Abstract

Aspergillus carbonarius exhibits excellent abilities to utilize a wide range of carbon sources and to produce various organic acids. In this study, wheat straw hydrolysate containing high concentrations of glucose and xylose was used for organic acid production by A. carbonarius. The results indicated that A. carbonarius efficiently co-consumed glucose and xylose and produced various types of organic acids in hydrolysate adjusted to pH 7. The inhibitor tolerance of A. carbonarius to the hydrolysate at different pH values was investigated and compared using spores and recycled mycelia. This comparison showed a slight difference in the inhibitor tolerance of the spores and the recycled mycelia based on their growth patterns. Moreover, the wild-type and a glucose oxidase deficient (Δgox) mutant were compared for their abilities to produce organic acids using the hydrolysate and a defined medium. The two strains showed a different pattern of organic acid production in the hydrolysate where the Δgox mutant produced more oxalic acid but less citric acid than the wild-type, which was different from the results obtained in the defined medium This study demonstrates the feasibility of using lignocellulosic biomass for the organic acid production by A. carbonarius.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For the past decades, lignocellulosic biomass has received extensive research attention as renewable raw materials for the production of varieties of fuels and chemicals. The abundance of lignocellulosic biomass on the earth reveals the potential as industrial precursors for the production of commodity chemicals. The advantages of using lignocellulosic biomass, compared with other raw materials obtained from crude oil or edible food crops, are demonstrated from different points of view including environmental sustainability, low greenhouse gas emission, food security and planting cost (Nanda et al. 2015). With the developments in the technologies of pretreatment and saccharification, the sugars originally existing in the lignocellulosic biomass in the form of polysaccharides can be degraded and eventually released as fermentable sugars for downstream processes. So far, a significant amount of efforts have been focused on utilizing the lignocellulosic biomass in the bioconversion processes based on microbial systems for varieties of products, especially biofuels (Dionisi et al. 2015; Elkins et al. 2010; Quevedo-Hidalgo et al. 2013; Soo et al. 2015). However, the inhibitory effects resulting from the inhibitory compounds (e.g. acetic acid, furfural and 5-hydroxymethylfurfural), which are mainly generated by the side reactions during the biomass pretreatment, remain an issue for microbial growth (Jönsson et al. 2013; Sakai et al. 2007; Zha et al. 2014). Besides, the efficiency of utilizing both hexoses and pentoses in the cultivation is considered as another important criterion for selecting appropriate industrial strains, for example, the commonly used yeast for bioethanol production, Saccharomyces cerevisiae, is incapable of metabolizing pentoses unless genetically engineered. Among the studied microorganisms, filamentous fungi have raised research interest due to their abilities to utilize a wide range of carbon sources and to naturally excrete various products, especially organic acids (Liaud et al. 2014; Magnuson and Lasure 2004). Fungal organic acid production has an important status in the commodity chemicals of industrial biotechnology. A number of organic acids are currently produced via biological processes employing filamentous fungi, such as the production of citric acid and gluconic acid by Aspergillus niger, itaconic acid production by Aspergillus terrus and kojic acid production by Aspergillus oryzae (Lu et al. 2015; Show et al. 2015; Okabe et al. 2009; Mohamad et al. 2010). The expanding market of organic acids, which arises from their wide applications as food additives, pharmaceuticals, detergents and so on, leads to an increasing demand of raw materials in the industry. Therefore, the industrial production of organic acids in conjunction with utilization of lignocellulosic biomass becomes an inevitable trend in the future.

