Abstract

Good-quality drinking water is an essential requirement for a healthy and sustainable future. In the current scenario, people living in remote areas of the world are deficient of potable water, especially in developing nations. Desalination technologies available today are energy intensive and aggravate carbon emissions as most energy requirements are fulfilled by using fossil fuels. Solar still is a simple and direct solar desalination device used for water distillation. The major problem associated with a solar still is its low productivity. The main aim of this review paper is to discuss various modifications in a solar still which resulted in productivity enhancement. Different parameters affecting a passive solar still performance and their optimum values for maximum productivity are also thoroughly analysed in this paper. Water depth is an important operating parameter that influences still productivity, and various results showed that maximum productivity is achieved mostly at minimum water depths.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

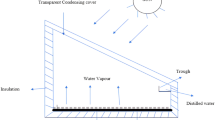

Amongst all water resources available on planet earth, only 3% are fresh water resources (Durkaieswaran and Murugavel 2015). Majority of fresh water is found in icecaps and glaciers which are not physically accessible. Only a small amount is present in rivers, lakes and underground that are used by the people for drinking. In the present scenario, the large-scale consumption of fresh water has resulted in plummeting fresh water resources. Moreover, the disposal of industrial effluents in the rivers and underground is contaminating the freshwater resources (Kumari and Rani 2014). This makes a large amount of potable water unfit for drinking and sanitation purposes (Kumari and Rani 2014). Therefore, desalination of seawater and brackish water becomes imperative for the availability of safe drinking water. The potable water produced from desalination methods like membrane process, nano-filteration, multi stage flash distillation and ion exchange process is costly. These methods are energy intensive and most of the energy requirements are fulfilled by using fossil fuels which aggravates environmental pollution. Solar still is a simple and affordable water treatment device used for distillation and desalinating water. It is simple in design and easily fabricated from locally available materials (Omara et al. 2013a; Rajaseenivasan et al. 2017). Solar still consists of three main components, namely, basin liner, saline water mass and a glass cover inclined at the latitude of still location. The still basin is painted matt black in order to absorb maximum solar radiations. Solar radiations transmitting through glass cover are absorbed by basin water, basin liner and inner walls of still. Water evaporates and gets condensed on relatively cooler inner surface of the glass cover. Condensed droplets glides down the glass surface and collected in a channel inside the still. They are further collected in a container located outside the still. Storage tank is used to maintain desired water depth in still basin.

The main limitation of solar still is its low productivity. Recent experimental studies conducted shows an average water output of 2–3 L/m2day from a conventional still (Bhargva and Yadav 2019a, b) (Velmurugan and Srithar 2011; Nagarajan et al. 2017). A review of various efficient methods to increase the productivity of a solar still is suggested and analysed by Rahim (2001), Arunkumar et al. (2019b) and Katekar and Deshmukh (2020a, b). The various modifications in solar still design are done by previous researchers for improving the water output. The water output is increased by 20% when a single-slope solar still with internal reflectors is experimentally compared with a double-slope solar still (Al-Hayeka and Badran 2004). The blackened layers of sponge placed in still basin increased the distillate output by 58% (Sellami et al. 2017). When a porous rectangular black sponge is placed in the still basin, the water output is improved by 17% in comparison to simple basin type still (Rashidi et al. 2018d) and a volume of fluid simulation method showed 39% rise in still output when the porosity of sponge is 0.4 (Rashidi et al. 2018b, c). The partitioning of still absorber resulted in enhancing the still output by 4.8% (Rashidi et al. 2016; Rashidi et al. 2017) (Rashidi et al. 2017). The experiments performed on a single-slope solar still proved it more economical and efficient than a pyramid solar still (Fath et al. 2003). A rise in water output is observed by using quartzite rock (Murugavel et al. 2010), sand reservoir (Tabrizi and Sharak 2010) (Dumka et al. 2019) and pumice stones in still basin (Bilal et al. 2019) as sensible heat storage materials. Due to high heat storage capacity, the use of blue metal stones sized 12mm (Nithyanandam et al. 2017) and asphalt basin liner (Badran 2007) also increased the still productivity. The effect of using internal and external reflectors on still performance is experimentally studied in the winter season (Tanaka 2009a, b). Results showed a remarkable rise of about 100% in still productivity. It is concluded that using an inclined external reflector is less beneficial in summers than in winters (Tanaka 2009a, b) (Khalifa and Ibrahim 2009). The still efficiency is improved by 29% with internal reflectors and fins (Bataineh and Abbas 2020). The effect of using different wick materials, namely, light cotton cloth, sponge sheet, coir mate, and waste cotton pieces in the still basin is experimentally studied (Murugavel and Srithar 2011) and maximum productivity is achieved with light cotton cloth. The still output is improved by 9% using woollen wick (Saravanan and Murugan 2020) and by 16.9% with bamboo cotton wick (Bhargva and Yadav 2019a, b) in comparison to jute wick. A linen wick used with carbon black nanoparticles improved the still output by 80.5% (Sharshir et al. 2020). Phase change materials are used to expedite the evening time water output from the still. An exhaustive review of the applications of various phase change materials in solar still is presented by Katekar and Deshmukh (2020a, b). The application of a corrugated wick absorber and phase change material resulted in 87.4% increment in still productivity (Kabeel et al. 2017). The efficient condensation of vapours in still basin is important to improve the still output. A review of different methods used to improve the condensation rate is presented comprehensively (Patel and Modi 2020). A water-cooled glass is used and experiments were performed for distinct cooling water flow rates (Abu-Arabi et al. 2020). The results showed improvement in water output with the increase in flow rate of cooling water. Silicon based nanoparticles are used on various condensing surfaces to boost the film condensation (Zanganeh et al. 2020). The application of forced water and air cooling of glass is experimentally studied and an improved water output of 8.6l and 8.0l is obtained from the still respectively (Hassan et al. 2020a, b). The still productivity is improved by 3% using a solar powered cooling fan for glass cover (Bani-Hani et al. 2017). Various heat-absorbing materials like charcoal (Naim and El Kawi 2003), black dye mixed in brackish water (Layek 2018) and black volcanic rock (Abdallah et al. 2009) improved the still productivity significantly. The use of fin absorber plate in still basin enhanced still productivity by 15.5% due to increase in surface area and rate of heat transfer (Ayuthaya et al. 2013). The square and solid circular shaped fins (Jani and Modi 2019) and hollow circular fins (Kabeel et al. 2020b) placed in still basin also improved the still output. The application of nanoparticles in a solar still is gaining momentum due to high still output achieved in recent studies. A review on the role of nanoparticles in improving the still water output is conducted exhaustively (Rashidi et al. 2019). The use of copper oxide (CuO) and flake graphite nano-particles (Sharshir et al. 2017a, b) in still basin resulted in increasing the still output to a considerable extent. The coating TiO2 nanoparticles (Shanmugan et al. 2020) and Al2O3-H2O nanofluid (Rashidi et al. 2018b) (Subhedar et al. 2020) improved the water output from solar still. A simulative study on the Al2O3-H2O nanofluid induced solar still showed a rise in entropy generation with an increase of solid volume fraction (Rashidi et al. 2018a). The effect of various climatic conditions on the performance of a simple basin type solar still is studied (Boukar and Harmim 2001; Subhedar et al. 2020). Different design parameters and their impact on still output are studied (Keshtkar et al. 2020) to understand the most influencing parameters. It was observed that still productivity was strongly influenced by solar intensity and ambient temperature. Tiwari and Tiwari (2006) studied the effect of water depth on heat transfer in a passive solar still. Results showed high daytime productivity at lower water depths and high night time productivity at higher water depths. The water output from solar still is decreased when the water flow rate is increased (Modi et al. 2020) (Kabeel et al. 2019c). The water output from still is increased to high values by integrating with solar collectors. The still output is enhanced with a parabolic trough (Kumar et al. 2020) (Hassan et al. 2020a, b) (Madiouli et al. 2020) (Elashmawy and Alshammari 2020), Parabolic trough concentrator and an evacuated tube collector which are coupled to a still to increase the water output by 34% (Dawood et al. 2020). The application of Fresnel lens (Mu et al. 2019), evacuated tube collector (Shehata et al. 2020), parabolic dish (Kabeel et al. 2019a) and thermoelectric modules (Rahbar et al. 2017) in a solar still resulted in the enhancement of still output.

