Abstract

The need for fresh drinking water is increasing rapidly, and drinking water availability reduces day by day. Solar desalination is a viable option to change saltwater to fresh drinkable water. Solar still used for desalination includes processes like heating, evaporation, and condensation. The major problem faced by solar stills is that they have low productivity. Therefore, high demand for freshwater cannot be met. The present review aims to provide the researchers with an idea to select suitable methods for enhancing solar stills' performance. This article mainly focuses on the climatic, design, and operational parameters affecting the performance of solar stills. Results reveal that a combination of the incredible intensity of solar radiations, solar still type, and regions with optimum temperature can provide higher daily distillate output. Further, high productivity can be achieved with inclined solar stills by making an inclination angle equivalent to the location's latitude. A water depth of around 1 cm can provide the best output in terms of productivity for conventional solar stills. A combination of V-corrugated absorber plate with fins and energy storing materials coupled with external reflector plates can provide optimized conditions to enhance productivity. The performance of solar still can be improved by minimizing the gap between absorber plates and condensing cover. Finally, the sun tracking system, either single or dual axis in solar still, can enhance productivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

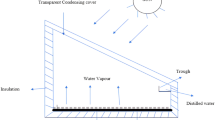

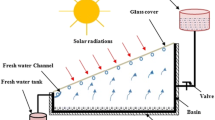

The presence of quality drinking water strongly influences the socio-economic development of a country. Near about 97% of water present on the earth is saline water [1]. This saline water can neither be used for industrial, agricultural, nor for drinking purposes. Presently the need of the hour is to convert saltwater into clean, usable water. To achieve this, the desalination process is the best alternative that includes heating, evaporation, and condensation processes. The best device available for the desalination process is solar still [2]. People around the globe are facing the problem of clean and potable water. Therefore, solar still can be considered as the best alternative that is cheap and possess low maintenance [3, 4]. However, low productivity concomitant with solar stills is hindering the distillate output per day [5]. Thereby, a comprehensive study involving different aspects that affect the output of solar still needs to be reviewed.

Furthermore, using renewable energy sources for power generation and heating/cooling purposes is an attractive idea [6]. As renewable energy is considered as green and clean energy [7], the different factors affecting solar still efficiency are categorized as climatic, operational, and design. Table 1 depicts the details of various factors affecting the performance of solar still. Out of these, the climatic factors are considered metrological factors that are not controlled by human beings. Therefore, it is necessary to concentrate on the operational and design aspects of solar stills for improving their overall performance [8, 9].

In the recent decade, due to global warming, a temperature rise is observed worldwide. Acute shortage of potable drinking water is reported due to a decrease in sources of ground-level water. Therefore, much attention is given to harnessing conventional and non-conventional resources. Solar energy is recognized as one of the cleanest energy sources utilized for power generation and other uses [3]. Solar still, in particular, has emerged as one of the best alternatives for generating potable water from saline water. The process of removing salt content from saline water and converting it into potable drinking water is known as desalination [10]. Seawater contains about 55% chlorine ions, 30.7% sodium ion, 7.7% sulfate ions, 3.6% magnesium ion, 1.2% calcium ions, and 1.1% potassium ions of dissolved matters that vary from place to place. The desalination process works on two methods, namely thermal and electrical desalination. The thermal desalination process utilizes solar energy or sun radiation [11, 12]. Solar radiations are used to heat the saline water resulting in evaporation of the saline water. Vapors formed owing to evaporation are collected on the condensing surface, and condensation of these vapors results in water droplets [13, 14].

On the other hand, there are several membranes and thermal processes like reverse osmosis (RO), multi-effect desalination (MED), multistage flashing (MSF), adsorption desorption desalination (ADD) and ion exchange (IEX) [15, 16]. However, high energy consumption and brine disposal problem are associated with these technologies. Figure 1 depicts the energy consumption from various desalination technologies. The most leading desalination technology by considering volume is RO with a portion of 65%, followed by MSF, MED, ED, and others with a portion of 21%, 7%, 3%, and 4%, respectively [17, 18]. Figure 2 represents the amount of water produced from different technologies.

Energy consumption from different technologies [15] (adapted with permission from ELSEV. B.V. with LIC. No. 5030650070249)

Amount of water produced from different technologies [17] (adapted with permission from ELSEV. B.V. with LIC. No. 5030640738937)

Malaiyappan and Elumalai [19] studied single-basin solar still by using glass, plastic, and aluminum as a basin material. Results show that aluminum material gives better performance than other materials, and the productivity of solar still depends upon the thermal conductivity of a material. Sameet al. [20] examined single-basin solar still performance in an arid region of Pakistan. The experiment conducted for eight days revealed an output of 1.7 L day−1. Gnanadasonet et al. [21] worked on single-basin solar still to enhance efficiency. Two similar-sized solar stills were fabricated for the experiments. The first still was tested experimentally at atmospheric pressure, while various modifications (use of fins, pebbles, coating of a basin with black paint) were done to test the second. Results show that modified solar still provides better performance as compared to the one without modification. Abujazaret et al. [22] designed an inclined stepped solar still to conduct experiments in Malaysia's Bangi region. The experimental setup comprised 28 trays with dimensions of 0.6 m height and 1.2 m length to enhance the evaporation rate. Results revealed productivity of 4.383 L m−2 day−1. Rashidi et al. [23] numerically studied nanoparticles' effect on the productivity of stepped solar still. Results show that increasing the concentration of nanoparticles from 0 to 5% enhanced the productivity of stepped solar still by 22%. Most of the research is performed on conventional solar stills but owing to their low productivity. These stills are not utilized in day-to-day life regularly.

Based on the current work, it is noted that a comprehensive assessment that affects the solar still performance based on climatic, design, and operational parameters is lacking. In the present work, a review of solar stills is carried out addressing the following points: (a) climatic conditions (intensity of radiation, ambient temperature, wind speed and latitude and longitude of location), (b) design parameters (selection of material, depth of water, absorber plate area, thermal energy storage materials, the thickness of insulation and insulating material, the inclination of the cover plate, cover plate thickness, use of internal/external reflectors, gap distance, sun-tracking system), and (c) operational parameters (salinity of water, the flow rate of water, use of dyes).

Parameters affecting the productivity of solar still

Climatic parameters

Various climatic parameters that affect the productivity of solar still are listed below.

-

The intensity of solar radiation

-

Wind speed

-

Ambient temperature

-

Dust and cloud cover

-

Latitude and longitude of the location

Intensity of solar radiation

Distillate output associated with solar still is strongly affected by the intensity of solar radiations. The higher the intensity of radiations, the better will be productivity [18, 24]. Hourly variation in atmospheric temperature (Ta), water temperature (Tw), glass temperature (Tg), and intensity of radiation is depicted in Fig. 3. It is observed that temperature rises from 8:00 to 14:00 and then starts to decline due to the low intensity of radiations. In the afternoon session between 12:00 and 13:00, the intensity of radiation and ambient temperature is at the higher side worldwide. The temperature of water and glass shows an increasing trend toward radiation intensity, enhancing the productivity in the afternoon session.

Variation in radiation intensity from morning to evening [13] (adapted with permission from Taylor & Francis with LIC. No. 5030750006189)

Moreover, maximum water and glass temperature are found in afternoon session; hence, productivity get increased [13]. The effect of solar intensity on the thermal output of single-slope solar still was investigated by Omar et al. [25]. Experimental results conclude that solar still output is directly relative to the concentration of solar radiations. Maximum productivity is obtained in the afternoon, attributing to higher intensity of radiation. Evaporative cooling system integrated with single-slope solar still was analyzed by Almuhanna [26]. Results revealed the intensity of solar radiations dictates the solar still productivity. It is further reported that 5.9 L m−2 is the distillate output achieved from the tests. Nafey et al. [27] studied various parameters that can affect the solar still performance and concluded that at a high degree of temperature, solar still can give better performance. Ghoneyemet al. [28] analyzed solar still and established empirical equations to express the dependency of solar still productivity on ambient temperature and solar radiation. A literature survey based on the location and intensity of radiation is depicted in Table 2.

Based on the above literature, it can be concluded that a combination of the incredible intensity of solar radiations and regions with high temperatures can provide better productivity in terms of daily distillate output. However, the solar still utilized for generating distillate output can significantly affect productivity. Single-basin multi-step solar basin (1100 W m−2 and 8.9 L m−2 day−1) and multi-wick solar still (1198 W m−2and 9.012 Lm−2) provide better productivity as compared to triangular prism solar still (1256 W m−2and 0.91 L m−2).

