority of fibrils of BC produced from algae-based glucose were slightly broader than microfibrils produced from glucose (Fig. 1c). On the other hand, three dimensional web-like structure of BC produced from glucose seemed denser than BC produced with algae-based glucose.

Overall, these micrographs showed algal-based glucose used for BC production from K.hansenii did not alter the major microfibril structures in the BC pellicles.

Fourier transform infrared spectroscopy

FT-IR spectroscopy which allows analysis of molecular composition was employed to detect the occurrence of new peaks or any peak shift that could be attributed to structural differences between BCs obtained from glucose and algae-based glucose. A spectrum of MCC was taken as a reference, and showed peaks at 3328 cm−1 for -OH stretching, 2888 cm−1 for C-H stretching, 1640 cm−1 for H-O-H bending vibration of water molecules, 1157 cm−1 for C-O-C bending which proves the basic cellulose peaks. The FT-IR spectra of MCC and of BCs (synthesized from glucose and algae-based glucose) were shown in Fig. 2.

FT-IR spectra of BC produced with glucose and algae-based glucose represented very similar pattern to MCC with slightly shifting. -OH stretching peak was found as 3346 cm−1 for both produced BCs. The bands for C-H stretching were found as 2902 cm−1, and 2905 cm−1, then H-O-H bending bands were found 1640 cm−1, and 1636 cm−1, for BC samples, respectively. One of the reasons for slight shifts of wavenumbers of spectra could be the bond length differences caused by electronegativity changes of neighbor atom. On the other hand, conjugation could be another reason for peak shifting (Kline 1999, Fan et al. 2012).

The band for C-O-C bending was assigned at 1158 cm−1 that was common for both of the samples’ spectra. The spectral band around 1730 cm−1 in Fig. 2c represents the C=O-stretching vibration which might be caused by the presence of impurities from esters or acids. However, the employment of biorefinery approach can significantly eliminate these impurities.

Conclusion

The use of C. vulgaris as a source of glucose for the production of BC was promising. Bacterial cellulose is an advantageous biomaterial with its unique properties. There is no information regarding the utilization of algae-based glucose for BC production among the variety of biotechnological applications of microalgae in literature. In this sense, a novel and very important biotechnological application of algae is proposed in this study. Accordingly, integrating the use of metabolic components in the algal biomass (e.g., starch, glucose) in BC production with biorefinery concept will lead to have various beneficial aspects, like achieving the goal of large scale production with low cost, having global economic importance and preserving the environment.

References

Bielecki S, Krystynowicz A, Turkiewicz M, Kalinowska H (2005) Bacterial cellulose. Biopolymers Online 5

Branyikova I, Marsalkova B, Doucha J, Branyik T, Bisova K, Zachleder V, Vitova M (2011) Microalgae: novel highly efficient starch producers. Biotechnol Bioeng 108:4

Chawla PR, Bajaj IB, Survase SA, Singhal RS (2009) Microbial cellulose: fermentative production and applications. Food Technol Biotechnol 47(2):107–124

Culture collection of algae and protozoa, Scottish Marine Institute, UK http://www.ccap.ac.uk/media/documents/3N_BBM_V.pdf (accessed 28 December 2013)

Doucha J, Lívanský K (2009) Outdoor open thin-layer microalgal photobioreactor: potential 5 productivity. J Appl Phycol 21:111–117

Douskova I, Doucha J, Livansky K, Machat J, Novak P, Umysova D, Zachleder V, Vitova M (2009) Simultaneous flue gas bioremediation and reduction of microalgal biomass production costs. Appl Microbiol Biotechnol 82:179–185

Dragone G, Fernandes BD, Abreu AP, Vicente AA, Teixeira JA (2011) Nutrient limitation as a strategy for increasing starch accumulation in microalgae. Appl Energy 88:3331–3335

Ertürk MD, Saçan MT (2013) Assessment and modeling of the novel toxicity data set of phenols to Chlorella vulgaris. Ecotoxicol Environ Saf 90:61–68

