Abstract

Immobilization of bacterial cells on suitable substrates is of utmost importance in the secondary treatment of wastewater using fixed-film reactors. Therefore, screening of efficient and cheaper materials for bacterial surface immobilization was carried out. Eleven waste materials were used as substrates, packed in a column, and bacterial surface immobilization was carried out using cow dung slurry/MLSS mixture. All the chosen substrates were screened for bacterial immobilization/biofilm formation by standard bacterial enumeration technique. The substrate with the highest biofilm-forming ability was used for secondary treatment of raw domestic wastewater. The results showed that high-density polyethylene and aluminium foil sheets have poor immobilizing characteristics with 2.2 × 108 and 2.4 × 108 CFU/cm2 respectively, whereas jute fibres were observed to be the most efficient among the substrates with 5.1 × 1023 CFU/cm2. The column packed with jute fibres was used for wastewater treatment. Various physico-chemical parameters were analyzed before and after treatment and there was a significant reduction in major parameters after treatment. The bacteria-immobilized jute fibres showed maximum immobilization potential and were highly efficient in wastewater treatment, and therefore these findings offer immense promise in the synthesis of composite polymers for bacterial immobilization and subsequent secondary treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

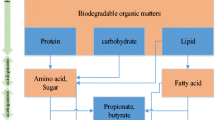

Of the major environmental challenges faced by the urban societies across the globe, large-volume generation of domestic wastewater is a serious issue which can prove to be risky if not treated prior to disposal (De-Bashan and Bashan 2010; Rudenko et al. 2018). In the conventional process train of domestic wastewater treatment, secondary treatment is the sequential treatment of the effluent from the primary treatment, primarily for the removal of residual organics and suspended solids (Sonune and Ghate 2004). Most of such methods for secondary treatment of wastewater use biological systems, which can be categorized into suspended systems and immobilized microbial systems (Nicolella et al. 2000). Numerous advantages have been reported in the literature for the immobilized systems such as increased biomass generation, higher metabolic activity and stronger resistance to process and environmental constraints (Wang et al. 2005; Zhou et al. 2008; Cai et al. 2011; Liu et al. 2012; Malovanyy et al. 2015). From the bioremediation perspective, immobilization can be defined as the entrapment or surface attachment of a wide variety of organisms or enzymes (Lopez et al. 1997). Thus, cell immobilization involves transport of cells from the bulk liquid phase to the surface of support, followed by cell adhesion, and colonization on the support surface (Kilonzo and Bergougnou 2012). Immobilization has been reported to occur by any of the following processes: covalent coupling/cross linking, encapsulation, entrapment and adsorption (Mallick 2002; Halecký and Kozliak 2020). Among the above, adsorption is the simplest method, which is also known as reversible immobilization (Martins et al. 2013; Siddiqui et al. 2020).

The basic principle of adsorption is the physical attraction of microorganisms with the carrier surfaces, which is based on weak forces (Bouabidi et al. 2019). Even though the forces are weak, they are still capable of binding because several of them are involved, including van der Waals forces, ionic and hydrophobic interactions, and hydrogen bonds. A key step in controlling cell immobilization on the support is cell support adhesion, which is governed by both electrostatic and hydrophobic interactions (Górecka and Jastrzębska 2011; Dufrêne 2015). Aggregation of microorganisms on the surface of the solid substrates results in the formation of biofilms. Use of biofilm reactors is very common in wastewater treatment systems, which include trickling filters, high-rate plastic media filters, rotating biological contactors, fluidized bed reactors, airlift reactors, granular filters and membrane-immobilized cell reactors. However, fixed-bed bioreactors include all the treatment systems, which use static media such as plastic profiles, rocks, sponges, granular carriers or membranes for biofilm formation (Lazarova and Manem 2000). In the last few decades, there has been growing interest in the use of immobilized cells in packed bed bioreactors for the treatment of wastewater (Feng et al. 1997; Lupton 2009; Banerjee and Ghoshal 2017).

Therefore, in this study, evaluation of commonly available waste substrates was carried out for efficient biofilm formation with increased cell biomass. All the substrates used for immobilization were already-utilized scrap materials, cheap, robust enough to withstand the flow of wastewater with coarse surfaces, and easily washable and reusable. The substrate with the highest immobilizing ability was used in the secondary treatment of domestic wastewater using the principles of microbial cell immobilization on solid substrates.

