Abstract

The use of proteins in blending with traditional polymers in the formation of thermoplastics can produce plastics with properties that are superior to traditional petroleum-based plastics. We investigated the physical and thermal properties of albumin and zein thermoplastic blends plasticized with glycerol and mixed with varying amounts of low-density polyethylene (LDPE). Several mechanical models were utilized to determine how tensile properties will be altered when varying amounts of protein/LDPE were added into the thermoplastic blend. When analyzed for thermal properties, we found that as the amount of LDPE in the thermoplastic blend increased, the resulting plastic possessed thermal properties that were more similar to pure LDPE plastics. In terms of mechanical properties, comparison between the experimental data and model predictions points to a synergistic effect between albumin and LDPE that leads to higher modulus, while a potential lack of compatibility between zein and LDPE leads to a plastic with lower modulus. Based on our results, the use of albumin and zein proteins when blended with LDPE in the production of thermoplastics has potential use in the areas of medical and food packaging applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In medical and food packaging applications, the use of traditional petroleum-based plastics such as polyethylene terephthalate (PET) and polyvinyl chloride (PVC) come with multiple drawbacks. Petroleum-based plastics lack any inherent antimicrobial properties, causing potential contamination in hospitals [1], as well as spoilage of food due to contamination [2]. The gradual leeching of chemicals from the plastic into the material contained within the plastic poses both health [3] and environmental issues [4], as well as a general lack of recycling of medical and food packaging plastics by the consumer [5]. In order to address these issues, alternative materials must be utilized to reduce the usage of petroleum-based plastics in medical and food packaging applications.

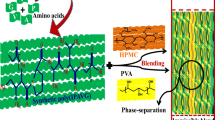

With these issues present, there have been multiple avenues of research conducted to determine new materials that can be utilized in medical and food packaging applications. The use of alternative raw materials from bio-based sources in the production of thermoplastics has been examined for multiple types of proteins, such as starch, protein, polylactic acids (PLAs), and polyhydroxyalkanoates (PHAs) [6]. The subject of proteins in plastic production in particular has been heavily examined, as the use of different proteins will lend different properties to the resulting plastic produced. The use of soy in tandem with acids and oils in plastic production have been found to produce a plastic that would be highly suitable for packaging applications [7], while the use of wheat gluten plastics provide a biodegradable alternative to the petroleum-based plastics that are currently used [8]. An advantage of the use of proteins in plastic production is their lower cost in comparison to traditional polymers such as high density polyethylene (HDPE), due to lower processing times and temperatures [9]. However, it will be necessary to examine proteins in greater detail for use in plastic production, as gradual deformation and creep of the resulting plastic may diminish its usefulness [10].

For this study, the proteins of albumin from the hen egg white and the zein protein from corn were examined for their utilization in thermoplastic applications. With the use of plasticizers, it is possible to utilize albumen protein in the production of plastics that could be utilized in the areas of food packaging and medical applications, with mechanical properties that are similar to traditional petroleum-based plastics [11, 12]. The use of albumin-based bioplastics also provides a potential for preventing the spread of bacteria, as albumin that was plasticized with glycerol did not promote the growth of bacteria (E. coli and B. subtilis) on the surface of the plastic [13]. As for zein plastic, it has been examined for potential use in both medical and food packaging applications [14, 15], as its amino-acid structure promotes drug and food preservative delivery while remaining insoluble in water.

Our objective for this study is to evaluate the thermal, mechanical, and surface properties of albumin–glycerol and zein–glycerol bioplastics and thermoplastic blends for potential use in medical or food packaging applications.

Materials and Methods

Materials

Albumin (purity ≥99 %) was obtained from Sigma-Aldrich Corporation (St. Louis, MO, USA); the zein purified protein was acquired from Acros Organics (New Jersey, USA); and the low density polyethylene (LDPE) powder (Mw ~ 25,000) (500 micron) was obtained from Alfa Aesar (Ward Hill, MA, USA). The glycerol used as a plasticizer was obtained from Sigma-Aldrich with a purity ≥99 %.