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. Fourier transform—materials analysis, DrSalih (Ed.), ISBN: 978–953–51-0594-7, InTech. Available from: http://www.intechopen.com/books/fourier-transform-materials-analysis/fourier-transform-infraredspectroscopy-for-natural-fibres (accessed 15 December 2015)

Ha JH, Shah N, Ul-Islam M, Khan T, Park JK (2011) Bacterial cellulose production from a single sugar α-linked glucuronic acid-based oligosaccharide. Process Biochem 46:1717–1723

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. Biochem J 58:345–352

Ho S-H, Huang S-W, Chen C-Y, Hasunuma T, Kondo A, Chang J-S (2013) Characterization and optimization of carbohydrate production from an indigenous microalga Chlorella vulgaris FSP-E. Bioresour Technol 135:157–165

Hu W, Chen S, Yang J, Li Z, Wang H (2014) Functionalized bacterial cellulose derivatives and nanocomposites. Carbohydr Polym 101:1043–1060

Huang Y, Zhu C, Yang J, Nie Y, Chen C, Sun D (2014) Recent advances in bacterial cellulose. Cellulose 21(1):1–30

Indrarti L, Yudianti R (2012) Development of bacterial cellulose/activated carbon composites prepared by in situ and cast-drying methods. Asian Trans Basic Appl Sci 2(5):21–24

Jeon BH, Choi JA, Kim HC, Hwang JH, Abou-Shanab RA, Dempsey BA, Regan JM, Kim JR (2013) Ultrasonic disintegration of microalgal biomass and consequent improvement of bioaccessibility/bioavailability in microbial fermentation. Biotechnol Biofuels 6:37

Katepetch C, Rujiravanit R, Tamura H (2013) Formation of nanocrystalline ZnO particles into bacterial cellulose pellicle by ultrasonic-assisted in situ synthesis. Cellulose 20:1275–1292

Kline MS (1999) Infrared spectroscopy: a key to organic structure, Yale University: Yale-New Haven Teachers Institute, http://www.yale.edu/ynhti/curriculum/units/1999/5/99.05.07.x.html (accessed 16 June 2015)

Krystynowicz A, Czaja W, Wiktorowska-Jezierska A, Gonçalves-Miskiewicz M, Turkiewicz M, Bielecki S (2002) Factors affecting the yield and properties of bacterial cellulose. J Ind Microbiol Biotechnol 29:189–195

Kurniawan H, Ye Y-S, Kuo W-H, Lai J-T, Wang M-J, Liu H-S (2013) Improvement of biofouling resistance on bacterial cellulose membranes. Biochem Eng J 78:138–145

Lammens TM, Franssen MCR, Scott EL, Sanders JPM (2012) Availability of protein-derived amino acids as feedstock for the production of bio-based chemicals. Biomass Bioenergy 44:168–181

Laurens LML, Dempster TA, Jones HDT, Wolfrum EJ, Wychen SV, McAllister JSP, Rencenberger M, Parchert KJ, Gloe LM (2012) Algal biomass constituent analysis: method uncertainties and investigation of the underlying measuring chemistries. Anal Chem 84:1879–1887

Li Y, Tian C, Tian H, Zhang J, He X, Ping W, Lei H (2012) Improvement of bacterial cellulose production by manipulating the metabolic pathways in which ethanol and sodium citrate involved. Appl Microbiol Biotechnol 96:1479–1487

Lin SP, Calvar IL, Catchmark JM, Liu J-R, Demirci A, Cheng K-C (2013) Biosynthesis, production and applications of bacterial cellulose. Cellulose 20:2191–2219

Liu C, Yang D, Wang Y, Shi J, Jiang Z (2012) Fabrication of antimicrobial bacterial cellulose—Ag/AgCl nanocomposite using bacteria as versatile biofactory. J Nanopart Res 14:1084

Lu M, Guan X, Wei D (2011) Removing Cd2+ by composite adsorbent Nano-Fe3O4/bacterial cellulose. Chem Res Chin Univ 27(6):1031–1034