Aspergillus, as the well-known industrial workhorses for organic acid production, has been the most widely-studied fungal genus over a period of decades. Many attempts have been made on the bioconversion of different types of raw materials to organic acids in Aspergillus species. Various lignocellulosic biomass, especially agro-industrial residues like cassava bagasse, coffee husk, sugar cane bagasse and wheat straw, have been investigated for their potential as substrates for organic acid production by Aspergilli (Pandey and Soccol 1998; Saber et al. 2010; Show et al. 2015; Mondala 2015). Theoretically, the most economically feasible process of using lignocellulosic biomass for fungal organic acid production is to grow fungi in the culture where fungi can secrete the enzymes to degrade the biomass and use the released sugars simultaneously for organic acid production. However, the slow degradation of lignocellulosic biomass cannot fulfill the sugar demand by fungi during the production phase. Therefore, the separate processes of saccharification from fermentation, in which high concentration of fermentable sugars are obtained from efficient hydrolysis, may be more suitable for organic acid production. In this study, we selected Aspergillus carbonarius, which was previously reported for its capabilities of producing organic acids from various types of carbon sources including glucose, xylose, sucrose and galactose (Weyda et al. 2014; Ghareib 1987; Yang et al. 2014a; Linde et al. 2014), to investigate its production of organic acids in a wheat straw hydrolysate. A. carbonarius is cultivated in static culture which has lower sensitivity to trace metals and better aeration than submerged culture in shake flasks (Darouneh et al. 2009). For investigation of inhibitor tolerance, fungal mycelia were recycled for organic acid production in the hydrolysate and compared with direct spore inoculation. In addition, an engineered strain devoid of glucose oxidase (Yang et al. 2014a) was used in a comparative study with the wild-type to examine the impacts of eliminating the extracellular conversion of glucose into gluconic acid on the production of other organic acids from the hydrolysate.

Materials and methods

Strains and culture media

A. carbonarius wild-type strain ITEM 5010 (ATCC® MYA-4641™) and a previously constructed Δgox mutant were employed in this study (Yang et al. 2014a). For preparation of spore suspensions, strains were grown in potato dextrose agar (PDA) medium at 30 °C for 5 days. For organic acid production, the defined medium contained: glucose, 70 g/L; xylose, 58 g/L, NH3NO4, 2.5 g/L; KH2PO4, 2.5 g/L; MgSO4·7H2O, 0.25 g/L; ZnSO4, 0.00062 g/L; CuSO4, 0.00015 g/L; FeSO4·7H2O, 0.0065 g/L, and the initial pH in the defined medium was adjusted to 7. The wheat straw hydrolysate used in this study was provided by Biogasol®, Denmark. The pretreatment and hydrolysis of wheat straw was carried out by Biogasol®, Denmark under the conditions described previously by Baroi et al. (2015). The composition of the liquid fraction of the wheat straw hydrolysate (Table 1) was determined in the same procedure as previously described (Baroi et al. 2015), and the liquid fraction of wheat straw hydrolysate for fungal culture was prepared as follows: the wheat straw hydrolysate was centrifuged at 10,000 rpm for 20 min, and the liquid fraction of the wheat straw hydrolysate was collected and filtered through filter paper Whatman® no. 42 to remove the remaining particles in the liquid; the filtrate was supplemented with the same amounts of nutrients (except glucose and xylose) for organic acid production as mentioned in the defined medium. The original pH value in the prepared hydrolysate was approx. 5. For organic acid production, the initial pH values were adjusted to 3 and 7 by adding 10 M HCl and NaOH powder, respectively. After pH adjustment, the hydrolysate was sterilized with 0.2 μM sterile filter (Nalgene®) and used immediately for fungal cultivation.

Organic acid production

The spores were harvested from the PDA medium with 5 mL sterile water, and the spore suspension was collected and filtered through the Mira-cloth for removal of excess mycelia. For the direct spore inoculation, the spores were inoculated into 50 mL liquid media (the hydrolysate or the defined medium) in 250 mL Erlenmeyer flasks at the final concentration of 5 × 104/mL, and the flasks were incubated stationary at 30 °C. For the cultivation with mycelia-recycling in the hydrolysate, the spores were inoculated into 50 mL hydrolysate (pH 7) in 250 mL Erlenmeyer flasks at the same concentration as described above. After 10 days stationary cultivation at 30 °C, cultivation broth under the mat-like mycelia was removed from the flasks. The fresh hydrolysate (50 mL) was added into the flask under the grown mycelia. The flasks were incubated stationary at 30 °C. All the cultivations in this study were carried out in triplicates.

Analysis

The samples were taken from the cultivation broth after gently shaking the flasks, and then filtered through 0.45 μM filters for the following analysis. HPLC analysis for sugars and organic acids were carried out in an Aminex 87H column (Biorad®) at 60 °C by using HPLC mobile phase (5 mM H2SO4) at a flow rate of 0.6 mL/min. The concentration of gluconic acid was measured using a D-gluconate kit and following the protocol provided by the supplier (Megazyme®).

