Abstract

This research utilized three animal proteins which are whey protein isolate (Wh) and two types of gelatin, including bovine gelatin (BG) and chicken gelatin (CG) from bovine shin bones and chicken feet respectively, to improve the mechanical properties of whole potato flour bioplastics. The goal is the development and characterization of eco-friendly bioplastic sheets by employing the compression molding method. The tensile, DMTA, FTIR and TGA characteristics of the blending bioplastics were compared with bioplastic made from whole potato flour as control. Results showed that protein treatments greatly enhanced the tensile strength (at least 2 times), tan δ (up to twice) and elongation at break (3 to 11 times). Furthermore, the thermal stability of studied bioplastics does not differ up to 200 °C. Among the blending bioplastics, the BG bioplastic had the highest tensile strength (5.67 MPa) and CG bioplastic had the highest elongation at break (20.50%). Meanwhile, the investigation of functional groups using Fourier-transform infrared spectroscopy (FTIR) confirmed better molecular interactions in the blending bioplastics. This research shows the feasibility of producing animal protein‐potato flour biodegradable edible bioplastic materials with different properties and, consequently, different applications, which contribute to adding a high value to different byproducts from the livestock/poultry industries.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, many researchers have been attracted by the bioplastics produced from bioresources. These plastics can be a good alternative to synthetic plastics [1,2,3,4]. However, most of the bioplastics are in the study stage and are produced on a laboratory scale. The review of the literature indicates that bioplastics have performance properties that are competitive with conventional plastics [5,6,7,8,9,10,11].

The main substance of bioplastics is renewable biomass sources, including various polysaccharides, proteins, and lipids. Starch is one of the most important polysaccharides, which is abundantly available in nature at a low price, and due to the proper polymeric nature, it is one of the most common biopolymers in the fabrication of bioplastics. These bioplastics can be made in forms of films, edible coatings and 3D volumes [7, 8]. This polymer is found in many agricultural product flours, such as wheat [12], maize, sorghum [13] and, potato (Solanum tuberosum). The annual worldwide production of potato is about 388 million tons [14], which in some parts of the world (e.g. Iran) due to overproduction and lack of suitable conditions for export, the product is wasted and destroyed.

Most studies have used pure potato starch for bioplastic production from potato [15,16,17,18,19,20,21,22,23,24,25]. Given that about 80% of potato is starch, therefore, the rest of the potato, including its protein, is not used and considered as waste [1, 25]. Also, the processing of starch extraction from potatoes is time-consuming and costly, which increases the production cost of bioplastics. The potato protein has high amino acids content, that have hydrophobic properties, and its lysine content is higher than many other proteins [25, 26]. The study on the viscoelastic behavior of bioplastics produced from potato protein shows that the complex modulus (E*) decreases with an increase in temperature. A comparative study of E* of potato protein bioplastics with bioplastics made from rice protein showed that the E* of potato protein bioplastics is relatively higher than rice protein bioplastics and similar to those obtained from low-density polyethylene (LDPE). Also, the loss factor (tanδ) curve peak for potato protein bioplastics appears at a higher temperature comparing to those made with wheat gluten as well as rice protein bioplastics, indicating that the bioplastics made from potato protein have high thermal stability [1].

However, due to some disadvantages of whole potato flour bioplastics, such as poor mechanical properties and fragile behavior, it cannot produce a favorable bioplastic alone. Previous studies show that proteins, in combination with starch, form a strong network of hydrogen bonds and intermolecular interactions that can produce three-dimensional stable materials [27,28,29].

Proteins as one of the biological polymers contain 20 different types of amino acids in their structures. This diversity provides a wide range of properties under various conditions and by creating multiple molecular interactions [30]. The strong molecular interactions (e.g. covalent, ionic and hydrogen bonds) in the structure of protein-based bioplastics create a unique network in their structure, which results in better mechanical properties than the bioplastics produced from polysaccharides and lipids [31]. In recent years, various protein sources have been used to make bioplastics [32,33,34,35,36,37,38,39,40,41,42,43,44,45].

The protein needed to make bioplastics can be produced from a variety of biological sources including plant proteins such as corn zein [44], soy protein [40, 42], wheat gluten [30], and pea protein [37], as well as animal proteins such as egg albumin protein [2, 34], keratin [6, 11], bloodmeal [45], whey protein [46,47,48], collagen and gelatin [22, 31]. These proteins are renewable sources whose per capita production is high. Studies show that they have a high potential for bioplastic production [49]. The results of a study showed that using animal protein in combination with potato/corn starch produces high transparency bioplastics with acceptable mechanical properties [2]. Processing conditions (compression molding, extrusion, and combination of extrusion and compression molding) affect the viscoelastic and tensile properties of bioplastics. Moreover, the samples prepared by the compression molding method showed the best mechanical and transparency properties [3].

