Abstract

Bioplastic materials from renewable polymers, like proteins, constitute a highly interesting field for important industrial applications such as packaging, agriculture, etc., in which thermo-mechanical techniques are increasingly being used. This study assesses bioplastic materials produced by injection from blends previously prepared in a batch mixer using various protein concentrates and isolates. A mixing time of 5 min has been selected in order to ensure correct homogenous blends. A comparison between different protein-based specimens was performed by dynamic mechanical thermal analysis, tensile strength, water uptake and transmittance tests. The comparison reveals that the protein nature and the percentage of plasticizer lead to bioplastics with different properties and, consequently, different applications. Protein concentrates and isolates, wastes and surpluses from the food industry, may be useful for producing bioplastics with suitable mechanical properties and processability, as well as biodegradability, by means of suitable mixing and injection moulding conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The role of plastic materials in society has changed throughout history. At the beginning, they were used due to their cheapness. However, they were not only associated with low quality and inauthenticity [1], but also their tactile properties were generally considered unsatisfactory by the public [2]. It was not until the 1950s that plastics began to develop a market, based on new materials which were flexible, light in weight and soft to the touch [3]. Nevertheless, nowadays there is a high level awareness of the environmental risks associated with global plastic production. Tons of plastics are discarded every day and they can persist for centuries, most of the time ending up in the seas and oceans. In order to mitigate the negative impact of the use of plastic derived from fossil fuels (among them climate change), bioplastics, that is, plastics derived from renewable resources, have been considered a desirable alternative. These materials have demonstrated their suitability as an alternative to traditional plastics. Specifically, developments in their physical structure, reductions in their production costs and their use in diverse applications make them suitable for industrial processing [4].

Proteins, lipids and polysaccharides have been proposed as biopolymer sources for many years [5]. In particular, starch is widely used as a packaging material, usually mixed with biodegradable polyesters [6, 7]. Regarding proteins to manufacture bioplastics, research studies have investigated not only plant proteins such as zein, wheat gluten and soybean [8], but also, in some cases, animal proteins, such as milk proteins, collagen, gelatine, etc. [9]. Moreover, it seems that this study is going one step further, towards the use of food industry surpluses and wastes to manufacture bioplastics. In fact, the need for cost-competitive [10] and biodegradable materials has led to products from agricultural sources being exploited as an alternative to synthetic polymers [11].

In this research, five biopolymers sources have been selected, including both animal and plant proteins. The freshwater red-swamp crayfish (Procambarusclarkii) was introduced into Europe in the early 1960s. Since then, the species has undergone rapid widespread growth [12]. This development has also led to the generation of a large amount of crayfish surpluses, as is frequently the case in the fish and shellfish industry. Unfortunately, a high proportion of this product is not, in the end, used for human food consumption [13].

Egg white protein (albumen) is traditionally used by the food industry; however, there is a surplus of this by-product, since the food industry is mostly interested in the egg yolk. In addition, egg white has shown to have excellent availability in the formation of network protein [14].

Soy protein is the major co-product of soybean oil and is one of the cheapest proteins in nature [15]. In fact, soy proteins have commonly been used for food and animal feed for many years. On the other hand, the potential of using soy protein has been recognised as a new polymer for biodegradable resins [16].

Utilization of pea protein can also be justified due to its price (2.5–2.8 $/kg), which is lower than that of other protein isolates like whey protein (13.5–28 $/kg) or even soy protein (3–3.8 $/kg) [17].

Globally, rice is cultivated on 145 million hectares, which are mostly located in Asia. In the European Union, the production of this crop occupies some 410,000 hectares, mostly in the Mediterranean area [18]. Overall, it is estimated that 100 million tons of rice residues and by-products are generated each year [19]. Currently, rice residues are treated as waste production, and are used as animal feed [19] or sometimes incinerated for energy purposes [20].

However, proteins themselves do not have sufficient plasticity to be handled and show brittle properties. Thus, a plasticiser is required, to reduce the glass transition temperature (Tg) and improve the mobility of the polymeric chains. Glycerol (GL) is widely used in biopolymer-based biodegradable materials [21, 22]; it is cheap and is an excellent plasticiser.

