Abstract

In our previous study, we found that Enterobacter strain TS3 is able to decolorize of textile wastewater (TW) through a fermentative polyhydroxyalkanoate (PHA) production process. This current study aimed to enhance the ability of strain TS3 to produce PHA using TW by a UV-light radiation-based mutagenesis system, and to enhanced PHA by multiple-round UV-light radiation. The highest PHA-production mutant was obtained in the second rounds of UV-light radiation. The radiation time was optimized to 40 s in the first round followed by 20 s at a distance of 60 cm of plates. The mutant strain TS3-UV2 yielded PHA production at 84.96 ± 1.32% cell dry mass (CDM). The highest PHA concentration (88.66 ± 1.00% CDM) is achieved at pH 7, 150 rpm and 35 °C for 60 h of incubation. Under optimal condition, the mutant yielded 0.53 times more production of PHA than the parent strain. Moreover, the decolorization efficiency of TW was observed to be 72.32% under optimal PHA conditions. Interestingly, the mutant strain could synthesize the medium-co-long-chain-length PHA (mcl-co-lcl PHA), while short-co-medium-chain-length PHA (scl-co-mcl PHA) was observed in the wild type using TW as substrate. Therefore, the mutation and optimization strategy appear to be suitable for producing high-density PHA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Worldwide, approximately 35 kg of plastic per capita are consumed annually and this quantity is increasing every day. The largest plastic waste comes from the packaging industry: two-thirds is generated by households and one-third by industry and commerce [1]. Today, most plastic is derived from petrochemicals such as polyethylene (PE) and polypropylene (PP). However, plastic typically become garbage once used and is a major concern due to its many negative environmental impacts. The major disadvantage of synthetic plastics is that they do not degrade naturally and many toxins are produced during their production and combustion [2, 3]. Many environmentally friendly plastics are being studied, among which are PHA. PHA are a family of polyesters that can synthesized and stored intracellularly by microorganisms. The properties of PHA are similar to those of synthetic plastics that made from petrochemicals, such as PE and PP [4], whereas PHA can be completely biodegraded by PHA depolymerase at a high rate in approximately 3 to 9 months and the products after biodegradation are environmentally friendly. However, the major limitation of PHA production is the high costs [5]. Therefore, the commercial use of PHA is dependent on low production costs and the feasibility of mass production. Reducing the production costs and increasing production estimates can be done in several ways, such as using low-cost substrates or engineering the nutrient metabolic control.

Southern Thailand has a famous straw mat weaving industry. The process to dye the product generates wastewater. If the wastewater is not completely treated, it will affect the environment, which is currently a major problem in the world. Normally, TW is treated using a physical method (precipitation) [6]. However, the disadvantages of current physical methods include long treatment times, a large amount of sludge after treatment and incomplete degradation of chemical toxicity in the dye [7].

Currently, there are many studies producing PHA using wastewater as substrate. However, low content of PHA was reported. Bacillus megaterium and Sphingobacterium sp. produced 60.02% and 46.50% of PHA using TW, respectively [8, 9]. In our previous study, Enterobacter isolated from TW showed a good ability to decolorize TW and produce PHA at 83.94% CDM, respectively. Moreover, this strain produced scl-co-mcl PHA, which had not been previously reported. Therefore, this TW is interesting for use as a precursor for PHA production. However, to our knowledge no application of UV-radiation to improved PHA production in Enterobacter sp. have been reported. PHA productivity is ultimately controlled by the organism’s genome [10]. Consequently, genetic alteration is an attractive route for the process development of this biotechnology. The improvement of microbial strains for the production of PHA has attracted attention in the commercial fermentation process [11]. There are many reports of increased PHA production yield through genetic improvements using mutagenesis via mutagenic agents, such as ultraviolet (UV), X-rays and gamma radiation. Shamala and Divyashree [12] used gamma irradiation for Bacillus flexus mutation, which resulted in cell damage and isolated 45% and 54% PHA on biomass. Sangkharak and Prasertsan [13, 14] mutated Rhodobacter sphaeroides U17, N20 and Bacillus licheniformis PHA-007 using UV and N-methyl-N’-nitro-N-nitrosoguanidine (NTG) and found that the PHA production increased 2.25-, 3.28- and 3.18-fold, respectively, compared to the wild type. In the current study, UV radiation was selected as it is a standard mutagen and its mutability has been studied extensively due to its ubiquity in nature and convenience of handling. A major benefit of UV radiation is that the circulation and use of such mutants created by this approach are not subjected to the restrictions as those mutants genetically generated and modified. In addition, UV radiation is also applied in many fields, such as UV disinfection technology in clinical microbiology [15] and evolution engineering in biotechnology [16]. Irradiation with UV radiation induces thymine dimer lesions in DNA sequences [17]. The unrepaired lesions increase the rate of replication errors, i.e., mutations. The UV-induced mutation rates can be kept consistent regardless of the differences in the UV dose, viabilities against UV and/or spontaneous mutation rates. The broad spectrum and high upper limit of the speed in the mutability of UV suggest ubiquitous roles of UV radiation in accelerating the evolutionary process [18]. Therefore, this strain can be used to increase the production of PHA.

This study aimed to improve PHA production in Enterobacter strain TS3 using UV radiation. Afterward, the mutant strain was used to optimize the effects of environmental conditions to increase the production of PHA. PHA production was confirmed using Fourier transform infrared spectroscopy (FTIR) and gas chromatography-mass spectrometry (GC-MS) analysis. The thermal properties of the isolated PHA were analyzed using differential scanning calorimetry (DSC). In addition, the mutant was also analyzed to determine its ability to decolorize TW. The PHA production capacity and decolorization of the mutant were compared with those of the wild type.