Fungal biomass measurement

The fungal cultures were filtered through filter paper followed by a thoroughly washing step with distilled water until pH reached 6.0. The washed fungal cells on the filter paper were dried at 100 °C for 48 h before weighing. The filter paper was dried at 100 °C for 48 h before use.

Results

Morphology of A. carbonarius in static culture

The wild-type was grown in the hydrolysate for organic acid production with initial pH adjusted to three different values (3, 5 and 7). The cultivation was carried out stationary in 250 mL Erlenmeyer flasks at 30 °C. The spores that were inoculated to the hydrolysate with initial pH values of 3 and 5 remained dormant throughout the cultivation. In the hydrolysate with initial pH adjusted to 7, the germination of spores was observed on day 2, and the mycelial growth became visible on the surface of the hydrolysate from day 3. On day 5, mat-like mycelia had formed on the surface of the hydrolysate. On day 7, intensive sporulation was observed on the top of the mycelia (Fig. 1a–c).

Organic acid production by A. carbonarius wild-type from the hydrolysate

The initial concentrations of measured compounds in the hydrolysate are shown in Table 1. In the hydrolysate with initial pH 7, furfural was depleted by the wild-type after 2 days cultivation, and a significant decrease in the concentrations of acetic acid and glucose was observed from day 3 (Fig. 2a, b). Acetic acid was depleted very rapidly by day 5 (Fig. 2b). The glucose consumption increased dramatically from day 4 and approx. 90 % of glucose was consumed from day 4 to day 7. Xylose was also consumed by the wild-type from day 5 while there was still plenty of glucose left in the hydrolysate. However, the consumption of xylose was slower than that of glucose and in total, 30 g/L xylose was consumed by the wild-type after 10 days cultivation (Fig. 2a). In the hydrolysate with initial pH values at 3 and 5, no sugar consumption was observed by the end of the cultivation, which was also in consistency with the morphological observations (Fig. 2c).

Cultivation of A. carbonarius wild-type in the hydrolysate with initial pH 7 a sugar consumption and organic acid production, b conversion of detected inhibitors, c total sugar consumption at three pH values after 10 days (data shown are mean values from triplicates with error bars indicating the standard deviation)

The production of organic acids was therefore observed only in the hydrolysate with initial pH 7. From day 3, gluconic acid was produced by A. carbonarius prior to other organic acids. The concentration of gluconic acid increased rapidly to 19.8 g/L until day 4 and remained at this value for the rest of the cultivation (Fig. 2a). Citric acid and oxalic acid were detected at concentrations of 1.9 and 2.1 g/L respectively on day 4. From day 6, the production of citric acid and oxalic acid slowed down significantly and reached 12.6 and 6.5 g/L after 10 days, respectively (Fig. 2a). The wild-type consumed xylose from day 5 to day 10. However, the utilization of xylose did not result in a further increase in the concentration of any organic acid after day 7 when the glucose was depleted. The pH value changed in full compliance with the organic acid production obtained during the cultivation. The cultivation pH decreased gradually from day 3 and reached approx. 3 on day 5 (Fig. 2b). No further decrease in culture pH was observed after day 5.

Recycling fungal mycelia for organic acid production from the hydrolysate

Mat-like mycelia obtained from the first batch cultivation for 10 days in the hydrolysate with initial pH 7 was used in the following cultivation. After fresh hydrolysate with three different pH values (3, 5 and 7) was added into the second batch cultivation, respectively, recycled mycelia floated on the surface of the culture. In the hydrolysate with initial pH 3, neither fungal growth nor sugar consumption was observed by the end of the cultivation (Fig. 3c). Oppositely, both sugar consumption and organic acid production were obtained in the hydrolysate with initial pH 5 and 7, but the fungal biomass only increased significantly in the hydrolysate with initial pH 7 (Fig. 3d). Rapid glucose consumption was observed in the hydrolysate with initial pH 5 and 7 on day 1. However, there was no further glucose consumption in the hydrolysate with initial pH 5. In the hydrolysate with initial pH 7, glucose consumption slowed down from day 2 to day 4, and the recycled mycelia consumed only 4.2 g/L glucose during this period. After day 4, the recycled mycelia utilized glucose more rapidly, and 58.2 g/L glucose was consumed by day 10 (Fig. 3a). Acetic acid and furfural were depleted before day 4, and 25.8 g/L xylose was also consumed simultaneously with glucose by the recycled mycelia (Fig. 3a–c).