The mixture of protein and plasticiser can be processed with plastic processing technologies, from physicochemical or casting methods [23] to thermo-plastic/mechanical methods (compression moulding or extrusion) [24]. However, while injection moulding is among the most common processing methods used with synthetic polymers, it has scarcely been used with biopolymers [25]. It is interesting to demonstrate the importance of processing conditions as well as the relation between protein and plasticizer. The processing conditions may depend on the thermic behaviour of the protein systems (flours and plasticized blends) and the latter is also very important because it has to be taken into account the relation between the real protein content and the amount of plasticizer used.

The overall objective of this work was to assess the potential of the aforementioned biopolymer sources of protein concentrates, or isolates (as some of them are called), for the production of bioplastic materials that could have some comparable properties to synthetic polymers but a low environmental impact. To achieve this objective, a preliminary study of the blends was carried out to select the suitable injection parameters. Then, mechanical properties of final bioplastics were evaluated by dynamic mechanical analysis and tensile tests. In addition, water uptake capacity and transparency measurements were carried out.

Materials and Methods

Materials

Albumen protein isolate (API) was provided by OVOSEC S.A, soy protein isolate (SPI) by Protein Technologies International (SUPRO 500E, Leper, Belgium), pea protein isolate (PPI) by Roquette (Lestrem, France) and rice protein concentrate from rice husk (RPC) by Remy Industries (Leuven-Wijgmaal, Belgium), and all of them had been produced by spray drying. Further, crayfish flour concentrate (CFC) was supplied by ALFOCAN S.A. (Isla Mayor, Seville, Spain), this, unlike the other protein systems, having been obtained by rotary drum drying. Table 1 lists the composition for all these protein systems. The protein content was determined in quadruplicate using a LECO CHNS-932 elemental analyzer (Leco Corporation, St. Joseph, MI, USA) [26] and expressed as g kg−1 of N × 6.25, those with a protein content of 900 g kg−1 or higher on dry basis being considered protein isolates according to Pearson’s classification [27]. Lipid content was analysed by Soxhlet extraction. The rest corresponds to moisture [28] and mineral content (quantified by ash content, [29]) depending on the system (concentrate or isolate). Lastly, just one plasticiser used, GL, and this was purchased from Panreac Química, S.A. (Spain).

Sample Preparation

Blends with constant protein/plasticiser ratios were manufactured by a two-stage thermo-mechanical procedure. Initially, blends were mixed in a Haake Polylab QC two-blade counter-rotating batch mixer (ThermoHaake, Karlsruhe, Germany) at 25 °C and 50 r.p.m. for 60 min, monitoring the torque and temperature during the mixing process. Two different protein/plasticiser ratios were analysed in order to select a suitable proportion of each compound: 700–300 g kg−1 and 600–400 g kg−1 (denoted as 70/30 and 60/40 systems, respectively). Lower protein/plasticizer ratios would lead to an excess of plasticizer that yields too low consistent blends to be properly processed and an increase of this ratio would produce some shear-induced cross-linking effects leading to excessively brittle specimens. The term protein corresponds to protein type products and the ratio for each protein type products (concentrate or isolates) was selected on the basis of the optimal injection moulding processability of each corresponding blend, which turned to be 70/30 for the protein concentrates and 60/40 for the isolates. In this way, all the actual protein/plasticiser ratios are similar, barely ranging between 1.2 and 1.8.

Secondly, the dough-like materials selected after the mixing process were subsequently processed by injection moulding using a MiniJet Piston Injection Moulding System II (ThermoHaake) to obtain a bioplastic specimen. Two types of moulds were used to prepare the specimen: a 60 × 10 × 1 mm rectangular shape mould, for both DMTA experiments and transparency measurements; and a dumbbell-shaped mould, as recommended in ISO 527-2 [30] for tensile testing of plastics.

Characterization of Blends

The most suitable processing variables such as temperatures in the pre-injection mixing chamber or mould were selected after taking calorimetry measurements. Differential scanning calorimetry (DSC) experiments were performed with a Q20 differential scanning calorimeter (TA Instruments, USA), using 5–10 mg samples, in hermetic aluminium pans. A heating rate of 10 °C min−1 was selected. The sample was purged with a nitrogen flow of 50 mL min−1.

