Abstract

A protocol was established for plant regeneration from leaf protoplasts of guava (Psidium guajava L.) using mixture-amount (concentration) experiments. A protoplast yield of 3.7 × 106 (viability >90 %) was obtained when 1 g leaf strips were digested in a solution of ∼0.75 M osmoticum with 6 % (w/v) enzyme containing cellulase: macerase: hemicellulase as proportion of ∼0.4: 0.5: 0.1. Protoplasts developed the maximum number of microcalli using 1.0 mg l−1 α-naphthaleneacetic acid (NAA). Maximum shoot formation (>12) via organogenesis from resulting calli was obtained using >3.4 mg l−1 PGRs containing kinetin (K): 6-benzylaminopurine (BAP) at a ratio of 0.6:0.4. Shoots were rooted in medium containing indole-3-butyric acid and plantlets were successfully acclimatized. Results of polynomial response models revealed that: (1) Osmolarity was the primary determinant for protoplast yield and viability, irrespective of osmoticum type; (2) Most of the variation in protoplast yield was driven by macerase concentration; (3) Protoplast viability was driven mainly by cellulase concentration; (4) NAA was superior to BAP for callus induction, an antagonistic proportional effect was observed when they were blended; and (5) K was more effective than BAP in shoot regeneration, but due to synergistic blending the response was highest when both were present. Overall, guava was amenable to protoplast culture and the mixture-amount design effectively characterized this protoplast system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Key message

Guava proved amenable to leaf protoplast culture. Protoplast yield of 3.7 × 106 Pp g−1 and satisfactory callus and shoot regeneration were obtained in optimal condition identified by mixture-amount experiments.

Introduction

Developing an efficient protoplast-to-plant system is a prerequisite to the application of protoplast-based plant-improvement technologies such as somatic hybridization, electroporation, microprotoplast-mediated chromosome transfer, and organelle or DNA microinjection. Protocols for protoplast culture of many fruit species have been developed (Patat-Ochatt et al. 1988; Ochatt 1992; Grosser and Gmitter 1990; Witjaksono and Grosser 1998; Ara et al. 2000; Yu et al. 2000; Haicour et al. 2009; Rezazadeh et al. 2011). In the case of guava (Psidium guajava L.), despite several published protocols for in vitro culture through embryogenesis (Chandra et al. 2004) and shoot culture (Amin and Jaiswal 1987; Liu and Yang 2011; Usman et al. 2012) there are no reports on protoplast isolation and culture. Guava is a commonly known fruit crop and is widely cultivated throughout tropics and subtropics. The fruit is either consumed fresh or processed and is an excellent source of vitamin C (200 mg 100 g−1) and dietary fiber. Developing an efficient guava protoplast system requires two crucial steps—(1) isolation of high yields of viable protoplasts and, (2) efficient plant regeneration from protoplast-derived calli. These steps are strongly affected by the osmolarity of the digesting and culture solutions, digesting enzyme concentrations and composition, and media addenda such as plant growth regulators (PGRs). Different osmotic stabilizers (osmoticum) such as mannitol (Hidaka and Omura 1992; Niedz 1993; Qiao et al. 1998; Witjaksono and Grosser 1998; Da Gloria et al. 2000; Guo et al. 2000; Matsumoto et al. 2002; Wakita et al. 2005) and sorbitol (Jumin and Nito 1996; Ortin-Parraga and Burgos 2003) or combinations of both (Frearson et al. 1973; Myers et al. 1989; Ara et al. 2000) have been frequently used to provide the required osmolarity for isolation and culture. Pectinases and cellulases in different proportions and concentrations are typically used for plant protoplast isolation (Patat-Ochatt et al. 1993; Ara et al. 2000; Da Gloria et al. 2000; Ortin-Parraga and Burgos 2003; Fiuk and Rybczynski 2007; Meyer et al. 2009; Castelblanque et al. 2010; Sheng et al. 2011; Grzebelus et al. 2012). For development of protoplast calli and shoot regeneration PGRs such as auxins and cytokinins have been widely included in culture media in a wide range of concentrations at different stages (Revilla et al. 1987; Patat-Ochatt et al. 1988; Ochatt 1992; Kuchuk et al. 1998; Assani et al. 2001; Nassour et al. 2003; Du and Bao 2005; Wakita et al. 2005; Borgato et al. 2007; Meyer et al. 2009; Castelblanque et al. 2010; Prange et al. 2010; Sheng et al. 2011; Grzebelus et al. 2012).

The proportion and concentration of the above mentioned factors are highly likely to influence the efficiency of a protoplast system. Optimization of factors affecting protoplast isolation and culture have mostly used factorial experimental designs (Ochatt 1992; Qiao et al. 1998; Witjaksono and Grosser 1998; Nassour et al. 2003; Ortin-Parraga and Burgos 2003; Duquenne et al. 2007; Rezazadeh et al. 2011) or one-factor-at-a-time (OFAT) (Park and Son 1992; Qiao et al. 1998; Nassour et al. 2003; Ortin-Parraga and Burgos 2003; Wakita et al. 2005; Castelblanque et al. 2010) experiments which examine the main effects of the factors and/or their interactions. The factorial design has the limitation that proportional and concentration effects are confounded (Anderson and Whitcomb 2002) or when separate effects of proportion and total concentration are sought (Evens and Niedz 2010). A strategy to overcome these limitations is using a mixture-amount design, a class of response surface designs (Niedz and Evens 2011a) in which effects of proportion and concentration and their interactions can be determined (Cornell 2002). Furthermore, mixture-amount designs are more efficient than OFATs or factorial designs for identifying useful formulations in tissue culture, and can discover desirable combination of components within the experimental space (Niedz and Evens 2011a).The simple design of this category, known as a mixture design, has been applied to food (Deka et al. 2001) and agricultural research such as intercropping (Dhekale et al. 2003), formulation of fertilizers (Schrevens and Cornell 1993; Batra et al. 1999) and entomology (Lapointe et al. 2008). In this design one total mixture amount is used and response is a function of proportion of different components in the mixture. Mixture-amount designs, in addition to quantifying the proportional effects of the components, are able to detect the effects of concentration and if proportion and concentration interact by adding it as an additional factor (amount) to design; this type of design has recently been used for in vitro experiments of citrus (Niedz and Evens 2008, 2011a, b).

In this study, we set up guava protoplast experiments using mixture-amount designs to determine the proportional and amount effects for osmotica, digesting enzymes, and PGRs. A natural result of clearly quantifying these effects is the identification of the best combination of factors for an efficient guava protoplast system. The ranges of components and concentrations were based on our previous experience and the review of the literature.

Materials and methods

Protoplast isolation

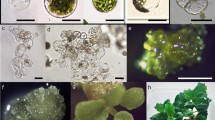

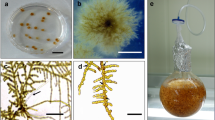

Leaves were collected from axenic shoot cultures (Fig. 1a) of guava cv. Beaumont maintained on MS (Murashige and Skoog 1962) containing 1.5 mg l−1 6-benzylaminopurine (BAP). 250 mg of leaf strips (<0.5 mm) were transferred to a 100-ml Erlenmeyer flask containing 5 ml of enzyme solution that included enzyme, cell and protoplast washing (CPW) salts (Frearson et al. 1973), and osmoticum. The flask containing the leaf strips and enzyme cocktail was then incubated in darkness at 27 °C on a rotary shaker at 45 rpm. Enzyme concentrations used were representative of published protocols and all enzyme solutions were adjusted to pH 5.8 and filter-sterilized with 0.22 µm Millipore (Millex®) filter. After 10 h incubation, suspensions were passed through a 75-µm sterile stainless steel sieve and 40-µm nylon sieve, respectively. The filtrate was transferred to a 15-ml Falcon tube and centrifuged at 100×g for 5 min. After discarding the supernatant, protoplast pellets were washed twice with the same media of the corresponding osmolarity excluding enzymes and re-suspended in CPW salts with osmoticum. Protoplasts were purified through density gradient centrifugation by placing 2 ml of crude protoplast suspension on the top of a 4 ml of 25 % sucrose pad. After centrifugation at 80×g for 3 min, protoplasts were collected by cut-tip Pasteur pipette (from intermediate density) and re-suspended in fresh medium (Fig. 1b). Protoplast yield was determined using a haemocytometer and expressed as the number of protoplasts per gram of leaf tissue (Pp g−1). Viability was measured by fluorescein diacetate (FDA) staining (Widholm 1972) immediately after isolation (Fig. 1c). For yield and viability responses, sterile techniques were not used since the protoplasts were observed 10 h after incubation.