Materials and methods

Substrates for immobilization

Not easily-biodegradable and cheaper solid waste materials were used as substrates for biofilm production. Eleven substrates including high-density polyethylene (HDPE), polyethylene terephthalate (PET), coconut shell (CS), waste tyre rubber (WTR), jute fibre mat (JFM), polyvinyl chloride (PVC), broken clay pots (BCP), ceramic tile chips (CTC), wooden chips (WC), aluminium foil sheets (AFS) and polystyrene foam (PF) were collected from a local scrap shop. All the eleven materials were selected because of its easier availability as scrap. Moreover, coarse surface nature and the presence of inert attachment surfaces of the above materials are highly suitable for bacterial immobilization and subsequent biofilm formation (Nerenberg 2016). All the substrates were cut into appropriate sizes (4 × 4 cm2 approximately) so as to fit the column for packing, and used.

Setup of a packed bed reactor (PBR)

A miniature PBR (Fig. 1) was constructed using acrylic tubes, PVC pipes and a PVC dummy. The column had an outlet at the bottom and a sprayer was fixed on top. The dimensions of the column were measured (height = 0.67 m, diameter = 0.09 m, volume = 0.0043 m3) and the volume of the reservoir/feeder tank used was 0.0165 m3. The eleven materials mentioned above (attachment substrates for biofilm) were cut into appropriate sizes (as mentioned earlier) and packed randomly into the column in such a way that all the materials were distributed throughout the column. The outlet of the column was connected to a reservoir/feeder tank containing the effluent/medium/inoculum and a miniature submersible pump with a flow rate of 120 L/h (LPH) was used for recirculation. During recirculation, the medium/effluent was trickled back on to the top of the column, allowing continuous flow and treatment of the sample.

Surface immobilization/biofilm formation

Immobilization was carried out based on the principles of physical adsorption. The PBR column was packed with all the substrate materials, which were placed throughout the entire length of the column. The reservoir/feeder tank was filled with a mixture containing equal volume of 5% fresh cow dung slurry and mixed liquor suspended solids (MLSS). The column was allowed to run with the mix for a week and on the eighth day, 500 mL of rice starch water was added to the inoculum mix as the sole carbon source. For nitrogen and phosphorus sources, urea (250 ppm of N) and diammonium phosphate (DAP) (5 ppm of P), respectively, were added to the mix to enhance the growth and formation of biofilm on the surface of the substrates, following which, the reactor column was allowed to run for 2 days. The carbon, nitrogen and phosphorus concentrations were standardized, the data of which are not shown in this study.

Evaluation of biofilm formation

On day 10, the column was stopped, drained off and total heterotrophic bacterial load on the surface of each of the substrate was determined by plating technique. The substrate materials were taken out from the column with care and lined up on a tray. For sampling, the conventional method of swabbing was used, which involved the use of a sterile cotton swab with an applicator stick for releasing microorganisms from surfaces (Pérez-Rodríguez et al. 2008). The swabs were then immersed into the extracting solution (0.1% sterile peptone water), vortexed, serially diluted in sterile saline and spread plated on to the plates containing standard medium (nutrient agar) for estimating total heterotrophic bacteria. The plates were incubated overnight at 37 °C and the CFU/cm2 of each substrate was calculated.

Secondary treatment of domestic wastewater

Use of PBR column with single substrate

The substrate which showed the maximum immobilizing property in terms of heterotrophic bacterial biomass was packed inside the entire column (Fig. 2). As mentioned earlier, the single-substrate column was also allowed to run with MLSS/cow dung mix for biofilm formation; once the biofilms are established on the substrate by surface immobilization after running for 10 days (standardized based on multi-substrate column study), the column containing active substrate was used for treatment of raw sewage.

Collection of samples

MLSS (used for biofilm formation) sample was procured from the Chennai Metro Water Supply and Sewerage Board (CMWSSB), Sewage Treatment Plant (STP), Koyambedu, Chennai. Raw untreated sewage sample was collected from the Madras Christian College (MCC) farm STP; the source of the effluent was from the entire campus of MCC, including academic and residential blocks.

