Abstract

Ethanol production derived from Saccharomyces cerevisiae fermentation of a hydrolysate from floriculture waste degradation was studied. The hydrolysate was produced from Chrysanthemum (Dendranthema grandiflora) waste degradation by Pleurotus ostreatus and characterized to determine the presence of compounds that may inhibit fermentation. The products of hydrolysis confirmed by HPLC were cellobiose, glucose, xylose and mannose. The hydrolysate was fermented by S. cerevisiae, and concentrations of biomass, ethanol, and glucose were determined as a function of time. Results were compared to YGC modified medium (yeast extract, glucose and chloramphenicol) fermentation. Ethanol yield was 0.45 g g−1, 88 % of the maximal theoretical value. Crysanthemum waste hydrolysate was suitable for ethanol production, containing glucose and mannose with adequate nutrients for S. cerevisiae fermentation and low fermentation inhibitor levels.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

First generation biofuel sustainability concerns, controversy generated about their positive and negative effects on environmental issues, as well as social and economic benefits, (Hill et al. 2006; Gnansounou 2011; Janssen and Rutz 2011), justify the search for new biofuel sources. Lignocellulosic biomass from agricultural and forestry residues represent low cost raw material alternatives (Saha 2004), which can be used for ethanol production reducing the impact on land resources, and not compromising food security (Blaschek et al. 2010).

Since Colombia is the second flower producer in the world, the use of floriculture waste to produce second generation bioethanol could be an interesting alternative to support this agricultural sector, affected negatively for the past 5 years by the revaluation of the Colombian peso. In 2009, 7,509 hectares were planted with flowers, most of them Rose, Dianthus caryophyllus, and Chrysanthemum, which generate 1 t/ha of plant waste per week (Asocolflores 2009). Therefore, there is a great amount of waste produced after cut-off and harvest with few alternatives of use and valorization. In addition, flower waste accumulation has generated a negative environmental impact on landscape, with unpleasant odors, plagues, water pollution and generation of pests (Asocolflores 2002).

Despite the advantages of lignocellulosic biomass as feedstock for fermentable sugars, lignocellulose’s structure requires pre-treatment with dilute acids or steam explosion to hydrolyze and obtain suitable substrates for fermentation (Kumar et al. 2009). These procedures consume energy and can have a negative impact on the environment. Although lignocellulose hydrolysates can be metabolized by yeast or other microorganisms to produce ethanol, their fermentation is more difficult than that of traditional substrates obtained from molasses or starch. The bases of these differences are diverse. For one, hemicellulose hydrolysate contains pentoses and not only hexoses, with xylose as the predominant sugar during hardwood degradation. Second, the presence of a wide variety of inhibitory compounds, whose composition and concentration depend on the lignocellulosic material type, the pre-treatment implemented, and the hydrolysis process, all can have an effect on microorganism metabolism and ethanol production. Thus, fermentative microorganisms must be capable of producing ethanol from hydrolysates containing pentoses and inhibitors, at high yield and productivity without producing adverse byproducts, such as chemicals harmful to health or the environment (Taherzadeh and Niklasson 2004).

During lignocellulosic material hydrolysis a wide variety of inhibitory compounds for some microorganisms are released. Based on their origin, inhibitors are divided into three groups: weak acids, furan derivatives, and phenolic compounds (Palmqvist and Hahn-Hägerdal 2000a). Hemicellulose is hydrolyzed into xylose, mannose, acetic acid, galactose and glucose. At high temperatures and pressures xylose is further degraded to furfural. Similarly, degradation of hexoses produces hydroximethylfurfual (HMF). Phenolic compounds are generated by partial breakdown of lignin and it has also been reported that these compounds are formed during carbohydrate degradation (Palmqvist and Hahn-Hägerdal 2000a).

In search of maximum ethanol conversion from lignocellulose degradation different methodologies have been evaluated. Some of them increase processing time, use synthetic media or high doses of commercial enzymes. These procedures can reduce productivity, profitability and competitiveness. Quevedo-Hidalgo et al. (2012), reported operating conditions for Chrysanthemum waste degradation not employing the strategies afore mentioned. The process requires Chrysanthemum waste milling, followed by 24 h P. ostreatus degradation. The product is a hydrolysate rich in fermentable sugars (21.2 g l−1) with 78 % of them corresponding to glucose.

