Abstract

This study is aimed at analyzing the behavior of ring footings on layered foundation systems. The influence of layer stratification, foundation type, and subgrade strength on the behavior of ring footings was studied. Various laboratory model experiments were performed for the ring and solid circular footings on homogenous and two-layered unreinforced and reinforced foundation systems. The layered system consisted of medium dense sand (DrT = 65%) of varying thickness (H = 0.66–2.66D) overlying the subgrade (lower layer) of varying relative density (DrB = 30%, 50%, 80%). The results show that the top layer thickness (H), subgrade relative density (DrB), foundation type, and the type of geosynthetic material utilized for reinforcement viz. geogrid, and geotextile considerably influences the performance of footings. As the top layer thickness and subgrade strength increased, the improvement factors for reinforced layered foundation systems decreased due to the lack of strain mobilization for the membrane action. The maximum contribution of the geosynthetic reinforcement to the bearing pressures was witnessed for the top layer thickness of H = 0.66D and loose subgrade system of DrB = 30%. The pressure settlement responses for all the cases indicate that the ring footing outperformed the circular footings and hence can be used as an effective and economical alternative to the conventional footings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The bearing capacity and settlement of a foundation depend on the footing shape, sub-soil conditions, and shear strength parameters (Hanna 1981). Many empirical equations are available in the literature to calculate the carrying capacity and settlement of circular, strip, and square footings on homogeneous and multi-layer soil strata. On the other hand, the behavior of ring foundations, which have proved to be efficient and cost-effective alternatives for axisymmetric loading conditions like silos, chimneys, storage tanks, etc. is yet to be studied extensively. Fisher (1957) was the first to investigate the behavior of ring footings. He presented a method for calculating the settlement of a ring footing in a semi-infinite elastic medium. Egorov (1965) introduced a few relations for calculating the settlements and bearing pressure for the ring footing. Bowles (1997) used the finite element method to calculate the bearing pressure and settlement of ring footings. In a series of laboratory tests on model ring footings, Ohri et al. (1997) discovered that the bearing capacity for dune sand is maximized for an internal to the external radius (ri/ro) ratio of 0.38. According to Hataf and Razavi (2003), the radius ratio for the maximum bearing capacity ranges from 0.2 to 0.4. They proposed a semi-empirical relation evaluating the carrying capacity of ring footings on the sand. Verma et al. (2005) investigated the model ring footing behavior subjected to vertical loads while being supported on sand beds reinforced with geocells of varied diameters and heights. Laman and Yildiz (2007) experimenaly investigated the effect of geogrid reinforcement on the ultimate bearing capacity of ring foundations supported by a sand bed.

One of the most promising techniques for increasing the load-carrying capacity of foundation soils is the utilization of soil reinforcement, which dates back to Vidal’s study in (1966). The concept of soil reinforcement was advanced further with the development of geosynthetics. Binquet and Lee (1975) carried out the first investigations on the influence of soil reinforcement on the improvement of load carrying capacity, which was later followed by other researchers. Since the advent of ground improvement methods, geotechnical engineers have been very interested in improving the engineering behavior of soil. The use of geosynthetic reinforcement has greatly helped in reducing the cost required for ground improvement and has streamlined the construction processes. Adding reinforcements (such as geosynthetics, discrete fibers arranged randomly or aligned along the weak planes/zone of the soil, metal strips), densifying the weak soil up to a substantial depth, replacing the weak soil with strong soil up to a significant depth, are all ways to improve the engineering properties of soils. A number of studies (Akinmusuru and Akinboladeh 1981; Guido et al. 1986; Huang and Tatsuoka 1990; Khing et al. 1993, 1994; Das et al. 1994; Adams and Collin 1997; Shin et al. 2002; El Sawwaf 2007, 2009) have demonstrated that using soil reinforcement to improve the load settlement behavior of cohesionless soils beneath shallow foundations is an efficient and affordable technique. They used a variety of materials, including geotextiles, geogrids, and aluminum strips for soil reinforcement in their studies. The impact of these materials on the soil's carrying capacity have been examined in nearly all of these studies. The number of reinforcement layers (N), the depth of the first layer of reinforcement (u), and the vertical spacing between the layers (z) have all been varied. The carrying capacity was also examined for varying types of soil, its density, the form, and the size of the footings. The bearing capacity ratio (BCR), which compares the bearing capacity of reinforced soil to that of unreinforced soil, is frequently used to assess the increase in bearing capacity. When the reinforcement was inserted at the proper depth, the BCR for reinforced soil was found to be greater than unity.

