Abstract

Composite gels of whey protein isolate (WPI) and potato starch (PS) were formed by calcium chloride induced cold gelation to obtain microstructures where native starch granules were encased in the WPI network. Gels were then subjected to heat treatment and PS gelatinized inside the protein network. In vitro starch digestibility was investigated using the INFOGEST protocol to explore if the protein gel was able to protect gelatinized starch granules from enzymatic attack during digestion. This study was focused on the impact of gel particle size and protein concentration on glucose release from the matrix. Mechanical and rheological properties of the composite gels were also evaluated after heat treatment. Glucose release from the matrix was reduced until the intestinal step of the simulated digestion when gels were ground to a particle size of ~1 mm. When gels were cut to a particle size of ~5 mm glucose release was decreased until the end of the test. In this case, at the end of the digestion glucose release was reduced by 15.5 and 20.5% for composite gels with 8 and 10% WPI respectively, whereas no significant reduction was observed for the gel with 6% WPI. Therefore, the effect of the WPI network on starch digestibility depended on particle size and on protein concentration. Mechanical and rheological properties of the gels were related to starch digestibility: PS hydrolysis rate decreased with increasing hardness and elasticity of the gels. This work contributes to a better understanding of starch digestion in soft food matrices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The World Health Organization (WHO) estimated that approximately 422 million adults suffered diabetes in 2014 [1]. The prevalence of the disease has nearly doubled across the globe since 1980 and according to the International Diabetes Federation (IDF) over 600 million people will be diagnosed with diabetes by 2045 [2].

Evidence has shown that nutrition plays a crucial role in the self-management of diabetes and the prevention of long-term complications [3]. The adoption of a low glycemic index (GI) diet as part of an overall healthy eating lifestyle has been shown to significantly improve glycemic control, cardiovascular risk factors (e.g. total cholesterol, HDL), beta cell function and to decrease the need for anti-hyperglycemic agents among individuals with diabetes [4]. Moreover, reducing the GI and/or glycemic load (GL) of ingested foods together with reducing nutrient density and increasing physical activity, may delay type 2 diabetes for people with an impaired glucose tolerance by targeting obesity and overweight [5]. There is therefore a growing need for the development of specific foods with a slow and steady postprandial release of glucose to help managing disorders of glucose metabolism.

This calls for a better understanding of the digestion of complex carbohydrates, like starch, in solid food matrices. Indeed, other constituents of the food matrix may affect the final digestibility of the ingested starch [6]. In particular, the presence of a protein barrier surrounding the starch granules in processed products such as pasta has been related to a reduction of in vitro starch digestibility [7,8,9,10,11,12,13]. A lower rate and degree of in vitro starch hydrolysis in thermogels of whey protein/wheat starch [14] and whey protein/chitosan/wheat starch [15] has also been observed. Hence, protein gels appear as interesting matrices to encase starch and modulate its digestibility. In addition, they may help reducing overeating by increasing satiation and satiety [16,17,18] and mimic some of the organoleptic attributes of fat and carbohydrates [19].

Whey proteins are known to form gels by different mechanisms, among them, cold gelation [20]. Currently, cold-set whey protein gels have been used to enhance the bioavailability of heat-sensitive bioactive molecules and micronutrients [21], to modulate lipid digestion [22,23,24] and to create new food textures [19]. In cold gelation, native starch can be embedded in a whey protein network while avoiding starch gelatinization until further processing. Additionally, whey proteins have been shown to reduce postprandial glycemia in patients with type 2 diabetes by stimulating secretion of insulin and incretins as well as by delaying gastric emptying [25, 26]. Starch digestibility in food matrices has been traditionally assessed by an in vitro enzymatic method developed by Englyst et al. [27]. This approach evaluates the amounts of glucose likely to be available for rapid and slow absorption in the human small intestine and is useful to estimate the future glycemic response of a food. However, a standardized in vitro digestion method for food was recently developed by the European INFOGEST network [28]. This group of experts described a static model, easy to set up and apply, aiming at harmonizing the protocols simulating human digestion so that results among studies could be compared worldwide. Since its publication, the harmonized INFOGEST in vitro method has been used to study starch digestibility in various food matrices like pasta [29], bean paste [30], black rice [31] and chickpeas [32], among others.

The objective of this study was to evaluate if whey protein isolate (WPI) networks formed by cold gelation were able to restrict the in vitro digestibility of potato starch (PS) after heat treatment. Indeed, through cold gelation native starch can be entrapped in a whey protein gel while avoiding gelatinization until further processing, different from thermal gelation where the formation of the protein network occurs after starch gelatinization [14, 19, 33, 34]. The hypothesis of this study is that a protein gel can protect gelatinized starch granules from enzymatic attack during digestion. In vitro starch digestibility was investigated using the harmonized INFOGEST protocol [28] and the impact of particle size and protein concentration on PS digestibility were assessed. A better understanding of starch digestion in soft protein gels will be helpful for the design of low-calorie and/or satiety-inducing foods with controlled postprandial glycemic responses.

Material & Methods

Materials

BiPro® whey protein isolate (WPI) with a moisture content of 4.6% and a protein content of 97.7% (d.b.) was purchased from Davisco (Davisco Foods Intl., MN, USA) and native potato starch (PS), composed of approx. 20% amylose and 80% amylopectin, with a moisture content of approx. 20% and a carbohydrate content of 99.6% (d.b.) was from a local supermarket (Santiago, Chile).