Materials and methods

Bacterial inoculum preparation

The Enterobacter strain TS3 (GenBank number MN508473) isolated from TW (Ban Phraek Weaving Group, Phatthalung, Thailand) by Rakkan et al. [6] was used in this study. This strain was prepared in an Erlenmeyer flask containing PHA-producing medium; 10% of each isolate was added to the medium and incubated at 35 °C and 150 rpm for 24 h.

Textile wastewater

TW was collected from the Ban Phraek Weaving Group (Phatthalung, Thailand). Samples were kept on ice and transferred to the laboratory. To prepare the TW, the pH was adjusted to 7 and the sample was autoclaved at 121 °C for 10 min. After preparation, the TW was used to optimize the parameters for PHA production. The characteristics of the TW were determined previously, including pH 6.92, total dissolved solids (TDS) 407 mg/l, settleable solids 3 mg/l, total suspended solids (TSS) 20 mg/l, oil and grease 2 mg/l, sulfide 0.02 mg/l, temperature 27.5 °C, total Kjeldahl nitrogen (TKN) 40 mg/l and chemical oxygen demand (COD) 5,600 mg/l [19].

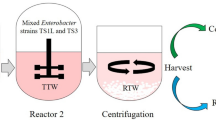

Sequential and repeated mutagenesis

The Enterobacter strain TS3 (wild type), grown in PHA-producing medium incubated at 35 °C and 150 rpm for 24 h, was harvested at the logarithmic phase and centrifuged at 10,000 rpm for 10 min at 4 °C. After this, the cells were washed using sodium chloride and then spread on PHA detection agar (20 g/l glucose, 2 g/l (NH4)2SO4, 13.3 g/l KH2PO4, 1.2 g/l MgSO4·7H2O, 1.7 g/l citric acid, 10 ml/l trace elements solution, and 15 g/l agar containing 0.5 µg/ml Nile Red stain) [14]. The plates were placed under a UV lamp at a distance of 60 cm for various periods from 0 to 60 s (1st round mutagenesis). After UV radiation, the plates were kept in the dark for 1 h. The colonies grown were observed under UV-light at the wavelength of 235 nm. The positive colonies showed bright orange or pink fluorescence were picked up. Selected mutant was incubated in PHA-producing medium at 150 rpm, 35 °C for 3 days. After that, the mutant strains were harvested and analysed for PHA production using GC. The mutant strain yielding the highest levels of PHA was subjected to repeat treatment by UV radiation. After each treatment, the mutant strain was firstly selected under UV-light in detection medium and incubated in PHA-producing medium. The strain with the highest PHA production was selected for the optimization study [5]. A schematic diagram of the mutagenesis of strain TS3 is shown in Fig. 1.

Effects of environmental conditions

The effects of environmental conditions on PHA production were analyzed in 500 ml Erlenmeyer flasks containing 100% TW as substrate, with a working volume of 250 ml. The mutant obtained from the 2nd round of mutagenesis was selected and optimized. 10% inoculum containing 106 cells/ml was incubated at 35 °C for 48 h at an agitation speed of 150 rpm. Subsequently, the optimal pH (5–9), temperature (25–40 °C), agitation speed (100–300 rpm) and cultivation time (0–96 h) were evaluated. After 48 h, the samples were collected and centrifuged for 10 min at 10,000 rpm at 4oC in a centrifuge. The pellet was tested to determine the cell growth, total cell mass, PHA concentration and content. The supernatant was subjected to decolorization measurement. The optimal conditions for PHA production were selected according to the highest PHA production. Moreover, PHA production was further characterized by FTIR, GC and DSC.

Analytical methods

Cell growth measurement

The pellet was washed twice with distilled water and then suspended in distilled water. After mixing, growth was monitored by measuring the absorbance at 600 nm [20].

Total cell mass analysis

The total cell mass was determined by weighing the CDM. Briefly, the pellet was resuspended in distilled water and centrifuged again for washing. The washed cells were dried at 100 °C for 24 h in a hot air oven and then cooled in a desiccator. The samples were weighed and the total cell mass was reported in g/l [14].

PHA concentration and content

PHAwere analysed in whole-cell samples or after extraction with chloroform and purification by repeated precipitation from a chloroform solution with ethanol. The PHAs content and composition were determined by subjecting 8 mg of lyophilized cells or 2 mg of isolated PHAs, respectively, to methanolysis which was performed in a mixture of chloroform and methanol containing 15% (v/v) sulfuric acid. The resulting hydroxyacyl methyl esters were analysed with a gas chromatograph [3]. Compared to those of authentic standards [21]. The authentic standards are consisting of methyl butyrate (C4:0), methyl pentanoate (C5:0), methyl hexanoate (C6:0), methyl heptanoate (C7:0), methyl octanoate (C8:0), methyl nonanoate (C9:0), methyl decanoate (C10:0), methyl undecanoate (C11:0), methyl laurate (C12:0), methyl tridecanoate (C13:0), methyl myristate (C14:0), methyl pentadecanoate (C15:0), methyl palmitate (C16:0), methyl heptadecanoate (C17:0), methyl stearate (C18:0), methyl oleate (C18:1), methyl linoleate (C18:2), and methyl linolenate (C18:3) from NU-CHEK-PREP, Inc, U.S.A.

The initial structural assignments of the methyl esters analysed were based on their retention times. Gas chromatographic analysis was performed on a Hewlett Packard GC-6890 system equipped with an HP-INNOWAX capillary column (length, 30 m; internal diameter, 0.25 mm; film thickness, 0.25 μm) and an FID [19].

Decolorization measurement

The decolorization efficiency was measured as described by Rakkan and Sangklarak [6]. The samples were centrifuged at 10,000 rpm for 10 min. Decolorization efficiency was analysed by measuring the absorbance of the culture supernatant at 540 nm. The decolorizing efficiency was expressed as the percentage of decolorization.