Wind speed

Another significant factor influencing the productivity of solar stills is wind speed. Sebaii [29] evaluated the effect of wind speed on active and passive-type solar stills experimentally. Additionally, numerical calculations have also been computed. Results infer that solar still productivity is directly relative to the wind speed. Soliman [30], Garg and Mann [31] also predicted that productivity enhances higher wind speed and solar radiations. Tiwari et al. [32] studied the parameters affecting active and passive distillation. Results inferred that the distillate output of solar still increases with increasing wind velocity up to a certain peak point. Productivity remains constant after attaining peak point. Zurigat et al. [33] worked on a regenerative solar desalination unit and concluded that wind velocity has a substantial effect on the productivity of solar still. Productivity can be enhanced by increasing the wind velocity from 0 to 10 m s−1 to about 50%, depicted in Fig. 4. Reddy et al. [34] carried out a thermal analysis on basin type of solar still and invented a correlation model on the effect of wind speed on radiative, convective, and evaporative heat transfer coefficient. The active and passive solar still critical or typical speeds were 10 and 8 m s−1 for summer and winter seasons. However, there is sufficient literature available based on the wind speed effect influencing productivity. Research on the optimum values of wind speed that can increase the overall production is lacking.

Effect of wind speed on the productivity of solar still [27] (adapted with permission from ELSEV. B.V. with LIC.No.4827130278404)

Dust and cloud cover

Accumulation of dust and dirt particles on the solar still glass surface can reduce solar energy conduction and reduce productivity. Hegazy [35] studied the influence of dust particles on the solar still output in Egypt's Central regions. Experiments were conducted for one month without cleaning the glass cover. Results revealed that the presence of dust and dirt particles reduced the productivity of solar still significantly. Accumulation of dust on evacuated tube collectors was examined by Nasharet al. [36]. For the experiments, two collector blocks, one with dust and dirt particles and the other in cleaned condition, were used. Results show that the dusty collector block's heat was 60–70% lower than the clean collector. Nashar [37] investigated the seasonal effect of deposition of dust on the evacuated tube collector. The experimentation was carried out in Abu Dhabi, United Arab Emirates. Results inferred that dust deposition could drop the glass transmittance by 10 to 18%. Zamfiret et al. [38] studied the influence of cloud cover on flat plate solar collectors' efficiency. Results indicated that cloudy conditions dictate the output from solar collectors. Most of the investigations carried out in dusty environments reveal that productivity reduces with such natural occurrences, and subtle precautions can enhance productivity.

Latitude and longitude of the location

The experimental setup's latitude and longitudinal location plays a pivotal role in determining the overall productivity of the solar stills [39]. Researches carried out with these parameters at different locations worldwide are presented in a tabular form in Table 3. This information is utilized to build up a variation pattern among the optimum cover tilt angle and latitude of the location. Longitude and latitude are imaginary lines that run across the earth. Longitudes are vertical lines that meet at the North and South poles, whereas latitudes are horizontal lines running from East to West. Experimental results inferred that latitude coordinate location influences the productivity than coordinates of longitude [40]. Further, it also noted that productivity is maximum with inclined solar stills when the inclination angle is made equivalent to that location's latitude.

Design parameters

Various design parameters affecting the solar still productivity are listed below:

-

Selection of material

-

Depth of water

-

Absorber plate area

-

Thermal energy storage materials

-

The inclination of the cover plate

-

Cover plate thickness

-

Use of internal and external reflectors

-

Gap distance

-

Sun tracking system

-

The thickness of insulation and insulating material

Selection of material

Evaluating the properties (thermal conductivity, absorptivity and transmissivity) of still material is the first step in the fabrication of solar stills, since the selection of materials for the various components of solar still plays a vital role. Researchers have investigated the various materials for basin and cover plate of solar stills. Burbano [41] studied the efficiency of solar still by using different basin materials. In the study, stainless steel and aluminum were utilized as basin materials. Results showed that aluminum could give better results than stainless steel due to its good thermal conductivity. Alaudeen et al. [42] analyzed the solar stills by considering glass as basin material. Solar still with basin size of 1 × 1 × 0.2 m3 was tested with various heat-storing materials. Tests infer a considerable enhancement in the solar still output by incorporating corrugated sheets as the basin material. Badran et al. [43] performed experiments on a single-slope, solar still using an asphalt basin liner. Test results revealed that the productivity enhanced by around 51% by using an asphalt basin liner. Ghoneyem et al. [28] designed and fabricated basin solar still with different cover plate materials (glass and plastic). Experimental results inferred that the glass cover plate with the minimum thickness (3 mm) substantially influences the solar still distillate output. Apart from the investigations above, cast iron has also been used as basin material. However, rusting and corrosion of cast iron have restricted the utilization of solar stills. Therefore, based on the literature, it can conclude that aluminum and glass with nominal thickness can be used as basin and cover plate material, respectively, for better output.

Depth of water

The depth of water in the solar still is one of the significant design factors that must be assessed to enhance the overall distillate output from stills. The productivity of solar still is maximum at a minimum depth of water. Figure 5a and b shows the effect of water depth on the efficiency and annual yield of solar still. Retaining the minimum depth of water in solar still is a challenging task. To achieve this, various augmentation techniques have been put forth by many researchers. The details of the results attained for water depth and solar still type are mentioned in Table 4.

Effect of water depth on the (a) efficiency and (b) annual yield of solar still [143] (adapted with permission from ELSEV.B.V. with LIC. No. 4827130436034 and 4827130628421)

From the above literature, it is observed that the depth of water influences productivity inversely. Maintaining a minimum water depth is a difficult and challenging task due to the evaporation of water droplets continuously. It is also reported that wet clothes are used to maintain water's required depth in the solar stills. However, it is concluded that the water depth of around 1 cm in the basin can give the best output in terms of productivity in the case of conventional (single basin) solar still. Using high water depth, the amount of water existing in the basin will be more due to which time required for heating the water and evaporation.

In contrast, at shallow water depths like 2 to 5 mm, the basin's water is significantly less. It may not be uniformly distributed over the steps because of dry spots due to rapid evaporation. In such conditions, though the depth of water is less, the productivity of the still may decrease; hence, it is essential to have an optimum depth of water that will enhance the still's productivity [44, 45].

Absorber plate area

The absorber plate is mainly used to absorb maximum solar radiation; thereby, the absorber plate's area plays a vibrant role in designing solar still [46]. Copper, aluminum, steel are most widely used as materials for absorber plate [47]. Many researchers have proved that the performance of a solar still improves by enhancing the surface area of evaporation [48]. Numerous augmentation techniques to increase surface area are formulated by many investigators. Velmurugan et al. [49] developed a galvanized iron absorber plate with 25 trays. Fins and sponges were also incorporated to enhance the exposed surface area. Results show that productivity improved by the incorporation of fins and sponges on the absorber plate. Hansen and Murugvel [50] performed experiments by considering different absorber configurations. The integrated solar still was tested with different geometries of absorbers, namely flat grooved and fin-shaped. Results reveal that fin-type absorber yields higher productivity (25.7% higher than flat absorber). Figure 6 depicts the variation in overall efficiency with different types of the absorber.

Variation in efficiency with type of absorber [50] (adapted with permission from ELSEV.B.V with LIC. No. 4827130774445)

Performance of inclined solar still with absorber plate possessing rectangular grooves and ridges was studied by Anburaj et al. [51]. Tests reveal yield of solar still was around 4.27 Ld ay−1 owing to the excessive heat absorbed in energy storage materials placed in rectangular grooves. Kabeel et al. [52] investigated pyramid solar still having V-grooved absorber plate with phase change material depicted in Fig. 7. Results show that an 87% increase in distillate output as compared to conventional pyramid solar still was observed. Elshamy et al. [53] studied tubular solar still using a flat plate and semicircular corrugated absorber shape. Figure 8 shows a semicircular corrugated absorber. Experimental results showed that the semicircular absorber plate gave 4.3 L m−2 distillate output (26.46% higher than the flat plate absorber). Deu [54] worked on a non-continuous absorber area and determined the thermal efficiency and overall thermal losses of semispherical solar collector. Effect of hollow circular and hollow square fins on the surface of the mild steel absorber plate was investigated by Jani and Modi [55]. For the experiments, circular fins and square plate fins (Fig. 9a and b) made up of mild steel with dimensions of 25 × 20 × 2 mm were used. Experimental results showed that absorber plates with hollow circular fins gave more distillate output than hollow square fins. The productivity of any solar still is strongly influenced by the evaporative area. Integration of fins in a basin of solar still increases the surface area and enhances the rate of evaporation, leading to improving the productivity of solar still [56]. Sathyamurthy et al. [57] studied the influence of fin on an absorber plate of tubular solar still. The result of experimentation shows improvement in surface area and evaporation rate that leads to accelerating the productivity of still. Panchal et al.[58] assessed the impact of vertical and inclined fin and compared the results with CSS. The results show that 27 and 25% increment in the productivity of still is obtained with inclined and vertical fins compared to CSS. Finally, it can be concluded that a combination of V-corrugated absorber plate with fins and energy-storing materials can provide optimized conditions to enhance productivity.