In this study, the experimental and theoretical research conducted on a single-slope solar still in the last one decade has been discussed in a detailed manner. Different design modifications in a solar still along with the effect of various parameters on still performance are highlighted and reviewed comprehensively in this study. On the basis of experimental and theoretical results, the most influencing parameters which affect the still performance are also identified and highlighted. The most recent research studies conducted on solar still for improvement in water output are analysed and represented in this study. This article encapsulates the latest advancements in solar still along with the most influential parameters for enhancement in water output.

Factors affecting solar still performance

Productivity of solar still is greatly influenced by various design, operating and climatic parameters. These parameters include collector area, water depth, glass cover temperature, water temperature, wind velocity, ambient temperature, glass cover thickness and inclination. Numerous researchers have worked on these parameter variations to understand their optimum value at which maximum productivity is obtained. The design and operating parameters can be varied during experiment to obtain maximum distillate output. But climate-related parameters are uncontrolled and cannot be varied. Some of the important design and operating parameters and their influence on the still output are mentioned below.

Water depth

Water depth influences the freshwater productivity to a considerable extent. Reduced water depth results in increasing evaporation rate of basin water as small quantity of water mass at lower depths quickens evaporation rate and enhances still productivity (Rajaseenivasan et al. 2014). The water output of 3.27 kg is achieved for a double-slope solar still operating at a saline depth of 1 cm (Manokar et al. 2020). The results from the experiments conducted on a pyramid still (Kabeel et al. 2019c) indicated a decrease in water output when water depth is increased from 1 to 3.5 cm. An experimental investigation of a tubular still at distinct water depths showed maximum output (4.5 kg/sq.m) at 0.5 cm depth and minimum output (3 kg/sq.m) at 3 cm depth (Kabeel et al. 2019b). The overall performance of an active solar still improved surprisingly with increased water depth when tested for 10 days continuously (Taghvaei, Taghvaei et al. 2014). It is observed that for all solar–collecting areas, as water depth decreases, the still productivity and efficiency increase (Taghvaei et al. 2015). Khalifa and Hamood (2009b) analysed various research studies concerning the effect of water depth on still performance. An overall decreasing trend of productivity is observed as the water depth increases. Elango and Murugavel (2015) varied water depth from 1 to 5cm and achieved maximum hourly and daily productivity at 1-cm water depth.

Glass thickness and inclination

The transmittance effect of glass cover with thickness 4mm, 5mm and 6mm is experimentally investigated by Panchal (2016). Results showed maximum productivity increase of 27% and 12% for 4-mm thick glass cover in comparison to 5mm and 6mm, respectively. The water output of still is improved by 3.5% when the glass thickness is reduced to 2 mm from 4 mm (Keshtkar et al. 2020). The glass cover inclination also influences the performance of solar still. In summers, at 10°inclination, solar still receives maximum solar radiations which results in 24.45% increase in productivity. In winters, at 45° inclination, the productivity increased by 34.28% (El-Samadony et al. 2016). The maximum productivity of a passive slope still is achieved when it is oriented in south-facing direction (Rajamanickam and Ragupathy 2012). The north-south orientation of still resulted in higher water output in comparison to east-west orientation (Modi et al. 2021). The glass cover of thickness 4 mm and 30° inclination is used in a double slope still to attain maximum productivity of 4.9 kg/sq.m (Salem, Salem et al. 2020). The difference in daily water output of experimental and numerical studies conducted on a pyramid still is minimum for a glass inclination of 40° (El-Sebaii and Khallaf 2020).

Temperature difference between basin water and inner glass cover surface

Evaporation rate of basin water is greatly influenced by the temperature difference between water and inner surface of glass cover. Glass cover absorbs latent heat of condensation of vapours which increases its temperature. This decreases the temperature difference, further decreasing the still productivity (Eltawil and Omara 2014). Solar still integrated with flat plate collector has higher temperature difference of water and inner glass surface than a conventional still (Morad et al. 2015). Abdenacer and Nafila (2007) theoretically calculated that the maximum still productivity and efficiency are achieved at maximum temperature difference between basin water and inner surface of glass cover. The difference in temperatures of glass and water is observed to be higher for water-cooled glass cover than air-cooled glass cover (Shoeibi et al. 2021).

Wind velocity

Sathyamurthy et al. (2015) studied the effect of wind velocity on still performance. Increased wind velocity decreases the temperature of glass cover and increases the condensation rate. Castillo-Téllez et al. (2015) investigated the effect of different wind velocities 2.5 m/s, 3.5 m/s, 5.5 m/s and 6.9 m/s on the performance of solar still. The results indicated performance enhancement up to 5.5 m/s wind velocity. When the velocity increases beyond 5.5 m/s, the still performance decreases. El-Sebaii (2011) performed a theoretical analysis on a passive solar still and calculated critical water depth. It was concluded that still productivity increases with wind velocity beyond critical water depth. For water depth less than critical water depth still productivity decreases as wind velocity increases. An approximate rise of 14% in water output is reported when velocity of outside air is increased to 6 m/s from 1 m/s (Keshtkar et al. 2020).

Solar intensity and ambient temperature

On a bright sunny day, solar intensity increases and reaches its maximum value at noon (Essa et al. 2020b) and then decreases afterwards till the evening. Ambient temperature is dependent on the amount of solar radiations entering earth’s atmosphere. As solar intensity increases, the temperature of various parts of still also increases. This temperature increase is higher for a stepped still than a conventional still (Abdullah 2013). The maximum solar radiations are observed at 1 P.M and maximum ambient temperature at 3 P.M (Rashidi et al. 2017). This time difference is due to thermal capacity, moisture content and density of surrounding air. The water output of still directly depends on solar intensity of the region. The water output increase with a rise in solar intensity (Narayanan et al. 2020).

Insulation material and thickness

The experiments conducted on a cascaded solar still with insulations, namely, glass wool, cellular glass, phenolic foam, and fibre glass resulted in highest water output with phenolic foam (Khanmohammadi and Khanmohammadi 2019). The optimum value of insulation thickness is theoretically calculated as 0.1m for an active solar still operating at a water depth of 0.03m (Tiwari et al. 2009). The application of thermocol insulation (Elango et al. 2015) (Karthikeyan et al. 2020) used in a passive solar still resulted in improving the water output. Glass wool insulation of 5cm thickness (Kabeel 2009) and saw dust insulation (Velmurugan et al. 2009) are also utilized in solar stills to minimise the heat losses. Khalifa and Hamood (2009a, b) studied the effect of insulation thickness on still productivity. Styrofoam sheet of thicknesses 30mm, 60mm and 100mm are used in the experiment. It was observed that operating water temperature and productivity increase with insulation thickness up to 60mm. Sahoo et al. (2008) conducted experiments in a passive solar still and achieved 6% increase in productivity by using thermocol insulation. The experiments performed on a pyramid still with insulation resulted in an approximate rise of 19% in comparison to a conventional still (Manokar et al. 2020).

Productivity enhancement methods

The still productivity is enhanced by applying various design modifications. These modifications expedite the rate of heat transfer occurring inside and outside the still. Solar still augmented with different wick materials, fins and glass cover cooling improves the evaporation and condensation rate. The use of sensible and latent heat storage materials boosts night time productivity of the still (Fig. 1).

Fins

Fins increase the heat transfer area and enhance the convection heat transfer between basin liner and basin water. The convective heat transfer coefficient also increases due to an additional fin surface. This increases overall performance of the still. Alaian et al. (2016) enhanced the solar still performance by using a pin-finned wick absorber at the still basin. This increases the evaporation surface and also increases productivity by 23%. Rajaseenivasan and Srithar (2016) experimentally investigated the effect of using square and circular fins in the still basin. Fins are covered with wick and the system is tested at distinct water depths from 1 to 4cm. The maximum productivity of 4.55 kg/m2 day is achieved with square fins at 1-cm water depth. The use of square fins and circular fins increases the productivity by 36.7 and 26.3% in comparison to a conventional still. The economic analysis showed a payback time of less than a year. Panomwan Na Ayuthaya et al. (2013) utilized a pin fin absorber plate in still basin to enhance the still productivity. An increase of 12% is achieved in comparison to the conventional still. El-Naggar et al. (2016) integrated metallic fins to the basin liner and experimentally investigated the effect on still performance. The schematic diagram is shown in Fig. 2. The maximum daily productivity and efficiency of 4.8 kg/m2 and 55.37% are obtained.