Plant regeneration from leaf-derived protoplasts of guava. a In vitro-derived shoot cultures as protoplast donor; b purified protoplasts; c protoplast stained with fluorescein diacetate (FDA), viable protoplasts appear in bright green; d, e regenerated microcalli; f, g microcalli on shoot regeneration medium; h, i shoot regeneration; j, k rooted shoots; l potted plants (bars in b, c 20 µm, d–g 1 cm)

Protoplast culture

The basal medium was MS salts without NH4NO3 plus 20 mg l−1 thiamine–HCl, 10 mg l−1 pyridoxine, 2 mg l−1 nicotinic acid, 5 mg l−1 pantothenic acid, 30 mg l−1 ascorbic acid, 1.5 mg l−1 l-glutamine, 100 mg l−1 myo-inositol, 50 mg l−1 proline, 30 g l−1 sucrose plus osmotica (sorbitol and/or mannitol based on the formulations of treatment points). The pH was adjusted to 5.8 and the media were filter sterilized. Protoplast culture was performed in two steps under aseptic condition: alginate bead culture, described below, and spread culture.

Sodium alginate (Sigma) was dissolved in osmoticum at concentration of 4 % (w/v) (twice the final concentration) by stirring for 4 h then filter sterilized. Protoplasts were re-suspended at 1 × 105 protoplast per ml (Pp ml−1) [(twice the final initial plating density (i.e., 5 × 104 Pp ml−1)] in calcium-free culture medium then mixed with alginate solution by gently swirling the tubes. The mixture was then dropped (40 µl droplets) into medium containing the same composition minus Na-alginate and plus 50 mM CaCl2. After 1 h, the solidified Ca-alginate beads were washed twice × 10 min with the culture medium and 10 beads were suspended in 10 ml of culture medium containing different proportion and concentrations of α-naphthalene acetic acid (NAA) and BAP (described later) in a 100-ml Erlenmeyer flask and then incubated on a rotary shaker at 30 rpm. Cultures were maintained at 27 °C under a 4-h photoperiod provided by cool-white fluorescent lamps at 15 µmol m−2 s−1. Dilution was carried out by replacing 15 % of the liquid phase (culture minus alginate beads) with mannitol-free medium every 4 days.

After 3 weeks, cell colonies were released from Ca-alginate beads according to the method described by Scheurich et al. (1980) with some modifications. Three alginate beads were incubated for 30 min in a 2-ml Eppendorf tube containing 1.5 ml 20 mM sodium citrate buffer at pH 7.4, and included 10 gentle inversions every 5 min. Released microcolonies were pelleted by slow centrifugation (45×g), and after removing supernatant, microcolonies were washed once more with citrate buffer and then with liquid culture media and re-suspended in 0.5 ml liquid culture media containing different amounts of NAA and BAP. The content of each tube was spread on the surface of solidified medium (8 % agar w/v, Sigma) in 65 mm × 10 mm Petri dishes containing NAA and BAP. The concentration of NAA and BAP were the same in both bead culture and spread culture. The number of visible microcalli (Fig. 1d, e) per cm2 of culture surface per single bead was determined.

After 4 weeks, 3 microcalli (∼3 mm3) (Fig. 1f, g) were picked up and placed onto each 65 mm × 10 mm Petri dishes containing shoot regeneration media supplemented with kinetin (K) and BAP as design points formulated. Cultures were kept at 27 °C under 16 h photoperiod of ∼40 µmol m−2 s−1. After 8 weeks, the number of shoots (Fig. 1h, i) of 4 or more leaves per each callus was measured and compared. Shoots were rooted (Fig. 1j, k) on MS medium containing 0.1 mg l−1 indole-3-butyric acid (IBA) for 4 weeks and plantlets were transferred ex vitro into potting mixture consisting (v/v) of 10 % perlite, 70 % peat moss and 20 % vermiculite and irrigated with 1/8 MS salts for 4 weeks (Fig. 1l).

Experimental design and data analysis

A set of design points were selected from the design space to satisfy the D-optimal criteria sufficient for fitting up to the quadratic polynomials for mixture-amount designs through crossing component mixture (proportion) with total amount (concentration). To examine the goodness of model fit the following tests were conducted. The normality and constant variance assumptions were examined using normal probability plots of residuals and plots of residuals versus fitted values, respectively. The Box–Cox plots were used to identify and perform the required transformation (the best estimate of the lambda) for correcting the nonnormality (Box and Cox 1964).The influence of each observation on the fitted values in the regression and ANOVA model was identified with DFITS and DFBETAS plots (Belsley et al. 1980). Adequate precision of the model was determined by comparing the range of the predicted values at the design point (ŷ) (maximum predicted response − minimum predicted response) to the average variance (V-bar) of the predicted responses (desire values >4) (Anderson and Whitcomb 2005). Potential outlier points were checked with externally studentized “outlier-t test” (Weisberg 1985; Myers 1990) and Cook’s distance (Cook and Weisberg 1982) graphical plots. The R2 statistics were estimated for each selected model (Myers and Montgomery 2002). The PRESS was estimated to determine how well the model predict the new experiment (small values are desirable). Regression coefficients were expressed in coded forms; coding normalizes the factor range by linear transformations of their actual units through centering them at zero with a range of −1 to +1, this can directly reveal the relative impacts of variables on the model response. Where the lack-of-fit test was not significant the model proved to accurately fit the data, and different models did not remove additional variation in the residuals. The software application Design-Expert® ver 9 (Stat-Ease, Inc, Minneapolis, MN, USA) was used for the experimental design construction, model evaluation, and analyses. For each experiment the design points and data collection method are described as follows:

-

Effect of osmolarity on protoplast yield and viability The experiment was set up as a two-component mixture-amount design to determine the optimum osmolarity for protoplasts. The design included two mixture components, mannitol and sorbitol, and one numeric factor, amount (concentration) [mannitol + sorbitol]. Components proportions ranged from 0 to 1 and total concentration ranged from 0.6 to 1.2 M. To assure the release of enough yield of protoplast to judge the effect of osmoticum, cellulase “Onuzuka’’ R-10 (Yakult Honsha, Tokyo, Japan) and macerase (macerozyme® R-10) (Yakult Honsha, Tokyo, Japan) were included in the digesting solution each at 0.5 % (w/v). The experiment included 9 model point, 8 lack-of-fit points, and 7 points to estimate pure error as 24 design points. Protoplast yield (Pp g−1) and viability (%) at each design point were estimated from three 100-ml Erlenmeyer flasks, each containing 250 mg leaf strips in 5 ml digesting solution.

-

Effect of digesting enzymes on protoplast isolation The experiment to find the optimum formulation of enzyme solution for protoplast isolation was conducted as a constrained mixture-amount design and included three mixture components, cellulase, macerase and hemicllulase (from Aspergilus niger (Sigma)) crossed by a numeric factor, total concentration of enzymes. The enzyme cocktail was prepared in CPW with 0.75 M mannitol obtained from the osmolarity experiment. Component proportions ranged from 0.25 to 0.625 for cellulase and macerase and from 0.0 to 0.375 for hemicellulase, and total concentration ranged from 2 to 6 % (w/v). The experiment had 29 design points and included 18 model points, 5 lack-of-fit points and 6 points to estimate pure error. Protoplast yield and viability were estimated as previous experiment.

-

Effect of NAA and BAP on protoplast callus regeneration The experiment was arranged as a mixture-amount design, and included two mixture components NAA and BAP and a numeric factor, concentration [NAA + BAP] to find the best formulation for callus regeneration. Protoplasts were prepared in a solution of 0.75 M osmoticum with 6 % (w/v) enzyme containing cellulase:macerase:hemicellulase as 0.4:0.5:0.1. NAA and BAP proportions ranged from 0 to 1 and total concentration ranged from 1 to 3 mg l−1. The experiment consisted of 21 design points and included 9 model points, 6 lack-of-fit points and 6 points to estimate pure error. The same formulation for each design point was used in both consecutive stages of bead culture and spreading. The average number of visible microcallus per cm2 of culture surface per bead was calculated for each design point in three 65 mm × 10 mm Petri dishes 4 weeks after spreading.

