Abstract

A systematic study of bioconversion of lignocellulosic sugars to acetic acid by Moorella thermoacetica (strain ATCC 39073) was conducted. Four different water-soluble fractions (hydrolysates) obtained after steam pretreatment of lignocellulosic biomass were selected and fermented to acetic acid in batch fermentations. M. thermoacetica can effectively ferment xylose and glucose in hydrolysates from wheat straw, forest residues, switchgrass, and sugarcane straw to acetic acid. Xylose and glucose were completely utilized, with xylose being consumed first. M. thermoacetica consumed up to 62 % of arabinose, 49 % galactose and 66 % of mannose within 72 h of fermentation in the mixture of lignocellulosic sugars. The highest acetic acid yield was obtained from sugarcane straw hydrolysate, with 71 % of theoretical yield based on total sugars (17 g/L acetic acid from 24 g/L total sugars). The lowest acetic acid yield was observed in forest residues hydrolysate, with 39 % of theoretical yield based on total sugars (18 g/L acetic acid from 49 g/L total sugars). Process derived compounds from steam explosion pretreatment, including 5-hydroxymethylfurfural (0.4 g/L), furfural (0.1 g/L) and total phenolics (3 g/L), did not inhibit microbial growth and acetic acid production yield. This research identified two major factors that adversely affected acetic acid yield in all hydrolysates, especially in forest residues: (i) glucose to xylose ratio and (ii) incomplete consumption of arabinose, galactose and mannose. For efficient bioconversion of lignocellulosic sugars to acetic acid, it is imperative to have an appropriate balance of sugars in a hydrolysate. Hence, the choice of lignocellulosic biomass and steam pretreatment design are fundamental steps for the industrial application of this process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The current global interest in renewable resources and biorefineries has created momentum and new opportunities in the area of biochemical manufacturing. In order for current biorefineries to be competitive with legacy-based fossil fuel technologies, a more efficient process for the production of bio-based chemicals needs to be developed. One such bio-based chemical is acetic acid, an important carboxylic acid with a broad spectrum of industrial and household applications, including polymers, paints, foods and pharmaceuticals. Acetic acid is a major building block for chemicals such as polyvinyl and cellulose acetate, which is further used in the production of fibers and fabrics [19].

Currently, more than 65 % of global acetic acid manufacturing processes are based on methanol carbonylation utilizing rhodium complex (rhodium iodides) catalyst [19, 41]. Other procedures involve oxidation of acetaldehyde, liquid phase oxidation of n-butane or naphtha, and chemical conversion of syngas produced through gasification of coal [12]. The United States’ acetic acid production is 788 MM gal/year with spot market price at $2.50 per gallon [7, 12]. In comparison, bioethanol production is 15,135 MM gal/year [6] with a price of $1.80 per gallon [14]. Hence, production of acetic acid, a high-value commodity produced through bioconversion of lignocellulosic biomass, is economically viable [35]. Acetogenic bacteria have shown to be promising candidates for the production of acetic acid [15].

Moorella thermoacetica, a gram-positive, thermophilic, and anaerobic bacterium (previously known as Clostridium thermoacetica), is a homoacetogen in which acetate is the major product of its metabolic pathway [24]. M. thermoacetica is a robust and versatile heterotroph with optimum growth conditions of 55–60 °C and pH 6.8 [16]. This bacterium has a unique metabolic capability. It is able to produce acetic acid by metabolizing certain sugars including xylose, fructose and glucose. Xylose is consumed first, followed by fructose and glucose [2, 3, 11]. Conversion of glucose and fructose occurs through the Embden–Meyerhof–Parnas glycolytic pathway [16, 23] while xylose is converted through the pentose phosphate pathway [30]. Furthermore, M. thermoacetica is able to synthesize acetic acid from carbon dioxide through the acetyl-CoA Wood–Ljungdahl pathway [16, 23]. As a result, syngases may be utilized as a substrate (chemolithoautotrophic growth on H2/CO2 or CO/CO2) [15, 16, 24]. Typical acetic acid production in a batch fermentation using purified glucose (20 g/L) is around 13 g/L [35]. The highest acetic acid production reported was 31 g/L using a CO/CO2 gas mixture [20]. On average, bacterial tolerance of acetate is between 30 and 50 g/L in batch fermentation [37].