Characterization of Bioplastics

Dynamic Mechanical Thermal Analysis (DMTA)

DMTA was carried out with an RSA3 dynamic mechanical analyser (TA Instruments, New Castle, DE, USA), on rectangular specimens using dual cantilever bending. All the experiments were carried out at a constant frequency (6.28 rad s−1) and strain (between 0.01 and 0.30 %, within the linear viscoelastic region). The selected heating rate was 3 °C min−1 and the temperature range covered was from −30 to 130 °C. All the samples were coated with Dow Corning high vacuum grease to avoid water loss.

Tensile Strength Measurements

Tensile tests were performed using the 10-kN Insight Electromechanical Testing System (MTS, Eden Prairie, MN, USA), according to ISO 527-2 [30] for tensile testing of moulding and extrusion plastics. Young’s modulus, maximum stress and strain at break were measured in at least five duplicates for each product using type IV test specimens and a strain rate of 1 mm min−1 at room temperature.

Water Uptake Capacity

Water uptake capacity was measured according to ASTM D570 [31]; using the aforementioned rectangular specimens (60 × 10 × 1 mm). The specimens underwent drying (conditioning) in an oven at 50 ± 2 °C for 5–6 h to determine dry weight, and were then placed into distilled water and weighed at 2 and 24 h of immersion. Finally, they again underwent drying (reconditioning) and were weighed to determine the loss of soluble material. All the experiments were performed in triplicate at room temperature. According to the methodology used, water absorption capacity and loss of soluble material are determined by the following equations:

Transparency Measurements

Transparency measurements were performed with a Genesys-20 spectrophotometer (Thermo Scientific, Waltham, MA, USA). Transmittance (%) of 1 mm thick rectangular specimens was measured using a wavelength of 600 nm. Air was used as the blank (100 % transmittance).

Statistical Analysis

At least three replicates were carried out for each measurement. Statistical analyses were performed with t tests and one-way analysis of variance (ANOVA, p < 0.05) using PASW Statistics for Windows (Version 18, SPSS, Chicago, IL). Standard deviations were calculated for some selected parameters.

Results and Discussion

Preparation and Characterization of Blends

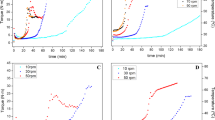

It is very important to select suitable mixing conditions. Specifically, extensive mixing is required to obtain a homogeneous dough-like blend. However, very long mixing periods must be avoided in order to avoid premature crosslinking reactions (structuration) of protein chains [32]. As a consequence, both torque and temperature values must be monitored throughout the mixing process (temperature data not shown). Figure 1 shows torque as a function of mixing time up to 60 min for the five protein systems (based on crayfish, albumen, soy, rice and pea) for the two different protein/GL ratios: 60/40 (Fig. 1a) and 70/30 (Fig. 1b).

Evolution of torque over the mixing process of different protein/glycerol blends with different protein systems: crayfish flour concentrate (CFC), albumen protein isolate (API), soy protein isolate (SPI), rice protein concentrate (RPC) and pea protein isolate (PPI), for the two different protein/GL ratios: 60/40 (a) and 70/30 (b)

Figure 1a shows that generally all 60/40 systems exhibit a similar profile with an early peak, followed by a practically constant torque. However, an increase in the torque is observed at around 50 min in the SPI system. In addition, 60RPC/40GL and 60API/40GL dough-like materials exhibit constantly low torque values, typical of liquid-like behaviour and, on the other hand, in the 60CFC/40GL system, the torque values after the initial peak are very high, corresponding to an overly solid-like material. Figure 1c, d show the temperature profiles for the systems studied. Temperature profiles always show a growth, which is rather coincident with the increase in torque, followed by a trend towards a constant value, which verifies the appearance of exothermic polymerization reactions.

In general, 70/30 systems have higher torque values than the 60/40 blends. This difference can be attributed to an increase in the consistency of the blends as a consequence of the higher proportion of protein in the blend. In addition, all profiles obtained for 70/30 blends showed an early local maximum (at <3 min) that corresponds to the initial mixing, but after that, different behaviours can be observed. For 70API/30GL and 70SPI/30GL, a second maximum is observed, probably due to shear-induced structuring. In fact, as previously mentioned, the torque increase coincides with a temperature increase, probably attributable to crosslinking reactions. The rest of the systems exhibit relatively constant low values during the first minutes (8, 17 and 38 min for PPI, CFC and RPC, respectively), followed by an increase and then values again remain constant (between 15 and 30 Nm).

