Abstract

Silica aerogels are gaining significant importance and have attracted considerable interest due to their extraordinary properties and numerous applications. Silica aerogels are highly porous with high surface area and very low density and thermal conductivity. Usually they are prepared and synthesized via sol-gel technique, which involves making a sol containing a precursor, a solvent and a catalyst. The properties possessed by the final product depend upon numerous factors such as ratio of precursor to solvent and the drying method employed. Due to the flexibility of synthesis methods and the production of aerogels with tailored properties, silica aerogels have found numerous commercial applications and are being investigated of their suitability in several areas, such biomedical and aerospace engineering. Despite having exceptional properties, silica aerogels come with drawbacks such as brittleness and low mechanical strength, which can be resolved by fabricating composites extending the potential applications. This paper reviews the synthesis of silica aerogels via sol-gel technique, and the applications where this extraordinary material has shown promising results. The different materials used for the fabrication of composites to improve and enhance the physical and chemical properties of silica aerogels are also presented.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

It was American scientist Samuel Stephens Kistler who discovered the first known aerogel in 1930 s but the major interest in this material grew around 1970s with the possibility of being used as a catalyst [1, 2]. Aerogels are very light solid materials having high porosity, low density and thermal conductivity (Table 1) [3]. Aerogels’ general classification is provided in Fig. 1. Aerogels are also referred to as “frozen smoke” due to the foam like structure and can have a porosity of up to 99.8 % (Fig. 2) [2, 4, 5].

Reprinted with permission from Ref. [4]. Copyright Elsevier B.V. 2020

Aerogels’ classification.

Reprinted with permission from Ref. [6]. Copyright Elsevier B.V. 2019

Photographs of the laboratory-synthesized silica aerogels: a inorganic aerogel produced in monolithic form; b hybrid aerogel produced in powder; c hybrid aerogel produced in monolithic form.

Aerogels properties render them suitable for industrial and commercial applications, such as insulation, electrical, optical and energy storage devices [11,12,13,14,15,16,17]. Aerogels can be either made of a single material (carbon, silica, alumina etc.) or by combination of different materials forming composites with diverse properties. Composite aerogels are becoming commercially available and drive the demand for several applications. Of particular interest are the bioaerogels, which are based on biomaterials such as alginate and are suitable for biomedical applications [9, 18]. Gurav et al. have reviewed various industrial applications of silica aerogels in detail [3]

Among aerogels, silica aerogels are the most researched. Silica is an abundantand cheap material suitable for materials synthesis for commercial applications [19, 20]. A silica aerogel is a network of interconnecting chains, wherein each chain is made of spherical nanoparticles [10]. Silica aerogels are prepared using the sol-gel technique. The first step is the preparation of a sol comprising of precursor, water and a catalyst [21,22,23]. Precursors are mainly the source of silica and compounds such as tetramethoxysilane (TMOS) and tetraethoxysilane (TEOS) are used [4, 24]. Due to the toxicity of some precursors the trend is to use biomaterials which are abundant and cheap. Sol to gel transition comprises of two steps, namely wet gel formation and drying with an intermediate aging process. Gel drying is a critical step as the properties possessed by the final product are highly influenced by the temperature and pressure applied [9, 25,26,27]. Typically, when hydrogel is the starting material, aerogels are produced by use of supercritical drying, xerogels by conventional drying and cryogels by freeze-drying (Fig. 3) [28, 29]. It is important to note that the cryogels derived from freeze-drying of hydrogels are different than the cryogels synthesized by cryogelation, i.e. in temperature below the freezing point of the system [30,31,32]

Concerning previously published reviews, Dorcheh and Abbasi [5] reviewed the synthesis, characterization and properties of silica aerogels in a paper published in 2008 focusing on using different drying methods. The work of Gurav et al. published in 2010 presents the sol-gel chemistry, synthetic strategies and applications of silica aerogels [3]. In 2014 Maleki et al. [33] reviewed the methods for mechanical reinforcing of silica aerogels. Smirnov and Gurikov published a review in 2017 focusing on approaches that allow tailoring of aerogel properties to meet application-driven requirements [34]. In a paper published in 2017, Amonette and Matyas published a review on functionalized silica aerogels focusing on gas-phase purification, sensing, and catalysis [35]. The same year, Slosarczyk [36] reviewed the synthesis and characterization of silica aerogels focusing on carbon-fiber based silica aerogel nanocomposites. Similarly, in 2018 Lamy-Mendes et al. [14] reviewed silica aerogel composites with carbon nanomaterials such as carbon nanotubes, carbon nanofibers and graphene. Recently, in 2020 Karamikamkar et al. reviewed precursor systems for silica-based aerogel production with improved mechanical properties [4]. Lee et al. review paper on silica aerogel-organic materials composites was also published in 2020 composites focusing on their mechanical properties [37]. Literature review shows that although there are several review papers on silica aerogels they are mostly focusing on specific aspects. An up to date review on silica aerogels, including hybrid composites, is timely following those published in 2008 by Dorcheh and Abbasi [5] and in 2010 by Gurav et al. [3]

2 Synthesis of silica aerogels

As is the case for all aerogels, silica aerogel synthesis is typically based on sol-gel technique and therefore starts with preparation of colloidal mixture of precursor, solvent and catalyst. Figure 3 provides the overview of the key processes in aerogels synthesis. Briefly, the sol-gel process involves the following steps: precursors mixing, hydrolysis, polycondensation, gelation, aging and drying.