To the best of our knowledge, no papers have been published regarding the fermentation of lignocellulosic sugars to acetic acid. Previous efforts regarding production of acetic acid utilizing M. thermoacetica have by and large concentrated on developing industrially suitable culture media and fermentation setups using purified sugars. M. thermoacetica has complex nutrient requirements in which a typical cultivation medium includes a carbon source, trace metals, salts, reducers, yeast extract and buffer solution [15]. One major issue has been the development of a cost effective growth medium using different substitutions for yeast extract [8, 25, 32, 40]. Corn steep liquor (CSL) pretreated with dolime (calcium and magnesium oxide, CaO-MgO) and vitamin supplementation has shown to be a promising replacement, since final acetate concentration was improved by 110 % (19–40 g/L in a fed-batch fermentation) [32]. Various fermentation setups have also been evaluated to optimize acetate production [29, 31, 33, 38]. Results from fed-batch fermentation and continuous stirred-tank reactors (CSTR) using cell recycle membrane systems were shown to have a higher concentration of acetate (34–38 g/L) when compared to one-step CSTR (25.5 g/L) [32].

A number of commercial and solvent extracted sugars have also been evaluated for the production of acetic acid. Brownell and coworker utilized extracted xylose from debarked poplar wood chips (Soxhlet extraction using benzene–ethanol) and commercial oat spelt xylan, obtaining an average acetate yield of 70 % [10]. Commercial glucose from α-cellulose and pulp mill sludge were also utilized, with overall acetate yields of 60 and 85 %, respectively. The authors stipulated that acetate production was limited by toxic materials from the sludge [9].

Since there have not been any published studies on fermentation of lignocellulosic sugars to acetic acid, this is the first report on the conversion of lignocellulosic sugars including glucose, xylose, arabinose, galactose, and mannose to acetic acid by M. thermoacetica. The objective of this work is to examine M. thermoacetica in fermentation of four different types of hydrolysates obtained after steam pretreatment of lignocellulosic biomass including wheat straw, forest residues, switchgrass, and sugarcane straw. These hydrolysates are xylose rich streams, M. thermoacetica’s preferred sugar for production of acetic acid. The ultimate goal of our research is to establish a bioconversion process of lignocellulosic biomass to acetic acid using both hexose and pentose fractions after steam pretreatment.

Materials and methods

Moorella Thermoacetica strain (ATCC 39073)

Moorella thermoacetica (ATCC 39073) was acquired from the American Type Culture Collection (Manassas, VA, USA), grown in a growth medium containing the following compounds (g/L): yeast extract, 10.0; glucose, 10.0; xylose, 10.0; l-Cysteine Hydrochloride Monohydrate 1.0; KH2PO4 7.0; NaHCO3 16.0; K2HPO4 5.5; (NH4)2SO4 1.0; MgCl2-6H2O, 0.33; CaCl2 0.05; NaMoO4-2H2O 0.0025; Fe(NH4)2SO4-6H2O 0.04; Co(NO3)2-6H2O 0.03; Na2SeO3 0.0002; NiCl2-6H2O 0.0002. The pH level of the medium was adjusted to 7.3 using 5 M NaOH [2, 16, 35].

Culture media conditions

Cells were grown to high density through three sequential passagings, from 50 to 200 mL, in stoppered and crimp-sealed Wheaton serum bottles. Prior to inoculation, Wheaton serum bottles containing growth medium were sparged with filter-sterilized 100 % CO2 and inoculated with 10 % by volume serum bottles incubated at 58 °C for 36 h in dark conditions (incubator in Bactron II anaerobic chamber, Sheldon Manufacturing, Inc.). The third passage (200 mL) was used as the inoculum for fermentation. After 36 h of growth, cell cultures were harvested and centrifuged at 4000 rpm (Beckman GS-15R, Germany) for 5 min. They were subsequently decanted to yield cell pellets with a concentration of 7 g/L dry cell weight (DCW). The concentration of dry cell weight was measured based on optical density using a UV spectrophotometer (Shimadzu UV-1700, Columbia, MD, USA) and standard curves that related 600 nm absorbance to DCW per liter.

Water-soluble fraction (hydrolysate)

The water-soluble fractions (hydrolysates) used in this study were produced from wheat straw, forest residues, switchgrass, and sugarcane straw. Each lignocellulosic biomass was soaked to saturation in deionized (DI) water overnight prior to SO2-catalyzed steam explosion. The detailed procedure of steam explosion experiments has been described previously by Ewanick [17]. Briefly, samples of 200 g oven-dried weight (ODW) lignocellulosic biomass were impregnated overnight with anhydrous 3 % (w/w) SO2. The samples were subsequently loaded in a steam gun and kept for five minutes at a temperature of 195 °C (190 °C for sugarcane straw) (Fig. 1). The water-soluble fraction (hydrolysate) from steam explosion of each lignocellulosic biomass was recovered by filtration and kept at 4 °C until use. The initial concentration of sugars present in the hydrolysates was measured.