-

Effect of K and BAP on shoot regeneration A mixture-amount design with two components of K and BAP and a numeric factor, concentration [K + BAP], was performed to find the best formulation for shoot regeneration. Component proportion ranged from 0 to 1 and concentration ranged from 1 to 4 mg l−1. The experiment consisted of 28 design points including 9 model points, 11 lack-of-fit points and 8 points to estimate pure error. Three clumps of callus were picked up and placed on the culture media and the number of shoots with more than two leaves was assessed after 8 weeks. Each point represents three 65 mm × 10 mm Petri dishes.

Results

Effect of osmolarity on protoplast yield and viability

Protoplast yield ranged from 0.116 to 1.283 × 10 6 Pp g−1 (Table 1). A summary of the ANOVA, selected polynomial (reduced quadratic sorbitol:mannitol mixture × quadratic osmoticum concentration) and model information are presented in Table 2. A base 10 log transformation of the data was performed as suggested by Box–Cox procedure. The model was highly significant (p < 0.0001) and the lack-of-fit test was not significant (p = 0.1299). Five significant terms were revealed by ANOVA (Table 2). Insignificant linear mixture suggested that there were no differences in protoplast yield between equal concentration of osmoticum (two extreme ends of the design space) where sorbitol:mannitol was 0.0:1.0 and 1.0:0.0. Significant mixture*concentration indicated that protoplast yield varied between different levels of each osmoticum. The osmoticum*concentration2 revealed a curvature in response, a trend of initial increase in protoplast yield along with increase in osmoticum concentration (up to 0.8 M) then a decrease (above 0.8 M). The range of protoplast yield in concentration range (0.6–1.2 M) for mannitol (0.125–1.283 × 10 6 Pp g−1) was wider than that of sorbitol (0.215–1.010 × 10 6 Pp g−1) as F values suggest (~950 for mannitol and ~230 for sorbitol). This shows that changing the mannitol concentration could change the protoplast yield more than that of sorbitol concentration. The effect of osmoticum type and the proportional effect of sorbitol*mannitol on protoplast yield was not significant. However, the proportion of sorbitol*mannitol (the quadratic mixture) showed a weak interaction with concentration (F = 5.59, p = 0.0321) on yield which was not influential. The region of the design space that resulted in the highest protoplast yield (>1 × 106 Pp g−1) was a band from approximately 0.7–0.85 M of osmoticum (the optimal point was 0.75 M of either sorbitol or mannitol) in the direction of concentration (Fig. 2a).

Contour plots of protoplast yield (×106) (a) and viability percentage (b). The design space is a sorbitol:mannitol mixture crossed with total osmoticum amount [concentration (sorbitol + mannitol)]. The proportional effects of sorbitol and mannitol are captured along the x-axis and their concentration effects are captured along y-axis; this design structure separates the effect of proportion and effect of concentration. The similar response of the two osmotica at the same concentration is evident by the lack of a gradient in contour lines across the plane in the x-axis direction. The lack of curves in the contour lines shows non-significant blending effect of sorbitol and mannitol. The curvature in response across the plane in the y-axis direction for yield, an initial increase then decrease in protoplast yield, along with increase in osmoticum concentration resulted in the significant term osmoticum*concentration2. The range of protoplast yield along the y-axis for mannitol was wider than that of sorbitol

Protoplast viability ranged from 85 to 94 % (Table 1). A summary of ANOVA, selected polynomial (reduced linear sorbitol:mannitol mixture × linear osmoticum concentration) and model information are presented in Table 3. The model was highly significant (p < 0.0001) and the lack-of-fit test was not significant (p = 0.0627). The ANOVA contained two significant terms (p < 0.0001) (Table 3). The insignificant linear mixture term showed that viability at equal concentration of each osmoticum when used alone is not different. Insignificant term, removed from the model, of the sorbitol*mannitol showed that changing the proportion of two osmotica in a certain concentration resulted in the same viability (no blending effect). These results suggest that changes in protoplast viability are largely due to changes in osmoticum concentration. The region of the design space that resulted in the highest protoplast viability (>92 %) was a band from approximately 0.6–0.75 M of osmoticum (the optimal point was 0.6 M) (Fig. 2b).

Overall, the region of the design space that resulted in the highest protoplast yield (>1 × 106 Pp g−1) and viability (>92 %) was a band across the design space where the osmoticum concentration was between 0.70 and 0.75 M. Therefore, the optimal point that satisfies responses of yield and viability was at 0.75 M osmolarity.

Effect of digesting enzymes on protoplast isolation

Protoplast yields ranged from 1.399 to 3.723 × 106 Pp g−1 (Table 4; Fig. 3a–c). A summary of the ANOVA, selected polynomial model (reduced quadratic cellulase:macerase:hemicellulase mixture × quadratic enzyme concentration) and model information are presented in Table 5. A base 10 log transformation of the data was performed as suggested by Box–Cox procedure. The model was highly significant (p < 0.0001) and the lack-of-fit test was not significant (p = 0.4058). The ANOVA contained twelve significant terms (Table 5). Significant linear mixture showed differences in protoplast yield between all equal concentration of enzymes (vertices of the design space) when one enzyme is in its highest proportion. Due to the presence of constraints on components of enzyme mixture in this experiment, however, it is difficult to clearly compare the components singly. The proportional effects of enzymes on protoplast yield were significant and the effect of the double blends of macerase*hemicellulase (F = 502.18) and cellulase*macerase (F = 423.32) were higher than the effect of either of them. For cellulase*hemicellulase (F = 85) however the term was significant but regression coefficients shows that relatively small differences occur when only these two enzyme exists in a mixture. The non-linear changes along high number of contour line between two vertices (on double blend axis) of macerase and hemicellulase and macerase and cellulase further shows these effect (Fig. 3a–c). The proportion of cellulase*macerase significantly interacted with concentration (F = 144.41), the highest effect in low enzyme concentration obtained by the blend in which a wider range of cellulase were needed while, at higher enzyme concentration a higher proportion of macerase (for example 0.48) produced highest response. The proportion of 50:50 at low concentrations increased the yield from 1.8 to 2.3 × 106 Pp g−1 between 2 and 4 % while; from 4 to 6 % it increased from 2.35 to 3.5 × 106 Pp g−1. The blending effect of cellulase*hemicellulase and cellulase*macerase had interaction with quadratic concentration; synergistic effect is increased as concentration increased. The effect of component*concentration on protoplast yield was significant; macerase*concentration (F = 2975.88, p < 0.0001) showed that most of variation in protoplast yield is driven by macerase concentration. By increasing the enzyme concentration the macerase showed a nonlinear increase in the protoplast yield and it tends to increase the number of protoplast at higher rate as the concentration is increased. However the macerase*concentration2 was significant but its effect was low. Significant hemicellulase*concentration term (F = 765.5, p < 0.0001) revealed that in the case of increasing the enzyme concentration from 2 to 4 %, hemicellulase could slightly increase the yield while at 4–6 % it largely increased the yield. Significant cellulase*concentration (F = 741.67, p < 0.0001) showed that cellulase concentration could affect protoplast yield. The regions with highest response are moving toward the vertex of macerase, and demands higher concentration of hemicellulase instead of cellulase. It seems that hemicellulase works at higher enzyme concentration. The high yield (>3.7 × 106 Pp g−1) was obtained when enzyme concentration of 6 % containing macerase:cellulase:hemicellulase as 0.4–0.56:0.27–0.36:0.08–0.24 was used (Fig. 3c).

