Abstract

A series of intrinsically black polyimide (PI) films have been designed and synthesized by the copolymerization of pyromellitic dianhydride (PMDA), 4,4′-oxydianiline (ODA) and 4,4′-diaminodiphenylamine (NDA) via a two-step polycondensation procedure, followed by the high temperature imidization reaction of the poly(amic acid) (PAA) intermediates. Incorporation of the electron-rich NDA diamine apparently enhanced the formation of charge transfer complex (CTC) between the electron-donating diamine units and the electron-accepting dianhydride moiety; thus greatly absorbing the visible light and endowing the derived PI films deep colors. PI-5 with the 100% molar ratio of NDA in the diamines exhibited a cutoff wavelength value of 555 nm, which was 127 nm higher than that of PI-1 without NDA component. The PI films were nearly totally opaque at the wavelength of 500 nm when the molar ratio of NDA exceeded 80% in the diamines. PI-5 showed International Commission on Illumination (CIE) lab color parameters of 23.36 for L*, 46.43 for a*, and 40.26 for b*, indicating the essentially black plus red color instead of the yellow plus blue color for PI-1 film (L* = 89.93, a* = −11.09, and b* = 84.23). In addition, introduction of NDA into the copolymer films increased the high temperature dimensional stability of the films. PI-5 exhibited a glass transition temperature (Tg) and coefficient of thermal expansion (CTE) of 431.6 °C and 18.8 × 10−6 /K, respectively, which were superior to those of the PI-1 film (Tg = 418.8 °C, CTE = 29.5 × 10−6 /K). At last, incorporation of NDA components somewhat decreased the tensile properties and thermal decomposition temperatures of the PI films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyimide (PI) films represent a class of high performance polymer films characterized by their excellent combined properties, including good thermal and dimensional stability at elevated temperature, good mechanical and dielectric properties, and good environmental inertness [1,2,3].

The standard wholly aromatic PI films are commonly referred as “golden films”, on one hand due to their valuable comprehensive properties mentioned above; and on the other hand, due to their golden appearance. The origination of the coloration of the PI films has been proven to be due to the formation of charge transfer complex (CTC) between the alternating electron-donor (diamine) and electron-acceptor (dianhydride) moieties in PI films [4,5,6]. During the formation of intra-and inter-molecular CTC in PI films, the visible light is strongly absorbed, leaving the yellow or brown appearance of the normal PI films, as illustrated in Fig. 1 [7,8,9,10,11]. In order to tailor the coloration of PI films, the molecular design by adjusting the electronic transition energy from the highest occupied molecular orbital (HOMO) located around the imide nitrogen (>N-) to the lowest unoccupied molecular orbital (LUMO) located around the carbonyl (>C=O) carbons should be a very effective pathway [5]. Figure 1 shows the common molecular design for developing colorless PI film by reducing the CTC formation [12] and deep-color or black PI films by enhancing CTC formation [13]. In view of the coloration of PI films is dominated by the electron-donating property of the diamine and the electron affinity of dianhydrides, the coloration of the PI films might be lightened by decreasing the electron density of the diamine moiety or deepened by increasing the electron density of the diamine monomers when the dianhydride structure is fixed.

In recent years, black PI films attracted increasing attention from both of the academic and engineering fields due to their extraordinary desired properties in specific high-tech fields [14]. The black PI films usually possess the intrinsic properties of common PI films and exhibit black appearance at the same time; thus have found various applications in areas where high temperature resistance, opaqueness, chemical inertness, and aesthetics are simultaneously concerned. For example, black PI films can be used as the coverlay for flexible printing circuit board (FPCB) in microelectronic industry, which could protect the inner circuit layer from ultraviolet light degradation, and on the other hand, protect the inner circuit design with intellectual property rights from being imitated. In addition, black PI films have been widely used as high temperature resistant label, loudspeaker, adhesive tape, thermal control blanket in either electrical, electronic areas or in aerospace fields, as illustrated in Fig. 2.

