Abstract

This study explores the possibility of producing ethanol using the acid hydrolysate of three abundant agar-containing red seaweeds (agarophytes): Gelidium amansii, Gracilaria tenuistipitata, and Gracilariopsis chorda. The main component in the seaweed samples was agar, which ranged from 20 to 51 % (g g−1 dry weight). After optimizing acid hydrolysis, 100 g of seaweed was hydrolyzed at 130 °C for 15 min with 0.2 M H2SO4. Then, 120 mL of a 1:2 mixture of the hydrolysate broth and basal medium was fermented in a 200-mL bottle at 30 °C for 96 h. Of the three seaweeds, G. amansii had the best ethanol yield, producing 0.23 g g−1 of galactose or 45 % of the theoretical yield. This yield increased to 60 % after detoxification of the hydrolysate with activated carbon.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bioethanol has taken priority as a renewable biofuel to replace our dependence on fossil fuels. The USA has set a target of 28.4 billion L of biofuels by 2012, while European legislation has mandated the use of biofuels in 5.75 % of transportation by 2010 and 10 % by 2020 (Klinke et al. 2004; Gray et al. 2006; Deverell et al. 2009; Dixon et al. 2010; Afionis and Stringer 2012; Boucher 2012). Unlike fossil fuels, bioethanol is a renewable energy source produced via the fermentation of sugars. It will also reduce the greenhouse effect. Consequently, attention has focused on bioethanol as an alternative renewable fuel. Currently, bioethanol is produced from terrestrial plants, such as corn and sugarcane. The future limitation of terrestrial resources has led to the use of marine resources, and seaweed is a good alternative for producing bioethanol, comparable to terrestrial plants (Horn et al. 2008; Wi et al. 2009; Adams et al. 2009; Bruhn et al. 2011; Meinita et al. 2011). The main polysaccharides in marine seaweeds are alginates in brown seaweeds and agar and carrageenan in red seaweeds (de Ruiter and Rudolph 1997). These red seaweed polysaccharides are galactans consisting entirely of galactose and 3,6-anhydrogalactose. Chemically, agar consists of β-d-galactose and 3,6-anhydro-l-galactose residues with a few methyl ethers and pyruvate groups, while carrageenan contains β-d-galactose-4-sulfate and 3,6-anhydro-d-galactose-2-sulfate. In different genera, the substitution pattern of methyl ethers and pyruvate groups and the amount of 3,6-anhydrogalactose vary (Percival 1979; de Ruiter and Rudolph 1997; Jol et al. 1999).

In total, about 55,000 t of hydrocolloid are produced from 1 million t of wet seaweed annually, with a value of US$585 million, while the value of the agar industry itself is estimated to be US$132 million annually (McHugh 2003). Agar is obtained mostly from polysaccharides from red seaweed, primarily from the orders Gracilariales and Gelidiales. Gelidium species usually occur on rocky shores, while Gracilaria species grow mostly in sandy habitats. Higher-quality agar is extracted from Gelidium species, based on the gel strength (McHugh 1987). The Gelidium used for commercial agar extraction grows naturally, and most is harvested in France, Indonesia, Korea, Mexico, Morocco, Portugal, and Spain (McHugh 2003). The genus Gracilaria can grow both in tropical and temperate regions and is either collected from the wild or cultivated in Argentina, Chile, Indonesia, Korea, Namibia, Philippines, and Vietnam (McHugh 2003).

This study examines the production of bioethanol from three different agarophytes: Gelidium amansii, Gracilaria tenuistipitata, and Gracilariopsis chorda. These species have high biomasses and contain large amounts of agar. G. amansii is abundant in East and Southeast Asia and used commercially. G. tenuistipitata is used widely in China, Philippines, and Vietnam because of its high-quality agar (Yokoya et al. 2004). G. chorda also contains high-quality agar (Orosco et al. 1992). These representative agarophyte seaweeds were compared as potential alternative resources for bioethanol production.