The enzymes α-amylase (A9857, activity ≥150 units/mg) from Aspergillus oryzae, pepsin (P7000, activity ≥250 units/mg) from porcine gastric mucosa, pancreatine (P1750, activity 4 x USP) from porcine pancreas, invertase (I4504, activity ≥300 units/mg) from baker’s yeast and bile porcine extract (B8631) were obtained from Sigma-Aldrich (Sigma Chemical Co., St. Louis, MO, USA), as well as the glucose oxidase/peroxidase enzymatic glucose assay kits (GAGO20). Amyloglucosidase (E-AMGDF, activity 3260 U/mL) from Aspergillus niger was purchased from Megazyme International (Megazyme International Co., Wicklow, Ireland). All other chemicals were standard analytical grade and distilled water was used for the preparation of all mixtures.

Sample Preparation

Composite gels of WPI and PS were prepared by cold gelation. A solution of 11% (w/w) native WPI in distilled water (pH of the solution = 6.8) was heated in a water bath at 80 °C for 30 min, in order to obtain a dispersion of protein aggregates. After cooling for 30 min in a water bath at 20 °C, the solution was diluted with distilled water to reach the protein concentration needed. PS was added to the cold dispersion of WPI aggregates and stirred for 15 min, before the addition of the CaCl2 solution under continuous stirring, in order to obtain a final mixture of 6, 8 or 10% (w/v) WPI, 5% (w/v) PS and CaCl2 10 mM. These formulations were chosen to avoid starch sedimentation and to produce soft and elastic cold-set gels. For in vitro digestion, mechanical properties and cryo-SEM studies, samples were transferred to stoppered glass tubes (cylinders of 15 cm long × 2 cm of diameter). For the measure of thermal properties, 50 mg of each sample was sealed in a 100 μl aluminum pan and for rheological measurement, samples were cast onto disposable plates of 25 mm in diameter and 1 mm of height. All samples were finally stored overnight at 4 °C. Controls were: (1) a 5% (w/v) dispersion of PS in a CaCl2 solution (10 mM); (2) a gel of pure WPI (10%, w/v) with 10 mM CaCl2 and, (3) a blend of ground WPI gel (10% w/v, CaCl2 10 mM) and a dispersion of PS (5% w/v), having the same final total solids content as the composite gel of WPI 10% w/v and PS 5% w/v.

Heat Treatment

In order to maximize PS gelatinization, gel samples and controls (in glass tubes) were heated in distilled water at 90 °C for 30 min and immediately cooled in iced water for 5 min. To obtain the mixture of WPI gel and PS dispersion (control (3)), both preparations were heated separately under the above conditions and mixed after cooling.

In Vitro Digestion

According to Chen et al. [35], the projected area of particles in the bolus of a soft food after chewing may vary between ~1 and 6 mm2. Samples with a small particle size (~1 mm or less) were obtained by grinding the gel with a domestic kitchen hand blender as recommend by the INFOGEST network [28] (Braun MultiQuick 5 MQ505, 30s at velocity no. 1) and sieving (U.S.A. Standard Test Sieve No. 18, 1 mm stainless steel wire mesh, W.S. Tyler, Mentor, OH, USA). Samples with a large particle size were obtained by cutting the gel into cubes (~5 mm sides), according to Guo, Bellissimo & Rousseau [22].

In vitro starch digestibility was assessed according to the guidelines of the INFOGEST in vitro digestion method [28]. This standardized in vitro static protocol comprises three digestion stages: oral, gastric and intestinal phases. For each stage, the composition and pH of the simulated digestive fluids and enzymes activities were carefully reproduced according to Minekus et al. [28] recommendations.

Oral Phase (pH 7)

The Simulated Salivary Fluid (SSF) was pre-incubated for 10 min at 37 °C. Five grams of the ground or cut samples were mixed in a 50 mL conical falcon tube with 3.5 mL of SSF stock solution, 25 μL of 0.3 M CaCl2 solution, 975 μL of distilled water and 0.5 mL of amylase solution 1500 U/mL (dissolved in SSF) and adjusted to a final volume of 10 mL. The mixture was incubated at 37 °C for 2 min in a shaking water bath at 100 rpm. Then the pH of the solution was lowered by adding 0.15 mL of 1 M HCl solution to inactivate the amylase activity.

Gastric Phase (pH 3)

7.5 mL of Simulated Gastric Fluid (SGF) stock solution, 5 μL of 0.3 M CaCl2 solution, 845 μL of distilled water and 1.6 mL of pepsin solution 25,000 U/mL (dissolved in SGF) were added to the oral phase mixture, to a final volume of 20 mL. The mixture was incubated at 37 °C for 2 h in a shaking water bath (100 rpm). After this period, the pH of the solution was increased with 0.14 mL of 1 M NaOH solution to inactivate the pepsin activity.

Intestinal Phase (pH 7)

10 mL of Simulated Intestinal Fluid (SIF) stock solution, 40 μL of 0.3 M CaCl2 solution, 1.32 mL of distilled water, 2.5 mL of 160 mM bile extract, 5 mL of pancreatin solution and 1 mL of invertase solution (both dissolved in SIF) and 65 μL of amyloglucosidase, were added to the previous mixture (after the oral and gastric phase) to a final volume of 40 mL. In this digestion step, the protocol was modified according to Dartois et al. [36] to adjust the enzymatic composition to the specificity of the study of starch digestibility. The pancreatin enzyme/starch (dry weight basis) ratio was 1.3:100 (w/w), the invertase enzyme/starch (dry weight basis) ratio was 1:1000 (w/w) and the amyloglucosidase enzyme/starch (dry weight basis) ratio was 0.26:1 (v/w). The resulting mixture was incubated at 37 °C for 1 h in the shaking water bath (100 rpm).