Saccharomyces cerevisiae is generally used for ethanol production using starch and feedstock from sugar. Glucose, sucrose, maltose, maltotriose, fructose, mannose, and galactose are sugars metabolized by S.cerevisiae (Drapcho et al. 2008). However this yeast cannot ferment xylose nor arabinose (Cerveró et al. 2010). The purpose of the present study was to investigate the process of ethanol production by S. cerevisiae from sugars present in hydrolysate from the degradation of Chrysanthemum waste with P. ostreatus.

Materials and methods

Chrysanthemum waste (stems and leaves) were supplied by Cultivos del Norte (Tocancipá, Colombia). Before degradation residues were milled to a particle size smaller than 1 mm. Lignin, cellulose, and hemicellulose content were analyzed by neutral detergent fiber method (NDF) (Van Soest et al. 1991). Microorganism, P. ostreatus (HPB/P3) and S. cerevisiae (SOL/M5) were obtained from Pontificia Universidad Javeriana (Bogotá, Colombia).

Chrysanthemum waste degradation with P. ostreatus to produce hydrolysate

Fungal inoculums were prepared by growing 50 g Chrysanthemum waste, 2 g yeast extract, 5 g peptone, 0.075 g MnSO4.H2O, 1 g KH2PO4, 0.5 g MgSO4.7H20, and 175 g wheat bran in 250 ml Erlenmeyer flasks containing 50 ml media on static culture at 30 ± 2 °C. Media was inoculated with ten fungal disks (5 mm diameter) isolated from the edge of a 7-day old mycelium grown on bran extract agar in Petri dishes. After 7 days, mycelial biomass was obtained and inoculated (5 % of dry mycelium based on substrate volume) in 250 ml Erlenmeyer flasks.

Degradation was performed in a 1.5 l bioreactor (TECFERM, Procesos Biotecnológicos y Medioambientales, Bogotá, Colombia) equipped with a Rushton turbine and a Watlow temperature controller capable of maintaining temperature within 30 ± 1 °C (St. Louis, MO, USA). The reactor was initially charged with 400 ml containing 0.1 M sodium citrate buffer (pH 5.6), 7.5 mM copper sulfate, and 7.5 mM manganese sulfate. Chrysanthemum waste (6.3 % w/v) was then added and the solution was sterilized at 121 °C for 15 min. When temperature reached 30 ± 2 °C P. ostreatus (5 % p/v) was added to the reactor with an agitation speed of 240 ± 5 rpm and an aeration rate of 2 vvm. After 24 h degradation the culture was centrifuged at 10,800 g for 15 min at 4 °C (Sorvall RC-6 plus Thermo Scientific Co Waltham, MA, USA) to separate fungal biomass and insoluble components. Finally, the hydrolysate was filtered through a Millipore membrane (0.45 μm).

Reducing sugars concentration was measured by 3,5-dinitrosalicilic acid (DNS) technique (Miller 1959), using an Evolution 60 UV–VIS Thermo Scientific Co spectrophotometer (Waltham, MA, USA). A calibration curve was fitted using glucose as standard at concentrations from 0.5 to 2 g l−1. Total protein was quantified using Bradford technique with bovine serum albumin as a standard with concentrations ranging from 100 to 1,000 mg l−1 (Bradford 1976).

Cellobiose, glucose, xylose, galactose, arabinose, and mannose concentrations were determined by HPLC (Shimadzu Prominence LC-20AT Tokyo, Japan) equipped with an Aminex HPX-87P column (300 mm × 7.8 mm, Bio-Rad, USA) and a refractive index detector (Shimadzu RID-10A). For the mobile phase purified water was used at 0.4 ml min−1 and an 84 °C column temperature. Reference standards (>99 % purity) were purchased from Sigma-Aldrich (St Louis, MO, USA).