Aerogel synthesis scheme. Open access Ref. [9]. Copyright 2019, Elsevier B.V

2.1 Formation of wet gel

It was in 1968 when Stober et al. [38] published a paper presenting a method for the controlled growth of monodispersed spherical silica particles of colloidal dimensions by means of hydrolysis of alkyl silicates. The reactions took place in alcoholic solutions and in the presence of ammonia as catalyst. Since then the method has been extensively used and modified for tailored silica materials synthesis [8, 39], including silica aerogels [40, 41].

The desired properties and the physical appearance highly depend upon the type of sol prepared and the synthesis procedures and reagents. Silica aerogels, therefore, can be achieved and synthesized in various forms such as chunks, granulates powder and others and their properties can be tailored for specific applications [42, 43]. Sol preparation is crucial as the desired properties of silica aerogel rely highly upon it. Different types of solvents, catalysts and precursors can be used to achieve diverse properties. The precursor is the main source of silica that ultimately hydrolyze to form a gel. Conventionally, two types of precursors are used for silica aerogel synthesis; silicon alkoxides and inorganic salts. Tetramethoxysilane (TMOS), tetraethoxysilane (TEOS), polyethoxydsilane (PEDS), methyltriethoxysilane (MTES) and several others have been used as silicon alkoxide precursors [2, 3, 44]. However, these precursors are expensive and hazardous. The current direction is towards cheap and non-hazardous materials while maintaining the same properties as can be achieved through silicon alkoxides. Water glass (sodium silicate) solution is becoming the precursor of choice [3, 45,46,47]. This solution can be made by mixing silica and sodium hydroxide solution. The silica required to make sodium silicate can be extracted from biomass, for instance rice husk which contains 19–22 % of silica. The amount of silica in rice husk also depends upon the origin and rice type [7, 20]. Typically, the solvents used are alcohols such as ethanol, methanol and acetone. Among these, the ethanol is preferably used as it helps in enhancing pore size and surface area more compared to others [24, 48]. Catalysts play a pivotal role by initializing the hydrolysis process, if required, and controlling the rate of gelation. The catalysts employed are either acids or bases. The acid catalyzed sol gives a denser material with less porosity whereas the base catalyzed forms a more porous silica aerogel. In order to achieve the optimal results, it is necessary to control and monitor the pH and gelation time [49, 50]. It has been reported that the base-catalyzed environment generally produces better silica aerogel materials in terms of quality, porosity, uniform distribution and enhanced cross linking capability [51, 52].

2.2 Fluid exchange of wet gel and aging

The aging process has considerable influence on the properties of an aerogel such as porosity, surface area and pore size. Various researchers have studied the effects of prolonged aging [11, 42]. With the prolongation of aging time and temperature, the specific surface area is shown to decrease due to Ostwald ripening processes [7]. Increased aging time results in aerogels with reduced bulk density and linear shrinkage whereas ambient dried gels are shown to possess increased pore size and pore volume [42, 43, 53]. Similarly, the solvent used has a effect on the pore size, pore volume, surface area and optical transmittance of the derived aerogels [54]. Kim and co-authors discussed in detail the effects of different solvents on sodium silicate-based silica aerogel. They used ethanol, toluene and hexane [55].

2.3 Drying

Drying is the final and the most important step as it determines the nature of gel obtained (Fig. 4). The commonly synthesized gels are aerogels, xerogels and cryogels. The fundamental differentiating factor between them is the type of drying method used. The aerogels are usually synthesized via supercritical drying, xerogels via ambient pressure drying while the cryogels are dried using freeze-drying. Hence, all three types of gels show different properties such as porosity and surface area among others. Nevertheless, these properties are also highly dependent upon the type or precursor used to synthesize the basic gel network (silica aerogels, carbon aerogels, polymer aerogels etc.). Silica aerogels can have average pore diameter of 20–40 nm surface area of 600–1000 m2/g, organic and carbon xerogels can have pore size of 2–4 nm with surface area of 300–400 m2/g and cryogels can be mesoporous, such as carbon cryogels, with surface areas greater than 800 m2/g or supra-macroporous with low BET surface area [30]. When coming from the same material, for instance cellulose, the surface area of aerogels can be an order of magnitude higher than this of cryogels and xerogels can have a surface area near to zero [28].

The effect of drying on a hydrogel obtained from cellulose solution. From left to right; hydrogel, aerogel (supercritical drying), cryogel (freeze drying) and xerogel (vacuum drying). Reproduced with permission from Ref. [28]. Springer International Publishing AG

2.3.1 Supercritical drying (SCD)

The high-temperature supercritical drying (HTSCD) was initially employed by Kistler in 1931 and is still used extensively for the production of silica aerogels [56]. This method is carried out in an autoclave using methanol or ethanol as organic solvents and raising temperature and pressure. The pressure is kept above the critical pressure of the solvent and the solvent is slowly vented out at constant temperature. After reaching the ambient pressure, the autoclave is cooled down to room temperature [6, 11, 57, 58]. Because of the high temperature, this method poses fire hazards, which is a strong disadvantage [6, 50]. An alternative is the low-temperature supercritical drying (LTSCD) in which liquid CO2 is used as it has a critical point very close to ambient pressure [5, 58]. Silica aerogels synthesized via LTSCD are less expensive and hydrophilic in nature. The hydrophilicity can be changed through surface modification [2, 55].