Treatment

The effluent was allowed to stand for 1 h to allow the sediments/larger flocs to settle down and was run through the column packed with immobilized single substrate for 4 h for secondary treatment. The treatment process was aerobic; sparged column was not used in this study as the column used was miniature in size, the substrates were less densely packed so as to allow natural convection of air, and lastly the wastewater was sprayed to aid the aeration. The treatment time was based on standard retention times employed for most of the biological treatment processes (Pepper et al. 2011). The pre-treated and post-treated effluent samples were analyzed for various physicochemical parameters such as pH, total dissolved solids (TDS), total suspended solids (TSS), alkalinity, hardness, chloride, ammonia, nitrite, nitrate, total kjeldahl nitrogen (TKN), total phosphorus and biochemical oxygen demand (BOD). The analyses protocols followed were according to the Standard Methods for Water and Wastewater Examination (American Public Health Association (APHA) 2005). The results were tested for significant reduction compared to those of untreated effluent.

Statistical analysis

All analyses were performed as experimental triplicates. Mean values of all replicate sets of data are presented with standard deviation values. The one-tailed paired Student’s t test was used to determine statistical significance between the parameters of untreated and treated effluent samples at P < 0.05.

Results

Surface immobilization/biofilm formation

Biofilm formation on all the substrates was observed after running through the mixture of MLSS and cow dung. The immobilized biofilms onto the solid surfaces are shown in Fig. 3. The total number of heterotrophic bacterial CFU per unit area was calculated for each substrate with countable colonies in different dilutions, the values of which are as follows: HDPE: 2.2 × 108 CFU/cm2; PET: 3.8 × 1017 CFU/cm2; CS: 4.6 × 1023 CFU/cm2; WTR: 4.6 × 1017 CFU/cm2.; JFM: 5.1 × 1023 CFU/cm2; PVC: 3.7 × 1023 CFU/cm2; BCP: 3.7 × 1023 CFU/cm2; CTC: 3.2 × 1023 CFU/cm2; WC: 4.7 × 1023 CFU/cm2; AFS: 2.4 × 108 CFU/cm2; PF: 3.6 × 1023 CFU/cm2. The above results were obtained from the multi-substrate column, and the values along with standard deviation are given in Table 1. The substrates such as jute fibre mat, coconut shell, polyvinyl chloride, broken clay pots, ceramic tile chips, wooden chips and polystyrene foam have very good surface immobilization potentials and thus showing high heterotrophic bacterial biomass. High-density polyethylene and aluminium foil sheets showed poor immobilizing characteristics with low heterotrophic bacterial biomass densities. Polyethylene terephthalate and waste tyre rubber showed moderate biofilm forming capabilities. However, among all the substrate materials, jute fibre mat was observed to be the best for immobilization of biofilms. In terms of difference compared to the second best substrate—wooden chips—, jute fibre mat showed 8.5% increase in immobilized heterotrophic bacterial biomass. The percent increase in biomass levels on substrates with high-immobilizing potentials compared to CTC (the substrate showing the lowest CFU/cm2 among the high-immobilizing substrates) is shown in Fig. 4. Likewise, JFM showed 2.3 × 1015 times increase compared to high-density polyethylene, which showed the lowest immobilization potential.

Treatment of domestic wastewater

Biofilm-immobilized jute fibre mat was used for the treatment of raw sewage sample as the substrate showed the highest immobilization characteristics. Table 2 shows the mean values of all the pre- and post-treated physico-chemical parameters of the effluent, which was treated in a single-substrate column. All the major physicochemical parameters showed reduction following treatment. The results from the student’s t test show a P value of < 0.05 for all the significant parameters. The significant difference indicates that results are statistically significant and shows only a 2% chance of error in the sample being tested if the null hypothesis was actually true. The percentage reduction between the parameters of the treated and the raw untreated sample is shown in Table 3.

Discussion

In wastewater treatment, technologies that depend on immobilized system have several advantages over those with the suspended system. They are highly cost effective as the immobilized microbial systems can be used several times without any significant loss of activity (Devi and Sridhar 2000; Nzila et al. 2016). Moreover, there is no need to replenish biocatalysts as immobilized biofilms can be used in continuous and semi-continuous production processes (Mrudula and Shyam 2012; Tikhomirova et al. 2018). Apart from the above, the other benefits are operational stability and flexibility, ease of handling, smaller space needs, minimal retention times, resistance to environmental changes, higher biomass concentration, enhanced uptake rate, increased ability to degrade recalcitrant compounds and lesser sludge production (Kourkoutas et al. 2004).