Contour plots of protoplast responses from mixture-amount design of cellulase:macerase:hemicellulase crossed with enzyme concentration. a–c protoplast yield at 2–6 % enzyme concentration: the 3 plots are the 3 concentrations testes, 2, 4, and 6 %, and the values on each base (side) and opposite vertex (apex) are the lowest and highest proportion of each component, respectively. The proportion of each component for each point is found where the perpendicular from that point intersects the axis of each component; d interaction of cellulase*concentration on viability: the proportional effects of cellulase and macerase are captured along the x-axis and the concentration effects of cellulase alone, macerase alone or their blends are captured along the y-axis. A non-linear response (note the distance between the contour lines as concentration increased) across the y-axis for cellulase shows the interaction of cellulase*concentration on yield.; e overlaid optimization plot of protoplast yield and viability: yellow region stretching from center down to the corner of maximum macerase and least cellulase represents the optimal region for protoplast yield and viability which shows that the peak yield and viability are obtained when all 3 enzymes are used. Within this region all points would satisfy the specifications such as the preference of one component or the desired values of responses. For example, if the macerase is relatively expensive, it could be replaced by higher proportion of hemicellulase. (Color figure online)

Protoplast viability ranged from 86 to 92.6 % (Table 4). A summary of the ANOVA, selected polynomial model (reduced linear cellulase:macerase:hemicellulase mixture × quadratic enzyme concentration) and model information are presented in Table 6. The model was highly significant (p < 0.0001) and the lack-of-fit test was not significant (p = 0.4364). The ANOVA contained five significant (p < 0.05) terms (Table 6). The non-significant linear mixture term suggested that there were no differences in protoplast viability between all equal amounts of enzymes where they are at their highest proportions. The proportional effects of the enzymes on protoplast viability were not significant and were not included in the model. The cellulase*concentration term (F = 25.61, p < 0.0001) had the greatest effect on protoplast viability (Fig. 3d). Cellulase*concentration2 was the next term with the largest effect and shows a curvature in the viability response related to cellulase concentration. A concentration of 6 % enzyme with the proportion of cellulase >0.3 resulted in >90 % viability.

Overlaid contour plot showed a protoplast yield of >3.7 and >90 viability with 6 % enzyme concentration in the region of cellulase:macerase:hemicellulase as 0.3–0.5:0.4–0.6:0.09–0.16 (Fig. 3e). Therefore, the optimal concentration of enzymes that satisfies responses of yield and viability is 2.4 % cellulase, 3 % macerase and 0.6 % hemicellulase.

Effect of NAA and BAP on protoplast callus regeneration

The number of visible microcalli per cm2 of culture surface per bead ranged from 4.3 to 18.33 (Table 7; Fig. 4). A summary of the ANOVA, selected polynomial (reduced quadratic NAA:BAP mixture × linear PGR concentration) and model information are presented in Table 8. An inverse square root transformation of the data was performed as suggested by Box–Cox procedure. The model was highly significant (p < 0.0001) and the lack-of-fit test was not significant (p = 0.1372). The ANOVA contained three significant terms (Table 7). The significant linear mixture term (F = 221.55, p < 0.0001) had the greatest effect on number of microcalli produced and indicated a difference between NAA and BAP where their proportions are as 0.0:1.0 and 1.0:0.0 (two extreme ends of the design space) (Fig. 4). For example, at concentration of 1–3 mg l−1 the number of microcalli with NAA alone was 15–19 while it was ∼4 with BAP alone. The proportional effect of NAA*BAP was also significant (F = 17.47, p = 0.006), and revealed an antagonistic blending effect. BAP*concentration was significant (F = 8.34, p = 0.0102) on the number of microcalli with slight influence. The highest number of microcalli (18) was obtained in a medium containing 1.0 mg l−1 NAA (Fig. 4).

Contour plot of the number of microcalli per cm2 of culture surface per bead from guava protoplast using mixture-amount (concentration) design of α-naphthalene acetic acid (NAA):6-benzylaminopurine (BAP). The proportional effects of NAA and BAP are captured along the x-axis and the concentration effects of NAA alone, BAP alone or NAA + BAP are captured along the y-axis. The contour lines show a sharp gradient along the x-axis shows the differences between the same concentration of two PGRs. Antagonistic blending effect of NAA and BAP was evident by non linear response across the proportionality axis. This antagonistic effect is increased as concentration increased (along the y-axis) this is evident by the gradients of lines, for example, at a proportion of 0.5:0.5 and up to a concentration of 1.5 mg l−1 the value for number of microcalli is above 12 while above the 1.5 mg l−1 the values tend to decline as concentration rises. There was no significant differences in number of microcalli between the lowest and highest concentration of each PGR, which is evident by the contour lines, where this is <6 for BAP and >16 for NAA along the y-axis

Effect of K and BAP on shoot regeneration

Number of shoots from single callus ranged from 3.0 to 13.8 (Table 9; Fig. 5). A summary of the ANOVA and selected polynomial (reduced quadratic K:BAP mixture × quadratic PGRs concentration) and model information are presented in Table 10. A base 10 log transformation of the data was performed as suggested by Box–Cox procedure. The models was highly significant (p < 0.0001) and the lack-of-fit test was not significant (p = 0.124). The ANOVA contained seven significant terms (Table 10). The significant linear mixture term showed that cytokinin types in equal amount where their proportions are 0.0:1.0 or 1.0:0.0 (two extreme ends of design space) could produce different numbers of shoots. For example, with K or BAP alone shoot number at concentration of 1 mg l−1 were 3.8, 2.9; at 2 mg l−1 were 5.9, 3.9, at 3 mg l−1 were 7.8, 4.5, and at 4 mg l−1 were 9.8, 5.4, respectively. Component*concentration terms significantly affected shoot number; K*concentration was more effective than BAP*concentration, as the range of shoot production for K (3.8–9.8) (F = 71.29) was higher than that of BAP (2.9–5.4) (F = 33.37). The term component*concentration2 showed that increasing K and BAP concentration after a certain level could either slowly increase the shoot number or decrease it. For example, for K the speed of increasing shoot number is decreased to a level of plateau (within the space captured); at first it increased up to 3 mg l−1 then this increase was slow. However BAP concentration2 was significant but the rate of increase was slow after 1.6 mg l−1 and it was almost unchanged.

Contour plot for the number of shoot regenerated from protoplast-derived callus of guava using mixture-amount (concentration) design of kinetin:6-benzylaminopurine (BAP). The proportional effects of kinetin and BAP are captured along the x-axis and the concentration effects of kinetin alone, BAP alone or kinetin + BAP are captured along y-axis. Cytokinin types in equal amount when used alone produced different numbers of shoots which is evident by contour lines (along x-axis). A strong positive blending effect of K and BAP on shoot number is evident by curvature in the contour lines along the x-axis. For example, the greatest number of shoots produced by K or BAP alone was 8 and 5, respectively. However, the point which had a blend of K and BAP as proportion of 0.6:0.4 produced the greatest number of shoots (>12)

The single largest effect was the K*BAP term (F = 80.87, p < 0.0001) which revealed a strong blending effect on shoot number. The greatest number of shoots produced by K or BAP alone was 8 and 5, respectively (Fig. 5). However, the region of the K and BAP blend of approximately 0.6 and 0.4 produced the greatest number of shoots (>12). The second largest effect was the K*Concentration term (F = 71.29, p < 0.0001) which revealed that the proportion of K was interacting with concentration. The reason the K*Concentration term was large was because K was the dominant cytokinin at 0.6 proportion in the most effective blend. The BAP*Concentration term was also significant, though less so then K*Concentration (F of 33.37 vs. 71.29) (Table 10). Because shoot number increased as the concentration increased and was maximal at the highest concentration of 4 mg l−1 (Fig. 5), the concentration that maximizes shoot number may not have been reached and lies outside of the concentration range examined. Nevertheless, the optimal point within the present design space that satisfies the highest number of shoots included 2.4 mg l−1 kinetin and 1.6 mg l−1 BAP.

Discussion

To our knowledge this is the first report of guava protoplast isolation and culture. Young plants derived from protoplasts in this study showed no detectable morphological variation. The optimum formulations for osmoticum, digesting enzymes and PGRs were determined. Furthermore, the effect of some features of media formulation including proportion, concentration and their interaction were quantified using mixture-amount experimental designs. Protoplast yields >3.7 × 106 Pp g−1 can provide enough protoplasts for 4–75 ml of culture media, as protoplasts are generally cultured at an initial plating density of 5 × 104–1 × 106 Pp ml−1 (Davey et al. 2005). Protoplast callus production and subsequent shoot regeneration demonstrated that guava is amenable to protoplast culture. Therefore, the procedure developed here will enable us to utilize plant improvement technologies that require protoplasts to develop improved guava cultivars. Isolated protoplasts can also be used as an important and versatile tool in studying whole-plant physiological responses through cell-based experiments involving gene expression regulation, signal transduction and protein targeting. The findings of this study for each experiment are separately discussed below.