Overliming

Prior to fermentation, each hydrolysate was conditioned by an overliming (OL) process in which the pH level was increased from 1.9 to 10.0 with Ca(OH)2 (industrial and chemical purposes, Graymont, USA). The pH level was next readjusted to 5.0 with sulfuric acid. The overliming process was carried out based on procedure described by the National Renewable Energy Laboratory (NREL) [27].

pH-Controlled batch fermentation

Four different lignocellulosic hydrolysates, as well as their corresponding purified sugars models, were fermented. Figure 1 presents a simplified scheme of fermentation experiments. All fermentation experiments were performed in triplicate using a 1.3 L Bioflo 115 (New Brunswick Scientific Co., Inc., Edison, NJ, with a proportional-integral-derivative (PID) controller) bioreactor with 500 mL of working volume. The bioreactors were kept under anaerobic conditions using filter-sterilized 100 % CO2 gas sparged into the bottom of the fermenter vessel continuously prior to inoculation. Sparging was maintained at the headspace after inoculation and throughout fermentation. Inoculation was performed with 10 % v/v using three-stage seeded bacterial cells grown on glucose and xylose in a 1:1 ratio. All fermentations were maintained at 58 °C with continuous agitation of 175 rpm and CO2 gas flow rate of 1 standard liter per minute (SLPM) and monitored for 72 h. A solution of 5 M NaOH was added to sustain a pH value of 6.8 throughout fermentation. Samples were taken at the time of inoculation and at specific intervals thereafter. One milliliter aliquots were immediately centrifuged (10,000 rpm) for 5 min at 4 °C to separate microbial cells and supernatant. The supernatant was filtered using a 0.2 µm syringe filter and then stored at −20 °C until analysis. The bacterial growth was monitored during fermentations based on optical density (OD). The OD was measured at 600 nm by spectrophotometer (Shimadzu UV-1700, Columbia, MD, USA). Conversion of OD to dry cell mass was carried out based on procedure described by NREL [13].

Hydrolysate fermentation

Prior to fermentation, all overlimed hydrolysates were supplemented with nutrients used in growth medium and pH adjusted to a value of 7.3. Xylose concentration in all hydrolysates was spiked to 20 g/L to establish a baseline. All hydrolysates were filter sterilized using a 500 mL rapid flow bottle top with 0.2 µm sterile filter.

Purified sugars fermentation

Purified sugars fermentation was performed as a control for each type of hydrolysate. The media was prepared similarly to growth medium except for sugar content. Purified glucose, arabinose, galactose and mannose (obtained from Sigma Aldrich with purity ≥99 %) were added based on their corresponding concentration measured in each hydrolysate. For all controls, xylose concentration was kept at 20 g/L. The fermentation of all purified sugars models was performed in the same manner as the fermentation of the hydrolysates.

Flask fermentation

Flask fermentations were performed in stoppered and crimp-sealed Wheaton serum bottles with 100 mL working volume filled with purified fermentation medium and sparged with filter-sterilized 100 % CO2. The media was prepared similarly to growth medium except for sugar content. Purified sugars including glucose, xylose, arabinose, galactose and mannose were added to fermentation medium as it was required for the experiments. The serum bottles inoculated with 10 % by volume serum bottles and incubated at 58 °C for a period of 48–50 h in shaking incubator with agitation at 175 rpm.

HPLC analysis

Monomeric sugars

The concentration of monomeric sugars (arabinose, galactose, glucose, xylose and mannose) was measured on a Dionex (Sunnyvale, CA, USA) high-performance liquid chromatography (HPLC, ICS-3000) system equipped with AS (auto sampler), ED (electrochemical detector), dual pumps and anion exchange column (Dionex, CarboPac PA1). Deionized water at 1.0 mL/min was used as eluent and post column addition of 0.2 M NaOH at a flow rate of 0.5 mL/min ensured optimal baseline stability and detector sensitivity. After each analysis, the column was reconditioned with 0.25 M NaOH. Ten microliters of each sample was injected after filtration through a 0.2 µm syringe filter (Restek Corp., Bellefonte, PA, USA). Standards were prepared containing arabinose, galactose, glucose, xylose and mannose to mirror the concentration range of the samples. Fucose was added to all samples as an internal standard for Dionex HPLC instrument to calibrate peaks.

Acetate, 5-hydroxymethylfurfural and furfural analysis

Acetic acid, 5-hydroxymethylfurfural (HMF) and furfural (FF) were measured using refractive index detection on a Shimadzu Prominence LC. The separation of these compounds was achieved by an anion exchange column [REZEX RHM-Mono saccharide H+ (8 %); Phenomenex, Inc., Torrance, CA, USA] with an isocratic mobile phase that consisted of 5 mM H2SO4 at a flow rate of 0.6 mL/min. The column oven was maintained at a constant temperature of 63 °C. Ten microliters of each sample was injected after being appropriately diluted in deionized water and filtered through a 0.2 µm syringe filter. The standards were prepared and used to quantify the unknown samples.