It is important to point out that to be easily injectable the dough-like materials should ideally have torque values between 15 and 25 Nm (that is, an intermediate behaviour between these limits). However, in order to ensure proper comparison, the active compound must be approximately constant (between 450 and 550 g kg−1 approximately). On this basis, the most suitable ratio for RPC and CFC (both protein concentrate systems) would correspond to 454 and 547 g kg−1 of protein, respectively. For the protein isolate systems, 60/40 (protein/GL) was selected, corresponding to 499, 546 and 505 g kg−1 of protein for API, SPI and PPI, although the torque of SPI and API are lower than ideal. Finally, the mixing time was selected to ensure correct mixing, obtaining a homogenous system (after the initial maximum peak). Specifically, the mixing time selected was 5 min, as this avoided the second maximum corresponding to shear-induced structuring that appeared in some systems.

Differential Scanning Calorimetry (DSC)

Heat flow patterns obtained from DSC measurements in a temperature range between −30 and 140 °C are shown in Fig. 2 for protein powders (Fig. 2a) and for the different protein/GL systems selected (Fig. 2b).

It is important to differentiate between endothermic dips and the Tg. Endothermic dips are related to changes in the aggregation states in protein flours or blends, whereas Tg is the temperature at which a reversible thermodynamic transition occurs for vitreous materials. The different values for the endothermic dips and Tg of the protein flours and blends studied have been included in Table 2.

Some endothermic dips that appear in Fig. 2a (protein systems) are absent in Fig. 2b (protein/plasticiser systems). This could be associated with an ageing-related physical caking of the powder, a phenomenon that occurs over time in glassy or partially glassy polymers below their Tg and is a manifestation of the non-equilibrium nature of the glassy state [33]. As it can be observed in Table 2, these endothermic dips are located at 70 °C for CFC (similar to Farahnaky et al. [34]), 64 °C for API (similar to Rao and Labuza [35]), 66 °C for SPI (similar to Guerrero and de la Caba [36]), 71 °C for RPC (10 °C lower than the dip described by Ju et al. [37]) and 63 °C for PPI. On the other hand, there are significant differences between the Tg with the different protein flours (Fig. 2a), though all of them show values between 90 °C (for SPI) and 100 °C (for PPI). While these values are similar to those found in the literature, results are highly influenced by moisture content.

As regards the endotherms obtained for all the protein/GL blends (Fig. 2b), it may be observed how all the thermal events are displaced towards lower temperature (Table 2) due to the plasticizing effect of GL that induces significant changes in the microstructure. It is worth mentioning that the use of temperatures higher than the Tg leads to systems showing higher mobility and lower viscosity, which may be also relevant for processing. Therefore, the temperature in the injection chamber was selected to be greater than or similar to Tg. In fact, these results are considered in the selection of injection moulding conditions (“Preparation and Characterization of Bioplastics” section).

It is also interesting how the Tg changes with the amount of GL. Systems with a lower proportion of GL have higher values of Tg due to the significant changes which are produced in the microstructure of the blends by the plasticiser, and Tg is displaced to lower values by increasing the amount of plasticiser.

Preparation and Characterization of Bioplastics

The Processing parameters for the pre-injection cylinder were 60 °C and residence time of 100 s, maintaining the same temperature and increasing the pressure from 0.1 to 50 MPa in 0.1 s during injection (the same conditions were used for all the proteins). In fact, to prevent thermally-induced protein crosslinking effects before the injection stage, neither the temperature nor the residence time should be increased very far. In addition, for the packing stage, the time and the pressure selected are again the same for all the proteins (a pressure of 50 MPa for 20 s, decreasing to 20 MPa for 200 s). However, two different groups of proteins can be considered as a function of the mould temperature (injection temperature): 100 °C for CFC and 120 °C for API, SPI, RPC and PPI (exposure to higher temperatures for a long time typically leading to protein degradation). These conditions should allow protein crosslinking and thereby the formation of the final network structure. The processing conditions of each system are shown in Table 3.