Glucose Content Analysis

For each sample, five different falcon tubes were prepared and withdrawn one by one at different steps and times of the in vitro digestion assay: after the oral phase, the gastric phase, and after 15, 30 and 60 min of intestinal digestion. Previous work showed that no further changes occurred after 60 min of intestinal digestion.

The mixture contained in the falcon tube and at the specific digestion step needed, was mixed with four times its volume of absolute ethanol in order to stop the enzymatic hydrolysis and filtered to remove the remaining solid particles. After 30 min, 0.1 mL of the filtered and stirred mixture was incubated with 0.5 mL of amyloglucosidase/invertase in acetate buffer (10 mg invertase, 0.1 mL amyloglucosidase per 10 mL of acetate buffer at pH 5.2) during 30 min at ambient temperature33. This allows the conversion of oligosaccharides to glucose. The resulting aliquot was finally filtered with a Ministart® NML cellulose acetate hydrophilic syringe filter (Sartorius Stedim Biotech GmbH, Goettigen, Germany) and glucose content was analyzed using the glucose oxidase/peroxidase assay kit GAGO20. The results are expressed as milligrams of glucose released per gram of PS. Each measurement was performed in duplicate.

Thermal Properties

Samples in hermetically sealed pans were first equilibrated at ambient temperature for 1 h. Then, they were heated from 20 to 90 °C at 10 °C/min, kept at 90 °C for 30 min, cooled back to 20 °C at 10 °C/min and finally heated from 20 to 90 °C at 1 °C/min with a Mettler Toledo DSC 822 (Mettler-Toledo Inc., Columbus, OH, USA). The equipment was calibrated using indium and a pan containing 50 mg of distilled water was used as a reference. Indeed, previous work (data not shown) showed that when using an empty pan as a reference part of the transitions occurring in this range of temperature was overlaid by the exothermic peak of water evaporation. Resulting thermograms were analyzed with the STARe Thermal Analysis Evaluation software, version 14.0 (Mettler-Toledo Inc., Columbus, OH, USA). Each measurement was performed in triplicate.

Mechanical Properties

The mechanical properties of gels after the heat treatment were analyzed by uniaxial compression using a TA.XT2 Texture Analyzer (Texture Technology Corp., Scarsdale, NJ, USA). Cylinders (20 mm diameter × 10 mm height) of gels were compressed with a 75 mm diameter plate at a constant deformation speed of 0.1 mm/s up to fracture or a final compression strain of 80%. Measurements were conducted at room temperature (ca. 20 °C). Two sections of each gel sample were measured and three replications of each treatment were performed. The presented results are the compressive hardness in kPa (i.e., the maximum force divided by the original cross-sectional area) and the fracture strain in %, for each experimental condition.

Rheological Properties

For all rheological measurements, a TA Instruments Discovery Hybrid Rheometer HR-3 equipped with an advanced Peltier plate and a solvent trap and evaporation blocker (TA Instruments Corp., New Castle, DE, USA) was used. The solvent trap of the 40 mm top parallel plate was filled with distilled water and the gap size was 1 mm. Temperature sweeps were carried out from 20 to 90 °C and from 90 to 20 °C with a heating/cooling rate of 1 °C/min, at a constant frequency of 1 Hz and a constant strain of 1.0%, which was in the linear viscoelastic region (LVR) for all samples. An axial force of compression of 0.5 N ± 0.1 N was used as conditioning to avoid losing contact between the plates and the sample during the test. After this oscillatory temperature ramp, gels were equilibrated for 15 min at 20 °C and submitted to an amplitude sweep test in order to measure the rheological properties of the gels after heat treatment. Amplitude sweeps were performed at 20 °C at a constant frequency of 1 Hz, between 0.02 and 2000% strain (γ), measuring 10 points per decade. Each measurement was performed in triplicate. From amplitude sweep curves, the plateau value of G’ (G’0) and tan δ were both evaluated at γ = 0.01%. The critical strain, corresponding to the LVR of the gels was defined as the value of γ for which G’ has dropped to 90% of G’0.

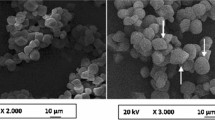

Cryo-SEM

The microstructure of composite gels before and after heat treatment were investigated with cryo-SEM, according to Ong et al. [37] with modifications. Composite gels of WPI 10% and PS 5% were selected. A Hitachi SU8000 scanning electron microscope, equipped with a cryo-preparation system and a vacuum transfer device, was used (Hitachi, Ltd., Tokyo, Japan). A piece of the gel was mounted on a copper holder and immersed into a freshly prepared nitrogen slush for 15 s. The frozen sample was then immediately transferred into the cryo-preparation chamber using the vacuum transfer device. The sample was fractured using a chilled scalpel blade in the chamber which was maintained at −120 °C under a high vacuum condition. The sample was then etched at −90 °C for 30 min. No coating was used. Finally, the sample was transferred under vacuum onto a nitrogen gas cooled module, maintained at −110 °C and observed at 2.0 kV.

Statistical Analysis

Results correspond to the mean ± standard deviation. Statistical significance of the results was tested using analysis of variance (ANOVA) and differences between group means were analyzed by LSD multiple-range test with a probability level of 0.05 (p < 0.05). Statistical analysis was carried out with Statgraphics Centurion software, version 17.1.12 (Statpoint Technologies, Inc. Warrenton, VA, USA).