Acetic acid forms during pretreatment through cleavage of the acetyl group in hemicellulose [1, 4, 5, 21]. In this study, acetic acid was detected in all four hydrolysates with initial concentrations between 4 and 5 g/L at the beginning of fermentation (data not shown). Produced acetic acid in fermentation of hydrolysates was calculated by subtracting the initial acetic acid concentration from the final acetic acid concentration. Acetic acid yield was calculated based on dividing the produced acetic acid by total initial sugars at the beginning of fermentation.

Phenolic measurement

Total phenolics were measured based on colorimetric reaction using the Folin–Ciocalteau (FC) method. Gallic acid was utilized as an equivalent to the phenolic compounds. Gallic acid (0.500 g) was dissolved in ethanol (10 mL) and diluted to 100 mL in a volumetric flask using distilled/deionized water. A set of standards with differing concentrations of gallic acid was prepared to create a calibration curve. Sodium carbonate solution was used for colorimetric reaction [39].

Results and discussion

Fermentation of xylose, glucose, arabinose, galactose, and mannose to acetic acid

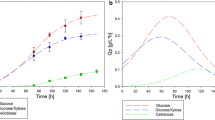

To examine the ability of M. thermoacetica to ferment lignocellulosic sugars to acetic acid, fermentations of four different types of lignocellulosic hydrolysates were conducted. Hydrolysates obtained from steam pretreated wheat straw, forest residues, switchgrass, and sugarcane straw were used as media for production of acetic acid by M. thermoacetica (ATCC 39073). The purified sugars models (controls) consisted of purified sugars with the same concentrations as measured in hydrolysates (described in “Materials and methods” section). A typical fermentation profile for sugar consumption, acetic acid production, and cell growth for each hydrolysate is shown in Fig. 2, plots a–d.

In general, it was shown that in all hydrolysates, xylose was the initial sugar that was completely metabolized by M. thermoacetica. Glucose started to be metabolized after more than half of xylose was consumed, while minimal amounts of arabinose, galactose and mannose were gradually consumed over a period of 72 h of fermentation. The fastest xylose consumption (35 h) was observed in sugarcane straw and switchgrass hydrolysates, while the slowest (50 h) was observed in forest residues hydrolysate (Fig. 2, plots b, d). Xylose uptake commenced by M. thermoacetica without any lag phase in three hydrolysates, while wheat straw hydrolysate had a lag phase of 12 h. Glucose was completely consumed within a range of 40 h (fastest in sugarcane straw hydrolysate) to 70 h (slowest in forest residues hydrolysate). Low concentrations of minor sugars including arabinose, galactose and mannose were detected in all hydrolysates except for forest residues, which had a considerable amount of these sugars (Table 1). The consumption of minor sugars was incomplete and the lowest consumptions of minor sugars were observed in the following samples: arabinose in switchgrass (37 %), and galactose and mannose in sugarcane straw (18 and 28 %, respectively). Conversely, the highest consumptions of minor sugars were observed in the following samples: arabinose and galactose in wheat straw (62 and 49 %, respectively) and mannose in switchgrass (66 %).

In fermentation of controls, a similar trend in sugars consumption was observed (plots for controls not shown). Xylose uptake in sugarcane straw and switchgrass controls was the same as the corresponding hydrolysates, while in wheat straw and forest residues controls, xylose was consumed slower (60 and 65 h, respectively, data not shown). The pattern for glucose consumption was also comparable to hydrolysates. However, glucose in the forest residues control was not completely utilized over the fermentation period of 72 h (1 g/L remained, plots not shown). The incomplete consumption of arabinose, galactose and mannose in controls were different from hydrolysates. The lowest consumptions of minor sugars were observed in the following controls: arabinose and galactose consumption in forest residues control (42 and 13 %, respectively) and mannose in switchgrass control (12 %). The highest consumptions of minor sugars were observed in the following controls: arabinose and mannose in sugarcane straw control (54 and 55 %, respectively) and galactose in switchgrass control (36 %) (Data not shown).

The highest cell concentration was observed in wheat straw hydrolysate (23 g/L), while the lowest was observed in sugarcane straw hydrolysate (21.4 g/L) (Table 1; Fig. 2). In purified sugars models, the highest cell concentration was found in wheat straw control (24.5 g/L), while the lowest cell concentration was observed in forest residues control (19 g/L). Cell concentration was higher (0.2–1.5 g/L) in each control compared to its hydrolysate except for the purified sugars model for forest residue (Table 1).

Acetic acid yield was calculated based on concentration of produced acid and total initial sugars (Table 1). The highest acetic acid yield was observed in steam pretreated sugarcane straw hydrolysate with 71 % of theoretical yield (17.2 g/L) while the lowest yield was observed in forest residues hydrolysate with 38 % of theoretical yield (18.2 g/L). Acetic acid yield was higher for all hydrolysates compared to their corresponding controls except for forest residues control (39 %) and switchgrass control (55 %). All conversions of lignocellulosic sugars to acetic acid were as good as or higher than their corresponding controls.