At present, the state of art process for preparing black PI films is to use the composite method, that is, to combine the inorganic black fillers, such as carbon black (CB), graphite or graphene, carbon nanotubes (CNT) with the organic PI matrix, so as to afford the final composite film black appearance [15]. However, due to the conductive nature of the common inorganic black fillers, the derived PI composite films usually suffer from the deterioration of electrical properties [16]. The doped films usually display lowered electrical resistivities by several orders of magnitude compared to the undoped PI film matrix. Meanwhile, the tensile properties of the PI composite films are usually sacrificed due to the aggregation and non-uniform distribution of the nano- or micro-scale black fillers [17]. For example, Lin, et al. reported conductive PI composite films containing CB and graphite granules whose surface resistivity could be as low as 0.1 Ω/cm2 [18]. Atar, et al. reported electrically- conductive CNT-POSS-PI flexible films for space applications [19]. The CNT-POSS-PI films based on the PI matrix from pyromellotic dianhydride (PMDA) and 4,4′-oxydianiline (ODA) exhibited sheet resistivities as low as 200 Ω/□. Kwon, et al. reported the fabrication of PI composite films based on chemically synthesized CB and PI derived from PMDA and ODA for high temperature application [20]. Incorporation of the active CB increased the thermal decomposition temperature by 76 °C and the glass transition temperature by 204 °C, respectively. However, the elongation at break of the PI films decreased from 46.9% to 6.3% when the CB content was 40% in the films. Thus, the intrinsically black PI films with maintained electrical and mechanical properties are highly desired in many high-tech fields. However, to the best of our knowledge, few works have been reported on research and development of intrinsically black PI films via molecular design methodology.

As illustrated in Fig. 1, the color of PI films can actually be deepened by enhancing the CTC formation in the PIs; that is increasing the electron density of diamine units while maintaining the electron transfer pathway at the same time (conjugated molecular skeleton) when the dianhydride is fixed. It has been well established that the nitrogen-containing diamines usually possess the electron-rich feature and have been widely used in the R&D of PI films with color-adjustable functions, such as electrochromic and photochromic applications [21]. The common nitrogen-containing diamines with high electron density are shown in Fig. 3. For example, the PI films derived from the electron-rich triphenylamine (TPA) diamine (DA-2) have been widely used for electrochromic application [22]. The triarylamine unit can be easily oxidized to form stable radical cations and the oxidation process is always associated with a noticeable change of coloration [23].

In the current work, an electron-rich aromatic diamine, 4,4′-diaminodiphenylamine (NDA) was incorporated into the structure of poly(pyromellitic dianhydride-co-4,4′-oxydianiline) (PMDA-ODA) film in order to enhance the CTC formation and blacken the color of the yellow PI films. Effect of the incorporation of NDA on the thermal, tensile, and optical properties of the PI films were investigated in detail.

Experimental

Materials

Pyromellitic dianhydride (PMDA) were purchased from Tokyo Chemical Industry Co., Ltd., Japan and dried in vacuum at 180 °C overnight prior to use. 4,4’-Oxydianiline (ODA) was purchased from Wakayama Seika Kogya Co. Ltd., Japan and used as received. 4,4′-Diaminodiphenylamine sulfate hydrate was purchased from Tokyo Chemical Industry Co., Ltd., Japan and used as received. Hydrazine monohydrate (NH2-NH2·H2O) was purchased from Sigma-Aldrich, USA and used as received. N,N-dimethylacetamide (DMAc) was distilled over CaH2 prior to use.

Measurements

Inherent viscosity was measured using an Ubbelohde viscometer with a 0.5 g/dL DMAc solution at 25 °C. Attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectrum was obtained on a Bruker Tensor-27 FT-IR spectrometer. 1H-NMR was performed on a AV 400 spectrometer operating at 300 MHz using DMSO-d6 as the solvent and tetramethylsilane as the reference. The number average molecular weight (Mn) and weight average molecular weight (Mw) of the PI resins were measured using a gel permeation chromatography (GPC) system developed by Shimadzu Co. Ltd., Japan with a LC-20 AD dual-plunger parallel-flow pumps (D1-LC), a SIL-20A is a total-volume injection- type autosampler, a CTO-20A column oven, and a RID-20A detector. HPLC grade N-methyl-2- pyrrolidone (NMP) was used as the mobile phase at a flow rate of 1.0 mL/min. Polystyrene (Shodex, Type: SM-105, Showa Denko Co. Ltd., Japan) was used as the standard. Wide-angle X-ray diffraction was conducted on a Rigaku D/max-2500 X-ray diffractometer with Cu-Kα1 radiation, operated at 40 kV and 200 mA. UV-Vis spectra were recorded on a Hitachi U-3210 spectrophotometer at room temperature. Prior to test, PI films were dried at 100 °C for 1 h to remove the absorbed moisture. Yellow index and haze values of the PI films were measured using an X-rite color i7 spectrophotometer with PI film samples at a thickness of 20 μm. The color parameters were calculated according to a CIE Lab eq. L* is the lightness, where 100 means white and 0 implies black. A positive a* means a red color, and a negative one indicates a green color. A positive b* means a yellow color, and a negative one indicates a blue color.

