Abstract

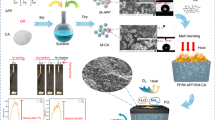

Novel intumescent flame retardant polypropylene (PP) composites were prepared based on a char forming agent (CFA) and silica-gel microencapsulated ammonium polyphosphate (Si-MCAPP). The thermal and flame retardancy of flame retardant PP composites were investigated by limiting oxygen index, UL-94 test, cone calorimetry, thermogravimetric analysis, scanning electron micrograph, and water resistance test. The results of cone calorimetry show that the flame retardant properties of PP with 30 wt% novel intumescent flame retardants (CFA/Si-MCAPP = 1:3) improve greatly. The peak heat release rate and total heat release decrease, respectively, from 1,140.0 to 156.8 kW m−2 and from 96.0 to 29.5 MJ m−2. The PP composite with CFA/Si-MCAPP = 1:3 has the excellent water resistance, and it can still obtain a UL-94 V-0 rating after 168 h soaking in water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polypropylene (PP) as one of the most widely used polyolefins has broad applications in many areas such as cars, architectural materials, and so on. However, as we know it is combustible and releases smoke and poisonous gas while burning. Easy combustibility restricts the range of its applying fields. Therefore, it is necessary to make this plastic flame retardant to reduce the emission of smoke, poisonous gases, and so on [1]. The halogenated organic compounds were good fire retardant additives for PP, especially synergizing with antimony trioxide. However, halogenated flame retardant PP composites have serious disadvantages such as the evolution of toxic gases and corrosive chemical fumes. Thus, more and more researchers are exploring halogen-free flame retardants. The effective halogen-free flame retardants are intumescent flame retardants (IFRs) [2, 3]. It is mainly composed of an acid source, a carbon source, and a gas source.

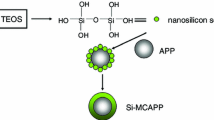

Among many intumescent flame retardant PP methods, a traditional and widely studied IFRs system is based on ammonium polyphosphate (APP), pentaerythritol (PER), and melamine [4–6]. Unfortunately, APP and PER are not durable due to the water solubility, so the flame retardant effect of those IFRs system is not permanent, and limits the application of IFRs in PP composites. In order to overcome poor water resistance problem, the technique of microencapsulation is a good choice. Microencapsulation protects encapsulated inner substances from some degrading reagents such as water. Microencapsulated APP has been synthesized with different materials such as PVA–melamine–formaldehyde resin, polyurethane, urea–melamine–formaldehyde resin, silica gel, and so on, and has been used in flame retardant polymer such as PP, PU, and so on [7–10]. Silica-gel microencapsulated APP (Si-MCAPP) is a kind of ammonium polyphosphate which is well microencapsulated by SiO2 gel. Si-MCAPP as one of the novel microencapsulated APP with good water resistance has attracted more and more attention [7]. Due to low surface energy, silicon-containing compounds tend to migrate and concentrate on the surface of polymer materials, and can form a protective silica layer during combustion, which can protect the matrix from further thermal decomposition. Furthermore, the synergistic effect between silicon-containing compounds and IFRs has been demonstrated and researches have shown that silicon improves the thermal stability and flame retardancy of IFR polymer composites [11–13]. So, Si-MCAPP is expected to have better flame retardancy than those of other microencapsulated APP.

Another solution to solve poor water resistance problem of flame retardants is to synthesize new carbon sources with good water resistance property. Among those new char formers, triazine derivative—CFA-containing chemical groups of hydroxyethylamino, triazine rings and ethylenediamine has been regarded as an excellent macromolecule char forming agent with excellent flame retardant properties and water resistance. Until now, CFA has been used in many polymer matrices such as PP, EVA, and so on [14–17].

In this work, CFA and Si-MCAPP were selected to form novel IFRs, and then the influence of these novel intumescent flame retardants on the thermal and flame retardant properties of PP were investigated by limiting oxygen index (LOI), UL-94 test, thermogravimetric analysis (TG), and scanning electron micrograph (SEM), especially by cone calorimetry and water resistance test. Through this research, we hope to provide an efficient intumescent flame retardant technique with excellent water resistance ability.

Experiment

Materials

PP (homopolymer, melt-flow rate = 2.5 g/10 min) was supplied as pellets by Yangzi Petrochemical Co. (China). CFA and Si-MCAPP were synthesized in our previous work [7, 16], and the structure of CFA is shown in Fig. 1. Si-MCAPP is a kind of ammonium polyphosphate which is well microencapsulated by SiO2 gel. APP and pentaerythritol (petol) (powder, average size < 10 μm) were kindly provided by KeYan Co. (Hefei, China).