Schematic diagram of solar still with fin absorber (El-Naggar et al. 2016)

Panchal and Sathyamurthi (2017) experimentally compared the performance of still with and without porous fins. Still with porous fins enhances the productivity by 42.3% in comparison to the still without porous fins. Some other research works using different types of fins for improving the still output are shown in Table.1.

Wick materials

Wick increases effective area of evaporation and improves the heat transfer rate. Also basin water heats up quickly because of slow movement of water in a wick. A wick has higher heat storage capacity and enhances thermal performance of a still. The impact of various wick materials on still output is reviewed by Abdullah et al. (2021a, b). Omara et al. (2016) experimentally investigated corrugated absorber solar still integrated with wick and internal reflectors. A double-layer wick is used over the corrugated absorber. A constant water depth of 1cm is maintained throughout the experiment. An increase of approximately 146% in still productivity is observed in comparison to a conventional still. Productivity is increased by 90% when corrugated absorber still is used with wick only. Haddad et al. (2017) Abdullah et al. (2019) designed a basin type solar still with a vertically rotating wick integrated at back side of the wall in order to increase the evaporation area. This system is driven by a 25 W electric motor. The vertically rotating wick provides a fillip to the productivity by 14.72% in comparison to the solar still without wick. Hansen et al. (2015) examined the effect of water coral fleece fabric, wood pulp paper wick and polystyrene sponge wick materials on still performance. Due to better porosity, absorbency and capillary rise water coral fleece wick material with productivity 4.28 kg/m2 performed better in comparison to others. Pal et al. (2017) conducted experimental analysis of a single-basin double-slope solar still using black cotton and jute wicks. The use of black cotton wick enhances the still productivity by 28% in comparison to jute wick. Karthick Munisamy et al. (2017) used terrycloth, jute, polyester cloth and fur fabric as wick materials in a tilted solar still. The maximum productivity of 3.63 L/day is obtained using fur fabric wick material. The schematic diagram tilted wick solar still is shown in Fig. 3.

Schematic diagram of tilted wick solar still (Karthick Munisamy et al. 2017)

The other studies conducted to understand the effect of different wick materials on still output are shown in Table.2.

Sponges

Sponge acts as a source of heat storage and keeps absorber temperature high enabling evening time productivity. Arjunan et al. (2011) performed theoretical and experimental analysis on the effect of using sponge liner of variable thickness in still basin. Still productivity increased by 35.2% using sponge liner of thickness 5mm than conventional still. The use of black-painted sponge layer of 5mm thickness as shown in Fig. 4 enhances the still productivity by 58% in comparison to conventional still (Sellami et al. 2017). Rababa’h (2003) conducted experiments to understand the effect of using sponge cubes in still basin. At higher water depths, the portion of sponge exposed above the water surface reduces. This resulted in an increased capillary rise which enhances the evaporation rate of water from the sponge. Increasing the sponge size exposed more surface of it above basin water level. This reduced the capillary rise of water in sponge and resulted in decreased evaporation rate and still productivity.

Schematic diagram of solar still with sponge layer on basin liner (Sellami et al. 2017)

Thermal energy storage materials

Thermal energy storage materials have high heat storage capacity. The heat energy absorbed during sunshine hours is utilized in enhancing evening hour productivity. Sensible and latent heat storage materials are two types of thermal energy storage materials used to improve the still performance.

Sensible heat storage materials

Servotherm medium oil and sand were used in still basin by Deshmukh and Thombre (2017) as sensible heat storage materials as shown in Fig. 5. The water depth is kept constant at 0.6cm, and the heat storage material depth is varied during the experiment. The maximum productivity of still is obtained at 5mm storage depth using servotherm oil.

Schematic diagram of solar still with sensible heat storage material in basin (Deshmukh and Thombre 2017)

The use of pebbles as heat storage material enhances the still productivity by 9.5% in comparison to a conventional still (Arjunan et al. 2017).

Latent heat storage materials

A review study on the application of various phase change materials in solar stills (Katekar and Deshmukh 2020a, b) encapsulated their impact on still output. Latent heat storage materials change their phase by absorbing heat during daytime and again change phase by releasing heat during night time. This heat release is utilized for evaporating basin water during night time. The use of paraffin wax as a phase change material enhanced the still productivity by approximately 68% (Kabeel and Abdelgaied 2016). Aluminium oxide (Al2O3) nanoparticles dispersed in paraffin wax phase change material are used by Rajasekhar and Eswaramoorthy (2015). The results showed 5% increase in productivity with nanoparticles than using PCM without nanoparticles. Shalaby et al. (2016) experimentally investigated the use of a v-corrugated copper absorber and paraffin wax as PCM as shown in Fig. 6.

Schematic diagram of solar still with corrugated absorber and PCM (Shalaby et al., 2016)

To dispel the problem of air trapping in paraffin wax on solidification, copper tubes were inserted through the gaps drilled on one side of the storage tank. This allows proper exit of air bubbles from storage tank. The results showed an increase of 72.7% in overnight productivity and a decrease of 7.2% in daylight productivity with PCM. Al-harahsheh et al. (2018) used PCM filled tubes in still basin for heat storage during daytime. Sodium thiosulfate pentahydrate due to its high latent heat of fusion, small change in volume on phase change and easy availability at low cost is used as PCM. Results showed enhancement in night time productivity with the use of PCM. Kabeel et al. (2018) conducted experiments to test different PCM’s and analysed their effects on still performance. Capric palmatic an inorganic PCM and A48 an organic PCM were used in still basin. Application of both PCMs in still basin enhanced still performance, but organic PCM A48 is preferred due to its eco-friendliness. The results indicated that solar still productivity increased by 92% using A48 PCM. Govindaraj et al. (2017) studied the effect of different fin orientations on the heat transfer rate of paraffin wax PCM-filled spherical-shaped capsule. Paraffin wax was used as PCM. The results showed that the orthogonal orientation of fin reduced the total time for charging and discharging of PCM by 22 and 15% in comparison to circumferential orientation of fin respectively. Arunkumar et al. (2017) utilized PCM-filled vacant copper balls in the basin of single-slope solar still for performance enhancement. The effect of integrating compound parabolic concentrator and compound conical concentrator on the still performance was also studied. The results indicated that still productivity is increased using PCM by 20.8% (compound conical concentrator with single slope solar still) and 2.6% (compound parabolic concentrator with pyramid solar still), respectively. Arunkumar et al. (2013) analysed the effect of using paraffin wax PCM filled in empty copper balls situated in the hemispherical basin of a single-slope solar still. A parabolic dish concentrator was used to concentrate solar radiations at the bottom of hemispherical basin. The schematic diagram and photograph of experimental set-up and the photograph of PCM filled copper balls are shown in Fig.7.

(a) schematic diagram of experiment set-up. (b) Photograph of PCM filled copper balls. (c) Photograph of parabolic concentrator integrated single slope solar still with hemispherical basin (Arunkumar et al., 2013)

The results indicated that due to thermal energy storage in PCM, the freshwater productivity of the still increased by 26.7% in comparison to still without PCM. Some of the recent studies conducted to know the effect of various heat storage materials on still output is shown in Table 3.

Internal and external reflectors

The productivity of still enhances with the application of reflectors inside and outside the still. Internal and external reflectors reflect solar radiations onto absorber and increase the basin water temperature. This results in expediting evaporation rate and increasing the distillate output from the still. The application of an external reflector in a double-slope still improved the still output to a good extent (Patel et al. 2020b). In winters, the application of internal reflectors in still basin proved more beneficial than summers in enhancing water output (Bataineh and Abbas 2020). A rise of 57% is achieved with the use of internal reflectors in still basin (Abdullah et al. 2020). Omara et al. (2013a, b) experimentally investigated the effect of using internal reflectors on inside vertical walls of the stepped still. The results showed 18% increase in productivity with the use of internal reflectors. This system when augmented with external reflectors further bolster productivity by 50% (Omara et al. 2014). An increase of 22 and 34% in annual efficiency and productivity is observed when internal reflectors are used in a passive solar still. This increase is higher in winters than in summers (Estahbanati et al. 2016). Tanaka (2011) theoretically calculated the effect of using internal and external reflectors on still performance. The schematic diagram is shown in Fig. 8. Total solar radiations reflected by external reflector and absorbed by basin liner are also calculated. The results showed 62% productivity increase in winters when internal and external reflectors are used.