Mechanical Characterization

Dynamic Mechanical Thermal Analysis (DMTA)

The elastic behaviour of the bioplastics can be studied by DMTA. Figure 3a shows the values of elastic modulus (E′) obtained from DMTA, whereas in Fig. 3b the loss tangent (tan δ) is plotted, which change with temperature depending on the protein used for obtaining the bioplastics. Almost all the systems exhibit a similar viscoelastic behaviour, covering two regions: the transition from the glassy to rubbery region, where the value of E′ decrease with temperature until it reaches a minimum (between 80 and 100 °C) and then remaining constant, which corresponds to the rubbery plateau region. However, the profile for the crayfish protein differed in that E′ decreased to markedly lower values and then increased again, implying thermosetting potential. It should be noticed that CFC is the system with higher lipid content that may also contribute some plasticising effect. Moreover, this shape of curve indicates that the temperature during the processing of the bioplastic could be increased (yielding higher values for E′ and a profile similar to those obtained for plant proteins), although it cannot be increased very far because it could cause complete denaturation of protein (de-structuration). It is important to point out that E′ values remain constant or only increase slightly after the minimum for plant proteins. Considering the SPI profile, its E′ values are intermediate between those of the other plant proteins and similar to those obtained by Liu et al. [38]. Further, API and RPC have the most elastic behaviour, their E′ values being higher, and the profile for API is consistent with that described elsewhere [11]. It may be also taken into account that RPC is the system displaying a higher actual protein/glycerol ratio.

Results from mechanical tests carried out for different protein/glycerol biobased specimens (CFC, API, SPI, RPC and PPI): a storage modulus (E′) and b loss tangent (tan δ) values from dynamic mechanical analysis (DMA) temperature ramp measurements performed at constant frequency (1 Hz) and heating rate (3 °C min−1)

In addition, the analysis of the loss tangent (tan δ) was performed in order to assess the compatibility of the protein/plasticiser mixture (Fig. 3b). All systems show a marked maximum value corresponding to the plasticised protein-based material obtained for all the systems after the injection moulding process, indicating good compatibility between protein and plasticiser (GL), regardless of the protein used. However, once again, it is also important to note the difference between other systems and CFC-biobased plastic specimens, in which tan δ takes much higher values, possibly related to the transition observed at a temperature ca. 100 °C. Nevertheless, these results should be taken into account carefully, since values for CFC specimens are close to the sensitivity limit of the measurement device.

Tensile Strength Measurements

Figure 4a displays the stress–strain curves obtained for different protein/GL specimens. Two different profiles can be distinguished. On the one hand, in the curves for PPI, SPI and API, an initial linear region, this corresponds to the elastic or Young’s modulus, followed by a plastic deformation stage, with a continuously decreasing gradient. Finally, a sudden decrease in stress, which corresponds to the rupture of the material, takes place. On the other hand, CFC and RPC present a profile which is formed only by the initial linear region with a high constant stress–strain ratio. Lastly, the specimen obtained with PPI is the one with the highest stress values.

In addition, Fig. 4b shows the values of the tensile parameters from tensile tests performed on these bioplastics: Young’s modulus, maximum tensile strength and strain at break. Looking at the results, systems with the 70/30 protein/plasticiser ratio have the highest values of Young’s modulus, while systems based on the 60/40 protein/plasticiser ratio had the highest values for the strain at break. Thus, the Young’s modulus seems to be dependent on the actual protein/plasticiser ratio, which is also higher for 70/30 systems, particularly for RPC. Moreover, these systems show very low values for the strain at break, which is consistent with the high values found for the modulus. However, it may be also taken into account the high ash content of these systems (RPC and CFC), as may be observed in Table 1.

For SPI, the Young’s modulus obtained was 5 MPa, lower than the value described by Pateau et al. [39] but with a lower proportion of plasticiser, and also, the value for maximum stress shown in Fig. 4b is lower than that reported by Tummala et al. [40] and Liu et al. [38] (who both obtained values around 9–10 MPa). On the other hand, for albumen protein, the value for the maximum stress (1.7 MPa) is very close to the value given by Martin-Alfonso et al. [41]. Notably, the PPI-based bioplastic is the system which showed the highest values for both strain at break and maximum stress, indicating stronger interactions between protein chains. This effect can be associated to a high total sulfhydryl content, which is typical of legume proteins such as PPI [42]. Such interactions provide bioplastic materials with better mechanical properties that may in some cases induce both an increase in strain and strength and consequently in toughness. This seems to be the case of PPI-based bioplastic.