The presence of process derived compounds from steam explosion pretreatment was detected in all hydrolysates (Table 1). These compounds include 5-hydroxymethylfurfural (HMF) from degradation of hexoses, furfural (FF) from degradation of pentoses, and phenolics from degradation of lignin [1, 4, 5, 21]. The highest concentration of process derived compounds was observed in switchgrass hydrolysate, with values of: HMF 0.4 g/L, FF 0.1 g/L and phenolics 2.9 g/L. In all hydrolysates, M. thermoacetica did metabolize HMF and FF in the first 12 h of fermentation. However, the bacterial strain did not consume phenolic compounds. Furthermore, total phenolics and furans did not inhibit microbial growth or acetic acid production since acetic acid yield in all hydrolysates was as good as or higher than their corresponding controls.

In our preliminary experiments, it was observed that M. thermoacetica was not able to consume arabinose, galactose and mannose in a fermentation of a single sugar, with attempts resulting in a cluster of dead cells (data not shown). The effect of minor sugars on acetic acid yield was investigated in two separate flask fermentations, using mixed sugars with equal concentrations (Table 2). In one fermentation, inoculant was pre-grown on the same mixture of sugars, while in the second fermentation, inoculant was pre-grown on a 1:1 ratio of glucose to xylose. Table 2 shows that M. thermoacetica could completely metabolize xylose and glucose while the consumption of other sugars was incomplete (<40 %), resulting in a very low acetic acid yield (30 % of theoretical yield).

Thus far there have not been any studies regarding fermentation of mixed lignocellulosic sugars by M. thermoacetica. In a study by Balasubramanian and coworkers [3], fermentation of mixed purified sugars, with an average concentration of 5 g/L for each sugar (including xylose, glucose, fructose, arabinose, galactose and mannose), was investigated. In the experiment, Balasubramanian’s group used M. thermoacetica’s inoculant with a very low cell concentration (~2 %, v/v) and observed fermentation over a period of over 135 h. Xylose and glucose were completely consumed in 110 h of fermentation [3]. By contrast, in our experiments, glucose and xylose were completely utilized in 50 h of fermentation. Incomplete consumption of minor sugars (arabinose, galactose and mannose) was observed in both studies.

Effect of glucose to xylose ratio on acetic acid yield

A possible explanation for incomplete metabolism of sugars to acetic acid may be the glucose to xylose ratio in lignocellulosic hydrolysates. We observed low acetic acid yield (38 % of theoretical yield) in forest residues hydrolysate with high glucose to xylose ratio (9:20 ratio). By contrast, high acetic acid yield (71 % of theoretical yield) was observes in sugarcane straw hydrolysate with low glucose to xylose ratio (2:20 ratio). To better understand this incomplete conversion, subsequent fermentation experiments were carried out. Table 3 shows pH-controlled batch fermentation results from the mixtures of glucose and xylose with different concentrations. The concentration of glucose and xylose in fermentation number (no.) 1 corresponds to wheat straw, switchgrass and sugarcane straw hydrolysates. Glucose and xylose concentration in fermentation no. 3 is similar to forest residues hydrolysate. In this set of experiments, glucose and xylose consumption as well as acetic acid yield were monitored over periods of 50, 75 and 96 h of fermentation. Over a 50 h period of fermentation, the highest acetic acid yield based on total sugars (75 % of theoretical yield) was observed in mixtures with a high concentration of glucose to xylose (20–3 and 20–9 g/L). In these mixtures, xylose and glucose were completely metabolized in all cases except fermentation no. 4, which had a residual glucose level less than 1 g/L. In contrast, low acetic acid yield was observed in fermentation no. 3 and 4 (50 and 59 % of theoretical yield, respectively) with considerable residual glucose and xylose (Table 3, fermentation no. 1 and 3). After 75 h of fermentation, media with a high glucose concentration (Table 3, fermentation no. 2 and 4) presented a higher acetic acid yield (75 and 77 % of theoretical yield, respectively) than fermentation media with high xylose concentration (Table 3, fermentation no. 1 and 3, 67 and 70 % of theoretical yield, respectively). A similar trend in acetic acid yield was also observed after 96 h of fermentation. Our results verified that glucose to xylose ratio had a significant influence on duration of sugars uptake, causing lag phase behavior in M. thermoacetica.