Thermogravimetric analysis (TGA) was performed on a TA-Q50 thermal analysis system at a heating rate of 20 °C/min in nitrogen. Dynamic mechanical analysis (DMA) was recorded on a TA-Q800 thermal analysis system at a heating rate of 5 °C/min and a frequency of 1 Hz in nitrogen. Thermomechanical analysis (TMA) was recorded on a TA-Q 400 thermal analysis system in nitrogen at a heating rate of 10 °C/min. The tensile properties were performed on an Instron 3365 Tensile Apparatus with 80 mm × 10 mm × 0.05 mm specimens at a drawing rate of 2.0 mm/min. At least six test specimens were tested for each PI film and results were averaged. Volume resistivity (ρV) of the PI films was measured with a HEST-200 surface and volume resistivity tester (Beijing HuaCe Co. Ltd., China) according to GB/T 1410–2006 at room temperature.

Synthesis of 4,4′-diaminodiphenylamine (NDA)

NDA was synthesized in our laboratory by the alkalization of the commercially available 4,4′-diaminediphenylamine sulfate hydrate (NDA·H2SO4) via hydrazine monohydrate (NH2-NH2·H2O) as follows or synthesized according to a reported procedure [24]. NDA·H2SO4 (89.20 g, 0.3 mol), active carbon powder (1.0 g) and anhydrous ethanol (100 mL) were added into a 500-mL three-necked flask equipped with a mechanical stirrer, a nitrogen inlet, a thermometer, and a dropping funnel. The reaction mixture was heated and maintained at 60 °C for 1 h. Then, hydrazine monohydrate (24.04 g, 0.75 mol) was added dropwise into the mixture during 1 h under the nitrogen flow. After addition, the reaction mixture was heated to reflux for another 3 h. The mixture was then filtered hot in a glove box. The filtrate was cooled to room temperature and placed in the glove box overnight. The precipitated pale-brown crystals were filtrated, washed with deionized water, and dried in vacuo at 80 °C overnight. The crude solid was recrystallized from ethanol to afford pale-brown crystals (Yield: 45.43 g, 76%); mp: 163.1 °C (DSC peak temperature).

FT-IR (KBr, cm−1): 3408, 3389, 3333, 1612, 1510, 1312, 1275, 802, and 517. 1H-NMR (300 MHz, DMSO-d6, ppm): 6.75 (m, 1H), 6.66–6.64 (m, 4H), 6.46–6.44 (m, 4H), and 4.47 (s, 4H). Elemental analysis: C12H13N3: Cald. C, 72.33%, H, 6.58%, N, 21.09%; Found: C, 72.17%, H, 6.63%, N, 21.03%.

Polyimide synthesis

Five PIs, including two homopolymers derived from PMDA and ODA for PI-1 and PMDA and NDA for PI-5, respectively, and four copolymers from PMDA, ODA, and NDA (PI-2~PI-4), were synthesized via a two-step polycondensation reaction with DMAc as the solvent, followed by high temperature imidization procedure of the poly(amic acid) (PAA) intermediates. The preparation can be illustrated by the synthesis of PI-4.

For the synthesis of PI-4, ODA (4.0048 g, 0.02 mol) and NDA (15.9400 g, 0.08 mol) were added to a 500-mL three-necked flask equipped with a mechanical stirrer, a nitrogen inlet and a cold water bath. DMAc (160.2 g) was added and a gentle stream of nitrogen was passed through the solution. After stirring for 10 min, a clear diamine solution was obtained. PMDA (21.8120 g, 0.10 mol) was then added in one batch and an additional volume of DMAc (30.0 g) was added to wash the residual dianhydride, and at the same time to adjust the solid content of the reaction system to be 18 wt%. The cold water bath was removed after 4 h. The mixture was stirred at room temperature for 20 h to yield a viscous deep brown PAA-4 solution.