2.3.2 Ambient pressure drying (APD)

Commercially, most of the aerogels are produced by supercritical drying, which is expensive and energy intensive process. APD is considered to be a suitable alternative as is cheaper although it involves surface modification, contact angle manipulation and strengthening of network using silylating agents [25, 51, 58,59,60]. During silylation the Si-OH group is replaced by R-alkyl group, resulting in aerogels possessing hydrophobic properties [25, 51, 61]. TMS (trimethylsilyl) groups introduced in the silylation process make the gel to shrink at ambient pressure. Moreover, these groups prevent the liquid infusion during the evaporation. The aerogels dried via APD show enhanced properties in terms of porosity, density and thermal conductivity compared to HTSCD-dried aerogels [18, 59, 60, 62]. However, processing time is between four to seven days and the large amount of chemicals, some of which hazardous, makes this method too costly for large-scale production. However, Bhagat et al. [61] reduced drying duration to one day by using trimethylchlorosilane (TMCS) and hexamethyldisilazane (HMDS) on water-glass solution, producing aerogels of low density and high thermal conductivity. Nevertheless, temperature range to achieve thermally stable aerogel is between 325 and 500 °C.

Many of the researchers have conducted an economic analysis and presented the efficient ways of drying to reduce the cost [6, 63, 64]. Dowson et al. [65] presented a comparison base on Life Cycle Assessment for the aerogels dried with HTSCD and LTSCD. The authors found the drying process to have the major economic impact on the overall aerogel preparation. Garrido et al. [6] made an economic assessment of the silica based aerogels synthesized via APD and found that the cost can be reduced significantly by adopting a hybrid drying method called subcritical drying. Pinto et al. studied the environmental impact of the subcritical production of silica aerogels [66]. The authors used Life Cycle Analysis and concluded that comparing the production of aerogels using subcritical and supercritical drying, and besides the economic and safety advantages, the former may lead to the consumption of less energy resources and cause lower environmental impacts.

2.3.3 Freeze-drying (FD)

This drying method usually involves freezing at low temperature and sublimation under vacuum. Silica, cellulose, clay, graphene and carbon aerogels have been successfully produced by the freeze-drying [67]. For silica aerogels and composite aerogels, freeze-drying at very low temperatures of -50 to -83 oC under vacuum (5–30 Pa) have been reported [68,69,70,71]. Although it is cheaper than supercritical drying and prevents shrinkage [72] it is not widely employed due to the crystallization of solvent in the pores which ultimately creates cracks [48, 67, 72]. Despite the setbacks, this method is still used for silica aerogel composite fabrication. The freeze-drying of a hydrogel does not lead to materials with cryogel properties due to the formation of ice crystals in a gel rather than in a solution [31]. Cryogels formed by cryogelation exhibit superior properties in comparison to hydrogel-derived cryogels.

2.4 Industrial production of silica aerogels

Silica and carbon-based aerogels dominate the industrial production of aerogels. Monsanto Chemicals did the first industrial production of aerogels in ‘50s. Major manufacturers of aerogels are BASF, American Aerogel Corporation, Dow Corning, Cobot Corporation, Svenska Aerogel AB, Airglass AB, JIOS AEROGEL, Aspen Aerogels Inc, Active Space Technologies and Acoustiblok UK Ltd. The market was valued at $353.6 mn in 2015 and is expected to reach a valuation of $1100.2 mn by the end of 2024. Insulation materials based on silica aerogels produced by Aspen Aerogels and Cabot Corp. (USA) are well-established in the market [34]. The price of bulk quantity aerogel blanket is from around $40 to $150/m2. The industrial production of silica aerogels depends on the availability and cost of the raw materials used for their manufacturing. Conventional silica production is energy intensive because the precursor of silica, sodium silicate, is procured by the reaction of quartz sand with sodium carbonate at high temperatures [73]. Wholesale price of indusial grade fumed silica ranges from $2.8 to $5.5/kg. Silica is ubiquitous across plants, ranging from 0.1 to more than 10 % dry weight [74]. Besides organic silicates and water glass, ashes of various biowastes, such as rice husk, maize stalk, bagasse, bamboo leaves and wheat husk have been used as a silica source for several applications including aerogel production [2, 73, 75]. Silica is ubiquitous across plants, ranging from 0.1 to more than 10% dry weight [74]. Xu et al. reviewed the silica production from lignocellulosic biorefinery feedstocks [74]. The studied feedstocks were pearl millet-napiergrass, napiergrass, annual sorghum, pearl millet, perennial sorghum, switchgrass, sunn hemp, giant miscanthus and energy cane. Silica yield among feedstock entries ranged from 41 to 3249 kg/ha. Rice contains 19–22% of silica, which is much higher than many other biomass sources [76, 77]. The company “Green Earth Aerogels” has commercialized the production of silica aerogels from rice husks [2].

3 Applications of silica aerogels

The unique properties of aerogels made them suitable for several applications as shown in Table 2.