The preparation of samples

PP, Si-MCAPP, and CFA were dried in vacuum oven at 80 °C overnight before use. Then PP, Si-MCAPP, and CFA were melt-mixed in a twin-roller mill (XSS-300, China) for 10 min; the temperature of the mill was maintained at 175 °C and the roller speed was 60 rpm. The samples are listed in Table 1. The resulting composites were hot-pressed into sheets with suitable thickness and size for UL-94, LOI, and cone calorimeter tests.

Determination of water resistance of flame-retarded PP material

The flame-retarded PP materials were put in distilled water at 70 °C and were kept at this temperature for various time periods. The specimens were subsequently removed, dried in the vacuum oven, and evaluated by burning tests.

Characterization

Thermogravimetric analyses were carried out using a Mettler-Toledo TGA/SDTA851e instrument from 35 to 800 °C at a linear heating rate of 20 °C min−1 under an air flow rate of 50 ml min−1. Samples were measured in an alumina crucible with a mass of about 3–6 mg.

The combustion properties were evaluated using a cone calorimeter. All samples (100 × 100 × 3 mm3) were exposed to a Stanton Redcroft cone calorimeter under a heat flux of 50 kW m−2 according to ISO-5660 standard procedures.

The scanning electron microscopy image of the residue after the cone calorimetry experiment was taken using a DXS-10 scanning electron microscope produced by Shanghai Electron Optical Technology Institute. The char was adhibited on the copperplate, and then coated with gold/palladium alloy ready for imaging.

LOI was measured according to ASTM D2863, and the apparatus used was an HC-2 oxygen index meter (Jiangning Analysis Instrument Company, China). The specimen dimensions used for test were 100 × 6.5 × 3 mm3. The vertical burning test was carried out on a CFZ-2-type instrument (Jiangning Analysis Instrument Company, China), and the specimens used for the test are 100 × 13 × 3 mm3.

Results and discussion

LOI and UL-94 analysis of flame-retarded PP composites

Figure 2 shows the LOI results for the various flame retardant PP compositions. PP is an easily combustible polymeric material, and the LOI value of PP is only 17.5 %. When CFA with 30 wt% is added in PP, the LOI value of PP composites is 24.0 %, and this PP composite is easy to burn. Si-MCAPP can increase the LOI value of the PP composites much better than that of CFA, its LOI reaches to 27.0 %. However, it still can get burned. Neither of the above samples can reach UL-94 V-0 rating. The above results show that Si-MCAPP and CFA alone have low efficiency in flame retardancy of PP. When CFA and Si-MCAPP are combined, the LOI value of PP composite is remarkably increased. The LOI value of PP/CFA/Si-MCAPP (1:1) is 34.0 % and the LOI increases with an increasing amount of Si-MCAPP. The sample of PP/CFA/Si-MCAPP (1:3) gives the largest LOI value of 40.0 %. The results of UL-94 vertical burning rate show that all the PP/CFA/Si-MCAPP composites can pass UL-94 V-0 rating, when the mass ratio of CFA to Si-MCAPP is between 1:3 and 1:1 with 30 wt% loadings. With the addition of 25 wt% IFRs (CFA/Si-MCAPP = 1:3) flame retardant PP composite can obtain V-0 rating. Even with the addition of 20 wt% IFRs (CFA/Si-MCAPP = 1:3), the flame retardant PP composite still passes UL-94 V-1 rating.

Water resistance of flame retardant PP composites

Water resistance test of Sample PP3 (CFA/Si-MCAPP = 1:3) and Sample PP9 (PER/APP = 1:3) with 30 wt% as the total amount of additives is carried on. Both of the samples are treated with water at 70 °C for different times and their flame retardant properties are evaluated (Table 2). It can be found that before water treatment both the samples can pass UL-94 V-0 rating. After being soaked in water for 24 h, Sample PP8 with PER/APP = 1:3 shows a very poor water resistance. The sample looses UL-94 rating and burns seriously. The sample with CFA/Si-MCAPP = 1:3 has very excellent resistance property, after 168 h the sample can still obtain a UL-94 V-0 rating. The water resistance test demonstrates that flame retardant PP prepared based on CFA/Si-MCAPP has excellent water resistance.