Due to the high price of proteins, the production and usage of protein-based bioplastics are limited. By using proteins that exist as wasted material, the production of bioplastics would be commercialized economically [50,51,52]. One of these proteins is whey protein, which is a kind of animal protein and is obtained from milk as a byproduct of cheese or casein production. The annually available whey protein from dairy industry byproducts of the world is about 180 to 190 million tons [53]. Several articles have been published on implementing whey protein for application in the packaging [54]. Researches are underway to optimally extract whey protein for use in several industries [55,56,57]. However, nearly half of the produced whey protein currently enters the environment as wastewater [58].

Gelatin is also another low-priced animal protein that is derived from the local collagen of skins, bones, and white connective tissues of animals by partial hydrolysis [59, 60]. Usually, skin and bone of beef and pork are used as main sources for the commercial production of gelatin [61]. In recent years, due to ethical considerations, as well as some health concerns about the prevalence of communicable diseases between animals and humans (e.g. mad cow), the use of gelatin from other sources, such as fish and poultry, are preferred [33, 39]. Gelatin is resistant to oxygen and carbon dioxide permeability and widely used in food, photography, medical and pharmaceutical industries [62,63,64,65]. The functional properties of bioplastics prepared from gelatin are also affected by the type of sources used for gelatin extraction [31].

Despite extensive studies on bioplastics, there is a lack of study on the bioplastic performance provided from whole potato flour blended with various sources of protein, including gelatin and whey protein. Most of the meat consumed per capita in Muslim countries, including Iran, come from poultry and cattle. Since the waste of the livestock and poultry industries are rich in protein, therefore, the use of these proteins, while reducing environmental pollution, also enables the production of biodegradable bioplastics. We hypothesized that the application of gelatin from two halal gelatin sources including bovine bone and chicken feet along with whey protein into whole potato flour industrial bioplastic sheet would lead to an improved bioplastic mechanical, viscoelastic and thermal properties. Therefore, the major objective to undertake the present study was to develop a sustainable whole potato flour blending-based bioplastic sheets using gelatin and whey protein to enhance their functional properties.

Materials and Methods

Materials

Three different protein sources have been used in this study. Whey protein isolate (90 wt% protein content) was purchased from Behtam Powder Co., Karaj, Iran. The bovine gelatin (87 wt% protein content) was extracted from bovine shin bones based on the method used by Hosseiniparvar et al. [66] and Nicolas-Somonnot et al. [67]. Chicken gelatin (89 wt% protein content) was extracted from chicken feet according to the method reported by Irwandi et al. [68]. The whole potato flour was prepared from Agria variety of potato with mesh size less than 200 μm. Some compositional characteristics of employed materials in this study are shown in Table 1. Also, glycerol was purchased from Merck (Darmstadt, Germany) and used as the plasticizer. The experiments were carried out at the Department of Biosystems Engineering, Ferdowsi University of Mashhad.

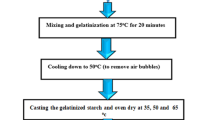

Sample Preparation

Bioplastic samples were manufactured by a thermo-mechanical procedure which includes two stages, mixing of raw materials to obtain a dough-like mixture, and, then, molding under heat and pressure. In this study, the functional properties of three types of blending bioplastics including bovine gelatin- potato flour (BG) (20 wt% bovine gelatin + 50 wt% potato flour + 30 wt% glycerol), chicken gelatin-potato flour (CG) (20 wt% chicken gelatin + 50 wt% potato flour + 30 wt% glycerol), and whey protein-potato flour (20 wt% whey protein + 50 wt% potato flour + 30 wt% glycerol) were compared with control bioplastic (P) (70 wt% potato flour + 30 wt% glycerol). Mixing of ingredients (potato flour, proteins, and glycerol) was done in a twin conical screw mini extruder at 25 °C and 50 r.p.m. for 60 min. Compression-molded bioplastics were obtained, at a gauge pressure of 10 MPa and a temperature of 120 °C for 7 min in a hot plate press, as described by Jerez et al. [4]. Finally, the resulting 185 mm × 30 mm × 3 mm samples (Fig. 1) were placed at 25–28 °C for 24 h before performing the tests.

Tensile Properties

For the tensile tests, dumbbell-shaped specimens were cut from samples and then the tensile tests were carried out at 25–28 °C using an Instron machine (SDL ATLAS, THE–5000 N, Tinius Olsen, United Kingdom). These tests were performed to measure the tensile properties of specimens (dependent variables) including tensile strength, tensile modulus, and elongation at break, with a constant strain rate of 10 mm/min, according to ASTM D–638–14 [69].