In any case, all protein/GL bioplastic specimens exhibit lower tensile strength than synthetic polymers, such as LDPE, according to the normalized values obtained following ASTM standard test methods.

Water Uptake Capacity and Soluble Matter Loss

Figure 5 shows a comparison of water uptake measurements obtained after immersion of bioplastic samples for 2 and 24 h, as well as the water-soluble matter loss for different protein-based bioplastic specimens. As it can be observed, the bioplastic system that had the highest water uptake was the PPI-biobased plastic, followed by SPI and API systems, respectively. Values for API are similar to those found by Martin-Alfonso et al. [41]. It is worth noting the very low values found for CFC-based specimens that can be related to the higher amount of lipids compared to those for the plant protein-based specimens. Water absorption capacity is high, and shows the hydrophilic character of proteins like pea or soy, the latter having 8 % lower absorption at 24 h than the value obtained by Pateau et al. [39].

It is also important to mention that the PPI-based specimen has a lower value for water absorption at 24 h than at 2 h, unlike the characteristics of the other bioplastics tested (those based on SPI, API, RPC or CFC). This effect may be related to water not only tending to fill the voids generated by GL solubilisation, but also tending to hydrate the hydrophilic parts of protein surfaces. That is, in the PPI system, hydrophilic protein sites have been hydrated in the first 2 h, but the GL has not yet been released, and this results in a water uptake value exceeding 100 %. Then, as GL is released the water uptake falls to below 100 %, and as a consequence water uptake seems to be lower after 24 h. Finally, the loss of soluble matter for all the specimens is between 35 and 50 %, corresponding to the amount of GL which is almost completely lost.

Transparency Measurements

Figure 6 shows the evolution of the transmittance index for different protein systems. Usually in polymers, transparency is related to crystallinity. It has also been found that the transparency of bioplastics is to some extent dependent on the injection parameters. Specifically, some structural changes which have an effect on mechanical properties were found to be attributable to the injection process and this may also be responsible for structural changes which cause crystallinity in bioplastic systems. However, in our case, the transparency of the specimen strongly depends on its composition. Thus, non-protein components of the concentrates/isolates seem to affect the transparency profile of these bioplastics. Specifically, the protein-based bioplastics having high ash content (RPC and CFC) are opaque, whereas API-based one is at the opposite end of the spectrum. SPI and PPI-based bioplastics, having low ash content, exhibit transparency although with lower transmittance index than API, which suggest a less amorphous degree (Fig. 6).

Concluding Remarks

From the results obtained, it is apparent that protein concentrates and isolates, wastes and surpluses from the food industry may be useful for producing bioplastics by means of a two-stage thermo-mechanical process (mixing and injection moulding), provided that suitable processing conditions are selected.

For the all protein/GL blends investigated, use of a certain amount of plasticiser (in the range of 30–40 %) was found effective in order to achieve good processability. In general, a lower protein/plasticiser ratio leads to an excess of plasticiser that yields insufficiently consistent blends for processing and gives rise to specimens showing GL exudation. On the other hand, increasing this ratio would produce some shear-induced crosslinking effects, leading to excessively brittle specimens.

A good compatibility was found for all protein-based systems. In general, using a higher protein/plasticiser ratio leads to a higher Young’s Modulus and maximum stress and, conversely, a lower protein/plasticiser ratio contributes to lower transparency and greater strain at break and, consequently, a greater ability to absorb energy before rupture.

Finally, protein-based bioplastics are very promising materials for the substitution of conventional petroleum plastics in certain applications, since they have suitable mechanical properties and processability, as well as biodegradability.

References

Sparke P (1990) The plastic age: from modernity to post modernity. B.A.S Printers, London

Walker JA, Attfield J (1990) Design history and the history of design. Pluto Press, London

Cleminshaw D (1989) Design in plastics. Rockport, Beverly

Karana E (2012) Characterization of “natural” and “high-quality” materials to improve perception of bio-plastics. J Clean Prod 37:316–325. doi:10.1016/j.jclepro.2012.07.034

Averous L (2004) Biodegradable multiphase systems based on plasticized starch: a review. J Macromol Sci Rev C44:231–274. doi:10.1081/mc-200029326