Results & Discussion

Microstructure of the Composite Gels

After the cold gelation process, native starch granules were homogeneously distributed and embedded in the WPI network (Fig. 1a). The dense structure of native PS was clearly identifiable inside the gel microstructure (Fig. 1b). After heating at 90 °C for 30 min, the microstructure of the composite gel was extensively modified by the gelatinization of PS (Fig. 1c). Swollen starch granules remained encased in the continuous protein matrix and were clearly detached from the network (Fig. 1d). Since no interpenetration of the protein phase and the gelatinized starch was observed by cryo-SEM, mechanical interactions that may exist between the two phases should be limited to the surface of the PS granules. Similar separated microstructures were observed by Yang et al. [38] for wheat starch and Fu & Nakamura [39] for potato starch, in WPI gels produced by thermal gelation.

Starch Gelatinization Inside the Protein Matrix

Figure 2 shows typical DSC thermograms obtained for the PS dispersion and the composite gels during the first step of the heating program. Mean values for the onset, peak, endset temperatures and the enthalpy change, attributed to PS gelatinization, are summarized in Table 1.

Gelatinization of the PS dispersion occurred between 59 and 69 °C, with an endothermic peak at 64 °C. The enthalpy of gelatinization (ΔH) was 13.5 ± 1 J/g. These results are consistent with thermal properties reported in the literature for native PS [40,41,42,43,44,45,46]. In the three composite gels, PS gelatinization was delayed by ~ 4 °C under the same experimental conditions. This delay may be due to a strong interaction between the hydroxyl groups of whey protein molecules and water, which may lead to higher energy requirements for the transition to take place, as was observed in starch-water-carregeenan systems [47, 48]. However, ΔH of starch gelatinization was not modified by the presence of the protein network, regardless of the protein concentration. After the isothermic step at 90 °C for 30 min, no transition was measured when samples were reheated from 20 to 90 °C at 1 °C/min, meaning that no further gelatinization occurred. Thus, it appears that the presence of the whey protein network did not influence the extent of starch gelatinization. The reduction in starch hydrolysis in vitro was probably not related to differences in PS gelatinization.

In Vitro Digestibility of Starch Inside the Protein Matrix

Results obtained at each step of the in vitro procedure (oral, gastric and intestinal), for each particle size and protein concentration, are detailed below.

Oral Step

After the oral step, the glucose released from the PS paste was 19.4 mg/g of PS and significantly different from all samples containing WPI, except for the composite gel 10% WPI, 1 mm (Fig. 3). In the case of the composite gels, glucose released averaged 16.8 mg/g of PS for particle size 1 mm, and 14.6 mg/g of PS for size 5 mm (Fig. 3). When no matrix was formed (i.e., the mixture of the WPI gel and the PS paste), glucose released was 17.4 mg/g of PS. Thus, during the oral step, the digestibility of PS is slightly reduced when protein is present, which may be related to a lower enzyme to total solids ratio.

As shown in Fig. 1d, the dense structure of native PS granules was lost after heat treatment, making them porous and more susceptible to enzymatic attack. Size reduction of the gels, either by grinding (particle size 1 mm) or cutting (particle size 5 mm) ruptured the gel structure. The high shear during grinding certainly resulted in a greater release of PS from the matrix compared to the gentle cutting of the gel into cubes, which retained most of the starch within the gel matrix. In addition, possible cracks in the microstructure may have fostered the accessibility of α-amylase to the interior of the particles.

Numerous in vitro carbohydrate digestion methods exist for analyzing the glycemic properties of foods and complicate comparisons between studies. As a matter of fact, differences in the time of simulated gastric digestion, in the method used to mimic chewing, in the choice of amylolytic enzyme, in pH or in stirring mode, have a substantial influence on the results obtained [49]. Most importantly, the oral digestion step is often neglected in studies on starch digestibility. After 2 min of oral digestion in vitro, a significant amount of glucose was released from all samples (Fig. 3), supporting that this first step of the human digestion process should not be omitted in simulated in vitro studies. Hoebler et al. [50] also reported that even during only 20 to 30 s of oral food processing, approximately 25% of the starch in spaghetti and 50% of the starch in bread were already hydrolyzed. Similarly, it was demonstrated that α-amylase from saliva played an important role in the breakdown kinetics of bread boluses in in vitro models [51] and that between 25 and 50% of the starch in bread and pasta boluses were hydrolyzed by salivary α-amylase in vivo [52]. Moreover, Tamura et al. [53] pointed out that the digestion rate of starch in cooked rice grains during the intestinal phase was influenced by changes which occurred during the previous oral digestion step.

Gastric Step

Glucose released after the gastric step of the in vitro digestion was lower when the protein matrix was present as compared to the control PS paste (Fig. 4). The amount of glucose released was reduced between 29.2% and 38.6% for all WPI concentrations and particle sizes. But when no matrix was formed around PS granules no significant difference in glucose release was observed with the control sample of PS paste. So, at this step, the protein network prevented the release of the gelatinized PS trapped inside the matrix, regardless of particle size or protein concentration. Even after 2 h under simulated gastric conditions, the WPI gel was not significantly affected and the barrier effect of the protein matrix was effective.

Besides gluten, other proteins (exogenous or not) may form a matrix around starch granules during thermal processing of foods. Recently, Oñate Narciso & Brennan [54] showed, with an enzymatic assay including pepsin and pancreatin, that fortification of glutinous rice starch with whey protein concentrate or with pea protein modified starch digestibility in vitro after cooking. Using the enzymatic method developed by Englyst et al. [27], López-Barón et al. [55] also observed that the addition of denatured and/or hydrolyzed plant proteins (pea, rice and soybean) significantly delayed starch hydrolysis in cooked wheat starch-protein mixtures. Similarly, Chen et al. [56] reported that the addition of soy protein delayed the in vitro digestion of gelatinized corn starch in the stomach. With regard to PS, Lu et al. [57] observed a reduction in starch digestibility in PS/potato protein processed blends, using the Englyst method [27].