Dynamic Mechanical Thermal Analysis (DMTA)

The DMTA test was performed with a DMA–Triton (Tritec 2000 DMA, United Kingdom) to investigate the viscoelastic behavior of the fabricated bioplastics under sinusoidal loading. This experiment was performed in three points bending mode on rectangular (30 mm × 10 mm × 3 mm) specimens according to ASTM D5023–01 [70]. The selected temperature ramp was set at 5 °C/min with a temperature range from − 90 °C to + 160 °C and the loading was done by applying a sinusoidal strain with a constant angular frequency of 1 Hz. In this loading, the amount of strain was always less than 0.22525 m/m, so that the test was definitively done in the linear viscoelastic region. Subsequently, the values of the storage modulus E' (elastic response) and the loss modulus E" (viscous response) were obtained as a function of temperature. Complex modulus (E*2 = Eʹ2 + Eʺ2) and loss factor (tan δ) were used as a function of temperature to report the results of this experiment.

Fourier-Transform Infrared Spectroscopy (FTIR)

FTIR spectroscopy was performed using Avatar 370 FT-IR, Thermo Nicolet, USA with 4 cm−1 resolution between the wavenumber of 4000 and 500 cm−1. An average of 8 scans was used for the analysis.

Thermogravimetric Analysis (TGA)

TGA was performed using a TGA instrument (TGA50, Shimadzu, Japan) to study the thermal stability and thermal decomposition of samples by applying temperature ranged from 25 to 700 °C, with a heating rate of 20 °C/min. This test was performed on a platinum plate with a nitrogen flow rate of 50 mL/min. The results of this test were reported based on percentages of residual mass from the initial mass of samples at each temperature (% TG).

Statistical Analysis

Significance in the mechanical properties was statistically analyzed using one-way analysis of variance (ANOVA) by IBM SPSS Statistics 19 software at an α level of 0.05 employing Duncan's method for comparison of mean values.

Results and Discussion

Tensile Properties

The results of the tensile test for the BG, CG, and Wh bioplastics and the control bioplastic (P) are shown in Table 2. Comparing the tensile strength (the second column of Table 1), it can be seen that the values of tensile strength for the blending bioplastics are significantly higher than that of the control bioplastic. The BG bioplastic has the highest tensile strength (5.67 MPa) and the CG bioplastic (5.07 MPa), Wh bioplastic (4.43 MPa) and P (2.22 MPa) are ranked, respectively. Therefore, it can be concluded that adding protein to bioplastics made from potato flour, significantly improves the tensile strength of the final product. These values are much higher than those reported for other bioplastics including: wheat gluten (WG) + 20 wt% corn starch (CS) (0.13 MPa), wheat gluten + 20 wt% potato starch (PS) (0.32 MPa), wheat gluten (0.52 MPa) [71], whole wheat flour (WWF) (0.88 MPa) [72] and cellulose of wheat straw reinforced by date palm fibers bioplastics (CWS + DPF) (< 1.99 MPa) [73]. However, compare to polyhyroxybutyrate (PHB) (27.2 MPa), biocomposites of PHB + potato peel waste fermentation residue (PPW–FR) fibers (> 6.8 MPa) and egg white (EW) bioplastics (7.1 MPa), they have lesser tensile strength [2, 74] (Table 2).

The comparison of tensile modulus in the bioplastics (third column of Table 2) shows that the control bioplastic has the highest tensile modulus (279.38 MPa) and then different blending bioplastics including Wh (188.04 MPa), BG (127.65 MPa) and CG (97.98 MPa) are placed respectively. These results indicate that adding protein decreases in tensile modulus, implying more flexibility of protein-based bioplastics. Based on previous researches, the more flexibility of bioplastics shows the more mobility of polymer chains [75]. This means that the molecules are freer to move inside the polymeric matrix with less force.

Based on the results of elongation at break (fourth column of Table 2), there is also a significant difference between the control sample and other samples as suggested by Duncan's method. The CG bioplastic has the highest elongation (20.50%) and then the BG (14.85%), Wh (5.63%) and control (1.81%) bioplastics are placed respectively. This indicates that adding protein provides bioplastics with improved flexibility. As a summary of tensile tests, it can be said that incorporating protein to the whole potato flour not only increases the tensile strength of bioplastics but also improves their elasticity and flexibility.

Dynamic Mechanical Thermal Analysis (DMTA)

The DMTA results including the complex modulus (E*) and the loss factor (tanδ) for the blending and control bioplastics are shown in Fig. 2. By increasing temperature from − 90 °C to + 160 °C, in E* curves (Fig. 2a), a relative plateau region at the temperature range of − 90 °C to − 10 °C is initially observed for all the investigated bioplastics. This region, which appears in all polymers, is named the glass region and the resulting modulus in this region is called the glass modulus (Eg) [76]. For all bioplastic samples, the means of Eg are clustered around 1GPa. By examining the tanδ curves in this temperature range, around − 30 °C, in all investigated bioplastics, a fairly small peak is seen, which is related to the glass transition temperature (Tg) of glycerol [77].