Preparation of Compression Molded Samples

The molding of thermoplastic blends was performed on a 24-ton bench-top press (Carver Model 3850, Wabash, IN, USA) with electrically-heated and water-cooled platens. Stainless steel molds were used to form dog bone-shaped thermoplastic blends for antibacterial analysis of plastic surface. To form the plastics, protein, and plasticizer were mixed manually in predetermined w/w ratios to be placed into the molds described in Table 1. The mixture of protein, polymer, and plasticizer was prepared in small batches of varying masses based on density of materials for dog bone plastics (≤6 g for albumin/albumin-LDPE blends, and ≤4 g for zein, zein–LDPE blends, and LDPE since zein and LDPE is less dense compared to albumin), while the DMA flexbars (prepared with spacers) were made of 2 g of albumin, zein, LDPE, albumin–LDPE, and zein–LDPE plastics.

Subsequently, the mixture was filled into the flexbar or dog bone cavity of the stainless steel molds, with plungers placed on top of the molds to prevent the mixture from leaking. After covering with a plunger, the molds were then compressed for a 5-min molding time at 120 °C, followed by a 10-min cooling period for the protein plastics. Samples were prepared under a pressure of at least 40 MPa, as a certain minimum amount of pressure must be applied in order to be able to mold a plastic [16]. After the samples were cooled for 10 min under pressure, the pressure was released and the samples were removed. When plastic molding was completed, the plastic samples were conditioned at 21.1 °C and 65 % relative humidity for 24 h before characterization by thermal, dynamic mechanical, and scanning electron microscopy analysis.

Thermal Analysis of Albumin Plastic Blends and Zein Plastic Blends

Thermal gravimetric analysis (TGA) was performed using a Mettler Toledo TGA/SDTA851e, with material examined from 25 to 500 °C under a N2 atmosphere with a heating rate of 10 °C min−1. Differential Scanning Calorimetry (DSC) was performed using a Mettler Toledo DSC821e, with materials examined from −20 to 250 °C under a N2 atmosphere with a heating rate of 10 °C min−1. For all sample testing, the weight of each sample was set between 2.0 and 4.0 mg to ensure consistent results and determine optimum plastic molding conditions.

Dynamic Mechanical Analysis of Albumin Plastic Blends and Zein Plastic Blends

DMA flex bars of the protein plastics were analyzed for their viscoelastic properties through the use of dynamic mechanical analysis (DMA) [17] by using a DMA 8000 dynamic mechanical analyzer from Perkin Elmer. The analyzer examined the viscoelastic properties of the plastics by determining both the storage and loss modulus. The two types of moduli differ by which storage modulus (E′) is an indication of the elastic region of the material where energy is stored, while loss modulus (E″) is the amount of energy that is dissipated through heat in the viscous region. The resulting moduli were then put in ratio form (E″/E′) to calculate tan δ, which denotes the viscoelasticity of a given material [18]. DMA was conducted from 25 to 120 °C, with a temperature ramp of 2 °C min−1. The settings of the analyzer were set to dimensions of 9 × 2.5 × 12.5 mm3 using a dual-cantilever setup at a frequency of 1 Hz with a displacement of 0.05 mm. Each sample type was analyzed in duplicate.

Mechanical Properties and Modeling of Albumin Plastic Blends and Zein Plastic Blends

The mechanical properties of the conditioned plastic blends were measured by using the Instron testing system (Model 3343) interfaced with the Blue Hill software. The test was performed according to the standard test method for tensile properties of plastics (ASTM D 638-10, Type I) with a 5 mm min−1 crosshead speed, a static load cell of 1000 N, and a gauge length of 4 cm. Samples were run in quintuplicate (n = 5) for each blend type in order to ensure precision.