Effect of osmolarity on protoplast yield and viability

The model showed that osmoticum molarity was the primary determinant of protoplast yield and viability rather than sorbitol and mannitol. The literature describes similar responses by inclusion of different osmotica singly (Perales and Schieder 1993; Qiao et al. 1998; Witjaksono and Grosser 1998; Guo et al. 2000; Matsumoto et al. 2002; Ortin-Parraga and Burgos 2003; Wakita et al. 2005) or in combination (Frearson et al. 1973; Myers et al. 1989; Ara et al. 2000). In a comparative study using mango protoplasts, and an OFAT experiment, mannitol was superior to sorbitol or a mixture of both (Rezazadeh et al. 2011). In terms of the influence of mannitol and sorbitol on the cell, it is known that mannitol is an inert sugar alcohol with more stability than sorbitol (Evans 1976), while sorbitol is subjected to uptake by cells (Warren 1991) which in turns could cause an interruption in the solute balance and bring about protoplast rupture or shrinkage. Our results showed that at the same range of concentration, mannitol caused more variation in protoplast yield than sorbitol, which means that yield is more sensitive to mannitol than sorbitol. These properties along with the fact that protoplasts from different plant sources differ in their osmotic regulation, could to some extent explain the different range of responses with osmotica. Our results, however, clearly suggest that the use of mannitol and sorbitol in a guava protoplast system could be based on availability or price.

Effect of digesting enzymes on protoplast isolation

A wide range of enzyme proportions have been used in the digestion solution; the concentration of cellulase was two-fold of macerase for Chamelaucium uncinatum (Ratanasanobon and Seaton 2013), macerase was one-third of cellulase for Musa acuminate cv. Mas (AA) (Xiao et al. 2007), or the same (1.5 %) for Gentiana kurroo (Royle) (Fiuk and Rybczynski 2007). Our findings along with other protocols using a wide range of enzyme concentrations with different composition and proportions (Mills and Hammerschlag 1994; Witjaksono and Grosser 1998; Da Gloria et al. 2000; Ortin-Parraga and Burgos 2003; Xu et al. 2006; Ratanasanobon and Seaton2013) suggest that specific formulations are required for protoplast isolation of any species.

The proportion of macerase*hemicellulase and macerase*cellulase, were effective on protoplast yield. This could be due to the fact that macerase as a pectinase enzyme not only provides cellulose digesting enzymes (cellulase and hemicellulase) with detached cells through digesting intercellular pectic cements but also boosts their cell wall degradation activities by digesting pectin substances within the cell walls. Comparatively, the proportional effect of the two cellulose digesting enzymes, cellulase and hemicellulase, was significant but weaker. Nevertheless, such proportional effects seems reasonable as each enzyme breaks down different substrates in the cell wall and a proper proportion is required, however such proportion depends on the total concentration of enzyme (cellulase*hemicellulase*concentration2); the higher proportion of hemicellulase is needed as total concentration increased. The concentration-dependent proportional effect of hemicellulase with other components in our mixture -amount experiment shows the variation in protoplast responses of different plant species. For example, hemicellulase had no effect in apricot protoplasts (Ortin-Parraga and Burgos 2003) while by increasing its concentration (from 1 to 2 %) in presence of pectinase the protoplast yield of mango decreased from 11.86 to 2.54 × 106 (Ara et al. 2000).

The term component*concentration was significant and revealed that macerase concentration is the main determinant factor in protoplast yield. Separation of intact cells by digestion of intercellular pectin by macerase is central to protoplast isolation of guava and any changes in this stage would affect the final stage of cell wall degradation. Several reports are available on the effects of different levels of enzymes on protoplast yield. Ochatt (1992) found that the concentration of macerase could significantly affect protoplast yield of some Prunus clones. For poplar (Populous alba L.), increasing cellulase from 1 to 2 % decreased the protoplast yield, the activity of cellulase however was dependent on pectolyase (Qiao et al. 1998). Increasing cellulase from 0.5 to 1.5 % and macerase from 0.1 to 0.5 % increased protoplast yield of Spathyphyllum wallisii, with no effect on protoplast yield of Anthurium scherzerianum (Duquenne et al. 2007). In another study, protoplast yield of Helianthus annuus was significantly different between the cellulase concentrations of 0.5, 1.0, and 1.5 % (Kativat et al. 2012).

Protoplast viability was determined by the enzyme concentration predominantly by cellulase concentration. Contrary to our finding, increasing enzyme concentration decreased protoplast viability in mango (Ara et al. 2000) and Pleargonium × Hortorum, nonetheless, in the latter case high yield was accompanied by high viability (Nassour et al. 2003). Different reports on the effect of enzymes concentration on protoplast viability are available. Ortin-Parraga and Burgos (2003) working with apricot protoplasts found that the inclusion of hemicellulase doubled the viability from 43 to 83 %, while Ara et al. (2000) noticed that a two-fold increase in hemicellulase decreased the viability of mango protoplasts by 25 %. No significant differences in viability between the cellulase concentrations of 0.5, 1.0, and 1.5 % were observed for Helianthus annuus L. (Kativat et al. 2012), whereas increasing cellulase from 1 to 2 % sharply decreased the protoplast viability of poplar (Qiao et al. 1998). Protoplast viability for Spathyphyllum wallisii increased then declined with increasing cellulase concentration; but little change was observed with increasing macerase concentration (Duquenne et al. 2007), while high concentrations of cellulase and pectinase reduced the protoplast viability of Pelargonium × hortorum (Nassour et al. 2003). The increased protoplast viability of guava was accompanied by high yield which was brought about by high concentrations of enzymes. This phenomenon is probably due to the fact that increase in protoplast releasing rate in the presence of higher concentration of enzymes is higher than the rate of protoplast death. Similar trends have been reported for protoplast isolation of apricot (Ortin-Parraga and Burgos 2003) and P. cerasifera (Ochatt 1992). Our results also showed that viability is not affected by many properties of digesting solution such as linear mixture (the differences between enzymes alone) or proportional effects (antagonistic or synergistic blending effects of enzymes).

Effect of BAP and NAA on protoplast callus regeneration

Protoplast culture is initially judged by plating efficiency in terms of cell division and/or microcolony formation. A large number of microcalli were obtained for guava using NAA alone. NAA was superior to BAP in microcalli production, but increasing the NAA concentration above 1 mg l−1 had an adverse effect. Inhibitory effects of high concentration of NAA in protoplast culture of Asparagus officinalis L. has been previously reported (May and Sink 1995). Proportion of NAA*BAP also influenced microcalli formation of guava and showed antagonistic blending effects in our study. Auxins and cytokinins are essential for protoplast culture (Davey et al. 2005) and protoplast culture of several plant species such as Solanum virginianum L. (Borgato et al. 2007), Alnus firma (Wakita et al. 2005), and poplar (Populus alba L.) (Qiao et al. 1998) and hybrid poplar (Populus nigra × P. maximowiczii) (Park and Son 1992) were dependent on auxin and cytokinin. In this study we found that NAA was necessary to support the cell division up to microcallus formation, while BA was not required. Our results are in line with those of Dovzhenko et al. (2003) who reported 30 % protoplast plating efficiency for Arabidopsis thaliana in presence of auxin alone. No microcolony formation in the absence of auxin has been reported for apricot (Ortin-Parraga and Burgos 2003). In another study, Perales and Schieder (1993) reported that different concentrations or combinations of BA, NAA and zeatin had no major influence on protoplast regeneration frequency of some apple cultivars; nevertheless, no microcallus was observed when NAA was absent from the culture media.

In this study increasing the concentration of BAP alone did not change the formation of microcalli formation, while in some studies the cytokinin alone or in combination with auxin have been reported to initiate cell colony formation. Dovzhenko and Koop (2003) found that the presence of either cytokinin or auxin in the media could initiate colony formation from protoplasts of Beta vulgaris (L.). Successful application of cytokinin have been reported for mango leaf protoplast culture (BAP + kinetin) (Rezazadeh et al. 2011) and peach (Prunus persica L.) (BA + zeatin) (Mills and Hammerschlag 1994), while for protoplast culture of apple (Patat-Ochatt et al. 1988), Populus Alba and Alnus firma (Wakita et al. 2005), and chicory (Nenz et al. 2000) both cytokinin and auxin were essential.