% Decolorization = [(Initial absorbance- Final absorbance)/Initial absorbance] × 100.

PHA characterization

FTIR analysis

The infrared spectra of the PHA were recorded in the wavenumber range from 650 to 4,000 cm− 1 using FTIR spectrophotometry (Jasco FTIR-6100, Japan) [19].

GC-MS analysis

The monomers of PHA were determined using methanolysis, analysed by the GC-MS method and compared with the authentic standard [21]. The conditions of GC-MS analysis followed those of Rakkan et al. [19].

DSC analysis

DSC was employed to record the thermal transitions of the extracted polymer. The polymer sample was heated from − 90 to 450 °C at 10 °C/min in helium using a differential scanning calorimeter (DSC8500, Perkin Elmer, USA). The glass transition temperature (Tg) was taken as the midpoint of the heat capacity change and the melting point (Tm) was taken as the summit of the melting peak [22].

Comparison studies between the wild-type and mutant strains

Comparison studies between the wild-type and mutant strains were conducted under optimal conditions. The optimal conditions for the production of PHA by the wild type were as follows: 100% TW as the sole substrate, pH 6.92, 150 rpm, 35 °C and 48 h of incubation [19]. The optimal conditions for the production of PHA by the mutant strain were as follows: 100% TW as the sole substrate, pH 7, 150 rpm, 35 °C and 60 h of incubation. After cultivation, the CDM and PHA production and decolorization efficiency were analyzed.

Statistical analysis

All experiments were run in triplicate. A completely randomized design was used throughout this study. Data were subjected to analysis of variance (ANOVA) and mean comparison was carried out using Duncan’s multiple range test [23]. All analyses were performed using the statistical package for social science, SPSS (SPSS 24 for Windows, SPSS Inc., Chicago, IL, USA).

Results and discussion

PHA production of the wild type

In our previous study, 5 strains of Enterobacter were isolated and identified by Rakkan et al. [14]. However, strain TS3 (wild type) produced the highest PHA production at 83.94 ± 2.72% CDM under optimal conditions. It can produce scl-co-mcl PHA monomers consisting of 6.38 mol% 3-hydroxybutyrate (3HB), 8.32 mol% 3-hydroxyvalerate (3HV), 36.00 mol% 3-hydroxyhexanoate (3HHx), 18.05 mol% 3-hydroxyoctanoate (3HO), 18.26 mol% 3-hydroxydecanoate (3HD), 6.45 mol% 3-hydroxy-5-dodecenoate (3H5DD) and 6.55 mol% 3-hydroxydodecanoate (3HDD), when using TW as a substrate [19]. Therefore, Enterobacter strain TS3 has the potential to produce PHA using TW. Using TW as a substrate for the production of PHA has the advantages of low production costs with simultaneous treatment of wastewater and is an environmentally friendly method. However, there are productivity limitations. Therefore, we increased the productivity by the sequence mutagenesis technique.

Sequential mutagenesis of PHA production

From our previous study, we found that Enterobacter strain TS3 is able to utilize TW as substrate for polyhydroxyalkanoate (PHA). More than 83% of PHA was produced by this strain [6]. Therefore, the possibility of strain TS3 for PHA production is large. Thus, the improvement of PHA production using TW as substrate of Enterobacter strain TS3 is important with respect to its PHA production potential and performance in the industry. The ability of strain TS3 to produce PHA using TW was increased by a UV-light radiation-based mutagenesis system. After the 1st round of mutagenesis, high PHA production (0.58 ± 0.01 g/l, 84.96 ± 1.32% CDM) for the radiation time of 40 s was observed by strain TS3-UV1 (Table 1). Therefore, the strain TS3-UV1 was chosen for 2nd round mutagenesis. After the 2nd round of mutagenesis, the strain TS3-UV2 showed the highest PHA production (0.71 ± 0.01 g/l, 86.99 ± 1.20% CDM) for the radiation time of 20 s. Thereafter, PHA production had been deceased after 3rd round of UV-radiation (data not shown). The mutants showed significantly higher PHA production than that of the wild-type strain. The production of PHA from mutants TS3-UV2 was 0.52 times greater than that of the wild type, showing a significant accumulative effect on the PHA production by UV-induced mutagenesis. Similar results were reported by Katircioglu et al. [24] for mutant strains using acriflavin, 5-bromourasil (80 to 180 µg/ml) and UV with Bacillus sp. gave yields of PHA in the range of 17.37 to 63.45% DCW, which were higher than those of the parent strains (15 to 48% DCW). The PHA production of Rhodobacter sphaeroides U17 and N20 was improved 2.25 and 3.28 times (compared with the wild type) after a single treatment of UV and NTG, respectively [5]. Sangkharak and Prasertsan [8] mutated Bacillus licheniformis PHA-007 using UV and NTG and PHA accumulation increased 3.18 times compared to that in the wild type. PHA production increased after UV treatment because UV light influenced the alteration of genes involved in PHA synthesis. UV light may cause two adjacent pyrimidine residues (cytosine or thymine) to form a dimer, which may cause an error in the subsequent DNA replication, resulting in a mutation. They may cause error at the next replication and so result in mutation. The gene responsible for the PHA synthesis may increase on the DNA of bacteria due to mutation, as a result increase in PHA production [25]. In this study, TS3-UV2 was selected to study the effects of environmental conditions on PHA production.