These unique properties have led to diverse applications such as thermal insulation, catalysis, storage media, ion exchange etc. The most pivotal application is thermal insulation. Due to its high porosity and low thermal conductivity, various forms of aerogels such as monoliths, granules, or powders have been used for thermal insulation in buildings, appliances, automobiles and even solar devices [3]. On the other hand, aerogels being the lightest synthetic solids with high surface area are showing remarkable results when used as a catalyst [50, 54]. Aerogels that are transparent and have a low refractive index are used as light-weight optics and Cherenkov detectors. These materials are also used as energy absorber and for hypervelocity particle trapping as these can be modified to possess higher elasticity with light weight [3]. Just like mechanical properties, aerogels have also shown promising results when used as capacitors and dielectrics for ICs as these may have lowest dielectric constant with higher surface area [13]. Due to the ability to bind with other metal oxides, silica aerogels have been used as composite materials for various applications [14, 46, 60, 91], which will be discussed in the next section. Several researchers have described the synthesis of different silica aerogel composites such as silica carbon, silica titania, silica and alumina microfibers and activated carbon fiber composite aerogels [3, 22, 36]. Hydrophobic silica aerogels have been used as absorbents for organic solvents and oils [25, 58, 79]. Aerogels have found their use as sensors as they usually possess high porosity and surface area. Wang et al. [16] studied silica aerogel thin films and found that the electrical resistance decreased as humidity increased. Similarly, Li et al. [80] studied the use of aerogels as biosensors. Silica aerogels have attracted significant attention towards integrated circuits applications due to their unique properties such as ultra-dielectric constant, porous nature and high thermal stability [51, 55, 80]. The high surface area of silica aerogels make them suitable as catalysts and catalyst carriers [54]. These same properties show the possibility of aerogels to be used gas filters, encapsulation & absorbing media and hydrogen fuel storage [81]. Sintered aerogels can be used for thickening, storage and transport of liquids as they are known to resist the gas/liquid tensions. Silica aerogels films with high surface area were used for dye sensitized solar cells. Silica aerogels have very low thermal conductivity, which make them a suitable material for insulation [82]. Most recently, Naim et al. [83] used caffeine imprinted surface-funtionalized silica aerogel to adsorb polycyclic aromatic hydrocarbons [83]. Asmussen et al. [49] developed a silver functionalized silica aerogel to capture Iodine from radioactive waste. NASA used aerogels to trap space dust particles and as thermal insulators for Mars Rover and space suits [84]. Silica is a popular material in biomedical research as it is biocompatible when introduced into the human body. Recently, Esquivel-Castro et al. published a review on biocompatible aerogels applications for drug delivery [8]. As is clear, the unique properties of silica aerogels offer a variety of new possibilities in innovative applications.

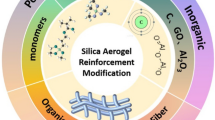

4 Silica aerogel hybrid composites

Silica aerogels are remarkable materials but they come with some disadvantages. For instance, they may be fragile and sensitive to relatively low pressures [37]. Recent developments in synthesis have made it possible to produce silica composite aerogels with improved properties [10, 14, 24, 59, 60, 83]. For instance high mechanical strength silica aerogels can be obtained by combining silica with carbons, organoalkoxysilanes and polymers [37]. Silica-carbon composites have been extensively studied and is a combination which provides interesting properties [19, 85, 86]. Another important development was the doping of noble metals such as gold in an ambient pressure dried silica aerogel [87]. Ren and Zhang [88] used growth approach of Au nanoparticles by reducing agent during pre-hydrolysis. Compared to native silica aerogels, surface modification through cross-linking with epoxies was reported to enhance module by two orders of magnitude [89]. Mechanical strength and photocatalytic properties of aerogels were shown to improve when cross-linked with mineral such as TiO2 [22, 79]. However, the cross-linking approach increases the density and lowers the thermal insulation of the aerogels [90]. Silica aerogel composites have been studied for biomedical applications, especially drug delivery [8]. Table 3 shows the different silica aerogel composites synthesized with enhanced properties. Formation of aerogel composites is mostly achieved by sol-gel process.

Gupta and Ricci [45] reported the synthesis of silica aerogel composite having high strength and compressive modulus compared to native silica aerogel granulate but with 12 times higher density. This shows the epoxy infiltration in the pores and compromising the aerogel properties. Similarly, Ge et al. [46] investigated the thermal conductivity offered by epoxy binder silica aerogel composite. Most recently, Saad et al. [83] imprinted surface-functionalized caffeine on to the porous silica aerogels for the adsorption of polycyclic aromatic hydrocarbons (PAHs) (Fig. 5). They found the caffeine-silicon and water-silicon ratios to have significant influence over the adsorption capacity. After the adsorption capacities were compared of the imprinted aerogels and non-imprinted ones, the researchers found the former to possess higher adsorption capacity than the later.

SEM micrographs for imprinted (a, b, c) and non-imprinted (d, e, f) silica aerogels. Reproduced with permission from Ref. [83] Copyright Elsevier Inc. 2019

de Fátima et al. [59] synthesized granular silica-based aerogels at ambient pressure having hybrid network of monoliths by using TEOS and DMDES as two co-precursors (Fig. 6). The ratios between the precursors used and water and precursors was found to have an influence over the properties possessed by the end product. To improve the hydrophobicity, stability and three-dimensional pore structure, they aged the prepared material in solution of hexamethyldisilazane in 2-PrOH. Thus they could successfully synthesize the granular silica-based aerogels containing minimum amounts of organic co-precursors at ambient pressure and possessing balanced overall properties.

Scheme of the preparation of the hybrid aerogel monoliths. Reproduced with permission from Ref. [59] Copyright Elsevier Ltd. 2020

Wang et al. [24] synthesized porous aerogels by using TEOS, hydroquinone and dihydroxybenzene using acid catalyst (Fig. 7). Efficient, simple and cost effective sol-gel method was employed. The hydroquinone-TEOS (HT) bridged silica aerogels showed improved mechanical strength, high surface area, high porosity and hydrophobic in nature [24]. Kaya et al. [95] synthesized silica aerogels and xerogels from inexpensive materials such as bean pod and ash steel slag. They prepared both the gels using sol-gel method and compared the results via characterization. They achieved a surface area of 371 m2/g in silica aerogel synthesized from steel slag (Fig. 8).

