Abstract

Seaweed resources can be used as raw materials to produce bioethanol, a renewable biofuel, to overcome fossil fuel depletion and environmental problems. Red seaweeds possess high amount of bioethanol-producible carbohydrates. Among 55 species tested, the carrageenophyte Kappaphycus alvarezii (also known as cottonii) was selected as the best resource for bioethanol production. This species is one of the most abundant and easily cultured red seaweeds. The main components of carrageenan are d-galactose-4-sulfate and 3,6-anhydro-d-galactose-2-sulfate, which are potentially fermentable d-typed carbohydrates. The seaweed powder was hydrolyzed with 0.2 M sulfuric acid and fermented with brewer’s yeast. The ethanol yield from the K. alvarezii hydrolysate was 0.21 g g−1-galactose, which corresponded to a 41% theoretical yield. It revealed a relative ethanol production of 66% comparing to that of pure galactose.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bioethanol has attracted attention as an alternative renewable fuel to replace our dependency on fossil fuel. Unlike fossil fuels, bioethanol is a renewable energy source produced through sugar fermentation (Chandel et al. 2007) of terrestrial plants such as corn and sugar cane. However, future limitations on terrestrial resources will require that we shift our focus from terrestrial-based resources to marine-based resources. Seaweed has been researched as a potential resource for bioethanol production (Horn et al. 2000; Wi et al. 2009; Goh and Lee 2010). The potential volume of ethanol producible from seaweed was estimated to be 23,400 L ha−1 y−1 (Adams et al. 2009). Converting seaweed to bioethanol rather than using terrestrial plant resources has some advantages, i.e., no negative impact on food security, rich in sugar content, lower lignin content than lignocellulosics, and higher mass production (Adams et al. 2009; Wi et al. 2009). The most common polysaccharides from seaweeds are galactans (agar and carrageenan) from red seaweeds and alginate from brown seaweeds (de Ruiter and Rudolph 1997). Galactans consist entirely of galactose and 3,6-anhydrogalactose. The substitution pattern of the sulfate groups and the amount of 3,6-anhydrogalactose vary in different genera, influenced by ecological conditions (Percival 1979; de Ruiter and Rudolph 1997; Jol et al. 1999). Carrageenan is mostly obtained from Eucheuma, Chondrus, and Gigartina (Percival 1979). There are three basic molecular types of carrageenans: kappa-carrageenan from Kappaphycus alvarezii (also known as cottonii), iota-carrageenan from Eucheuma spinosum, and lambda-carrageenan from Gigartina pistillata or Chondrus crispus (Jol et al. 1999; Pereira et al. 2009). McHugh (2003) estimated that 168,400 t y−1 of carrageenan could be harvested as a main polysaccharide resource from seaweed around the world. The rhodophyte K. alvarezii is one of the largest tropical carrageenophytes and one of the most abundant biomass resources produced by aquaculture. It is very fast-growing, known to double its biomass in 15 days, and being cultivated between about 20° north and south of the equator, mostly in Indonesia and Philippines (Neish 2008). Production of about 12–18 dry t ha−1 y−1 is fairly typical for well-tended family farms. In this study, we focused on K. alvarezii, which is the most promising candidate for bioethanol production because of its high amount of biomass and d-typed galactose. The seaweed powder was hydrolyzed to monosugars by sulfuric acid treatment and then fermented to produce ethanol using brewer's yeast.

Materials and methods

Seaweed material

Dried specimens of Kappaphycus alvarezii were collected mostly from Karimunjawa, Indonesia, during 2007 and 2010. The seaweed samples were rinsed in distilled water to eliminate salt and debris, and dried again to a constant weight at 60°C. The dried seaweed was finely ground into a powder using a coffee grinder for 5 min. To compare tissues collected at different locations, dried specimens were obtained from different local farmers who attended the First Indonesian Seaweed Forum and Exhibition, Makassar, in October 2008; the specimens were used directly without rinsing.

Acid hydrolysis

For the main ethanol production, acid hydrolysis was conducted in 250-mL flasks. Ten grams of seaweed powder were hydrolyzed with 100 mL of 0.2 M H2SO4 in an autoclave at 130°C for 15 min. For optimizing parameters of acid hydrolysis, it was conducted in 100-mL flasks with 50 mL of 0.2 M H2SO4. After hydrolysis, the residue was separated from the liquid by filtration using glass fiber. The clean yellowish liquid after removing the residue was used for analyzing sugar content and for bioethanol production after adjusting to pH 5 with NaOH.