Effects of environmental conditions on PHA production

The environmental conditions are important for the production of PHA. The PHA production of strain TS3-UV2 was improved using an optimization strategy. Therefore, we studied the environmental conditions affecting PHA production as follows: pH (5–9), temperature (25–40 °C), agitation speed (100–300 rpm) and time of cultivation 0–96 h (PHA production was determined every 12 h) using 100% TW as a substrate.

pH

The pH is an important factor for cell growth, enzymatic activities and PHA accumulation because of its effect on the bioavailability of trace elements [26] and the regulatory enzymes responsible for the synthesis of PHA, β-ketothiolase, acetoacetyl-CoA reductase and PHA polymerase [27]. Therefore, the effect of varying the pH from 5 to 9 to produce PHA from strain TS3-UV2 was determined. Figure 2 A shows that strain TS3-UV2 obtained PHA production at pH 5–9 of 37.93 ± 1.29 to 86.99 ± 1.20% CDM (0.11 ± 0.02 to 0.62 ± 0.02 g/l). The highest PHA production was observed at pH 7, which was 86.99 ± 1.20% CDM (0.62 ± 0.02 g/l). A similar optimal pH was also found for TS3 (wild type), which yielded the highest PHA production at pH 7 [19]. The optimal pH for PHA production has been reported to be 6-7.5 [28, 29]. Enterobacter aerogenes-produced PHA were observed at 38% CDM at pH 6.5 [30]. Samrot et al. [31] found that Enterobacter cloacae SU-1 accumulated a higher concentration of PHA (94% CDM) at pH 7.5. Shaaban [32], Raj et al. [33] and Javaid et al. [34] found pH 7 to be the optimum for PHA production by Stenotrophomonas maltophilia. At pH values lower than and above 7, the production of PHA by strain TS3-UV2 (37.93 ± 1.29 to 77.78 ± 1.25% DCW) decreased. Therefore, pH 7 was selected to study the cultivation temperature.

Cultivation temperature

Temperature is an important factor in the survival of bacteria. A low temperature could inhibit cell growth and proliferation, alter protein expression patterns and weaken metabolic activity, whereas a high temperature could induce nucleic acid or protein denaturation [35]. Different microorganisms have different optimum temperatures for cell growth and various functional activities. Therefore, the effect of temperatures of 25, 30, 35 and 40 °C on PHA production by strain TS3-UV2 was evaluated. Figure 2B shows the PHA production at different temperatures. The maximum PHA accumulation was observed at 86.99 ± 1.20% CDM (0.71 ± 0.01 g/l) at 35 °C. A similar optimal temperature was also observed for TS3 (wild type) [19, 36]. However, the optimal temperature for PHA production depends on the species. Enterobacter cloacae SU-1 produces high PHA concentrations at 30 °C [31], while Enterobacter aerogenes and Enterobacter sp. SEL2 prefer an incubation temperature of 37 °C [30, 37]. In the current study, TS3-UV2 under lower (25–30 °C) and higher (40 °C) cultivation temperatures showed PHA content of 74.37 ± 1.36 to 75.41 ± 0.95% DCW in the cells and PHA concentrations of 0.18 ± 0.02 to 0.46 ± 0.01 g/l. PHA production decreased due to the slowing of polymerase enzyme activity [38]. In this study, an incubation temperature of 35 °C was selected to study the agitation speed.

Agitation speed

Agitation plays an important mixing and shearing role in fermentation processes. It not only improves mass and oxygen transfer between the different phases, but also maintains homogeneous chemical and physical conditions in the medium by continuous mixing [39]. Therefore, the influence of agitation speeds of 100–300 rpm on PHA production were studied. Figure 2 C shows the PHA production at agitation speeds of 100, 150, 200, 250 and 300 rpm. PHA production increased from 70.00 ± 1.01 to 86.99 ± 1.20% CDM at agitation speeds of 100–150 rpm. The highest PHA production (86.99 ± 1.20% CDM, 0.71 ± 0.01 g/l) was obtained at an agitation speed of 150 rpm. Choonut et al. [40] also found that an agitation speed of 150 rpm stimulated maximum PHA production. Agitation speeds higher than 150 rpm resulted in lower PHA content of 50.00 ± 1.52 to 68.97 ± 0.95% CDM in the cells and PHA concentrations of 0.19 ± 0.02 to 0.40 ± 0.02 g/l. The optimum agitation speed for PHA production was 100–250 rpm [41,42,43,44].

Each bacterial species has a different oxygen demand, and in this study, the agitation speed of 150 rpm was most suitable for PHA fermentation by strain TS3-UV2. Furthermore, an agitation speed of 150 rpm was selected to determine the cultivation time.

Cultivation time

Cultivation time is an important factor associated with bacterial growth and PHA accumulation. The effects of various cultivation times for mutant strain TS3-UV2 on PHA production was evaluated by growing this strain in TW for different durations (0–96 h). The results revealed that PHA production increased when the cultivation time increased from 0 to 60 h and the PHA content and concentration were 0.00 ± 0.00 to 88.66 ± 1.00% CDM and 0.00 ± 0.00 to 0.73 ± 0.03 g/l, respectively. It was found that a 60 h incubation time resulted in the highest PHA production, which gradually diminished with increasing incubation time (Fig. 2D). The optimum PHA biosynthesis incubation time differs for each strain of bacteria. For example, strains C. taiwanensis, C. necator (CCUG52238T), V. harveyi MCCB 284 and B. thermoamylovorans PHA005 achieved the maximum PHA production at 28, 36, 72 and 120 h of incubation, respectively [29, 40, 42, 44].