The reaction between hydroquinone and TEOS and the resulting aerogels. Reproduced with permission from Ref. [24]. Copyright Elsevier Inc. 2020

N2 adsorption-desorption isotherms of silica xerogel/aerogel synthesized from a steel slag and b bean pod ash. Reproduced with permission from Ref. [95]. Copyright Elsevier B.V. and The Society of Powder Technology Japan 2019

Ebisike et al. [21] prepared a hybrid aerogel of chitosan-silica using sol-gel method. Chitosan and silica were obtained from agricultural waste of crab shell and bamboo leaves. The synthesis was accomplished at ambient pressure. Asmussen et al. [49] developed a silver-functionalized aerogel (AgAero) as a novel material for effective iodine capture from radioactive waste. Du et al. [60] prepared silica aerogel composite by reinforcing mullite-fiber and without surface modification or solvent exchange. Unlike other complex preparation procedures, the study used a facile and simple method. The prepared silica aerogel composite was synthesized at ambient pressure and showed low thermal conductivity, therefore making it suitable and effective as thermal insulating material. Rocha et al. [96] prepared fiber reinforced silica aerogel composite and evaluated its compliance in terms of its thermal insulation property for Mars exploration. The researchers simulated the Mars environment in the laboratory and assessed if the composite exhibited the same thermal insulation property. It was shown that the thermal cycling or environment did not affect the insulation performance of the aerogels and therefore qualify it to withstand Mars environmental conditions [96]. A number of papers has been published the last decade on the mechanical and thermal properties of aerogels and composites using computational modeling through molecular dynamics (MD) simulations [97,98,99,100]. These studies investigated the mechanical properties of aerogels under large deformation [101], fracture mechanical properties [99], nanoindentation tests on pure [98] and graphene-reinforced nanocomposites [102]. Patil et al. [66] modeled silica aerogel nanocomposites by adding randomly dispersed glass fibers. They used LAMMPS (Large Scale Atomic/Molecular Massively Parallel Simulator) to carry out MD simulations. The influence of weight % as well as length to diameter ratio on the mechanical properties was investigated (Figs. 9 and 10). It was found that in the tensile tests, weight % of glass fibers improved the tensile strength and elastic modulus with the decrease in ultimate tensile strain [66].

Schematic representation of silica aerogel nanocomposites. Reproduced with permission from Ref. [10]. Copyright Elsevier Ltd 2020

a Comparison of tensile stress–strain curves of pure silica aerogel and nanocomposites b Snapshots of the nanocomposite model with weight of 25.82% of glass fiber at different strains during the tensile test. Silica aerogel matrix is represented in light gray. Reproduced with permission from Ref. [10]. Copyright Elsevier ltd 2020

Talebi et al. [103] prepared a novel material by merging silica aerogel with polyester (PET). The aim was to use the material as a blanket for sound absorption in buildings. Researchers used polyester (PET) needle punched nonwoven fabrics as the reinforcement substrates. The process involved series of barbed needles and consolidation of fibers of carded web. Consequently, the blankets were prepared by in situ synthesis of silica aerogel on a consolidated nonwoven fibers of carded web via two step sol-gel process of tetraethoxysilane followed by ambient pressure drying (Fig. 11). The composite showed promising results and a suitable candidate for sound absorption in buildings [103]. Similarly, Karamikamkar et al. [4] reviewed the various methods found in the literature for the improvement of the mechanical properties of silica aerogels. The study explored the synthesized silica aerogel composites along with novel properties and applications of these material systems in a wide area. Many studies focused on the production of silica aerogel composites with glass fibers. Parmenter and Milstein [43] synthesized fiber-reinforced silica aerogel composite and they found that with the increase of fiber reinforcement, fiber percentage, compressive strength and hardness increased while the fracture strain decreased. Yuan et al. [92] produced glass fiber reinforced aerogel composite using randomly dispersed glass fibers into aerogel powder. Glass fibers were found to enhance composite strength but lowered thermal insulation. Liao et al. [91] tailored laminated nanocomposites of silica aerogels with four glass fiber layers which improved the mechanical properties of nanocomposites. Zhou et al. [69] used methltrimethoxysilane (MTMS) and water glass precursor to synthesize glass fiber-reinforced silica aerogel composites and they observed improvement of the overall mechanical strength and flexibility of composites.

The untreated nonwoven fabrics geometry. Reproduced with permission from Ref. [103] Copyright 2019

5 Conclusions, opportunities and challenges

The unique properties of silica aerogels have made them versatile materials suitable for diverse applications from environmental applications to Mars exploration. This success is a result of several innovations over more than 80 years that addressed synthesis and properties drawbacks. For instance, the high cost and hazardous nature of silicon alkoxides have given way to sodium silicate as a preferable precursor and ambient pressure drying over supercritical drying have significantly reduced the production costs. Environmental-friendly and cheaper raw materials are gaining attention, especially for commodity applications. Lignin, starch, cellulose and other agricultural by-products are some examples of low cost and environmentally friendly raw materials. Another major issue is related to aerogels brittleness and poor mechanical properties. These can be addressed by embedding different materials into the aerogels during sol-gel process to synthesize silica aerogel hybrid composites. Hybrid silica aerogel composites possess enhanced properties such as higher strength and flexibility at the cost of low thermal conductivity and increased density.

The aerogels market is driven by the increasing demand for energy-efficiency both in terms of prices and reduction of greenhouse gas emissions [104]. Despite the success in terms of research, a recent market analysis values the aerogel market, dominated by silica aerogels, at under $300 million. This figure is below expectations, which demonstrates that the industry is still in its infancy covering only specific applications [105]. This is mainly a result of properties limitations, such as brittleness, and high price tag. Thus, the development of aerogels suitable for large-scale and low cost production with broad uses in mature industries (e.g. automotive, oil and gas industries) is necessary. In this direction is the recent research, which allowed the synthesis of transparent versions of silica aerogels suitable for solar thermal collectors [106, 107]. Another potential direction is the development of different cost-effective suitable for high-tech applications but the poor machinability limits the use of silica aerogels in applications where microstructures are necessary. A recent paper published in Nature discussed the use of additive manufacturing as an alternative route for silica aerogels miniaturization [108]. This 3D-printing process is free from the issues of subtractive manufacturing and allows the development of new applications suitable for industrial production. Another example is aero-propulsion systems where aerogels weight and space constraints can be resolved by a single-layered micro-thick thermally sprayed coatings [109]. Besides the technical aspects, another challenge in the development of large-scale production are the gaps between basic research, industrial applications and government regulators [110], but this is nothing new and past success with other materials can provide useful lessons.