Still with V-grooved absorber plate [52] (adapted with permission from ELSEV. B.V. with LIC. No. 4827041335546)

Semicircular absorber plate [53] (adapted with permission from ELSEV.B.V. with LIC. No. 4827130949744)

a Hollow circular and (b) square fins [55] (adapted with permission from ELSEV.B.V. with LIC. No. 4827060084558 and 4827060273211)

Use of thermal energy storage materials

Enhancing the productivity of solar still necessitates the temperature of basin water to be high [59]. Various augmentation techniques are employed to achieve temperature rises, such as thermal energy-absorbing and storing materials, the use of phase change materials, and the use of nanoparticles [39, 60]. A nanofluid is a substance that contains nanosized particles [61]. Sun-oriented thermal advancements utilize the whole solar spectrum to give high temperature [62]. Figure 10 shows various thermal energy storage materials. Incorporating materials that are energy absorbent has a very prominent role in the fabrication of solar stills [63]. A substantial amount of work is reported on the usage of energy-storing materials [62]. The productivity of solar still was examined by using black granite gravel, Sakthivel and Shanmugasudar [64]. Black granite gravel was sprayed on the basin area with an average thickness of 6 mm to act as energy storage material. The mathematical model was developed to predict the temperature of gravel, glass, and water. Results show that the utilization of black granite gravel observes a 17 to 20% increase in yield. Abdallah et al. [65] studied the effect of thermal energy-absorbing material on solar still. Experimental results show that black rocks absorb the incident radiations better than metallic sponge wire and result in enhanced productivity by 20%. Figure 11 represents the results of experimentation.

Different thermal energy storage materials [256] (adapted with permission from ELSEV. B.V. with LIC. No. 4827060462673)

Water collection by four solar stills in three days [65] (adapted with permission from ELSEV. B.V. with LIC. No. 4827060671855)

Murugavel et al. [66] investigated the effect of wick materials (cotton, jute, sponge) on the performance of solar still. Results show that black cotton cloth offers greater yield as compared to other wick materials. Further, Kalidasa et al. [67] studied the influence of several sensible heat-soaring materials (quartzite rock, red brick pieces, concrete cement, washed stones, and iron scraps) on the productivity of single-basin double-slope solar still. Results show that quartzite rock material offers enhanced productivity as compared to other materials. Nafey et al. [68] investigated the influence of black rubber (energy-soaring material) with variable thickness. Results reveal that enhanced performance is attained by black rubber possessing a thickness of 10 mm.

Further, Kabeel et al. [69] examined the influence of sensible storage material on single-basin solar still. For the experimental study, graphite was used as a sensible storage material due to its high thermal conductivity. Results revealed that daily production of still was around 7.7 L m−2 that are much higher than traditional single-basin still. Samuel et al. [70] studied the utilization of low-cost energy storage materials. Theoretical and experimental tests using spherical salt storage material were conducted. Results infer that solar still gave maximum productivity up to 3.7 L m−2 compared to conventional single-basin solar still. Omara and Kabeel [71] performed experiments on sand bed solar still using black and yellow sand. Additionally, the effect of the height of sand beds was also studied. Results show that black sand with 0.01 m height gives 42% more yield than conventional solar still, while yellow sand with the same height gives 17% more yield. Figure 12 depicts the cumulative distillate output with different types of sand. In addition to energy storage materials, phase change materials have also been used to improve solar still’s productivity. Phase change materials are also called latent heat storage materials because of their unique property of absorbing energy and adapting to physical state change [72]. Paraffin wax is utilized as a phase change material more popularly due to its better thermal properties (specific heat 2320 J kg−1 0C; thermal conductivity 0.23 Wm−10C; density 802 kg m−3) [73]. Table 5 depicts the summary of phase change materials used on different types of solar stills.

Cumulative output with different types of sand [71] (adapted with permission from Taylor & Francis with LIC. No. 5032200472931)

Moreover, hybrid nanoparticles are the combination of two or more organic or inorganic components [74, 75]. These materials have gigantic exploration interest due to their special properties, like quantum confinement effect and extremely large surface-to-volume ratios [76]. These nanofluids are utilized for various solar applications like flat plate collectors, parabolic collectors, evacuated tubes, and solar still [77,78,79]. Nanomaterials' properties depend on their size, shape, and other structure porosity [80]. Gazar et al. [81] assessed the performance of conventional solar still with alumina and copper oxide as a hybrid nanofluid. The result of the experiment inferred a 27 and 21% rise in productivity in the summer and winter season, respectively, with the integration of hybrid nanofluid. Kabeel et al. [82] studied the impact of paraffin wax and graphite nanoparticles as hybrid material on CSS performance. The result shows a 63 to 94% enhancement in productivity.

Effect of insulating material and thickness of insulation

Generally, heat loss occurs from the lower and lateral surfaces of the basin due to the absence of insulation at these surfaces, affecting the overall production. The productivity of any solar still gets decreased due to a large amount of heat loss through the basin and sidewalls of a still. Most of the researchers reported that only 38.40% of solar energy was used for evaporation. The remaining 61.60% of energy gets wasted as heat loss from the solar still. About 35.70 and 25.70% of energy were lost from the glass cover and side-bottom of the still, respectively [83, 84]. Therefore, it is necessary to minimize the heat loss that can be attained by providing adequate padding using different insulating materials. Numerous researchers have widely investigated insulating materials such as sawdust, polyurethane, and gypsum. The research showed that the required thickness of insulation directly depends on insulating constituents' thermal conductance. Solar still productivity improves with an increase in the thickness of insulation depicted in Fig. 13. It is observed that the daily productivity increases from around 1.8 to 3.3 L m−2 as the thickness of insulating material increased from 0 to 0.1 m, indicating that proper insulation is necessary to reduce the heat losses and enhance productivity. A detailed summary of insulating materials and the thickness of insulation are presented in Table 6.

Effect of thickness of insulation on the productivity of solar still [257] (adapted with permission from ELSEV. B.V. with LIC. No. 4827070493761)

Inclination of the cover plate

As discussed in the previous sections, solar still productivity strongly depends on latitude coordinates and the intensity of radiations on saline water [61]. To receive a higher amount of solar radiation from the sun, the solar still covers plate's inclination angle cover plate is a crucial factor that needs to be considered. Most of the investigations revealed that the inclination angle must be equivalent to that particular location's latitude so that the maximum intensity of radiations can be achieved throughout the year. Further, it is observed that varying the tilt angle concerning the latitude coordinates decreases the overall productivity (Fig. 14). Table 7 summarizes the inclination angle of the cover plate used for different configurations of solar still. Also, Fig. 15 represents the condensing cover of solar still at different inclination angles. The result depicts the monthly variation of distillate output nearly the same for all the cover plate's inclination angle.

Effect of thickness of insulation on the productivity of solar still in January and July [209] (adapted with permission from ELSEV. B.V. with LIC. No. 4827070699983)

Variation of inclination angle with annual yield [183] (adapted with permission from ELSEV. B.V. with LIC. No. 4827070896397)

Thickness of cover plate

The thickness of the cover plate and condensing cover material are two other factors that can significantly influence the productivity of solar stills [85]. Highly transmissive materials like glass are widely used as cover plate material for solar stills owing to their high affinity to absorb radiations. Additionally, it is also absorbed that lower cover plate thickness is favored for stills with higher productivity. Figure 16a and b depicts the influence of glass cover thickness and condensing cover materials on the solar still productivity, respectively. Results reveal that maximum solar still productivity is attained with a 2-mm-thick cover plate and decreases with the increase in cover plate thickness. Figure 16b shows the productivity attained with copper, glass, and plastic cover plates. Results show that plastic and glass cover plates possessing lower density can provide productivity similar to copper. Therefore, the cover plate's material and thickness need to be correctly selected to achieve good productivity. Table 8 depicts a review of the effect of cover plate thickness on the productivity of solar still (Fig. 17).

a Effect of thickness of glass cover on yield and b effect of condensing cover material on daily yield [167] (adapted with permission from ELSEV. B.V. with LIC. No. 4827071047892 and 4827071198971)

Effect of thickness of glass cover on output [85] (adapted with permission from Springer with LIC. No. 5032200235394)

Use of internal and external reflectors

Conventional solar stills have the constraint of low output. Many researchers have worked on the use of reflectors to improve solar still productivity [86]. The use of reflectors comes into consideration when the intensity of radiation from the sun is low or the atmospheric temperature is low. There are three types of reflectors, namely internal, external reflectors (top and bottom) and a combination of internal and external reflectors, shown in Figs. 18, 19, and 20, respectively. Internal reflectors are positioned on the inner side of solar still to enhance productivity significantly. These reflectors are used to centralize all the solar radiations onto the water. Tamimi [87] experimented on single-slope solar still. Mirrors were used as internal reflectors, located on the inner walls of the still. Results show a considerable increase in solar still productivity.