Hydrolysis of seaweed biomass by dilute sulfuric acid is a well-known method to obtain fermentable hydrolysates (Meinita et al. 2011; Meinita et al. 2012a). However, the hydrolysates obtained contain not only fermentable sugars but also some by-product compounds such as 5-hydroxymethylfurfural and levulinic acid that might act as fermentation inhibitors (Meinita et al. 2012b). Therefore, in this study, knowing about these inhibitors and how to minimize their effects on agarophyte hydrolysates is very important.

Materials and methods

The red seaweed (Rhodophyta) G. tenuistipitata was collected from Vietnam, while G. amansii and G. chorda were collected from Indonesia and South Korea. The seaweed samples were transported to the laboratory, washed with distilled water to remove salts and impurities, and dried completely for 1 week at room temperature. The dried seaweed was then ground to a fine powder in an electrical grinder for 10 min.

Acid hydrolysis

Acid hydrolysis was carried out in 250-mL flasks. Samples consisting of 10 g of seaweed powder in 100 mL of 0.2 M H2SO4 were hydrolyzed in an autoclave at 130 °C for 15 min (Meinita et al. 2011; Meinita et al. 2012a). Then, the residues were separated from the liquid by filtration, the sugar content of the liquid was determined, and the liquid was fermented to produce ethanol.

Fermentation

Commercial Saccharomyces cerevisiae (JENICO, Korea) in a basal medium was used for fermentation. The basal medium consisted of 0.02 % (NH4)2SO4 and 0.006 % NaH2PO4 and was adjusted to pH 5 (Prescott 1959). Fermentation was carried out in 120 mL of a 1:2 mixture of hydrolysate and basal medium in 200-mL bottles in triplicate (Meinita et al 2011; Meinita et al 2012a). The samples were incubated in a shaking incubator at 30 °C for 96 h with gentle mixing at 120 rpm. The mixture was sampled periodically to measure the sugar and ethanol contents.

Sugar and ethanol analysis

Total carbohydrate was determined using the phenol sulfuric acid method (Kochert 1978). Monosaccharides (galactose and glucose) were determined using high-performance liquid chromatography (HPLC) with a Shodex Sugar KS-802 column (300 × 8.0 mm). Degassed HPLC water was used as the mobile phase at a flow rate of 0.5 mL min–1. The column temperature was maintained at 60 °C. The by-product inhibitors levulinic acid and 5-hydroxymethylfurfural (HMF) were determined by HPLC with an Alltech IOA-1000 organic acid column (300 × 7.8 mm) equipped with a refractive index detector and kept at 60 °C (Meinita et al 2011; Meinita et al 2012a). The mobile phase was 5 mN sulfuric acid at a flow rate of 0.3 mL min–1. Reducing sugars were determined using the dinitrosalicylic acid method (Chaplin 1986). The ethanol content was measured using gas chromatography (Agilent model 6890N Series) with a 2B-WAX column (Agilent, USA). The injection volume was 2 μL, with an inlet split ratio of 30:1. The initial and maximum oven temperatures were 35 and 250 °C, respectively (Meinita et al. 2011; Meinita et al. 2012a).

Results and discussion

Agar was the main component of the three different red seaweed samples, ranging from 34.4 to 59.9 % [g g−1 dry weight (DW)]. G. amansii had the highest carbohydrate content [59.9 % (g g−1 DW)], compared to G. tenuistipitata [40.8 % (g g−1 DW)] and G. chorda [34.4 % (g g−1 DW)]. Mouradi-Givernaud et al. (1999) determined that the agar content of one Gelidiae species was about 40 % of algal dry weight and reached a maximum of 44.5 %. Levring et al. (1969) reported that the amount of agar in G. amansii varied from 25 to 30 %. Orosco et al. (1992) found that G. chorda contains 24~34.8 % agar in different parts of the plant.