The lag phase behavior in M. thermoacetica was also confirmed by bacterial cell growth profile during 96 h of fermentation. For example, in fermentations no. 2 and 4, where glucose was the major sugar, maximum cell concentration was achieved rapidly (39 and 36 h of fermentation, respectively) (Fig. 3). On the contrary, in fermentations no. 1 and 3, where xylose was the major sugar, obtaining maximum cell concentration took a longer time (55 and 59 h of fermentation, respectively) (Fig. 3). This behavior is believed to be due to the presence of carbon catabolite repression (CCR), which is common among microorganisms, such as Clostridium acetobutylicum [22, 28, 34]. CCR is a regulatory mechanism by which consumption of preferred carbon source, usually glucose, suppresses the consumption of secondary carbon sources [18, 34, 36]. CCR is a complex metabolic performance and substantially differs among microorganisms [34] which may reduce the productivity of the overall fermentation process [22]. Therefore the likelihood of CCR behavior in M. thermoacetica is not unusual. M. thermoacetica, exhibits the opposite of CCR behavior in a sense that xylose is the preferred carbon source. In our fermentations including (i) hydrolysates and their controls, (ii) different mixtures of glucose and xylose, and (iii) mixture of five sugars, the glucose uptake was clearly repressed by xylose which emphasizes the potential presence of CCR mechanism in M. thermoacetica.

This lag phase behavior was specifically notable in forest residues hydrolysate (Fig. 2, plot b; Table 1), in which acetic acid yield was adversely affected by glucose to xylose ratio and high concentration of minor sugars. Thus, incomplete conversion of sugars was observed. Furthermore, bacterial pre-growth on a 1:1 ratio of glucose to xylose may also have a direct effect on acetic acid yield. Brumm observed a 20 % lower acetic acid yield in fermentation of xylose utilizing culture grown on an equivalent amount of fructose or glucose compared to culture pre-grown on xylose [11].

A previous study by Sugaya and coworkers [35] depicting the performance of M. thermoacetica reported 13 g/L of acetic acid (65 % of theoretical yield) from 20 g/L purified glucose over 89 h of pH-controlled batch fermentation. The authors utilized the same strain of M. thermoacetica (ATCC 39073) pre-grown on glucose (fermentation started with 0.25 g/L of cell biomass) [35]. By contrast, Balasubramanian and co-workers [3] were able to attain 15 g/L of acetic acid (76 % of theoretical acetic acid yield) from pH-controlled batch fermentation of 20 g/L purified xylose over 100 h of fermentation. Balasubramanian and coworkers [3] used M. thermoacetica (ATCC 49707) pre-grown on xylose (fermentation started with ~2 % dry cell concentration). It is important to note that M. thermoacetica utilized in our research had a higher performance when compared with the above studies. In our experiments, the highest acetic acid production over 72 h of pH-controlled batch fermentation was 70 % of theoretical yield in sugarcane straw hydrolysate, which includes five lignocellulosic sugars, phenolics and furan (Table 1).

To obtain optimal acetic acid yield, it is imperative to have lignocellulosic hydrolysate with a favorable balance of glucose to xylose and low concentration of minor sugars. The sugar ratio in sugarcane straw hydrolysate is a reliable example for obtaining acetic acid yield above 70 % of theoretical yield. Hence, steam explosion pretreatment design needs to be customized to extract xylose and glucose in a step-wise manner. In the initial step, it is important to collect as much xylose in the liquid stream (hydrolysate) as possible, while maintaining a low severity factor. The second step is to steam explode the solid stream to collect glucose in the water-soluble stream. The choice of lignocellulosic feedstock is also an important factor that affects acetic acid yield. Hardwoods and agricultural residues have great potential for the production of acetic acid. Softwoods are not a good option due to their high content of galactoglucomannan [26]. M. thermoacetica has proven to be a robust strain in the production of acetic acid from lignocellulosic sugars when the optimum concentrations of glucose and xylose are utilized.

Conclusions

For the first time, it was presented that M. thermoacetica (ATCC 39073) can effectively ferment xylose and glucose content in water-soluble fractions of steam exploded lignocellulosic biomass (including wheat straw, forest residues, switchgrass, and sugarcane straw) to acetic acid. In all fermentations, xylose was the major, and the first, sugar being consumed. Xylose consumption was faster in switchgrass and sugarcane straw hydrolysates (35 h) than wheat straw and forest residues hydrolysates (40 and 45 h, respectively). Glucose uptake was influenced by xylose, as glucose was metabolized when the majority of xylose was consumed. M. thermoacetica consumed less than 50 % of arabinose, galactose and mannose within 72 h of fermentation in a mixture of sugars. The highest cell biomass was observed in wheat straw hydrolysate (23 g/L), and the lowest in sugarcane straw hydrolysate (21.4 g/L). The highest acetic acid production based on total sugars was obtained from sugarcane straw with 71 % of theoretical yield, compared to 64 % in its control. The lowest acetic acid yield based on total sugar was observed in forest residues with 39 % of theoretical yield. Bacterial growth and acetic acid production were not influenced by process derived compounds (total phenolics up to 3 g/L and furans up to 0.5 g/L) as acetic acid yield in hydrolysates was as good as or better than fermentation of the corresponding purified sugars models. The variation observed in acetic acid yield among hydrolysates is due to incomplete metabolism of sugars, leading to a lag phase behavior in M. thermoacetica. This behavior originates from glucose to xylose ratio and the presence of arabinose, galactose and mannose. For efficient bioconversion of sugars to acetic acid, it is imperative to have an appropriate balance of lignocellulosic sugars in the hydrolysate. Hence, the choice of lignocellulosic biomass and steam pretreatment design are fundamental steps for the industrial application of this process.