References

O.R. Evans, W.E. Rhine, J.F. Nebo, J.R. Abeles, Jon C. 10, 233,303 (2020)

I. Smirnova, P. Gurikov, J. Supercrit. Fluids 134, 228 (2018)

J.L. Gurav, I.K. Jung, H.H. Park, E.S. Kang, D.Y. Nadargi, J. Nanomater. 2010, (2010)

S. Karamikamkar, H.E. Naguib, C.B. Park, Adv. Colloid Interface Sci. 276, 102101 (2020)

A. Soleimani Dorcheh, M.H. Abbasi, J. Mater. Process. Technol. 199, 10 (2008)

R. Garrido, J.D. Silvestre, I. Flores-Colen, M. de F. Júlio, M. Pedroso, J. Non. Cryst. Solids 516, 26 (2019)

Q. Feng, K. Chen, D. Ma, H. Lin, Z. Liu, S. Qin, Y. Luo, Colloids Surfaces A Physicochem. Eng. Asp. 539, 399 (2018)

T.A. Esquivel-Castro, M.C. Ibarra-Alonso, J. Oliva, A. Martínez-Luévanos, Mater. Sci. Eng. C 96, 915 (2019)

F.P. Soorbaghi, M. Isanejad, S. Salatin, M. Ghorbani, S. Jafari, H. Derakhshankhah, Biomed. Pharmacother. 111, 964 (2019)

S.P. Patil, P. Shendye, B. Markert, Scr. Mater. 177, 65 (2020)

A. Venkateswara Rao, N.D. Hegde, H. Hirashima, J. Colloid Interface Sci. 305, 124 (2007)

G. Zu, J. Shen, X. Wei, X. Ni, Z. Zhang, J. Wang, G. Liu, J. Non. Cryst. Solids 357, 2903 (2011)

M. Juzkow, Power Electron. 28, 58 (2002)

A. Lamy-Mendes, R.F. Silva, L. Durães, J. Mater. Chem. A 6, 1340 (2018)

D. Wang, F. Zhang, J. Tang, Electrochemistry 83, 84 (2015)

C.T. Wang, C.L. Wu, I.C. Chen, Y.H. Huang, Sensors Actuators, B Chem. 107, 402 (2005)

S. Bag, P.N. Trikalitis, P.J. Chupas, G.S. Armatas, M.G. Kanatzidis, Science (80-.). 317, 490 (2007)

Y. Kobayashi, T. Saito, A. Isogai, Angew. Chem. Int. Ed. Engl. 53, 10394 (2014)

N. Mittal, R. Kumar, G. Mishra, D. Deva, A. Sharma, Adv. Mater. Interfaces 3, 1 (2016)

S. Azat, A.V. Korobeinyk, K. Moustakas, V.J. Inglezakis, J. Clean. Prod. 217, 352 (2019)

K. Ebisike, A.E. Okoronkwo, K.K. Alaneme, J. King Saud Univ. - Sci. 32, 550 (2020)

Z. Xu, L. Gan, Y. Jia, Z. Hao, M. Liu, L. Chen, J. Sol-Gel. Sci. Technol. 41, 203 (2007)

A. Venkateswara Rao, S.D. Bhagat, H. Hirashima, G.M. Pajonk, J. Colloid Interface Sci. 300, 279 (2006)

Q. Wang, D.B. Mahadik, P. Meti, Y.D. Gong, K.Y. Lee, H.H. Park, Microporous Mesoporous Mater. 294, 109863 (2020)

S.D. Bhagat, C.S. Oh, Y.H. Kim, Y.S. Ahn, J.G. Yeo, Microporous Mesoporous Mater. 100, 350 (2007)

E.J. Zanto, S.A. Al-Muhtaseb, J.A. Ritter, Ind. Eng. Chem. Res. 41, 3151 (2002)

R. Rodríguez-Dorado, C. López-Iglesias, C.A. García-González, G. Auriemma, R.P. Aquino, and P. Del Gaudio, Molecules 24, 4 (2019)

N. Buchtová, T. Budtova, Cellulose 23, 2585 (2016)

G. Hayase, S. Nagayama, K. Nonomura, K. Kanamori, A. Maeno, H. Kaji, K. Nakanishi, J. Asian Ceram. Soc. 5, 104 (2017)

A. Baimenov, D.A. Berillo, S.G. Poulopoulos, V.J. Inglezakis, Adv. Colloid Interface Sci. 276, 102088 (2020)

O. Okay, Polymeric Cryogels Macroporous Gels with Remarkable Properties (2014)

Z.J. Rogers, S.A. Bencherif, Gels 5, 6 (2019)

H. Maleki, L. Durães, A. Portugal, J. Non. Cryst. Solids 385, 55 (2014)

I. Smirnova, P. Gurikov, Annu. Rev. Chem. Biomol. Eng. 8, 307 (2017)

J.E. Amonette, J. Matyáš, Microporous Mesoporous Mater. 250, 100 (2017)

A. Ślosarczyk, Nanomaterials 7, (2017)

K.Y. Lee, D.B. Mahadik, V.G. Parale, H.H. Park, J. Korean Ceram. Soc. 57, 1 (2020)

W. Stöber, A. Fink, E. Bohn, J. Colloid Interface Sci. 26, 62 (1968)

Y.J. Wong, L. Zhu, W.S. Teo, Y.W. Tan, Y. Yang, C. Wang, H. Chen, J. Am. Chem. Soc. 133, 11422 (2011)