Internal and external reflector [258] (adapted with permission from ELSEV. B.V. with LIC. No. 4827091362308)

(a) Top and (b) bottom external reflector [259] (adapted with permission from ELSEV. B.V. with LIC. No. 4827100328386)

Combined internal and external reflector [260] (adapted with permission from ELSEV. B.V. with LIC. No. 4827100874630)

External reflectors are utilized to improve the direction of radiation beams transmitted through the glass cover. Generally, suitable reflective materials such as mirror-finished metal plates are used to produce external reflectors. Further, there are two types of external reflectors, external top reflectors, and external bottom reflectors depicted in Fig. 19a and b. However, incorporating internal and external reflectors separately has resulted in enhanced productivity [86]. A detailed summary to depict the review of the effect of various reflectors on solar still is presented in Table 9. Incorporating reflector plates, either internal, external, or both, can significantly increase the distillate output in solar stills.

Gap distance between absorber plate and condensing cover

It was observed from various studies that solar still output could be enhanced by reducing absorber plates and condensing cover gaps. If the gap is optimum, saturated fluid will reach the condensing surface in less time, enabling to improve the continuous air movement [88]. Keshtkar et al. [88] performed CFD modeling to observe the impact of gap distance between the cover plate and basin of a solar still. The investigation inferred at a gap distance of 8 cm still provides the highest distillate out than the 4 and 12 cm gap. Therefore, it was presumed that to achieve maximum productivity from solar still, the gap between cover and surface of water basin essentiality is optimum. Outcomes of the experimentations are depicted in Fig. 21.

Impact of gap distance on the productivity of still [88] (adapted with permission from ELSEV. B.V. with LIC. No. 4827101056725)

Rahbar and Esfahan [89] analyzed the effect of gap distance on the single-basin solar still production theoretically and numerically. Results inferred that when the height of the solar still was minimized, the distance between the glass cover and water surface also gets minimal, thereby improving the convective heat transfer coefficient and, therefore, an enhanced condensation rate. Jamil et al. [90] investigated the effect of varying the gap plate distance on solar still productivity. Figure 22b shows the gap distance between the absorber and condensing surface. H1 was the highest gap distance, while H4 was the lowest. Experimental results for the varying gap are shown in Table 10. Results revealed that productivity gets enhanced by maintaining optimum gap distance. The gap distance between the glass cover and water surface is minimum (in the case of H3 and H4), which improves the convective heat transfer coefficient and thus increases condensation rate, leading to improvement in solar still performance. The optimum gap between absorber plates and condensing cover needs to be considered in detail to have higher productivity of solar stills.

a Conventional single-slope solar still and b gap distance between absorber and condensing surface [90]

Sun tracking system

The primary purpose of the development of a sun tracking system is to enhance solar still productivity. One can increase the incident solar radiations on still by tracking the sun's location in the sky. The slant angle of the sun is one of the vital factors in solar applications [91]. Sun tracking system is a computerized device that rotates solar still direction as per the sun's movement. Mainly there are two types of sun trackers, namely, single-axis tracker and dual-axis tracker [92]. Single-axis trackers can track the sun only from East to West direction, while dual-axis trackers can track the sun's location on any day and anytime. From most of the literature, it was clear that the sun tracking system enhances solar still productivity when compared with a fixed system. Maliani et al. [93] and Abdelghani [94] demonstrated that with the sun tracking system's utilization, the temperature of the water increases quickly. Abdallah and Badran [95] found out that a 22% improvement in solar still productivity was observed by incorporating a sun tracking system. Figure 23 shows water collected for both fixed still and still with a sun tracking system. Khalifa and Mutawalli [96] used a two-axis sun tracking system and concluded that a 75% improvement in solar still performance could be attained. Abdallah and Nijmeh [97] worked on a two-axis sun tracking system; results show that a 41.34% increase in collected solar energy on the water's surface was achieved. Abdallah et al. [98] investigated modified design of single-basin system with sun tracker. Results show that stepwise basin with sun tracking system gives highest thermal performance of 380%. Sun tracking system can be affective to increase the productivity of solar stills.

Collected water for both fixed still and still with sun tracking system [95] (adapted with permission from ELSEV. B.V. with LIC. No. 4827101365161)

Operational parameters

Various operational parameters that affect productivity are listed below.

-

The salt content of water

-

The flow rate of water

-

Use of dyes

-

Others

Salt content of water

The concentration of salt present in the water is known as the salinity of water [99]. Generally, the salinity of salt is measured in g(salt) kg−1(seawater). From various literature, it is observed that the productivity of solar still declines by increasing salt concentration in the water. Bilal et al. [100] studied the effect of salinity of water on basin-type solar still. Results show that the salinity of water reduces solar still productivity, as depicted in Fig. 24. Hoque et al. [101] studied the effect of salinity of water on solar still productivity with synthetic saline water. Results show that with increasing total dissolved salts (TDS) value from 2000 to 8000 ppm, the productivity of solar still declined by 7.8%. Shirsatha et al. [102] studied the effect of salinity of water on doubly inclined solar still and concluded that solute in water decreases solar still productivity. Mahdi et al. [103] conducted the experiments on wick-type solar still. Results show that at 2.50% of saline water, efficiency was 39%, while for 5.00% saline water, efficiency was 33%. Further, it was also concluded that the efficiency of solar still decreases linearly with increasing salt concentration. Rai et al. [104] experimented on single-basin solar still and found out that an increase of salt concentration in water increases the surface tension and reduces the evaporation rate, and leads to a decrease in productivity.

Effect of salinity of water on daily water accumulation [100] (adapted with permission from ELSEV. B.V. with LIC. No. 4827111118425)

Flow rate of water

From most of the literature, it was found that the efficiency of solar still declines as the flow rate of water increases [105]. Tabrizi et al. [106] designed weir-type cascade solar still and studied the effect of water flow rate on productivity and internal heat and mass transfer. Results show that a decrease in the productivity and rate of heat and mass transfer was observed with increasing flow rate. When the mass flow rate was 0.065 kg min−1 and 0.2 kg min−1, the productivity was 7.4 kg m−2 and 4.3 kg m−2, respectively. Kerfah et al. [107] studied the effect of the volumetric flow rate of water on the evaporation rate and found out that the evaporation rate was maximum at a minimum volumetric flow rate (3 × 10−6m3sec−1). Mahdi et al. [103] designed wick-type solar still and studied the effect of water flow rate on efficiency. Results illustrate that solar still efficiency decreases as the flow rate of water increases, as shown in Fig. 25. Further, Suneja and Tiwari [108] studied the effect of water flow rate over the condensing cover of solar still and concluded that a particular flow rate of water evaporative heat transfer coefficient declines.

Effect of the flow rate of water on the efficiency of solar still [103] (adapted with permission from ELSEV. B.V. with LIC. No. 4827111258653)

Use of dyes

In the case of a conventional solar still, heat is transferred from the bottom to the water's surface with the convection mode of heat transfer [109]. As previously discussed, higher intensity of solar radiations enhances the productivity of solar still. Therefore, to gain a large amount of solar radiation from the sun, a dye is mixed with water to absorb maximum radiation from the sun. Cooper [110] reported that to improve solar still productivity, it is necessary to improve water's absorptivity, which can be improved by adding blue and red dyes in water. Results of the study show that the addition of dyes can improve the absorptivity of the water. Sodha et al. [111] and Pandey [112] studied the effect of dye on solar still productivity. Results show productivity enhances with dye's addition as the dyes help improve the evaporation rate shown in Fig. 26. As a result of this, an increase in distillate output is observed. Rajvanshi [113] studied the effect of black naphthylamine, red carmoisine, and dark green dyes at various concentrations. Results show that 29% rise in solar still productivity is attained when black dye with 172.5 ppm was used.