Soils in nature exhibit inherent variability, as a result, foundations are typically built on multi-layered soil profiles. Depending on the thickness of the top layer, the influence zone of the foundation, which includes the potential failure zone, may reach a significant depth, and two or more layers within that depth will therefore have an impact on the foundation behavior. The majority of the experimental and theoretical studies available in the literature have been carried out on ring footings supported on the subsoil of uniform relative density. The influence of many factors affecting the bearing capacity of footings, such as soil layer thickness (Kumar and Walia 2006; Kumar et al 2007; Prasad and Chakraborty 2021; Nguyen et al. 2023), soil properties (Ghazavi 2008; Papadopoulou and Gazetas 2020; Das et al. 2021; Lai et al. 2022), and footing shape (Sawaaf and Nazir 2012; Sharma and Kumar 2017, 2018, 2021) has been a subject of consideration in very few experimental studies. Sawwaf and Nazir (2012) investigated the performance of eccentrically loaded small-scale ring footings on reinforced layered soil strata. They stated that the improvement in the performance of ring footing on reinforced compacted sand is significantly dependent on the relative density of the sand and the radius ratio of the ring footing. The recommended ri/ro (where ri is the internal radius and ro is the external radius) for optimum ring footing response was reported to be 0.39. The improvement in the behavior of ring footing with increasing depth of replaced top layer was reported to be significant only up to a value of H/Do = 1.5. Also, the addition of soil reinforcement resulted in a substantial decrease in the required depth of the replaced sand layer for the same footing settlement and a significant increase in the bearing load, resulting in a cost-effective ring footing design. Sharma and Kumar (2017) studied the effect of relative density on the performance of fiber-reinforced layered soil foundations. For all the evaluated relative density combinations, the greatest increase in terms of bearing capacity and settlement reduction was observed when ri/ro = 0.40. They concluded that the improvement in bearing capacity and settlement reduction is maximized by increasing the thickness of the top layer reinforced with randomly distributed fibers. Using finite element modeling, Khatri et al.(2022) studied the behavior of ring footings on dense sand underlain by loose sand. The bearing capacity was reported to increase very significantly as the thickness of the dense sand layer increased up to a specific optimum thickness before reaching a constant value.

The majority of the experimental and numerical investigations on ring footings present in the literature were conducted to find the optimum radius ratio and bearing capacity factors for ring footings on homogeneous strata. (Egorov 1965; Haroon and Misra 1980; Al-Sanad et al. 1993; Ismael 1996; Ohri et al. 1997; Hataf and Razavi 2003; Zhao and Wang 2008; Gholami and Hosseininia 2017; Benmebarek et al. 2017). However, the behavior of geosynthetic reinforced ring foundation systems has not been explicitly studied in the context of varying subsoil configurations and subgrade strengths. The present study aims to gain a better insight into the performance of ring and solid circular foundation systems on geosynthetic reinforced two-layer strata. A number of physical tests on model footings have been performed to investigate the effect of the following parameters:

-

Effect of the top layer thickness (H)

-

Effect of relative density (DrB = 30%, 50%, 80%) of the lower layer

-

Effect of foundation type i.e. solid circular, and ring footing with radius ratio, ri/ro = 0 and 0.4 respectively.

-

Effect of reinforcement type i.e. geogrid and geotextile on the performance of both ring and solid circular footing.

2 Mechanism of Geosynthetic Reinforcement

2.1 Confinement Effect

Before loading the reinforced soil, there is no relative movement between the soil and the geosynthetic material. Relative displacement between the soil and the geosynthetic material takes place after the application of load which causes the development of friction and subsequent mobilization of tension in the reinforcement. Due to the frictional interaction and interlocking between the fill and the geosynthetic material, the additional shear stresses that would otherwise be imparted to the soft/loose lower layer (subgrade) are absorbed by the reinforcement(Hufenus et al. 2006). This improves the distribution of pressure on the subgrade, which lowers the settlement.

2.2 Pocket Effect

The pocket effect is caused by vertical deformation, which results in a concave shape in the tensioned geosynthetic material (Dash et al. 2001; Rajagopal et al. 1999). The curved reinforced material, due to its stiffness, generates an upward force that sustains the applied pressure and thus improves bearing capacity (Perkins et al. 1999). The material functions as a tensioned membrane, with the pressure on the loose lower layer/subgrade being much lesser than the pressure applied to the top layer on the upper concave side.

3 Test Materials

3.1 Sand

The present study was carried out using locally available river sand. The coefficient of curvature and coefficient of uniformity of sand were 0.76 and 3.67 respectively. The effective size (D10) was 0.2 mm. The sand was classified as poorly graded (SP) according to the Unified Soil Classification System. The values of maximum and minimum void ratios were found to be 0.65 and 0.32 respectively. The layer stratification was achieved by varying the relative density of the lower sand layer (DrB = 30%, 50%, 80%) and the thickness of the top layer (H), which was maintained at a constant relative density (DrT) of 65%.

3.2 Ring and Circular Footing

Footings made of mild steel plates of 25 mm thickness were utilized in the study. To achieve the radius ratio of 0.4, the external (Do) and internal (Di) diameters of the ring footing were kept as 150 mm and 60 mm, respectively. The external diameter of the circular footing (D), was kept the same as the diameter of the ring footing (D = Do), i.e.150 mm. A thin layer of sand was fixed to the bottom surface of the footing with epoxy glue to create the rough base condition of the footing.