Fermentation inhibitor determination

Presence of some common hydrolysate inhibitors during fermentation was evaluated. 5-hydroxymethylfurfural, furfural, 4-hydroxybenzoic acid, 4-hydroxybenzaldehyde, vanillin acid, syringic acid, vanillin, syringaldehyde, p-coumaric acid, and ferulic acid concentrations were determined by HPLC, (Shimadzu Prominence LC-20AT), using a Chromolith C18 column (Merck, Darmstadt, Germany). Methanol-acetic acid–water (4:7:89) was used as the mobile phase at 2 ml min−1, with a column temperature of 30 °C. Eluate was detected by a UV at 270 nm. 100 % mobile phase gradient at t = 0 min, t = 20 min methanol-mobile phase (16:84), and t = 25 min 100 % mobile phase for a total of 30 min. Acetic acid concentration was determined by HPLC (Shimadzu) using an Aminex column (HPX-87H 300 mm × 7.8 mm Bio-Rad), and 0.005 N sulfuric acid as the mobile phase at a 0.6 ml min−1 and 60 °C column temperature. The eluate was detected by diode array detector at 210 nm (Shimadzu SPD-M20A Tokyo, Japan).

Fermentation process

S. cerevisiae was inoculated massively in YGC agar (yeast extract 10 g l−1, peptone 20 g l−1, glucose 20 g l−1 and chloramphenicol 0.1 g l−1, agar 15 g l−1), incubated at 30° C for 24 h. Harvested yeast corresponded to 1.75 g dry weight per liter. At this stage Chrysanthemum waste hydrolysate without nutrient addition and YGC modified (YGCM) medium were used as substrates. Reducing sugar concentration and hydrolysate sugar profile are presented in the result section. For the YGCM medium, glucose concentration was modified using the same concentration of the hydrolysate as a positive control. YGCM media consisted of: 10 g l−1 yeast extract, 20 g l−1 peptone, 0.1 g l−1 chloramphenicol, and 15.2 g l−1glucose. Concentration of glucose at t = 0 for hydrolysate fermentation was 14.4 g l−1 and 11.4 g l−1 for YGCM fermentation. For data analysis glucose concentration at t = 0 was taken into account.

Anaerobic batch experiments were performed at 30 °C in 10 ml closed bottles containing 6 ml fermentation medium (lignocellulosic hydrolysate and YGCM) with inoculum agitated at 150 rpm for 14 h in an orbital shaker. Three bottles were removed at intervals of 2 h to quantify biomass, ethanol, mannose and glucose. Changes in biomass concentration throughout the fermentation process were measured by optical density at 620 nm (Evolution 60 UV–VIS spectrophotometer Thermo Scientific Co Waltham, MA, USA). Dry matter content was determined from a standard curve at 620 nm.

Ethanol, glucose and mannose concentrations were determined by HPLC (Shimadzu LC-20AT Prominence Tokyo, Japan), using an Aminex HPX-87H column (Bio-Rad Philadelphia, PA, USA) and refractive index detector (Shimadzu RID-10A Tokyo, Japan) with Sulfuric acid (0.005 N) as the mobile phase at 0.6 ml min−1. Samples (20 μl) were automatically injected. The column temperature was set at 60 °C. Calibration curves were determined for the following standards: glucose, mannose and ethanol. Glucose and mannose (>99 % purity) were purchased from Sigma-Aldrich (St. Louis, MO, USA), and ethanol (>99.5 % purity) was obtained from Merck (Darmstadt, Germany).

Statistical analysis

Results are presented as mean ± standard deviations (n = 3 with replicates per fermentation). For each reaction time coefficient of variation for biomass, ethanol, and glucose were determined using Excel Microsoft Office 2010 (Microsoft Corp., United USA).

Results and discussion

Degradation process

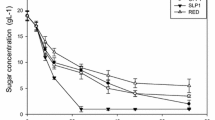

As determined by DNS reducing sugar concentration was 21.2 g l−1. Samples were analyzed after 24 h by HPLC with the following sugar percentages: 2.8 % cellobiose, 80.3 % glucose, 0.2 % xylose, and 16.5 % mannose (Fig. 1). Glucose was present at the highest percentage among the reducing sugars evaluated. This carbohydrate is important for its wide variety of applications.