By increasing temperature, the E* gradually decreases with a gentle slope, which is due to the onset of a thermal transition in bioplastics, because bioplastics gradually approach to their glass transition temperatures. With more gradual increase of temperatures up to + 130 °C, the E* once again finds a relatively stable trend and forms another plateau region. This plateau region at high temperatures is related to the rubber region of the bioplastics and is called the rubber modulus (Er) [76]. This area is considered one of the rheological indicators of polymers and the materials in this area have pseudo–gel behavior [78].

In diverse biological systems, including protein-potato flour bioplastics, which are a combination of globular proteins and polysaccharides, this region, represents a situation that falls between a temporary entangled network and permanent covalent crosslinks [79]. The mean values of Er obtained in the rubber region for the control bioplastic, Wh, CG, and BG blending bioplastics were calculated to be 5.11, 5.10, 1.81 and 0.80 MPa, respectively (Table 3). Between the glass and rubber regions, the bioplastics exhibit viscoelastic behavior, which is a combination of elastic solids and viscose fluids behavior. In this area, the E* of bioplastics is continuously reduced as the temperature increases. According to Fig. 2a, BG bioplastics have the highest reduction in E* with increasing the temperature, and then CG and Wh bioplastics are placed. The lowest reduction is also for the control bioplastic.

The E*, in the temperature range of − 10 °C to + 30 °C, is related to the thresholds of working temperatures of the bioplastics in normal in different seasons. The control bioplastic has the highest values and then Wh, BG and CG blending bioplastics are placed respectively. These results are consistent with the values of the tensile modulus obtained from the tensile tests carried out at room temperature. For temperatures above + 30 °C, the ranking of E* for the investigated bioplastics was: P > Wh > CG > BG. These results also indicate that the control and the Wh bioplastics have the highest functional stability at different temperatures. While the bioplastics made from gelatin, increasing the temperature, especially at temperatures above + 30 °C, results in a sharp decrease in E*. The values obtained from the tanδ curves, which include the viscose response of the bioplastics, are also consistent with these results. Among the blending bioplastics made from gelatin, bovine gelatin bioplastic (BG) is more unstable than the chicken feet gelatin bioplastic (CG) and has the highest tanδ for temperatures above + 30 °C.

From the evolution of tanδ curves with temperatures (Fig. 2b), it is observed that by increasing the temperature, the loss factor in all bioplastics increases, consequently, the viscose portion increases in the behavioral state of the bioplastics. Also for temperatures higher than zero, all the blending bioplastics have two thermal transitions associated with the two peaks. But the control bioplastic has one peak in a broad transition region. The first peak point is the glass transition temperature (Tg, also known as α transition), at which the E* declines significantly. For the BG, CG, and Wh blending bioplastics, the Tg appears at about + 39, + 34 and + 42 °C, respectively, while for the control bioplastic this is observed at around + 54 °C (Table 3). Therefore, it can be concluded that adding protein to the whole potato flour, reduces the Tg of the bioplastics. The second peak point for the Wh, CG, and BG bioplastics appears at + 80, + 82 and + 80 °C, respectively. In general, results of the tanδ indicate that the portion of viscous fluid, as well as the area under the tanδ curve in the BG bioplastic, is the highest, and then the CG, Wh and control bioplastics are placed, respectively. Therefore, the energy dissipation potential of the blending bioplastics is higher, especially in impact loads, compared to the control bioplastic.

The existence of a broad temperature peak for Tg [1], as well as several peak points in the tanδ curve of biopolymers and biological blends, have also been reported elsewhere [74, 77]. Potato flour-protein blends can demonstrate a variety of different interactions between the components, such as protein-polysaccharide, protein–protein, polysaccharide-polysaccharide and biopolymer-plasticizer (glycerol). These interactions create a relatively complex and heterogeneous composition in all four types of bioplastics. The multiplicity of tanδ curve peak points may be due to the complexity of the potato flour and proteins, the existence of free branches of polysaccharides and polypeptides that do not create a cross–linking composition, poor bonds between protein and glycerol molecules and agglomeration of compounds, which have been reported as potential factors for phase separation [20, 77]. Also the nature of used materials has been reported as a potential to the multiplicity of tanδ curve peak points [74]. Especially for materials with semicrystalline nature, the crystal–crystal slippage occurs just below the melting transition temperature [9]. It was also reported that the thermodynamic mechanism of phase separation in polysaccharide-protein bioplastics largely depends on the percentage of starch in the mixture and the coalescence of materials increases with increase in the percentage of starch in the composition [22]. Also, one indicator of existing phase separation is the reduction of tensile properties due to the concentration of stress at points where the phase separation has appeared. Since the tensile tests showed improved tensile strength and elongation at break for the blending bioplastics, the two peaks in the loss factor curves are probably due to the nature of the blending bioplastics.