Intestinal Step

After 15 min of intestinal digestion in vitro, glucose release was significantly reduced for composite gels with a particle size of 5 mm, compared to the PS paste (Fig. 5). Regarding the other experimental conditions, no significant differences were observed with the control sample. Furthermore, as for the PS paste, glucose release from the system already reached a maximum, that is, no further significant changes were measured after 30 and 60 min of intestinal digestion.

For composite gels with a particle size of 5 mm, glucose release was inversely related to the protein concentration of the gel, i.e., glucose values increased when protein concentration decreased. The same trend was observed after 30 and 60 min of intestinal digestion in vitro (Fig. 5). Hence, enzymatic attack to starch granules hidden inside the gel pieces was hindered by the protein network. As stated by Aguilera [58], the digestion of solid matrices in the gut depends largely on their breakdown into small particles, the particle size and surface area, and the nature of these surfaces. A clear negative correlation between particle size and starch digestibility has been observed in cereals [59,60,61,62,63,64], peas [65, 66] and sweet potato [67]. However, the effect of particle size on starch digestibility in starch-based products is not well understood yet. On one hand, Colona et al. [68] reported that grinding cooked spaghetti increases enzyme susceptibility of starch granules compared to intact spaghetti and Granfeldt & Björck [69] confirmed that grinding increases significantly the glycemic index (from 61 to 73). On the other hand, Ranawana, Henry & Pratt [70] concluded that the degree of mechanical breakdown during mastication does not influence starch digestibility in spaghetti. Alam et al. [71] reached the same conclusion about brittle cereal foams and Nordlund et al. [72] observed a relation between particle size of masticated breads and the insulin response but not with the postprandial glucose. It should be noted that there are major differences between most of these works and our study: the protein network is generally gluten, foods have a lower moisture content than the gels, and they have a higher ratio of starch to protein. Starch digestibility in model composite gels formed by cold gelation of proteins have not been systematically investigated despite their potential application as soft food matrices [19].

After 30 min of intestinal digestion, starch hydrolysis was still reduced compared to the control sample for composite gels made with 8 and 10% WPI (particle size 5 mm). At this point, the maximum glucose release had been reached for all experimental conditions and similar results were observed after 60 min of intestinal digestion (Fig. 5).

So, at the end of the digestion protocol, starch digestibility in vitro was significantly reduced in composite gels with 10 and 8% WPI (− 20.5% and − 15.5%, respectively) when particle size was 5 mm (Fig. 5). Therefore, upon further intestinal digestion, protection of starch against enzymatic attack by the WPI network depended on the protein concentration. This means that the microstructure of the network has to be carefully considered in order to efficiently reduce starch digestibility. Microstructural differences in the matrix induced by the protein concentration [73] or salt levels [14] may have a significant effect on the disintegration of the WPI gelled structure. Also, in low cross-linked networks, the matrix might be too loose to reduce starch hydrolysis by a barrier effect, while in highly aggregated networks large pores might form, making the system more susceptible to α-amylase attack [14].

Molecular diffusion in polymer gels depends strongly on the network structure [74]. As may be deducted from Fig. 1d, the tortuosity of the WPI network around PS granules may lengthen the path for enzymes, leading to a barrier effect of the protein matrix [7]. It is therefore expected that enzyme diffusion, and consequently glucose release from the matrix, should be negatively correlated with the protein network density.

Mechanical and Rheological Properties Related to In Vitro Digestion

The study of the microstructure of the composite gels after heat treatment, through the study of their rheological and mechanical properties, may also give us some clue as to their susceptibility to α-amylase attack. Guo et al. [22] observed that the manipulation of gel strength and microstructure modified the extent and rate of lipid digestion in WPI emulsion gels. In this case, harder gels better retained their structure during in vitro digestion and were more efficient in delaying lipolysis [24].

No significant difference in gel hardness was observed between a pure 10% WPI gel and the 10% WPI composite gel (hardness of 154 ± 16 kPa and 174 ± 11 kPa, respectively, Table 2) after heat treatment. So, in this case the hardness of the protein gel was not significantly modified by the addition of PS (5% w/v). This is in accordance with the microstructure exhibited in Fig. 1d. which shows that the continuous protein matrix was detached from the gelatinized starch granules, hence, responsible for taking the load in the compression test.

Regarding WPI concentrations in the composite gels, no significant difference in gel hardness was measured between composite gels made of 8 and 10% WPI (187 ± 11 kPa and 174 ± 11 kPa, respectively). However, the composite gel made of 6% WPI was significantly softer (hardness of 125 ± 13 kPa). Fracture strain was ~ 58% for all samples, so, failure was not significantly influenced by the composition of the gels.

In addition to the study of the mechanical properties of the composite gels, rheological measurements were performed to indirectly observe the microstructure of the WPI and PS gels after heat treatment. As shown in Fig. 6, all samples behaved as viscoelastic gels with dominating elastic properties, i.e., the storage modulus G’ was higher than the loss modulus G” (tan δ <1) in the LVR. Above a certain strain value (i.e., 2 – 4%), all samples showed a shear thinning behavior probably due to the successive breakdown of the WPI particle gel. G’0, the plateau value of G’ in the LVR, was 45.1 ± 1.5 kPa, 86.2 ± 7.0 kPa and 112.1 ± 25.1 kPa for the composite gels made of 6, 8 and 10% WPI, respectively. So, G’0 increased with the increasing protein content, suggesting that more crosslinks were formed when a higher WPI% was used, resulting in a denser and more complex network [75]. Alting et al. [76] also observed an increase in the storage modulus plateau value of cold-set gels with increasing whey protein concentration. No significant differences in the extension of the LVR were observed between the three composite gels: the critical strains measured were 2.3 ± 1.7%, 3.1 ± 1.8% and 1.6 ± 0.6% for the composite gels made of 6, 8 and 10% WPI, respectively.