The hydrolysis percentage obtained from Chrysanthemum waste was 58 %. This value was calculated based on Chrysanthemum waste cellulose and hemicellulose composition (Quevedo-Hidalgo et al. 2012). Compared with other lignocellulosic materials, as animal manure (Wen et al. 2004), rice straw (Vlasenko et al. 1997), and corncob (Chen et al. 2007), it is an acceptable hydrolysis percentage. Hydrolysis percentages and time reported in these studies ranged from 38 to 85 % and from 60 to 96 h, respectively. Grinding, acidic or steam explosion pre-treatments were used followed by enzymatic hydrolysis with commercial cellulases and cellobiases. Furthermore, our work presents the benefits of a shorter processing time (24 h) with no use of commercial enzymes for hydrolysis, thus reducing production costs.

Most research regarding sugar production from agricultural and forestry waste implement physical, chemical or enzymatic pre-treatments to increase hydrolysis yield. For example, cellulose hydrolysis without pre-treatment typically yields less than 20 % whereas after pre-treatment exceeds 90 % (Hamelinck et al. 2005). Few studies have reported biological treatment, because sugars represent a carbon source for microorganism growth that is quickly consumed. As a case in point, El-Gammal et al. (1998) degraded sugar cane bagasse with Phanerochaete chrysosporium or Coriolus versicolor in solid state fermentation for 8 weeks, obtaining maximum reducing sugar concentration of 15.6 and 6.8 g l−1 respectively.

Despite of this, biological treatments, including white rot fungi degradation, have been widely studied for enzyme production (Schlosser et al. 1997; Verma and Madamwar 2002; Lechner and Papinutti 2006; Elisashvili et al. 2006; Levin et al. 2008; Liew et al. 2010), de-lignification for production of waste suitable for livestock feed (Adamovic 1998; Shrivastava et al. 2011), biomass production (Yildiz et al. 2002; Nyochembeng et al. 2008; Kurt and Buyukalaca 2010; Papaspyridi et al. 2010), and lignocellulose degradation (Kerem et al. 1992; Yu et al. 2008; Gupta et al. 2011)

Chrysanthemum waste degradation compound determination

Phenolic compounds are major inhibitors in lignocellulosic hydrolysates (Palmqvist and Hahn-Hägerdal 2000b). Its presence results in inhibitory effect on S. cerevisiae fermentation and ethanol production as reported by Palmqvist and Hahn-Hägerdal (2000a), who found that the presence of 4-hydroxybenzoic acid at 1 g l−1 caused a 30 % decrease in ethanol yield. Vanillin, less toxic than 4-hydroxybenzoic acid at 1 g l−1 resulted in 25 % ethanol yield decrease, while vanillin acid had no effect at concentrations up to 1 g l−1 (Palmqvist and Hahn-Hägerdal 2000a). Considering these results, we evaluated the presence of 4-hydroxibenzoic acid, 4-hydroxibenzaldehyde, vainillinic acid, siringic acid, vainillin, siringaldehyde, p-cumaric acid and ferulic acid. Our results demonstrated that phenolic compounds were not detected or were at low concentrations in the hydrolysate. This result is critical, since it presents an advantage over other methodologies.

Hydrolysate analyzed by Quevedo-Hidalgo et al. (2012), contains enzymes such as laccase and manganese peroxidase, which we suggest degraded phenolic compounds. A detoxification process was reported by Jönsson et al. (1998), who added laccase to hydrolysates and subsequently fermented with S. cerevisiae. Their work reported greater ethanol productivity for laccase treated samples compared to untreated samples. Chandel et al. (2007), degraded bagasse with HCl and the hydrolysate from this process was treated with laccase, reducing phenol content up to 77.5 %.

Furfural and 5-hydroxymethyl furfural are bioconvertible fermentation inhibitors (Palmqvist and Hahn-Hägerdal 2000b), justifying our evaluation of their presence in the hydrolysate. As for phenolic compounds, our results evidenced that these compounds were not detected or were at low concentrations in the hydrolysate. Low weak acid concentration (<100 mM) has shown a stimulatory effect on ethanol production by S. cerevisiae. On the other hand, higher concentrations (>200 mM) of carboxylic acids decrease ethanol yield (Palmqvist and Hahn-Hägerdal 2000a). Acetic acid was present in the hydrolysate at 21.3 mM, therefore it was not a limitation for ethanol production.