Schematic diagram of solar still with internal and external reflector (Tanaka 2011)

Pearce and Denkenberger (2006) concluded that use of compound parabolic concentrator has a remarkable economic benefit in producing potable water. Fig.9 shows the different heat and mass transfer processes occurring in the compound parabolic concentrator integrated solar still.

Different heat and mass transfer processes happening in the compound parabolic concentrator integrated solar still (Pearce and Denkenberger 2006)

Arunkumar et al. (2016) used 5 sets of compound parabolic concentrator integrated tube solar still to preheat the saline water which was then directed to the basin of a single slope solar still. The photograph of experimental set-up is shown in Fig. 10

Experiment set-up photograph (Arunkumar et al. 2016)

Experimental results indicated that the freshwater productivity increased by 74.1% using extracted heat. Arunkumar et al. (2015) integrated a parabolic dish concentrator to a single-slope solar still and examined the effect of PCM and glass cover cooling on the performance of still. A considerable improvement in still productivity is observed with the use of parabolic dish concentrator, glass cooling and PCM. Experimental results also indicated that the cost efficiency of the system decreased using glass cooling.

Nano-fluids

The nanoparticles expedite the heat transfer in the still basin, and their application is diverse in a solar still. Nano fluids have very high thermal conductivities, high heat absorption and high coefficient of heat transfer. The carbon black nanoparticles (1.5% concentration) are mixed in basin water to improve the evaporation rate of water (Sharshir et al. 2020). Kabeel et al. (2014) used cuprous oxide and aluminium oxide nanoparticles in still basin. The experimental results showed a productivity increase of 94% and 89% using cuprous and aluminium oxide nano particles respectively. Flake graphite nanoparticles due to their good absorbing properties also find application in solar stills. The still productivity is enhanced by approximately 51% with the use of flake graphite nanoparticles (Sharshir et al. 2017a, b). Arunkumar et al. (2019a, b) experimentally investigated the effect of using a stainless steel absorber plate coated with copper oxide nanoparticles on the still performance. The use of copper oxide nanoparticles resulted in the enhancement in productivity and efficiency of the still with maximum values attained at 2995 ml/m2/day and 53%, respectively.

Glass cooling

The cooling of glass cover increases the temperature difference between basin water and inner glass cover. This improves condensation rate of vapours and enhance still performance. Still performance increases at higher mass flow rates of cooling water (Abu-Arabi et al. 2020) (Shoeibi et al. 2020). (Sharshir et al. 2017a, b). It is also recommended not to increase flow rate further due to slow rise of cooling rate and increase in operating cost. For evenly distribution of cooling water over glass cover, cotton gauze cooling is used by Suneesh et al. (2014). The productivity of 4.3 L/m2d is achieved which is further enhanced to 4.6 L/m2d with the air flow over the cooling cover. The use of external fan for glass cover cooling in winters decreases the productivity of a double-slope solar still (Al-Garni 2012). This is due to the increased heat transfer between basin water and glass surface which reduces the evaporation rate.

Various absorber configurations

The main aim of using distinct absorber configurations is to increase the exposed surface area to enhance the heat transfer rate inside the still. Omara et al. (2011) compared the experimental performances of finned absorber and corrugated absorber used in a solar still. Water depth is maintained constant at 5cm and saline water quantities of 30L and 50L are used. The results showed 19% increase in productivity of finned absorber still in comparison to corrugated absorber still. Moreover, the use of v-corrugated absorber and PCM in a pyramid still enhanced the productivity to 6.6 kg/m2d (Kabeel et al. 2017). Abdelal and Taamneh (2017) used an absorber plate made up of carbon nanotube-modified epoxy composites. The carbon nanotube weight of 5 and 2.5% is utilized in making the absorber plate. The experimental results showed 109 and 65% increase in productivity, respectively. Hansen and Murugavel (2017) used different absorber configurations in solar still as shown in Fig.11 and experimentally investigated their effect on still performance.

Photographs of (a) flat plate absorber, (b) grooved absorber, (c) fin absorber (Hansen and Murugavel 2017)

The use of fin absorber resulted in better productivity and efficiency in comparison to grooved and flat absorber.

Other modifications

Some other modifications includes using of wind turbine powered water fan and PV panel operated water stirrers in still basin to enhance heat transfer rate. The use of co-axial pipes, preheated water supply and vapour adsorption basin in a passive solar still also resulted in productivity enhancement.

Wind turbine powered propeller

Omara et al. (2017) investigated the effect of using a wind turbine powered propeller on still productivity. A small wind turbine is designed and attached to a propeller which is installed in still basin as shown in Fig. 12.

(a) Schematic diagram of solar still with water propeller. (b) Picture of propeller, bevel gears and bearings (Omara et al., 2017)

Water fan enhances evaporation and condensation rate and increases productivity by 17% at 3-cm water depth and 30rpm rotational speed.

Glass basin with preheated water supply

Rajaseenivasan et al. (2016) fabricated and experimentally investigated a glass basin which is divided into evaporator section and preheating section as shown in Fig.13.

Schematic diagram of solar still with preheated water supply (Rajaseenivasan et al. 2016)

Saline water enters preheating section and gets evaporated in the evaporator section. Hollow fins are used in preheating section to increase the exposed heat transfer area. Fins are filled with heat storage materials like charcoal, river sand and metal scraps to increase heat capacity of the basin. The results showed productivity rise at low water depths. Also, the use of heat storage materials decreases daytime productivity but enhances night time productivity. Maximum productivity of 3.63 kg/day is achieved with the use of charcoal as heat storage material.

Water stirrer

Rajaseenivasan et al. (2017) investigated the effect of four stirrers in still basin operated by a solar PV panel of 40 W capacity as shown in Fig. 14.

Schematic diagram of solar still with water stirrers (Rajaseenivasan et al. 2017)

Charcoal and paraffin wax are used as thermal energy storage materials. Water depth is maintained constant at 1 cm, and basin height is varied in the experiment. Performance of this modified still is compared with a conventional still. The results showed an increase in basin water temperature and productivity with decreased basin height. The distillate output is increased by 30% with highest value of 5.23 kg/m2 day.

Co-axial pipes in basin

Kabeel and Abdelgaied (2017) designed and tested a solar still consisting multi groups of two co-axial copper pipes. The higher surfaces of outer pipes have holes of 3-mm diameter with a distance of 1.5 mm between them. Saline water flows in the annular space of co-axial pipes as shown in Fig.15.

Schematic diagram of solar still with coaxial pipes in basin (Kabeel and Abdelgaied 2017)

The still is customized with pipes of different inner diameter and annular space. Still using pipe with inner diameter 41.28 mm and annular space 5 mm resulted in maximum productivity rise of 98% in comparison to other combinations.

Solar still integrated with vapour adsorption basin

Kannan et al. (2014) investigated a solar still integrated with an adsorbent bed network of pipes as shown in Fig. 16.

Schematic diagram of solar still with vapor adsorption basin (Kannan et al. 2014)

Activated carbon and methanol are filled in the annular space of inner and outer pipes. Saline water gets preheated during its flow from inner pipes of adsorbent bed and is re-circulated to the storage tank. Still is also customized with the combination of sponge, gravels, sand and black rubber as heat storage material. The maximum productivity of 4.3 kg/m2day is achieved with a combination of sponge, sand and black rubber used as heat storage materials.

Solar collectors

The integration of distinct solar collectors to the solar still is the most influencing modification to improve the still output. The extra heat supplied to basin water using solar collector increases the water temperature and the rate of evaporation. Figure 17 shows a single-slope still coupled to a parabolic trough collector and a heat exchanger in the still basin (Hassan et al. 2020a, b).

The heat transfer oil is pumped to heat exchanger before circulating from a tube placed at focal line of the parabolic trough. The external heat supplied to basin water resulted in improvement of still output by 102%. Figure 18 shows a Fresnel lens coupled to a single slope still (Mu et al. 2019). The application of a Fresnel lens expedites the phase change process and improves the still output to a very large extent.