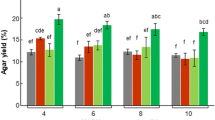

Figure 1 shows the sugar, ethanol, and by-product (HMF and levulinic acid) contents of the acidic hydrolysates of the three red seaweeds. The highest amount of reducing sugar was found in G. amansii (29.2 g L−1), followed by G. tenuistipitata (26.6 g L−1) and G. chorda (23.4 g L−1). The galactose concentration in G. amansii, G. tenuistipitata, and G. chorda was 20.0, 18.7, and 13.6 g L−1, respectively. G. amansii produced the most ethanol (0.83 g L−1), followed by G. tenuistipitata (0.60 g L−1) and G. chorda (0.5 g L−1). Of the three seaweeds, G. amansii possessed the highest total carbohydrate, reducing sugar, and galactose contents and produced the most ethanol (Fig. 1). In this study, we also found HMF and levulinic acid as sugar degradation by-products in the hydrolysate samples (Fig. 1b). Of the three red seaweeds, G. amansii had the highest HMF content (4.8 g L−1), while G. chorda had the highest levulinic acid content (0.42 g L−1). The presence of by-product compounds should be considered. Some studies found that by-products of the acid hydrolysis process have inhibitory effects. Azhar, as cited by Alves et al. (1998), found that 1 g L−1 HMF inhibited cell growth and fermentation by S. cerevisiae. At up to 100 mmol L−1 acetic, formic, and levulinic acids increased the ethanol yield, while the ethanol yield decreased at higher concentrations (Larsson et al. 1999).

The content of sugars, ethanol, and by-products (HMF and levulinic acid) in acidic hydrolysate of G. amansii, G. tenuistipitata, and G. chorda. a Content of reducing sugar (black bar), galactose (light gray bar), and glucose (dark gray bar) produced from acid hydrolysis. b Content of HMF (black bar) and levulinic acid (light gray bar) produced from acid hydrolysis and the ethanol content (dark gray bar) produced from fermentation of hydrolysates. The hydrolysis was carried out by diluting 10 g of hydrolysated red seaweed samples in 100 mL of 0.2 M H2SO4 at 130 °C for 15 min; n ≥ 3, error bars are standard deviation

Table 1 shows the removal of the by-products from the acidic hydrolysates of the three red seaweeds upon treatment with activated carbon. The HMF was removed completely, while activated carbon treatment had little effect on levulinic acid, especially in the hydrolysate of G. amansii.

In this study, we also found that the ethanol yield increased upon removal of HMF and levulinic acid (Table 2). The fermentation of the acidic hydrolysate of G. amansii containing 4.8 g L−1 of galactose gave 0.9 g L−1 of ethanol in 36 h (Fig. 2). During fermentation of the acidic hydrolysate of G. amansii, the galactose was exhausted after 36 h, whereas it was also exhausted after 18 h in the control (pure galactose). This suggests that the sugar consumption was consistent with the time of optimum ethanol production.

a Time course of ethanol production (empty triangle with broken line), galactose (empty circle with thin line), and glucose (filled circle with broken line) during the fermentation period of acidic hydrolysate of G. amansii compare to the control (galactose) (empty triangle with thin line) and ethanol production of the control (pure galactose) (filled square with broken line). Fermentation was carried out in a 135-mL flask at 30 °C and 120 rpm. Samples were taken aseptically at different times; n ≥ 3, error bars are standard deviation. b Time course of reducing sugar (filled triangle with thick line), levulinic acid (filled circle with thick line), and HMF (empty triangle with thick line) during the fermentation period of acidic hydrolysate of G. amansii. Fermentation was carried out in a 135-mL flask at 30 °C and 120 rpm. All of samples were taken aseptically at different times; n ≥ 3, error bars are standard deviation

The fermentation of the acidic hydrolysate of G. amansii gave 0.03 g of ethanol L−1 h−1, which was lower than that of the control (0.071 g L−1 h−1). Therefore, by-products (inhibitors or toxic compounds) such as HMF and levulinic acid might inhibit yeast growth and decrease ethanol production. The ethanol yield in the fermentation of the acidic hydrolysate of G. amansii was 0.23 g g−1 of galactose, which corresponded to 45 % of the theoretical yield. This yield increased to 0.39 g g−1 of galactose after the by-products were removed with activated carbon treatment (Table 2).