To model the mechanical properties of the thermoplastic blends produced, several models were utilized to predict the modulus and elongation of the resulting thermoplastic blend. For predicting the stiffness of a given blend, the utilization of Kerner–Hashin equations assume that the material (protein or LDPE) dispersed into the phase of the plastic matrix itself will adopt a sphere-like shape. When it was assumed that there was strong adhesion between the phases in the plastic, the equation utilized was [19]:

where E, E1, E2 were the moduli for the binary blend of protein–LDPE, the matrix, and the dispersed phase; φ1, φ2 were the volume fractions of the matrix of protein–LDPE and the dispersed phase; and ν1 was the Poisson ratio (estimated at 0.3 for polymeric solids [20, 21]) for the protein–LDPE matrix. For volume fractions of the LDPE and the proteins, the density of the protein material was assigned a value of 1 g/cm3. However, if there is no adhesion between protein and LDPE (simplifying E2 to equal zero), the model will change to [19, 22]:

The use of Kerner–Hashin equations for modelling the expected modulus of a given composite was determined based on the fact that this allows for the most consistent of approximations for two phase composites in which one phase is dispersed as spheres in the other phase [19, 23].

When modeling the phase inversion region, it was necessary to utilize a Davies equation that allows for the observation of dual-phase continuity [24], as this will allow for an consistent model for determining the potential elasticity of a given two-phase composite material [25], as well as help determine phase inversion [24]:

To model the predicted elongation of a given blend, a Nielsen equation was utilized, which assumes that there was good adhesion between the protein–LDPE phases [26]:

where εc was the elongation to break of the thermoplastic blend, ε0 is the protein or LDPE that constitutes the matrix of the thermoplastic blend, and ϕ is the volumetric fraction of the protein or LDPE that is dispersed within the matrix.

Results and Discussion

Thermal Properties of Albumin and Zein Plastic Blends

In the thermogravimetric analysis of bioplastic and thermoplastic blends, we detect the thermal degradation properties of the plastics, as shown in Fig. 1. For both pure albumin and zein bioplastics, we first observe bound water loss between 60 and 75 °C, then initial degradation peaks between 220 and 230 °C and 315–325 °C, indicative of the onset of degradation of first the glycerol contained in the plastics [27], then the proteins in the plastic [28, 29]. The albumin-based plastics will have higher degradation peaks where glycerol degradation occurs due to the plastics containing more glycerol (25 %) when compared to zein plastics (20 %). However, the zein plastics possess higher degradation peaks at protein degradation temperature due to zein plastics possessing more protein (80 %) when compared to the albumin plastics (75 %). As we increase the amount of LDPE in the resulting blend, the magnitude of these initial degradation peaks decreases to the point where it is marginal, as LDPE will not degrade at these temperatures. The most prominent degradation peak observed for both types of blends is the degradation that occurs at 475 °C, which is indicative of the onset of LDPE degradation [30]. However, as we decrease the amount of LDPE contained in the thermoplastic blend, the magnitude of mass loss is lessened to the point where it is slight for samples that have less than 10 % of LDPE in their formulation. For blends that contain high levels of protein, since most of the mass has already been lost at lower temperatures, any additional mass loss change is marginal. Based on our results, as the amount of LDPE is increased in the plastic formulations, the thermal degradation properties will become more similar to LDPE degradation patterns than the protein plastics.

For the DSC analysis as shown in Fig. 2, we can discern the thermal transitions that will occur for plastics. In the pure protein based plastics, we find that there is a more broad and shallow endothermic peak at 50–150 °C for albumin, but a much more narrow and deep endothermic peak at 60–80 °C for zein plastics. These varying endothermic peaks indicate a difference in the glass transition temperatures for the protein-based plastics, as zein possesses a lower denaturing temperature (60–80 °C) [31] in comparison to albumin (84.5 °C) [32]. When we increase the amount of LDPE contained in the thermoplastic blend, these initial endothermic peaks are less noticeable, as an endothermic peak of 115–120 °C becomes more prominent, indicative of the melting of LDPE in the thermoplastic blends [33]. After 235 °C, there is an onset of an endothermic peak for the protein-containing plastics, as this is the temperature at which thermal degradation of amino acids will occur.