Thermal stability

TG was used to investigate the thermal behavior of CFA/Si-MCAPP systems, and the TG curves are shown in Fig. 3. It can be seen that the decomposition of CFA consists of two main steps i.e., 254–344, 344–700 °C. CFA itself has a good charring ability, and produces 59.2 % char residue at 500 °C, 39.8 % at 600 °C, and 11.0 % at 800 °C. The degradation of Si-MCAPP can be divided into two temperature regions. The first region with 5 wt% loss is at 285 °C. The volatile products in this region are mainly NH3 and H2O, and a crosslinked polyphosphoric acid layer is formed in this step [7]. The second region is the main decomposition process, which occurs between 500 and 700 °C. The residue of Si-MCAPP is 80.6 % char residue at 500 °C, 73.4 % at 600 °C, and 32.4 % at 800 °C, respectively.

It can be observed that CFA/Si-MCAPP (1:3) system produces, respectively, 70.3 % char residue at 500 °C, 66.0 % at 600 °C, and 40.0 % at 800 °C. But the calculated char residue of CFA/Si-MCAPP system by calculating the datum of Si-MCAPP and CFA should be 75.3 % at 500 °C, 65.5 % at 600 °C, and 27.0 % at 800 °C, respectively. At temperature higher than 600 °C, the CFA/Si-MCAPP system shows greatly improved thermal stability than that of calculated one. It demonstrates that some synergistic effects exist between CFA and Si-MCAPP due to chemical interactions between CFA and Si-MCAPP, such as the phosphorylation reaction and the stabilization of polyphosphoric acid by forming bridges or crosslinks between adjacent chains, which can inhibit the further decomposition of the system at high temperature. CFA/Si-MCAPP (1:1) system produces, respectively, 64.9 % char residue at 500 °C, 60.6 % at 600 °C, and 22.5 % at 800 °C. Comparing between CFA/Si-MCAPP (1:1) with CFA/Si-MCAPP (1:3), it can be observed that CFA/Si-MCAPP (1:3) is thermally stabler than CFA/Si-MCAPP (1:1).

Figure 4 shows the decomposition of flame retardant PP composites. The curve for pure PP shows one step degradation of total mass loss in the range of 230–400 °C, and has no char residue beyond the temperature of 400 °C. Compared to pure PP, the flame retardant PP composites (Fig. 4) show poorer thermal stability before 270 °C, mainly due to the decomposition of Si-MCAPP, the formation of ester mixtures between –P–OH group in Si-MCAPP and –OH group in CFA and the formation of a char layer. Above 270 °C, the flame retardant PP composites have much better thermal stability and have about 15 % char compared with almost nothing for pure PP. The ratio of CFA/Si-MCAPP affects the thermal stability of the flame retardant PP composite. Sample PP3 with the ratio of CFA/Si-MCAPP = 1/3 has 19.5 % char left at 600 °C, and has higher thermal stability than that (15.1 % char left) of sample PP5 with the ratio of CFA/Si-MCAPP = 1/1. From the above results it can be concluded that CFA/Si-MCAPP has a synergistic effect and can obviously improve the thermal stability of PP. Meanwhile, the ratio of CFA/Si-MCAPP is also very important.

Cone calorimeter test

Cone calorimetry is a small-scale test for the combustion of the materials, but it has good correlation with real fire disaster and provides a wealth of information on the combustion behavior [18, 19]. The heat release rate (HRR) and total heat release (THR) are regarded as important parameters to evaluate the developing, spreading, and intensity of fires. The HRR curves of PP and flame retardant PP composites are shown in Fig. 5. From the figure it is clear that pure PP burns intensely, with only a peak heat release rate (pHRR) of 1140.0 kW m−2. With the addition of CFA or Si-MCAPP with 30 wt% in PP, the pHRR value of PP composites is 638.1 and 616.7 kW m−2, respectively. Si-MCAPP can decrease the pHRR value of the PP composites better than that of CFA. Just as LOI results demonstrate that Si-MCAPP and CFA alone have low efficiency in flame retardancy of PP. When CFA and Si-MCAPP are mixed with a certain ratio, the pHRR value of PP composite is remarkably decreased. The pHRR value of the sample with CFA/Si-MCAPP = 1:3 is the lowest (156.8 kW m−2), with 86.2 % decrease compared with that of pure PP. As the CFA:Si-MCAPP ratio increases, the pHRR value of flame retardant PP composites increases from 156.8 to 408.0 kW m−2 (PP6). The reason for the decrease of the HRR value can be due to the formation of the intumescent protective char layer through etherification, dehydration, expansion, and crosslinking process, when PP composites are subjected to high temperature. The blowing agent decomposes to produce gaseous products and causes the char to swell. With the presence of the efficient protective char layer, the amount of heat and combustible gas decreases greatly, and the further degradation of inner PP is prevented, so the HRR value decreases [20, 21].