The TW decolorization efficiency of a mutant strain

We also studied the TW decolorization efficiency of mutant and wild type strains under optimal PHA conditions consisting of 100% TW as the sole substrate, pH 7, 150 rpm, 35 °C and 60 h incubation. The mutant strain showed the highest TW decolorization efficiency, of 72.32% under optimal PHA conditions (Fig. 3), compared with 63.43% for the wild type (0.57-fold). Normally, the Enterobacter strain decolorizes and degrades TW via two mechanisms. The first mechanism is a change to oxime-, methoxy-phenyl by an oxidoreductase. Afterward, oxime- and methoxy-phenyl groups are converted to pyruvate, which can be converted into acetyl-CoA by dearomatization and amino acids. Acetyl-CoA undergoes the tricarboxylic acid cycle (TCA cycle) to produce NADH2 and FADH2 (substrates of the electron transport chain). In the second mechanism, TW degradation, oxidative deamination and carboxylation lead to the production of phthalic acid and di(2-propylpentyl) ester, which can be transformed into different fatty acids and aldehydes (carbonic acid, allyl nonyl ester, tetradecanoic acid, hexadecanoic acid methyl ester, hexadecanoic acid, bis(2-ethylhexyl) ester, 9-decanoic acid, squalene, n-hexadecanoic acid, octadecanoic acid and hexadecanoic acid ethyl ester). Phthalate, fatty acids and aldehydes can directly/indirectly enter fatty acid oxidation reactions (beta-oxidation) to produce acetyl-CoA, NADH2 and FADH2 [6, 45]. Therefore, the decolorization efficiency was increased after UV treatment because UV light influenced the alteration of genes involved in the decolorizing and degradation of TW (such as the oxidoreductase enzyme), as a result increase in decolorization efficiency [25].

PHA characterization

PHA functional groups

The functional groups of the polymer were confirmed using FTIR spectroscopy in the 4,000-650 cm− 1 spectral range. The spectra of the PHA are shown in Fig. 4. The hydroxyl group in a polymer chain (mcl PHA) was observed at 3,316.31 cm− 1 [14, 19]. The signal observed at 2,945.46 cm− 1 is assigned to an asymmetric methyl group. The stretching vibration at 2,917.68 cm− 1 is allocated to the asymmetric CH2 of the lateral monomeric chains. The absorption at 2,849.72 cm− 1 is assigned to symmetrical CH3 and the intensity of the band has been reported to be due to conformational disorder that occurs in the process of crystallization [19], suggesting that the polymer is less crystalline. A strong signal at 1,734.33 cm− 1 was assigned to the carbonyl (C = O) ester bond stretching vibration, which is also associated with the amorphous region of the polymer and can be considered a PHA marker peak. The vibration at 1,462.84 cm− 1 has been assigned to bacterial protein amide II (NC = O) in the cell. Absorption at 1,376.01 cm− 1 is assigned to terminal CH3 groups. In the region of 1,300–700 cm− 1, the stretching of the ethers features C–O–C and C–C linkages of mcl PHA [19]. Therefore, the polymer extracted from TS3-UV2 is confirmed to be mcl-co-lcl PHA.

PHA monomers

PHA monomers produced by strain TS3-UV2 were analyzed by GC-MS and were achieved by converting PHA into methyl esters. As shown in Table 2, the strain TS3-UV2 accumulated mcl-co-lcl PHA consisting of 3(HDD-co-HTD-co-HHD-co-HOD) at 4.40 (C12), 16.54 (C14), 64.74 (C16) and 14.32 (C18) mol% (Fig. 5). Interestingly, the content of 3HHD monomer was also enhanced by 2.08 times compared with the wild type. The PHA with a high 3HHD fraction had higher thermal stability than PHA with a low 3HHD, suggesting an improved application property [46]. PHA with high 3HHD is suitable for a range of biomedical applications where flexible biomaterials are required, such as heart valves and other cardiovascular applications as well as matrices for controlled drug delivery. In addition, mcl-PHA with high 3HHD fraction are more structurally diverse than scl-PHA and hence can be more readily tailored for specific applications. Other strains of Enterobacter can produce mcl-PHA, such as Enterobacter loacae SU-1 [31] and Enterobacter FAK 1384 [47]. However, the production of mcl-co-lcl PHA has not yet been reported by Enterobacter before.

DSC of PHA

DSC is useful to study the thermodynamic properties, heat of fusion and melting temperature of polymers, which are important to evaluate their potential industrial applications [48]. The Tg value was not detected in the DSC of mcl-co-lcl PHA produced from TS3-UV2. The Tm and enthalpy of fusion (∆Hm) values were 131.15 °C and 16.84 J/g, respectively (Fig. 6). Commercially produced PHA are typically the PHB type (consisting of carbon 4 atoms) and the Tm value of PHB is approximately 160–175 °C [48]. Therefore, this results in it being brittle, which is related to the high degree of crystallinity and it may lack the superior mechanical properties required for biomedical and packaging applications. PHB and PHA contain 4–8 carbon atoms [49]. The PHA we produced consisted of 12–18 carbon atoms and Tm was less than that of PHB. Therefore, the PHA that we produced are attractive for biomedical and packaging applications. Guo et al. [22] also produced mcl-co-lcl PHA using Pseudomonas mendocina strains NK-01, C7C1 and C7C1 and found that the Tm can be reduced to 54.90, 55.70 and 55.00 °C, respectively. Normally, scl PHA tend to be hard, crystalline and brittle polymers with high melting points, whereas mcl- and lcl PHA are usually soft and elastomeric with lower melting points than scl PHA [50]. Therefore, the mutant strain is interesting for applications because it produces mcl-co-lcl PHA, a novel PHA composition.