Fermentation

Commercial brewer's yeast, freeze-dried Saccharomyces cerevisiae (Jenico, Seoul, South Korea), was directly used for the bioethanol fermentation. The basal medium consisted of 0.02% (NH4)2SO4 and 0.006% NaH2PO4, adjusted to pH 5 (Prescott and Dun 1959). Fermentation broth was consisted of hydrolysate and basal medium with a ratio of 1:2. The fermentation was conducted with 3 mL broth in 8-mL screw cap vials during 24 h for optimization and scaled up to 120 mL in 200-mL reagent bottles with cap during 72 h for main ethanol production. The medium was incubated in a shaking incubator at 30°C with gentle shaking at 120 rpm. Samples of 0.5 mL for measuring sugars and ethanol content were collected at each time during fermentation.

Analysis of biochemicals, by-products, and ethanol

From dry tissue samples, total carbohydrate was determined by the phenol-sulfuric acid method (Kochert 1978), using carrageenan as the standard. Total lipids were extracted with hexane and isopropanol (3:2) as the solvent (Radin 1981) and were quantified gravimetrically. The amount of soluble protein in the tissue was estimated according to the method of Lowry et al. (1951) after heating the tissue suspension to 100°C in 1 N NaOH for 2 h to obtain complete solubilization of the protein. Bovine serum albumin was used as the standard for protein determination. Ash content was determined by heating tissue samples at 575°C for 5 h. Moisture content was measured by drying tissues at 105°C for 18 h until they reached a stable weight. After acid hydrolysis, the amount of reducing sugar in the hydrolysate was determined using dinitrosalicylic acid (Chaplin 1986). Contents of monosaccharides (galactose and glucose) and by-products (levulinic acid and 5-hydroxy-methyl-furfural) were quantified by each standard curve using high-performance liquid chromatography with an Alltech IOA 1000 organic acid column (7.8 mm ID × 30 cm), which was equipped with a refractive index detector and maintained at 60°C. The mobile phase was 2.5 mM sulfuric acid at a flow rate of 0.3 mL min−1. Ethanol content was quantified using gas chromatography (Agilent Model 6890 N, USA) with a 2B-WAX column (Agilent Technologies, USA). The injection volume was 2 μL with an inlet split ratio of 30:1. The initial and maximum oven temperatures were 35°C and 250°C, respectively. Ethanol yield (Y) was calculated using the following equation: Y = [EtOH]max/[Sugar]ini, where [EtOH]max = maximum ethanol concentration achieved during fermentation (g L−1), [Sugar]ini = sum of the initial galactose and glucose concentrations at onset of fermentation (g L−1). Percent theoretical yield (Y%) was calculated as: Y% = (Y/0.51) × 100, where 0.51 = theoretical maximum ethanol yield per unit of hexose sugar from glycolytic fermentation (g g−1). Relative ethanol production (%) was calculated by dividing the ethanol yield of hydrolysate by the ethanol yield of pure galactose with [Sugar]ini concentration, and multiplied by 100.

Activated charcoal treatment

To remove fermentation inhibitors from the H2SO4 hydrolysate, 5% (w/v) activated charcoal was added to the hydrolysate and shaken at 30°C for 30 min with a 130 rpm shaking rate (Miyafuji et al. 2003). After removing the charcoal by filtration, the clean hydrolysate was used to determine sugar and inhibitor contents and then fermented for ethanol production. The removal rate (%) by the charcoal was calculated as a relative rate: [(B − A)/B] × 100, where B is amount of each compound before treatment, and A is amount of each compound after treatment.