In the present study, waste substrates were used that are cheap and readily available in the urban society. However, the substrates were chosen from different groups of materials including the synthetic and natural ones. Moreover, the materials used in the study had coarse surface nature with inert attachment surfaces, which are highly suitable for biofilm formation and subsequent wastewater treatment (Nerenberg 2016). Jute fibre mat was found to be the most efficient substrate for immobilization of bacteria and formation of biofilms. It is due to the reason that fibrous matrices provide adequate supporting surfaces for cell adsorption (Talabardon et al. 2000; Chu et al. 2009). The natural fibres such as jute possess high specific surface area, void volume, mechanical permeability, less toxicity, low cost and high availability (Huang and Yang 1998; Saleem et al. 2020). Therefore trapping of cells occurs more naturally than other materials (Yang and Lo 1998). In addition, the JFM was also rigid with its integrity intact even after several weeks of running the reactor. Among fixed-film reactors, very commonly used technologies like rotating biological contactor (RBC) are very effective for moderate-scale treatment plants. These reactors use materials such as polyethylene and expanded polystyrene for constructing the immobilized surfaces (Antonie 2018). Based on the results obtained in this study, it can be suggested that the sturdiness of the plastics and the efficiency of natural fibrous materials can be combined to synthesize fibre-reinforced polymers. Although many fibre-reinforced polymers including jute fibre-reinforced polymers are in use, not many studies have been conducted in waste treatment systems. Further studies are warranted on pilot-scale studies involving novel composite polymers.

Mixed liquor suspended solids (MLSS) was used for bacterial immobilization as it consists of mostly of microorganisms in the active state, which thus ensures that there is sufficient quantity of active biomass available for biofilm formation (Pepper et al. 2011). Cow dung was mixed with MLSS as it contains partially digested high fibre thus making the MLSS thick and increases the efficiency of immobilization on the surface of the substrates. Moreover, biofilm formation happened at an increased rate due to supplementation of carbon, nitrogen and phosphorus sources along with cow dung, which also lots of microbial populations and certain nutritive value (Akpomie Olubunmi and Ejechi Bernard 2016). For enumeration of total bacteria on the immobilized surfaces, many methods have been recommended, but in this study, swab method was used. It is an easy to perform, inexpensive and highly reliable technique. Enhanced microbial recovery is achieved by dipping the swab in sterile diluent prior to swabbing under sterile conditions (Pérez-Rodríguez et al. 2008).

With regard to sewage treatment, aerobic processes always have an advantage of rapid treatment rates and higher treatment efficiency (Pronk et al. 2015). Thus the flow rate set was adequate enough to have sufficient sloughing of the biomass to ensure efficient aerobic treatment. There was a significant reduction in most of the parameters and the reduction pattern, particularly for BOD, nitrate, phosphorus and TKN, is in line with treatment efficiency of domestic wastewater using immobilized systems (Pepper et al. 2011). Increase in pH might be due to the changes in carbon dioxide, carbonate–bicarbonate equilibrium caused by closed and compact physicochemical conditions (Dickson 2010). Enormous reduction in nitrate levels was observed in the treated effluent which may be due to nitrate assimilation, nitrate respiration, and nitrate dissimilation (Pepper et al. 2011). Total dissolved solids (TDS) is a measure of the combined content of all the contaminants and in this study, TDS seems to have reduced because of the reduction of other parameters. Results also show a significant increase in alkalinity, which may be attributed to the presence of sulfate-reducing organisms, which in the presence of organic matter reduce sulfate thereby increasing alkalinity of wastewater (Ayangbenro et al. 2018).

Conclusion

From this study, it can be concluded that search for a better attachment substrate for surface immobilization of microorganisms is inevitable. Development of novel synthetic and composite substrates is essential to improve the bioremediation rate, both in the construction of fixed-film reactors and also in the development of integrated reactors, which use both suspended and immobilized systems. Further research is warranted to use natural fibrous substances in the making of composite carrier-immobilized systems.