Comparison between wild-type and mutant strains and the potential of TW as a substrate for PHA

The differences between the wild type and mutant can be categorized into 3 parts, including the biomass and PHA content, PHA characteristics and decolorization efficiency. The same conditions were used for the wild type and mutant to yield the highest biomass and PHA. The optimal conditions of both strains using 100% TW as the sole substrate were pH 6.92, 150 rpm and 35 °C. Under these optimal conditions, the mutant produced more PHA (0.01 g/l.h) than the wild type (0.007 g/l.h). In addition, the characteristics of PHA from the wild type and mutant also differed. The wild-type strain, which produced scl-co-mcl PHA, consisting of 3-hydroxybutyrate (3HB, C4), 3-hydroxyvalerate (3HV, C5), 3-hydroxyhexanoate (3HHx, C6), 3-hydroxyoctanoate (3HO, C8), 3-hydroxydecanoate (3HD, C10), 3-hydroxy-5-dodecenoate (3H5DD, C12:1, Δ5) and 3-hydroxydodecanoate (3HDD, C12), is 3(HB-co-HV-co-HHx-co-HO-co-HD-co-H5DD-co-HDD), which was observed to be 6.38, 8.32, 36.00, 18.05, 18.26, 6.45 and 6.55 mol%. This strain showed the highest 3HHx at 36.00 mol% [19]. Meanwhile, the mutant strain produced mcl-co-lcl PHA and this strain showed the highest 3HHD (lcl) at 64.74 mol%, which is interesting for biomedical applications. The differences between the wild type and mutant are given in Table 2. The use of TW as a substrate for the production of PHA resulted in high PHA production with low production costs while simultaneously treating wastewater and it is an environmentally friendly product and method. From our previous study, the result showed Enterobacter strain can degrade dye in TW using two mechanisms. The first mechanism, dye was changed to oxime-, methoxyphenyl by oxidoreductase. Afterward, oxime-, methoxy-phenyl changed to pyruvate which can be converted into acetyl-coA by dearomatisation. The second mechanism, dye was degraded by oxidative deamination and carboxylation lead to produce phthalic acid, di(2-propylpentyl) ester, which can be transformed into different fatty acids and aldehydes. Acetyl-coA, fatty acids and aldehydes from both mechanisms can directly/indirectly enter into PHA biosynthesis pathway. Therefore, the color of TW was decrease with an increase of PHA production when the dye was used by bacteria [6].

Conclusion

An optimized UV-light radiation-based mutagenesis system to increase PHA production by Enterobacter was firstly reported. PHA production was largely accumulated to 84.96% CDM on the second round of radiation. The use of TW as a substrate for PHA production has numerous possible industrial applications. Bacteria enhanced by mutation can be used to effectively increase the production volume and treat the coloration of wastewater. The mutant strain TS3-UV2 accumulated highest PHA (88.66 ± 1.00% CDM and 0.73 ± 0.03 g/l) when grown at pH 7 and 35 °C for 60 h of incubation. Growth of Enterobacter TS3-UV2 generates a mcl-co-lcl PHA polymer containing 4.40 mol% 3HDD, 16.54 mol% 3HTD 64.74 mol% 3HHD and 14.32 mol% 3HOD. This is the first report on UV mutagenesis of Enterobacter strain TS3, which improved PHA production and yielded the highest mcl-co-lcl PHA production. Furthermore, research for upscale PHA production on the road to commercialization and the application of PHA for biomedical field is one of the future research directions.

References

Miller R, Bates SM (2010) The majestic plastic bag-a mockumentary. https://www.plasticgarbageproject.org/en/plastic-life. Accessed 26 August 2021

Sangkharak K, Prasertsan P (2011) Utilization of biodiesel waste as a feedstock for the production of polyhydroxybutyrate by Cupriavidus necator. Afr J Biotechnol 1:17812–17824. https://doi.org/10.5897/AJB11.2184

Kemavongse K, Prasertsan P, Upaichit A, Methacanon P (2008) Poly-β-hydroxyalkanoate production by halotolerant Rhodobacter sphaeroides U7. World J Microb Bio 24:2073–2085. https://doi.org/10.1007/s11274-008-9712-8

Reddy CSK, Ghai R, Rashmi, Kalia VC (2003) Polyhydroxyalkanoates: an overview. Bioresour Technol 87:137–146. https://doi.org/10.1016/S0960-8524(02)00212-2

Sangkharak K, Prasertsan P (2007) Optimization of polyhydroxybutyrate production from wild type and two mutant strains of Rhodobacter sphaeroides using statistical method. J Biotechnol 132(3):331–340. https://doi.org/10.1016/j.jbiotec.2007.07.721

Rakkan T, Sangkharak K (2020) Enhanced decolourisation and biodegradation of textile wastewater using single and mixed cultures of a newly isolated Enterobacter strain. Curr Microbiol 77:4085–4094. https://doi.org/10.1007/s00284-020-02246-2

Kaushik P, Malik A (2009) Fungal dye decolourization: recent advances and future potential. Environ Int 35:127–141. https://doi.org/10.1016/j.envint.2008.05.010

Tamboli DP, Kagalkar AN, Jadhav MU, Jadhav JP, Govindwar SP (2010) Bioresource technology production of polyhydroxyhexadecanoic acid by using waste biomass of Sphingobacterium sp. ATM generated after degradation of textile dye Direct Red 5B. Bioresour Technol 101:2421–2427. https://doi.org/10.1016/j.biortech.2009.11.094

Joyline M, Aruna K (2019) Production and characterization of polyhydroxyalkanoates (pha) by Bacillus megaterium strain JHA using inexpensive agro-industrial wastes. Int J Recent Sci Res 10:33359–33374. https://doi.org/1010.13140/RG.2.2.36677.60641

Sangkharak K, Prasertsan P (2013) The production of polyhydroxyalkanoate by Bacillus licheniformis using sequential mutagenesis and optimization. Biotechnol Bioproc E 18:272–279. https://doi.org/10.1007/s12257-012-0615-z

Vu VH, Pham TA, Kim K (2009) Fungal strain improvement for cellulase production using repeated and sequential mutagenesis. Mycobiol 37:267–271. https://doi.org/10.4489/MYCO.2009.37.4.267