Results

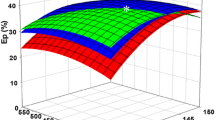

Carbohydrate was the main component in various seaweed species and reached a maximum of approximately 64% (w/w) as a dry weight basis in our preliminary experiments. K. alvarezii, a major carrageenan producer, possessed the highest amount of carbohydrate among the 54 seaweed species tested (data not shown). We conducted sulfuric acid hydrolysis using K. alvarezii to maximize productivity of galactose content and ethanol fermentation from the hydrolysate. The process was optimized by applying different H2SO4 concentrations (0 to 1 M), hydrolysis times (0 to 30 min), amounts of seaweed materials (0 to 133 g L−1), and inoculum amounts of S. cerevisiae (0 to 6.7 g L−1). Among different H2SO4 concentrations, the highest production of reducing sugar, galactose, and ethanol was obtained with 0.2 M H2SO4 under the standard conditions of hydrolysis at 130°C for 15 min and fermentation with 3.3 g L−1 of S. cerevisiae for 24 h (Fig. 1a). It yielded 30.5 g L−1 reducing sugar, 25.6 g L−1 galactose, and 1.31 g L−1 ethanol from the acid hydrolysis. At lower and higher concentrations than 0.2 M H2SO4, the reducing sugar, galactose, and ethanol concentrations decreased. The hydrolysis time with 0.2 M H2SO4 was optimal at 15 min under standard conditions of hydrolysis at 130°C (Fig. 1b). Increasing the hydrolysis time to longer than 15 min resulted in decreased production of reducing sugars, galactose, and ethanol, suggesting that higher H2SO4 concentrations and longer reaction times might degrade the sugar compounds and produce more by-product inhibitors such as 5-hydroxy-methyl-furfural and levulinic acid. The optimal amount of K. alvarezii powder was 100 g L−1 under standard conditions of hydrolysis at 130°C for 15 min with 0.2 M H2SO4 (Fig. 1c). Figure 1d shows the effect of different S. cerevisiae inoculum amounts on ethanol production. The highest ethanol production was obtained with an inoculum amount of 3.3 g L−1. Thus, the optimum conditions were concluded at 130°C hydrolysis for 15 min with 0.2 M H2SO4, 100 g L−1 seaweed and 3.3 g L−1 yeast, same as the standard conditions.

Determining various parameters to optimize ethanol production conditions of a K. alvarezii hydrolysate. a effect of H2SO4 concentration on seaweed hydrolysis. b hydrolysis time with 0.2 M H2SO4. c amount of seaweed used for H2SO4 hydrolysis. d amount of yeast inoculum used for fermentation. Amounts of reducing sugar (black circle) and galactose (white circle) released after H2SO4 hydrolysis were measured, and fermentation was conducted in broth of hydrolysate and basal medium (1:2) to determine ethanol production (black up-pointing triangle). Values represent the mean±SD (n ≥ 3)

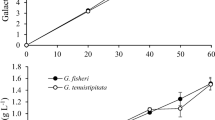

We measured the time course of main ethanol fermentation from the 120 mL K. alvarezii hydrolysate (Fig. 2). The K. alvarezii hydrolysate containing 50.0 g L−1 reducing sugar, 20.4 g L−1 galactose, and 0.8 g L−1 glucose was fermented in broth, and produced 1.5 g L−1 of ethanol in 24 h. The broth consisted of hydrolysate and basal medium with a ratio of 1:2. The ethanol production rate in the early phase of the culture was relatively slow but rapidly increased after 12 h and reached a maximum after 24 h of fermentation. The galactose was exhausted after 24 h. Sugar consumption was consistent with the ethanol production time, and ethanol productivity was 0.063 g L−1 h−1, which was lower than that of a reference (0.095 g L−1 h−1) containing pure galactose of the same concentration. This result indicated that some inhibitors or toxic compounds against fermentation might have been present and decreased ethanol production. The ethanol yield during fermentation of the K. alvarezii hydrolysate was 0.21 g g−1 of the sum of galactose and glucose, which corresponded to a 41% theoretical yield. This was a relatively lower result compared to the ethanol yield of 0.32 g g−1 of pure galactose, which corresponds to 63% of the theoretical yield in the reference. Thus, it shows a relative ethanol production of 66% comparing to the ethanol yield by pure galactose, namely 34% was inhibited in fermentation by hydrolysate by-products.

Time course of sugar consumption and ethanol production during fermentation of a K. alvarezii hydrolysate. Amounts of reducing sugar (black circle), galactose (white circle), and ethanol production (black triangle) were measured. Fermentation was conducted in broth of hydrolysate and basal medium (1:2). Values represent the mean±SD (n ≥ 3)

Activated charcoal was used to remove the fermentation inhibitors from the acid hydrolysate (Table 1). During H2SO4 hydrolysis of the K. alvarezii, fermentation inhibitor by-products, such as levulinic acid (1.07 g L−1) and 5-hydroxy-methyl-furfural (4.67 g L−1), were detected in the hydrolysate. The 5-hydroxy-methyl-furfural was mostly removed (75.6%) by charcoal, whereas 43% of the levulinic acid and sugars also were removed by charcoal. The charcoal treatment was not specific to the inhibitors, even though the ethanol yield increased only slightly.