Fourier-Transform Infrared Spectroscopy (FTIR)

The results of FTIR spectroscopy of the investigated bioplastics are shown in Fig. 3a. The peaks of 2884, 1026, and 1925 cm−1 are reported as characteristic peaks for glycerol [6, 77]. Since the main component of the investigated bioplastics is starchy compounds, therefore in the FTIR spectrum of the bioplastics, most abundant functional groups reported for starch shows a broadband from −OH stretching (3383 cm−1), aliphatic CH2 in the starch chain (2930 cm−1), C=C stretching (1657 cm−1), carboxylic groups −COOH (1416 cm−1), etheric bonds −COO (1156 cm−1), and aromatic C−H (706 cm−1) [80,81,82]. The peaks between 700−500 cm−1 are also related to thiols and thio–substituted compounds (sulfur–containing compounds) [83].

a FTIR spectroscopy of BG, CG, and Wh blending bioplastics compared to control bioplastic (P), a) O–H band, b) aliphatic CH2, c) C=C and amide I bands, d) amide II band, e) carboxylic band −COOH, f) C–C band, g) etheric band −COO, h) aromatic C−H band; b Amide region spectra. Peaks indicated by the rectangles represent the characteristic peaks of the glycerol

Some of the peaks observed in the FTIR results are related to bonds created by the participation of polypeptide chains. For example the peaks of 1658 cm–1 and 1543 cm–1 are related to amide I (C=C stretching) and amide II (C–N stretching and N–H bending) respectively (Fig. 3b) [11]. The presence of these peaks in control bioplastic is due to the presence of protein in the structure of whole potato flour. The characteristic peaks intensity shows that the use of protein in raw materials of bioplastics made from whole potato flour significantly increases the intensity of characteristic bands of amide I in all of the protein-based blending bioplastics, and this intensity for the BG bioplastic is the highest. These results are mainly due to strong hydrogen bonds between the O–H groups of starch and glycerol and the N–H and C–O groups of proteins. By investigating the changes in the amide II band, changes in the bonds are further confirmed. The amide II band is formed by the N–H bending and C–N stretching [6]. This band reflects the changes in the hydrogen bonds around the peptide chains [84]. The results also show that the position of amide II peak in all blending bioplastics is shifted to higher wavenumbers compared to the control bioplastic. This shift can be attributed to the formation of new hydrogen bonds between N–H groups of proteins and O–H groups of starch and glycerol, which partially disrupts and weakens the internal hydrogen bonds in proteins.

Strong peaks related to H–containing functional groups, including O–H, aliphatic CH2 and aromatic C–H, are seen in all bioplastics, but their intensity is low in the control bioplastics. Considering that the initial moisture content of the blending bioplastics was higher than that of the control bioplastic, this might be due to dehydration of structure that the control bioplastic forms in comparison to the blending bioplastics [85], which makes it difficult to move the polymeric chains. In contrast, an increase in the intensity of these groups leads to a softening and improvement in the movement of polymeric chains, which is consistent with the results obtained for the tensile modulus and the elongation at the break for the bioplastics.

On the other hand, the intensity of the bands, related to the hydroxyl groups (3383 cm–1) and carboxyl groups (1416 cm–1) in the control and Wh bioplastics, were less than that of the gelatinous bioplastics. It indicates better structural stability for the control and Wh bioplastics in comparison with the gelatin blending bioplastics [82], which is consistent with the results obtained for the complex modulus.

Thermogravimetric Analysis (TGA)

The variations of TGA based on the percentage of remaining mass relative to temperature (TG) are shown in Fig. 4, for the investigated bioplastics. The reduction of mass in all samples by increasing temperature can be due to the evaporation of volatile organic compounds, followed by continuous thermal degradation of the biological materials, resulting from the greater decomposition of the C–C and C–H bonds [86].

By observing the thermal decomposition process in the investigated bioplastics, it can be said that the thermal degradation process of the bioplastics is carried out in three steps. The first step occurs between the temperatures of 25 °C to 200 °C, where the weight changes of the samples were eventually up to 12% and are not affected by the containing compounds of the bioplastics. It is more related to the loss of volatile materials with low molecular weight and part of the residual moisture in the structure of the bioplastics [46]. At this step the difference between the bioplastics is negligible.