The THR curves of PP and flame retardant PP composites are shown in Fig. 6. It can be found from Fig. 6 that the THR decreases from 96 MJ m−2 in PP to 93.4 and 81.7 MJ m−2 in PP/CFA and PP/Si-MCAPP, finally to 89.4 MJ m−2 at CFA:Si-MCAPP = 2:1 (PP6) and to 29.5 MJ m−2 at CFA:Si-MCAPP = 1:3 (PP3). Obviously the ratio of CFA and Si-MCAPP effects the flame retardant behavior of flame retardant PP composites. From the result of PP3 and PP6, it can be observed only with suitable ratio, flame retardant PP composite can get the best flame retardant properties.

SEM analysis of char residue after combustion

SEM (Fig. 7) also shows very different char morphology of the flame retardant PP composites obtained during LOI test. Investigation on the morphology of the char is helpful to explain the differences in the flame retardancy among the flame retardant PP composites. For PP/Si-MCAPP (PP1) without CFA (Fig. 7b), a compact charred layer is formed, but it is not able to swell and form intumescent char layer due to the lack of a carbon source. PP/CFA (PP2) without Si-MCAPP (Fig. 7a) shows a loose char layer with a lot of holes on the surface, and this kind of charred layer has poor protective effect during combustion. The intumescent charred layer of sample PP3 (Fig. 7c) is very compact and much char stacked together seemed to possess bigger thickness and less susceptible to crack, which provides a much better barrier to the transfer of the heat, combustible gases, and free radicals during a fire [22]. So, it can be concluded that when CFA and Si-MCAPP are synergized together at a certain ratio, a high quality of charred layer can be formed. It can also be found that the ratio of Si-MCAPP and CFA influence the morphology of the intumescent charred layer. For PP5 (Fig. 7d) with the CFA/Si-MCAPP ratio is 1:1, char layer is swollen and has some holes, so the flame retardant ability is not as good as that of PP3.

Conclusions

Novel intumescent flame retardant PP composites were prepared based on CFA and Si-MCAPP. The thermal and flame retardancy of flame retardant PP composites were investigated. With the addition of 30 wt% IFRs (CFA/Si-MCAPP = 1:3), the LOI value can reach 40.0 %. When the loading of IFRs is only 25 wt% in PP, the flame retardant PP composite still obtains UL-94 V-0 rating. The results of Cone calorimetry experiments show that the pHRR and THR significantly decrease with the addition of 30 wt% IFRs (CFA/Si-MCAPP = 1:3) in PP. The pHRR and THR decrease, respectively, from 1,140.0 to 156.8 kW m−2 and from 96.0 to 29.5 MJ m−2. The water resistance test proves that the PP composites with CFA/Si-MCAPP = 1:3 has the best water resistance property, and it can still pass UL-94 V-0 rating after 168 h soaking in water. SEM indicates that CFA/Si-MCAPP system can form excellent and compact char residue, which can better endure the oxidation of high temperature. From the above results, we can summarize that the combining of CFA and Si-MCAPP in PP matrix can prepare novel flame retardant PP composites with good flame retardant properties and with excellent water resistance ability.

References

Liu Y, Yi JS, Cai XF. The investigation of intumescent flame-retarded polypropylene using poly(hexamethylene terephthalamide) as carbonization agent. J Therm Anal Calorim. 2012;107(3):1191–7.

Vandersall HL. Intumescent coating systems, their development and chemistry. J Fire Flammabl. 1971;2:97–140.

Camino G, Costa L, Trossarelli L. Study of the mechanism of intumescence in fire retardant polymers: part VI mechanism of ester formation in ammonium polyphosphate-pentaerythritol mixtures. Polym Degrad Stab. 1985;12(3):213–8.

Chiu SH, Wang WK. Flame retardancy of polypropylene filled with ammonium polyphosphate, pentaerythritol and melamine additives. Polymer. 1998;39(10):1951–5.

Bourbigot S, Le Bras M. Carbonization mechanisms resulting from intumescence-part II. Association with an ethylene terpolymer and the ammonium polyphosphate–pentaerythritol fire retardant system. Carbon. 1995;33(3):283–94.