The addition of PS did not influence significantly the storage modulus of the protein gel (G’0 = 107.1 ± 3.5 kPa for the pure 10% WPI gel) but slightly extended the LVR (critical strain of 0.5 ± 0.1% for the control gel). This is also in accordance with the microstructure shown in Fig. 1d., i.e., starch granules acted as inactive fillers and did not interact with each other or with the protein network. According to these results, gel strength and microstructure were related to starch digestibility. More elastic gels, with a denser microstructure (8 and 10% WPI) protected better PS granules from the enzymatic attack than the less elastic gel (6% WPI), during the intestinal step of the simulated digestion (particle size 5 mm) (Fig. 5). The gastric and intestinal phases both involve the action of proteases that are able to degrade the whey protein network. Throughout the digestion process, the microstructure of the surface of the gel is loosened which in turn accelerate the diffusion of proteases and will eventually lead to the disintegration of the gel [73]. Consequently, the progressive softening and breakdown of the network by proteases will expose more PS granules to starch-degrading enzymes as the digestion moves forward, as evidenced in Fig. 5. It is then expected that a denser microstructure will have a slower rate of protein hydrolysis which will result in a slower rate of starch hydrolysis. And indeed, the results of this study show that the final amount of glucose released from the matrix, as well as the starch hydrolysis rate during the intestinal step of the digestion, depended on the concentration in WPI of the gels (Fig. 5). Luo et al. [73] measured a slower proteolysis rate of WPI gels when the protein concentration was increased from 15 to 20 wt% and concluded that WPI gel digestion was determined by the summed effect of enzyme diffusion limitation, hydrolysis rate and microstructure transformation. Also, Macierzanka et al. [77] showed that particulate gels resisted better the proteolysis than fine stranded gels. However, Opazo-Navarrete et al. [78] did not found a correlation between the microstructure, the hardness and the rate of proteolysis in WPI gels.

Structure and material properties have a significant impact on the rate and extent of food breakdown and release of nutrients in the mouth and the stomach [79]. Rheological and mechanical properties of the gels may be relevant not only to control starch digestibility in vivo but also do design specific food textures. Food hardness has a direct influence on the breakdown in the mouth: the harder the food, the smaller the bolus particle size [35]. For example, heat-set whey protein emulsion gels with increasing hardness led to median particle sizes from 4 to 0.95 mm, respectively, after mastication [80]. Then, food particle size and hardness also influence gastric emptying. The rate of disintegration in the stomach generally decreases with the increase of food hardness [79]. According to the results of this study, the negative correlation between digestibility and hardness may restrict the use of whey protein encasing of starch granules to foods with a rather “strong” and “chewy” texture. In addition, the breakdown patterns in the mouth and the stomach of the composite cold-set gels should be carefully considered since particle size was a determinant factor for starch digestibility reduction in vitro.

The main factors affecting the digestibility of starch in a whey protein network formed by cold gelation are summarized in Fig. 7.

Conclusions

WPI networks formed by cold gelation restricted the in vitro digestibility of PS after heat treatment as measured by glucose release using a three-stage digestion assay. This effect first depended on particle size reduction of the gels. Gels with a particle size of ~ 1 mm protected PS from enzymatic attack until the intestinal step of the simulated digestion, while gels with a particle size ~ 5 mm were a barrier for starch-degrading enzymes until the end of the digestion protocol. Then, glucose release from the matrix depended on WPI concentration in the gels. At the end of the digestion, PS hydrolysis was reduced by 20.5 and 15.5% for composite gels with 10 and 8% WPI respectively (particle size 5 mm), whereas no significant reduction was observed for the gel with 6% WPI. Moreover, mechanical and rheological properties of the gels were related to starch digestibility. The rate of PS hydrolysis decreased with increasing hardness and elasticity of the gels. Therefore, the microstructure of the protein network also has to be carefully considered to modulate starch digestibility in such composite gels. This work contributes to a better understanding of starch digestion in soft food matrices. The use of whey protein gels appears as an interesting strategy to design low-calorie food products with a slower postprandial release of glucose from gelatinized starch. In future work, the breakdown properties of WPI & PS cold-set gels in the human mouth and stomach will be investigated.

References

World Health Organization, Global Report on Diabetes (Switzerland, Geneva, 2016)

International Diabetes Federation, IDF Diabetes Atlas, Eighth (International Diabetes Federation, Brussels, 2017)

A. Boles, R. Kandimalla, P.H. Reddy, Biochim. Biophys. Acta Mol. Basis Dis. 1863(5), 1026–1036 (2017)

M. Janghorbani, M.R. Salamat, M. Amini, A. Aminorroaya, Diabetes Metab. Syndr. Clin. Res. Rev. 11, S439–S444 (2017)

N. Bansal, World J. Diabetes 6(2), 296–303 (2015)

J. Singh, A. Dartois, L. Kaur, Trends Food Sci. Technol. 21(4), 168–180 (2010)

A. Fardet, C. Hoebler, B. Bouchet, D.J. Gallant, J.L. Barry, Reprod. Nutr. Dev. 27, 133 (1998)

W.K. Heneen, K. Brismar, Starch/Staerke 55(12), 546–557 (2003)

E.H.J. Kim, J.R. Petrie, L. Motoi, M.P. Morgenstern, K.H. Sutton, S. Mishra, L.D. Simmons, Food Biophys. 3(2), 229–234 (2008)