The viscous PAA-4 solution was diluted with DMAc to afford a solid content of 12 wt%. Then, the obtained PAA-4 solution was filtered through a 0.45 μm Teflon syringe filter. The purified solution was cast onto a clean glass substrate with a doctor’s blade. The thickness was controlled by adjusting the distance of the slit between the knife and the substrate. The thickness of the PI films for the FT-IR and UV-Vis measurements was controlled to be 10 μm and 20 μm, respectively. Those for the thermal and mechanical property measurement were adjusted to be 30–50 μm.

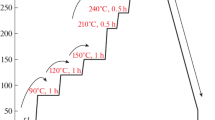

PI-4 film was obtained by thermally baking the PAA-4 solution in an air oven with the following procedure: 80 °C/2 h, 150 °C/1 h, 200 °C/1 h, 250 °C/1 h, 300 °C/1 h, and 350 °C/1 h. The glass substrate was cooled to room temperature and immersed into the deionized water. Free-standing PI-4 film was obtained as a black film.

PI-1, PI-2, PI-3 and PI-5 were prepared according to the similar procedure mentioned above, except that the molar ratio of ODA:NDA was 100:0 for PI-1, 50:50 for PI-2, 40:60 for PI-3, and 0:100 for PI-5.

Results and discussion

PI synthesis and film preparation

A series of PI films were designed and prepared according to the procedure shown in Fig. 4. The PAA precursors were synthesized first and the inherent viscosities and molecular weights were measured. As tabulated in Table 1, the PAAs had inherent viscosity values in a range from 0.98 to 1.33 dL/g. As we know, inherent viscosity is a viscometric method for measuring the molecular size of the polymer. The inherent viscosity values indicated moderate to high molecule weights of the PAAs. The relative molecular weights and the distribution of the PAAs were determined by GPC measurements. As shown in Table 1, the number average molecular weights (Mn) of the PAAs decreased with the increased NDA contents in the polymers. Meanwhile, the polydispersity indices (PDI: Mw/Mn) of the PAAs increased correspondingly. The decrease of the molecular weights and the increased PDI value of the PAA might be due to the side reaction of the PMDA with the secondary amine (-NH-) in NDA. Although the secondary amine had lower reactivity compared to the primary amine (-NH2) in NDA, some side reactions, such as branch reaction might occur; thus causing the unbalanced molar ratio of anhydride to amine. This might deteriorate the mechanical properties of the derived PI films to some extent, which will be discussed below.

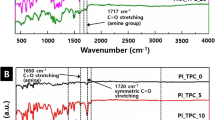

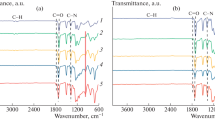

The chemical structure of the PI films was confirmed by the ATR-FTIR measurements. Figure 5 shows the ATR-FTIR spectra of PI films along with that of NDA. The characteristic absorptions of primary amino (-NH2) in NDA (3408 and 3389 cm−1) disappeared in the spectra of PIs, while the absorption of secondary amino (-NH) in NDA (3333 cm−1) existed in the spectra of PI-2~PI-5, indicating successful introduction of the NDA unit in the polymers. In addition, the absorptions at 1772 and 1707 cm−1, due to the asymmetric and symmetric carbonyl stretching vibrations of the imide groups, were all observed in the spectra of PI films. Also, the absorption at 1375 cm−1 assigned to the C-N stretching vibration of the imide structure could be observed for the PI films.

All the PI films exhibited flexible and tough nature although they showed different tensile behaviors in the stress-strain measurements, as could be depicted from Fig. 6 and the tensile property data in Table 2. The PI films showed tensile strength (Ts) of 96.0–131.0 MPa, which gradually decreased with the increased NDA contents in the films. The elongation at break values exhibited similar trend. The deterioration of the tensile properties of the PI films could mainly be attributed to the decreased molecular weights of the PAAs, as discussed above. Interestingly, although the tensile strength and elongation at break values of the PI films incrementally deteriorated with the increased NDA contents, the tensile modulus of the PI films increased apparently. PI-5 film showed a TM value of 2.5 GPa, which was 0.7 GPa higher than that of PI-1. Although the NDA-containing PI films showed inferior tensile properties to their PI-1 analogue, they were high enough to meet the demands of practical applications.