Cultivation of recycled mycelia in the hydrolysate at three pH values a sugar consumption and organic acid production in the hydrolysate at pH 7, b conversion of detected inhibitors and cultivation pH in the hydrolysate at pH 7, c total sugar consumption and gluconic acid production at three pH values after 10 days of cultivation, d comparison of fungal biomass between two batch cultivations at three pH values (data shown are mean values from triplicates with error bars indicating the standard deviation)

For organic acid production, gluconic acid production emerged after 1 day from the hydrolysate with initial pH 7. The recycled mycelia produced 10.5 g/L gluconic acid during the first day, but the concentration of gluconic acid only reached 13.5 g/L after 10 days cultivation (Fig. 3a). The production of oxalic acid and citric acid began from day 3, and reached 4.6 and 3.9 g/L respectively on day 6 (Fig. 3a). After day 6, there was no further increase in either citric acid or oxalic acid production. Meanwhile, the cultivation pH decreased from 7 to 5.5 after 1 day and remained at this level until day 3. The final cultivation pH reached 3 from day 6 until the end of the cultivation (Fig. 3b). In the hydrolysate with initial pH 5, pH decreased from 5 to 4.5 after 1 day and remained at this level for the rest of the cultivation. In total, 8.4 g/L gluconic acid was produced by the recycled mycelia (Fig. 3c).

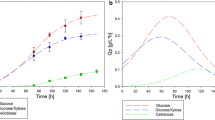

Comparison of organic acid production between the wild-type and Δgox mutant

The organic acid production by the Δgox mutant and the wild-type were compared during cultivation for 10 days in the hydrolysate with initial pH 7 and in the defined medium mimicking the concentrations of glucose and xylose in the hydrolysate. In the defined medium, only slight differences in the production of organic acids were observed between the Δgox mutant and the wild-type (Table 2). Both the wild-type and the Δgox mutant lowered the pH from 7 to 2.5 within 3 days after inoculation, and co-consumption of xylose and glucose was observed in both of the strains. After 10 days, glucose and xylose were almost depleted (Fig. 4a, b).

In the hydrolysate adjusted to pH 7, both the wild-type and the Δgox mutant consumed sugars and converted acetic acid and furfural in the same way (Fig. 5a, b). Furfural and acetic acid were depleted within the first three days before the utilization of sugars started. The organic acid production profile in the hydrolysate was different from the profile in the defined medium (Table 3). The maximum titers of organic acids were already reached after day 5 for the Δgox mutant and after day 6 for the wild-type until day 10 where the experiment stopped (Fig. 5c, d). Probably due to the elimination of gluconic acid production in the Δgox mutant, the pH decreased more slowly in the hydrolysate with the Δgox mutant than the wild-type during the cultivation (Fig. 5e). Although the pH started decreasing in both of the cultures from day 3, the pH level was lowered to 3 in the culture with the wild-type on day 6 while it was still 3.5 in the culture with the Δgox mutant. The wild-type consumed glucose more rapidly than the Δgox mutant. However, the utilization of sugars (glucose and xylose) slowed down dramatically in both the wild-type and the Δgox mutant after day 6. Then no further increase in organic acid production was observed in the two strains.

Cultivation of the wild-type and the Δgox mutant in the hydrolysate at pH 7 a sugar consumption and the conversion of acetic acid by the wild-type, b sugar consumption and the conversion of acetic acid by Δgox mutant, c organic acid production by the wild-type, d organic acid production by the Δgox mutant, e cultivation pH (data shown are mean values from triplicates with error bars indicating the standard deviation)