While we observed an antagonistic effect of BAP and NAA on guava protoplasts, combinations of a relatively high concentration of NAA to BA for Pelargonium × hortorum (Nassour et al. 2003), Prunus spss. (Ochatt 1992), apple (Patat-Ochatt et al. 1988), banana (Assani et al. 2001), Nicotiana (Draget et al. 1988), primrose (Kuchuk et al. 1998), apricot (Ortin-Parraga and Burgos 2003) and chicory (Nenz et al. 2000), and a high ratio of cytokinin to auxin in peppermint (Jullien et al. 1998) and sugar beet (Beta vulgaris L.) (Dovzhenko and Koop 2003) have been reported to be effective in protoplast culture.

Two major PGRs, auxin and cytokinin, control plant cell division (Das et al. 1956; Pasternak et al. 2000; Hopkins and Huner 2008) through complicated pathways depending on species, genotypes and tissues (Coenen and Lomax 1997). The complexity of hormonal responses could be due to different cell types in tissues containing different levels of endogenous PGRs (Pasternak et al. 2000). Leaf mesophyll protoplasts of fully expanded leaves are believed to have relatively low level of endogenous auxin (Bhalerao et al. 1999) and probably cytokinin (Pasternak et al. 2000), which might fail to regenerate since protoplasts division requires auxin and cytokinin (Cooke and Meyer 1981; Bergounioux et al. 1988; Takahashi et al. 1994; Carle et al. 1998; Trehin et al. 1998; Schell et al. 1999). During the cell cycle, cytokinin levels significantly increase before mitosis (Redig et al. 1996). It is believed that auxin could induce DNA synthesis and cytokinin could accomplish mitosis in tobacco cell (John et al. 1993; Laureys et al. 1998; Valente et al. 1998) and protoplasts (Jouanneau and Tandeau de Marsac 1973) culture. The key role of PGRs in protoplast regeneration does not necessarily imply the inclusion of exogenous PGRs in culture media. In some citrus protoplast cultures (Vardi et al. 1982; Sim et al. 1988) and petunia tumor protoplast culture (Phillips and Darrell 1988) the PGR free media have been reported to support growth. In our experiment, BAP was not required for callus production; this may be because adequate levels of endogenous cytokinin are present.

Effect of K and BAP on shoot regeneration

Shoot production was satisfactory in the media containing a blend of K and BAP. In protoplast culture, shoot regeneration from callus is predominantly induced by the use of either cytokinin singly (Qiao et al. 1998) or in combination with low (Ochatt and Power 1988; Patat-Ochatt et al. 1988; Ochatt 1992; Park and Son 1992; Perales and Schieder 1993; Jullien et al. 1998; Dorion et al. 1999; Borgato et al. 2007; Castelblanque et al. 2010; Verma and Mathur 2011) or in rare cases a high (Umate et al. 2005) auxin concentration. Therefore, we included two cytokinins, K and BAP, to find if each singly or in combination as different proportions of different concentrations are influential on shoot regeneration from protoplast-derived calli. When applied singly, K was superior to BAP in shoot regeneration. Cytokinin type and concentration have been reported to be determinant in shoot regeneration from protoplast culture. In protoplast culture of sugar beet (Beta vulgaris L.), thidiazuron failed to induce shoot regeneration, whereas BA induced shoot regeneration; BAP at 2 mg l−1 was effective while at 4 mg l−1 had an inhibitory effect (Dovzhenko and Koop 2003). In contrast, Perales and Schieder (1993) demonstrated that in protoplast culture of some apple cultivars thidiazuron is more effective than BA in shoot induction. In protoplast culture of poplar, BA was found ineffective in shoot regeneration, whereas thidiazuron and kinetin were effective; kinetin was superior to thidiazuron; K at 10 µM and thidiazuron at 1 µM were effective while thidiazuron at 10 µM had no effect (Qiao et al. 1998). Leaf protoplast culture of Solanum virginianum L. resulted in shoot regeneration when zeatin was included in the media (Borgato et al. 2007). For protoplast culture of hybrid poplar zeatin was more effective than BA and 6-(γ,γ-dimethylallylamino) purine (2iP); BA below 4.4 µM and above 6.7 µM failed to produce shoots while 2iP and zeatin at a wide range of concentrations (2.5–20 µM) produced a wide range of shoot regeneration; zeatin (1.3–8.1 shoots), BA (0.3–0.9 shoots) and 2iP (0.3–3.3 shoots) (Park and Son 1992).

The most shoots were produced from K and BAP blends at the highest concentration. Because factorial or OFAT experiments cannot detect blending effects, the K and BAP synergy identified would not have been found without using mixture amount design. The reason that factorial designs cannot detect blending effects is because the effects of proportion and concentration are confounded. If we had used a mixture-design without including amount, such concentration dependency and concentration-dependent proportional shift could not have been detected. Such interaction between the proportional effects of two cytokinins and concentration on shoot regeneration of sweet orange (Niedz and Evens 2011b) and between the proportional effect of auxin and cytokinin on shoot regeneration of grapefruit (Niedz and Evens 2011a) have been previously detected using such designs. Overall, our findings showed that cytokinin type and also their blends and total concentration could significantly affect the shoot production response. This means that one can produce a result beyond the potential of each cytokinin by simply using the proper blend.

Abbreviations

- 2iP:

-

6-(γ,γ-Dimethylallylamino) purine

- BAP:

-

6-Benzylaminopurine

- CPW:

-

Cell and protoplast wash solution (Frearson et al. 1973)

- IBA:

-

Indole-3-butyric acid

- K:

-

Kinetin

- MS:

-

Murashige and Skoog medium (1962)

- NAA:

-

α-Naphthaleneacetic acid

- OFAT:

-

One-factor-at-a-time

- PGRs:

-

Plant growth regulators

- Pp g−1 :

-

Protoplasts per gram (of leaf tissue)

- Pp ml−1 :

-

Protoplast per ml (of culture medium)

References

Amin MN, Jaiswal VS (1987) Rapid clonal propagation of guava through in vitro shoot proliferation on nodal explants of mature trees. Plant Cell Tissue Organ Cult 9:235–244

Anderson MJ, Whitcomb PJ (2002) Mixture DOE uncovers formulations quicker. Rubber and Plastic News 16–18. www.rubbernews.com

Anderson MJ, Whitcomb PJ (2005) RSM simplified: optimizing processes using response surface methods for design of experiments. Productivity Press, New York

Ara H, Jaiswal U, Jaiswal VS (2000) Plant regeneration from protoplasts of mango (Mangifera indica L.) through somatic embryogenesis. Plant Cell Rep 19:622–627

Assani A, Haicour R, Wenzel G, Cote F, Bakry F, Foroughi-Wehr B, Ducreux G, Aguillar ME, Grapin A (2001) Plant regeneration from protoplasts of dessert banana cv. Grande Naine (Musa spp., Cavendish sub-group AAA) via somatic embryogenesis. Plant Cell Rep 20:482–488

Batra PK, Prasad R, Gupta VK, Khanduri OP (1999) A strategy for analysis of experiments involving split application of fertilizer. Stat Appl 1:175–187

Belsley DA, Kuh E, Welsch RE (1980) Regression diagnostics: identifying influential data and sources of collinearity. Wiley, Hoboken

Bergounioux C, Perennes C, Brown SC, Gadal P (1988) Cytometric analysis of growth-regulator-dependent transcription and cell-cycle progression in Petunia protoplast cultures. Planta 175:500–505

Bhalerao RP, Ljung K, Eklof J, Sandberg G (1999) The role of IAA gradients in leaf and lateral root development. Physiol Plant 42(Suppl):40

Borgato L, Pisani F, Furini A (2007) Plant regeneration from leaf protoplasts of Solanum virginianum L. (Solanaceae). Plant Cell, Tissue Organ Cult 88:247–252

Box GEP, Cox DR (1964) An analysis of transformations. J R Stat Soc Ser B 26:211

Carle SA, Bates GW, Shannon TA (1998) Hormonal control of gene expression during reactivation of the cell cycle in tobacco mesophyll protoplasts. J Plant Growth Regul 17:221–230

Castelblanque L, Garcia-Sogo B, Pineda B, Moreno V (2010) Efficient plant regeneration from protoplasts of Kalanchoe blossfeldiana via organogenesis. Plant Cell, Tissue Organ Cult 100:107–112

Chandra R, Bajpai A, Gupta S, Tiwari RK (2004) Embryogenesis and plant regeneration from mesocarp of Psidium guajava L. (guava). Indian J Biotechnol 3:246–248