Le Bras M, Bourbigot S, Christelle D. New intumescent formulations of fire-retardant polypropylene—discussion of the free radical mechanism of the formation of carbonaceous protective material during the thermo-oxidative treatment of the additives. Fire Mater. 1996;20(4):191–203.

Ni JX, Tai QL, Lu HD. Microencapsulated ammonium polyphosphate with polyurethane shell: preparation, characterization, and its flame retardance in polyurethane. Polym Adv Technol. 2010;21:392–400.

Zhou S, Lu HD, Song L. Microencapsulated ammonium polyphosphate with polyurethane shell: application to flame retarded polypropylene/ethylene–propylene diene terpolymer blends. J Macromol Sci Part A: Pure Appl Chem. 2009;46:136–44.

Wu K, Song L, Wang ZZ, Hu Y. Preparation and characterization of core/shell-like intumescent flame retardant and its application in polypropylene. J Macromol Sci Part A: Pure Appl Chem. 2009;46:837–46.

Wu K, Song L, Wang ZZ, Hu Y. Microencapsulation of ammonium polyphosphate with PVA–melamine–formaldehyde resin and its flame retardance in polypropylene. Polym Adv Technol. 2008;19:1914–21.

Lei ZQ, Cao YM, Xie F, Ren H. Study on surface modification and flame retardants properties of ammonium polyphosphate for polypropylene. J Appl Polym Sci. 2012;124(1):781–8.

Wang BB, Wang XF, Tang G, Hu Y. Preparation of silane precursor microencapsulated intumescent flame retardant and its enhancement on the properties of ethylene–vinyl acetate copolymer cable. Compos Sci Technol. 2012;72(9):1042–8.

Chen XL, Jiao CM, Zhang J. Microencapsulation of ammonium polyphosphate with hydroxyl silicone oil and its flame retardance in thermoplastic polyurethane. J Therm Anal Calorim. 2011;104:1037–43.

Bai P, Li B, Gao SL. Investigation on flame retardancy and antidripping of new intumescent flame retardant polypropylene film. Polym Polym Compos. 2010;18:495–502.

Feng CM, Zhang Y, Liu SW. Synthesis of novel triazine charring agent and its effect in intumescent flame-retardant polypropylene. J Appl Polym Sci. 2012;123:3208–16.

Nie SB, Hu Y, Song L. Synergistic effect between a char forming agent (CFA) and micro encapsulated ammonium polyphosphate on the thermal and flame retardant properties of polypropylene. Polym Adv Technol. 2008;19:1077–83.

Li B, Xu MJ. Effect of a novel charring–foaming agent on flame retardancy and thermal degradation of intumescent flame retardant polypropylene. Polym Degrad Stab. 2006;91:1380–6.

Nie SB, Zhang MX, Yuan SJ, Dai GL. Thermal and flame retardant properties of novel intumescent flame retardant low-density polyethylene (LDPE) composites. J Therm Anal Calorim. 2012;109:999–1004.

Wu K, Shen MM, Hu Y, Xing WY, Wang X. Thermal degradation and intumescent flame retardation of cellulose whisker/epoxy resin composite. J Therm Anal Calorim. 2011;104:1083–90.

Nie SB, Song L, Guo YQ, Hu Y. Intumescent flame retardation of starch containing polypropylene semibiocomposites: flame retardancy and thermal degradation. Ind Eng Chem Res. 2009;48:10751–8.

Jiao CM, Chen XL. Synergistic effects of zinc oxide with layered double hydroxides in EVA/LDH composites. J Therm Anal Calorim. 2009;98:813–8.

Nie SB, Hu Y, Song L. Study on a novel and efficient flame retardant synergist-nanoporous nickel phosphates VSB-1 with intumescent flame retardants in polypropylene. Polym Adv Technol. 2008;19:489–95.

Acknowledgements

The work was financially supported by China Postdoctoral Science Foundation (2012M511913), Science Fund of Anhui Education Department (KJ2012A074), Scientific and Technological Fund for Selected Projects of Returned Overseas Chinese Professionals (Research on methods of fire area assessment) and Doctoral Research Fund of Anhui University of Science and Technology (Research on regularity of coal temperature changes in sealed fire areas of coal mines).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, S., Peng, C., Yuan, S. et al. Thermal and flame retardant properties of novel intumescent flame retardant polypropylene composites. J Therm Anal Calorim 113, 865–871 (2013). https://doi.org/10.1007/s10973-012-2815-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2815-3