M. Moner-Girona, A. Roig, E. Molins, J. Llibre, J. Sol-Gel. Sci. Technol. 26, 645 (2003)

H. Cai, Y. Jiang, J. Feng, S. Zhang, F. Peng, Y. Xiao, L. Li, J. Feng, Mater. Des. 191, 108640 (2020)

D.B. Mahadik, A.V. Rao, R. Kumar, S.V. Ingale, P.B. Wagh, S.C. Gupta, J. Porous Mater. 19, 87 (2012)

K.E. Parmenter, F. Milstein, J. Non. Cryst. Solids 223, 179 (1998)

C.J. Lee, G.S. Kim, S.H. Hyun, J. Mater. Sci. 37, 2237 (2002)

N. Gupta, W. Ricci, J. Mater. Process. Technol. 198, 178 (2008)

D. Ge, L. Yang, Y. Li, J.P. Zhao, J. Non. Cryst. Solids 355, 2610 (2009)

C.Q. Hong, J.C. Han, X.H. Zhang, J.C. Du, Scr. Mater. 68, 599 (2013)

R. Daoussi, S. Vessot, J. Andrieu, O. Monnier, Chem. Eng. Res. Des. 87, 899 (2009)

R.M. Asmussen, J. Matyáš, N.P. Qafoku, A.A. Kruger, J. Hazard. Mater. 379, 119364 (2019)

P. Gerard, Aerogel Synthesis. Catalyst Preparation (CRC Press, Boca Raton, 2006)

S.D. Bhagat, Y.H. Kim, M.J. Moon, Y.S. Ahn, J.G. Yeo, Solid State Sci. 9, 628 (2007)

M.A.B. Meador, E.F. Fabrizio, F. Ilhan, A. Dass, G. Zhang, P. Vassilaras, J.C. Johnston, N. Leventis, Chem. Mater. 17, 1085 (2005)

P. Shajesh, S. Smitha, P.R. Aravind, K.G.K. Warrier, J. Sol-Gel. Sci. Technol. 50, 353 (2009)

H. Maleki, N. Hüsing, Appl. Catal. B Environ. 221, 530 (2018)

M.R. Kim, J.H. Oh, K.S. Oh, J.K. Lee, 10,197,211 (2019)

A.M. Ibrahim, B.T. Chiad, W.A.A. Twej, R.A. Mohammed, Iraqi J. Sci. 60, 119 (2019)

M.Y. Nassar, I.S. Ahmed, M.A. Raya, J. Mol. Liq. 282, 251 (2019)

S.D. Bhagat, A.V. Rao, Appl. Surf. Sci. 252, 4289 (2006)

M. de F. Júlio, L.M. Ilharco, Materialia 9, 100527 (2020)

D. Du, Y. Jiang, J. Feng, L. Li, J. Feng, Vacuum 173, 109117 (2020)

S.D. Bhagat, Y.H. Kim, Y.S. Ahn, J.G. Yeo, Appl. Surf. Sci. 253, 3231 (2007)

A. Venkateswara Rao, M.M. Kulkarni, G.M. Pajonk, D.P. Amalnerkar, T. Seth, J. Sol-Gel. Sci. Technol. 27, 103 (2003)

I. De Marco, S. Miranda, S. Riemma, R. Iannone, Chem. Eng. Trans. 49, 319 (2016)

I. De Marco, S. Riemma, R. Iannone, J. Supercrit. Fluids 143, 305 (2019)

M. Dowson, M. Grogan, T. Birks, D. Harrison, S. Craig, Appl. Energy 97, 396 (2012)

I. Pinto, J.D. Silvestre, J. de Brito, M.F. Júlio, J. Clean. Prod. 252, (2020)

Y. Pan, X. Cheng, T. zhou, L. Gong, H. Zhang, Mater. Lett. 229, 265 (2018)

Y. Pan, S. He, L. Gong, X. Cheng, C. Li, Z. Li, Z. Liu, H. Zhang, Mater. Des. 113, 246 (2017)

T. Zhou, X. Cheng, Y. Pan, C. Li, L. Gong, H. Zhang, Appl. Surf. Sci. 437, 321 (2018)

F. He, X. He, W. Yang, X. Zhang, L. Zhou, J. Non. Cryst. Solids 488, 36 (2018)

J. Zhu, J. Hu, C. Jiang, S. Liu, Y. Li, Carbohydr. Polym. 207, 246 (2019)

H. Tamon, H. Ishizaka, T. Yamamoto, T. Suzuki, Dry. Technol. 19, 313 (2001)

P. Terzioğlu, S. Yücel, Ç Kuş, Asia-Pacific J. Chem. Eng. 14, 1 (2019)

Y. Xu, N. Porter, J.L. Foster, J.P. Muir, P. Schwab, B.L. Burson, R.W. Jessup, Agronomy 10, 1 (2020)

J.A. Adebisi, J.O. Agunsoye, S.A. Bello, M. Haris, M.M. Ramakokovhu, M.O. Daramola, S.B. Hassan, Part. Sci. Technol. 38, 667 (2020)

S. Azat, E. Arkhangelsky, T. Papathanasiou, A.A. Zorpas, A. Abirov, V.J. Inglezakis, Comptes Rendus Chim. 23, 77 (2020)

H. Nguyen, M.Jamali Moghadam, H. Moayedi, J. Mater. Cycles Waste Manag. 21, 1039 (2019)

J. Choi, D.J. Suh, Catal. Surv. from Asia 11, 123 (2007)

L. Casas, A. Roig, E. Rodríguez, E. Molins, J. Tejada, J. Sort, J. Non. Cryst. Solids 285, 37 (2001)

Y.K. Li, D.K. Yang, Y.C. Chen, H.J. Su, J.C. Wu, and Y. W. Chen-Yang, Acta Biomater. 6, 1462 (2010)