The PI films exhibited an amorphous nature and the WXRD spectra are shown in Fig. 7. The PI films exhibited similar molecular packing status with the broad peaks around 14-15o and 29–30 o, respectively. This is mainly due to the similar molecular configuration of ODA and NDA diamines.

Optical properties

The purpose of the current work is to endow the common yellow PI films black colors via enhancement of CTC formation. Figure 8 illustrates the appearance of PAA solutions and the derived PI films at the thickness of 20 μm. Basically, the color of the PI films gradually deepens with the increased NDA content in the film. It can be clearly seen that the PI films containing NDA components all exhibited deep colors and PI-4 and PI-5 were almost opaque.

The UV-Vis spectra of the NDA-PI films are shown in Fig. 9 and the optical data are tabulated in Table 3. It can be clearly seen from spectra that the UV cutoff wavelength (λcut) values of the PI films increased from 428 nm of PI-1 to 555 nm of PI-5. Incorporation of NDA unit in the PI films greatly decreased the optical transmittance of the films. For example, the 10um-thick PI films became totally opaque at the wavelength of 500 nm when the content of NDA reached 80% (molar ratio) in the diamine components, while PI-1 film without NDA showed a 63.2% of transmittance at the same wavelength.

In order to clarify the colors of the NDA-containing PI films, the CIE Lab parameters of the films were tested. As for the evaluation system, L* represents lightness of the film and the value of 100 means white and 0 implies black. The parameter of positive a* stands for red color and negative value green color. The positive b* indicates yellow and negative value blue color. Thus, in the current work, the lower L* value and positive a* (red) plus negative b* (blue) values are preferred for the PI films in order to obtain a black color (the presence of all three primary colors, red, green and blue) [25, 26]. Figure 10 shows the CIE lab color parameters of the PI films and the data are summarized in Table 3. It can be deduced the color change trend of the PI films with the increased NDA content. With the increase of NDA content in the PI films, the L* value of the film decreased from 89.93 (PI-1) to 23.36 (PI-5), a* value changed from the negative value of PI-1 (−11.09) to the positive values of PI-2~PI-5, and the b* value also decreased gradually. Therefore, the colors of the PI films basically changed from white to black (L* value decreased), from yellow to blue (b* value decreased) and from green to red (a* value increased). All the trends are toward to the direction of black color. Although there is still some distance between the color of the NDA-containing PI films (L* as low as 23.36 for PI-5) to the ideal black color (L* = 0), the molecular design of deepening the colors of common wholly aromatic PI films via enhancing the formation of CTC by introducing NDA component into the film was proven to be effective. The future work might be focused on the molecular and structural design for further decreasing the L* value and adjusting the a* and b* values of the PI films.

CIE lab color parameters of PI films Figure 10 contains poor quality small text inside the artwork. Please do not re-use the file that we have rejected or attempt to increase its resolution and re-save. It is originally poor, therefore, increasing the resolution will not solve the quality problem. We suggest that you provide us the original format. We prefer replacement figures containing vector/editable objects rather than embedded images. Preferred file formats are eps, ai, tiff and pdf.We have uploaded the original figure as attached file (fig 10.tif).

Thermal properties

Good thermal stability is also one of the most important property requirements for the applications of black PI films. The effects of incorporation of NDA component on the thermal properties of the PI films were tested by TGA, DMA and TMA measurements and the data are summarized in Table 2. Figure 11 depicts the TGA plots of the PI film recorded in the range of 50 to 750 °C in nitrogen. It can be seen that incorporation of NDA slightly decreased the initial thermal decomposition temperature of the PI films due to the unstable nature of secondary amine (-NH-) at elevated temperatures. The 5% weight loss temperature (T5%) of PI-5 was 514.6 °C, which was 66.4 °C lower than that of PI-1 film. After 500 °C, the thermal decomposition of the PI films accelerated and left around 60% of their original weight at 750 °C.