Variation of productivity with and without dye [111] (adapted with permission from ELSEV. B.V. with LIC. No. 4827120038517)

Other techniques

So far, we have discussed climatic, design, and operational parameters that affect solar still performance. In this section, we will discuss some other modifications done by various researchers on solar still. The performance of the solar still can be improved by preheating the inlet water [114]. The condensation and evaporation rate of preheated water is more than ordinary water [115]. Various techniques are utilized to preheat water, which includes integration of solar ponds, heat pipe, and flat plate collector [116,117,118,119,120]. Preheating water is mainly performed by passing the water over a solar panel before the solar still basin. Elbar and Hassan [121] assessed the performance of solar still by preheating the saline water. The experimental work results show preheating 60% of the saline water upsurge the productivity by 20.9%, contrasted with sun-powered desalination framework without preheating. Subramanian et al. [122] utilized a flat plate collector for preheating the saline water in modified pyramid solar still. Results of the experiment depict a 60% rise in productivity compared to ordinary solar still. From the above literature work, it is concluded that preheating helps to enhance the water temperature. When the higher temperature water is passed through the basin of a still, the heat needed for evaporating the saltwater is less, and hence the profitability is increased. Refalo et al. [123] utilized the solar chimney within solar still in association with copper pipe condenser. Solar chimney and condenser were utilized to enhance convective heat transfer and rate of condensation, respectively. Figure 27 depicts the solar still with the utilization of chimney and condenser. Results show considerable enhancement in productivity (5.1 L m−2 day−1) of still.

Solar still with chimney and condenser [261] (adapted with permission from ELSEV. B.V. with LIC. No. 5030780458402)

A large portion of research work demonstrated that the combination of wick material with a suitable absorber plate design gives a large amount of distillate yield [124]. In the case of a wick-type solar still, the sun-oriented radiation falling on the glass cover passes through it and arrives at the wick surface, where it is absorbed. A portion of the energy is used for warming the water coursing through the wick because of capillary action[125]. Much heat gets caught inside the still, and an exchange of energy occurs from the wick surface to the glass cover and to the surrounding air [126]. Agrawal et al. [127] utilized black jute cloth inside the basin of solar still that offers a large amount of surface area for the evaporation. Results of the experiment inferred a 62% improvement in productivity as compared to CSS. Ahmed and Ibrahim [128] studied the effect of five different wick materials on CSS performance. The experiment results show that black cotton sheet is the most effective wick material as it provides 36.9% enhancement in productivity compared to CSS. The impact of four different wick materials on pyramid solar still performance was carried out by Saravanan and Murugan [129]. For the experimentation purpose, polyester, terry cotton, jute cloth, and woolen fabric were selected. The experiment results show productivity improved by 9.4%, 20.9%, and 33.1% utilizing woolen fabrics than jute, terry cotton, and polyester, respectively.

Experimental and theoretical analysis of solar still was assessed by Mahian et al. [130] by utilizing a heat exchanger with silicon dioxide and copper nanoparticles. Figure 28 depicts solar still with a heat exchanger. The results of the experiment inferred that the utilization of a heat exchanger with nanofluid is advantageous. Furthermore, it was concluded that copper/water nanofluids give better performance than silicon dioxide/water owing to its higher thermal conductivity. Solar flat plate collector is mainly utilized to convert solar energy into thermal energy [131, 132]. Halima et al. [133] numerically investigate the performance of solar still combined with heat pump. The utilization of the heat pump was advantageous for enhancing the temperature of the water. Figure 29 depicts the layout of solar still with heat pump. Results reveal a 75% enhancement in the productivity of proposed still when contrasted with conventional solar still. Shatat and Mahkamov [134] experimentally investigate multistage solar still performance in association with the evacuated solar collector, as shown in Fig. 30. The experiment's results depict productivity of the proposed still was found to be 5 kg m−2 day, which is significantly higher than conventional still.

Schematic layout of solar still with heat exchanger [130] (adapted with permission from ELSEV.B.V. with LIC. No. 4827120260851)

Solar still integrated with heat pump [133] (adapted with permission from ELSEV. B.V. with LIC. No. 4827120405908)

Schematic layout of multistage solar still with evacuated solar collector [134] (adapted with permission from ELSEV.B.V. with LIC. No. 4827120535708)

Rabhar and Efahani [135] investigated portable solar still by the utilization of thermoelectric modules. These modules enhance the temperature difference between glass cover and basin surface; consequently, solar still productivity increases significantly. Figure 31a depicts the schematic layout of solar still experimental setup with the thermoelectric module. Results of the experiment reveal the daily efficiency of still was 7%. Somwanshi and Tiwari [136] studied the impact of cooling glass cover in association with the cooling water from the desert cooler (Fig. 31b). The flow of cold water helps to increase the temperature difference between condensing and evaporative areas. The experiment tested for Jodhpur, and Chennai's climatic conditions reveal that yearly productivity increases up to 7.4 and 9.9%, respectively. Table 11 depicts the review of various modifications and their effect on the productivity of solar still. The profitability of a still is affected by the temperature distinction among condensing and evaporative surfaces. Growing the distinction between water–glass temperatures improves the profitability still [137]. To keep up this temperature distinction high, fans, condensers, and glass cover cooling was used. Constant supply of air or water film over the glass cover leads to reduce the temperature of glass [138]. Patel et al. [139] assessed double-slope solar still incorporation with a separate cooling coil condenser. The entire vapors generated during the evaporation process are condensed due to the integration of the cooling coil condenser that leads to enhance the productivity of still. Kabeel and Abdelgaied [140] studied the impact of glass cover cooling on pyramid solar still. The experiment's result shows daily efficiency of solar still with cooling cover improves by 97 to 98% compared to traditional pyramid still.

a Still with a thermoelectric module and b still with desert cooler [136] (adapted with permission from ELSEV. B.V. with LIC. No. 4827120659991 and 4827120788850)

As of late, attention has been pinpointed around the improvement of different designs of solar still. Pyramid solar still is one of the results of such advancement [141]. The top cover's shape seems to a pyramid; hence, these stills are popularly known as pyramid still. Triangular and square are the two basic types of pyramid solar stills. Madhhachi and Smaisim [142] designed and tested square pyramid solar still. The performance of the solar still was measured for the four seasons in Iraq. Results of the experiments show a 60% rise in the efficiency of design still compared to others. The impact of insulation and water depth on pyramid solar still performance was studied by Muthu Manokar et al. [143]. The experiment was mainly conducted with varying water depth from 1 to 3.5 cm and providing the insulation. The experiment results show at 1 cm water depth and still with insulation provides the highest distillate output, which seems to be improved by 19.46% compared to single-basin solar still. The impact of granite material, forced evaporation, and forced condensation on pyramid still was studied by Modi and Nayi [144]. Experimental results inferred still with forced evaporation, and granite material provides the highest yield (2.25 L m−2) and is more efficient. The pyramid solar still performance with the integration of evacuated tubes and nanoparticles was studied by Sharshir et al. [145]. The experiment results show improvement in productivity by 27.85% and 33.59% by utilizing copper oxide and carbon black, respectively.

Conclusion and future recommendations

In the present article, a review of various factors affecting the productivity of solar stills is discussed. A review of solar stills is carried out considering the climatic conditions, design, and optional parameters of solar stills. The following conclusions are drawn from the study.

-

Combining the good intensity of solar radiations, solar still type and regions with high temperature can provide better productivity in daily distillate output.

-

Productivity can be enhanced by increasing the wind velocity from 0 to 10 ms−1 to about 50%.

-

The presence of dust and dirt particles on the condensing surface reduces the glass cover's transmission capacity. Therefore, condensing cover must be cleaned regularly.

-

Maximum productivity can be attained with inclined solar stills when the inclination angle is made equivalent to that location's latitude. The maximum intensity of radiations can be achieved throughout the year by inclining the cover of still equivalent to the location's latitude.

-

Aluminum material with nominal thickness can be used as basin material due to its thermal conductivity and corrosion-resistant abilities.

-

Minimum depth of water around 1 cm for conventional solar still enhances evaporation and provides higher productivity.

-

The rate of evaporation increases with an increase in the surface area of the absorber plate. A stepped basin will provide a higher surface area. The utilization of fins can also improve surface area.

-

For better distillate output of solar stills during the low intensity of radiations, energy storage materials (graphite, black rubber, and quartzite rock) and phase change materials (paraffin wax, lauric acid, and stearic acid) are widely used.

-

An increase in the thickness of insulating material reduces heat losses in solar still and thereby enhances productivity. Foam, sawdust, and thermocol are widely used insulating materials

-

Highly transmissive materials like glass are widely used with minimum thickness up to 3 to 4 mm

-

Reflector plates, either internal, external, or both, can significantly increase the distillate output in solar stills.

-

The performance of solar still can be improved by minimizing the gap between absorber plates and condensing cover.

-

Incorporating a sun tracking system, either single or dual axis in solar still, can enhance productivity.

-

Higher salinity and mass flow of water decrease the efficiency of solar stills.

-

The use of dyes on the surfaces of solar still can also increase productivity.