3.3 Geogrid

Geogrid used for testing was supplied by M/S Strata Systems (India) Pvt. Ltd.StratagridTM. Biaxial geogrid was used as reinforcement. These high-performance geo-grids are produced from knitted polyester yarns with high molecular weight and tenacity. The physical and mechanical parameters specified by the manufacturer are listed in Table 1.

3.4 Geotextile

A non-woven geotextile was used as soil reinforcement beneath the footings. The geotextile material (needle punch, HSN Code 5603) was procured from Ganpathi Enterprises Jaipur, India. The properties of geotextile provided by the manufacturer are listed in Table 2.

4 Experimental Setup

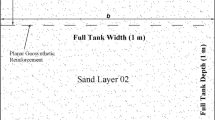

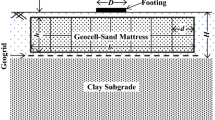

A loading frame assembly was used to conduct model tests in a testing tank sized 1 m × 1 m × 1 m. The sand in the testing tank was filled using the “raining” technique. To determine the appropriate height of fall for a specific relative density, the unit weights obtained were 17.02 kN/m3, 17.80 kN/m3, 18.4 kN/m3, and 19.04 kN/m3 for the relative densities of 30%, 50%, 65%, and 80%, respectively. The sand was deposited in 100 mm thick layers. For reinforced configurations, geogrid/geotextile was positioned at the interface over which the top layer was rained. The schematic of the layer configurations is presented in Fig. 1 and the experimental setup is shown in Fig. 2. A straight piece of wood was used to level the sand’s top surface while taking the necessary precautions to maintain the relative density at the top. The footings were positioned in the middle of the tank once the sand had been filled and leveled. Concentric load application was ensured by carefully aligning the loading arrangement with the centerline. A manually operated loading jack system was used to apply load on the footings. Two linear variable displacement transducers (LVDTs) were stowed on either side (diametrically opposite) of the footing. Two datum bars were also used to position the LVDTs, which were mounted on magnetic bases. The footing's settlement was determined by averaging the settlements recorded by the two settlement transducers. The settlement transducers were linked to a high-precision data acquisition system. The data acquisition system is based on the static measurement program for data collection. The load on the footing was assessed using a pre-calibrated proving ring. A specific load increment was sustained on the footing until the settlement stabilized. The loading continued until failure, which was indicated by excessive settlements for a specific load increment. Details of the experimental program are presented in Table 3.

5 Results

The results of the tests are reported in terms of the pressure-settlement responses for various foundation configurations with differing layer thicknesses (H) and subgrade strengths. To present the analysis and findings, this paper utilizes the normalized forms of footing settlement (S) and top layer thickness (H) in terms of footing diameter (D) as S/D and H/D, respectively. The behavior of footings on layered soil strata compared to the homogeneous strata and that of reinforced layered strata over unreinforced layered soil strata is quantified by analyzing the pressure-settlement responses in terms of improvement factors as I.Fu and I.F respectively. The improvement factors I.Fu and I.F are determined using Eqs. (1) and (2) as the ratio of two bearing pressures at equivalent footing settlement levels (S/D).

The bearing pressures of unreinforced and geogrid/geotextile-reinforced layered foundations are represented in the equations by qu and qr, respectively, whereas qh represents the bearing pressure of homogenous beds.

5.1 Pressure–Settlement Responses

5.1.1 Homogeneous Strata

A number of tests on homogenous sand beds with varied relative densities (DrB = 30%, 50%, 65%, and 80%) were performed in series A. The tests were performed to compare the performance of footings on homogeneous soil with stratified configurations. Tests were performed for both ring and circular footings, as shown in Fig. 3. Higher bearing pressure values were reported for ring footings. With the improvement in relative density, both the initial stiffness (the initial curvature/slope of the pressure-settlement curves) and the bearing pressure enhanced significantly. The bearing pressures were found to be 88 kPa, 196 kPa, 336 kPa, and 452 kPa for DrB = 30%, 50%, 65%, and 80% respectively for rings at S/D = 10%. The corresponding values of bearing pressure for varied relative densities of sand bed in circular footings were found to be 64 kPa, 168 kPa, 260 kPa, and 420 kPa respectively.