Coenen C, Lomax TL (1997) Auxin-cytokinin interactions in higher plants: old problems and new tools. Trends Plant Sci 2:351–356

Cook RD, Weisberg S (1982) Residuals and influence in regression. Chapman and Hall, New York

Cooke R, Meyer Y (1981) Hormonal control of tobacco protoplast nucleic acid metabolism during in vitro culture. Planta 152:1–7

Cornell JA (2002) Experiment with mixtures: designs, models and the analysis of mixture data. Wiley, New York

Da Gloria FJM, Mourao FDA, Mendes BMJ (2000) Plant regeneration from protoplast of Brazilian citrus cultivars. Pesquisa Agropecuaria Brasileira 35:727–732

Das NK, Patau K, Skoog F (1956) Initiation of mitosis and cell division by kinetin and indole acetic acid in excised tobacco pith tissue. Physiol Plant 9:640–651

Davey MR, Anthony P, Power JB, Lowe KC (2005) Plant protoplasts: status and biotechnological perspectives. Biotechnol Adv 23:131–171

Deka BC, Sethi V, Parsad R, Batra PK (2001) Application of mixtures methodology for beverages from mixed fruit juice/pulp. J Food Sci Technol 38:615–618

Dhekale JS, Prasad R, Gupta VK (2003) Analysis of intercropping experiments using experiments with mixture methodology. J Indian Soc Agric Stat 56:260–266

Dorion N, Wies N, Burteaux A, Bigot C (1999) Protoplast and leaf explant culture of Lycopersicon cheesmanii and salt tolerance of protoplast-derived calli. Plant Cell, Tissue Organ Cult 56:9–16

Dovzhenko A, Koop HU (2003) Sugarbeet (Beta vulgaris L.): shoot regeneration from callus and callus protoplasts. Planta 217:374–381

Dovzhenko A, Dal Bosco C, Meurer J, Koop HU (2003) Efficient regeneration from cotyledon protoplasts in Arabidopsis thaliana. Protoplasma 222:107–111

Draget KI, Myhre S, Skjak-Braek G, Ostgaard K (1988) Regeneration, cultivation and differentiation of plant-protoplasts immobilized in Ca-alginate beads. J Plant Physiol 132:552–556

Du L, Bao M (2005) Plant regeneration from protoplasts isolated from embryogenic suspension cultured cells of Cinnamomum camphora L. Plant Cell Rep 24:462–467

Duquenne B, Eeckhaut T, Werbrouck S, Huylenbroeck JV (2007) Effect of enzyme concentrations on protoplast isolation and protoplast culture of Spathiphyllum and Anthurium. Plant Cell, Tissue Organ Cult 91:165–173

Evans PK (1976) Higher plant protoplasts: isolation and properties. In: Peberdy JF, Rose AH, Rogers HJ, Cocking EC (eds) Microbial and plant protoplasts. Academic Press, London, pp 51–70

Evens TJ, Niedz RP (2010) Quantification of nutrient-replete growth rates in five ion hyperspace for Chlorella vulgaris (Chlorophyceae) and Peridinium cinctum (Dinophyceae). Eur J Phycol 45:247–257

Fiuk A, Rybczynski JJ (2007) The effect of several factors on somatic embryogenesis and plant regeneration in protoplast cultures of Gentiana kurroo (Royle). Plant Cell, Tissue Organ Cult 91:263–271

Frearson EM, Power JB, Cocking EC (1973) Isolation, culture and regeneration of petunia leaf protoplasts. Dev Biol 33:130–137

Grosser JW, Gmitter FG Jr (1990) Protoplast fusion and citrus improvement. Plant Breed Rev 8:339–374

Grzebelus E, Szklarczyk M, Baranski R (2012) An improved protocol for plant regeneration from leaf- and hypocotyl-derived protoplasts of carrot. Plant Cell, Tissue Organ Cult 109:101–109

Guo WW, Deng XX, Yi HL (2000) Somatic hybrids between navel orange (Citrus sinensis) and grapefruit (C. paradisi) for seedless triploid breeding. Euphytica 116:281–285

Haicour R, Assani A, Trang VB, Guedira A (2009) Protoplast isolation and culture for banana regeneration via somatic embryogenesis. Fruits 64:261–269

Hidaka T, Omura M (1992) Regeneration of somatic hybrid plants obtained by electrical fusion between Satsuma mandarin (Citrus unshiu) and rough lemon (C. jambhiri) or Yuzu (C. junos). Jpn J Breed 42:79–89

Hopkins WG, Huner NPA (2008) Introduction to plant physiology. Wiley, Hoboken

John PCL, Zhang K, Dong C, Diederich L, Wightman F (1993) p34cdc2 related proteins in control of cell cycle progression, the switch between division and differentiation in tissue development, and stimulation of division by auxin and cytokinin. Austr J Plant Physiol 20:503–526

Jouanneau JP, Tandeau de Marsac N (1973) Stepwise effects of cytokinin activity and DNA synthesis upon mitotic cycle events in partially synchronized tobacco cells. Exp Cell Res 77:167–174

Jullien F, Diemer F, Colson M, Faure O (1998) An optimizing protocol for protoplast regeneration of three peppermint cultivars (Mentha × piperita). Plant Cell, Tissue Organ Cult 54:153–159

Jumin HB, Nito N (1996) Plant regeneration via somatic embryogenesis from protoplasts of six plant species related to Citrus. Plant Cel Rep 15:332–336

Kativat C, Poolsawat O, Tantasawat PA (2012) Optimization of factors for efficient isolation of protoplasts in sunflower (Helianthus annuus L.). Austr J Crop Sci 6:1004–1010

Kuchuk N, Herrmann RG, Koop HU (1998) Plant regeneration from leaf protoplasts of evening primrose (Oenothera hookeri). Plant Cell Rep 17:601–604

Lapointe SL, Evens TJ, Niedz RP (2008) Insect diets as mixtures: optimization for a polyphagous weevil. J Insect Physiol 54:1157–1167

Laureys F, Dewitte W, Witters E, Van Montagu M, Inze D, Van Onckelen H (1998) Zeatin is indispensable for the G2-M transition in tobacco BY-2 cells. FEBS Lett 426:29–32

Litz RE, Grosser JW (1998) Isolation, culture and regeneration of avocado (Persea americana Mill.) protoplasts. Plant Cell Rep 18:235–242

Liu X, Yang G (2011) Clonal propagation of guava (Psidium guajava L) on nodal explants of mature elite cultivar. Int J Plant Biol 2:7–10

Matsumoto K, Vilarinhos AD, Oka S (2002) Somatic hybridization by electrofusion of banana protoplasts. Euphytica 125:317–324

May RA, Sink KC (1995) Genotype and auxin influence direct somatic embryogenesis from protoplasts derived from embryogenic cell suspensions of Asparagus officinalis L. Plant Sci 108:71–84

Meyer L, Serek M, Winkelmann T (2009) Protoplast isolation and plant regeneration of different genotypes of Petunia and Calibrachoa. Plant Cell, Tissue Organ Cult 99:27–34

Mills D, Hammerschlag FA (1994) Isolation of cells and protoplasts from leaves of in vitro propagated peach (Prunus persica) plants. Plant Cell, Tissue Organ Cult 36:99–105

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassays with tobacco tissue cultures. Physiol Plant 15:473–479

Myers RH (1990) Classical and modern regression with applications. PWS-KENT Publishing, Boston

Myers RH, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiments. Wiley, New York

Myers JR, Grosser JW, Taylor NL, Collins GB (1989) Genotype-dependent whole plant regeneration from protoplasts of red clover (Trifolium pratense L.). Plant Cell, Tissue Organ Cult 19:113–127

Nassour M, Chassériaux G, Dorion N (2003) Optimization of protoplast-to-plant system for Pelargonium × hortorum ‘Alain’ and genetic stability of the regenerated plants. Plant Sci 165:121–128

Nenz E, Varotto S, Lucchin M, Parrini P (2000) An efficient and rapid procedure for plantlet regeneration from chicory mesophyll protoplasts. Plant Cell, Tissue Organ Cult 62:85–88

Niedz RP (1993) Culturing embryogenic protoplasts of ‘Hamlin’ sweet orange in calcium alginate beads. Plant Cell, Tissue Organ Cult 34:19–25