Photograph of the Fresnel lens integrated single slope still (Mu et al. 2019)

The experimental results showed a formidable increase of 467% in water output with Fresnel lens. Many other solar external heat sources namely evacuated tube collector (Alwan et al. 2020; Bhargva and Yadav 2020; Patel et al. 2020a, b), a flat plate collector (Eltawil and Omara 2014; Raju and Narayana 2018; Patel et al. 2020a, b; Alwan et al. 2021), hybrid photovoltaic thermal collector (Singh et al. 2016; Winston et al. 2018) and a solar pond (El-Sebaii et al. 2008; Appadurai and Velmurugan 2015; Bisht et al. 2020) resulted in the improvement in water output of the still. It is inferred from the review of recent articles that a multiple number of modifications in a solar still is prevalent to improve the still output. The most recent studies conducted on the solar still for the improvement in the water output are shown in Table 4.

Future prospects

Some of the future work and prospects pertaining to the solar still research are as follows:

-

The arrangement for chemical treatment of water obtained from solar still could make it a complete device for extraction of potable water from brackish water.

-

The active solar still could be made completely solar powered using PV panels for operating DC pumps used for circulating heat transfer fluid to the heat exchanger.

-

The application of various nanoparticles with different concentrations in the still basin should be explored further for improving the still output.

-

The research on the use of different solar concentrators like parabolic dish and Scheffler reflector to improve the water output could be explored further.

-

The different techniques used for increasing night time water output could be explored further by the application of various heat storage materials.

-

The higher still water output during night time is attainable and more feasible for active solar stills using phase change materials because of faster charging rate. The use of solar concentrators namely parabolic trough, parabolic dish, and Scheffler concentrator for charging the PCM could be explored further for improving the night time water output from the still.

Conclusions

A literature review is carried out on understanding different still modifications and various parameters affecting still performance. The main highlights of the study are as follows:

-

Solar still productivity increases as the water depth decreases because of maximum heat absorption and quick evaporation rate at minimum water depths.

-

The transmittance effect and productivity increases with the decrease in glass cover thickness. The maximum productivity is achieved when still is oriented in south facing direction and glass cover is inclined at latitude of the location.

-

Increased temperature difference between basin water and inner surface of glass cover and moderate wind velocities enhanced the condensation rate. The still productivity decreases at very high wind velocities.

-

Intensity of solar radiation increases up to afternoon and decreases after that. Water temperature and still productivity also follow the same trend.

-

The use of pin fins, square fins, and metallic fins in basin liner increases the exposed heat transfer area and enhances the overall still performance.

-

Use of Jute, black cotton and fur fabric wick materials slows down the movement of water in still basin and thus increases the evaporation rate and still productivity.

-

Blackened sponge layer and sponge liner have high storage capacity and their use resulted in ensuring good evening time productivity.

-

Sensible heat storage materials like servotherm oil and pebbles enhanced still performance by enabling off sunshine hour productivity. The use of paraffin wax also increases night productivity. It is the most widely used latent heat storage material due to low cost and easy availability.

-

Using internal and external reflectors ensures maximum trapping of solar radiations inside the still. Productivity rise of around 50% is reported when both reflectors are used simultaneously in the still.

-

Cuprous oxide, aluminium oxide and flake graphite nanoparticles have very high thermal conductivities. The use of these nanoparticles expedites heat exchange rate in the still basin and resulted in a productivity enhancement of around 94%.

-

Glass cover cooling using water and blowing air through external fan increased the temperature difference between basin water and glass cover. This resulted in enhancement of still productivity. Maximum performance is achieved at higher mass flow rates of cooling water over the glass cover.

-

The use of water fan and stirrers in still basin also increased the heat transfer in still basin.

Data availability

Data sharing is not applicable to this article as no datasets were generated during this study

References

Abdallah S, Abu-Khader MM et al (2009) Effect of various absorbing materials on the thermal performance of solar stills. Desalination 242(1–3):128–137

Abdelal N, Taamneh Y (2017) Enhancement of pyramid solar still productivity using absorber plates made of carbon fiber/CNT-modified epoxy composites. Desalination 419:117–124

Abdelgaied M, Harby K et al (2021) Performance improvement of modified tubular solar still by employing vertical and inclined pin fins and external condenser: an experimental study. Environ Sci Pollut Res 28(11):13504–13514

Abdenacer PK, Nafila S (2007) Impact of temperature difference (water-solar collector) on solar-still global efficiency. Desalination 209(1–3):298–305

Abdullah A (2013) Improving the performance of stepped solar still. Desalination 319:60–65

Abdullah A, Alarjani A et al (2019) Rotating-wick solar still with mended evaporation technics: experimental approach. Alex Eng J 58(4):1449–1459

Abdullah A, Essa F et al (2020) Improving the trays solar still performance using reflectors and phase change material with nanoparticles. J Energy Storage 31:101744

Abdullah A, Essa F et al (2021a) Effect of different wick materials on solar still performance–a review. Int J Ambient Energy 42(9):1055–1082

Abdullah A, Omara Z et al (2021b) Enhancing the solar still performance using reflectors and sliding-wick belt. Sol Energy 214:268–279

Abu-Arabi M, Al-harahsheh M et al (2020) Theoretical modeling of a glass-cooled solar still incorporating PCM and coupled to flat plate solar collector. J Energy Storage 29:101372

Alaian WM, Elnegiry EA et al (2016) Experimental investigation on the performance of solar still augmented with pin-finned wick. Desalination 379:10–15

Al-Garni AZ (2012) Enhancing the solar still using immersion type water heater productivity and the effect of external cooling fan in winter. Appl Sol Energy 48(3):193–200

Al-harahsheh M, Abu-Arabi M et al (2018) Solar desalination using solar still enhanced by external solar collector and PCM. Appl Therm Eng 128:1030–1040

Al-Hayeka I, Badran OO (2004) The effect of using different designs of solar stills on water distillation. Desalination 169(2):121–127

Alwan NT, Shcheklein S et al (2020) Experimental investigation of modified solar still integrated with solar collector. Case Stud Therm Eng 19:100614

Alwan NT, Shcheklein S et al (2021) Experimental analysis of thermal performance for flat plate solar water collector in the climate conditions of Yekaterinburg, Russia. Materials Today: Proceedings 42:2076–2083

Appadurai M, Velmurugan V (2015) Performance analysis of fin type solar still integrated with fin type mini solar pond. Sustain Energy Technol Assess 9:30–36

Arjunan T, Aybar H et al (2011) Effect of sponge liner on the internal heat transfer coefficients in a simple solar still. Desalin Water Treat 29(1–3):271–284

Arjunan TV, Aybar HŞ et al (2017) Experimental study on enhancing the productivity of solar still using locally available material as a storage medium. J Inst Eng (India): C 98(2):191–196

Arora S, Singh HP et al (2020) Performance and cost analysis of photovoltaic thermal (PVT)-compound parabolic concentrator (CPC) collector integrated solar still using CNT-water based nanofluids. Desalination 495:114595

Arunkumar T, Denkenberger D et al (2013) The augmentation of distillate yield by using concentrator coupled solar still with phase change material. Desalination 314:189–192

Arunkumar T, Denkenberger D et al (2015) Experimental study on a parabolic concentrator assisted solar desalting system. Energy Convers Manag 105:665–674

Arunkumar T, Velraj R et al (2016) Productivity enhancements of compound parabolic concentrator tubular solar stills. Renew Energy 88:391–400

Arunkumar T, Velraj R et al (2017) Effects of concentrator type and encapsulated phase change material on the performance of different solar stills: an experimental approach. Desal Water Treatment 87

Arunkumar T, Murugesan D et al (2019a) Effect of nano-coated CuO absorbers with PVA sponges in solar water desalting system. Appl Therm Eng 148:1416–1424

Arunkumar T, Raj K et al (2019b) A review of efficient high productivity solar stills. Renew Sust Energ Rev 101:197–220

Arunkumar T, Wang J et al (2020) Sensible desalting: investigation of sensible thermal storage materials in solar stills. J Energy Storage 32:101824