5.1.2 Unreinforced Layered Strata

Model tests on two layered strata with unreinforced medium dense sand layer (DrT = 65%) of varying thicknesses (H = 0.66, 1.33, 2, and 2.66D) overlying sub-grades of various strengths (DrB = 30%, 50%, and 80%) were conducted in series B. Figures 4 and 5 shows the pressure-settlement curves of the layered strata for ring footings and circular footings respectively. It is evident that there is an increase in the bearing pressure from 88Kpa for H/D = 0 (homogeneous) to 192 kPa for H/D = 0.66 at S/D = 10% due to the introduction of a relatively denser top layer (medium dense, DrT = 65%) over loose subgrade of DrB = 30%, for ring footings as shown in Fig. 4a. For a similar configuration, the bearing pressure for circular footings increases from 64 to 120 kPa as shown in Fig. 5a. Bearing pressure values were found to increase as the layer thickness (H) was increased. For DrB = 30% (at S/D = 10%), the bearing pressure values were enhanced from 192 to 284 kPa for the ring footing and 120 kPa to 240 kPa for circular footing as the thickness increased from H = 0.66 to 2.66D. However, on increasing the layer thickness beyond 2D, no significant improvement was observed. A perusal of Fig. 4a indicates that due to an increase in H from 2D to 2.66D, the bearing pressure rises marginally from 280 to 284 kPa for ring footing and an increase from 224 to 240 kPa was observed in case of circular footings as shown in Fig. 5a. For subgrades with DrB = 50%, a similar variation in foundation performance was observed, as shown in Figs. 4b and 5b. Figures 4c and 5c present the case of a comparatively loose sand layer overlying a very dense sand deposit. A decrease in bearing pressure from 452 to 352 kPa was witnessed for ring footings, and 420 kPa to 276 kPa for circular footings (at S/D = 10%) as the top layer thickness was varied from 0 to 2.66D. The observations are in agreement with the findings of A.M Hanna (1982) in the case of loose sand overlying dense sand.

5.1.3 Reinforced Layered Strata

The behavior of layered foundations with planar reinforcement (geogrid, geotextile) at the two-layer interface was investigated in test series C. The foundation configurations were maintained in the same manner as that of series B. Figures 6a, b present the pressure-settlement responses of geogrid-reinforced foundations with DrB = 30% and 80% respectively for ring footings, and Figs. 7a, b present the pressure-settlement responses of geogrid-reinforced foundations with DrB = 30% and 80% respectively for circular footings. For similar configurations, the responses of geotextile reinforced layered strata are presented in Figs. 8a, b for the ring footings and Figs. 9a, b for circular footings respectively. The figures also include responses from the corresponding homogeneous beds (series A) and unreinforced layered strata (series B). Both types of reinforcements (geogrids and geotextiles) performed more efficiently for smaller top layer thickness and loose subgrades. A perusal of Figs. 6a and 8a shows that the maximum bearing pressures at H = 0.66D for a geogrid-reinforced and geotextile reinforced system with a very loose subgrade (DrB = 30%) were 440 kPa and 272 kPa respectively, whereas the corresponding values for unreinforced layered bed and homogeneous bed were 192 kPa and 88 kPa, respectively. As the top layer thickness increased, the contribution of geosynthetics decreased.

For the case of the stiff lower layer (DrB = 80%), the contribution of geosynthetics was not significant and no prominent improvements were observed for both geogrid and geotextile reinforced configurations. The bearing pressure values at H = 0.66D were observed to be 528 kPa and 460 kPa for geogrid and geotextile reinforced systems respectively. The corresponding value for the unreinforced system was 416 kPa, indicating comparatively lower improvements as seen in Figs. 6b and 8b.

6 Discussions

The pressure-settlement responses discussed above illustrate that the layer thickness (H), subgrade strengths, S/D %, foundation type, and geosynthetic type had a significant impact on the performance of foundations. The implications of these parameters are discussed in this section. To quantify the observations made from pressure settlement curves, results are presented in terms of improvement factors. Compared to the unreinforced layered soil strata (series B), geosynthetic reinforced strata generally showed a significant improvement in bearing pressures for both types of planar reinforcements used.

6.1 Effect of Layer Thickness

6.1.1 Unreinforced Strata

The typical variations in improvement factors are shown in Fig. 10, which also illustrates the impact of top layer thickness (H/D) at S/D = 10%. With the increase in the thickness of the stiffer top layer, layered soil showed enhanced bearing pressures than homogeneous strata. The improvements were significant only up to H = 2D beyond which only marginal improvements were observed. In general, for H = 2D, the values of improvement factors for ring footings for DrB = 30% and 50%, were 3.18 and 1.63 respectively. For H = 2.66D, the values increased marginally to 3.2 and 1.69, respectively. The values recorded for circular footings for similar soil configuration were 3.5 and 1.61 at H = 2D and for H = 2.66D the values were observed to be 3.7 and 1.66 respectively. As per the results of the present study, H = 2D was found to be the optimum thickness that maximized the contribution from the top layer of the layered configurations. However, I.Fu values for the stiff subgrade of DrB = 80% were nearly constant despite variations in H/D. A reduction in the performance of footings on layered soils compared to homogeneous beds was observed as the thickness of the weaker top layer increased. The improvement factors varied between 0.9–0.7 for ring footings and 0.95–0.65 for circular footings.

For a relatively thinner top layer (H = 0.66D), the failure zone is primarily (predominantly) formed in the lower layer (DrB = 30%, loose sand) and the behavior is influenced significantly by the lower layer. As the top layer's thickness increases (H > 0.66D), a significant portion of the failure zone forms in the top layer of higher relative density (DrT = 65%, medium dense). In other words, as the thickness increases from H = 0.66D to 2.66D, the influence of the top layer dominates. Hence, the improvement is witnessed with increasing top layer thickness. A similar observation was reported by Azam and Wang (1991).