Viscoelastic Properties of Albumin Plastic Blends and Zein Plastic Blends

In the albumin plastics that have been blended with LDPE, as shown in Fig. 3a, as we increase the amount of LDPE utilized in the blend, there is a gradual increase in the tan delta peak temperature (80 °C for Alb-Gly plastics, 90–95 °C for plastics that contain 50 % or more of LDPE) as well as tan delta height, an indication of glass transition of the protein in the plastic [34]. This could be due to the gradual increase of interactions between protein with LDPE and LDPE–LDPE interactions, with LDPE–LDPE interactions more highly favored when the plastic is made of 50 % or more of LDPE. These changes in interactions within the plastic will impart viscoelastic properties on the resulting plastic that are more similar to pure LDPE plastics [35]. These interactions result in a material that will possess a lower initial tan delta value in comparison to pure, glycerol-plasticized, albumin bioplastics. However, we find that incorporating more than 20 % of LDPE in the albumin thermoplastic blend will result in a material that will have a lower initial modulus at 20 °C, as well as lower modulus at 120 °C. The thermoplastic blends possess lower modulus values as more LDPE is added due to LDPE–LDPE interactions produce a material that will possess a lower modulus in comparison to materials composed of material that consist of protein–protein and protein–glycerol interactions (as illustrated in Fig. 3a) [11, 36].

When we analyze the zein thermoplastic blends, as shown in Fig. 3b, there is not a significant difference in the initial modulus and tan delta of the plastics as we increase the amount of LDPE in the thermoplastic blends. However, as we increase temperature to a certain point (55–95 °C for 5 and 10 % LDPE, 80–120 °C for 20 % LDPE), an elevation of tan delta values as well as shift of tan delta curves to higher temperatures occurs. For the 5 % LDPE samples, this sharp rise in tan delta caused by the temperature increase allowed for the material to exhibit flow properties, with the testing apparatus determining the material had broken (too low of a modulus value) and stopping the testing. This shift in tan delta values might be due to the increase of protein–LDPE interactions, and a decrease in protein–protein and protein–glycerol interactions [37]. When the amount of LDPE contained in the blend is at least 35 %, we witness tan delta values that are more similar to pure LDPE than zein–glycerol plastics. This change in viscoelastic properties can be due to the increase of LDPE–LDPE interactions in the material, resulting in an increase in storage modulus values and decrease in tan delta values [38]. As the amount of LDPE in the plastic increases, there will be a resulting decrease in the protein–protein and protein–glycerol interactions. We also witness a dramatic increase in tan delta values for plastics that contain at least 10 % LDPE in the blend at 115 °C, which is an indication of the beginning of melting of LDPE, which begins to occur between 105 and 115 °C [33]. Once there is at least 35 % of LDPE in the zein thermoplastic blend, the resulting thermoplastic blend has more similar viscoelastic properties to pure LDPE thermoplastics than pure zein bioplastics, as there is enough molecular interaction within the plastic to form a stable material.

Mechanical Properties of Albumin Plastic Blends and Zein Plastic Blends

To determine the mechanical properties of the plastics, it is necessary to conduct tensile testing to determine the modulus and extendibility of a given material, as shown in Fig. 4. For the albumin-based plastics, we find that the addition of LDPE of up to 65 % w/w into the thermoplastic blends will increase (with decreasing rate) the Young’s modulus of the resulting plastic compared to 100 % albumin bioplastics. The increase in modulus is drastic when just 5 % of the plastic mixture consists of LDPE, with an almost threefold increase of modulus witnessed. Such a large increase in the modulus of the material may be due to the decrease of the glycerol utilized as the plasticizer in the production process, with the resulting material possessing a structure that possesses higher rigidity and lower elongation potential [6]. However, there is a decrease in the modulus of the plastic around 80 % and above of LDPE, since resulting plastic exhibit mechanical properties similar to neat LDPE plastics. This increase in the modulus of the thermoplastic blends may be due to the fact that decreasing the amount of albumin and glycerol promotes LDPE–protein interfacial interaction, and prevents moisture gain from the environment, which increases material modulus [39]. The increased LDPE–protein interaction is lessened as more LDPE is added to the blend, as LDPE–LDPE interactions within the thermoplastic blend will increase, leading to mechanical properties more similar to clean LDPE plastics, such as higher extension and lower modulus. However, we find that maximum extendibility is achieved when the thermoplastic blend contains either no LDPE or is almost solely LDPE, as only the thermoplastic blend that contains 80 % LDPE is comparable to pure albumin–glycerol or pure LDPE plastics. This lack of relative extendibility in the thermoplastic blends may be due to extension of plastics being dependent upon the ability for polymer chains to move into unoccupied volume when stress is applied, with the addition of materials that prevent movement decreasing the extendibility of the resulting material [40].