Ke TY, Sun XZS (2003) Thermal and mechanical properties of poly(lactic acid)/starch/methylenediphenyl diisocyanate blending with triethyl citrate. J Appl Polym Sci 88:2947–2955. doi:10.1002/app.12112

Yang Y, Zhang K, Song Y-H, Zheng Q (2011) Preparation and properties of wheat gluten/rice protein composites plasticized with glycerol. Chin J Polym Sci 29:87–92. doi:10.1007/s10118-010-9185-8

Cuq B, Gontard N, Guilbert S (1998) Proteins as agricultural polymers for packaging production. Cereal Chem 75:1–9. doi:10.1094/cchem.1998.75.1.1

Pommet M, Redl A, Morel MH, Guilbert S (2003) Study of wheat gluten plasticization with fatty acids. Polymer (Guildf) 44:115–122. doi:10.1016/s0032-3861(02)00746-2

Zheng H, Tan ZA, Zhan YR, Huang J (2003) Morphology and properties of soy protein plastics modified with chitin. J Appl Polym Sci 90:3676–3682. doi:10.1002/app.12997

González-Gutiérrez J, Partal P, García-Morales M, Gallegos C (2011) Effect of processing on the viscoelastic, tensile and optical properties of albumen/starch-based bioplastics. Carbohydr Polym 84:308–315. doi:10.1016/j.carbpol.2010.11.040

Geiger W, Alcorlo P, Baltanas A, Montes C (2005) Impact of an introduced Crustacean on the trophic webs of Mediterranean wetlands. Biol Invasions 7:49–73. doi:10.1007/s10530-004-9635-8

Kirjavainen J, Westman K (1999) Natural history and development of the introduced signal crayfish, Pacifastacus leniusculus, in a small, isolated Finnish lake, from 1968 to 1993. Aquat Living Resour 12:387–401. doi:10.1016/s0990-7440(99)00110-2

Aguilar JM, Jaramillo A, Cordobes F, Guerrero A (2010) Influence of thermal processing on the rheology of egg albumen gels. Afinidad 67:28–32

Tian H, Wang Y, Zhang L et al (2010) Improved flexibility and water resistance of soy protein thermoplastics containing waterborne polyurethane. Ind Crops Prod 32:13–20. doi:10.1016/j.indcrop.2010.02.009

Sun XZS, Kim HR, Mo XQ (1999) Plastic performance of soybean protein components. J Am Oil Chem Soc 76:117–123. doi:10.1007/s11746-999-0057-8

Kowalczyk D, Baraniak B (2011) Effects of plasticizers, pH and heating of film-forming solution on the properties of pea protein isolate films. J Food Eng 105:295–305. doi:10.1016/j.jfoodeng.2011.02.037

Ferrero A, Tinarelli A (2007) Chapter 1—rice cultivation in the EU ecological conditions and agronomical practices. In: Karpouzas EC (ed) Pesticide risk assessment in rice paddies. Elsevier, Amsterdam, pp 1–24

Njie M, Reed JD (1995) Potential of crop residues and agricultural by-products for feeding sheep in a gambian village. Anim Feed Sci Technol 52:313–323. doi:10.1016/0377-8401(94)00710-q

Li J, Liu J, Liao S, Yan R (2010) Hydrogen-rich gas production by air–steam gasification of rice husk using supported nano-NiO/γ–Al2O3 catalyst. Int J Hydrogen Energy 35:7399–7404. doi:10.1016/j.ijhydene.2010.04.108

Lukubira S, Ogale A (2015) Thermoformable Anhydride–Glycerol modified meat and bone meal bioplastics. J Polym Environ 23:517–525. doi:10.1007/s10924-015-0727-6

Trujillo-de Santiago G, Rojas-de Gante C, García-Lara S et al (2015) Thermoplastic processing of blue maize and white sorghum flours to produce bioplastics. J Polym Environ 23:72–82. doi:10.1007/s10924-014-0708-1

Genadios A (2002) Proteins based films and coting. CRC Press, New York

Jerez A, Partal P, Martinez I et al (2007) Protein-based bioplastics: effect of thermo-mechanical processing. Rheol Acta 46:711–720. doi:10.1007/s00397-007-0165-z