Figures 4c and 5c present the response of unreinforced layered foundations with dense sand (DrB = 80%) as the lower layer for ring footing and circular footings respectively. As can be observed, regardless of variations in sand layer thickness, bearing pressures for layered strata are less than the homogeneous strata. The failure surface for a relatively thinner top layer (H = 0.66D) extends to the dense subgrade beneath it, which offers more resistance. The bottom layer's contribution decreases as the top layer thickness increases, forming a rupture surface inside the top layer. In other words, when the thickness increases, H > 0.66D, the contribution of the top layer, which is relatively weaker, dominates. The stiffness of curves keeps reducing and hence a drop in performance is witnessed. This is a typical foundation behavior for weak sands overlying dense sands, as observed by Hanna (1982).

6.1.2 Reinforced Strata

The reinforcement at the two-layer interface enhanced the bearing pressures compared to the unreinforced systems. The maximum improvement due to reinforcement was witnessed for H/D = 0.66 regardless of the type of reinforcement used (geogrid, geotextile). The magnitude of improvement beyond H = 0.66D was seen to reduce tremendously as seen in Figs. 11 and 12. For H/D > 1.33, the effect of reinforcement on the performance of the footing was practically negligible. Hence, the placement of reinforcement below a depth of 1.33D does not contribute to the improvement in performance. Similar findings were reported by Guido et al. (1985) and Khing (1993). For H/D > 1, the contribution of geogrid reinforcement decreased. At H = 0.66D the overburden due to the overlying soil mass is enough to produce friction at the soil reinforcement interface which means that the reinforcement is present within the effective zone. Reduced I.F values for H > 0.66D suggest the location of reinforcement outside the effective zone. At H/D ≥ 2 the I.F approached almost 1, indicating no contribution of geosynthetic reinforcement on the performance of the footings as the location of reinforcement is outside the failure zone.

6.2 Effect of Subgrade Strength

6.2.1 Unreinforced Strata

In general, it can be seen that the improvement factors tend to decline as subgrade strength increases. Figure 10 illustrates the impact of different lower layer strengths on the performance of foundations in terms of improvement factors (I.Fu). As DrB increased from 30 to 80%, the values of I.Fu declined from 3.22 to 0.78 for rings and 3.75 to 0.65 for circular footings. In this regard, it should be noted that the declining trend only applies to improvement factors, however with increasing subgrade strengths the corresponding bearing pressures are still enhanced as seen in Table 4.

6.2.2 Reinforced Strata

Reinforced strata exhibited higher bearing pressures than the corresponding unreinforced ones irrespective of the reinforcement type for all the subgrade strengths tested. At S/D = 10% and H/D = 0.66, the maximum bearing pressures of an unreinforced layered foundation system were approximately 192 kPa, 248 kPa, and 416 kPa for DrB = 30%, 50%, and 80% respectively for ring footings as shown in Table 4. The bearing pressure values for geogrid and geotextile reinforced circular footings are also presented in Table 4. With geogrid reinforcement, the corresponding bearing pressures raised to 440 kPa (I.F = 2.29), 440 kPa (I.F = 1.77), and 528 kPa (I.F = 1.26) respectively. The corresponding values for the geotextile-reinforced system were observed to be 272 kPa (I.F = 1.42), 312 kPa (I.F = 1.25), and 460 kPa (I.F = 1.10) respectively. The improvement in bearing pressures due to the use of planar reinforcement was more pronounced for loose subgrades.

Figs. 11 and 12 illustrate the variation in I.F of ring footings for various layer configurations (H = 0.66 to 2.66 D) and varying subgrade strengths (DrB = 30%, 50%, and 80%) at S/D = 10%. The I.F was observed to decline with increasing subgrade strengths. A similar observation was made for geotextile and geogrid reinforced circular footing systems. This is because the geosynthetic materials contribute only when sufficient deformations occur in soil, as in the case of loose subgrades. Hence improvement in the case of loose subgrades (easily deformable soil) is quite significant.

6.3 Effect of S/D Ratio

6.3.1 Unreinforced Strata

With an increase in S/D and H/D ratios, I.Fu was seen to enhance. As seen in Fig. 13, for ring and circular footings, however, the rate of improvement slows down, and beyond footing settlement of 6%, the slope flattens. This is because of the fact that beyond this point the foundation response is being affected by the loose sand layer below and the denser sand column (top layer) is being punched into the loose subgrade. For DrB = 80%, as shown in Fig. 13, the value of improvement factors was observed to be very less, signifying lower performance compared to homogeneous strata, which is due to the layer of loose sand overlying dense sand. Furthermore, it is evident that the improvement factors nearly remain the same for S/D values greater than 6%.