The second step occurs between 200 and 330 °C, which is related to the thermal degradation of components in the structure of the bioplastics. At this step, the inclination of TG curves changes significantly, with drastic weight loss. The rate of weight loss is clearly higher in blending bioplastics than the control bioplastics. This indicates that in this temperature range, the control bioplastic (Fig. 4d) has a higher thermal resistance than the blending bioplastics. The weight loss of bioplastics is ranked as CG < BG < Wh, which shows that the thermal resistance of the CG bioplastic (Fig. 4b) is more than BG (Fig. 4a) and Wh bioplastics (Fig. 4c). Mendes et al. [10] reported that the initial thermal degradation of starchy bioplastics is about 277 °C. The initial thermal degradation temperature of gelatin and whey protein is about 250 °C and 225 °C, respectively [5, 15]. Therefore, the higher thermal resistance of the control bioplastic than the blending bioplastics can be justified. The higher thermal resistance of the CG and BG bioplastics than the Wh bioplastic is also related to this reason.

The third step occurs between 330 and 600 °C, where the inclination of the TG curves is fairly mild. This step is related to the oxidative degradation of the remaining carbon residues from the second step [46]. At this step, contrary to the previous, the blending bioplastics exhibit more thermal resistance than the control bioplastics, which can be due to creation of cross–linking networks between polysaccharide in whole potato flour and polypeptides in proteins [29], the protein molecules partially trapped in the bioplastic structure. As a result, the thermal resistance of the blending bioplastics was higher compared to the control bioplastic at temperatures above 330 °C. The comparison between the blending bioplastics also shows that the CG bioplastic has less weight loss than the BG and Wh bioplastics.

Based on the results of the DTG curves, in all investigated bioplastics, the maximum mass loss temperature occurred between 310 and 320 °C. The latter occurred for the control bioplastic and the peak intensity was about 1.5 times higher than that of the blending bioplastics. The comparison of the blending bioplastics shows that the peak of weight loss in BG bioplastic occurred at higher temperatures than the CG and Wh bioplastics. However, the maximum value for all of the blending bioplastics is approximately equal. In addition to the peak point of the DTG curves, in all of the investigated bioplastics, there are numerous extreme points throughout the process, which are due to the complexity of the decomposition process and numerous compounds in the structure of the samples.

Conclusions

In this study, bioplastic plates were successfully made by potato flour and three animal proteins including whey protein isolate and two types of gelatin, including bovine gelatin and chicken gelatin from bovine shin bones and chicken feet respectively. It is shown that the blending bioplastics had greater tensile strength (at least 2 times), tan δ (up to twice) and elongation at break (3 to 11 times) than the control bioplastic. The addition of protein (especially gelatin) increases the damping properties in blending bioplastics, which shows their potential for exposed impact applications. Thermal analysis showed that the thermal stability of the blending bioplastics does not change compared to the control bioplastic, up to 200 °C. The blending bioplastics have lower glass transition temperatures compared to control bioplastics, which can be considered as evidence of a reduction in energy consumption in the bioplastics formation process. As a result, the obtained blending bioplastics show reliable mechanical and thermal properties, which can be useful in the food and packaging industry and other potential applications. These findings also provide an opportunity to enhance the potential value of the waste and byproduct resources of livestock and poultry industries.

References

Gomez-Heincke D, Martínez I, Stading M, Gallegos C, Partal P (2017) Food Hydrocoll 73:21

Gonzalez-Gutierrez J, Partal P, Garcia-Morales M, Gallegos C (2010) Bioresour Technol 101:2007

González-Gutiérrez J, Partal P, García-Morales M, Gallegos C (2011) Carbohydr Polym 84:308

Jerez A, Partal P, Martinez I, Gallegos C, Guerrero A (2007) Food Eng 82:608

Chuaynukul K, Prodpran T, Benjakul S (2014) Res J Chem Environ Sci 2:1

Dou Y, Zhang B, He M, Yin G, Cui Y (2016) Chin J Chem Eng 24:415

Thakur R, Pristijono P, Scarlett CJ, Bowyer M, Singh SP, Vuong QV (2019) Int J Biol Macromol 132:1079

Dai L, Zhang J, Cheng F (2019) Int J Biol Macromol 132:897

Madbouly SA, Schrader JA, Srinivasan G, Liu K, McCabe KG, Grewell D, Graves WR, Kessler MR (2014) Green Chem 16:1911

Mendes J, Paschoalin R, Carmona V, Neto ARS, Marques A, Marconcini J, Mattoso LHC, Medeiros ES, Oliveira JE (2016) Carbohydr Polym 137:452

Ramakrishnan N, Sharma S, Gupta A, Alashwal BY (2018) Int J Biol Macromol 111:352

Puglia D, Dominici F, Kenny JM, Santulli C, Governatori C, Tosti G, Benincasa P (2016) J Polym Environ 24:37

Trujillo-de Santiago G, Rojas-de Gante C, García-Lara S, Verdolotti L, Di Maio E, Iannace S (2015) J Polym Environ 23:72

FAOSTAT, Potato production in 2017. Region/World/Production Quantity/Crops from pick lists. UN Food Agric. Organ. Stat. Div. 2018, Accessed 20 Oct 2018.