Discussion

The abilities to utilize varieties of carbon sources for organic acid production (e.g. citric acid and fumaric acid) have been demonstrated with a number of filamentous fungi (Meng et al. 2014; Mondala 2015; Xu et al. 2010; Yang et al. 2014b). However, the efficiency of sugar utilization varies among different species. In this study, utilization of sugars from lignocellulosic biomass was investigated in A. carbonarius using a wheat straw hydrolysate and a defined medium with the same concentrations of glucose and xylose as in the hydrolysate. The results showed that A. carbonarius consumed glucose and xylose simultaneously during the cultivation, especially when it was grown in the defined medium. An efficient co-consumption of glucose and xylose was obtained during the production phase of cultivation in the defined medium, and the consumption of xylose was only slightly lower than glucose. When the wild-type was grown in the hydrolysate, co-consumption of glucose and xylose was also obtained but the consumption of xylose was slower than that in the defined medium. In some microorganisms, the presence of glucose can repress the utilization of pentose sugars in the culture containing both glucose and pentose (Colabardini et al. 2014; Ronne 1995; Subtil and Boles 2012), for example, A. niger and Saccharomycopsis lipolytica have been studied for their citric acid production in a defined medium containing both glucose and xylose, and the consumption of xylose was very low compared with glucose (Maddox et al. 1985). The rapid consumption of glucose by A. carbonarius wild-type in the hydrolysate partially resulted from the conversion of glucose to gluconic acid. Therefore, the consumption of glucose by the wild-type was faster than the xylose consumption in the hydrolysate, which differed from the sugar consumption obtained in the defined medium. Consumptions of glucose and xylose by the Δgox mutant in the hydrolysate were more similar, which might be a result of the deletion of the gluconic acid producing pathway. The efficient co-utilization of glucose and xylose in the hydrolysate indicates the potential for applying A. carbonarius to organic acid production from lignocellulosic biomass.

For microorganisms, one of the challenges in utilization of lignocellulosic hydrolysate is the microbial growth inhibition resulting from the different inhibitory compounds which are generated mainly from the biomass pretreatment. Although the microbial resistance to various types of inhibitors varies among species, there are some well-known inhibitors in lignocellulosic hydrolysates such as furfural, 5-hydroxymethylfurfural and acetic acid (Jönsson et al. 2013; Zha et al. 2014). To study the inhibitor tolerance by A. carbonarius in the hydrolysate, the initial cultivation pH was adjusted to three different values. The original pH in the hydrolysate was 5 which is the optimal pH for the enzymatic hydrolysis. A lower pH value of 3 was also chosen because it is the optimal initial pH for A. carbonarius to accumulate high amount of citric acid (Linde et al. 2014). However, no fungal growth was observed during the cultivation when the initial pH was adjusted to those two values. The inhibitory effect seemed to occur in the early phase of the cultivation as the fungal spores remained dormant. Based on the composition analysis of the hydrolysate, acetic acid was present at relatively high concentration compared to other known inhibitors (e.g. furfural). The presence of acetic acid especially in the undissociated form can lead to toxic effects on microbial growth, especially on spore germination. In A. niger, acetic acid can strongly inhibit the spore germination at low concentration (Fencl and Leopold 1959). A similar inhibitory effect of acetic acid on A. carbonarius was found in the defined media containing the same concentration of acetic acid as that measured in the hydrolysate (Table S1). An approach to eliminate this inhibitory effect is to convert acetic acid into the dissociated form by increasing cultivation pH. Addition of alkali is also considered an efficient detoxification method for lignocellulosic hydrolysates. It can decrease the furan aldehydes and phenols in the hydrolysate when the cultivation pH is increased above 9 (Jönsson et al. 2013; Martinez et al. 2001; Millati et al. 2002). In the hydrolysate with initial pH 7, the germination of spores started from day 2 followed by a rapid depletion of acetate, as well as furfural, indicating that the increased pH value can eliminate the inhibition on spores germination, and A. carbonarius is able to consume acetate and furfural. When the fungal mycelia from the first batch cultivation were recycled and used directly in the following cultivation, an inhibition on fungal growth was observed at the same pH values as in the first batch cultivation. At pH 3, there was still no fungal growth or glucose consumption during the cultivation, whereas at pH 5, glucose consumption occurred on day 1 mainly due to the conversion of glucose into the gluconic acid production. Fungal growth was observed only in the hydrolysate at pH 7, and the consumption of glucose and the conversion of acetic acid emerged in the recycled mycelia on day 1, which was earlier than that observed in the first batch cultivation. However, the conversion of acetic acid slowed down after day 1 while the pH value decreased from 7 to 5.5 during the cultivation. One possible explanation for this phenomenon is that the decreased pH value in the hydrolysate will lead to an increased concentration of undissociated acetic acid which can also inhibit the growth of pre-grown fungal cells as previously reported in A. niger (Taniguchik et al. 1977). The comparison of growth patterns between the cultivation with the spore inoculation and the recycled mycelia reveals that the inhibitory effects on the growth of A. carbonarius occur in both phases of spore germination and mycelial growth.