We compared the biochemical composition (carbohydrate, protein, lipid, and ash) and moisture content of seaweed samples collected at different locations in Indonesia (Table 2). A relatively high amount of total carbohydrate was detected in tissues collected at Papua and Lombok locations, whereas the lowest amount was observed in samples from the Madura region. High amounts of ash and moisture were detected in tissues from Madura and Kupang. Samples with more moisture content showed increased amounts of ash. Relatively high amounts of reducing sugars, galactose, and glucose were detected in tissue hydrolysates from most regions, except samples from Kupang and Madura. Generally, more 5-hydroxy-methyl-furfural and levulinic acid by-products are produced from tissue samples with greater sugar content. Relatively lower amounts of total carbohydrate from tissues and lower concentrations of reducing sugars, galactose, and glucose from the acid hydolysates of specimens from Kupang and Maura may be related to higher moisture content compared to the other specimens.

Discussion

We selected K. alvarezii as one of the most promising candidates for bioethanol production from seaweed resources, based on carbohydrate content and its capacity to produce ethanol. The carrageenan producer possessed the highest amount of carbohydrate among the 54 seaweed species tested in our preliminary experiments. Chapman and Chapman (1980) reported that K. alvarezii contains more than 50% carbohydrate on a carrageenan dry-weight basis. Carrageenan is a polymer of α-1,3 linked carrabiose (β-d-galactose-4-sulfate-β-1,4-3,6-anhydro-d-galactose-2-sulfate) substituted with sulfate groups, whereas agar consists of β-d-galactose-β-1,4-3,6-anhydro-L-galactose substituted with methyl ethers and a pyruvate group. Carrageenan has an advantage in that it is composed of d-galactose as a basic unit, compared to agar, which contains both d- and l-galactose. l-type sugars are generally non-usable during fermentation and may become reaction inhibitors; thus, one more step is needed to convert l-type sugars to d-type sugars (Yun et al. 2011). From the polysaccharides present in seaweed tissues, it is necessary to obtain fermentable sugars by hydrolysis to produce bioethanol. Acid hydrolysis is an inexpensive process than enzymatic hydrolysis from an economic point of view. The disadvantage of acid hydrolysis is that it is a complex reaction, which results in the production of by-product compounds that can inhibit ethanol-producing yeast and bacteria (Larsson et al. 1999; Klinke et al. 2004). The concentrations of 5-hydroxy-methyl-furfural and levulinic acid in the 0.2 M H2SO4 hydrolysate were approximately 4.67 and 1.07 g L−1, respectively (Table 1). According to Mussatto and Roberto (2004), four factors can minimize the toxification of by-products in fermentation: minimizing the formation of inhibitors during hydrolysis, removal of inhibitors before fermentation, development of microbial species able to resist inhibitors, and conversion of toxic compounds into products that result in no inhibition. In this study, we could not demonstrate the perfect processes to minimize and remove inhibitors because of the co-occurrence of fermentable sugars and by-products during hydrolysis and the non-specific absorption of inhibitors and sugars by the common adsorbent charcoal. Even though carbon adsorption has numerous applications in removing pollutants from air or water streams (Ahmedna et al. 2000), the activated charcoal is a form of carbon that has been processed to make it extremely porous and thus to have a very large surface area available for adsorption or chemical reaction. To increase specificity for binding an inhibitor, a specific ligand must be developed using affinity chromatography to remove inhibitors.

A sufficient and inexpensive biomass is necessary to produce ethanol economically, and seaweed culture is able to fulfill this demand. Approximately 7.5–8 million tons of wet seaweed is produced annually worldwide, either by natural wild seaweed collection or by culture (McHugh 2003). Seaweed has the ability to grow at a fast rate and yield high biomass because it requires less energy to produce supporting tissues than land plants, and nutrients are taken up over their entire surface of the plant (John et al. 2011). Among seaweed species, the carrageenophyte K. alvarezii is now produced in mass scale by aquaculture simply using asexual tissue propagation in tropical areas of Indonesia and Philippines. Indonesia produced at least 1.5 million tons of dry cottonii from 1.1 million ha of farming area in 2009 (Pambudi et al. 2010). From Table 2, we found that cottonii samples with more moisture content generally showed more amounts of ash and lower amounts of total carbohydrate and sugars. It is assumed that the remained moisture of seawater in tissues, not completely dried, contributed to ash amount and encouraged microorganisms in decaying carbohydrate and sugars during dry, transportation and storage of the tissues. Thus, cottonii tissues are suggested to be dried quickly and completely as much as possible. Carrageenan contains the basic unit of d-typed galactose, which is easily fermentable by yeast and bacteria. For these reasons, the carrageenophyte K. alvarezii might be one of the best candidate bio-resources for bioenergy production when the ethanol yield is increased after removing fermentation inhibitors.