When compared to the Kerner and Davies models, we find that the observed modulus values of albumin–LDPE thermoplastic blends are higher. This increase of modulus points to a compatibility of albumin protein with LDPE, with high levels of adhesion between the two phases and a synergistic effect when LDPE is added into an albumin protein-based matrix. As for elongation modeling, we find that the albumin–LDPE thermoplastic blend elongation values are close to values that are determined through the Nielson model, pointing to adhesion between albumin and LDPE phases in the plastic.

As for the zein thermoplastic blends (Fig. 5), as we add 5–20 % of LDPE to the blend, the resulting thermoplastic blends will possess a higher modulus, suggesting strong protein–LDPE interaction compared to albumin–LDPE thermoplastic blends. It is important to notice that the neat, zein thermoplastic blends showed higher modulus than neat, albumin thermoplastic blends, suggesting a strong protein–protein interactions. The significant loss of modulus in the thermoplastic blends at 35 % and above of LDPE may be due to zein being the main load bearing constituent of the thermoplastic blend, and with more LDPE (which exhibits low modulus), the load bearing capabilities of the resulting blends will decrease [41]. When the extension of the thermoplastic blend is examined, there is a slight decrease in the extendibility of the thermoplastic blend when LDPE is added, until it consists of at least 50 % LDPE. The lack of difference in extension may be due to the immiscible nature of the zein–LDPE blend. When molding or extruding immiscible material, it is possible to produce a material that will be able to transfer stress under low deformation due to pseudo-adhesion behavior between zein and LDPE [42]. However, when high deformation is applied, the material will be unable to withstand the same amount of strain as the pure protein or pure polymer plastics [37, 43].

When modeling the modulus of zein–LDPE thermoplastic blends through Kerner and Davies models, we find that the observed modulus values of zein–LDPE thermoplastic blends will be similar to the Kerner model for weak adhesion, as well as the Davies model. This decrease of modulus when material is added into a plastic matrix points to a lack of synergistic effect of zein protein with LDPE, with lower levels of adhesion between the two phases when compared to albumin–LDPE thermoplastic blends. After comparing the elongation data with modeling through the Nielson model, we find that the zein–LDPE thermoplastic blends elongation values are close to (or higher) values that are determined through the Nielson model, pointing to some adhesion between zein and LDPE phases in the plastic.

Conclusions

As we compare the thermal properties of the protein-thermoplastic blends, we find that adding more LDPE into the thermoplastic blend causes the resulting plastics to have thermal properties more similar to LDPE plastics than pure protein plastics. In terms of the mechanical properties, we have found that there is a synergistic effect between albumin and LDPE that will produce a plastic that possesses higher modulus and elongation when compared to pure LDPE and pure albumin plastics. However, this synergistic effect was not seen in the zein–LDPE blends, with a decrease in the modulus of the resulting thermoplastic pointing to an incompatibility between the two materials. In terms of future research, it will be necessary to study the use of different types of polymers such as PET or PVC in blending with protein to potentially improve the mechanical properties of the resulting thermoplastic blend. Additional types of protein such as soy and whey should also be examined, as these materials could prove to be highly suitable for medical or food packaging applications if they are blended with a polymer. If these plastics were to be utilized in food packaging, future testing would include test standards such as ASTM F1640-09: Standard Guide for Packaging Materials for Foods to Be Irradiated, or ASTM E1870-11: Standard Test Method for Odor and Taste Transfer from Polymeric Packaging Film, to determine if the use of protein-based plastics will decrease the food’s quality.