6.3.2 Reinforced Strata

At higher settlement levels, as shown in Fig. 14, a greater improvement in bearing pressure was seen for DrB = 30%. In other words, the improvement factors increased with an increase in settlement levels. Since the improvements are more profound at the smaller thickness of the top layer (H = 0.66D), it will be more reasonable to present the improvements corresponding to different subgrades at H = 0.66D as seen in Fig. 14. The improvement factors increased from 1.6 to 2.29 for DrB = 30% as S/D% increased from 2 to 10%. This is because at higher settlement levels there is greater strain mobilization, which causes friction between the soil and the reinforcement, thereby increasing the contribution of the geosynthetic material. However, for stiffer subgrades, (DrB = 50%, 80%) the range of I.F is narrow i.e. 1.5–1.77 for DrB = 50% and 1.15–1.27 for DrB = 80% as S/D varies between 2 and 10%. In other words, the improvement factor curves are flat for stiffer subgrades. The drop in performance for stiffer subgrades is attributed to restrained subgrade deformations, which leads to the insufficient generation of membrane resistance.

6.4 Effect of Reinforcement Type

The effect of geogrid and geotextile reinforcement on the foundations resting on two layer soil strata was analyzed in this study. The results show that the geogrid reinforcement led to larger improvement in bearing pressures and a considerable reduction in the settlements compared to the geotextile reinforcement as shown in Figs. 15 and 16 respectively.

Where Su = settlement of unreinforced layered strata, Sgg = settlement of geogrid reinforced strata,

Sgt = settlement of geotextile reinforced strata. The values of Sgt and Sgg represent the settlement of the geotextile and geogrid reinforced bed, respectively, at a bearing pressure that corresponds to S/D = 10% in unreinforced layered strata.

From Fig. 16, it is evident that with an increase in top layer thickness and lower layer strengths, the effectiveness of geogrid and geotextile decreases. Also, settlement reduction for geogrid is higher than geotextile because of its higher tensile strength. Although both geogrid and geotextile can be used as reinforcement, geogrids can be preferred over geotextiles to serve the purpose of soil reinforcement where a significant improvement in strength is required. This is because the passive resistance is mobilized against the transverse members in geogrids which contributes to higher performances in geogrids.

6.5 Effect of Foundation Type

Both ring and solid footings showed similar responses to various varying parameters. However, in terms of bearing pressures, ring footings, at a radius ratio of 0.4, performed better than circular footing for all the configurations tested and parameters varied in the study as shown in Table 4 and Fig. 17. The enhanced performance of the ring footings at a lower radius ratio is attributed to the “interference effect”. Experimental investigations regarding the interference of two interfering footings on cohesion-less soil were done by Stuart (1962) and Nadri and Hataf (2014). It was established that interference occurs within a certain range of the S/B ratio (where S denotes the spacing between the footings and B is the footing width). It is well established that beneath a footing three zones are formed, elastic zone (zone I), radial zone (zone II), and passive zone (zone III). For widely spaced footings interference does not occur and the footings behave independently. At a certain spacing, the outer spirals (Zone III, Rankin’s passive zone) of the two interfering footings eventually get intersected, and an inverted arch forms in the soil between the two footings. Due to the arching of soil between the footings, the combined system behaves as a single unit during loading. This unit's area is more than the combined area of two individual footings, resulting in an enhancement of bearing capacity. Similarly, when the footings come into contact, the arching effect is lost. The case of ring footings is analogous to the case of two interfering footings. Here, interference occurs due to the internal annular portion of ring footings. At higher radius ratios (ri/ro) the interference effect disappears in ring footings and hence the performance reduces. The same observation was reported by Sawaaf and Nazir (2012) and Sharma and Kumar (2017)

7 Limitations

The study aimed to investigate the impact of soil stratification and geosynthetic reinforcement on the behavior of ring footings resting on layered strata. However, only one type of geogrid and geotextile, one type of sand, and one radius ratio (0.4) of ring footing were used in the study. Additionally, the laboratory model ring footing was scaled down, which has an impact on the results of the experiment (Vesic 1973; Ovesen 1979). While problems in the field are related to prototype footings, test results obtained in this research are based on small scale laboratory model experiments. Although the practice of using small scale modeling to predict the behavior of a full scale foundation is common, it is also well-recognized that due to scale effects and the nature of soils, especially granular soils, laboratory models and prototypes may not exhibit the same behavior. The main causes of the differences are the variations in stress levels between prototypes and model testing, as well as the impact of the footing width/grain size ratio. The scale effects caused by differences in footing and soil particle size can be ignored as long as the footing dimensions are large enough in comparison to the soil particle size. However, the test results provide a useful insight into the foundation behavior and serve as a valuable reference for additional investigations using full-scale tests, centrifugal model tests, and numerical studies, which adds to the knowledge of the actual behavior.

8 Conclusions

In this study, various laboratory model experiments were performed for the ring and solid circular footings on homogenous and two-layered unreinforced and reinforced foundation systems. The effect of geogrid and geotextile reinforcement on the behavior of footings was also analyzed. The following conclusions can be drawn from the present study.

-

1.

The thickness of the top layer has a significant impact on the bearing pressure of the foundations. However, the influence of the top layer thickness on the behavior of foundations is significant up to a value of H = 2D. A further increase in the top layer thickness does not exhibit a substantial influence on the foundation behavior.

-

2.