S. cerevisiae fermentation with hydrolysate and YGCM medium

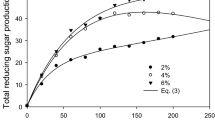

Figure 2 shows the behavior of the variables measured during fermentation of hydrolysate and YGCM medium. For the hydrolysate, glucose and mannose consumption was evidenced by their transformation to ethanol. Total glucose and mannose consumptions were 98.7 and 95.2 %, respectively. Maximum ethanol production (7.6 ± 0.24 g l−1) was attained after 10 h of fermentation. Results from S. cerevisiae fermentation in YGCM medium evidenced 98.8 % of glucose consumption, comparable to hydrolysate fermentation. Maximum ethanol concentration (5.4 ± 0.41 g l−1) was obtained after 8 h processing, 2 h less than that of the hydrolysate.

Figure 2b shows that within the first 4 h of fermentation glucose and mannose were rapidly consumed and their consumption rates were similar. However, ethanol concentration was cero during the first 2 h (Fig. 2c), indicating that glucose and mannose were used for the growth of the microorganism. During the next 4 h, when the growth rate of the microorganism was the highest (Fig. 2a), glucose consumption rate was higher than mannose. Ethanol concentration continued to increase, and at the end of the fermentation 95 % of the glucose and 55 % of the mannose had been consumed. Finally, between 8 and 12 h of fermentation, mannose consumption rate increased and was higher than the glucose; with maximum ethanol concentration obtained. The minimum mannose concentration (0.15 g l−1) was reached after 14 h of fermentation. We suggest this behavior was the result of S. cerevisiae’s capability of fermenting glucose and mannose. Both sugars are transported by the different members of the hexose transporter family, regardless of mannose’s greater K m value compared to glucose (van Maris et al. 2006). As mannose and glucose compete for the same hexose transporters, kinetics of mixed-substrate utilization is determined by their relative and absolute concentrations in hydrolysates (van Maris et al. 2006).

Yield and productivity for hydrolysate and YGCM fermentations are shown in Table 1. Yp/s was calculated for the samples with maximum concentration of ethanol, obtained after 10 and 8 h, respectively. For the Yp/s determination hydrolysate glucose and mannose were taken into account. For YGCM medium fermentation Yp/s was greater compared to hydrolysate (94 vs. 88 %). Further studies based on this difference should be carried-out to achieve a theoretical value between 90 and 93 % at an industrial scale (Bai et al. 2008; Dodić et al. 2009; Kuhad et al. 2010). In practice theoretical yield cannot be achieved because not all the glucose consumed is converted into ethanol. Some glucose is used for cell mass synthesis, cell maintenance, and production of other products such as glycerol, acetic, lactic and succinic acid. Under ideal conditions, yield should be between 90 and 95 % of the theoretical value (Drapcho et al. 2008).

Several studies describe the production of ethanol from lignocellulosic biomass using enzymatic hydrolysis followed by fermentation and simultaneous saccharification and fermentation (SSF). Table 2 shows the performance on studies implementing batch and fed batch fermentation. From the Table it can be concluded that ethanol concentrations varies depending on residue. From our results maximum ethanol concentration was close to the lower limit of the interval reported in Table 2. On the other hand, ethanol yield and volumetric ethanol productivity were close to the highest values reported in this table, which demonstrates the benefits of our process. Calculated volumetric ethanol productivity including the hydrolysis time was 0.22 g l−1 h−1, in agreement with the range reported for SSF processes in Table 2. Furthermore, hydrolysis was performed with P. ostreatus instead of commercial enzymes reducing production cost and increasing economic feasibility of the process.