The outcomes reported here offer a way to enhance the productivity of solar stills by considering the feasibility of incorporating advantageous modifications and avoiding the disparaging ones. The most noticeable challenge is to enhance the productivity of still by reducing the losses from the still. In view of the literature survey, researchers need to concentrate on the following areas:

-

Broad experimentation is required to recognize the impact of various configurations of the still with heat transfer and thermodynamics.

-

The software improvement is required to demonstrate and simulate solar stills concerning various discussed parameters.

-

In the case of a stepped solar still, the impact of changing the shape of steps needs to be observed with sensible heat storage materials (SHM) and nanoparticles.

References

Abujazar MSS, Fatihah S, Lotfy ER, Kabeel AE, Sharil S. Performance evaluation of inclined copper-stepped solar still in a wet tropical climate. Desalination. 2018;425:94–103. https://doi.org/10.1016/j.desal.2017.10.022.

Velmurugan V, Srithar K. Performance analysis of solar stills based on various factors affecting the productivity: a review. Renew Sustain Energy Rev. 2011;15:1294–304. https://doi.org/10.1016/j.rser.2010.10.012.

Kumar PN, Manokar AM, Madhu B, Kabeel AE, Arunkumar T, Panchal H, et al. Experimental investigation on the effect of water mass in triangular pyramid solar still integrated to inclined solar still. Groundw Sustain Dev. 2017;5:229–34. https://doi.org/10.1016/j.gsd.2017.08.003.

Modi KV, Nayi KH, Sharma SS. Influence of water mass on the performance of spherical basin solar still integrated with parabolic reflector. Groundw Sustain Dev. 2020;10:100299.

Alwan NT, Shcheklein SE, Ali OM. Case studies in thermal engineering experimental investigation of modified solar still integrated with solar collector. Case Stud Therm Eng. 2020;19:100614. https://doi.org/10.1016/j.csite.2020.100614.

Javadi MA, Ahmadi MH, Khalaji M. Exergetic, economic, and environmental analyses of combined cooling and power plants with parabolic solar collector. Environ Prog Sustain Energy. 2020;39:e13322.

He W, Namar MM, Li Z, Maleki A, Tlili I, Safdari SM. Thermodynamic analysis of a solar-driven high-temperature steam electrolyzer for clean hydrogen production. Appl Therm Eng. 2020;172:115152. https://doi.org/10.1016/j.applthermaleng.2020.115152.

Ahmadi MH, Ghazvini M, Sadeghzadeh M, Alhuyi Nazari M, Kumar R, Naeimi A, et al. Solar power technology for electricity generation: a critical review. Energy Sci Eng. 2018;6:340–61.

Jathar LD, Ganesan S, Shahapurkar K, Patil S, Darekar V, Chincholi V. Comprehensive review on the prediction of thermal behavior of solar stills with diverse designs. In: AIP conference of proceedings 2020.

Shatat M, Riffat SB. Water desalination technologies utilizing conventional and renewable energy sources. Int J Low Carbon Technol. 2014;9:1–19.

Wang Z, Horseman T, Straub AP, Yip NY, Li D, Elimelech M, et al. Pathways and challenges for efficient solar-thermal desalination. Sci Adv. 2019;5:eaax0763.

Bhatti MM, Phali L, Khalique CM. Heat transfer effects on electro-magnetohydrodynamic Carreau fluid flow between two micro-parallel plates with Darcy–Brinkman–Forchheimer medium. Arch Appl Mech. 2021. https://doi.org/10.1007/s00419-020-01847-4.

Jathar LD, Ganesan S. Assessing the performance of concave type stepped solar still with brick, sand, and concrete pieces. Int J Ambient Energy. 2020;0:1–17.

Jathar LD, Ganesan S. Statistical analysis of brick, sand and concrete pieces on the performance of concave type stepped solar still. Int J Ambient Energy. 2020. https://doi.org/10.1080/01430750.2020.1848918.

Pangarkar BL, Sane MG, Guddad M. Reverse osmosis and membrane distillation for desalination of groundwater: a review. ISRN Mater Sci. 2011;2011:1–9.

AlMadani HMN. Water desalination by solar powered electrodialysis process. Renew Energy. 2003;28:1915–24.

Ali M, Haj ME, Taha E, Soudan B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination. 2017. https://doi.org/10.1016/j.desal.2017.11.018.

Ahmadi MH, Alhuyi Nazari M, Ghasempour R, Pourfayaz F, Rahimzadeh M, Ming T. A review on solar-assisted gas turbines. Energy Sci Eng. 2018;6:658–74.

Malaiyappan P, Elumalai N. Single basin and single slope solar still: Various basin material thermal research. J Chem Pharm Sci. 2015;7:48–51.

Ali Samee M, Mirza UK, Majeed T, Ahmad N. Design and performance of a simple single basin solar still. Renew Sustain Energy Rev. 2007;11:543–9.

Gnanadason MK, Kumar PS, Wilson VH, Kumaravel A. Productivity enhancement of a-single basin solar still. Desalin Water Treat. 2015;55:1998–2008.

Abujazar MSS, Fatihah S, Kabeel AE. Seawater desalination using inclined stepped solar still with copper trays in a wet tropical climate. Desalination. 2017;423:141–8. https://doi.org/10.1016/j.desal.2017.09.020.

Rashidi S, Bovand M, Rahbar N, Esfahani JA. Steps optimization and productivity enhancement in a nanofluid cascade solar still. Renew Energy. 2018;118:536–45.

Nikam KC, Kumar R, Jilte R. Economic and exergoeconomic investigation of 660 MW coal-fired power plant. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10213-z.

Badran OO, Abu-Khader MM. Evaluating thermal performance of a single slope solar still. Heat Mass Transf Stoffuebertragung. 2007;43:985–95.

Almuhanna EA. Evaluation of single slop solar still integrated with evaporative cooling system for brackish water desalination. J Agric Sci. 2013;6:48.

Nafey AS, Abdelkader M, Abdelmotalip A, Mabrouk AA. Parameters affecting solar still productivity. Energy Convers Manag. 2000;41:1797–809.

Ghoneyem A, Ileri A. Software to analyze solar stills and an experimental study on the effects of the cover. Desalination. 1997;114:37–44.

El-Sebaii AA. Effect of wind speed on active and passive solar stills. Energy Convers Manag. 2004;45:1187–204.

Soliman SH. Effect of wind on solar distillation. Sol Energy. 1972;13:403–15.

Garg HP, Mann HS. Effect of climatic, operational and design parameters on the year round performance of single-sloped and double-sloped solar still under Indian arid zone conditions. Sol Energy. 1976.

Tiwari GN, Dimri V, Chel A. Parametric study of an active and passive solar distillation system: energy and exergy analysis. Desalination. 2009;242:1–18.

Zurigat YH, Abu-Arabi MK. Modelling and performance analysis of a regenerative solar desalination unit. Appl Therm Eng. 2004;24:1061–72.

Reddy RM, Reddy KH. Upward heat flow analysis in basin type solar still. J Min Metall Sect B Metall. 2009;45:121–6.

Hegazy AA. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew energy. 2001;22:525–40.

El-Nashar AM. The effect of dust accumulation on the performance of evacuated tube collectors. Sol Energy. 1994;53:105–15.

El-Nashar AM. Seasonal effect of dust deposition on a field of evacuated tube collectors on the performance of a solar desalination plant. Desalination. 2009;239:66–81.

Zamfir E, Oancea C, Badescu V. Cloud cover influence on long-term performances of flat plate solar collectors. Renew Energy. 1994;4:339–47.

Shahid A, Huang HL, Khalique CM, Bhatti MM. Numerical analysis of activation energy on MHD nanofluid flow with exponential temperature-dependent viscosity past a porous plate. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10295-9.

Bhatti MM, Abdelsalam SI. Thermodynamic entropy of a magnetized Ree-Eyring particle-fluid motion with irreversibility process: A mathematical paradigm. ZAMM Zeitschrift fur Angew Math und Mech. 2020;2020:1–17.

Burbano AM. Evaluation of basin and insulating materials in solar still prototype for solar distillation plant at kamusuchiwo community, high guajira. Renew Energy Power Qual J. 2014;1:547–52.

Alaudeen A, Thahir ASA, Vasanth K, Tom AMI, Srithar K. Experimental and theoretical analysis of solar still with glass basin. Desalin Water Treat. 2015;54:1489–98.

Badran OO. Experimental study of the enhancement parameters on a single slope solar still productivity. Desalination. 2007;209:136–43.

Sharshir SW, Peng G, Wu L, Yang N, Essa FA, Elsheikh AH, et al. Enhancing the solar still performance using nanofluids and glass cover cooling: experimental study. Appl Therm Eng. 2017;113:684–93. https://doi.org/10.1016/j.applthermaleng.2016.11.085.