The organic acid production by A. carbonarius was strongly influenced by the pH in the hydrolysate. When the wild-type was grown in the hydrolysate adjusted to pH 7, gluconic acid was produced prior to other organic acids after day 2 in response to the high glucose concentration. Normally, A. carbonarius decreases cultivation pH rapidly in the defined medium omitting additional pH maintenance, and low cultivation pH can significantly inhibit the gluconic acid production. However, the buffering capacity of hydrolysate slowed down the pH decrease in the hydrolysate. A shift from production of gluconic acid to oxalic acid and citric acid could clearly be observed along with the pH decrease in the hydrolysate. After the cultivation pH reached 3, citric acid was produced as the main organic acid until the glucose was exhausted in the hydrolysate. In contrast, when the wild-type was grown in the defined medium, the cultivation pH decreased to 2.5 within 3 days, which significantly inhibited the production of gluconic acid and oxalic acid, and citric acid accumulated as the main organic acid. When the fungal mycelia were recycled for the organic acid production in the hydrolysate with initial pH 7, the pattern of organic acid production was similar to that observed in the first batch cultivation. A. carbonarius produced gluconic acid immediately in response to high glucose concentration after the recycled mycelia was inoculated to the fresh hydrolysate. The gluconic acid production slowed down dramatically after day 1 followed by a lag phase of organic acid production until day 3, implying that the gluconic acid production on day 1 might result from an incomplete inhibition on the grown fungal mycelia in the hydrolysate. On the other hand, recycling the fungal mycelia did not give any beneficial effects on the production of citric acid or oxalic acid. The production of citric acid and oxalic acid by the recycled mycelia was lower than that obtained with the spore inoculation.

A previously constructed Δgox mutant was used in a comparative analysis of the impacts of deleting a glucose oxidase encoding gene (gox) on organic acid production in the wheat straw hydrolysate. In our previous study, it was shown that the disruption of the gox gene in A. carbonarius efficiently prevented the conversion of glucose to gluconic acid and led to increased production of oxalic acid and citric acid, when the Δgox mutant was cultivated in a defined medium with pH maintained at 5.5 by adding CaCO3 (Yang et al. 2014a). When the Δgox mutant in the present study was cultivated in the hydrolysate adjusted to pH 7, the disruption of the gox gene had similar impacts on the production of oxalic acid and gluconic acid as previously reported but not on citric acid production. For comparison, the Δgox mutant was also cultivated in the defined medium mimicking the concentrations of glucose and xylose in the hydrolysate. The results showed no significant difference in the production of citric acid by the Δgox mutant and the wild-type. The production of gluconic acid and oxalic acid were highly inhibited by low pH while the citric acid production was enhanced, which is in consistence with the previous findings in the well-known citric acid producer A. niger (Papagianni 2007; Yang et al. 2015). Therefore, the wild-type produced more citric acid in the hydrolysate than the Δgox mutant probably because the rapid pH decrease in the cultivation benefited citric acid production but inhibited the production of oxalic acid and gluconic acid. In contrast, when the Δgox mutant decreased pH more slowly than the wild-type due to the elimination of gluconic acid production, it produced more oxalic acid instead of citric acid compared with the wild-type. The impacts of disrupting the gox gene on citric acid production differed in the hydrolysate and the defined media. This comparative study implies that it is necessary to take into consideration the complexity of the lignocellulosic hydrolysates, including pH buffering capacity and potential inhibitors, when the genetic engineered strain is applied in organic acid production using lignocellulosic hydrolysates as substrate.

Conclusion

In this study, organic acid production of A. carbonarius was investigated in a wheat straw hydrolysate and compared with production in a defined medium. The efficient co-utilization of glucose and xylose and the high tolerance to the inhibitory compounds in the hydrolysate indicated the potential of A. carbonarius as a fungal cell factory for production of organic acids using lignocellulosic biomass. Moreover, the comparative study of the wild-type and the Δgox mutant showed that impacts of a specific genetic modification on organic acid production were different in the defined media and the lignocellulosic hydrolysate.