Cho S-W, Gällstedt M, Johansson E, Hedenqvist MS (2011) Injection-molded nanocomposites and materials based on wheat gluten. Int J Biol Macromol 48:146–152. doi:10.1016/j.ijbiomac.2010.10.012

Etheridge RD, Pesti GM, Foster EH (1998) A comparison of nitrogen values obtained utilizing the Kjeldahl nitrogen and Dumas combustion methodologies (Leco CNS 2000) on samples typical of an animal nutrition analytical laboratory. Anim Feed Sci Technol 73:21–28. doi:10.1016/s0377-8401(98)00136-9

Pearson AM, Hudson BJF (1983) Developments in food proteins, vol 2. Applied Science Publishers, London

AACC International. Approved methods of analysis, 11th edn. Method 44-15.02. Moisture—Air-Oven Methods. AACC International, St. Paul, MN

AACC International. Approved methods of analysis, 11th edn. Method 08-01.01. Ash content—Basic Method. AACC International, St. Paul, MN

ISO 527-2:2012. Plastics—Determination of tensile properties—Part 2: Test conditions for moulding and extrusion plastics, pp 527–532

ASTM D570 - 98 (2010) Standard test method for water absorption of plastics

Jerez A, Partal P, Martinez I et al (2007) Egg white-based bioplastics developed by thermomechanical processing. J Food Eng 82:608–617. doi:10.1016/j.jfoodeng.2007.03.020

Chartoff RP (1997) Chemical principles. Academic Press, New York

Farahnaky A, Guerrero A, Hill SE, Mitchell JR (2008) Physical ageing of crayfish flour at low moisture contents. J Therm Anal Calorim 93:595–598. doi:10.1007/s10973-007-8655-x

Rao Q, Labuza TP (2012) Effect of moisture content on selected physicochemical properties of two commercial hen egg white powders. Food Chem 132:373–384

Guerrero P, de la Caba K (2010) Thermal and mechanical properties of soy protein films processed at different pH by compression. J Food Eng 100:261–269. doi:10.1016/j.jfoodeng.2010.04.008

Ju ZY, Hettiarachchy NS, Rath N (2001) Extraction, denaturation and hydrophobic properties of rice flour proteins. J Food Sci 66:229–232. doi:10.1111/j.1365-2621.2001.tb11322.x

Liu WJ, Misra M, Askeland P et al (2005) “Green” composites from soy based plastic and pineapple leaf fiber: fabrication and properties evaluation. Polymer (Guildf) 46:2710–2721. doi:10.1016/j.polymer.2005.01.027

Paetau I, Chen CZ, Jane JL (1994) Biodegradable plastic made from soybean products. 1. Effect of preparation and processing on mechanical-properties and water-absorption. Ind Eng Chem Res 33:1821–1827. doi:10.1021/ie00031a023

Tummala P, Liu W, Drzal LT et al (2006) Influence of plasticizers on thermal and mechanical properties and morphology of soy-based bioplastics. Ind Eng Chem Res 45:7491–7496. doi:10.1021/ie0604391

Martin-Alfonso JE, Felix M, Romero A, Guerrero A (2014) Development of new albumen based biocomposites formulations by injection moulding using chitosan as physicochemical modifier additive. Compos B Eng 61:275–281. doi:10.1016/j.compositesb.2014.01.057

Tang C-H (2008) Thermal denaturation and gelation of vicilin-rich protein isolates from three Phaseolus legumes: a comparative study. Lwt Food Sci Technol 41:1380–1388. doi:10.1016/j.lwt.2007.08.025

Acknowledgments

This work is part of a research project sponsored by Andalousian Government, (Spain) (project TEP-6134) and by “Ministerio de Economía y Competitividad” from Spanish Government (Ref. MAT2011-29275-C02-02/01). The authors gratefully acknowledge their financial support. The authors also acknowledge to the Microanalysis Service and Functional Characterisation Service (CITIUS-Universidad de Sevilla) for providing full access and assistance to the LECO-CHNS-932 and DSC Q20 Calorymetry (TA instruments), respectively. The authors also thank University of Seville for the grant of the VPPI-US.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Felix, M., Perez-Puyana, V., Romero, A. et al. Production and Characterization of Bioplastics Obtained by Injection Moulding of Various Protein Systems. J Polym Environ 25, 91–100 (2017). https://doi.org/10.1007/s10924-016-0790-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0790-7