The effect of NDA component on the glass transition temperatures (Tg) and coefficient of thermal expansion (CTE) values of the PI films exhibited different trend with that of thermal decomposition, as evidenced by the DMA and TMA plots of the PI films. According to the storage modulus (Fig. 12a) and tan delta (Fig. 12b) curves revealed by DMA measurement, respectively, the incorporation of NDA silghtly increased the modulus and Tg values of the PI films. For instance, PI-5 exhibited a storage modulus of 1050 MPa at 400 °C, whereas PI-1 showed a value of only 370 MPa at the same temperature. In addition, PI-5 showed a Tg value of 431.6 °C (Table 2), which was 12.8 °C higher than that of PI-1 film. As for the high temperature dimensional stability, PI-5 exhibited a CTE value of 18.8 × 10−6/K in the temperature range of 50–250 °C according to the TMA plots in Fig. 13, which is also slightly lower than that of PI-1 film (CTE = 29.5 × 10−6/K). The improvement of glass transition behavior and dimensional stability of NDA-containing PI films might be attributed to the slightly crosslinked molecular structure of the PIs at elevated temperatures. The network structure caused by the partly crosslink of active -NH- unit at elevated temperature showed positive effects on the Tg and CTE values of the PI films; however negative effects on the T5% values. This might be due to the thermally unstable feature of the network structure at temperatures over 500 °C.

Electrical properties

The volume resistivities (ρV) of the PI films were measured and the data were compared so as to estimate the effect of NDA component on the electrical properties of the PI films. Figure 14 compares the volume resistivity values of all PI films. The values decreased slightly with the increased NDA contents in the films. For example, PI-1 showed a ρV value of 1.36 × 1016 Ω cm, while PI-5 showed a bit smaller value of 0.81 × 1016 Ω cm. This is mainly due to the electrical conductivity of the electron in NDA diamine along the conjugated migrating pathway in the PI molecules. Nevertheless, the ρV value of high than 1015 Ω cm guaranteed the good electrical insulating feature for the current PI films.

Conclusions

Color tailoring has been becoming one of the noticeable research topics for the research and development of functional PI films. The driven force mainly comes from the increasing demands of advanced optical PI films in microelectronics and display engineering. In the current work, the endeavors for blackening the conventional yellow PI film via molecular modification were performed. Experimental results revealed that it might be effective to achieve the purpose by incorporation of the electron-rich NDA diamine component. The derived PI films showed black and red colors with extended UV cutoff wavelength and decreased optical transmittance in the visible light region. Meanwhile, the intrinsic thermal stability of the PI films was maintained or slightly improved. The incorporation of NDA slightly decreased the volume resistivity values of the PI films; however, still maintained at a high level of electrical insulating class. Although the tensile properties of the PI films were deteriorated, the current properties could still meet the demand of practical applications. In our future work, the blackness of the PI films would be further enhanced by decreasing the L* value and adjusting the a* and b* values of the PI films via incorporation of novel electron-rich aromatic diamines.

References

Liaw DJ, Wang KL, Huang YC, Lee KR, Lai JY, Ha CS (2012) Advanced polyimide materials: Syntheses, physical properties and applications. Prog Polym Sci 37:907–974

Sazanov YN (2001). Russ J Appl Chem 74:1253–1269

Tsai CL, Yen HJ, Liou GS (2016) Highly transparent polyimide hybrids for optoelectronic applications. Reac Func Polym 108:2–30

Choi MC, Wakita J, Ha CS, Ando S (2009) Highly Transparent and Refractive Polyimides with Controlled Molecular Structure by Chlorine Side Groups. Macromolecules 42:5112–5120

Ando S, Matsuura T, Sasaki S (1997) Coloration of Aromatic Polyimides and Electronic Properties of Their Source Materials. Polym J 29:69–76

Ke FY, Song NH, Liang DH, Xu HY (2013) A method to break charge transfer complex of polyimide: A study on solution behavior. J Appl Polym Sci 127:797–803

Chen GF, Pei XL, Liu JT, Fang XZ (2013) Synthesis and properties of transparent polyimides derived from trans- and cis-1,4-bis(3,4-dicarboxyphenoxy)cyclohexane dianhydrides. J Polym Res 20:159