One of the major drawbacks in bioethanol production is lignocellulose recalcitrance. To overcome this disadvantage, biomass pretreatment has been devised to remove barriers and make cellulose more accessible to hydrolytic enzymes for glucose conversion (Balat 2011). On the one hand, if pre-treatments are not adequate, cellulase enzymes cannot easily hydrolyze the resulting residue. On the other hand, if the result is so severe, toxic compound production could be promoted, which inhibit microbial metabolism. Pre-treatment has been viewed as one of the most expensive processing steps in cellulosic biomass to fermentable sugars conversion (Balat 2011). In this paper we describe the use of biological pre-treatment for cellulose hydrolysis to obtain fermentable sugars in a single short process (24 h), making it economically attractive.

Our results demonstrated that hydrolysate composition provided all required components for ethanol production. Considering protein content in the hydrolysate, 448.7 mg l−1, addition of yeast extract or peptone as nitrogen sources was not necessary. This is an advantage over other studies where nitrogen addition was required, such as S. cerevisiae substrate fermentation from lignocellulosic material hydrolysis from yellow poplar and wood residues (Lee et al. 2011), and from cellulosic fines from corn stalks, barley straw, alfalfa, reed canary grass and timothy (Belkacemi et al. 2002). Furthermore, S. cerevisiae requires for growth and ethanol production certain minerals such as Ca, Mg, Mn, Co, Fe, Cu, K, Na, Zn (Drapcho et al. 2008). Most of them were present in the hydrolysate considering these metals were found in the Chrysanthemum waste (Quevedo-Hidalgo et al. 2012), so mineral addition was not necessary, another argument in favor of the process described in this work.

In conclusion, hydrolysate product derived from Chrysanthemum waste degradation followed by S. cerevisiae fermentation of mannose and glucose produced ethanol with 88 % yield over maximal theoretical value. Acetic acid, some furan derivatives and certain phenolic compounds although present in the hydrolysate, did not inhibit ethanol production. Most nutrients required by S. cerevisiae for fermentation were present in the hydrolysate, thus it was not necessary to add nutritional supplements for fermentation.

References

Adamovic M (1998) The biodegradation of wheat straw by Pleurotus ostreatus mushrooms and its use in cattle feeding. Animal Feed Sci Technol 71(3–4):357–362

Asocolflores (2002) Ministerio de Medio Ambiente y Sociedad de Agricultores de Colombia. Guía Ambiental para la floricultura. http://www.minambiente.gov.co/documentos/. Accessed 17 August 2011

Asocolflores (2009) Global Reporting Initiative (GRI). http://www.asocolflores.org/asocolflores/index.jsp?page=78&site=1&idFile=1800&fromPage=2&adminMode=false. Accessed 14 June 2012

Bai FW, Anderson WA, Moo-Young M (2008) Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol Adv 26(1):89–105

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energy Convers Manage 52(2):858–875

Ballesteros M, Oliva JM, Negro MJ, Manzanares P, Ballesteros I (2004) Ethanol from lignocellulosic materials by a simultaneous saccharification and fermentation process (SFS) with Kluyveromyces marxianus CECT 10875. Process Biochem 39(12):1843–1848

Belkacemi K, Turcotte G, Savoite P (2002) Aqueous/steam-fractionated agricultural residues as substrates for ethanol production. Ind Eng Chem Res 41:173–179

Blaschek H, Ezeji TC, Scheffran J (2010) Biofuels from agricultural wastes and byproducts: an introduction. In: Blaschek H, Ezeji TC, Scheffran J (eds) Biofuels from agricultural wastes and byproducts. Blackwell, Oxford, pp 3–9

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Cerveró JM, Skovgaard PA, Felby C, Sørensen HR, Jørgensen H (2010) Enzymatic hydrolysis and fermentation of palm kernel press cake for production of bioethanol. Enzym Microbial Technol 46(3–4):177–184

Chandel AK, Kapoor RK, Singh A, Kuhad RC (2007) Detoxification of sugarcane bagasse hydrolysate improves ethanol production Candida shehatae NCIM 3501. Bioresour Technol 98:1947–1950

Chen M, Xia L, Xue P (2007) Enzymatic hydrolysis of corncob and ethanol production from cellulosic hydrolysate. Int Biodeterior Biodegradation 59(2):85–89