Ayuthaya RPN, Namprakai P et al (2013) The thermal performance of an ethanol solar still with fin plate to increase productivity. Renew Energy 54:227–234

Badran OO (2007) Experimental study of the enhancement parameters on a single slope solar still productivity. Desalination 209(1–3):136–143

Bani-Hani E, Qassem H et al (2017) Experimental analysis of an improved solar still system with cooling fan and Preheating oil. Energy Engineering 114(5):55–71

Bataineh KM, Abbas MA (2020) Performance analysis of solar still integrated with internal reflectors and fins. Sol Energy 205:22–36

Beik AJG, Assari MR et al (2020) Passive and active performance of a multi-side-stepped square pyramid solar still; experimental and modeling. J Energy Storage 32:101832

Bhargva M, Yadav A (2019a) Experimental investigation of single slope solar still using different wick materials: a comparative study. Conference Series, IOP Publishing, Journal of Physics

Bhargva M, Yadav A (2019b) Productivity augmentation of single-slope solar still using evacuated tubes, heat exchanger, internal reflectors and external condenser. Energy Sources A: Recovery Util Environ Eff:1–21

Bhargva M, Yadav A (2020) Effect of shading and evaporative cooling of glass cover on the performance of evacuated tube-augmented solar still. Environ Dev Sustain 22(5):4125–4143

Bilal A, Jamil B et al (2019) Investigating the effect of pumice stones sensible heat storage on the performance of a solar still. Groundw Sustain Dev 9:100228

Bisht S, Dhindsa GS et al (2020) Augmentation of diurnal and nocturnal distillate of solar still having wicks in the basin and integrated with solar pond. Materials Today: Proceedings 33:1615–1619

Boukar M, Harmim A (2001) Effect of climatic conditions on the performance of a simple basin solar still: a comparative study. Desalination 137(1–3):15–22

Castillo-Téllez M, Pilatowsky-Figueroa I et al (2015) Experimental study on the air velocity effect on the efficiency and fresh water production in a forced convective double slope solar still. Appl Therm Eng 75:1192–1200

Dawood MMK, Nabil T et al (2020) Experimental study of productivity progress for a solar still integrated with parabolic trough collectors with a phase change material in the receiver evacuated tubes and in the still. J Energy Storage 32:102007

Deshmukh H, Thombre S (2017) Solar distillation with single basin solar still using sensible heat storage materials. Desalination 410:91–98

Dumka P, Sharma A et al (2019) Performance evaluation of single slope solar still augmented with sand-filled cotton bags. J Energy Storage 25:100888

Dumka P, Chauhan R et al (2020) Experimental and theoretical evaluation of a conventional solar still augmented with jute covered plastic balls. J Energy Storage 32:101874

Durkaieswaran P, Murugavel KK (2015) Various special designs of single basin passive solar still–a review. Renew Sust Energ Rev 49:1048–1060

Elango T, Murugavel KK (2015) The effect of the water depth on the productivity for single and double basin double slope glass solar stills. Desalination 359:82–91

Elango T, Kannan A et al (2015) Performance study on single basin single slope solar still with different water nanofluids. Desalination 360:45–51

Elashmawy M, Alshammari F (2020) Atmospheric water harvesting from low humid regions using tubular solar still powered by a parabolic concentrator system. J Clean Prod 256:120329

El-Naggar M, El-Sebaii A et al (2016) Experimental and theoretical performance of finned-single effect solar still. Desalin Water Treat 57(37):17151–17166

El-Samadony Y, El-Maghlany WM et al (2016) Influence of glass cover inclination angle on radiation heat transfer rate within stepped solar still. Desalination 384:68–77

El-Sebaii A (2011) On effect of wind speed on passive solar still performance based on inner/outer surface temperatures of the glass cover. Energy 36(8):4943–4949

El-Sebaii A, Khallaf AE-M (2020) Mathematical modeling and experimental validation for square pyramid solar still. Environ Sci Pollut Res 27(26):32283–32295

El-Sebaii A, Ramadan M et al (2008) Thermal performance of a single-basin solar still integrated with a shallow solar pond. Energy Convers Manag 49(10):2839–2848

Eltawil MA, Omara Z (2014) Enhancing the solar still performance using solar photovoltaic, flat plate collector and hot air. Desalination 349:1–9

Essa F, Abdullah A et al (2020a) Rotating discs solar still: new mechanism of desalination. J Clean Prod 275:123200

Essa F, Elsheikh AH et al (2020b) Eco-friendly coffee-based colloid for performance augmentation of solar stills. Process Saf Environ Prot 136:259–267

Estahbanati MK, Ahsan A et al (2016) Theoretical and experimental investigation on internal reflectors in a single-slope solar still. Appl Energy 165:537–547

Fallahzadeh R, Aref L et al (2020a) An experimental investigation on the performance of a new portable active bubble basin solar still. Appl Therm Eng 181:115918

Fallahzadeh R, Aref L et al (2020b) Experimental investigation of the effect of using water and ethanol as working fluid on the performance of pyramid-shaped solar still integrated with heat pipe solar collector. Sol Energy 207:10–21

Fath HE, El-Samanoudy M et al (2003) Thermal-economic analysis and comparison between pyramid-shaped and single-slope solar still configurations. Desalination 159(1):69–79

Govindaraj K, Panchabikesan K et al (2017) Effect of fin orientations in a spherically encapsulated phase change materials for effective heat transfer enhancement. Chem Eng Trans 62:277–282

Haddad Z, Chaker A et al (2017) Improving the basin type solar still performances using a vertical rotating wick. Desalination 418:71–78

Hansen RS, Murugavel KK (2017) Enhancement of integrated solar still using different new absorber configurations: an experimental approach. Desalination 422:59–67

Hansen RS, Narayanan CS et al (2015) Performance analysis on inclined solar still with different new wick materials and wire mesh. Desalination 358:1–8

Hassan H, Yousef MS et al (2020a) Assessment of parabolic trough solar collector assisted solar still at various saline water mediums via energy, exergy, exergoeconomic, and enviroeconomic approaches. Renew Energy 155:604–616

Hassan H, Yousef MS et al (2020b) Impact of condenser heat transfer on energy and exergy performance of active single slope solar still under hot climate conditions. Sol Energy 204:79–89

Jani HK, Modi KV (2019) Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Sol Energy 179:186–194

Kabeel A (2009) Performance of solar still with a concave wick evaporation surface. Energy 34(10):1504–1509

Kabeel A, Abdelgaied M (2016) Improving the performance of solar still by using PCM as a thermal storage medium under Egyptian conditions. Desalination 383:22–28

Kabeel A, Abdelgaied M (2017) Performance enhancement of modified solar still using multi-groups of two coaxial pipes in basin. Appl Therm Eng 118:23–32

Kabeel A, Omara Z et al (2014) Improving the performance of solar still by using nanofluids and providing vacuum. Energy Convers Manag 86:268–274

Kabeel A, Teamah MA et al (2017) Modified pyramid solar still with v-corrugated absorber plate and PCM as a thermal storage medium. J Clean Prod 161:881–887

Kabeel A, El-Samadony Y et al (2018) Comparative study on the solar still performance utilizing different PCM. Desalination 432:89–96

Kabeel A, Dawood MMK et al (2019a) Enhancement of single solar still integrated with solar dishes: an experimental approach. Energy Convers Manag 196:165–174

Kabeel A, Sharshir SW et al (2019b) Improving performance of tubular solar still by controlling the water depth and cover cooling. J Clean Prod 233:848–856

Kabeel AE, Sathyamurthy R et al (2019c) Effect of water depth on a novel absorber plate of pyramid solar still coated with TiO2 nano black paint. J Clean Prod 213:185–191

Kabeel A, Abdelgaied M et al (2020a) Augmentation of diurnal and nocturnal distillate of modified tubular solar still having copper tubes filled with PCM in the basin. J Energy Storage 32:101992

Kabeel A, El-Maghlany WM et al (2020b) Performance enhancement of pyramid-shaped solar stills using hollow circular fins and phase change materials. J Energy Storage 31:101610

Kannan R, Selvaganesan C et al (2014) Solar still with vapor adsorption basin: performance analysis. Renew Energy 62:258–264

Karthick Munisamy T, Mohan A et al (2017) Experimental investigation of tilted wick solar still using fabrics. Australian J Mechan Eng:1–6