Damaceanu MD, Constantin CP, Bruma M, Belomoina NM (2014) Highly fluorinated polyimide blends – Insights into physico-chemical characterization. Polymer 55:4488–4497

Ni HJ, Liu JG, Wang ZH, Yang SY (2015) A review on colorless and optically transparent polyimide films: Chemistry, process and engineering applications. J Ind Eng Chem 28:16–27

Matzumoto T, Mikami D, Hashimoto T, Kaise M, Takahashi R, Kawabata S (2009) Alicyclic polyimides – a colorless and thermally stable polymer for opto-electronic devices. J Phys Conf Ser 187:012005

Takizawa K, Wakita J, Azami S, Ando S (2011) Relationship between Molecular Aggregation Structures and Optical Properties of Polyimide Films Analyzed by Synchrotron Wide-Angle X-ray Diffraction, Infrared Absorption, and UV/Visible Absorption Spectroscopy at Very High Pressure. Macromolecules 44:349–359

Hu XF, Mu HL, Wang YX, Wang Z, Yan JL (2018) Colorless polyimides derived from isomeric dicyclohexyl-tetracarboxylic dianhydrides for optoelectronic applications. Polymer 134:8–19

Hasegawa M, Horie K (2001) Photophysics, photochemistry, and optical properties of polyimides. Prog Polym Sci 26:259–335

Romyen N, Thongyai S, Praserthdam P (2010) Surfactant-dispersed carbon black in polyimide nanocomposites: Spectroscopic monitoring of the dispersion state in the polymer matrix. J Appl Polym Sci 115:1622–1629

Zhang QQ, Xu Y, Yang Y, Li LS, Song CR, Su X (2018) Conductive mechanism of carbon black/polyimide composite films. J Polym Eng 38:147–156

Jiang XW, Bin YZ, Matsuo M (2005) Electrical and mechanical properties of polyimide–carbon nanotubes composites fabricated by in situ polymerization. Polymer 46:7418–7424

Xue PF, Bao KB, Li QY, Wu CF (2010) Impact of modification of carbon black on morphology and performance of polyimide/carbon black hybrid composites. Phys Chem Chem Phys 12:11342–11350

Lin JS, Chiu HT (2002). J Polym Res 9:189–194

Atar N, Grossman E, Gouzman I, Bolker A, Murray VJ, Marshall BC, Qian M, Minton TK, Hanein Y (2015) Atomic-Oxygen-Durable and Electrically-Conductive CNT-POSS-Polyimide Flexible Films for Space Applications. ACS Appl Mater Interfaces 7:12047–12056

Kwon J, Kim J, Lee J, Han P, Park D, Han H (2014) Fabrication of polyimide composite films based on carbon black for high-temperature resistance. Polym Compos 35:2214–2220

Chen CJ, Yen HJ, Hu YC, Liou GS (2013) Novel programmable functional polyimides: preparation, mechanism of CT induced memory, and ambipolar electrochromic behavior. J Mater Chem C 1:7623–7634

Hu YC, Chen CJ, Yen HJ, Lin KY, Yeh JM, Chen WC, Liou GS (2012) Novel triphenylamine-containing ambipolar polyimides with pendant anthraquinone moiety for polymeric memory device, electrochromic and gas separation applications. J Mater Chem 22:20394–20402

Yen HJ, Liou GS (2012) Solution-processable triarylamine-based electroactive high performance polymers for anodically electrochromic applications. Polym Chem 3:255–264

Kulszewicz-Bajer I, Rozalska I, Kurylek M (2004) Synthesis and spectroscopic properties of aniline tetramers. Comparative studies. New J Chem 28:669–675

Baldevbhai PJ, Anand RS (2012) Color Image Segmentation for Medical Images using L*a*b* Color Space. IOSR J Electron Commun Eng 1(2):24–45

Becerir B (2017). J Textile Eng Fashion Technol 1(6):240–244

Acknowledgements

Financial support from the Fundamental Research Funds of China University of Geosciences (No. 2652017345) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Tan, Yy., Liu, Jg. et al. Molecular design, synthesis and characterization of intrinsically black polyimide films with high thermal stability and good electrical properties. J Polym Res 26, 171 (2019). https://doi.org/10.1007/s10965-019-1835-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1835-0