Divyashree MS, Shamala TR (2009) Effect of gamma irradiation on cell lysis and polyhydroxyalkanoate produced by Bacillus flexus. Radiat Phys Chem 78:147–152. https://doi.org/10.1016/j.radphyschem.2008.08.010

Sangkharak K, Prasertsan P (2008) Nutrient optimization for production of polyhydroxybutyrate from halotolerant photosynthetic bacteria cultivated under aerobic-dark condition. Electron J Biotechn 11:83–94. https://doi.org/10.2225/vol11-issue3-fulltext-2

Rakkan T, Chana N, Chirapongsatonkul N et al (2022) Screening and identification of Basic Red 9-degrading bacteria from textile wastewater and their ability to produce medium- and long chain length polyhydroxyalkanoate. J Polym Environ 30:415–423. https://doi.org/10.1007/s10924-021-02206-2

Hijnen WA, Beerendonk EF, Medema GJ (2006) Inactivation credit of UV radiation for viruses, bacteria and protozoan (oo) cysts in water: a review. Water Res 40(1):3–22. https://doi.org/10.1016/j.watres.2005.10.030

Tillich UM, Lehmann S, Schulze K et al (2012) The optimal mutagen dosage to induce point mutations in Synechocystis sp. PCC6803 and its application to promote temperature tolerance. PLoS ONE 7(11):1–8. https://doi.org/10.1371/journal.pone.0049467

Black HS, deGruijl FR, Forbes PD et al (1997) Photocarcinogenesis: an overview. J Photochem Photobiol B 40(1):29–47. https://doi.org/10.1016/S1011-1344(97)00021-3

Shibai A, Takahashi Y, Ishizawa Y et al (2017) Mutation accumulation under UV radiation in Escherichia coli. Sci Rep 7:1–12. https://doi.org/10.1038/s41598-017-15008-1

Rakkan T, Chana N, Sangkharak K (2022) The integration of textile wastewater treatment with polyhydroxyalkanoate production using newly isolated Enterobacter strain TS3. Waste Biomass Valorization 13:571–582. https://doi.org/10.1007/s12649-021-01504-z

Steinbuchel A, Wiese S (1992) A Pseudomonas strain accumulating polyesters of 3-hydroxybutyric acid and medium-chain-length 3-hydroxyalkanoic acids. Appl Microbiol Biotechnol 37:691–697. https://doi.org/10.1007/BF00174829

Abe H, Doi Y, Fukushima T, Eya H (1994) Biosynthesis from gluconate of a random copolyester consisting of 3-hydroxybutyrate and medium-chain-length 3-hydroxyalkanoates by Pseudomonas sp. 61˗3. Int J Biol Macromol 16(3):115–119. https://doi.org/10.1016/0141-8130(94)90036-1

Guo W, Duan J, Geng W et al (2013) Comparison of medium-chain-length polyhydroxyalkanoates synthases from Pseudomonas mendocina NK-01 with the same substrate specificity. Microbiol Res 168(4):231–237. https://doi.org/10.1016/j.micres.2012.11.003

Steel RGD, Torrie JH (1980) Principles and procedures of statistics. McGraw-Hill, New York

Katircioglu H, Akin BS, Atici T (2004) Microalgal toxin(s): characteristics and importance. Afr J Biotechnol 3:667–674. http://www.academicjournals.org/AJB

Ashraf H, Haq IU, Qadeer MA, Iqbal J (2001) Screening of Bacillus licheniformis mutants for improved production of alpha amylase. Pak J Bot 33:518–525

Gomaa EZ (2014) Production of polyhydroxyalkanoates (PHAs) by Bacillus subtilis and Escherichia coli grown on cane molasses fortified with ethanol. Braz Arch Boil Technol 57:145–154. https://doi.org/10.1590/S1516-89132014000100020

Bhagowati P, Pradhan S, Dash HR, Das S (2015) Production, optimization and characterization of polyhydroxybutyrate, a biodegradable plastic by Bacillus spp. Biosci Biotechnol Biochem 79:1454–1463. https://doi.org/10.1080/09168451.2015.1034651

Palleroni NJ, Palleroni AV (1978) Alcaligenes latus, a new species of hydrogen utilizing bacteria. Int J Syst Bacteriol 28:41–424. https://doi.org/10.1099/00207713-28-3-416

Wei YH, Chen WC, Huang CK et al (2011) Screening and evaluation of polyhydroxybutyrate-producing strains from indigenous isolate Cupriavidus taiwanensis strains. Int J Mol Sci 12(1):252–265. https://doi.org/10.3390/ijms12010252

Arumugam A, Shereen MF (2020) Bioconversion of Calophyllum inophyllum oilcake for intensification of rhamnolipid and polyhydroxyalkanoates co-production by Enterobacter aerogenes. Bioresour Technol 296:1–6. https://doi.org/10.1016/j.biortech.2019.122321

Samrot AV, Avinesh RB, Sukeetha SD, Senthilkumar P (2011) Accumulation of poly[(R)-3-hydroxyalkanoates] in Enterobacter cloacae SU-1 during growth with two different carbon sources in batch culture. Appl Biochem Biotechnol 163:195–203. https://doi.org/10.1007/s12010-010-9028-7

Shaaban MT, Attia M, Mowafy EI (2012) Production of some biopolymers by some selective Egyptian soil bacterial isolates. J Appl Sci Res 8(1):94–105

Raj A, Kumar S, Singh SK (2013) A highly thermostable xylanase from Stenotrophomonas maltophilia: purification and characterization. Enzyme Res 2013(4):1–8. https://doi.org/10.1155/2013/429305

Javaid H, Nawaz A, Riaz N et al (2020) Biosynthesis of polyhydroxyalkanoates (PHAs) by the valorization of biomass and synthetic waste. Molecules 25(23):1–23. https://doi.org/10.3390/molecules25235539