Nikam KC, Kumar R, Jilte R. Exergy and exergo-environmental analysis of a 660 MW supercritical coal-fired power plant. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10268-y.

Goshayeshi HR, Safaei MR. Effect of absorber plate surface shape and glass cover inclination angle on the performance of a passive solar still. Int J Numer Methods Heat Fluid Flow. 2019;30:3183–98. https://doi.org/10.1108/HFF-01-2019-0018.

Silakhori M, Jafarian M, Arjomandi M, Nathan GJ. The energetic performance of a liquid chemical looping cycle with solar thermal energy storage. Energy. 2019;170:93–101.

Abdullah AS, Younes MM, Omara ZM, Essa FA. New design of trays solar still with enhanced evaporation methods: comprehensive study. Sol Energy. 2020;203:164–74.

Velmurugan V, Naveen Kumar KJ, Noorul Haq T, Srithar K. Performance analysis in stepped solar still for effluent desalination. Energy. 2009;34:1179–86.

Samuel Hansen R, Kalidasa MK. Enhancement of integrated solar still using different new absorber configurations: an experimental approach. Desalination. 2017;422:59–67.

Anburaj P, Samuel Hansen R, Kalidasa MK. Performance of an inclined solar still with rectangular grooves and ridges. Appl Sol Energy. 2013;49:22–6.

Kabeel AE, Teamah MA. Modified pyramid solar still with v-corrugated absorber plate and PCM as a thermal storage medium. J Clean Prod. 2017;161:881–7

Elshamy SM, El-Said EMS. Comparative study based on thermal, exergetic and economic analyses of a tubular solar still with semi-circular corrugated absorber. J Clean Prod. 2018;195:328–39.

Armenta-Deu C. Performance test in semispherical solar collectors with discontinuous absorber. Renew Energy. 2019;143:950–7.

Jani HK, Modi KV. Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Sol Energy. 2019;179:186–94.

Velmurugan V, Deenadayalan CK, Vinod H, Srithar K. Desalination of effluent using fin type solar still. Energy. 2008;33:1719–27.

Sathyamurthy R, Mageshbabu D, Madhu B, Muthu Manokar A, Rajendra Prasad A, Sudhakar M. Influence of fins on the absorber plate of tubular solar still: an experimental study. Mater Today Proc. 2020. https://doi.org/10.1016/j.matpr.2020.11.355.

Panchal H, Mevada D, Sadasivuni KK, Essa FA, Shanmugan S, Khalid M. Experimental and water quality analysis of solar stills with vertical and inclined fins. Groundw Sustain Dev. 2020. https://doi.org/10.1016/j.gsd.2020.100410.

Mousa H, Naser J. The effect of phase change material on the water temperature in a solar basin: theoretical and experimental investigation. J Energy Storage. 2019;25:100871. https://doi.org/10.1016/j.est.2019.100871.

Sadeghzadeh M, Ahmadi MH, Kahani M, Sakhaeinia H, Chaji H, Chen L. Smart modeling by using artificial intelligent techniques on thermal performance of flat-plate solar collector using nanofluid. Energy Sci Eng. 2019;7:1649–58.

Arain MB, Bhatti MM, Zeeshan A, Saeed T, Hobiny A. Analysis of arrhenius kinetics on multiphase flow between a pair of rotating circular plates. Math Probl Eng. 2020.

Silakhori M, Jafarian M, Arjomandi M, Nathan GJ. Experimental assessment of copper oxide for liquid chemical looping for thermal energy storage. J Energy Storage. 2019;21:216–21. https://doi.org/10.1016/j.est.2018.11.033.

Silakhori M, Jafarian M, Arjomandi M, Nathan GJ. Comparing the thermodynamic potential of alternative liquid metal oxides for the storage of solar thermal energy. Sol Energy. 2017;157:251–8. https://doi.org/10.1016/j.solener.2017.08.039.

Sakthivel M, Shanmugasundaram S. Effect of energy storage medium (black granite gravel) on the performance of a solar still. Int J Energy Res. 2008;

Abdallah S, Abu-Khader MM, Badran O. Effect of various absorbing materials on the thermal performance of solar stills. Desalination. 2009;32:68–82.

Kalidasa Murugavel K, Chockalingam KKSK, Srithar K. An experimental study on single basin double slope simulation solar still with thin layer of water in the basin. Desalination. 2008;220:687–93.

Murugavel KK, Sivakumar S, Ahamed JR, Chockalingam KKSK, Srithar K. Single basin double slope solar still with minimum basin depth and energy storing materials. Appl Energy. 2010;87:514–23. https://doi.org/10.1016/j.apenergy.2009.07.023.

Nafey AS, Abdelkader M, Abdelmotalip A, Mabrouk AA. Solar still productivity enhancement. Energy Convers Manag. 2001;42:1401–8.

Kabeel AE, Abdelgaied M, Eisa A. Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials. J Clean Prod. 2018;183:20–5.

Harris Samuel DG, Nagarajan PK, Sathyamurthy R, El-Agouz SA, Kannan E. Improving the yield of fresh water in conventional solar still using low cost energy storage material. Energy Convers Manag. 2016;112:125–34. https://doi.org/10.1016/j.enconman.2015.12.074.

Omara ZM, Kabeel AE. The performance of different sand beds solar stills. Int J Green Energy. 2014;11:240–54.

Sarafraz MM, Tlili I, Tian Z, Bakouri M, Safaei MR. Smart optimization of a thermosyphon heat pipe for an evacuated tube solar collector using response surface methodology (RSM). Phys A Stat Mech its Appl. 2019;534:122146. https://doi.org/10.1016/j.physa.2019.122146.

Safaei MR, Goshayeshi HR, Chaer I. Solar still efficiency enhancement by using graphene oxide/paraffin nano-PCM. Energies. 2019;12(10):1–13. https://doi.org/10.3390/en12102002.

Ghalandari M, Maleki A, Haghighi A, Safdari Shadloo M, Alhuyi Nazari M, Tlili I. Applications of nanofluids containing carbon nanotubes in solar energy systems: a review. J Mol Liq. 2020;313:113476. https://doi.org/10.1016/j.molliq.2020.113476.

Ahmadi MH, Ghazvini M, Sadeghzadeh M, Alhuyi Nazari M, Ghalandari M. Utilization of hybrid nanofluids in solar energy applications: a review. Nano Struct Nano Objects. 2019;20:100386. https://doi.org/10.1016/j.nanoso.2019.100386.

Aramesh M, Pourfayaz F, Haghir M, Kasaeian A, Ahmadi MH. Investigating the effect of using nanofluids on the performance of a double-effect absorption refrigeration cycle combined with a solar collector. Proc Inst Mech Eng Part A J Power Energy. 2020;234:981–93.

Toghyani S, Afshari E, Baniasadi E, Shadloo MS. Energy and exergy analyses of a nanofluid based solar cooling and hydrogen production combined system. Renew Energy. 2019;141:1013–25. https://doi.org/10.1016/j.renene.2019.04.073.

Safdari Shadloo M. Application of support vector machines for accurate prediction of convection heat transfer coefficient of nanofluids through circular pipes. Int J Numer Methods Heat Fluid Flow. 2020.

Peng Y, Zahedidastjerdi A, Abdollahi A, Amindoust A, Bahrami M, Karimipour A, et al. Investigation of energy performance in a U-shaped evacuated solar tube collector using oxide added nanoparticles through the emitter, absorber and transmittal environments via discrete ordinates radiation method. J Therm Anal Calorim. 2020;139:2623–31. https://doi.org/10.1007/s10973-019-08684-w.

Ma D. Hybrid nanoparticles: an introduction. Noble Met Oxide Hybrid Nanoparticles Fundam Appl. 2018;3–6.

El-Gazar EF, Zahra WK, Hassan H, Rabia SI. Fractional modeling for enhancing the thermal performance of conventional solar still using hybrid nanofluid: energy and exergy analysis. Desalination. 2021;503:114847.

Kabeel AE, Abdelgaied M, Eisa A. Effect of graphite mass concentrations in a mixture of graphite nanoparticles and paraffin wax as hybrid storage materials on performances of solar still. Renew Energy. 2019;132:119–28.

Katekar VP, Deshmukh SS. A review of the use of phase change materials on performance of solar stills. J Energy Storage. 2020;30:101398.

Ali Z, Zeeshan A, Bhatti MM, Hobiny A, Saeed T. Insight into the dynamics of Oldroyd-B fluid over an upper horizontal surface of a paraboloid of revolution subject to chemical reaction dependent on the first-order activation energy. Arab J Sci Eng. 2021. https://doi.org/10.1007/s13369-020-05324-6.