References

Almeida JRM, Modig T, Petersson A, Hahn-Hagerdal B, Liden G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. Chem Technol Biotechnol 82:340–349

Andreesen JR, Schaupp A, Neurauter C, Brown A, Ljungdahl LG (1973) Fermentation of glucose, fructose, and xylose by Clostridium thermoaceticum: effect of metals on growth yield, enzymes, and the synthesis of acetate from CO2. J Bacteriol 114:743–751

Balasubramanian N, Kim JS, Lee YY (2001) Fermentation of xylose into acetic acid by Clostridium thermoaceticum. J Appl Biochem Biotechnol 91–93:367–376

Ballesteros M, Negro M, Manzanares P, Ballesteros I, Saez F, Oliva JM (2007) Fractionation of Cynara Cardunculus (Cardoon) biomass by dilute acid pretreatment. Appl Biochem Biotechnol 137–140:239–252

Baral NR, Shah A (2014) Microbial inhibitors: formation and effects on acetone-butanol-ethanol fermentation of lignocellulosic biomass. Appl Microbiol Biotechnol 98:9151–9172

BBI International (2015) U.S. Ethanol Plants. Available via DIALOG. http://www.ethanolproducer.com/plants/listplants/US/Existing/All. Accessed 13 Mar 2015

Bloomberg (2015) Bloomberg database terminal. [Online]. Available at: Subscription Service. Accessed 13 Mar 2015

Bock SA, Fox SL, Gibbons WR (1997) Development of low cost, industrially suitable medium for the production of acetic acid from Clostridium thermoaceticum. Biotechnol Appl Biochem 25:117–125

Borden JR, Lee YY, Yoon H (2000) Simultaneous saccharification and fermentation of cellulosic biomass to acetic acid. Appl Biochem Biotechnol 84–86:963–970

Brownell JE, Nakas JP (1991) Bioconversion of acid-hydrolyzed poplar hemicellulose to acetic acid by Clostridium thermoaceticum. J Ind Microbiol 7:1–6

Brumm PJ (1988) Fermentation of single and mixed substrates by the parent and an acid-tolerant, mutant strain of Clostridium thermoaceticum. Biotechnol Bioeng 32:444–450

Clark B (2015) Chemical profile. US acetic acid. ICIS Chem Bus 287(9):34

Dowe N, McMillan J (2008) SSF experimental protocols-lignocellulosic biomass hydrolysis and fermentation laboratory analytical procedure (LAP) NREL/TP-510-42630

DTN/The Progressive Farmer (2015) Daily ethanol rack price. Available via DIALOG. http://www.dtnprogressivefarmer.com/dtnag/renewable-fuels. Accessed 13 Mar 2015

Drake HL (1994) Introduction to acetogenesis. In: Drake HL (ed) Acetogenesis. Chapman and Hall, London, pp 3–60

Drake HL, Daniel SL (2004) Physiology of the thermophilic acetogen Moorella thermoacetica. Res Microbiol 155:422–436

Ewanick SM, Bura R, Saddler JN (2007) Acid-catalyzed steam pretreatment of lodge pole pine and subsequent enzymatic hydrolysis and fermentation to ethanol. Biotechnol Bioeng 98:737–746

Fast AG, Schmidt ED, Jones SW, Tracy BP (2015) Acetogenic mixotrophy: novel options for yield improvement in biofuels and biochemicals production. Curr Opin Biotechnol 33:60–72

Grand View Research I (2015) Acetic acid market analysis by application (VAM, acetic anhydride, acetate esters, PTA) and segment forecasts to 2022. Available via DIALOG. http://www.grandviewresearch.com/industry-analysis/acetic-acid-market. Accessed 1 Aug 2015

Hu P, Rismani-Yazdi H, Stephanopoulos G (2013) Anaerobic CO2 fixation by the acetogenic bacterium Moorella thermoacetica. Am Inst Chem Eng 59(9):3176–3183

Jönsson LJ, Alriksson B, Nilvebrant N (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:1–10