The pressure-settlement responses in layered configuration showed improvements in bearing pressures with a layer of dense sand (DrT = 65%) overlying the loose subgrades (DrB = 30%), however, a detrimental effect was observed for the stiff subgrade of DrB = 80%, regardless of variations in sand layer thickness (H).

-

3.

The geosynthetic reinforcement at the two-layer interface improved the bearing stresses of the multilayer foundation system irrespective of the foundation type i.e. ring/circular footing. Compared to the unreinforced soil system, the improvement factors due to geosynthetic reinforcement was found to be 2.29 and 2.2 for ring and circular footings respectively.

-

4.

The optimum top layer thickness for geosynthetic reinforced layered soil systems was found to be to be H = 0.66D for DrB = 30%. As layer thickness and subgrade strength increased, the improvement factors for reinforced layered foundation systems were reduced. This is because of the lack of strain mobilization for the generation of membrane action in geosynthetics.

-

5.

Among the two types of planar reinforcements used, geogrids proved to be more effective at enhancing the bearing pressure and reducing the settlements. The maximum value of I.F for geogrid and geotextile was found to be 2.29 and 1.42 respectively in the case of ring footings.

-

6.

For all the cases of the geosynthetic reinforced and unreinforced soil beds, the ring footing (for ri/ro = 0.40) performed better than the circular footing. Hence ring footings can be used as an effective and economical alternative to conventional footings.

Data Availability

All the data was generated through experimental tests performed in the laboratory by the author.

References

Adams MT, Collin JG (1997) Large model spread footing load tests on geosynthetic reinforced soil foundations. J Geotech Geoenviron Eng 123(1):66–72

Akinmusuru JO, Akinbolade JA (1981) Stability of loaded footings on reinforced soil. J Geotech Eng Div 107(6):819–827

Al-Sanad HA, Ismael NF, Brenner RP (1993) Settlement of circular and ring plates in very dense calcareous sands. J Geotech Eng 119(4):622–638

Azam G, Wang MC (1991) Bearing capacity of strip footing supported by two-layer c-phi Soils. Transp Res Record, 1331

Benmebarek S, Saifi I, Benmebarek N (2017) Undrained vertical bearing capacity factors for ring shallow footings. Geotech Geol Eng 35:355–364

Binquet J, Lee KL (1975) Bearing capacity tests on reinforced earth slabs. J Geotech Eng Div 101(12):1241–1255

Bowles JE (1997) Foundation analysis and design, 5th edn. McGrawHill International Editions, New york

Das BM, Omar MT (1994) The effects of foundation width on model tests for the bearing capacity of sand with geogrid reinforcement. Geotech Geol Eng 12(2):133–141

Das PP, Khatri VN, Dutta RK (2021) Bearing capacity of ring footing on weak sand layer overlying a dense sand deposit. Geomech Geoeng 16(4):249–262

Dash SK, Krishnaswamy NR, Rajagopal K (2001) Bearing capacity of strip footings supported on geocell-reinforced sand. Geotext Geomembr 19:235–256

Egorov KE (1965) Calculation of bed for foundation with ring footing. In Proc. 6 th international conference of soil mechanics and foundation engineering 2:41–45

El Sawwaf MA (2007) Behavior of strip footing on geogrid-reinforced sand over a soft clay slope. Geotext Geomembr 25(1):50–60

El Sawwaf M (2009) Experimental and numerical study of eccentrically loaded strip footings resting on reinforced sand. J Geotech Geoenviron Eng 135(10):1509–1518

El Sawwaf M, Nazir A (2012) Behavior of eccentrically loaded small-scale ring footings resting on reinforced layered soil. J Geotech Geoenviron Eng 138(3):376–384

Fisher K (1957) Zur Berechnung der setzung von fundamenten in der form einer kreisformigen ringflache. Der Bauingenieur 32(5):172–174

Ghazavi M, Eghbali AH (2008) A simple limit equilibrium approach for calculation of ultimate bearing capacity of shallow foundations on two-layered granular soils. Geotech Geol Eng 26:535–542

Gholami H, Hosseininia ES (2017) Bearing capacity factors of ring footings by using the method of characteristics. Geotech Geol Eng 35:2137–2146

Guido VA, Biesiadecki G, Sullivan MJ (1985) Bearing capacity of a geotextile-reinforced foundation. In International conference on soil mechanics and foundation engineering 11:1777–1780

Guido VA, Chang DK, Sweeney MA (1986) Comparison of geogrid and geotextile reinforced earth slabs. Can Geotech J 23(4):435–440

Hanna AM (1981) Experimental study on footings in layered soil. J Geotech Eng Division, ASCE 107 (8):1113–1127

Hanna AM (1982) Bearing capacity of foundations on a weak sand layer overlying a strong deposit. Can Geotech J 19(3):392–396

Haroon H, Misra S (1980) A study on the behavior of annular footing on sand. Indian Geotech Soc IGC-80, Bombay, 87–91

Hataf N, Razav IM (2003) Behavior of ring footings on sand. Iranian J Sci Tech 27:47–56

Huang CC, Tatsuoka F (1990) Bearing capacity of reinforced horizontal sandy ground. Geotext Geomembr 9(1):51–82