Panchal H. Performance investigation on variations of glass cover thickness on solar still: experimental and theoretical analysis. Technol Econ Smart Grids Sustain Energy. 2016. https://doi.org/10.1007/s40866-016-0007-0.

Khalifa AJN, Ibrahim HA. Effect of inclination of the external reflector on the performance of a basin type solar still at various seasons. Energy Sustain Dev. 2009;13:244–9.

Tamini A. Performance of a solar still with reflectors and black dye. Sol Wind Technol. 1987;4:443–6.

Keshtkar M, Eslami M, Jafarpur K. Effect of design parameters on performance of passive basin solar stills considering instantaneous ambient conditions: a transient CFD modeling. Sol Energy. 2020;201:884–907. https://doi.org/10.1016/j.solener.2020.03.068.

Rahbar N, Esfahani JA. Productivity estimation of a single-slope solar still: theoretical and numerical analysis. Energy. 2013;49:289–97.

Chatzinikolaou S, Ventikos N, Bilgili L, Celebi UB. Energy, transportation and global warming. EnergyTransp Glob Warm. 2016. https://doi.org/10.1007/978-3-319-30127-3.

Yunus Khan TM, Soudagar MEM, Kanchan M, Afzal A, Banapurmath NR, Akram N, et al. Optimum location and influence of tilt angle on performance of solar PV panels. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09089-5.

Awasthi A, Shukla AK, Murali Manohar SR, Dondariya C, Shukla KN, Porwal D, et al. Review on sun tracking technology in solar PV system. Energy Rep. 2020;6:392–405. https://doi.org/10.1016/j.egyr.2020.02.004.

Maliani OD, Bekkaoui A, Baali EH, Guissi K, El Fellah Y, Errais R. Investigation on novel design of solar still coupled with two axis solar tracking system. Appl Therm Eng. 2020;172:115144. https://doi.org/10.1016/j.applthermaleng.2020.115144.

Abdelghani-Idrissi MA, Khalfallaoui S, Seguin D, Vernières-Hassimi L, Leveneur S. Solar tracker for enhancement of the thermal efficiency of solar water heating system. Renew Energy. 2018;119:79–94.

Abdallah S, Badran OO. Sun tracking system for productivity enhancement of solar still. Desalination. 2008;220:669–76.

Khalifa AJN, Al-Mutawalli SS. Effect of two-axis sun tracking on the performance of compound parabolic concentrators. Energy Convers Manag. 1998;39:1073–9.

Abdallah S, Nijmeh S. Two axes sun tracking system with PLC control. Energy Convers Manag. 2004;45:1931–9.

Abdallah S, Badran O, Abu-Khader MM. Performance evaluation of a modified design of a single slope solar still. Desalination. 2008;219:222–30.

Li H, Yan Z, Li Y, Hong W. Latest development in salt removal from solar-driven interfacial saline water evaporators: advanced strategies and challenges. Water Res. 2020;2020:115770.

Akash BA, Mohsen MS, Nayfeh W. Experimental study of the basin type solar still under local climate conditions. Energy Convers Manag. 2000;41:883–90.

Hoque A, Abir AH, Paul SK. Solar still for saline water desalination for low-income coastal areas. Appl Water Sci. 2019;9:1–8. https://doi.org/10.1007/s13201-019-0986-9.

Shirsath GB, Pala RGS, Muralidhar K, Khandekar S. Effect of salinity and water depth on the performance of doubly inclined solar still. Desalin Water Treat. 2018;124:72–87.

Mahdi JT, Smith BE, Sharif AO. An experimental wick-type solar still system: design and construction. Desalination. 2011;267:233–8.

Rai SN, Dutt DK, Tiwari GN. Some experimental studies of a single basin solar still. Energy Convers Manag. 1990;30:149–53.

Nikam KC, Kumar R, Jilte R. Thermodynamic modeling and performance evaluation of a supercritical coal-fired power plant situated in Western India. Energy Sources Part A Recover Util Environ Eff. 2020. https://doi.org/10.1080/15567036.2020.1806410.

Tabrizi FF, Dashtban M, Moghaddam H, Razzaghi K. Effect of water flow rate on internal heat and mass transfer and daily productivity of a weir-type cascade solar still. Desalination. 2010;260:239–47.

Kerfah R, Belkacem Z, Filali EG, Abdelhamid T. Effect of climatic and operational parameters on the performance of an indirect solar still. Int J Sustain Energy. 2015;34:578–93.

Suneja S, Tiwari GN. Effect of water flow on internal heat transfer solar distillation. Energy Convers Manag. 1999;40:509–18.

Sarafraz MM, Tlili I, Baseer MA, Safaei MR. Potential of solar collectors for clean thermal energy production in smart cities using nanofluids: experimental assessment and efficiency improvement. Appl Sci. 2019;9(9):1877. https://doi.org/10.3390/app9091877.

Cooper PI. Some factors affecting the absorption of solar radiation in solar stills. Sol Energy. 1972;13:373–81.

Sodha MS, Kumar A, Tiwari GN, Pandey GC. Effects of dye on the performance of a solar still. Appl Energy. 1980;7:147–62.

Pandey GC. Effect of dye on the performance of a double basin solar still. Int J Energy Res. 1983;7:327–32.

Rajvanshi AK. Effect of various dyes on solar distillation. Sol Energy. 1981;27:51–65.

Ahmadi MH, Baghban A, Sadeghzadeh M, Zamen M, Mosavi A, Shamshirband S, et al. Evaluation of electrical efficiency of photovoltaic thermal solar collector. Eng Appl Comput Fluid Mech. 2020;14:545–65. https://doi.org/10.1080/19942060.2020.1734094.

Muthu Manokar A, Kalidasa Murugavel K, Esakkimuthu G. Different parameters affecting the rate of evaporation and condensation on passive solar still: a review. Renew Sustain Energy Rev. 2014;38:309–22.

Al-harahsheh M, Abu-Arabi M, Mousa H, Alzghoul Z. Solar desalination using solar still enhanced by external solar collector and PCM. Appl Therm Eng. 2018;128:1030–40. https://doi.org/10.1016/j.applthermaleng.2017.09.073.

Velmurugan V, Srithar K. Solar stills integrated with a mini solar pond; analytical simulation and experimental validation. Desalination. 2007;216:232–41.

Badran OO, Al-Tahaineh HA. The effect of coupling a flat-plate collector on the solar still productivity. Desalination. 2005;183:137–42.

Velmurugan V, Pandiarajan S, Guruparan P, Subramanian LH, Prabaharan CD, Srithar K. Integrated performance of stepped and single basin solar stills with mini solar pond. Desalination. 2009;249:902–9.

Zhang L, Bhatti MM, Michaelides EE. Electro-magnetohydrodynamic flow and heat transfer of a third-grade fluid using a Darcy-Brinkman-Forchheimer model. Int J Numer Methods Heat Fluid Flow. 2020.

Abd Elbar AR, Hassan H. Energy, exergy and environmental assessment of solar still with solar panel enhanced by porous material and saline water preheating. J Clean Prod. 2020;277:124175. https://doi.org/10.1016/j.jclepro.2020.124175.

Subramanian RS, Kumaresan G, Ajith R, Sabarivasan U, Gowthamaan KK, Anudeep S. Performance analysis of modified solar still integrated with flat plate collector. In: Material Today Proceedings. Elsevier BV, 2020.

Refalo P, Ghirlando R, Abela S. The use of a solar chimney and condensers to enhance the productivity of a solar still. Desalin Water Treat. 2016;57:23024–37.

Jobrane M, Kopmeier A, Kahn A, Cauchie HM, Kharroubi A, Penny C. Internal and external improvements of wick type solar stills in different configurations for drinking water production: a review. Groundw Sustain Dev. 2021;2021:100519.

Grosu L, Mathieu A, Rochelle P, Feidt M, Ahmadi MH, Sadeghzadeh M. Steady state operation exergy-based optimization for solar thermal collectors. Environ Prog Sustain Energy. 2020;39:1–8.

Manikandan V, Shanmugasundaram K, Shanmugan S, Janarthanan B, Chandrasekaran J. Wick type solar stills: a review. Renew Sustain Energy Rev. 2013;20:322–35.

Agrawal A, Rana RS, Srivastava PK. Application of jute cloth (natural fibre) to enhance the distillate output in solar distillation system. Mater Today Proc. 2018;5:4893–902. https://doi.org/10.1016/j.matpr.2017.12.066.

Ahmed HM, Ibrahim GA. Performance evaluation of a conventional solar still with different types and layouts of wick materials. J Energy Technol Policy. 2016;6:5–14.