Karthikeyan J, Selvaraj P et al (2020) Day and night yield performance analysis of solar still for saline water using energetic materials with thermocol insulation. Materials Today: Proceedings 33:4848–4851

Katekar VP, Deshmukh SS (2020a) A review of the use of phase change materials on performance of solar stills. J Energy Storage 30:101398

Katekar VP, Deshmukh SS (2020b) A review on research trends in solar still designs for domestic and industrial applications. J Clean Prod 257:120544

Kateshia J, Lakhera VJ (2021) Analysis of solar still integrated with phase change material and pin fins as absorbing material. J Energy Storage 35:102292

Keshtkar M, Eslami M et al (2020) Effect of design parameters on performance of passive basin solar stills considering instantaneous ambient conditions: a transient CFD modeling. Sol Energy 201:884–907

Khalifa AJN, Hamood AM (2009a) Effect of insulation thickness on the productivity of basin type solar stills: an experimental verification under local climate. Energy Convers Manag 50(9):2457–2461

Khalifa AJN, Hamood AM (2009b) On the verification of the effect of water depth on the performance of basin type solar stills. Sol Energy 83(8):1312–1321

Khalifa AJN, Ibrahim HA (2009) Effect of inclination of the external reflector on the performance of a basin type solar still at various seasons. Energy for Sustainable Development 13(4):244–249

Khanmohammadi S, Khanmohammadi S (2019) Energy, exergy and exergo-environment analyses, and tri-objective optimization of a solar still desalination with different insulations. Energy 187:115988

Kumar A, Vyas S et al (2020) Experimental study of single slope solar still coupled with parabolic trough collector. Mater Sci Energy Technol 3:700–708

Kumari S, Rani J (2014) Assessment of water quality index of ground water in Smalkhan, Haryana. International Journal of Latest Research in Science and Technology (IJLRST) 3(6):169–172

Layek A (2018) Exergetic analysis of basin type solar still. Eng Sci Technol Int J 21(1):99–106

Madiouli J, Lashin A et al (2020) Experimental study and evaluation of single slope solar still combined with flat plate collector, parabolic trough and packed bed. Sol Energy 196:358–366

Manokar AM, Taamneh Y et al (2020) Effect of water depth and insulation on the productivity of an acrylic pyramid solar still–an experimental study. Groundw Sustain Dev 10:100319

Modi KV, Modi JG (2020) Influence of wick pile of jute cloth on distillate yield of double-basin single-slope solar still: theoretical and experimental study. Sol Energy 205:512–530

Modi KV, Nayi KH et al (2020) Influence of water mass on the performance of spherical basin solar still integrated with parabolic reflector. Groundw Sustain Dev 10:100299

Modi KV, Jani HK et al (2021) Impact of orientation and water depth on productivity of single-basin dual-slope solar still with Al 2 O 3 and CuO nanoparticles. J Therm Anal Calorim 143(2):899–913

Mohamed A, Hegazi A et al (2019) Enhancement of a solar still performance by inclusion the basalt stones as a porous sensible absorber: experimental study and thermo-economic analysis. Sol Energy Mater Sol Cells 200:109958

Mohammadi K, Taghvaei H et al (2020) Experimental investigation of a double slope active solar still: effect of a new heat exchanger design performance. Appl Therm Eng 180:115875

Morad M, El-Maghawry HA et al (2015) Improving the double slope solar still performance by using flat-plate solar collector and cooling glass cover. Desalination 373:1–9

Mu L, Xu X et al (2019) Enhancing the performance of a single-basin single-slope solar still by using Fresnel lens: experimental study. J Clean Prod 239:118094

Murugavel KK, Srithar K (2011) Performance study on basin type double slope solar still with different wick materials and minimum mass of water. Renew Energy 36(2):612–620

Murugavel KK, Sivakumar S et al (2010) Single basin double slope solar still with minimum basin depth and energy storing materials. Appl Energy 87(2):514–523

Nagarajan P, El-Agouz S et al (2017) Analysis of an inclined solar still with baffles for improving the yield of fresh water. Process Saf Environ Prot 105:326–337

Naim MM, El Kawi MAA (2003) Non-conventional solar stills part 1. Non-conventional solar stills with charcoal particles as absorber medium. Desalination 153(1–3):55–64

Narayanan SS, Yadav A et al (2020) A concise review on performance improvement of solar stills. SN Applied Sciences 2(3):1–15

Nithyanandam C, Baskar G et al (2017) Design and fabrication of the passive solar still using blue metal stone. Int J Ambient Energy 38(2):171–177

Omara Z, Hamed MH et al (2011) Performance of finned and corrugated absorbers solar stills under Egyptian conditions. Desalination 277(1–3):281–287

Omara Z, Eltawil MA et al (2013a) A new hybrid desalination system using wicks/solar still and evacuated solar water heater. Desalination 325:56–64

Omara Z, Kabeel A et al (2013b) Enhancing the stepped solar still performance using internal reflectors. Desalination 314:67–72

Omara Z, Kabeel A et al (2014) Enhancing the stepped solar still performance using internal and external reflectors. Energy Convers Manag 78:876–881

Omara Z, Kabeel A et al (2016) Experimental investigation of corrugated absorber solar still with wick and reflectors. Desalination 381:111–116

Omara Z, Abdullah A et al (2017) Improving the productivity of solar still by using water fan and wind turbine. Sol Energy 147:181–188

Pal P, Yadav P et al (2017) Performance analysis of modified basin type double slope multi–wick solar still. Desalination 422:68–82

Panchal H (2016) Performance investigation on variations of glass cover thickness on solar still: experimental and theoretical analysis. Technol Econ Smart Grids Sustain Energy 1(1):7

Panchal H, Sathyamurthi R (2017) Experimental analysis of single-basin solar still with porous fins. Int J Ambient Energy:1–7

Panchal H, Hishan SS et al (2020a) Solar still with evacuated tubes and calcium stones to enhance the yield: an experimental investigation. Process Saf Environ Prot 142:150–155

Panchal H, Kumar Sadasivuni K et al (2020b) Performance analysis of evacuated tubes coupled solar still with double basin solar still and solid fins. Int J Ambient Energy 41(9):1031–1037

Panchal H, Mevada D et al (2020c) Experimental and water quality analysis of solar stills with vertical and inclined fins. Groundw Sustain Dev 11:100410

Panomwan Na Ayuthaya R, Namprakai P et al (2013) The thermal performance of an ethanol solar still with fin plate to increase productivity. Renew Energy 54:227–234

Patel SK, Modi KV (2020) Techniques to improve the performance of enhanced condensation area solar still: a critical review. J Clean Prod 268:122260

Patel M, Patel C et al (2020a) Performance analysis of conventional triple basin solar still with evacuated heat pipes, corrugated sheets and storage materials. Groundw Sustain Dev 11:100387

Patel SK, Kumar B et al (2020b) Production of potable water from Gomti River by using modified double slope solar still with external mounted reflectors. Sol Energy 209:576–589

Pearce JM, Denkenberger D (2006) Numerical simulation of the direct application of compound parabolic concentrators to a single effect basin solar still. Proceedings of the 2006 international conference of solar cooking and food processing

Rababa’h HM (2003) Experimental study of a solar still with sponge cubes in basin. Energy Convers Manag 44(9):1411–1418

Rahbar N, Gharaiian A et al (2017) Exergy and economic analysis for a double slope solar still equipped by thermoelectric heating modules-an experimental investigation. Desalination 420:106–113

Rahim NHA (2001) Utilisation of new technique to improve the efficiency of horizontal solar desalination still. Desalination 138(1–3):121–128

Rajamanickam M, Ragupathy A (2012) Influence of water depth on internal heat and mass transfer in a double slope solar still. Energy Procedia 14:1701–1708

Rajaseenivasan T, Srithar K (2016) Performance investigation on solar still with circular and square fins in basin with CO2 mitigation and economic analysis. Desalination 380:66–74

Rajaseenivasan T, Raja PN et al (2014) An experimental investigation on a solar still with an integrated flat plate collector. Desalination 347:131–137

Rajaseenivasan T, Tinnokesh A et al (2016) Glass basin solar still with integrated preheated water supply–theoretical and experimental investigation. Desalination 398:214–221