B. Cuq, J. Abecassis, M-H. Morel, in Science Culinaire. Matière, Procécés, Dégustation, ed. by C. Lavelle (Belin, Paris, 2014), pp. 22–50

M. Petitot, J. Abecassis, V. Micard, Trends Food Sci. Technol. 20(11-12), 521–532 (2009)

W. Zou, M. Sissons, M.J. Gidley, R.G. Gilbert, F.J. Warren, Food Chem. 188, 559–568 (2015)

W. Zou, M. Sissons, F.J. Warren, M.J. Gidley, R.G. Gilbert, Carbohydr. Polym. 152, 441–449 (2016)

N. Yang, J. Luan, J. Ashton, E. Gorczyca, S. Kasapis, Food Hydrocoll. 42, 244 (2014)

N. Yang, J. Ashton, E. Gorczyca, S. Kasapis, Heliyon 3(10), e00421 (2017)

N. Bellissimo, T. Akhavan, Am. Soc. Nutr. Adv. Nutr. 6, 3025 (2015)

B. Benelam, Nutr. Bull. 34(2), 126–173 (2009)

C.L. Campbell, T.B. Wagoner, E.A. Foegeding, Food Struct. 13, 1–12 (2017)

C. Chung, B. Degner, D.J. McClements, LWT - Food Sci. Technol. 54, 336 (2013)

A. Brodkorb, T. Croguennec, S. Bouhallab, J. J. Kehoein, in Adv. Dairy Chem. Vol. 1B Proteins Appl. Asp., ed. by P. McSweeney, J. A. O’Mahony (Springer, New York, 2016), pp. 155–178

A. Abaee, M. Mohammadian, S.M. Jafari, Trends Food Sci. Technol. 70, 69–81 (2017)

Q. Guo, N. Bellissimo, D. Rousseau, Food Hydrocoll. 69, 264–272 (2017)

Q. Guo, A. Ye, M. Lad, D. Dalgleish, H. Singh, Soft Matter 10(8), 1214–1223 (2014)

Q. Guo, A. Ye, M. Lad, D. Dalgleish, H. Singh, Food Hydrocoll. 54, 255–265 (2016)

R.U. Almario, W.M. Buchan, D.M. Rocke, S.E. Karakas, BMJ Open Diabetes Res. Care 5(1), e000420 (2017)

L.E. Mignone, T. Wu, M. Horowitz, C.K. Rayner, World J. Diabetes 6(14), 1274–1284 (2015)

K.N. Englyst, H.N. Englyst, G.J. Hudson, T.J. Cole, J.H. Cummings, Am. J. Clin. Nutr. 69(3), 448–454 (1999)

M. Minekus, M. Alminger, P. Alvito, S. Ballance, T. Bohn, C. Bourlieu, F. Carrì, R. Boutrou, F.M. Corredig, D. Dupont, F.C. Dufour, L. Egger, M. Golding, L.S. Karakaya, B. Kirkhus, S. Le Feunteun, U. Lesmes, A. Macierzanka, A. Mackie, S. Marze, D.J. Mcclements, O. Enard, I. Recio, C.N. Santos, R.P. Singh, G.E. Vegarud, M.S.J. Wickham, W. Weitschies, A. Brodkorb, Food Funct. 5(6), 1113–1124 (2014)

T. Liu, N. Hamid, K. Kantono, L. Pereira, M.M. Farouk, S.O. Knowles, Food Chem. 213, 108–114 (2016)

Ł. Sęczyk, M. Świeca, U. Gawlik-Dziki, Food Funct. 6(11), 3560–3566 (2015)

I.Y. Bae, Y. Jun, S. Lee, H.G. Lee, LWT - Food Sci. Technol. 65, 158 (2016)

P. Ercan, S.N. El, Food Chem. 205, 163–169 (2016)

J.M. Aguilera, P. Baffico, J. Food Sci. 62(5), 1048–1066 (1997)

J.M. Aguilera, G.V. Rojas, Food Res. Int. 30(5), 349–357 (1997)

J. Chen, N. Khandelwal, Z. Liu, T. Funami, Arch. Oral Biol. 58(3), 293–298 (2013)

A. Dartois, J. Singh, L. Kaur, H. Singh, Food Biophys. 5(3), 149–160 (2010)

L. Ong, R.R. Dagastine, S.E. Kentish, S.L. Gras, LWT - Food Sci. Technol. 44, 1291 (2011)

N. Yang, Y. Liu, J. Ashton, E. Gorczyca, S. Kasapis, Food Chem. 137(1-4), 76–82 (2013)

W. Fu, T. Nakamura, Biosci. Biotechnol. Biochem. 81(4), 839–847 (2017)

J. Parada, J.M. Aguilera, Food Res. Int. 45(1), 238–243 (2012)

L.A. Muñoz, F. Pedreschi, A. Leiva, J.M. Aguilera, J. Food Eng. 152, 65 (2015)

J.-Y. Li, A.-I. Yeh, J. Food Eng. 50(3), 141–148 (2001)

W.S. Ratnayake, D.S. Jackson, Adv. Food Nutr. Res. 55, 221 (2009)

C. Cai, J. Cai, L. Zhao, C. Wei, Food Sci. Biotechnol. 23(1), 15–22 (2014)

K. Alvani, X. Qi, R.F. Tester, C.E. Snape, Food Chem. 125(3), 958–965 (2011)

K. Alvani, X. Qi, R.F. Tester, Starch/Staerke 64(4), 297–303 (2012)

A. Matignon, P. Barey, M. Desprairies, S. Mauduit, J.M. Sieffermann, C. Michon, Food Hydrocoll. 35, 597–605 (2014)

M.T. Molina, A. Leiva, P. Bouchon, Food Bioprod. Process. 100, 488–495 (2016)