Chen J, Zheng J, Li Y et al (2015) Characteristics of a novel thermophilic heterotrophic bacterium, Anoxybacillus contaminans HA, for nitrifcation-aerobic denitrifcation. Appl Microbiol Biotechnol 99(24):10695–10702. https://doi.org/10.1007/s00253-015-6870-0

Rakkan T, Chana N, Sangkharak K (2022) Nitrogen reduction in conjunction with polyhydroxyalkanoates production using mixed newly isolated Enterobacter. Waste Biomass Valorization 13(4):1–8. https://doi.org/10.1016/j.msea.2006.05.158

Naheed N, Jamil N (2014) Optimization of biodegradable plastic production on sugar cane molasses in Enterobacter sp. SEL2. Braz J Microbiol 45(2):417–426. https://doi.org/10.1590/S1517-83822014000200008

Singh G, Kumari A, Mittal A et al (2013) Poly β-hydroxybutyrate production by Bacillus subtilis NG220 using sugar industry waste water. Biomed Res Int 2013(4):1–10. https://doi.org/10.1155/2013/952641

Swamy J, Ramsay JA (1999) The evaluation of white rot fungi in the decoloration of textile dyes. Enzyme Microb Technol 24:130–137. https://doi.org/10.1016/S0141-0229(98)00105-7

Choonut A, Prasertsan P, Klomklao S, Sangkharak K (2020) Bacillus thermoamylovorans-related strain isolated from high temperature sites as potential producers of medium-chain-length polyhydroxyalkanoate (mcl-PHA). Curr Microbiol 77:3044–3056. https://doi.org/10.1007/s00284-020-02118-9

Kshirsagar P, Suttar R, Nilegaonkar S et al (2014) Scale up production of polyhydroxyalkanoate (PHA) at different aeration, agitation and controlled dissolved oxygen levels in fermenter using Halomonas campisalis MCM B-1027. J Biochem Technol 4(1):512–517

Zahari MAKM, Ariffin H, Mokhtar MN et al (2012) Factors affecting poly(3-hydroxybutyrate) production from oil palm frond juice by Cupriavidus necator (CCUG52238T). J Biomed Biotechnol 2012:1–8. https://doi.org/10.1155/2012/125865

Geethu M, Vrundha R, Raja S et al (2019) Improvement of the production and characterisation of polyhydroxyalkanoate by Bacillus endophyticus using inexpensive carbon feedstock. J Polym Environ 27:917–928. https://doi.org/10.1007/s10924-019-01397-z

Mohandas SP, Balan L, Lekshmi N et al (2016) Production and characterization of polyhydroxybutyrate from Vibrio harveyi MCCB 284 utilizing glycerol as carbon source. J Appl Microbiol 122(3):698–707. https://doi.org/10.1111/jam.13359

Ajar M, Skakeel S, Rehman A (2020) Microbial use for azo dye degradation-a strategy. Int Microbiol 23:149–159. https://doi.org/10.1007/s10123-019-00103-2

Poltronieri P, Kumar P (2017) Polyhydroxyalcanoates (PHAs) in industrial applications. In: Martínez L, Kharissova O, Kharisov B (eds) Handbook of Ecomaterials. Springer, Cham, pp 1–30. https://doi.org/10.1007/978-3-319-48281-1_70-1

Wecker P, Moppert X, Simon-Colin C et al (2015) Discovery of a mcl-PHA with unexpected biotechnical properties: the marine environment of French Polynesia as a source for PHA-producing bacteria. AMB Express 5(1):1–9. https://doi.org/10.1186/s13568-015-0163-y

Leyva-Porras C, Cruz-Alcantar P, Espinosa-Solís V et al (2019) Application of differential scanning calorimetry (DSC) and modulated differential scanning calorimetry (MDSC) in food and drug industries. Polymers 12(1):1–23. https://doi.org/10.3390/polym12010005

Elodie B, Patrizia C, Vera A et al (2014) Polyhydroxyalkanoate (PHA): review of synthesis, characteristics, processing and potential applications in packaging. EXPRESS Polym Lett 8:791–808. https://doi.org/10.3144/expresspolymlett.2014.82

Basnett P, Ravi S, Roy I (2016) Science and Principles of Biodegradable and Bioresorbable Medical Polymers Natural bacterial biodegradable medical polymers. pp 257–277. https://doi.org/10.1016/B978-0-08-100372-5.00008-8

Acknowledgements

The authors would like to acknowledge the support of Thailand Science Research and Innovation (TSRI) through the Royal Golden Jubilee Ph.D. (RGJ-PHD) Program through grant number PHD/00073/2559 for RGJ-PHD. Acknowledgment is also made to the Research Grant for Talented Mid-Career Researchers (SS65000399) from National Research Council of Thailand, Department of Chemistry, Faculty of Science, Thaksin University, Phatthalung Campus, Thailand and Professor Dr. Ken’ichiro MATSUMOTO.

Funding

This work was supported by Thailand Science Research and Innovation (TSRI) through the Royal Golden Jubilee Ph.D. (RGJ-PHD) Program through grant number PHD/00073/2559 for RGJ-PHD; The Research Grant for Talented Mid-Career Researchers (N42A650241) from National Research Council of Thailand (NRCT); Thaksin University.

Author information

Authors and Affiliations

Contributions

TR: methodology, writing-original draft, data collection and analysis. NC: mentoring. KS: conceptualization, writing-review and editing, visualization, supervision, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rakkan, T., Chana, N. & Sangkharak, K. Utilization of Textile Wastewater as A Substrate for Polyhydroxyalkanoate (PHA) and Enhanced Production by Mutant Enterobacter. J Polym Environ 31, 677–687 (2023). https://doi.org/10.1007/s10924-022-02563-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02563-6