References

Schultz M, Gill J, Zubairi S, Huber R, Gordin F (2003) Bacterial contamination of computer keyboards in a teaching hospital. Infect Control Hosp Epidemiol 24(4):302–303

Borch E, Kant-Muermans M-L, Blixt Y (1996) Bacterial spoilage of meat and cured meat products. Int J Food Microbiol 33(1):103–120

Halden RU (2010) Plastics and health risks. Annu Rev Public Health 31:179–194

Lee B-K, Ellenbecker MJ, Moure-Eraso R (2002) Analyses of the recycling potential of medical plastic wastes. Waste Manag 22(5):461–470

Hopewell J, Dvorak R, Kosior E (2009) Plastics recycling: challenges and opportunities. Philos Trans Biol Sci 364(1526):2115–2126

Mekonnen T, Mussone P, Khalil H, Bressler D (2013) Progress in bio-based plastics and plasticizing modifications. J Mater Chem A 1(43):13379–13398

Guerrero P, Hanani N, Kerry JP, de la Caba K (2011) Characterization of soy protein-based films prepared with acids and alcohol. J Food Eng 107(1):41–49

Patni N, Yadava P, Agarwal A, Maroo V (2014) An overview on the role of wheat gluten as a viable substitute for biodegradable plastics. Rev Chem Eng 30(4):421–430

Jerez A, Partal P, Martínez I, Gallegos C, Guerrero A (2007) Protein-based bioplastics: effect of thermo-mechanical processing. Rheol Acta 46:711–720

Dorigato A, Pegoretti A (2012) Biodegradable single-polymer composites from polyvinyl alcohol. Colloid Polym Sci 290(4):359–370

Jones A, Zeller MA, Sharma S (2013) Thermal, mechanical, and moisture absorption properties of egg white protein bioplastics with natural rubber and glycerol. Prog Biomat 2(12):1–13

Gillgren T, Stading M (2008) Mechanical and barrier properties of avenin, kafirin, and zein films. Food Biophys 3(3):287–294

Jones A, Mandal A, Sharma S (2015) Protein-based bioplastics and their antibacterial potential. J Appl Polym Sci 132:41931

Taylor J, Anyango JO, Taylor JRN (2013) Developments in the science of zein, kafirin, and gluten protein bioplastic materials. Cereal Chem 90(4):344–357

Shi W, Dumont M-J (2014) Review: bio-based films from zein, keratin, pea, and rapeseed protein feedstocks. J Mater Sci 49(5):1915–1930

Sue HJ, Wang S, Lane JL (1997) Morphology and mechanical behaviour of engineering soy plastics. Polymer 38(20):5035–5040

Menard K (1999) Dynamic mechanical analysis: a practical introduction. CRC Press, Boca Raton

Fried J (2003) Polymer science and technology, 2nd edn. Prentice Hall, Upper Saddle River

Kerner EH (1956) The elastic and thermo-elastic properties of composite media. Proc Phys Soc Lond Sect B 69(8):808

Greaves GN, Greer AL, Lakes RS, Rouxel T (2011) Poisson’s ratio and modern materials. Nat Mater 10:823–837

Zhang M, Atkinson KR, Baughman RH (2004) Multifunctional carbon nanotube yanes by downsizing an ancient technology. Science 306:1358–1361

Marsilla KIK, Verbeek CJR (2013) Properties of bloodmeal/linear low-density polyethylene blends compatibilized with maleic anhydride grafted polyethylene. J Appl Polym Sci 130(3):1890–1897