Kim J, Block DE, Mills DA (2010) Simultaneous consumption of pentose and hexose sugars: an optimal microbial phenotype for efficient fermentation of lignocellulosic biomass. J Appl Microbiol Biotechnol 88:1077–1085

Ljungdah LG (2009) A life with acetogens, thermophiles, and cellulolytic anaerobes. Annu Rev Microbiol 63:1–25

Ljungdahl LG (1986) The autotrophic pathway in acetate synthesis in acetogenic bacteria. Annu Rev Microbiol 40:415–450

Lundie L Jr, Drake HL (1984) Development of a minimally defined medium for the acetogen Clostridium thermoaceticum. J Bacteriol 159:700–703

Lundqvist J, Jacobs A, Palm M, Zacchi G, Dahlman O, Stalbrand H (2003) Characterization of galactoglucomannan extracted from spruce (Picea abies) by heat-fractionation at different conditions. Carbohydr Polym 51:203–211

Mohagheghi A, Ruth M, Schell DJ (2006) Conditioning hemicellulose hydrolysates for fermentation: effect of overliming pH on sugar and ethanol yields. Process Biochem 41:1806–1811

Ounine K, Petitdemange H, Raval G, Gay R (1985) Regulation and butanol inhibition of d-xylose and d-glucose uptake in Clostridium acetobutylicum. J Appl Environ Microbiol 49:874–878

Parekh SR, Cheryan M (1994) Continuous production of acetate by Clostridium thermoaceticum in a cell-recycle membrane bioreactor. Enzyme Microb Technol 16:104–109

Pierce E, Xie G, Barabote RD, Saunders E, Han CS, Detter JC, Richardson P, Brettin TS, Das A, Ljungdahl LG, Ragsdale SW (2008) The complete genome sequence of Moorella thermoacetica (f. Clostridium thermoacetica). Environ Microbiol 10:2550–2573

Schwartz RD, Keller FA (1982) Acetic acid production by Clostridium thermoaceticum in pH-controlled batch fermentation at acidic pH. Appl Environ Microbiol 43:1385–1392

Shah MM, Cheryan M (1995) Acetate production by Clostridium thermoaceticum in corn steep liqour media. J Ind Microbiol 15:424–428

Shah MM, Cheryan M (1995) Improvement of productivity in acetic acid fermentation with clostridium thermoaceticum. Appl Biochem Biotechnol 51(52):413–422

Stulk J, Hillen W (1999) Carbon catabolite repression in bacteria. J Curr Opin Microbiol 2:195–201

Sugaya K, Tuse D, Jones JL (1986) Production of acetic acid by Clostridium thermoaceticum in batch and continuous fermentation. Biotechnol Bioeng 28:678–683

Tracy BP, Jones SW, Fast AG, Indurthi DC, Papoutsakis ET (2012) Clostridia: the importance of their exceptional substrate and metabolite diversity for biofuel and biorefinery applications. Curr Opin Biotechnol 23:364–381

Wang G, Wang DI (1984) Elucidation of growth inhibition and acetic acid production by Clostridium thermoaceticum. Appl Environ Microbiol 47:294–298

Wang G, Wang DIC (1983) Production of acetic acid by immobilized whole cells of Clostridium thermoacetica. Appl Biochem Biotechnol 8:491–503

Waterhous A (2012) Folin-Ciocalteau Micro Method for Total Phenol in Wine. Available via DIALOG.http://waterhouse.ucdavis.edu/faqs/folin-ciocalteau-micro-method-for-total-phenol-in-wine. Accessed 4 Mar 2014

Witjitra K, Shah M, Cheryan M (1996) Effect of nutrient sources on growth and acetate production by Clostridium thermoaceticum. Enzyme Microb Technol 19:322–327

Yoneda N, Kusano S, Yasui M, Pujado P, Wilcher S (2001) Recent advances in processes and catalysts for the production of acetic acid. Appl Catal A Gen 221:253–265 (Published by Elsevier Science B.V.)

Acknowledgments

This research was supported by US Department of Agriculture with funding from Agriculture and Food Research Initiative (USDA AFRI Grant 2011-68005-30407). We would like to thank University of Washington-Denman Professorship funds in Bioresource Engineering as well as Biofuels and Bioproducts Laboratory Research Group. Our special thanks to Dr. Shannon Ewanick, Dr. Rodrigo Morales, and Naila Ribeiro Mori for providing hydrolysates, and undergraduate student, Mencius Leonard.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ehsanipour, M., Suko, A.V. & Bura, R. Fermentation of lignocellulosic sugars to acetic acid by Moorella thermoacetica . J Ind Microbiol Biotechnol 43, 807–816 (2016). https://doi.org/10.1007/s10295-016-1756-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-016-1756-4