The HMF and levulinic acid contents in hydrolyzed G. amansii samples were 0.7 and 0.2 g L−1, respectively. Interestingly, during fermentation, the amount of HMF decreased with the amount of reducing sugar (Fig. 2b). The initial concentration of reducing sugar from G. amansii was 9.8 g L−1, and the amount decreased progressively during fermentation. A similar pattern occurred with HMF, and by 36 h of fermentation, the HMF was eliminated completely. De Vrije et al. (2009) reported that in yeast metabolism, HMF depletion might be facilitated by alcohol dehydrogenase and xylose reductase.

The agar-containing seaweeds can be considered as a resource for ethanol production due to their high content of sugar, which can potentially be converted into ethanol. Of the three red seaweeds examined, G. amansii, G. tenuistipitata, and G. chorda, the acidic hydrolysate of G. amansii had the best fermentable sugar content and ethanol production. Nevertheless, the ethanol yield was still lower than the theoretical yield. This might be due to inhibitors contained in the acidic hydrolysates of seaweeds. Further studies will examine the inhibition effect and removal of by-products to maximize the production of ethanol from G. amansii.

References

Adams MJ, Gallagher JA, Donnison IS (2009) Fermentation study on Saccharina latissima for bioethanol production considering variable pre-treatments. J Appl Phycol 21:569–574

Afionis S, Stringer LC (2012) European Union leadership in biofuels regulation: Europe as a normative power? J Clean Prod 32:114–123

Alves LA, Felipe MGA, Silva JB, Silva SS, Prata AMR (1998) Pre treatment of sugar cane bagasse hemicellulose hydrolysate for xylitol production by Candida guilliermondii. J Appl Biochem Biotechnol 70–72:89–98

Boucher P (2012) The role of controversy, regulation and engineering in UK biofuel development. Energy Pol 42:148–154

Bruhn A, Dahl J, Nielsen HB, Nikolaisen L, Rasmussen MB, Markager S, Olesen B, Arias C, Jensen PD (2011) Bioenergy potential of Ulva lactuca: biomass yield, methane production and combustion. Bio Tech 102:2595–2604

Chaplin MF (1986) Monosaccharide. In: Chaplin MF, Kennedy JF (eds) Carbohydrate analysis: a practical approach. IRC, Oxford, pp 1–36

de Ruiter GA, Rudolph B (1997) Carrageenan biotechnology. Trends Food Sci Technol 8:389–395

Deverell R, McDonnell K, Ward S, Devlin G (2009) An economic assessment of potential ethanol production pathways in Ireland. Energy Pol 37:3993–4002

de Vrije T, Bakker RR, Budde AW, Lai MH, Mars AE, Claassen PA (2009) Efficient hydrogen production from lignocellulosic energy crop Miscanthus by extreme thermophilic bacteria Caldicellulosiruptor saccharolyticus and Thermotoga neapolitana. Biotechnol Biofuel 2:12. doi:10.1186/1754-6834-2-12

Dixon RK, McGowan E, Onysko G, Scheer RM (2010) US energy conservation and efficiency policies: challenges and opportunities. Energy Pol 38:6398–6408

Gray KA, Zhao L, Emptage M (2006) Bioethanol. Opin Chem Biol 10:141–146

Horn SJ, Aasen IM, Ostgaard K (2008) Ethanol production from seaweed extract. J Ind Microbiol Biotechnol 25:249–254