Lu Z, Zhang Y, Chi Y, Xu N, Yao W, Sun B (2011) Effects of alcohols on bacterial cellulose production by Acetobacter xylinum 186. World J Microbiol Biotechnol 27:2281–2285

Mann G, Schlegel M, Schumann R, Sakalauskas A (2009) Biogas-conditioning with microalgae. Agron Res 7:33–38

Mohite BV, Patil SV (2013) A novel biomaterial: bacterial cellulose & its new era applications. Biotechnol Appl Biochem. doi:10.1002/bab.1148

Mondal IH (2013) Mechanism of structure formation of microbial cellulose during nascent stage. Cellulose 20:1073–1088

Priyadarshani I, Rath B (2012) Commercial and industrial applications of micro algae—a review. J Algal Biomass Utilization 3(4):89–100

Rodrigues MA, Silva Bon EP (2011) Evaluation of Chlorella (Chlorophyta) as source of fermentable sugars via cell wall enzymatic hydrolysis. Enzyme Res Article ID 405603:1–5

Safi MC (2013) Microalgae biorefinery: proposition of a fractionation process. L’universite de Toulouse, Doctorat de

Scott SA, Davey MP, Dennis JS, Horst I, Howe CJ, Lea-Smith DJ, Smith AG (2010) Biodiesel from algae: challenges and prospects. Curr Opin Biotechnol 21:277–286. doi:10.1016/j.copbio.2010.03.005

Shah N, Ul-Islam M, Khattak WA, Park JK (2013) Overview of bacterial cellulose composites: a multipurpose advanced material. Carbohydr Polym 98:1585–1598

Sun D, Yang J, Wang X (2010) Bacterial cellulose/TiO2 hybrid nanofibers prepared by the surface hydrolysis method with molecular precision. Nanoscale 2:287–292

Ul-Islam M, Ha JH, Khan T, Park JK (2013) Effects of glucuronic acid oligomers on the production, structure and properties of bacterial cellulose. Carbohydr Polym 92:360–366

Varfolomeev SD, Wasserman LA (2011) Microalgae as source of biofuel, food, fodder, and medicines. Appl Biochem Microbiol 47:789–807

Watanabe K, Hori Y, Tabuchi M, Morinaga Y, Yoshinaga F, Horii F, Sugiyama J, Okano T (1994) Proceedings of ‘94 Cellulose R&D, 1st Annual Meeting of the Cellulose Society of Japan. Cellulose Society of Japan, ed. Tokyo, 45–50

Watanabe K, Tabuchi M, Morinaga Y, Yoshinaga F (1998) Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 5:187–200

Yen HW, Hu IC, Chen CY, Ho SH, Lee DJ, Chang JS (2013) Microalgae-based biorefinery—from biofuels to natural products. Biosour Technol 166–174

Zhong C, Zhang G-C, Liu M, Zheng X-T, Han P-P, Jia S-R (2013) Metabolic flux analysis of Gluconacetobacter xylinus for bacterial cellulose production. Appl Microbiol Biotechnol 97:6189–6199

Zhou LL, Sun DP, Hu LY, Li YW, Yang JZ (2007) Effect of addition of sodium alginate on bacterial cellulose production by Acetobacter xylinum. J Ind Microbiol Biotechnol 34:483–489

Zhu H, Jia S, Yang H, Jia Y, Yan L, Li J (2011) Preparation and application of bacterial cellulose sphere: a novel biomaterial. Biotechnol Biotechnol Equip 25:1

Acknowledgments

The support of this study by the Boğaziçi University Research Fund (No: 8502) is acknowledged. The authors would also like to thank Aziz Akın Denizci and Guldem Utkan for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible editor: Santiago V. Luis

Rights and permissions

About this article

Cite this article

Uzyol, H.K., Saçan, M.T. Bacterial cellulose production by Komagataeibacter hansenii using algae-based glucose. Environ Sci Pollut Res 24, 11154–11162 (2017). https://doi.org/10.1007/s11356-016-7049-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7049-7