Hufenus R, Rueegger R, Banjac R, Mayor P, Springman SM, Bronnimann R (2006) Full-scale field tests on geosynthetic reinforced unpaved roads on soft subgrade. Geotext Geomembr 24:21–37

Ismael NF (1996) Loading tests on circular and ring plates in very dense cemented sands. J Geotech Eng 122(4):281–287

Khatri VN, Kumar J, Das PP (2022) Bearing capacity of ring footings placed on dense sand underlain by a loose sand layer. Eur J Environ Civ Eng 26(8):3566–3582

Khing KH, Das BM, Puri VK, Cook EE, Yen SC (1993) The bearing-capacity of a strip foundation on geogrid-reinforced sand. Geotext Geomembr 12(4):351–361

Khing KH, Das BM, Puri VK, Yen SC, Cook EE (1994) Foundation on strong sand underlain by weak clay with geogrid at the interface. Geotext Geomembr 13(3):199–206

Kumar A, Walia BS (2006) Bearing capacity of square footings on reinforced layered soil. Geotech Geol Eng 24:1001–1008

Kumar A, Ohri ML, Bansal RK (2007) Bearing capacity tests of strip footings on reinforced layered soil. Geotech Geol Eng 25:139–150

Lai VQ, Shiau J, Keawsawasvong S, Tran DT (2022) Bearing capacity of ring foundations on anisotropic and heterogenous clays. FEA, NGI-ADP, and MARS. Geotech Geol Eng 40(7):3913–3928

Laman M, Yildiz A (2003) Model studies of ring foundations on geogrid-reinforced sand. Geosynth Int 10(5):142–152

Laman M, Yildiz A (2007) Numerical studies of ring foundations on geogrid-reinforced sand. Geosynth Int 14(2):52–64

Naderi E, Hataf N (2014) Model testing and numerical investigation of interference effect of closely spaced ring and circular footings on reinforced sand. Geotext Geomembr 42(3):191–200

Nguyen DK, Nguyen TP, Ngamkhanong C, Keawsawasvong S, Lai VQ (2023) Bearing capacity of ring footings in anisotropic clays:FELA and ANN. Neural Computing and Applications 1–22

Ohri M, Purhit D, Dubey M (1997) Behavior of ring footings on dune sand overlaying dense sand. In: Proceedings of the international conference on civil engineering

Ovesen NK (1979) The scaling law relationship-panel discussion. In Proc. 7th European conference on soil mechanics and foundation engineering, 4: 319–323

Papadopoulou K, Gazetas G (2020) Shape effects on bearing capacity of footings on two-layered clay. Geotech Geol Eng 38:1347–1370

Perkins SW, Ismeik M, Fogelsong ML (1999) Influence of geosynthetic placement position on the performance of reinforced flexible pavement systems. Proc Geosynth Conf, Boston 1:253–264

Prasad SD, Chakraborty M (2021) Bearing capacity of ring footing resting on two layered soil. Comput Geotech 134:104088

Rajagopal K, Krishnaswamy NR, Latha GM (1999) Behaviour of sand confined with single and multiple geocells. Geotext Geomembr 17:171–184

Sharma V, Kumar A (2021) Plate load tests on the ring and circular footings. In Indian geotechnical and geoenvironmental engineering conference, 209–217

Sharma V, Kumar A (2017) Strength and bearing capacity of ring footings resting on fibre-reinforced sand. Int J Geosynth Ground Eng 3:1–17

Sharma V, Kumar A (2018) Behavior of ring footing resting on reinforced sand subjected to eccentric-inclined loading. J Rock Mech Geotech Eng 10(2):347–357

Shin EC, Das BM, Lee ES, Atalar C (2002) Bearing capacity of strip foundation on geogrid-reinforced sand. Geotech Geol Eng 20(2):169–180

Stuart JG (1962) Interference between foundations with special reference to surface footings in sand. Geotechnique 12(1):15–22

Verma AK, Bhatt, DR, Patel BM, Shaikh A (2005) Behavior of ring footing on reinforced sand bed under monotonic loading. In: Proceedings of indian geotechnical conference, indian geotechnical society 17–19

Vesić AS (1973) Analysis of ultimate loads of shallow foundations. J Soil Mech Found Div 99(1):45–73

Vidal H (1966) La terre armee’, annals of L’institut technique de batiment et des travaux public. Serie Materiaux 30:223–224

Zhao L, Wang JH (2008) Vertical bearing capacity for ring footings. Comput Geotech 35(2):292–304

Acknowledgements

The authors are highly thankful to NIT Srinagar authorities for helping us execute this project at the institute.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

SF conceptualized and performed experiments and wrote the original draft. Dr. MYS contributed to the formulation of the methodology in addition to supervision and revision of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fayaz, S., Shah, M.Y. Behavior of Geosynthetic Reinforced Ring Footings Supported on Multilayered Soil Strata. Geotech Geol Eng 41, 4743–4759 (2023). https://doi.org/10.1007/s10706-023-02544-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02544-z