References

Baroi GN, Baumann I, Westermann P, Gavala HN (2015) Butyric acid fermentation from pretreated and hydrolysed wheat straw by an adapted Clostridium tyrobutyricum strain. Microb Biotechnol 8:874–882

Colabardini AC, Ries LNA, Brown NA, Dos Reis TF, Savoldi M, Goldman MHS, Menino JF, Rodrigues F, Goldman GH (2014) Functional characterization of a xylose transporter in Aspergillus nidulans. Biotechnol Biofuels 7:46

Darouneh E, Alavi A, Vosoughi M, Arjmand M, Seifkordi A, Rajabi R (2009) Citric acid production: surface culture versus submerged culture. Afr J Microbiol Res 3:541–545

Dionisi D, Anderson JA, Aulenta F, Mccue A, Paton G (2015) The potential of microbial processes for lignocellulosic biomass conversion to ethanol: a review. J Chem Technol Biotechnol 90:366–383

Elkins JG, Raman B, Keller M (2010) Engineered microbial systems for enhanced conversion of lignocellulosic biomass. Curr Opin Biotechnol 21:657–662

Fencl Z, Leopold J (1959) The inhibition of spore germination of the mould Aspergillus niger by acetic acid. Folia Microbiol 4:7–15

Ghareib M (1987) Assimilation of galacturonate by Aspergillus carbonarius. Folia Microbiol 32:211–215

Jönsson LJ, Alriksson B, Nilvebrant N- (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16

Liaud N, Liaud C, Giniés D, Navarro N, Fabre S, Herpoël Crapart I, Gimbert A, Levasseur S, Raouche J, Sigoillot J-C (2014) Exploring fungal biodiversity: organic acid production by 66 strains of filamentous fungi. Fungal Biol Biotechnol 1:1

Linde T, Hansen NB, Lübeck M, Lübeck PS (2014) Fermentation in 24-well plates is an efficient screening platform for filamentous fungi. Lett Appl Microbiol 59:224–230

Lu F, Ping K, Wen L, Zhao W, Wang Z, Chu J, Zhuang Y (2015) Enhancing gluconic acid production by controlling the morphology of Aspergillus niger in submerged fermentation. Process Biochem 50:1342–1348

Maddox IS, Spencer K, Greenwood JM, Dawson MW, Brooks JD (1985) Production of citric acid from sugars present in wood hemicellulose using Aspergillus niger and Saccharomycopsis lipolytica. Biotechnol Lett 7:815–818

Magnuson JK, Lasure LL (2004) Organic acid production by filamentous fungi. Adv Fungal Biotechnol Ind Agricult Med 3:307–340

Martinez A, Rodriguez ME, Wells ML, York SW, Preston JF, Ingram LO (2001) Detoxification of dilute acid hydrolysates of lignocellulose with lime. Biotechnol Prog 17:287–293

Meng J, Zhou P, Zhang J, Bao J (2014) High titer citric acid fermentation from corn stover hydrolysate by Aspergillus niger. J East China Univ Sci Technol 40:681–683

Millati R, Niklasson C, Taherzadeh MJ (2002) Effect of pH, time and temperature of overliming on detoxification of dilute-acid hydrolyzates for fermentation by Saccharomyces cerevisiae. Process Biochem 38:515–522

Mohamad R, Mohamed M, Suhaili N, Ariff A (2010) Kojic acid: applications and development of fermentation process for production. Biotechnol Mol Biol Rev 5:24–37

Mondala AH (2015) Direct fungal fermentation of lignocellulosic biomass into itaconic, fumaric, and malic acids: current and future prospects. J Ind Microbiol Biotechnol 42:487–506

Nanda S, Azargohar R, Dalai AK, Kozinski JA (2015) An assessment on the sustainability of lignocellulosic biomass for biorefining. Renew Sustain Energy Rev 50:925–941

Okabe M, Lies D, Kanamasa S, Park EY (2009) Biotechnological production of itaconic acid and its biosynthesis in Aspergillus terreus. Appl Microbiol Biotechnol 84:597–606