References

Akpomie Olubunmi O, Ejechi Bernard O (2016) Bioremediation of soil contaminated with tannery effluent by combined treatment with cow dung and microorganisms isolated from tannery effluent. J Bioremediat Biodegrad 7(4):1–5

Antonie RL (2018) Fixed biological surfaces-wastewater treatment: the rotating biological contactor. CRC Press, Boca Raton

American Public Health Association (APHA) (2005) Manual standard methods for the examination of water and wastewater, 21st edn. AWWA, WPCF, Washington, DC

Ayangbenro AS, Olanrewaju OS, Babalola OO (2018) Sulfate-reducing bacteria as an effective tool for sustainable acid mine bioremediation. Front Microbiol 9:1986

Banerjee A, Ghoshal AK (2017) Biodegradation of an actual petroleum wastewater in a packed bed reactor by an immobilized biomass of Bacillus cereus. J Environ Chem Eng 5(2):1696–1702

Bouabidi ZB, El-Naas MH, Zhang Z (2019) Immobilization of microbial cells for the biotreatment of wastewater: a review. Environ Chem Lett 17(1):241–257

Cai T, Chen L, Ren Q, Cai S, Zhang J (2011) The biodegradation pathway of triethylamine and its biodegradation by immobilized Arthrobacter protophormiae cells. J Hazard Mater 186:59–66

Chu YF, Hsu CH, Pavan KS, Lo YM (2009) Immobilization of bioluminescent Escherichia coli cells using natural and artificial fibers treated with polyethylenimine. Bioresour Technol 100:3167–3174

De-Bashan LE, Bashan Y (2010) Immobilized microalgae for removing pollutants: review of practical aspects. Bioresour Technol 101(6):1611–1627

Devi S, Sridhar P (2000) Production of cephamycin C in repeated batch operations from immobilized Streptomyces clavuligerus. Proc Biochem 36:225–231

Dickson AG (2010) The carbon dioxide system in seawater: equilibrium chemistry and measurements. In: Riebesell U (ed) Guide to best practices for ocean acidification research and data reporting. Office of the European Union, Washington, DC, pp 17–40

Dufrêne YF (2015) Sticky microbes: forces in microbial cell adhesion. Trends Microbiol 23(6):376–382

Feng Y, Racke KD, Bollag JM (1997) Use of immobilized bacteria to treat industrial wastewater containing a chlorinated pyridinol. Appl Microbiol Biotechnol 47:73–77

Górecka E, Jastrzębska M (2011) Immobilization techniques and biopolymer carriers. Biotechnol Food Sci 75:65–86

Halecký M, Kozliak E (2020) Modern bioremediation approaches: use of biosurfactants, emulsifiers, enzymes, biopesticides, GMOs. In: Filip J, Cajthaml T, Najmanová P, Černík M, Zbořil R (eds) Advanced nano-bio technologies for water and soil treatment. Springer, Cham, pp 495–526

Huang Y, Yang ST (1998) Acetate production from whey lactose using coimmobilized cells of homolactic and homoacetic bacteria in a fibrous-bed bioreactor. Biotechnol Bioeng 60:498–507

Kilonzo P, Bergougnou M (2012) Surface modifications for controlled and optimized cell immobilization by adsorption: applications in fibrous bed bioreactors containing recombinant cells. J Microbial Biochem Technol 4:22–30

Kourkoutas Y, Bekatorou A, Banat IM, Marchant R, Koutinas AA (2004) Immobilization technologies and support materials suitable in alcohol beverages production: a review. Food Microbiol 21(4):377–397

Lazarova V, Manem J (2000) Innovative biofilm treatment technologies for water and wastewater treatment. In: Bryers JD (ed) Biofilms II: process analysis and applications. Wiley, New York, pp 159–206

Liu H, Guo L, Liao S, Wang G (2012) Reutilization of immobilized fungus Rhizopus sp. LG04 to reduce toxic chromate. J Appl Microbiol 112:651–659

Lopez A, Lazaro N, Marques AM (1997) The interphase technique: a simple method of cell immobilization in gel-beads. J Microbiol Methods 30:231–234

Lupton FS (2009) U.S. patent no. 7,582,474. U.S. Patent and Trademark Office, Washington, DC

Mallick N (2002) Biotechnological potential of immobilized algae for wastewater N, P and metal removal: a review. Biometals 15:377–390

Malovanyy A, Trela J, Plaza E (2015) Mainstream wastewater treatment in integrated fixed film activated sludge (IFAS) reactor by partial nitritation/anammox process. Bioresour technol 198:478–487