Dodić S, Popov S, Dodić J, Ranković J, Zavargo Z, Jevtić Mučibabić R (2009) Bioethanol production from thick juice as intermediate of sugar beet processing. Biomass Bioenergy 33(5):822–827

Drapcho CM, Nhuan NP, Walker TH (2008) Biofuels engineering process technology. Mc Graw Hill, NewYork

El-Gammal A, Kamel Z, Adeeb Z, Helmy S (1998) Biodegradation of lignocellulosic substances and production of sugars and lignin degradation intermediates by four selected microbial strains. Polym Degrad Stab 61(3):535–542

Elisashvili V, Penninckx M, Kachlishvili E, Asatiani M, Kvesitadze G (2006) Use of Pleurotus dryinus for lignocellulolytic enzymes production in submerged fermentation of mandarin peels and tree leaves. Enzym Microb Technol 38(7):998–1004

Gnansounou E (2011) Assessing the sustainability of biofuels: a logic-based model. Energy 36:2089–2096

Gupta R, Mehta G, Khasa YP, Kuhad RC (2011) Fungal delignification of lignocellulosic biomass improves the saccharification of cellulosics. Biodegradation 22(4):797–804

Hamelinck CN, van Hooijdonk G, Faaij APC (2005) Ethanol from lignocellulosic biomass: techno-economic performance in short- middle- and long-term. Biomass Bioenergy 28:384–410

Hill J, Nelson E, Tilman D, Polasky S, Tiffany D (2006) Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc Natl Acad Sci USA 103(30):11206–11210

Janssen R, Rutz DD (2011) Sustainability of biofuels in Latin America: risks and opportunities. Energy Policy 39:5717–5725

Jönsson LJ, Palmqvist E, Nilvebrant NO, Hahn-Hägerdal B (1998) Detoxifcation of wood hydrolysates with laccase and peroxidase from the white-rot fungus Trametes versicolor. Appl Microbiol Biotechnol 49:691–697

Kerem Z, Friesem D, Hadar Y (1992) Lignocellulose degradation during solid-State fermentation: Pleurotus ostreatus versus Phanerochaete chrysosporium. Appl Environ Microbiol 58(4):1121–1127

Kuhad RC, Mehta G, Gupta R, Sharma KK (2010) Fed batch enzymatic saccharification of newspaper cellulosics improves the sugar content in the hydrolysates and eventually the ethanol fermentation by Saccharomyces cerevisiae. Biomass Bioenergy 34(8):1189–1194

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729

Kurt S, Buyukalaca S (2010) Yield performances and changes in enzyme activities of Pleurotus spp. (P. ostreatus and P. sajor-caju) cultivated on different agricultural wastes. Bioresour Technol 101(9):3164–3169

Lechner B, Papinutti V (2006) Production of lignocellulosic enzymes during growth and fruiting of the edible fungus Lentinus tigrinus on wheat straw. Process Biochem 41(3):594–598

Lee H, Cho H, Kim Y, Shin S, Kim SB, Han S, Lee J et al (2011) Tolerance of Saccharomyces cerevisiae K35 to lignocellulose-derived inhibitory compounds. Biotechnol Bioprocess Eng 16:755–760

Levin L, Herrmann C, Papinutti VL (2008) Optimization of lignocellulolytic enzyme production by the white-rot fungus Trametes trogii in solid-state fermentation using response surface methodology. Biochem Eng J 39(1):207–214

Liew CY, Husaini A, Hussain H, Muid S, Liew KC, Roslan HA (2010) Lignin biodegradation and ligninolytic enzyme studies during biopulping of Acacia mangium wood chips by tropical white rot fungi. World J Microbiol Biotechnol 27(6):1457–1468

Miller G (1959) Use of dinitrosalisyc acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Nyochembeng LM, Beyl CA, Pacumbaba RP (2008) Optimizing edible fungal growth and biodegradation of inedible crop residues using various cropping methods. Bioresour Technol 99(13):5645–5649

Öghren K, Bura R, Lesnicki G, Saddler J, Zacchi G (2007) A comparison between simultaneous saccharification and fermentation and separate hydrolysis and fermentation using steam-pretreated corn stover. Process Biochem 42:834–839