M. Koebel, A. Rigacci, P. Achard, J. Sol-Gel. Sci. Technol. 63, 315 (2012)

A.J. Hunt, C.A. Jantzen, W. Cao, in ASTM Spec. Tech. Publ., edited by R. S. Graves and D. C. Wysocki (ASTM International, West Conshohocken, PA, 1991), pp. 455–463

N. Saad, M. Chaaban, D. Patra, A. Ghanem, H. El-Rassy, Microporous Mesoporous Mater. 292, 109759 (2020)

M. Nuckols, J. Henkener, J. Chao, C. Shaffer, M. Swiergosz, Proc. Int. Conf. Offshore Mech. Arct. Eng. - OMAE 2006, (2006)

G. Mishra, N. Mittal, A. Sharma, ACS Appl. Mater. Interfaces 9, 19371 (2017)

N. Mittal, D. Deva, R. Kumar, A. Sharma, Carbon N. Y. 93, 492 (2015)

M.F. Bertino, J.F. Hund, G. Zhang, C. Sotiriou-Leventis, A.T. Tokuhiro, N. Leventis, J. Sol-Gel. Sci. Technol. 30, 43 (2004)

H. Ren, L. Zhang, Colloids Surfaces A Physicochem. Eng. Asp. 372, 98 (2010)

M.A.B. Meador, S.L. Vivod, L. McCorkle, D. Quade, R.M. Sullivan, L.J. Ghosn, N. Clark, L.A. Capadona, J. Mater. Chem. 18, 1843 (2008)

H. Wu, Y. Chen, Q. Chen, Y. Ding, X. Zhou, H. Gao, J. Nanomater. 2013, (2013)

Y. Liao, H. Wu, Y. Ding, S. Yin, M. Wang, A. Cao, J. Sol-Gel. Sci. Technol. 63, 445 (2012)

B. Yuan, S. Ding, D. Wang, G. Wang, H. Li, Mater. Lett. 75, 204 (2012)

X. Yang, Y. Sun, D. Shi, J. Liu, Mater. Sci. Eng. A 528, 4830 (2011)

J.L. Mohanan, S.L. Brock, Chem. Mater. 15, 2567 (2003)

G. Guzel Kaya, E. Yilmaz, H. Deveci, Adv. Powder Technol. 31, 926 (2020)

H. Rocha, U. Lafont, C. Semprimoschnig, Acta Astronaut. 165, 9 (2019)

W. Gonçalves, J. Morthomas, P. Chantrenne, M. Perez, G. Foray, C.L. Martin, Acta Mater. 145, 165 (2018)

S.P. Patil, V.G. Parale, H.H. Park, B. Markert, Mater. Sci. Eng. A 742, 344 (2019)

S.P. Patil, A. Rege, M. Itskov, B. Markert, J. Non. Cryst. Solids 498, 125 (2018)

L.D. Gelb, J. Phys. Chem. C 111, 15792 (2007)

S.P. Patil, A. Rege, M. Sagardas, Itskov, B. Markert, J. Phys. Chem. B 121, 5660 (2017)

S.P. Patil, Molecules 24, (2019)

Z. Talebi, P. Soltani, N. Habibi, F. Latifi, Constr. Build. Mater. 220, 76 (2019)

“business innovation observatory Aerogels, getting their second wind - Google Search.” https://www.google.com/search?q=business+innovation+observatory+Aerogels%2 C+getting+their+second+wind&oq=business+innovation+observatory+Aerogels%2 C+getting+their+second+wind&aqs=chrome.69i57j69i60.300j0j7&sourceid=chrome&ie=UTF-8 (accessed Apr. 13, 2021).

“Aerogels 2021–2031: Technologies, Markets and Players: IDTechEx.” https://www.idtechex.com/en/research-report/aerogels-2021-2031-technologies-markets-and-players/801 (accessed Apr. 13, 2021).

E. Strobach, B. Bhatia, S. Yang, L. Zhao, E.N. Wang, J. Non. Cryst. Solids 462, 72 (2017)

“Making a remarkable material even better | MIT Energy Initiative.” https://energy.mit.edu/news/making-a-remarkable-material-even-better/ (accessed Apr. 13, 2021).

S. Zhao, G. Siqueira, S. Drdova, D. Norris, C. Ubert, A. Bonnin, S. Galmarini, M. Ganobjak, Z. Pan, S. Brunner, G. Nyström, J. Wang, M.M. Koebel, W.J. Malfait, Nature 584, 387 (2020)

A.R.A. Talib, M.I.N. Bheekhun, Struct. Heal. Monit. Biocomposites, Fibre-Reinforced Compos. Hybrid Compos (Elsevier, 2018), pp. 191–225

C.A. García-González, T. Budtova, L. Durães, C. Erkey, P. Del Gaudio, P. Gurikov, M. Koebel, F. Liebner, M. Neagu, I. Smirnova, Molecules 24, (2019)

Author information

Authors and Affiliations

Contributions

Conceptualization, F.A. and S.A.S.; methodology, F.A. and V.J.I; investigation, F.A.; resources, S.A.S. and M.S.; writing—original draft preparation, F.A.; writing—review and editing, V.J.I.; supervision, S.A.S. and M.S; project administration, V.J.I; funding acquisition, V.J.I. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akhter, F., Soomro, S.A. & Inglezakis, V.J. Silica aerogels; a review of synthesis, applications and fabrication of hybrid composites. J Porous Mater 28, 1387–1400 (2021). https://doi.org/10.1007/s10934-021-01091-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-021-01091-3