Rajaseenivasan T, Prakash R et al (2017) Mathematical and experimental investigation on the influence of basin height variation and stirring of water by solar PV panels in solar still. Desalination 415:67–75

Rajasekhar G, Eswaramoorthy M (2015) Performance evaluation on solar still integrated with nano-composite phase change materials. Appl Sol Energy 51(1):15–21

Raju VR, Narayana RL (2018) Effect of flat plate collectors in series on performance of active solar still for Indian coastal climatic condition. J King Saud Univ Eng Sci 30(1):78–85

Rashidi S, Bovand M et al (2016) Optimization of partitioning inside a single slope solar still for performance improvement. Desalination 395:79–91

Rashidi S, Esfahani JA et al (2017) Partitioning of solar still for performance recovery: experimental and numerical investigations with cost analysis. Sol Energy 153:41–50

Rashidi S, Akar S et al (2018a) Volume of fluid model to simulate the nanofluid flow and entropy generation in a single slope solar still. Renew Energy 115:400–410

Rashidi S, Bovand M et al (2018b) Volume-of-fluid model for simulating vapor–liquid phase change in a solar still. J Thermophys Heat Transf 32(4):917–924

Rashidi S, Bovand M et al (2018c) Steps optimization and productivity enhancement in a nanofluid cascade solar still. Renew Energy 118:536–545

Rashidi S, Rahbar N et al (2018d) Enhancement of solar still by reticular porous media: experimental investigation with exergy and economic analysis. Appl Therm Eng 130:1341–1348

Rashidi S, Karimi N et al (2019) A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J Therm Anal Calorim 135(2):1145–1159

Sahoo B, Sahoo N et al (2008) Performance assessment of a solar still using blackened surface and thermocol insulation. Renew Energy 33(7):1703–1708

Salarabadi A, Rahimi M (2020) Experimental investigation of using an evaporation inhibitor layer in a solar still. Sol Energy 206:962–973

Salem MR, Salem MR et al (2020) Performance enhancement of a solar still distillation unit: a field investigation. Sol Energy 202:326–341

Saravanan A, Murugan M (2020) Performance evaluation of square pyramid solar still with various vertical wick materials–an experimental approach. Thermal Science and Engineering Progress (TSEP) 19:100581

Sathyamurthy R, El-Agouz S et al (2015) Experimental analysis of a portable solar still with evaporation and condensation chambers. Desalination 367:180–185

Sellami M, Belkis T et al (2017) Improvement of solar still performance by covering absorber with blackened layers of sponge. Groundw Sustain Dev 5:111–117

Shalaby S, El-Bialy E et al (2016) An experimental investigation of a v-corrugated absorber single-basin solar still using PCM. Desalination 398:247–255

Shanmugan S, Essa F et al (2020) Experimental study on single slope single basin solar still using TiO2 nano layer for natural clean water invention. J Energy Storage 30:101522

Sharshir S, Peng G et al (2017a) The effects of flake graphite nanoparticles, phase change material, and film cooling on the solar still performance. Appl Energy 191:358–366

Sharshir S, Peng G et al (2017b) Enhancing the solar still performance using nanofluids and glass cover cooling: experimental study. Appl Therm Eng 113:684–693

Sharshir SW, Eltawil MA et al (2020) Performance enhancement of stepped double slope solar still by using nanoparticles and linen wicks: energy, exergy and economic analysis. Appl Therm Eng 174:115278

Shehata AI, Kabeel A et al (2020) Enhancement of the productivity for single solar still with ultrasonic humidifier combined with evacuated solar collector: an experimental study. Energy Convers Manag 208:112592

Shmroukh AN, Ookawara S (2020) Evaluation of transparent acrylic stepped solar still equipped with internal and external reflectors and copper fins. Thermal Science and Engineering Progress (TSEP) 18:100518

Shoeibi S, Rahbar N et al (2020) Application of simultaneous thermoelectric cooling and heating to improve the performance of a solar still: an experimental study and exergy analysis. Appl Energy 263:114581

Shoeibi S, Rahbar N et al (2021) Energy matrices, exergoeconomic and enviroeconomic analysis of air-cooled and water-cooled solar still: experimental investigation and numerical simulation. Renew Energy 171:227–244

Singh D, Yadav J et al (2016) Experimental studies of active solar still integrated with two hybrid PVT collectors. Sol Energy 130:207–223

Subhedar DG, Chauhan KV et al (2020) Performance improvement of a conventional single slope single basin passive solar still by integrating with nanofluid-based parabolic trough collector: an experimental study. Materials Today: Proceedings 26:1478–1481

Suneesh P, Jayaprakash R et al (2014) Effect of air flow on “V” type solar still with cotton gauze cooling. Desalination 337:1–5

Suraparaju SK, Natarajan SK (2021a) Experimental investigation of single-basin solar still using solid staggered fins inserted in paraffin wax PCM bed for enhancing productivity. Environ Sci Pollut Res 28(16):20330–20343

Suraparaju SK, Natarajan SK (2021b) Productivity enhancement of single-slope solar still with novel bottom finned absorber basin inserted in phase change material (PCM): techno-economic and enviro-economic analysis. Environ Sci Pollut Res:1–22

Suresh C, Shanmugan S (2019) Effect of water flow in a solar still using novel materials. J Therm Anal Calorim:1–14

Taamneh Y, Manokar AM et al (2020) Extraction of drinking water from modified inclined solar still incorporated with spiral tube solar water heater. J Water Process Eng 38:101613

Tabrizi FF, Sharak AZ (2010) Experimental study of an integrated basin solar still with a sandy heat reservoir. Desalination 253(1–3):195–199

Taghvaei H, Taghvaei H et al (2014) A thorough investigation of the effects of water depth on the performance of active solar stills. Desalination 347:77–85

Taghvaei H, Taghvaei H et al (2015) Experimental investigation of the effect of solar collecting area on the performance of active solar stills with different brine depths. Desalination 358:76–83

Tanaka H (2009a) Effect of inclination of external reflector of basin type still in summer. Desalination 242(1–3):205–214

Tanaka H (2009b) Experimental study of a basin type solar still with internal and external reflectors in winter. Desalination 249(1):130–134

Tanaka H (2011) A theoretical analysis of basin type solar still with flat plate external bottom reflector. Desalination 279(1–3):243–251

Tiwari AK, Tiwari G (2006) Effect of water depths on heat and mass transfer in a passive solar still: in summer climatic condition. Desalination 195(1–3):78–94

Tiwari G, Dimri V et al (2009) Parametric study of an active and passive solar distillation system: energy and exergy analysis. Desalination 242(1–3):1–18

Velmurugan V, Srithar K (2011) Performance analysis of solar stills based on various factors affecting the productivity—a review. Renew Sust Energ Rev 15(2):1294–1304

Velmurugan V, Pandiarajan S et al (2009) Integrated performance of stepped and single basin solar stills with mini solar pond. Desalination 249(3):902–909

Vigneswaran V, Kumaresan G et al (2019) Augmenting the productivity of solar still using multiple PCMs as heat energy storage. J Energy Storage 26:101019

Winston DP, Pounraj P et al (2018) Experimental investigation on hybrid PV/T active solar still with effective heating and cover cooling method. Desalination 435:140–151

Xinxin G, Heng Z et al (2019) Experimental and theoretical investigation on a hybrid LCPV/T solar still system. Desalination 468:114063

Younis M, Habchi C et al (2020) Optimization of the performance of a solar still assisted by a rotating drum with a rough surface. Sol Energy 211:847–865

Zanganeh P, Goharrizi AS et al (2020) Nano-coated condensation surfaces enhanced the productivity of the single-slope solar still by changing the condensation mechanism. J Clean Prod 265:121758

Funding

There is no funding source for this research

Author information

Authors and Affiliations

Contributions

MB analyzed all the design, operating, and environmental parameters which influenced the performance of the solar still. AY identified different modifications in the design of solar still which resulted in productivity enhancement. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The author’s declare that they have no competing interests

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhargva, ., Yadav, A. Factors affecting the performance of a solar still and productivity enhancement methods: A review. Environ Sci Pollut Res 28, 54383–54402 (2021). https://doi.org/10.1007/s11356-021-15983-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-15983-z