Palmqvist E, Hahn-Hägerdal B (2000a) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74(1):25–33

Palmqvist E, Hahn-Hägerdal B (2000b) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74(1):17–24

Papaspyridi LM, Katapodis P, Gonou-Zagou Z, Kapsanaki-Gotsi E, Christakopoulos P (2010) Optimization of biomass production with enhanced glucan and dietary fibres content by Pleurotus ostreatus ATHUM 4438 under submerged culture. Biochem Eng J 50(3):131–138

Quevedo-Hidalgo B, Narváez-Rincón P, Pedroza-Rodríguez, A, Velásquez-Lozano, M (2012) Degradation of Chrysanthemum (Dendranthema grandiflora) wastes by Pleurotus ostreatus for the production of reducing sugars. Biotechnol Bioprocess Eng doi:10.1007/s12257-012-0227-7

Saha BC (2004) Lignocellulos biodegradation and applications in biotechnology. In: Saha BC, Hayashi K (eds) Lignocellulose biodegradation. ACS Symposium Series: American Chemical Society, Washington, pp 2–34

Schlosser D, Grey R, Fritsche W (1997) Patterns of ligninolytic enzymes in Trametes versicolor. Distribution of extra- and intracellular enzyme activities during cultivation on glucose, wheat straw and beech wood. Appl Microbiol Biotechnol 47(4):412–418

Shrivastava B, Thakur S, Khasa YP, Gupte A, Puniya AK, Kuhad RC (2011) White-rot fungal conversion of wheat straw to energy rich cattle feed. Biodegradation 22(4):823–831

Taherzadeh M, Niklasson C (2004) Ethanol from lignocellulosic materials: pretreatment, acid and enzymatic hydrolyses, and fermentation. In: Saha BC, Hayashi K (eds) Lignocellulose biodegradation. ACS Symposium Series: American Chemical Society, Washington, pp 49–68

van Maris JA, Abbott DA, Bellissimi E, Brink JV, Kuyper M, Luttik MA, Wisselink HW et al (2006) Alcoholic fermentation of carbon sources in biomass hydrolysates by Saccharomyces cerevisiae: current status. Antonie Van Leeuwenhoek 90:391–418

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. symposium: carbohydrate methodology, metabolism, and nutritional implications in dairy cattle. J Dairy Sci 74:3583–3597

Verma P, Madamwar D (2002) Production of ligninolytic enzymes for dye decolorization by cocultivation of white-rot fungi Pleurotus ostreatus and Phanerochaete chrysosporium under solid-state fermentation. Appl Biochem Biotechnol 102–103(1–6):109–118

Vlasenko EY, Ding H, Labavitch JM, Shoemaker SP (1997) Enzymatic hydrolysis of pretreated rice straw. Bioresour Technol 59(2–3):109–119

Wen Z, Liao W, Chen S (2004) Hydrolysis of animal manure lignocellulosics for reducing sugar production. Bioresour Technol 91(1):31–39

Yildiz S, Yildiz ÜC, Gezer ED, Temiz A (2002) Some lignocellulosic wastes used as raw material in cultivation of the Pleurotus ostreatus culture mushroom. Process Biochem 38(3):301–306

Yu H, Li L, Zhang X, Huang H (2008) Effects of wood species and enzyme production on lignocellulose degradation during the biodegradation of three native woods by Trametes versicolor. For Prod J 58(4):62–65

Acknowledgments

The authors acknowledge financial support from Pontificia Universidad Javeriana and the División de Investigación de la Sede Bogotá (DIB) at Universidad Nacional de Colombia. We also thank Cultivos del Norte for providing the Chrysanthemum waste and Maria Lucia Gutierrez for English editing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quevedo-Hidalgo, B., Monsalve-Marín, F., Narváez-Rincón, P.C. et al. Ethanol production by Saccharomyces cerevisiae using lignocellulosic hydrolysate from Chrysanthemum waste degradation. World J Microbiol Biotechnol 29, 459–466 (2013). https://doi.org/10.1007/s11274-012-1199-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-012-1199-7