Watt JP, Davies GF, O’Connell RJ (1976) The elastic properties of composite materials. Rev Geophys Space Phys 14(4):541–563

Sperling LH (1997) Polymeric multicomponent materials: an introduction. Wiley, New Jersey

Davies WEA (1971) The thoery of elastic composite materials. J Phys D Appl Phys 4:1325–1339

Neilson LE, Landel RF (1974) Mechanical properties of polymers and composites. Marcel Dekker Inc., New York

Castelló M, Dweck J, Aranda DAG (2009) Thermal stability and water content determination of glycerol by thermogravimetry. J Therm Anal Calorim 97(2):627–630

Magoshi J, Nakamura S, Murakami K-I (1992) Structure and physical properties of seed proteins. I. Glass transition and crystallization of zein protein from corn. J Appl Polym Sci 45(11):2043–2048

Wongsasulak S, Kit KM, McClements DJ, Yoovidhya T, Weiss J (2007) The effect of solution properties on the morphology of ultrafine electrospun egg albumen–PEO composite fibers. Polymer 48(2):448–457

Park JW, Oh SC, Lee HP, Kim HT, Yoo KO (2000) A kinetic analysis of thermal degradation of polymers using a dynamic method. Polym Degrad Stab 67(3):535–540

Kim JM, Whang JH, Kim KM, Koh JH, Suh HJ (2004) Preparation of corn gluten hydrolysate with angiotensin I converting enzyme inhibitory activity and its solubility and moisture sorption. Process Biochem 39(8):989–994

Herald TJ, Smith DM (1992) Heat-induced changes in the secondary structure of hen egg S-ovalbumin. J Agric Food Chem 40(10):1737–1740

Liu C, Wang J, He J (2002) Rheological and thermal properties of m-LLDPE blends with m-HDPE and LDPE. Polymer 43(13):3811–3818

Jerez A, Partal P, Martinez I, Gallegos C, Guerrero A (2007) Egg white-based bioplastics developed by thermomechanical processing. J Food Eng 82(4):608–617

Shieh Y-T, Chuang H-C (2001) DSC and DMA studies on silane-grafted and water-crosslinked LDPE/LLDPE blends. J Appl Polym Sci 81(7):1808–1816

Averous L, Moro L, Dole P, Fringant C (2000) Properties of thermoplastic blends: starch–polycaprolactone. Polymer 41(11):4157–4167

Corradini E, Mattoso LHC, Guedes CGF, Rosa DS (2004) Mechanical, thermal and morphological propertiesof poly(e-caprolactone)/zein blends. Polym Adv Technol 15(6):340–345

Verbeek CJR, van den Berg LE (2010) Extrusion processing and properties of protein-based thermoplastics. Macromol Mater Eng 295:10–21

Vaz CM, Mano JF, Fossen M, van Tuil RF, de Graaf LA, Reis RL, Cunha AM (2002) Mechanical, dynamic-mechanical, and thermal properties of soy protein-based thermoplastics with potential biomedical applications. J Macromol Sci Part B Phys 41(1):33–46

Carvalho AJF, Job AE, Alves N, Curvelo AAS, Gandini A (2003) Thermoplastic starch/natural rubber blends. Carbohydr Polym 53(1):95–99

Tian H, Wang Y, Zhang L, Quan C, Zhang X (2010) Improved flexibility and water resistance of soy protein thermoplastics containing waterborne polyurethane. Ind Crops Prod 32(1):13–20

Leclair A, Favis BD (1996) The role of interfacial contact in immiscible binary polymer blends and its influence on mechanical properties. Polymer 37(21):4723–4728

Herald TJ, Obuz E, Twombly WW, Rausch KD (2002) Tensile properties of extruded corn protein low-density polyethylene films. Cereal Chem 79(2):261–264

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jones, A., Sharma, S. Thermoplastic Blends from Albumin and Zein: Plastic Formation and Mechanical Properties Including Modeling. J Polym Environ 24, 309–317 (2016). https://doi.org/10.1007/s10924-016-0774-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0774-7