Niedz RP, Evens TJ (2008) The effects of nitrogen and potassium nutrition on the growth of nonembryogenic and embryogenic tissue of sweet orange (Citrus sinensis (L.) Osbeck). BMC Plant Biol 8:126. doi:10.1186/1471-2229-8-126

Niedz RP, Evens TJ (2011a) Mixture screening and mixture-amount designs to determine plant growth regulator effects on shoot regeneration from grapefruit (Citrus paradise macf.) epicotyls. In Vitro Cell Dev Biol Plant 47:682–694

Niedz RP, Evens TJ (2011b) The effects of Benzyladenine and Meta-Topolin on in vitro shoot regeneration of sweet orange. ARPN J Agric Biol Sci 6:64–73

Ochatt SJ (1992) The development of protoplast-to tree system for Prunus cerasifera and Prunus spinosa. Plant Sci 81:253–259

Ochatt SJ, Power JB (1988) Plant-regeneration from mesophyll protoplasts of Williams’ Bon Chretien (Syn. Bartlett) pear (Pyrus communis L). Plant Cell Rep 7:587–589

Ortin-Parraga F, Burgos L (2003) Isolation and culture of mesophyll protoplast from apricot. J Hort Sci Biotechnol 78:624–628

Park YG, Son SH (1992) In vitro shoot regeneration from leaf mesophyll protoplasts of hybrid poplar (Populus nigra × P. maximowiczii). Plant Cell Rep 11:2–6

Pasternak T, Miskolczi P, Ayaydin F, Meszaros T, Dudits D, Fehér A (2000) Exogenous auxin and cytokinin dependent activation of CDKs and cell division in leaf protoplast-derived cells of alfalfa. Plant Growth Regul 32:129–141

Patat-Ochatt EM, Ochatt SJ, Power JB (1988) Plant regeneration from protoplasts of apple rootstocks and scion varieties (Malus × domestica Borkh). J Plant Physiol 133:460–465

Patat-Ochatt EM, Boccon-Gibod J, Duron M, Ochatt SJ (1993) Organogenesis of stem and leaf protoplasts of a haploid Golden Delicious apple clone (Malus × domestica Borkh). Plant Cell Rep 12:118–120

Perales EH, Schieder O (1993) Plant regeneration from leaf protoplasts of apple. Plant Cell, Tissue Organ Cult 34:71–76

Phillips R, Darrell NJ (1988) A simple technique for single-cell cloning of crown gall tumor tissue: Petunia protoplast regeneration without exogenous hormones. Plant Physiol 133:447–451

Prange ANS, Serek M, Bartsch M, Winkelmann T (2010) Efficient and stable regeneration from protoplasts of Cyclamen coum Miller via somatic embryogenesis. Plant Cell, Tissue Organ Cult 101:171–182

Qiao J, Kuroda H, Hayashi T, Sakai F (1998) Efficient plantlet regeneration from protoplasts isolated from suspension cultures of poplar (Populus alba L.). Plant Cell Rep 17:201–205

Ratanasanobon K, Seaton KA (2013) Protoplast isolation for species in the Chamelaucium group and the effect of antioxidant enzymes (superoxide dismutase and catalase) on protoplast viability. In Vitro Cel Dev Boil Plant 49:593–598

Redig P, Shaul O, Inze D, Van Montagu M, Van Onckelen H (1996) Levels of endogenous cytokinins, indole-3-aceticacid and abscisic acid during the cell cycle of synchronized tobacco BY-2 cells. FEBS Lett 391:175–180

Revilla MA, Ochatt SJ, Doughty S, Power JB (1987) A general strategy for the isolation of mesophyll protoplasts from deciduous fruit and nut tree species. Plant Sci 50:133–137

Rezazadeh R, Williams R, Harrison D (2011) Factors affecting mango (Mangifer indica L.) protoplast isolation and culture. ScientiaHortic 130:214–221

Schell J, Bisseling T, Dulz M, Franssen H, Fritze K, John M, Kleinow T, Lessnick A, Miklashevichs E, Pawlowski K, Rohrig H, Van der Sande K, Schmidt J, Stenbiss HH, Stoll M (1999) Re-evaluation of phytohormone-independent division of tobacco protoplast-derived cells. Plant J 17:461–466

Scheurich P, Schnabl H, Zimmermann U, Klein J (1980) Immobilization and mechanical support of individual protoplasts. BBA Biomembr 598:645–651

Schrevens E, Cornell J (1993) Design and analysis of mixture systems: applications in hydroponic, plant nutrition research. Plant Soil 54:45–52

Sheng X, Zhao Z, Yu H, Wang J, Xiaohui Z, Gu H (2011) Protoplast isolation and plant regeneration of different doubled haploid lines of cauliflower (Brassica oleracea var. botrytis). Plant Cell, Tissue Organ Cult 107:513–520

Sim GE, Loh CS, Goh CJ (1988) Direct somatic embryogenesis from protoplasts of Citrus mitis Blanco. Plant Cell Rep 7:418–420

Takahashi Y, Ishida S, Nagata T (1994) Function and modulation of expression of auxin-regulated genes. Int Rev Cytol 152:109–144

Trehin C, Planchais S, Glab N, Perennes C, Tregear J, Bergounioux C (1998) Cell cycle regulation by plant growth regulators: involvement of auxin and cytokinin in the re-entry of Petunia protoplasts into the cell cycle. Planta 206:215–224

Umate P, Rao KV, Kiranmayee K, Sre TJ, Sadanandam A (2005) Plant regeneration of mulberry (Morus indica) from mesophyll-derived protoplasts. Plant Cell, Tissue Organ Cult 82:289–293

Usman M, Butt M, Fatima B (2012) Enhanced in vitro multiple shoot induction in elite Pakistani guava cultivars for efficient clonal plant multiplication. Afr J Biotechnol 11:10182–19187

Valente P, Tao W, Verbelen JP (1998) Auxins and cytokinins control DNA endoreduplication and deduplication in single cells of tobacco. Plant Sci 134:207–215

Vardi A, Spiegel-Roy P, Galun E (1982) Plant regeneration from Citrus protoplasts: variability in methodological requirements among cultivars and species. Theor Appl Genet 62:171–176

Verma P, Mathur AK (2011) Direct shoot bud organogenesis and plant regeneration from pre-plasmolysed leaf explants in Catharanthus roseus. Plant Cell, Tissue Organ Cult 106:401–408

Wakita Y, Yokota S, Yoshizawa N, Katsuki T, Nishiyama Y, Yokoyama T, Fukui M, Sasamoto H (2005) Interfamilial cell fusion among leaf protoplasts of Populus alba, Betula platyphylla and Alnus firma: assessment of electric treatment and in vitro culture conditions. Plant Cell, Tissue Organ Cult 83:319–326

Warren G (1991) Protoplast isolation and fusion. In: Stafford A, Warren G (eds) Plant cell and tissue culture. Open University Press, Buckingham, pp 48–81

Weisberg S (1985) Applied linear regression. Wiley, New York

Widholm JM (1972) The use of fluorescein diacetae and phenosafranine for determining viability of cultured plant cell. Stain Technol 47:189–194

Xiao W, Huang XL, Huang X, Chen YP, Dai XM, Zhao JT (2007) Plant regeneration from protoplasts of Musa acuminate cv. Mas (AA) via somatic embryogenesis. Plant Cell, Tissue Organ Cult 90:191–200

Xu XY, Liu JH, Deng XX (2006) Isolation of cytoplasts from Satsuma mandarin (Citrus unshiu Marc.) and production of alloplasmic hybrid calluses via cytoplast–protoplast fusion. Plant Cell Rep 25:533–539

Yu C, Chen Z, Lu L, Lin J (2000) Somatic embryogenesis and plant regeneration from litchi protoplasts isolated from embryogenic suspensions. Plant Cell, Tissue Organ Cult 61:51–58

Acknowledgments

This research was supported in part by Iranian Ministry of Agriculture and by Iranian Agricultural Research, Education & Extension Organization (AREEO). The assistance of Ms. Sedigheh Shokri in culture preparation is also appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rezazadeh, R., Niedz, R.P. Protoplast isolation and plant regeneration of guava (Psidium guajava L.) using experiments in mixture-amount design. Plant Cell Tiss Organ Cult 122, 585–604 (2015). https://doi.org/10.1007/s11240-015-0790-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11240-015-0790-7