Martins SCS, Martins CM, Fiúza LMCG, Santaella ST (2013) Immobilization of microbial cells: a promising tool for treatment of toxic pollutants in industrial wastewater. Afr J Biotechnol 12(28):4412–4418

Mrudula S, Shyam N (2012) Immobilization of Bacillus megaterium MTCC 2444 by Ca-alginate entrapment method for enhanced alkaline protease production. Braz Arch Biol Technol 55:135–144

Nerenberg R (2016) The membrane-biofilm reactor (MBfR) as a counter-diffusional biofilm process. Curr Opin Biotech 38:131–136

Nicolella C, Van Loosdrecht MCM, Heijnen JJ (2000) Wastewater treatment with particulate biofilm reactors. J Biotechnol 80:1–33

Nzila A, Razzak SA, Zhu J (2016) Bioaugmentation: an emerging strategy of industrial wastewater treatment for reuse and discharge. Int J Environ Res Public Health 13(9):846

Pepper IL, Gerba CP, Gentry TJ, Maier RM (2011) Environmental microbiology. Academic Press, Cambridge

Pérez-Rodríguez F, Valero A, Carrasco E, García RM, Zurera G (2008) Understanding and modelling bacterial transfer to foods: a review. Trends Food Sci Technol 19:131–144

Pronk M, De Kreuk MK, De Bruin B, Kamminga P, Kleerebezem RV, Van Loosdrecht MCM (2015) Full scale performance of the aerobic granular sludge process for sewage treatment. Water Res 84:207–217

Rudenko RR, Vasilevich EE, Zhdanova GO, Chizhick KI, Topchiy IA, Stom DI (2018) The use of urban sewage sludge as a substrate in a microbial fuel cell. Int J Eng 7:277–280

Saleem MH, Ali S, Rehman M, Hasanuzzaman M, Rizwan M, Irshad S, Shafiq F, Iqbal M, Alharbi BM, Alnusaire TS, Qari SH (2020) Jute: a potential candidate for phytoremediation of metals: a review. Plants 9(2):258

Siddiqui MF, Singh L, Maqbool F, Rahman Z, Rehman A, Adnan F, Qayyum S, Khan A (2020) Microbial biofilm cell systems for remediation of wastewaters. In: Hakeem KR, Bhat RA, Qadri H (eds) Bioremediation and biotechnology. Springer, Cham, pp 293–303

Sonune A, Ghate R (2004) Developments in wastewater treatment methods. Desalination 167:55–63

Talabardon M, Scwitzguelbel JP, Peringer P, Yang ST (2000) Acetic acid production from lactose by anaerobic thermophilic coculture immobilized in a fibrous-bed bioreactor. Biotechnol Prog 16:1008–1017

Tikhomirova TS, Taraskevich MS, Ponomarenko OV (2018) The role of laboratory-scale bioreactors at the semi-continuous and continuous microbiological and biotechnological processes. Appl Microbiol Biot 102(17):7293–7308

Wang L, Ridgway D, Gu T, Moo-Young M (2005) Bioprocessing strategies to improve heterologous protein production in filamentous fungal fermentations. Biotechnol Adv 23:115–129

Yang ST, Lo YM (1998) Production of cell-free xanthan gum fermentation broth by cell adsorption on fibers. Biotechnol Prog 14:259–264

Zhou L, Guiying L, Taicheng A, Jiamo F, Guoying S (2008) Recent patents on immobilized microorganism technology and its engineering application in wastewater treatment. Rec Pat Eng 2(1):28–35

Acknowledgements

We express our sincere thanks to the management of Madras Christian College for providing us with the necessary facilities and infrastructure. We also thank the CMWSSB officials for helping us by providing the MLSS for the study.

Funding

This is a self-supported study.

Author information

Authors and Affiliations

Contributions

SZ performed research, analyzed data, and wrote, reviewed and edited the paper. TSK performed research, and reviewed and edited the paper; NM performed research, and reviewed and edited the paper; and PHR designed the study, performed research, analyzed data and validated the findings, supervised research, and wrote, reviewed and edited the paper.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflict of interest among the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zimba, S., Kumar, T.S., Mohan, N. et al. Evaluation of various waste substrates for biofilm formation and subsequent use in aerobic packed-bed reactor for secondary treatment of domestic wastewater. World J Microbiol Biotechnol 37, 25 (2021). https://doi.org/10.1007/s11274-020-02992-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-020-02992-2