Jol CN, Neiss TG, Penninkhof B, Rudolph B, Ruiter GAD (1999) A novel high-performance anion-exchange chromatographic method for the analysis of carrageenans and agars containing 3,6-anhydrogalactose. Anal Biochem 268:213–222

Klinke HB, Thomsen AB, Ahring BK (2004) Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Appl Microbiol Biotechnol 66:10–26

Kochert G (1978) Carbohydrate determination by the phenol-sulfuric acid method. In: Hellebust JA, Craigie JS (eds) Handbook of phycological methods, vol II, Physiological and biochemical methods. Cambridge University Press, Cambridge, pp 95–97

Larsson S, Palmqvist E, Hagerdal BH, Tengborg C, Stenberg K, Zacchi G, Nilvebrant (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb Technol 24:151–159

Levring T, Hoppe HA, Schmid OJ (1969) Marine algae. A survey of research and utilization. Botanica marina handbook, vol. 1. Cram, De Gruyter & Co, , Hamburg, p 421

McHugh DJ (1987) Production and utilization of products from commercial seaweeds. Fisheries Technical Paper, FAO, Rome

McHugh D (2003) A guide to the seaweed industry. Fisheries Technical Paper, FAO, Rome

Meinita DNM, Kang JY, Jeong GT, Koo HM, Park SM, Hong YK (2012a) Bioethanol production from the acid hydrolysate of the carrageenophyte Kappaphycus alvarezii (cottonii). J Appl Phycol 24:857–862

Meinita DNM, Jeong GT, Hong YK (2011) Comparison of sulfuric and hydrochloric acids as catalysts in hydrolysis of Kappaphycus alvarezii (cottonii). Bioproc Biosyst Eng 35:123–128

Meinita DNM, Jeong GT, Hong YK (2012b) Detoxification of acidic catalyzed hydrolysate of Kappaphycus alvarezii (cottonii). Bioproc Biosyst Eng 3:93–98

Mouradi-Givernaud A, Amina-Hassani L, Givernaud T, Lemoine Y, Benharbet O (1999) Biology and agar composition of Gelidium sesquipedale harvested along the Atlantic coast of Morocco. Hydrobiologia 5:391–395

Orosco CA, Anong C, Nukaya M, Ohno M, Sawamura M, Kusunose H (1992) Yield and physical characteristics of Agar from Gracilaria chorda Holmes: comparison with those from Southeast Asian species. Nippon Suisan Gakkaishi 58:1711–1716

Percival E (1979) The polysaccharide of green, red and brown seaweeds: their basic structure, biosynthesis and function. Br Phycol J 14:103–117

Prescott SC, Dun CG (1959) Industrial microbiology, 3rd edn. McGraw-Hill, New York, p 120

Wi SG, Kim HJ, Mahadevan SA, Yang DJ, Bae HJ (2009) The potential value of the seaweed Ceylon moss (Gelidium amansii) as an alternative bioenergy resource. Bioresour Technol 100:6658–6660

Yokoya NS, West JA, Luchi AE (2004) Effects of plant growth regulators on callus formation, growth and regeneration in axenic tissue cultures of Gracilaria tenuistipitata and Gracilaria perplexa (Gracilariales, Rhodophyta). Phycol Res 52:244–254

Acknowledgments

This research was supported by a grant from the Samsung Advanced Institute of Technology, Korea. We are grateful for a postdoctoral fellowship from the Pukyong National University (MNAK) and the Brain Busan 21 program for graduate support. We thank to the Jenderal Soedirman University (UNSOED), Indonesia, for the collaboration research (Riset Unggulan UNSOED).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meinita, M.D.N., Marhaeni, B., Winanto, T. et al. Comparison of agarophytes (Gelidium, Gracilaria, and Gracilariopsis) as potential resources for bioethanol production. J Appl Phycol 25, 1957–1961 (2013). https://doi.org/10.1007/s10811-013-0041-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-013-0041-4