Ramos OL, Reinas I, Silva SI, Fernandes JC, Cerqueira MA, Pereira RN, Vicente AA, Poças MF, Pintado ME, Malcata FX (2013) Food Hydrocoll 30:110

Balakrishnan P, Sreekala MS, Kunaver M, Huskić M, Homas S (2017) Carbohydr Polym 169:176

Bergel BF, Luz LM, Santana RM (2018) Prog Org Coat 118:91

Bergel BF, Osorio SD, Luz LM, Santana RM (2018) Carbohydr Polym 200:106

Fahrngruber B, Eichelter J, Erhäusl S, Seidl B, Wimmer R, Mundigler N (2019) Eur Polym J 111:170

Malmir S, Montero B, Rico M, Barral L, Bouza R, Farrag Y (2018) Carbohydr Polym 194:357

Oleyaei SA, Zahedi Y, Ghanbarzadeh B, Moayedi AA (2016) Int J Biol Macromol 89:256

Podshivalov A, Zakharova M, Glazacheva E, Uspenskaya M (2017) Carbohydr Polym 157:1162

Moreno O, Atarés L, Chiralt A (2015) Carbohydr Polym 133:353

Nandi S, Guha P (2018) Carbohydr Polym 200:498

Waglay A, Karboune S, Alli I (2014) Food Chem 14:373

Refstie S, Tiekstra HAJ (2003) Aquaculture 216:283

Łupina K, Kowalczyk D, Zięba E, Kazimierczak W, Mężyńska M, Basiura-Cembala M, Wiącek AB (2019) Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2019.05.053

Haghighi H, Biard S, Bigi F, De Leo R, Bedin E, Pfeifer F, Siesler HW, Licciardello F, Pulvirenti A (2019) Food Hydrocoll 95:33

Pommet M, Redl A, Morel MH, Domenek S, Guilbert S (2003) Macromol Symp 197:207

Gomez-Martinez DP, Partal P, Martinez I, Gallegos C (2009) Bioresour Technol 100:1828

Nur Hanani ZA, Beatty E, Roos YH, Morris MA, Kerry JP (2012) J Food Eng 113:606

Araújo CS, Rodrigues AMC, Peixoto Joele MRS, Araújo EAF, Lourenço LFH (2018) Food Pack Shelf Life 16:23

Arfat YA, Ahmed J, Hiremath N, Auras R, Joseph A (2017) Food Hydrocoll 62:191

Lee RS, Pranata M, Ustunol Z, Almenar E (2013) J Food Eng 118:132

Martínez I, Partal P, García-Morales M, Guerrero A, Gallegos C (2013) J Food Eng 117:247

Nur Hanani ZA, Yee FC, Nor-Khaizura MAR (2019) Food Hydrocoll 89:253

Carvajal-Piñero JM, Ramos M, Jiménez-Rosado M, Perez-Puyana V, Romero A (2019) J Polym Environ 27:968

Sharma S, Luzinov I (2013) J Food Eng 119:404

Uranga J, Etxabide A, Guerrero P, de la Caba K (2018) Food Hydrocoll 84:313

Boontima B, Noomhorm A, Puttanlek C, Uttapap D, Rungsardthong V (2015) J Polym Environ 23:97

Moosavi MH, Khani MR, Shokri B, Hosseini SM, Shojaee-Aliabadi S, Mirmoghtadaie L (2020) Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.10.017

Wu X, Liu A, Wang W, Ye R (2018) Int J Biol Macromol 109:1319

Felix M, Perez-Puyana V, Romero A, Guerrero A (2017) J Polym Environ 25:91

Jones A, Sharma S (2016) J Polym Environ 24:309

Verbeek CJR, van den Berg LE (2011) J Polym Environ 19:1

Azevedo VM, Borges SV, Marconcini JM, Yoshida MI, Neto ARS, Pereira TC, Pereira CFG (2017) Carbohydr Polym 157:971

Jiang S, Zhang T, Song Y, Qian F, Tuo Y, Mu G (2019) Int J Biol Macromol 126:1266

Pluta-Kubica A, Jamróz E, Kawecka A, Juszczak L, Krzyściak P (2019) Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.11.102

Cuq B, Gontard N, Guilbert N (1998) Cereal Chem 75:1

Garrido T, Peñalba M, de la Caba K, Guerrero P (2019) Food Hydrocoll 86:11

Etxabide A, Uranga J, Guerrero P, de la Caba K (2017) Food Hydrocoll 68:192

Ryder K, Ali MA, Billakanti J, Carne A (2019) J Polym Environ 28:725

Cinelli P, Schmid M, Bugnicourt E, Wildner J, Bazzichi A, Anguillesi I, Lazzeri A (2014) Polym Degrad Stab 108:151