References

Adams MJ, Gallagher JA, Donnison IS (2009) Fermentation study on Saccharina latissima for bioethanol production considering variable pre-treatments. J Appl Phycol 21:569–574

Ahmedna M, Marshall WE, Rao RM (2000) Surface properties of granular activated carbons from agricultural by-products and their effects on raw sugar decolorization. Biores Technol 71:103–112

Chandel AK, Chan ES, Ravinder R, Narasu ML, Rao VL, Ravindra P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol Rev 2:14–32

Chaplin MF (1986) Monosaccharide. In: Chaplin MF, Kennedy JF (eds) Carbohydrate analysis: a practical approach. IRC Press, Oxford, pp 1–36

Chapman VJ, Chapman DJ (1980) Seaweeds and their uses. Chapman and Hall, London

de Ruiter GA, Rudolph B (1997) Carrageenan biotechnology. Trends Food Sci Technol 8:389–395

Goh CS, Lee KT (2010) A visionary and conceptual macroalgae-based third-generation bioethanol (TGB) biorefinery in Sabah, Malaysia as an underlay for renewable and sustainable development. Renew Sustain Energ Rev 14:842–848

Horn SJ, Aasen IM, Østgaard K (2000) Ethanol production from seaweed extract. J Ind Microbiol Biotechnol 25:249–254

John RP, Anisha GS, Nampoothiri KM, Pandey A (2011) Micro and macroalgal biomass: a renewable source for bioethanol. Biores Technol 102:186–193

Jol CN, Neiss TG, Penninkhof B, Rudolph B, Ruiter GAD (1999) A novel high-performance anion-exchange chromatographic method for the analysis of carrageenans and agars containing 3,6-anhydrogalactose. Anal Biochem 268:213–222

Klinke HB, Thomsen AB, Ahring BK (2004) Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Appl Microbiol Biotechnol 66:10–26

Kochert G (1978) Carbohydrate determination by the phenol-sulfuric acid method. In: Hellebust JA, Craigie JS (eds) Handbook of phycological methods, vol II, Physiological and biochemical methods. Cambridge University Press, Cambridge, pp 95–97

Larsson S, Palmqvist E, Hagerdal BH, Tengborg C, Stenberg K, Zacchi G, Nilvebrant NO (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb Technol 24:151–159

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

McHugh D (2003) A guide to the seaweed industry.: Fisheries Technical Paper. FAO, Rome

Miyafuji H, Danner H, Neureiter M, Thomasser C, Bvochora J, Szolar O, Braun R (2003) Detoxification of wood hydrolysates with wood charcoal for increasing the fermentability of hydrolysates. Enzyme Microb Technol 32:396–400

Mussatto SI, Roberto IC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bio Technol 93:1–10

Neish IC (2008) Good agronomy practices for Kappaphycus and Eucheuma. Seaplant.net Foundation, Indonesia

Pambudi L, Meinita MDN, Ariyati RW (2010) Seaweed cultivation in Indonesia: recent status. Mar Biosci Biotechnol 4:6–10

Percival E (1979) The polysaccharide of green, red and brown seaweeds: their basic structure, biosynthesis and function. Br Phycol J 14:103–117

Pereira L, Amado AM, Critchley AT, van de Velde F, Riberro-Claro PJA (2009) Identification of selected seaweed polysaccharides (phycocolloids) by vibrational spectroscopy (FTIR-ATR and FT-Raman). Food Hydrocolloid 23:1903–1909

Prescott SC, Dun CG (1959) Industrial microbiology. McGraw-Hill, New York

Radin NS (1981) Extraction of lipids with hexane-isopropanol. Method Enzymol 72:5–7

Wi SG, Kim HJ, Mahadevan SA, Yang DJ, Bae HJ (2009) The potential value of the seaweed Ceylon moss (Gelidium amansii) as an alternative bioenergy resource. Bioresour Technol 100:6658–6660

Yun EJ, Shin MH, Yoon JJ, Kim YJ, Choi IG, Kim KH (2011) Production of 3,6-anhydro-L-galactose from agarose by agarolytic enzymes of Saccharophagus degradans 2–40. Process Biochem 46:88–93

Acknowledgments

This research was supported by a grant from the Samsung Advanced Institute of Technology, Korea. We thank the Brain Busan 21 program for graduate support (MDNM, JYK).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meinita, M.D.N., Kang, JY., Jeong, GT. et al. Bioethanol production from the acid hydrolysate of the carrageenophyte Kappaphycus alvarezii (cottonii). J Appl Phycol 24, 857–862 (2012). https://doi.org/10.1007/s10811-011-9705-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-011-9705-0