Pandey A, Soccol CR (1998) Bioconversion of biomass: a case study of ligno-cellulosics bioconversions in solid state fermentation. Braz Arch Biol Technol 41:379–390

Papagianni M (2007) Advances in citric acid fermentation by Aspergillus niger: biochemical aspects, membrane transport and modeling. Biotechnol Adv 25:244–263

Quevedo-Hidalgo B, Monsalve-Marín F, Narváez-Rincón PC, Pedroza-Rodríguez AM, Velásquez-Lozano ME (2013) Ethanol production by Saccharomyces cerevisiae using lignocellulosic hydrolysate from Chrysanthemum waste degradation. World J Microbiol Biotechnol 29:459–466

Ronne H (1995) Glucose repression in fungi. Trends Genet 11:12–17

Saber WIA, El-Naggar NE, Abdal-Aziz SA (2010) Bioconversion of lignocellulosic wastes into organic acids by cellulolytic rock phosphate-solubilizing fungal isolates grown under solid-state fermentation conditions. Res J Microbiol 5:1–20

Sakai S, Tsuchida Y, Okino S, Ichihashi O, Kawaguchi H, Watanabe T, Inui M, Yukawa H (2007) Effect of lignocellulose-derived inhibitors on growth of and ethanol production by growth-arrested Corynebacterium glutamicum R. Appl Environ Microbiol 73:2349–2353

Show PL, Oladele KO, Siew QY, Aziz Zakry FA, Lan JC-, Ling TC (2015) Overview of citric acid production from Aspergillus niger. Front Life Sci 8(3):271–283

Soo C, Yap W, Hon W, Phang L (2015) Mini review: hydrogen and ethanol co-production from waste materials via microbial fermentation. World J Microbiol Biotechnol 31:1475–1488

Subtil T, Boles E (2012) Competition between pentoses and glucose during uptake and catabolism in recombinant Saccharomyces cerevisiae. Biotechnol Biofuels 5:14

Taniguchi K, Matsudak K, Teramura H, Wale K (1977) Effect of acetic acid on growth of Aspergillus niger. J Fac Sci Hokkaido Univ Ser 5 Bot 10:189–198

Weyda I, Lübeck M, Ahring BK, Lübeck PS (2014) Point mutation of the xylose reductase (XR) gene reduces xylitol accumulation and increases citric acid production in Aspergillus carbonarius. J Ind Microbiol Biotechnol 41:733–739

Xu Q, Li S, Fu Y, Tai C, Huang H (2010) Two-stage utilization of corn straw by Rhizopus oryzae for fumaric acid production. Bioresour Technol 101:6262–6264

Yang L, Lübeck M, Lübeck PS (2014a) Deletion of glucose oxidase changes the pattern of organic acid production in Aspergillus carbonarius. AMB Express 4:54

Yang Z, Bai Z, Sun H, Yu Z, Li X, Guo Y, Zhang H (2014b) Biomass pyrolysis liquid to citric acid via 2-step bioconversion. Microb Cell Fact 13:182

Yang L, Lübeck M, Lübeck PS (2015) Effects of heterologous expression of phosphoenolpyruvate carboxykinase and phosphoenolpyruvate carboxylase on organic acid production in Aspergillus carbonarius. J Ind Microbiol Biotechnol 42:1533–1545

Zha Y, Westerhuis JA, Muilwijk B, Overkamp KM, Nijmeijer BM, Coulier L, Smilde AK, Punt PJ (2014) Identifying inhibitory compounds in lignocellulosic biomass hydrolysates using an exometabolomics approach. BMC Biotechnol 14:22

Acknowledgments

Financial support from the Danish Strategic Research Program MycoFuelChem (DSF Grant No. 11-116803) is acknowledged. We thank laboratory technician Gitte Hinz-Berg for HPLC analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This study does not contain any experiment with human participants or animals performed by any of the authors.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, L., Lübeck, M., Souroullas, K. et al. Co-consumption of glucose and xylose for organic acid production by Aspergillus carbonarius cultivated in wheat straw hydrolysate. World J Microbiol Biotechnol 32, 57 (2016). https://doi.org/10.1007/s11274-016-2025-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-016-2025-4