Schmid M, Müller K (2019) In: Deeth HC, Bansal N (eds) Whey proteins: from milk to medicine. Academic Press, p 407. https://doi.org/10.1016/B978-0-12-812124-5.00012-6

Bacenetti J, Bava L, Schievano A, Zucali M (2018) J Food Eng 224:139

Chen W, Ma X, Wang W, Lv R, Guo M, Ding T, Ye X, Miao S, Liu D (2019) Food Hydrocoll 95:298

Nicolás P, Ferreira ML, Lassalle V (2019) J Food Eng 246:7

Schmid M, Dallmann K, Bugnicourt E, Cordoni D, Wild F, Lazzeri A, Noller K (2012) Int J Polym Sci 2012:7. https://doi.org/10.1155/2012/562381

Gomez-Guillen MC, Perez-Mateos M, Gomez-Estaca J, Lopez-Caballero E, Gimenez B, Montero P (2009) Trends Food Sci Technol 20:3

Norland RE (1990) In: Voight MN, Botta JK (eds) Advances in fisheries technology and biotechnology for increased profitability. Technomic Publishing Co, Lancaster, p 325

Karim AA, Bhat R (2009) Food Hydrocoll 23:563

Omrani-Fard H, Abbaspour-Fard MH, Khojastepour M, Dashti A (2018) Int Conf Promot Sci Reg Copp Food Agric Sci, 24th August, Mashhad, Iran.

Howe AM (2000) Curr Opin Colloid Interface Sci 5:288

Djagny KB, Wang Z, Xu S (2001) Crit Rev Food Sci Nutr 41:481

Ulubayram K, Nur Cakar A, Korkusuz P, Ertan C, Hasirci N (2001) Biomaterials 22:1345

Hosseiniparvar SH, Keramat J, Kadivar M, Khanipour E, Milani E (2006) Iran Food Sci Technol Res J 2:1

Nicolas-Somonnot MO, Treguer V, Leclerc JP, Sardin M, Brajoux JP, Moy J, Takerkart G (1997) Chem Eng J 67:55

Irwandi J, Faridayanti S, Mohamer ESM, Hamzah MS, Torla HH, Man YBC (2009) Int Food Res 16:381

ASTM International, D638–14 (2018) West Conshohocken, PA, US, www.astm.org.

ASTM International, D5023–01 (2018) West Conshohocken, PA, US, www.astm.org.

Jerez A, Partal P, Martínez I, Gallegos C, Guerrero A (2005) Biochem Eng 26:131

Omrani-Fard H, Ghazanfari-Moghaddam A, Shamsi M, Ataei SA (2012) Iran J Polym Sci Technol 25:74

Omrani-Fard H, Ghazanfari-Moghaddam A, Yusefi Ansari M (2014) J Agric Mach 4:21

Wei L, Liang S, McDonald AG (2015) Ind Crop Prod 69:91

Tummala P, Liu W, Drzal LT, Mohanty AK, Misra M (2006) Ind Eng Chem Res 45:7491

Gutierrez-Lemini D (2014) Engineering viscoelasticity. Springer, New York

Musa MB, Yoo MJ, Kang TJ, Kolawole EG, Ishiaku US, Yakubu MK, Whang DJ (2013) Res Re J Eng Technol 2:9

Ferry JD (1980) Viscoelastic properties of polymers, 3rd edn. Wiley, Toronto

Ross-Murphy SB (1995) Texture Stud 26:391

Ahmad M, Lee SS, Dou X, Mohan D, Ok YS (2012) Bioresour Technol 118:536

Rajapaksha AU, Vithanage M, Lim JE, Ahmed MBM, Ok YS (2014) Chemosphere 111:500

Yang X, Kwon EE, Dou X, Zhang M, Kim KH, Tsang DCW, Ok YS (2018) Sci Total Environ 626:478

Coates J (2000) In: Meyers RA (ed) Encyclopedia of analytical chemistry. US, Newtown, p 10815

Ullah A, Vasanthan T, Bressler D, Elias AL, Wu J (2011) Biomacromolecular 12:3826

Zhao L, Cao X, Mašek O, Zimmerman A (2013) Hazard Mater 256:1

Liang Y, Cheng B, Si Y, Cao D, Jiang H, Han G, Liu X (2014) Renew Energy 68:111

Acknowledgements

The authors are thankful to Ferdowsi University of Mashhad (FUM) for providing facilities and funding support [Grant No. 3/39891].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Omrani-Fard, H., Abbaspour-Fard, M.H., Khojastehpour, M. et al. Gelatin/Whey Protein- Potato Flour Bioplastics: Fabrication and Evaluation. J Polym Environ 28, 2029–2038 (2020). https://doi.org/10.1007/s10924-020-01748-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01748-1