J.W. Woolnough, J.A. Monro, C.S. Brennan, A.R. Bird, Int. J. Food Sci. Technol. 43(12), 2245–2256 (2008)

C. Hoebler, A. Karinthi, M.F. Devaux, F. Guillon, D.J. Gallant, B. Bouchet, C. Melegari, J.L. Barry, Br. J. Nutr. 80(05), 429 (1998)

G.M. Bornhorst, R.P. Singh, Food Biophys. 8(1), 50–59 (2013)

S. Jourdren, M. Panouille, A. Saint-Eve, I. Déléris, D. Forest, P. Lejeune, I. Souchon, Food Funct. 7(3), 1446–1457 (2016)

M. Tamura, Y. Okazaki, C. Kumagai, Y. Ogawa, Food Res. Int. 94, 6–12 (2017)

J. Oñate Narciso, C. Brennan, Starch-Stärke 70(9-10), 1700315 (2018)

N. López-Barón, Y. Gu, T. Vasanthan, R. Hoover, Food Hydrocoll. 69, 19–27 (2017)

X. Chen, X.W. He, B. Zhang, X. Fu, J.l. Jane, Q. Huang, Int. J. Biol. Macromol. 104, 481 (2017)

Z.H. Lu, E. Donner, R.Y. Yada, Q. Liu, Carbohydr. Polym. 154, 214–222 (2016)

J.M. Aguilera, Crit. Rev. Food Sci. Nutr. 10, 1–18 (2018)

V. Ranawana, J.A. Monro, S. Mishra, C.J.K. Henry, Nutr. Res. 30, 246 (2010)

G. Mandalari, Z. Merali, P. Ryden, S. Chessa, C. Bisignano, D. Barreca, E. Bellocco, G. Laganà, R.M. Faulks, K.W. Waldron, Eur. J. Nutr. 57(1), 319–325 (2018)

A.M. Farooq, C. Li, S. Chen, X. Fu, B. Zhang, Q. Huang, Int. J. Biol. Macromol. 118, 160–167 (2018)

K. Mahasukhonthachat, P.A. Sopade, M.J. Gidley, J. Food Eng. 96, 18 (2010)

G.J.S. Al-Rabadi, R.G. Gilbert, M.J. Gidley, J. Cereal Sci. 50(2), 198–204 (2009)

K.W. Heaton, S.N. Marcus, P.M. Emmett, C.H. Bolton, Am. J. Clin. Nutr. 47(4), 675–682 (1988)

G.T. Nguyen, M.J. Gidley, P.A. Sopade, LWT - Food Sci. Technol. 63, 541 (2015)

T. Tinus, M. Damour, V. Van Riel, P.A. Sopade, J. Food Eng. 113, 254 (2012)

G. Chen, P. Sopade, Int. J. Food Sci. Technol. 48(1), 150–156 (2013)

P. Colonna, J.L. Barry, D. Cloarec, F. Bornet, S. Gouilloud, J.P. Galmiche, J. Cereal Sci. 11(1), 59–70 (1990)

Y. Granfeldt, I. Björck, J. Cereal Sci. 14(1), 47–61 (1991)

V. Ranawana, C.J.K. Henry, M. Pratt, Nutr. Res. 30, 382 (2010)

S.A. Alam, S. Pentikäinen, J. Närväinen, U. Holopainen-Mantila, K. Poutanen, N. Sozer, Food Res. Int. 96, 1–11 (2017)

E. Nordlund, K. Katina, H. Mykkänen, K. Poutanen, Foods 5(4), 24 (2016)

Q. Luo, R.M. Boom, A.E.M. Janssen, LWT - Food Sci. Technol. 63, 161 (2015)

M. Tokita, Gels 2(2), 17 (2016)

M.A. Rao, Rheology of Fluids and Semisolid Foods Principles and Applications, 2nd edn. (Springer, Geneva, NY, 2007)

A.C. Alting, R.J. Hamer, C.G. De Kruif, R.W. Visschers, J. Agric. Food Chem. 51(10), 3150–3156 (2003)

A. Macierzanka, F. Böttger, L. Lansonneur, R. Groizard, A.S. Jean, N.M. Rigby, K. Cross, N. Wellner, A.R. MacKie, Food Chem. 134(4), 2156–2163 (2012)

M. Opazo-Navarrete, M.D. Altenburg, R.M. Boom, A.E.M. Janssen, Food Biophys. 13(2), 124–138 (2018)

H. Singh, A. Ye, M.J. Ferrua, Curr. Opin. Food Sci. 3, 85–93 (2015)

Q. Guo, A. Ye, M. Lad, D. Dalgleish, H. Singh, Food Hydrocoll. 33(2), 215–224 (2013)

Acknowledgments

This work was supported by CONICYT (the National Commission for Science and Technology, Chile) through FONDECYT Project no. 1150395 and is part of the doctoral thesis of Anaïs Lavoisier also under support of CONICYT doctoral fellowship no. 21160413. Cryo-SEM pictures were taken at the Max Planck Institute for Polymer Research (Mainz, Germany) and the authors thank Thomas Vilgis, Ingo Lieberwirth and Gunnar Glaβer for their assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lavoisier, A., Aguilera, J.M. Effect of a Whey Protein Network Formed by Cold Gelation on Starch Digestibility. Food Biophysics 14, 214–224 (2019). https://doi.org/10.1007/s11483-019-09573-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-019-09573-3